An intelligent feeding device for a variety of coating raw slurry for casting

An intelligent and coating technology, applied in the direction of casting molding equipment, manufacturing tools, tools, etc., can solve the problems of increasing the labor intensity of operators, not being able to realize the automatic identification of raw pulp, and affecting the progress of the project, so as to achieve small environmental and human factors. The effect of saving filling time and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

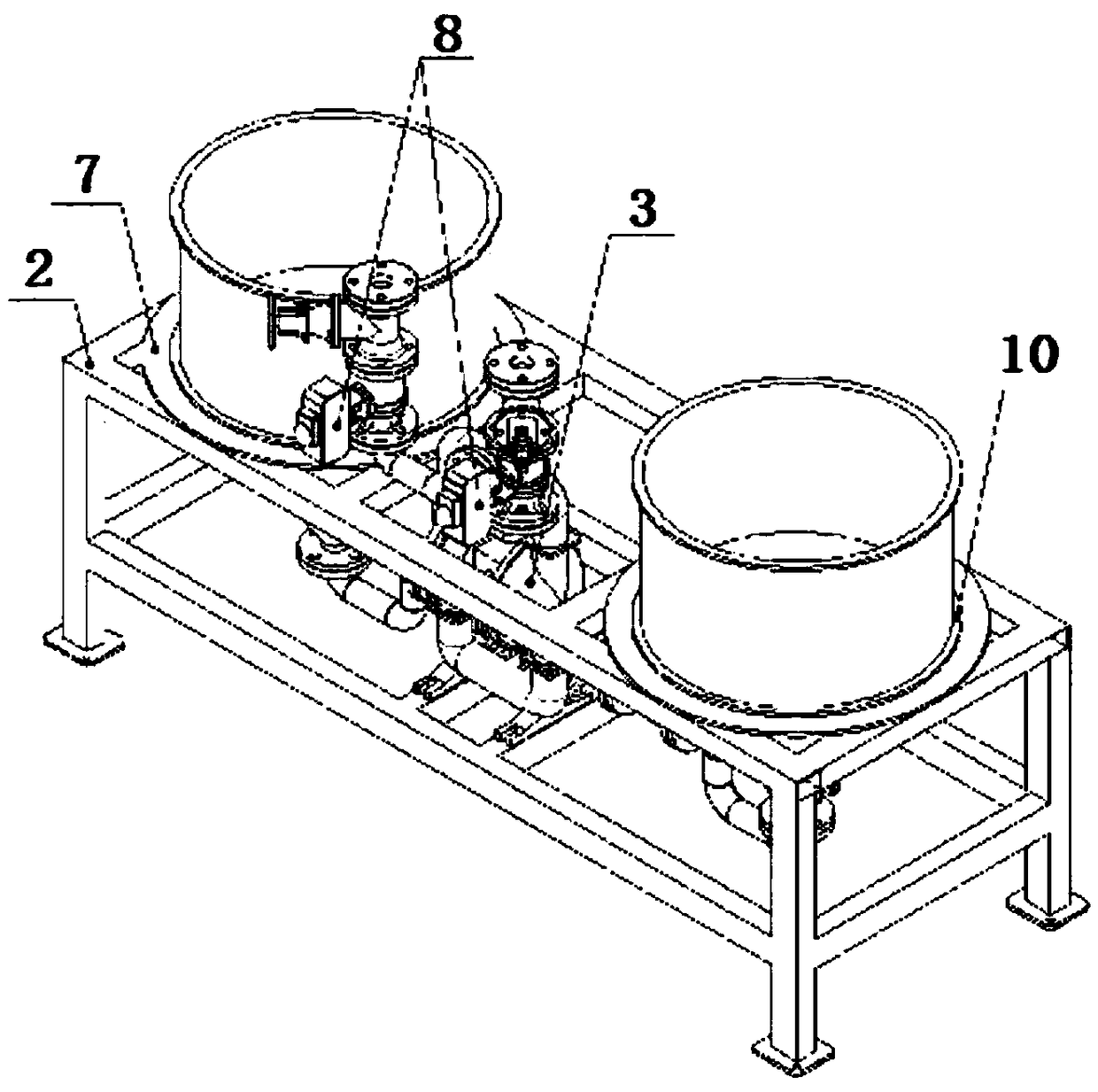

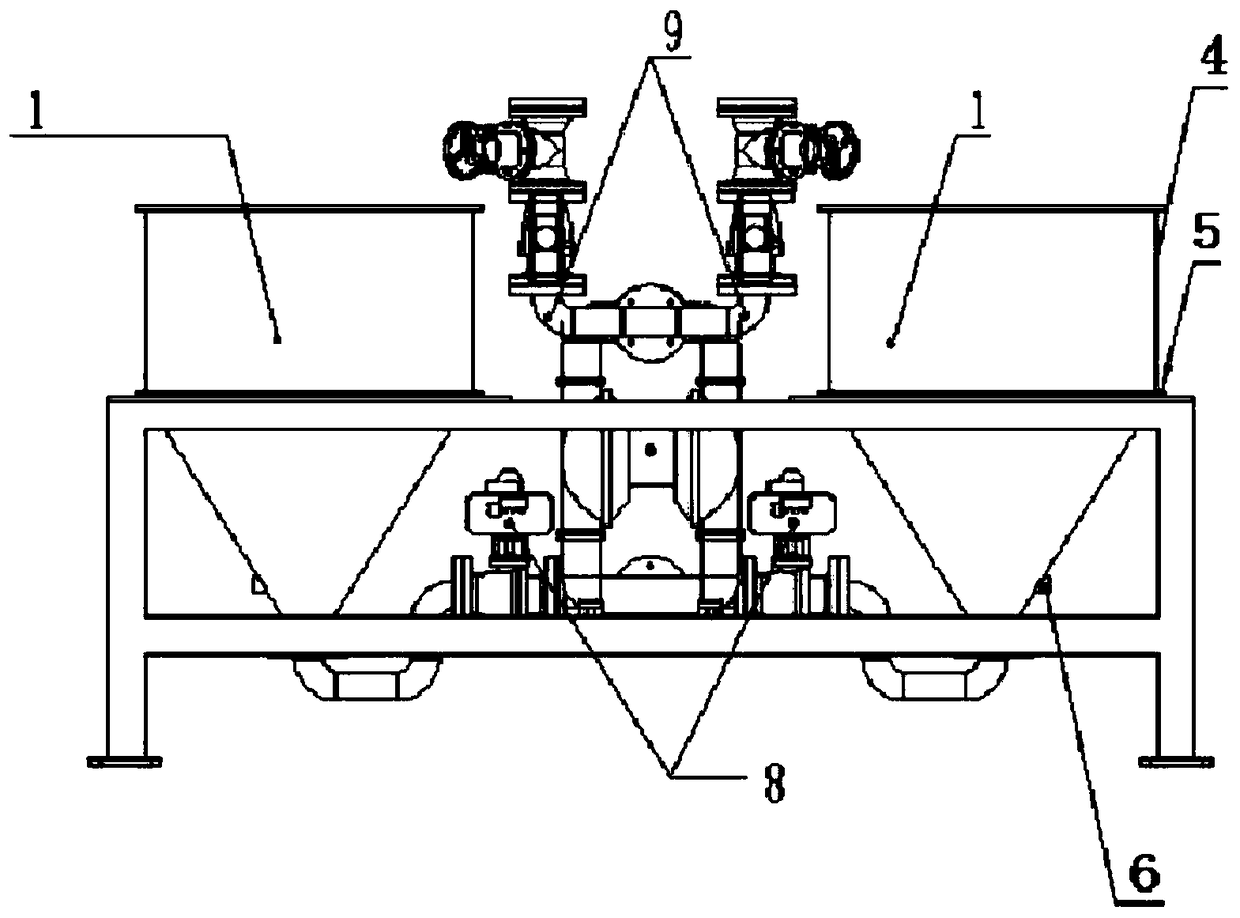

[0020] see figure 1 with figure 2 , the present invention provides a technical solution: an intelligent feeding device for a variety of coating raw slurry for casting, including a bracket 2 and an intelligent feeding assembly, the intelligent feeding assembly is composed of a loading hopper 1, a pneumatic diaphragm pump 3, a high liquid level tuning fork Switch 4, medium liquid level tuning fork switch 5, low liquid level tuning fork switch 6, displacement sensor 7, pneumatic ball valve 8, pipeline 9 and constant torque mold spring 10, the upper hopper 1 is installed on the upper end surface of the bracket 2, and the upper hopper 1 The lower end is connected to the lower end of the bracket 2, the pneumatic diaphragm pump 3 is installed in the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com