Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Reduced pressure capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

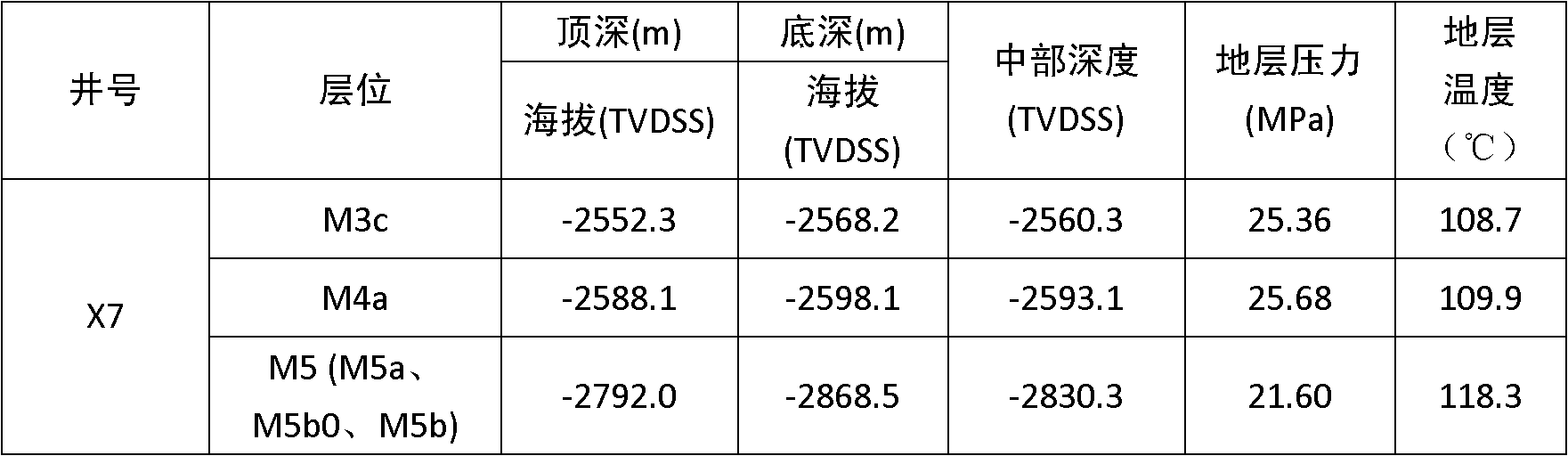

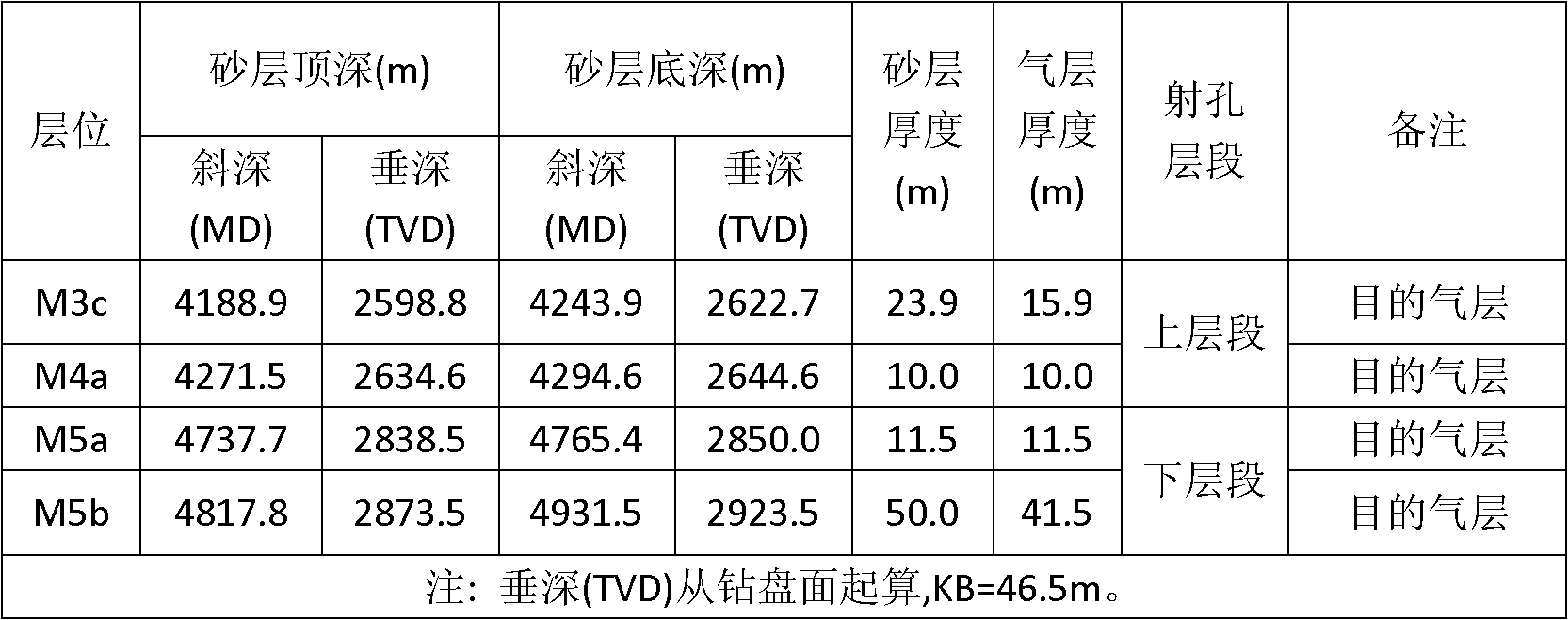

New method for forming manual well wall in oil and gas well by water-absorbing resin

InactiveCN102134979APrevent leakageEasy to transformDrilling compositionSealing/packingFresh water organismVolumetric Mass Density

The invention relates to a new method for forming manual well walls in an oil and gas wells by water-absorbing resin. In the method, the water-absorbing resin is mixed with freshwater or saline to form a well completion fluid or a workover fluid; the water-absorbing resin is starch-type water-absorbing resin or cellulose-type water-absorbing resin or synthetic water-absorbing resin and comprises the following components by weight percentage: 1 to 2% of water-absorbing resin, 0.2 to 0.5% of water-absorbing initiator, 0.2 to 0.5% of colloid protective agent, and the remaining quantity of water or monovalent saline. The density of the water-absorbing resin well-completion fluid or the workover fluid can be adjusted by adding monovalent salt NaCl or KCl; the solution apparent viscosity can be controlled by adjusting the concentration of the water-absorbing resin; and the dosage of the well completion fluid or the workover fluid can be designed according to the volume of a shaft. In the method, the physical and the chemical changes can occur under the high temperature to form a manual well wall, namely a gelatine temporary plugging layer; therefore, the bearing capability of the high-and low-pressure stratum can be effectively improved; the leakage of the well completion fluid or the workover fluid can be prevented at the producing layer, the operation safety and the capacity of the oil and gas well can be ensured, the construction technology is simple, and the cost is relatively low.

