Three-level charging-up optimizing control method and system for hydrogenation station high-efficiency hydrogenation

A technology for optimal control and hydrogen refueling stations, applied in general control systems, control/regulation systems, adaptive control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

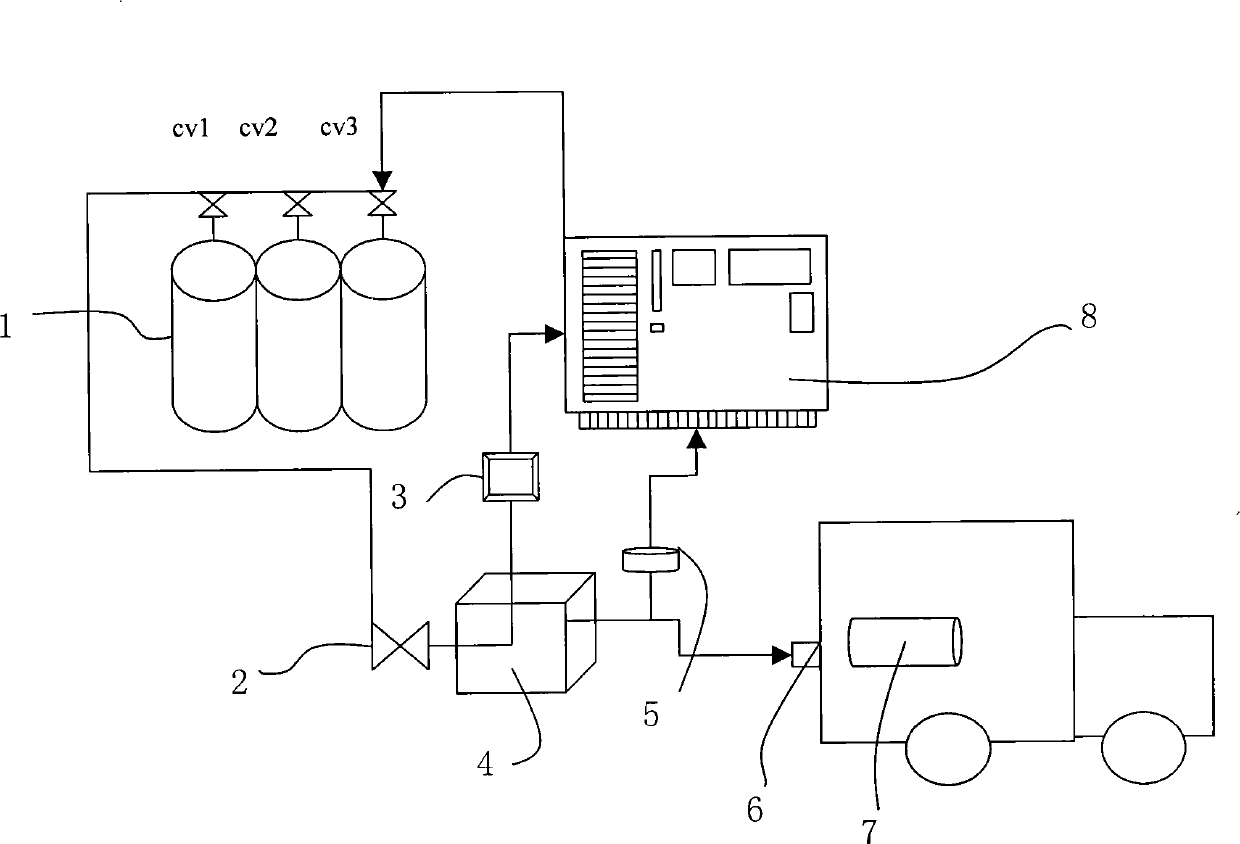

Method used

Image

Examples

example 1

[0062] Carry out three-level refueling optimization calculation for hydrogen refueling station, in which the volume of low-pressure hydrogen storage container V 1 =0.6m 3 , pressure P 1 =42MPa; medium pressure hydrogen storage container volume V 2 =0.4m 3 , pressure P 2 =45MPa; volume V of high-pressure hydrogen storage container 3 =0.2m 3 , pressure P 3 =70MPa; set the volume of the vehicle-mounted gas cylinder V=0.15m 3 , the pressure P after full inflation = 35MPa, the initial pressure P before each inflation 0 = 2 MPa.

[0063] According to the control method in the content of the invention, a programming solution is performed to obtain a non-inferior solution of the control method. Then, according to the purpose of process optimization and actual requirements, the optimal solution is selected and compiled into specific actual operation control steps.

[0064] The non-inferior solutions of the control method are shown in Table 1.

[0065]

[0066]

[0067]...

example 2

[0079] Hydrogen refueling station low pressure group fixed container volume V 1 =0.6m 3 , pressure P 1 =42MPa, medium pressure group fixed container volume V 2 =0.4m 3 , pressure P 2 =70MPa, high pressure group fixed container volume V 3 =0.2m 3 , pressure P 3 =70MPa, set the volume of the vehicle-mounted gas cylinder V=0.15m 3 , the pressure P after full inflation = 35MPa, the initial pressure P before each inflation 0 = 2 MPa.

[0080]

[0081]

[0082]

[0083] According to this control method, the above several filling modes can be obtained. The best method can be determined according to the specific filling requirements. For example, when the gas is filled to 8 tanks, the hydrogen utilization rate is η = m × n M = 65.47 % , And when the filling is 7 tanks, the hydrogen utilization rate is η ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com