Owner:CHINA NAT OFFSHORE OIL CORP +3

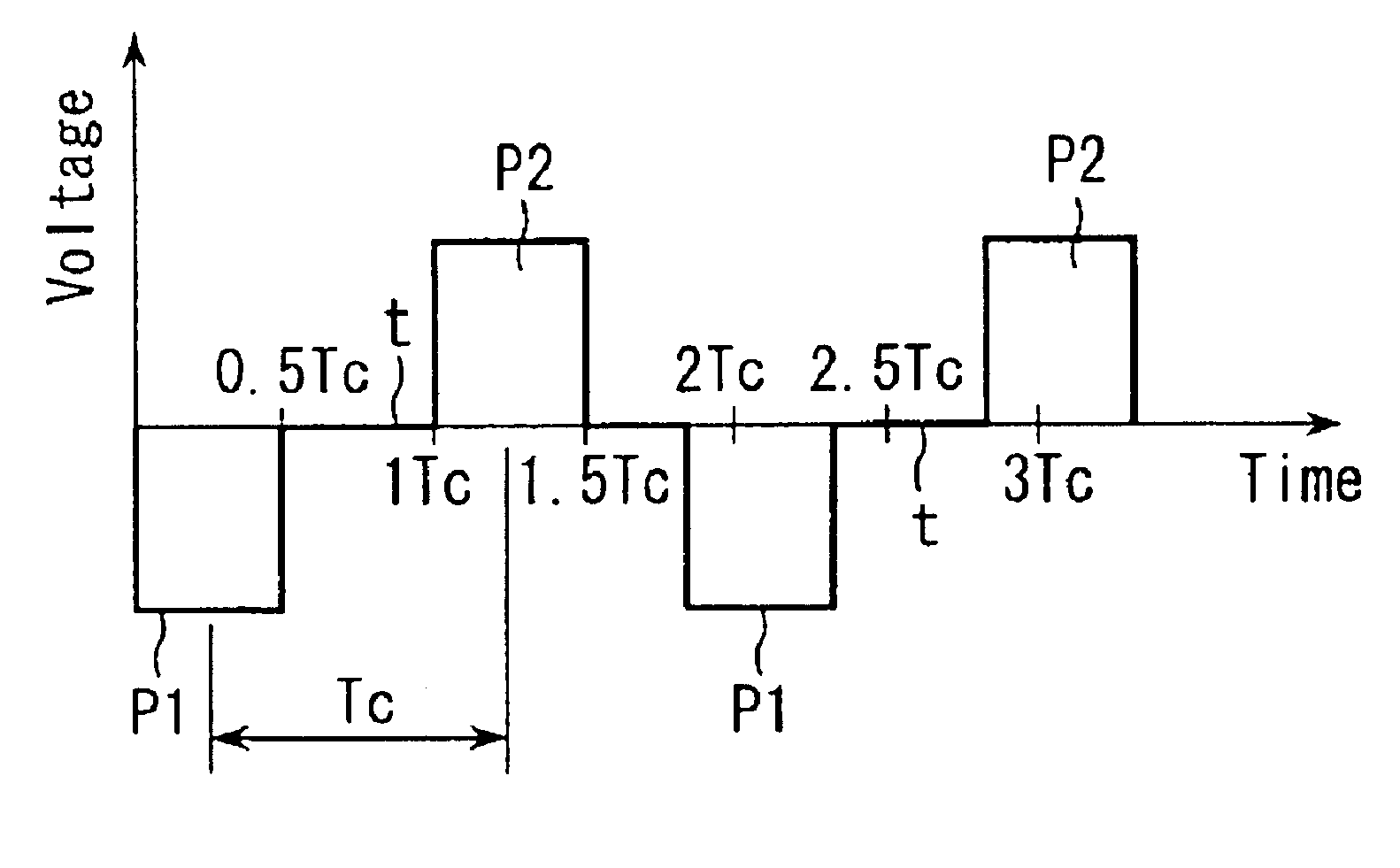

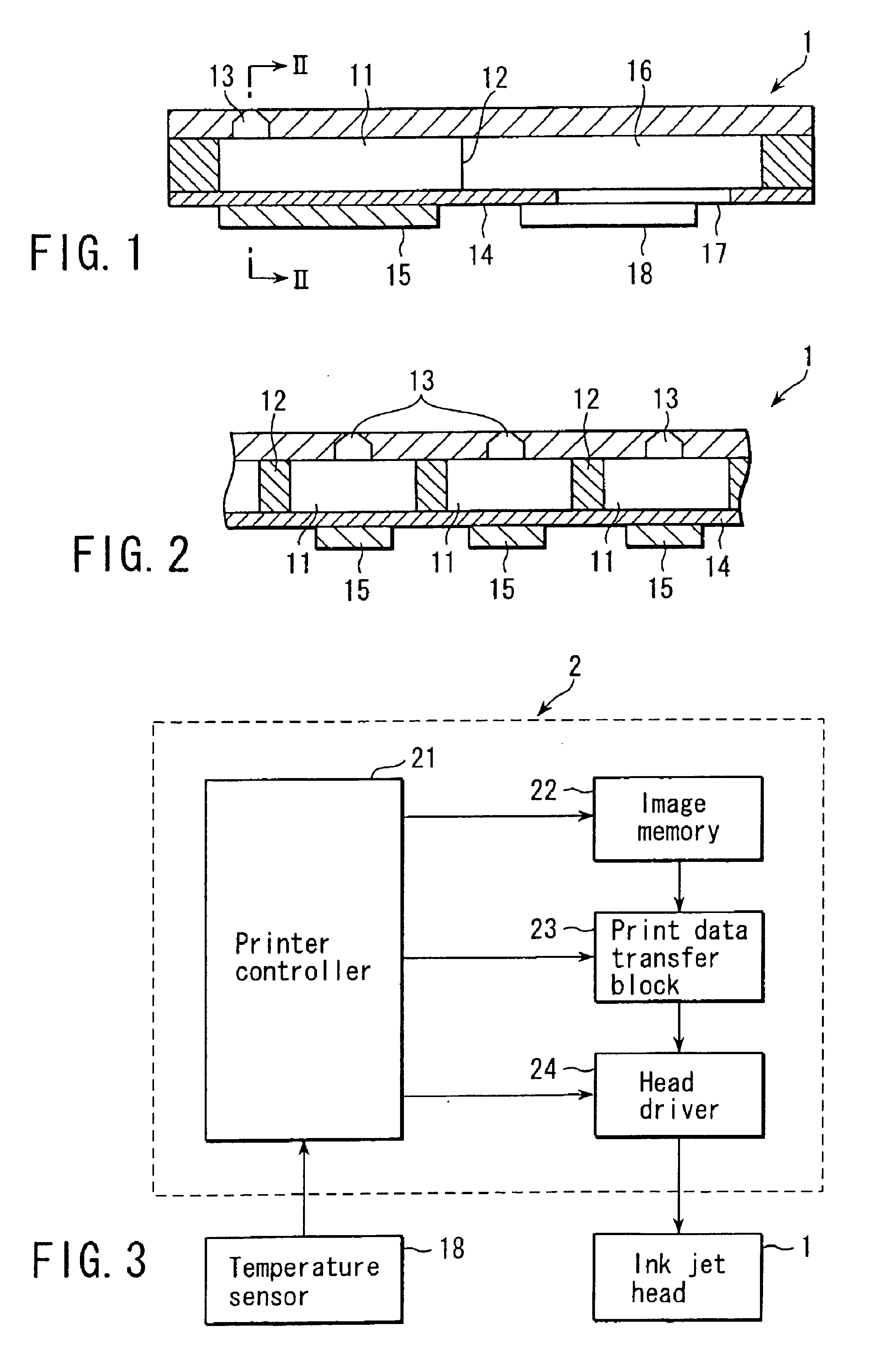

Ink jet recording apparatus

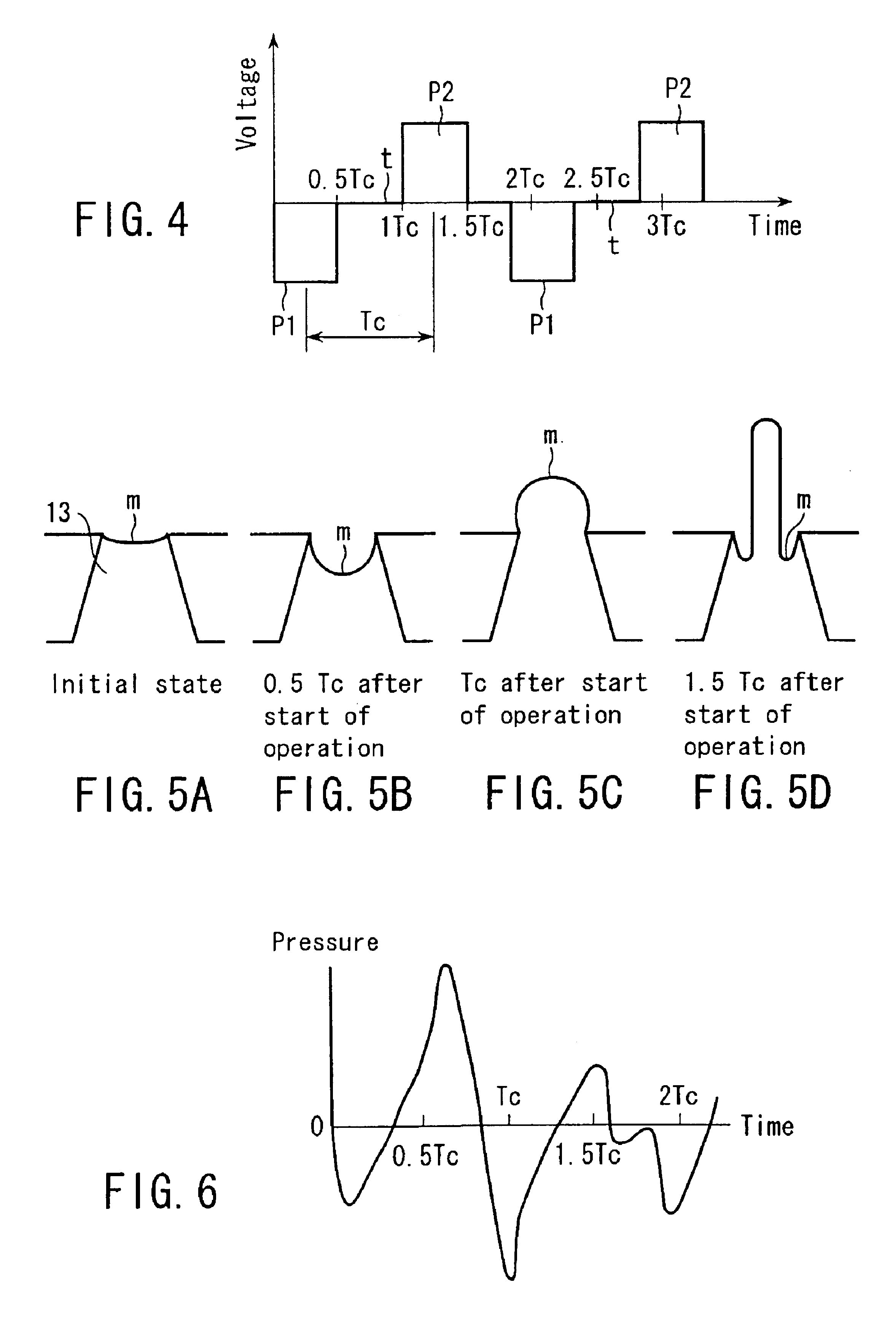

InactiveUS6840595B2Minimize the possibilityIncreasing and reducing capacityTypewritersOther printing apparatusTime lagResonance

An ink jet recording apparatus according to the present invention includes a pressure chamber stored with ink, a nozzle communicating with the pressure chamber and capable of discharging the ink from the pressure chamber, and an actuator for increasing and reducing the capacity of the pressure chamber in response to driving signals from a driving signal generator. The driving signal generator successively generate, an expansion pulse for increasing the capacity of the pressure chamber and a contraction pulse for reducing the capacity of the pressure chamber with a timing such that a time lag between the respective centers of the expansion pulse and the contraction pulse matches the resonance period of a meniscus generated in the nozzle by the ink in the pressure chamber. Thus, the ink jet recording apparatus continuously discharges a plurality of ink drops through the nozzle to form a pixel.

Owner:TOSHIBA TEC KK

Inflating making process and apparatus of spiral wound steel wire reinforced composite plastic pipe

The production method of spiral wrapped steel wire reinforced composite plastic pipe material by using air inflation process includes the following steps: continuously extruding formed polymer core pipe, cutting it into the pipe material with a certain length; charging pressure gas into the core pipe, and sealing to obtain rigid straight sealed gas-charged core pipe, feeding said core pipe into steel wire wrapping machine, right-hand and / or left-hand wrapping steel wire round the core pipe, at least wrapping one layer of steel wire as reinforcing body, then feeding said material into polymer outer layer combination device to obtain composite pipe material, diameter-setting and forming, cooling to obtain the invented product with high quality. Said pipe material is long in service life.

Owner:甘国工

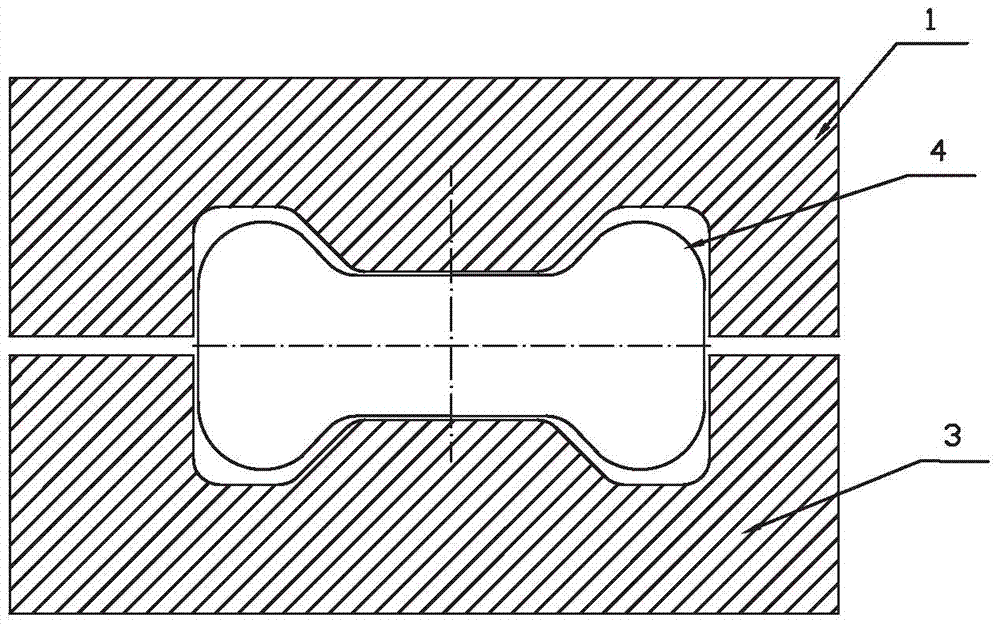

High-pressure forming method in pipe

The invention discloses a high-pressure forming method a in pipe. The method comprises the steps that the pipe is firstly placed in a die cavity of a pipe element to be formed of a lower mold, a sealing punch is driven by a side push cylinder to enter two ends of the pipe, and the end sealing of the pipe is completed; an upper mold is driven by a slide block of a mold assembling press machine to descend to a position with a certain height from the lower mold, high-pressure liquid is introduced into the pipe, and in addition, the inner pressure of the pipe is matched with the upper mold stroke until the mold assembling is completed; the pressure maintaining is carried out or the pressure is properly increased for shaping the pipe. The method has the advantages that the mold assembling force is utilized for promoting straight edge section materials to move towards the round corner position of a forming mold, so the pressure required for forming the round corner position is obviously reduced, the thick-wall and high-intensity steel pipe element forming requirements are met, and meanwhile, the requirements on the maximum tonnage of the mold assembling press machine, the pressure bearing capability required by the mold, the reliability of a sealing structure and the pressure of a pressure booster are reduced, so the production cost is reduced, in addition, the uniform wall thickness of the pipe is favorably realized, and the excessive thinning and cracking of the thick wall in the forming process is avoided.

Owner:DALIAN DESIGN INST CO LTD CHINA FIRST HEAVY IND +1

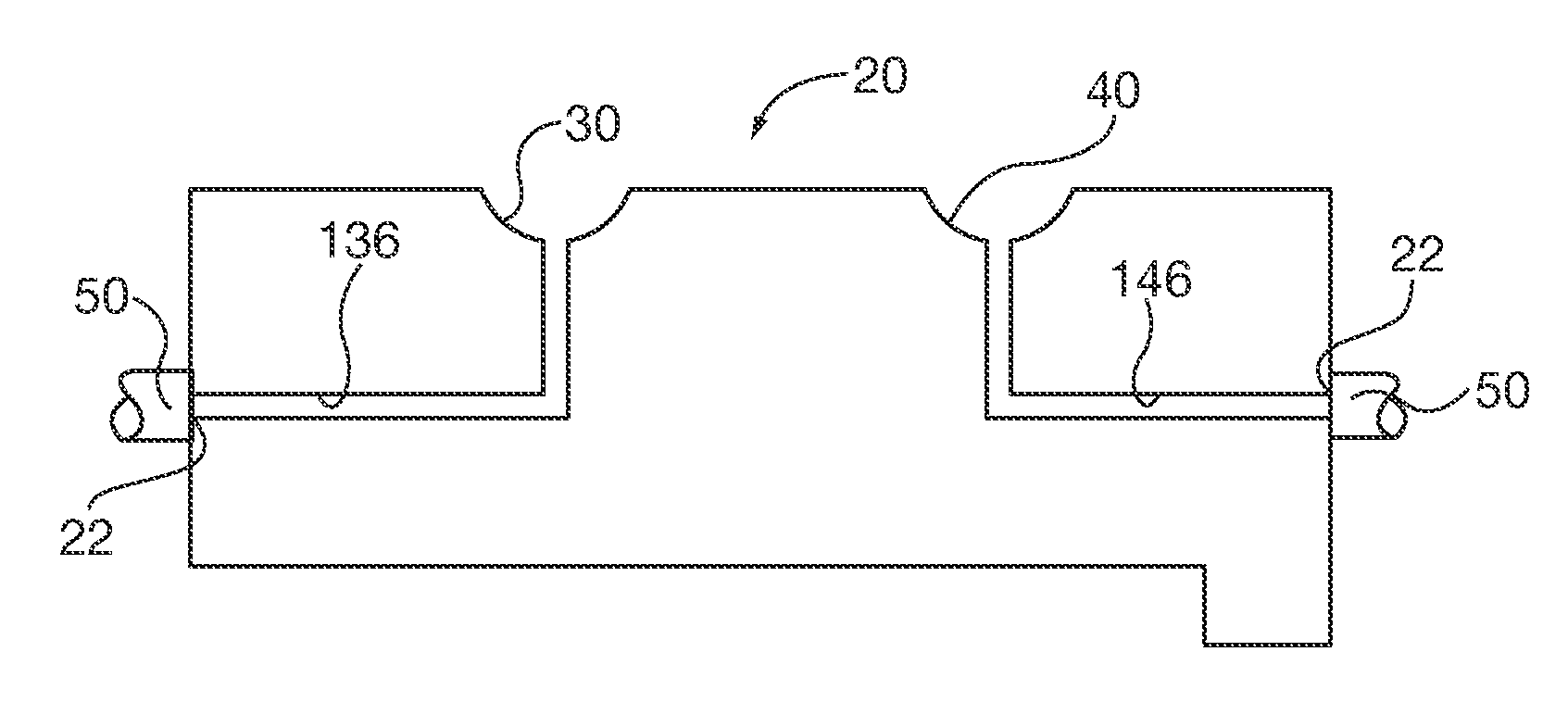

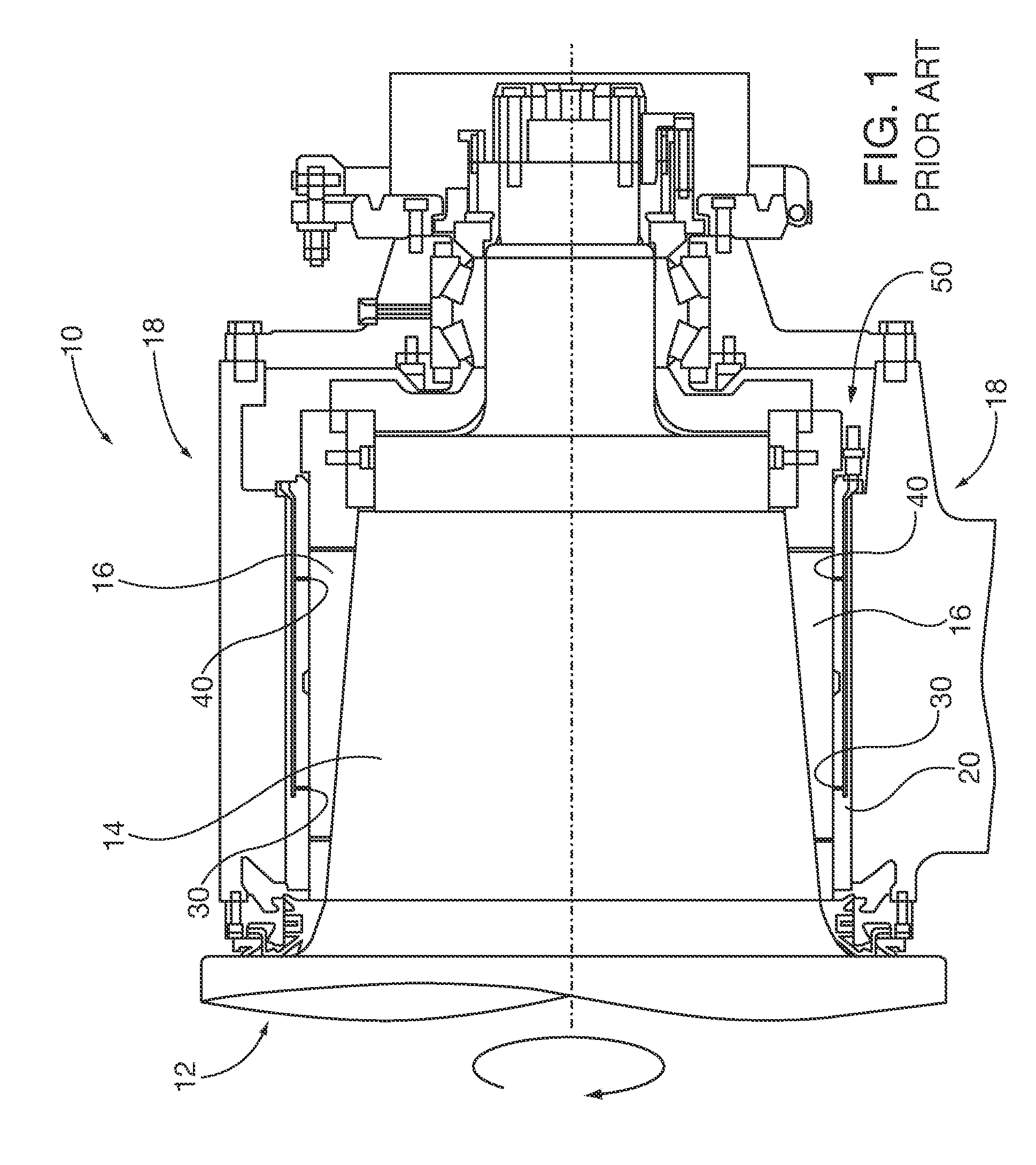

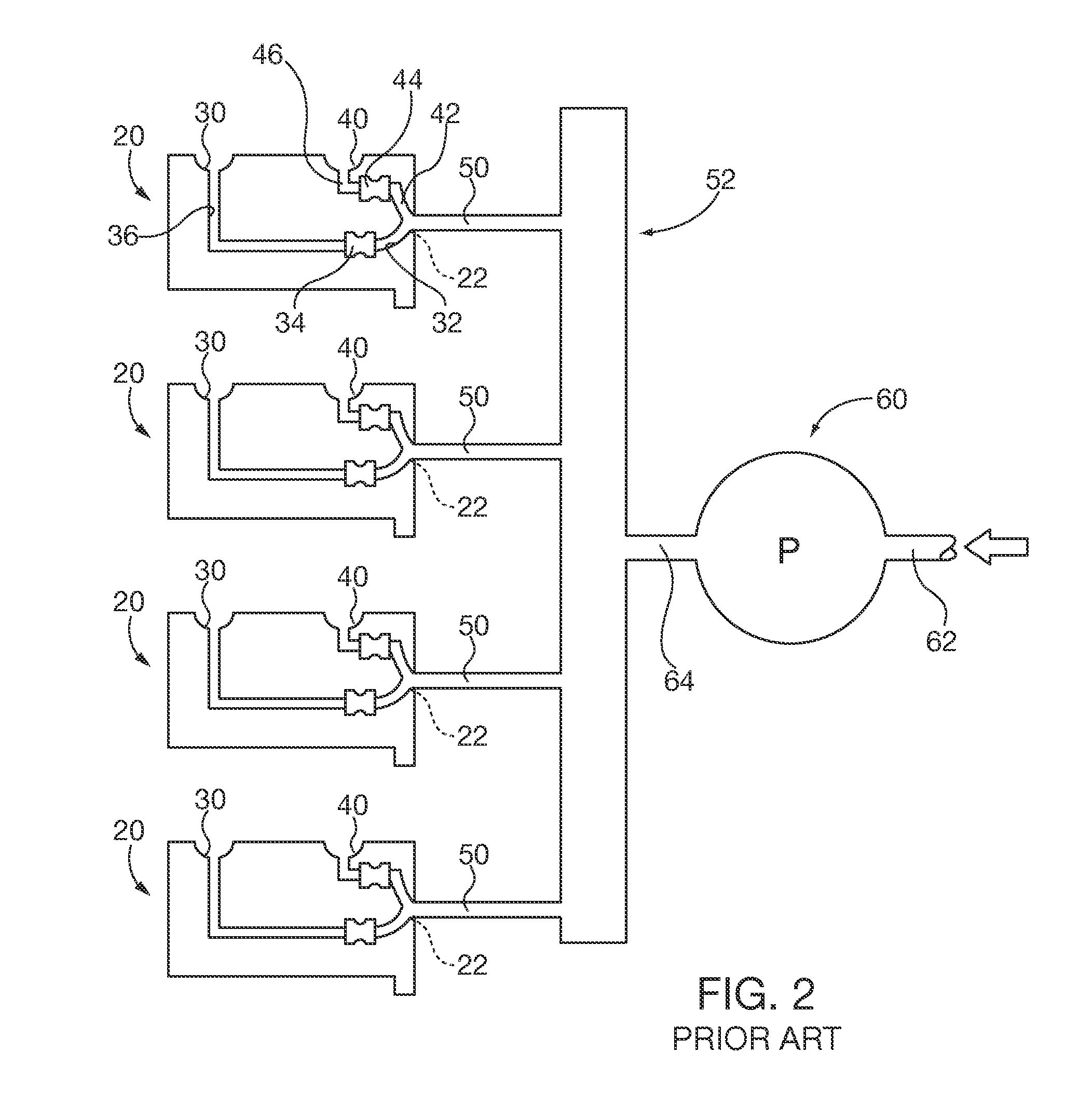

Hybrid hydrodynamic and hydrostatic bearing bushing and lubrication system for rolling mill

ActiveUS20130081438A1Lower cost of capitalReduce energy consumptionMetal rolling stand detailsRolling equipment maintainenceHydrostatic pressureLubrication

Rolling mill bearings incorporate bearing bushings with pluralities of hydrostatic pad recesses, that are preferably in conjunction hydrodynamic bearings also formed within the bushing. Each recess has an isolated lubricant passage that is adapted for coupling to a separate isolated source of pressurized lubricant. In some embodiments herein, the isolated pressurized lubricant source is supplied by a dedicated outlet of a pressure pump. In this manner each hydrostatic pad recess has a dedicated pressurized lubricant supply that is not interrupted by loss of lubricant pressure events in other bearing pads or elsewhere within the rolling mill lubrication system.

Owner:PRIMETALS TECH USA

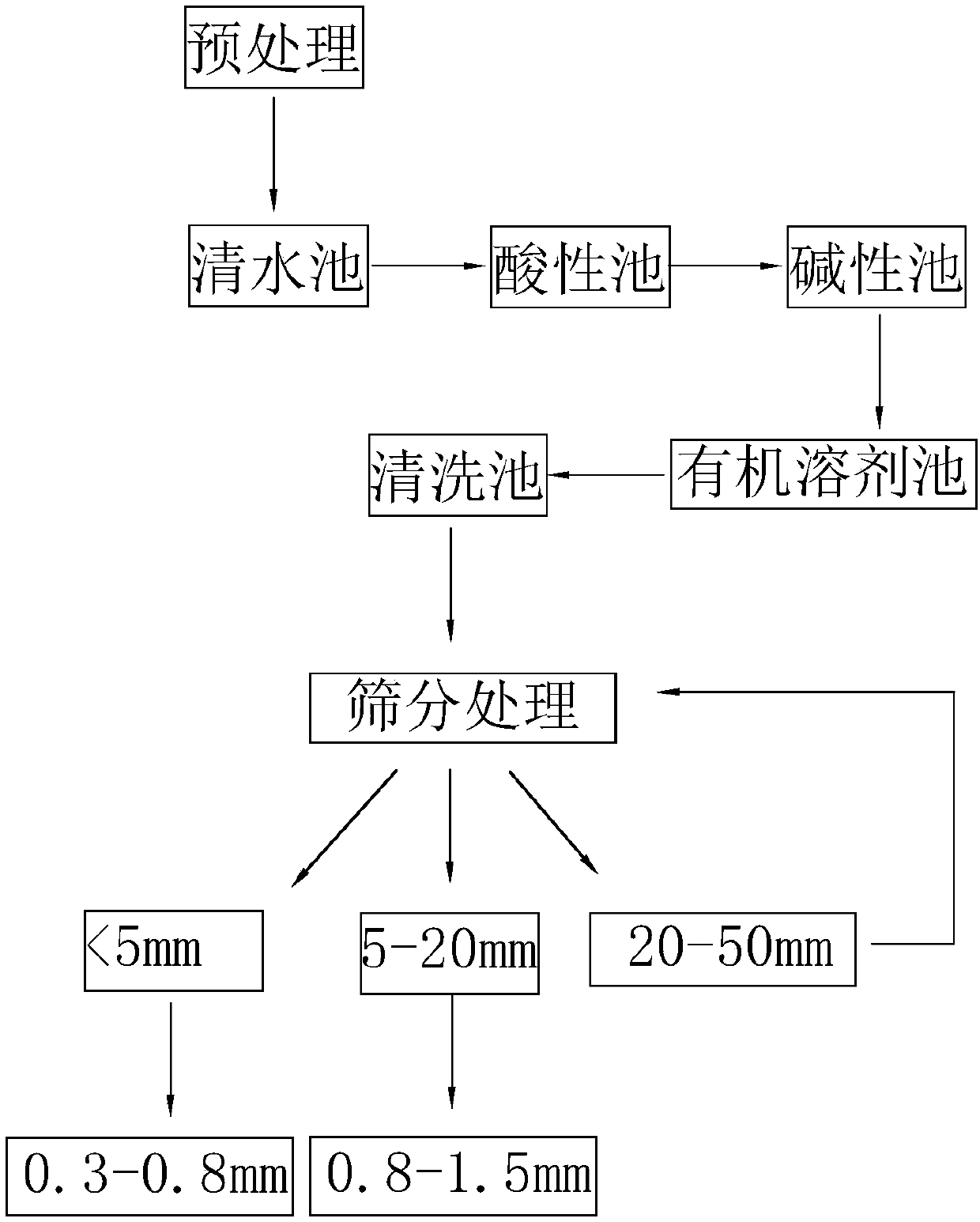

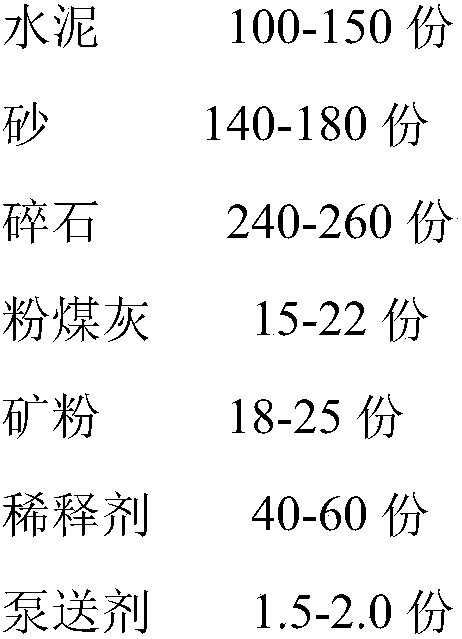

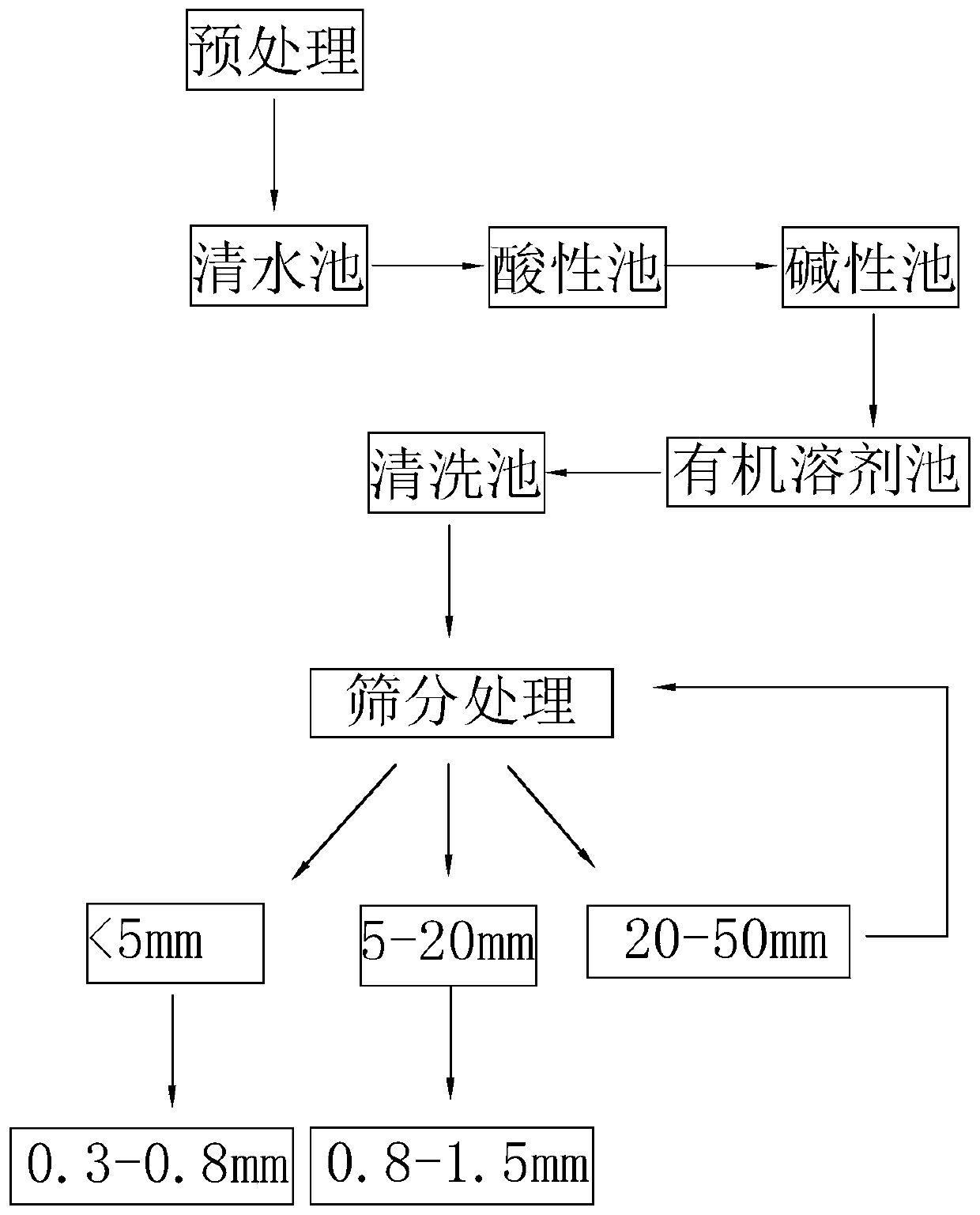

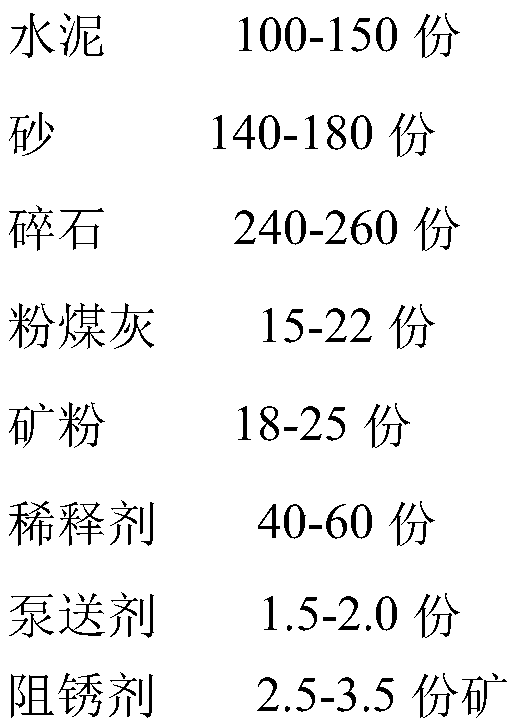

Concrete regeneration process and concrete formula

The invention relates to a concrete regeneration process and a concrete formula. The process comprises the following steps: step 1, pretreatment; step 2, impurity filtration; step 3, impurity adsorption; step 4, screening treatment; step 5, crushing treatment; and step 6, drying and collection. Various raw materials adopted in the scheme meet an environmentally-friendly concept, and in the raw materials, materials such as mineral powder, fly ash and mineral admixture are waste materials, and the process belongs to waste utilization and reasonable application of resources; recycled aggregate has the characteristics of high porosity, large water absorption rate and the like, and therefore the recycled concrete is a porous material; and human walking ways do not have high requirements on load-bearing capacity, and therefore the recycled concrete can be used through casting molding.

Owner:国泷集团有限公司

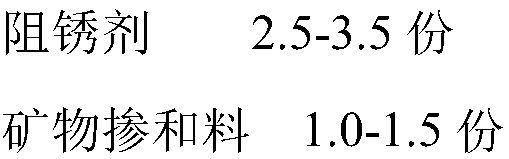

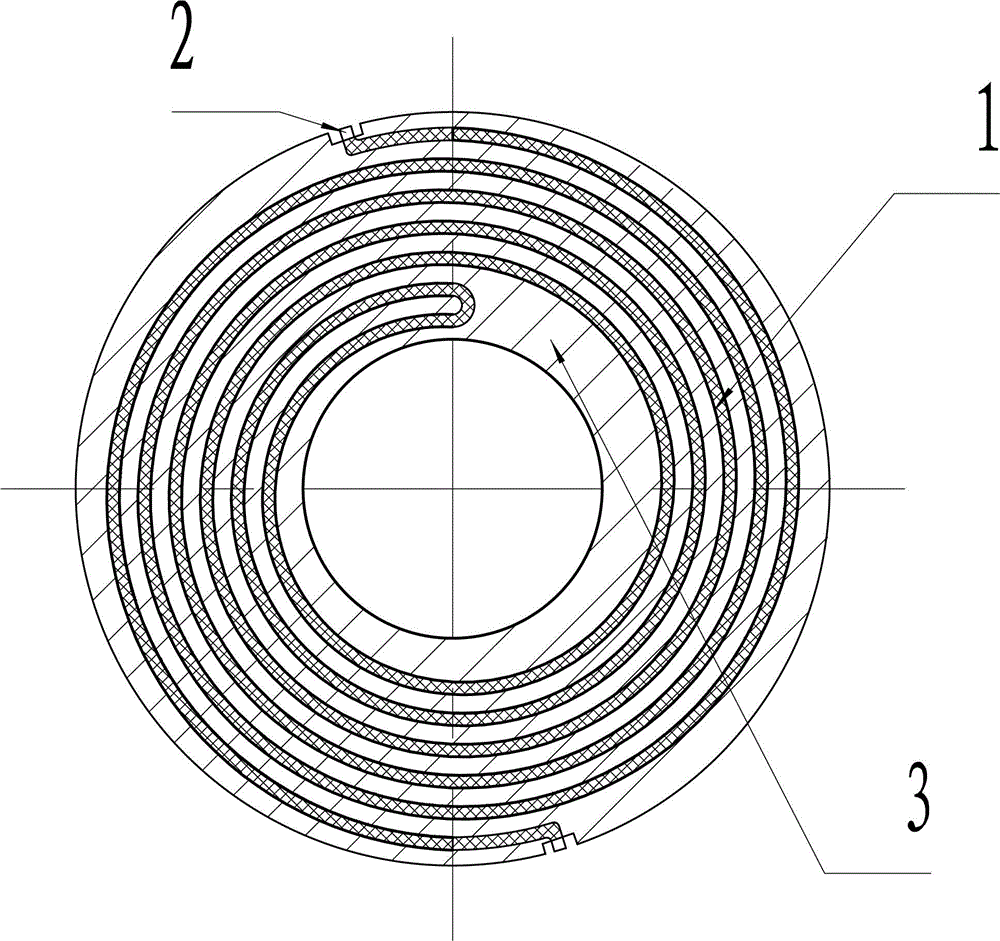

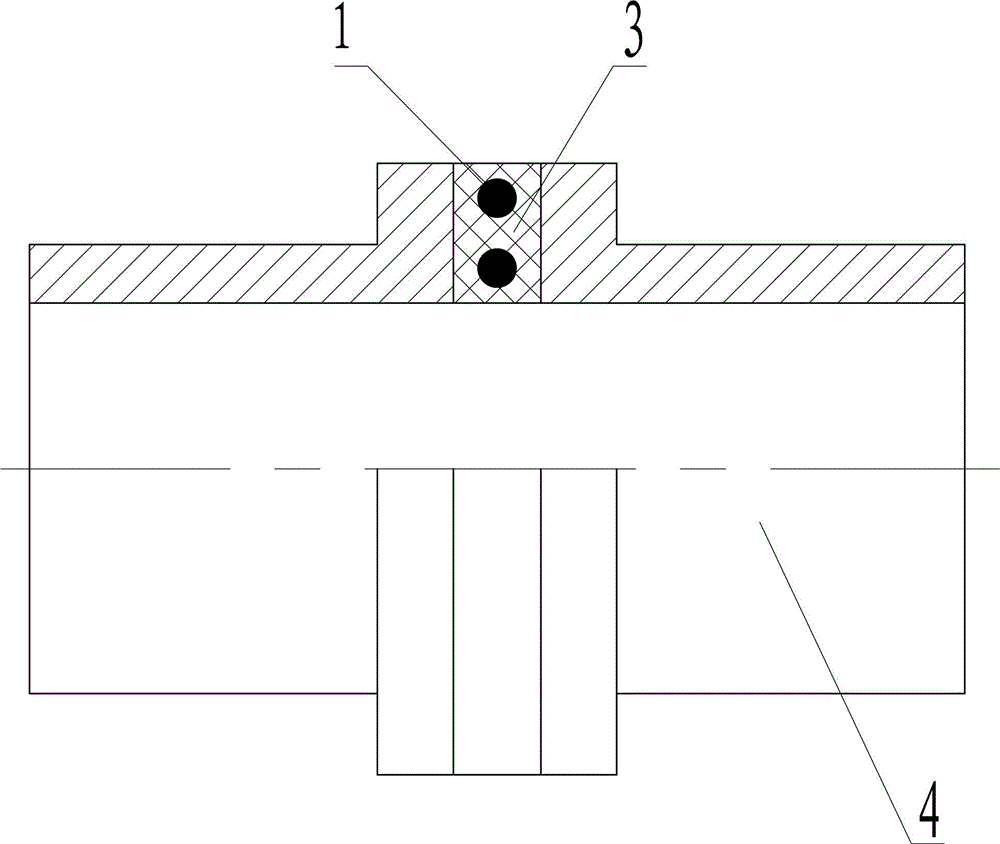

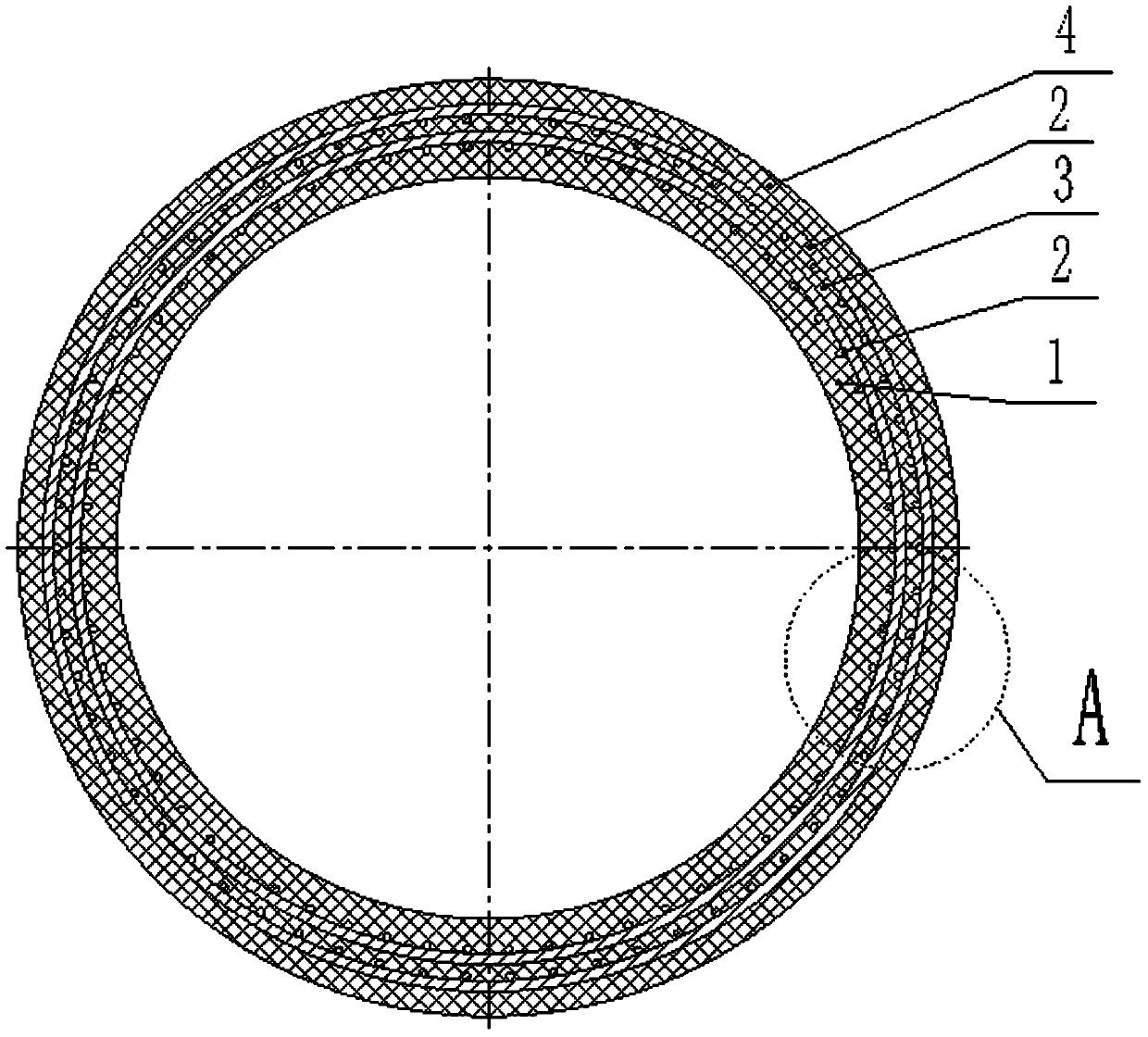

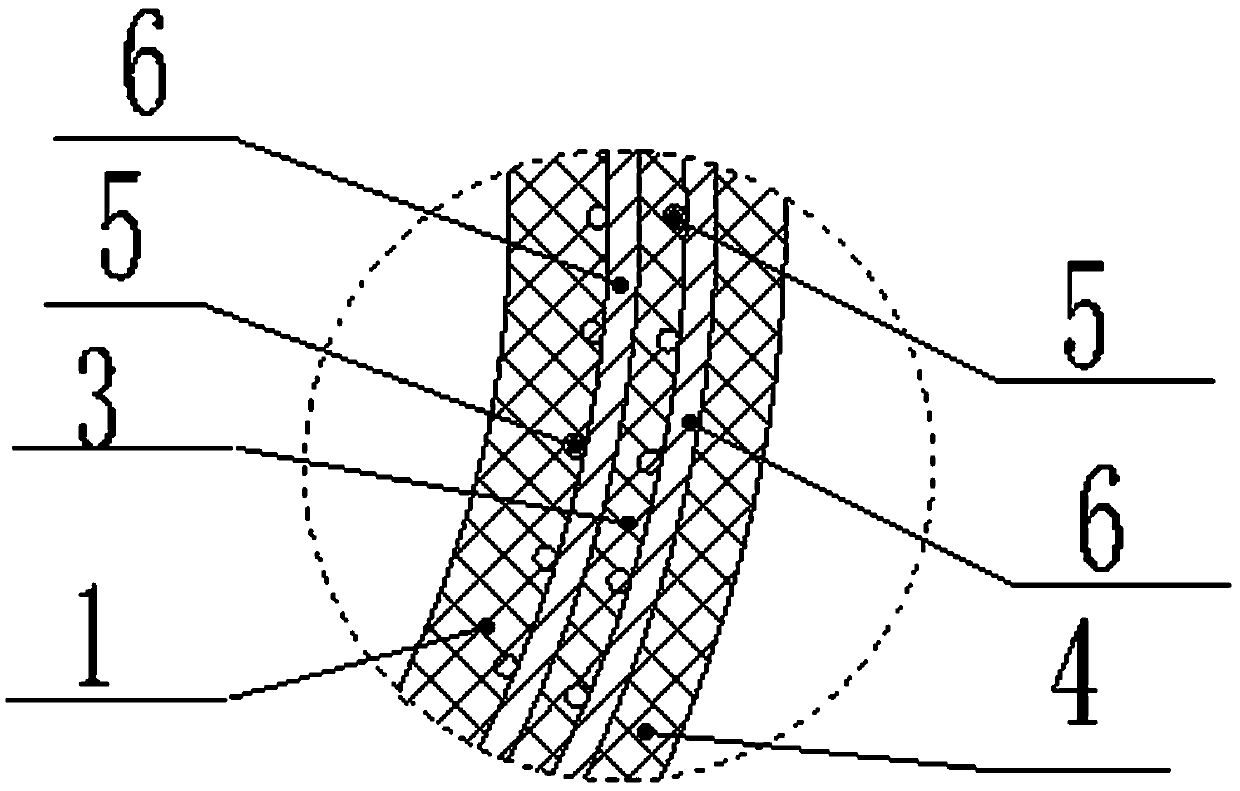

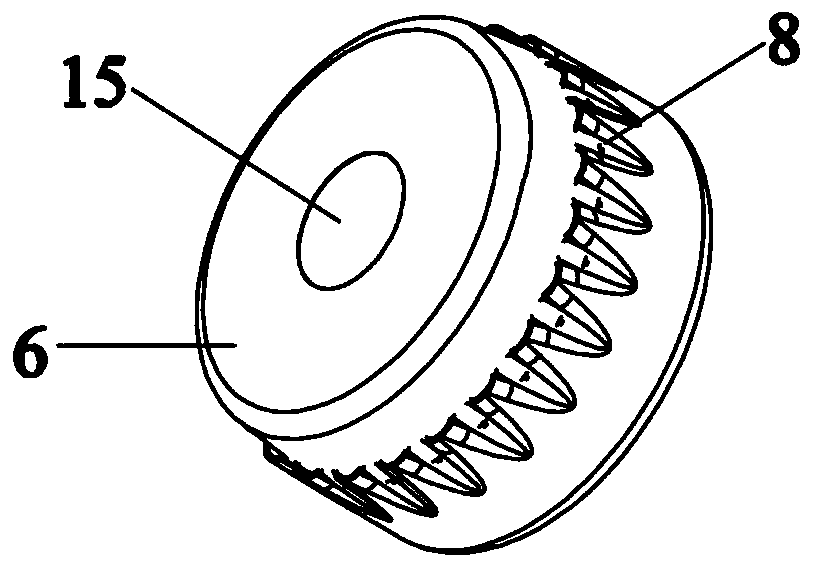

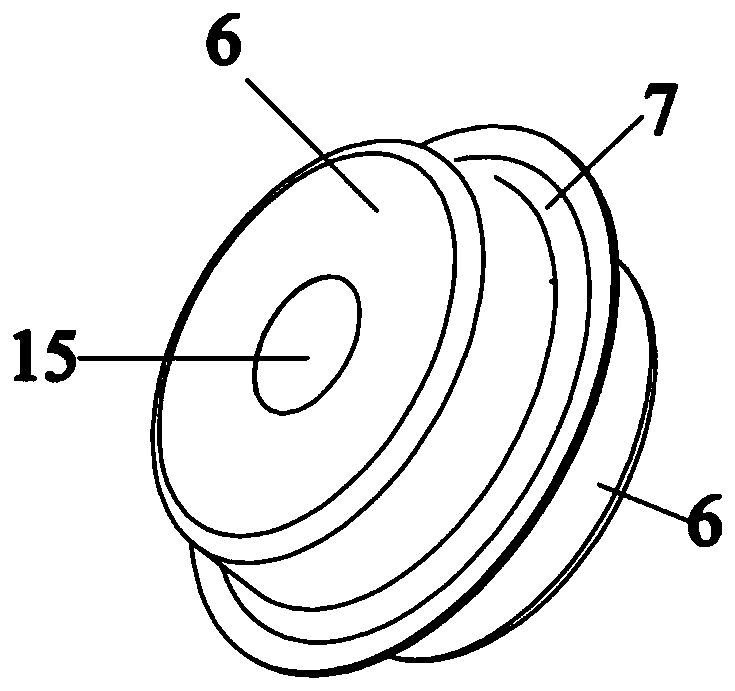

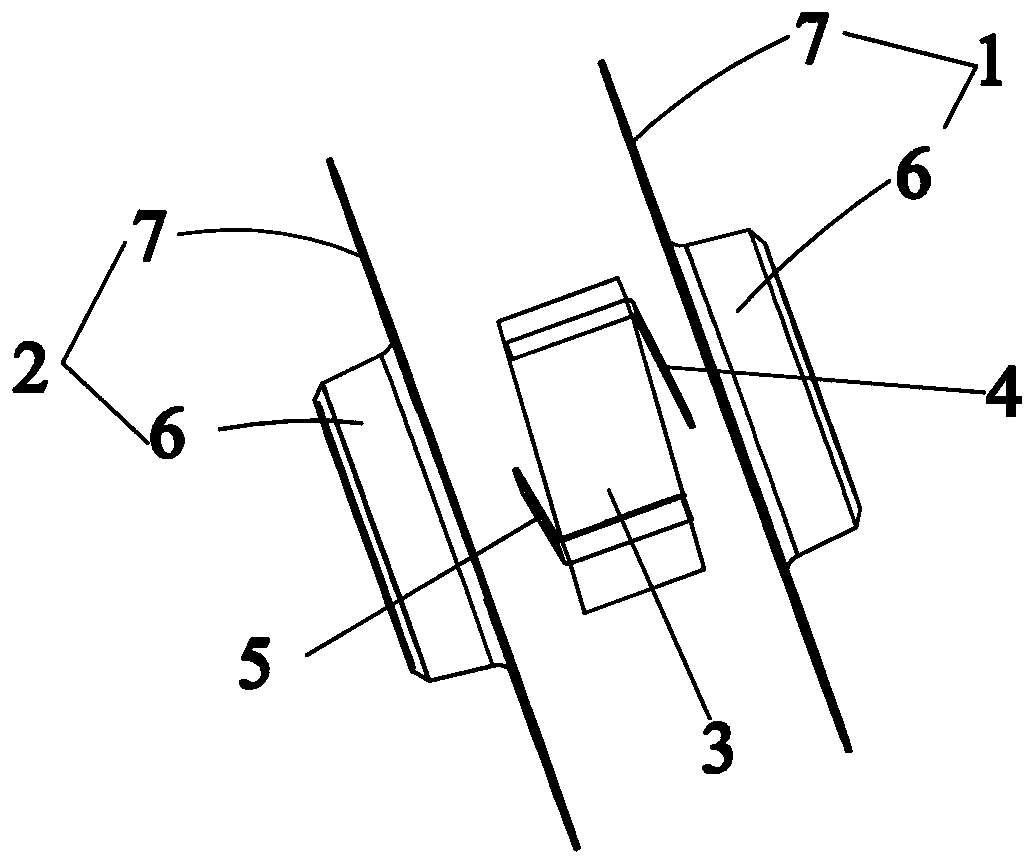

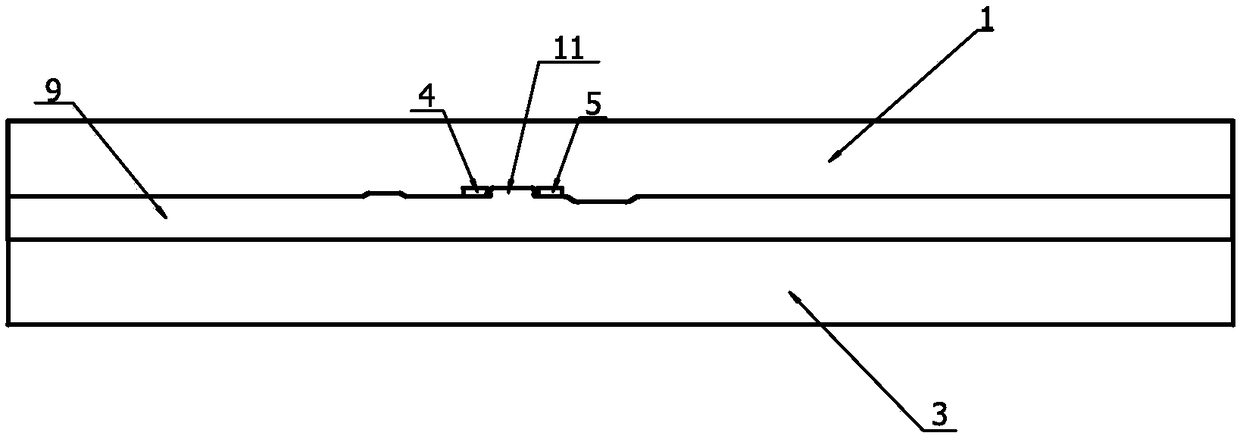

Electric melting pad and method for connecting plastic pipelines or pipelines with pipeline end surfaces made from plastic by virtue of same

InactiveCN105299372AAvoid uneven heatingReduced pressure capacityPipe connection arrangementsThermoplasticResistance wire

The invention discloses an electric melting pad and a method for connecting plastic pipelines or pipelines with pipeline end surfaces made from plastic by virtue of the same. The electric melting pad comprises a thermoplastic plastic pad, conductive resistance wires inlaid in the thermoplastic plastic pad and distributed in the form of Archimedes double helix, and two conductive electrodes connected with the conductive resistance wires, wherein the conductive electrodes are arranged in grooves in the external circular surface of the thermoplastic plastic pad; and the two plastic pipelines or the pipelines with pipeline end surfaces made from plastic can be connected by virtue of the electric melting pad. The conductive resistance wires in the electric melting pad disclosed by the invention are distributed in the form of Archimedes double helix, thus avoiding that one end of each of the conductive electrodes is arranged on the internal annular circular surface of the electric melting pad, and then preventing the possibility of outward leakage of a fluid along the conductive resistance wires, and the phenomenon of unbalanced heating of the parts of the electric melting pad can be avoided.

Owner:HUACHUANG TIANYUAN IND DEVING

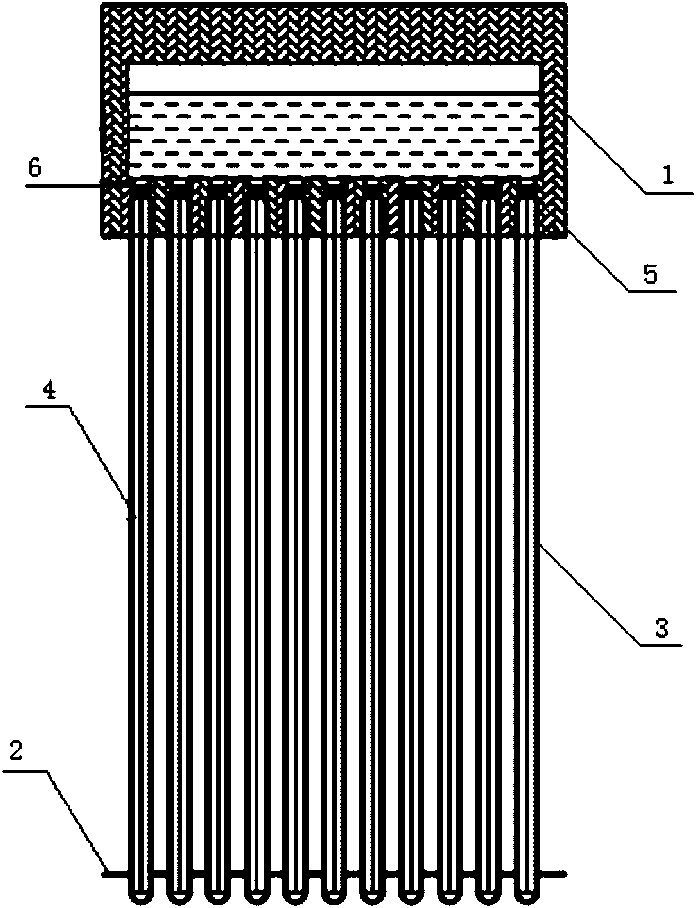

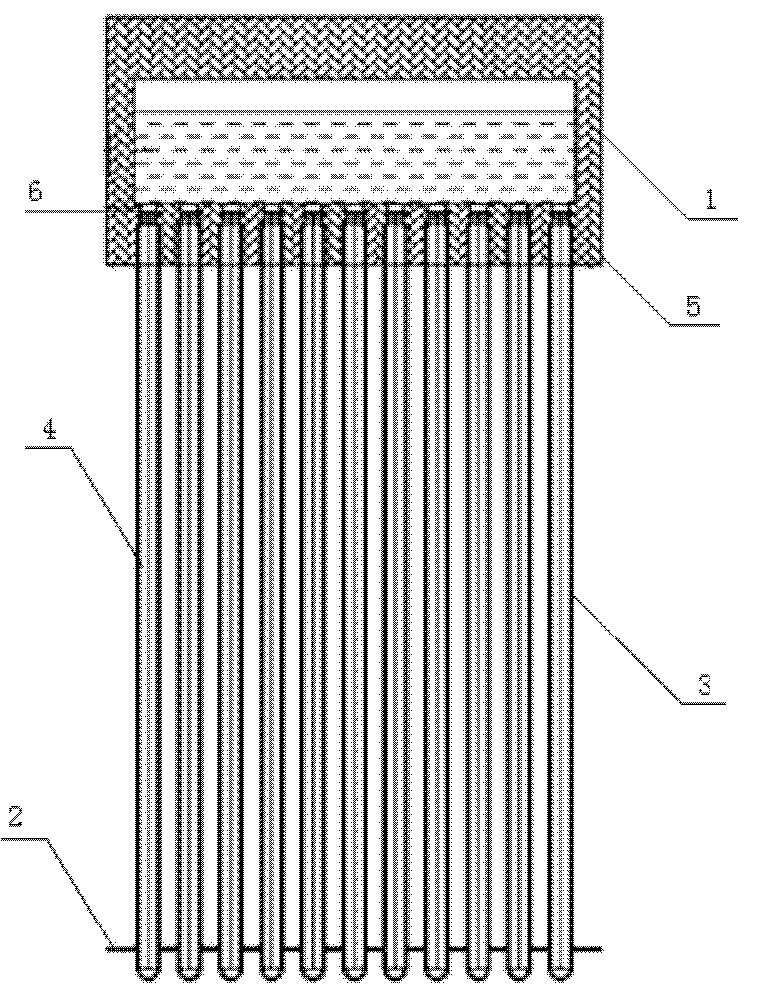

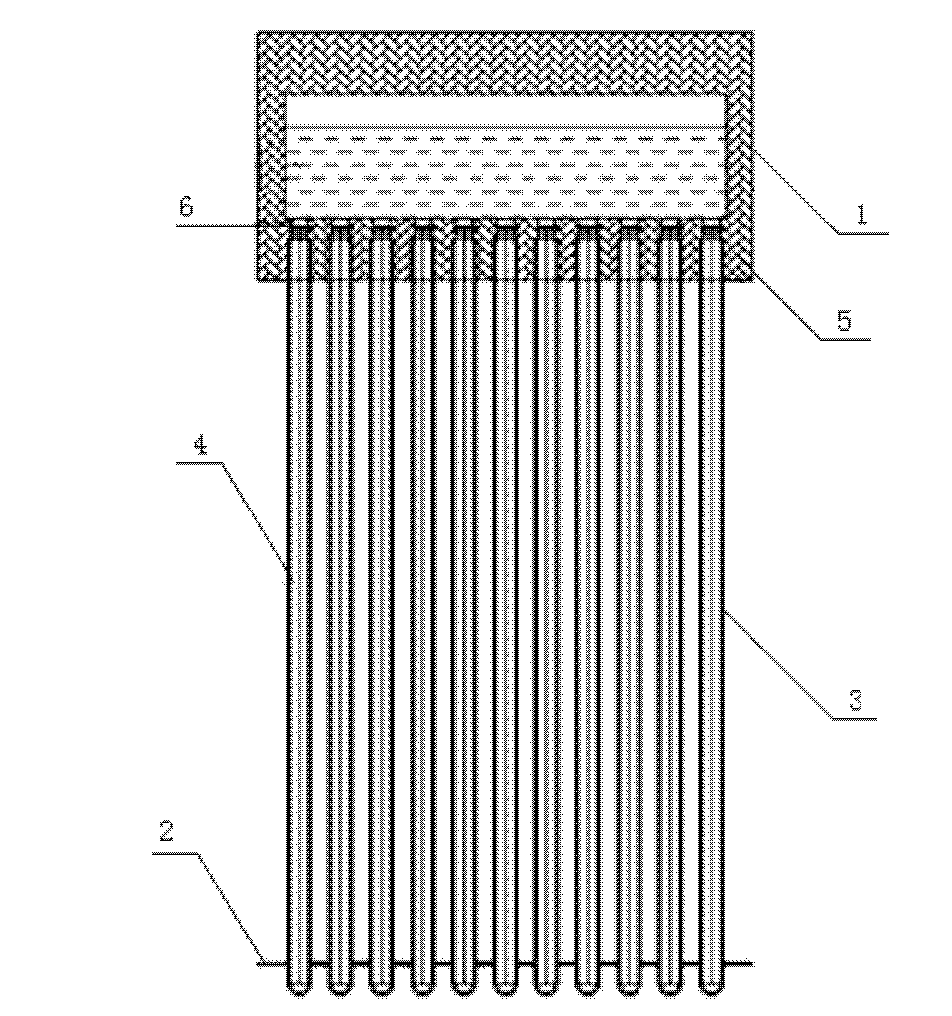

U-shaped tube type heat exchanger

InactiveCN101629764ALarge diameterIncrease the pipe diameterSolar heating energySolar heat devicesSolar water heating systemEngineering

The invention relates to a U-shaped tube type heat exchanger which belongs to the technical field of solar energy heat utilization. The U-shaped tube type heat exchanger comprises a heat collection tube and is characterized by being provided with a U-shaped tube bundle and a runner chamber, wherein the U-shaped tube bundle and the runner chamber are combined into a whole and arranged in the heat collection tube; the runner chamber and the heat collection tube are sealed by a high-temperature resistant silica gel ring; the U-shaped tube bundle is formed by longitudinally arranging a plurality of parallel through holes on alloy, and one end of every two tubes is welded form a U-shaped tube elbow to form a plurality of sets of U-shaped tubes; the runner chamber consists of a tube nest with through holes and an end cover, and a cavity is formed between the tube nest and the end cover; the middle part of the cavity is provided with a partition board which divides the cavity into two chambers; and an inlet and outlet of the U-shaped tube bundle are welded in the through holes of the tube nest and communicated with the two cavities. The invention has compact and reasonable structure, high heat exchange efficiency, reliable sealing, long service life and easy production and manufacture and is not only suitable for a hot water system of a single family, but also suitable for a large-area solar hot water system requiring high pressure.

Owner:JIANGSU OLYGE SOLAR TECH

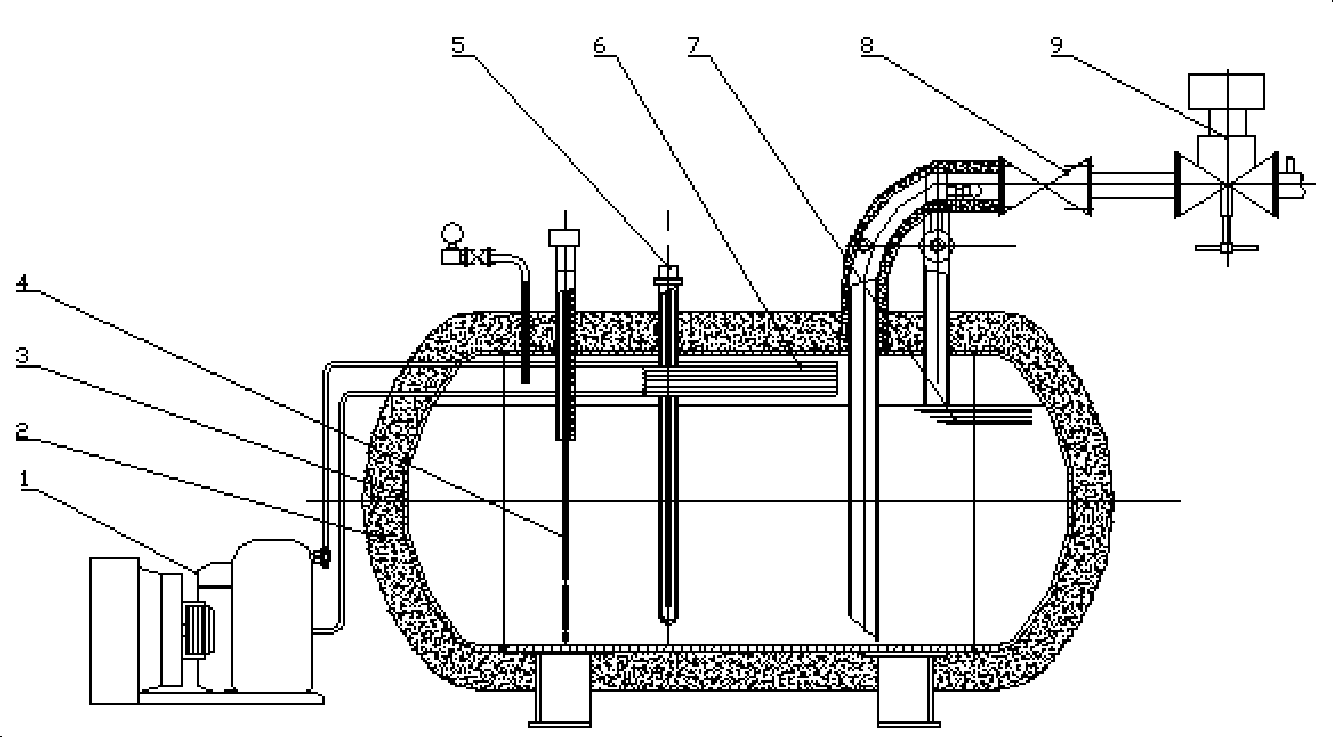

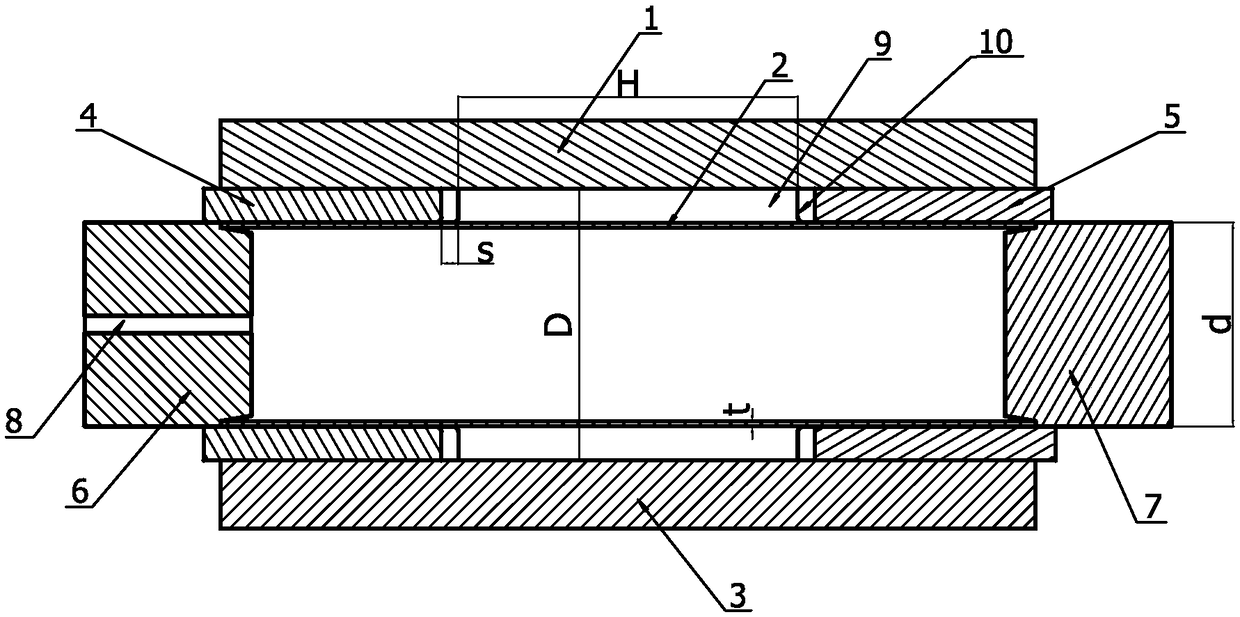

Constant-pressure storage type high-pressure carbon dioxide extinguishing device with built-in evaporator

The invention discloses a constant pressure storage type high-pressure carbon dioxide fire extinguishing device with a built-in evaporator, which comprises an evaporator (6), wherein the evaporator (6) is positioned in a storage container (3), and an inlet pipe and an outlet pipe of the evaporator (6) pass through the storage container (3) respectively and are connected with a refrigerating unit (1). The fire extinguishing device effectively solves the problems that a high pressure carbon dioxide fire extinguishing system has large occupied area and high manufacturing cost, and also effectively solves the problems that a fire extinguishing agent of a low pressure carbon dioxide fire extinguishing system has short conveying distance and is easy to generate ice blockage. At the same time, the fire extinguishing device has good refrigeration effect, and the pressure of carbon dioxide in the storage container can be maintained by adjusting the temperature of the carbon dioxide in the storage container.

Owner:VITALONG FIRE SAFETY GRP

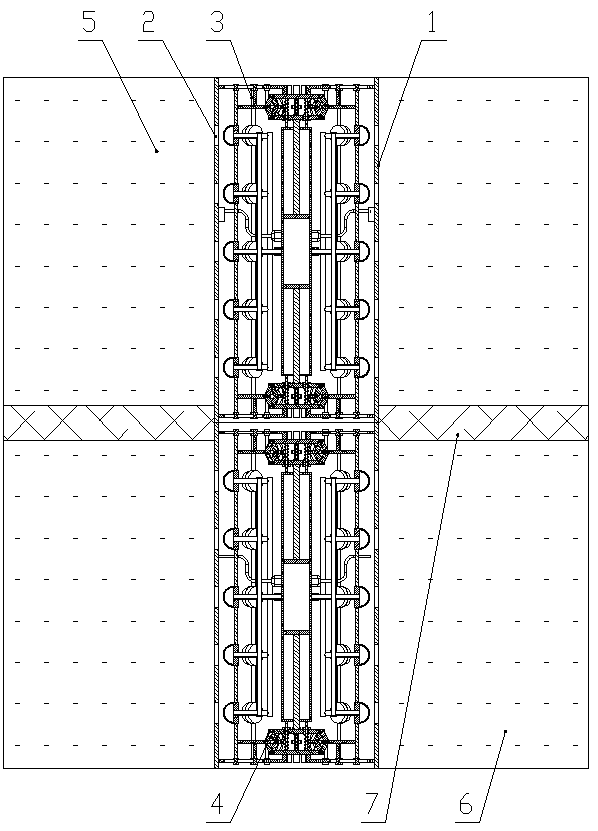

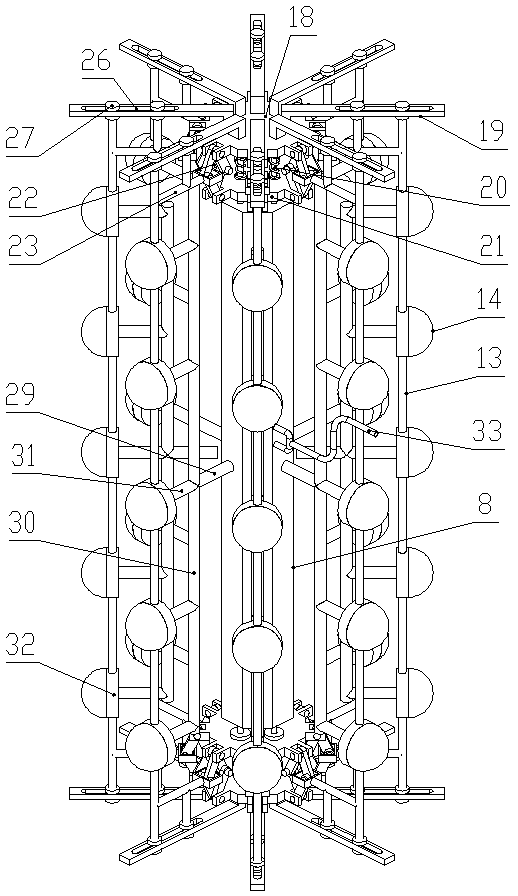

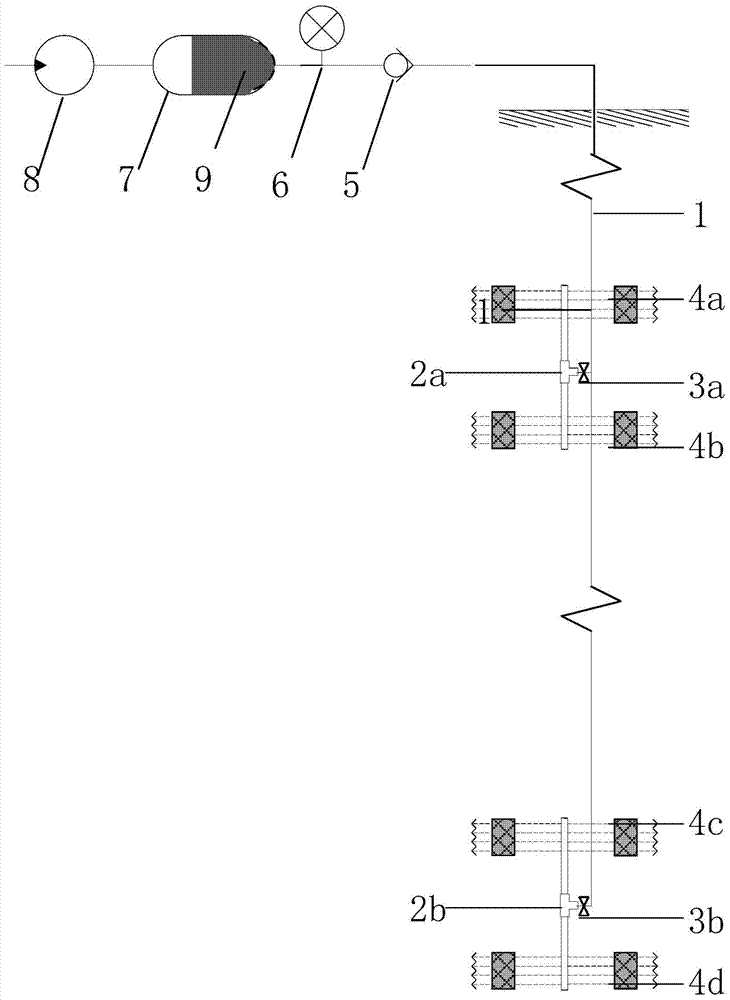

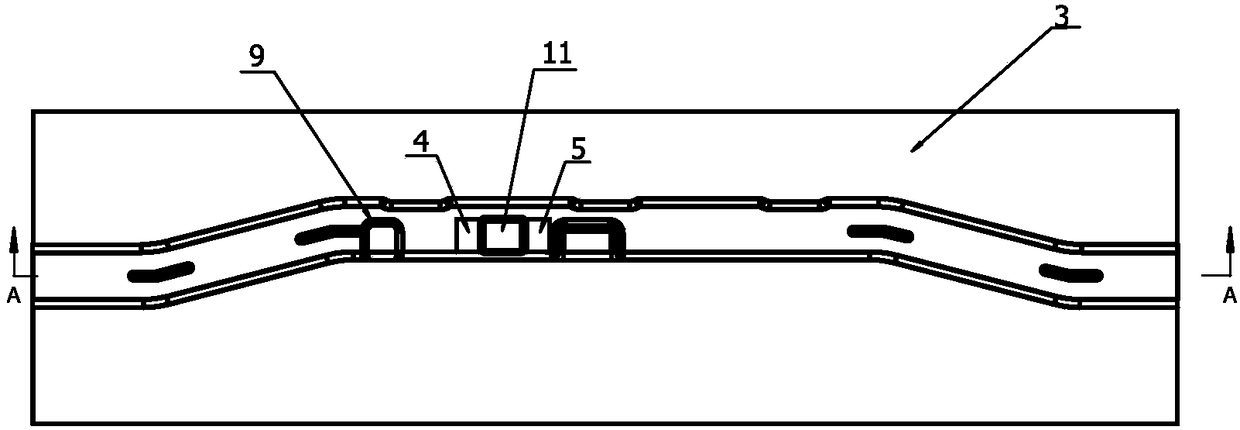

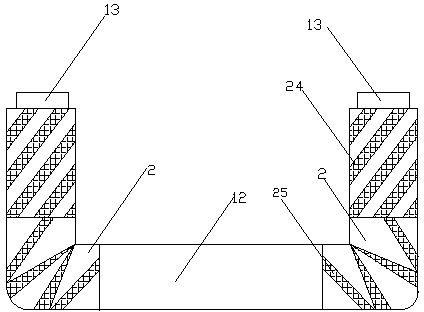

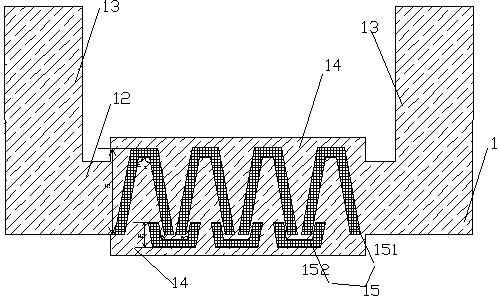

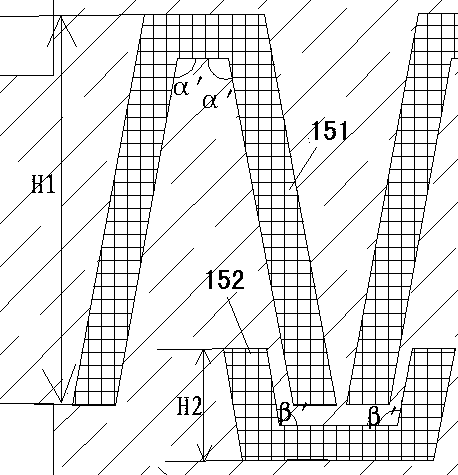

Distributed airbag pressure self-adjusting coalbed methane collecting device

ActiveCN109162677ATo achieve the effect of pressure regulationReduce air pressureFluid removalSealing/packingEngineeringHigh pressure

The invention provides a distributed airbag pressure self-adjusting coalbed methane collecting device which comprises a vertically arranged outer casing which is uniformly provided with a plurality ofventing holes, the outer casing is internally provided with an upper coalbed methane pressure regulating device for adjusting the opening degrees of venting holes at the same height and a lower coalbed methane pressure regulating device for adjusting the opening degrees of venting holes at the same height. The upper coalbed methane pressure regulating device is in an upper gas layer, the lower coalbed methane pressure regulating device is in a lower upper gas layer, and a ground layer is between the upper gas layer and the lower gas layer. The structures of the upper coalbed methane pressureregulating device and the lower coalbed methane pressure regulating device are the same. The distributed airbag pressure self-adjusting coalbed methane collecting device has the advantages of novel design and compact structure, the air pressure adjustment between gas layers of different pressures in a coalbed methane collecting process is achieved through a pure mechanical structure, therefore, both a high-pressure gas layer and an adjacent low-pressure gas layer can be properly pumped, and the difficulty in the efficient development of coalbed methane in multiple coal seams in the southwest is reduced.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

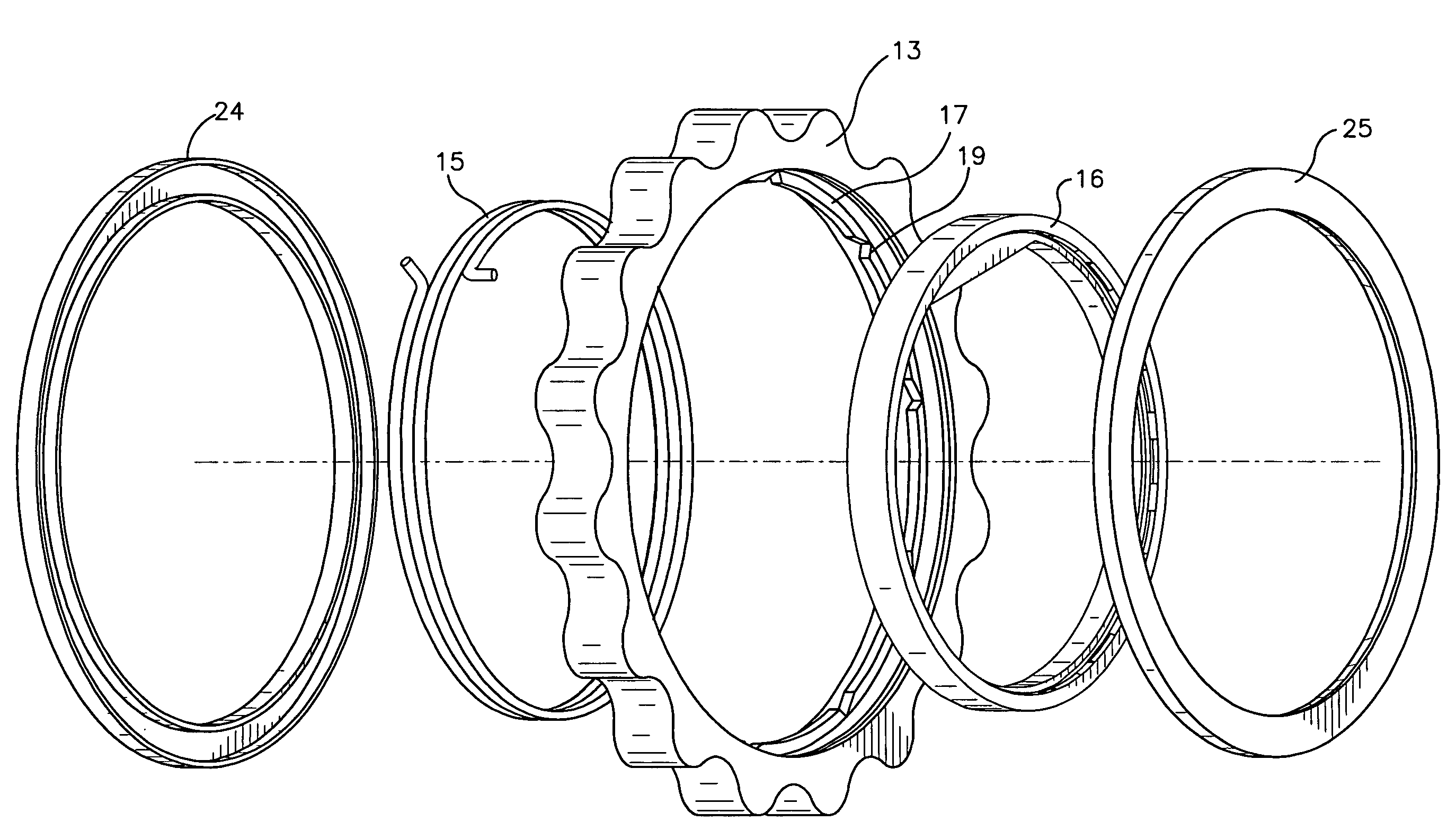

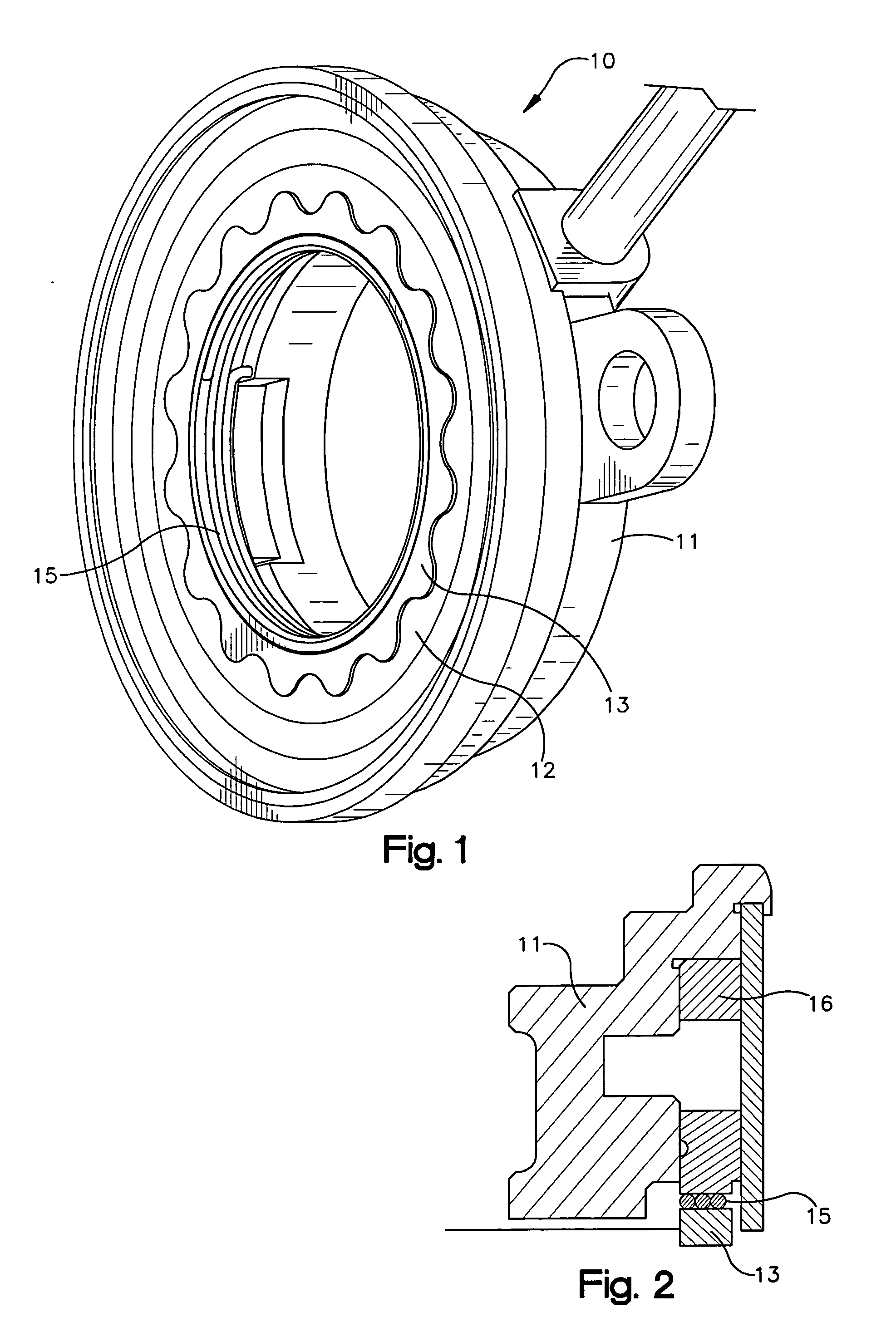

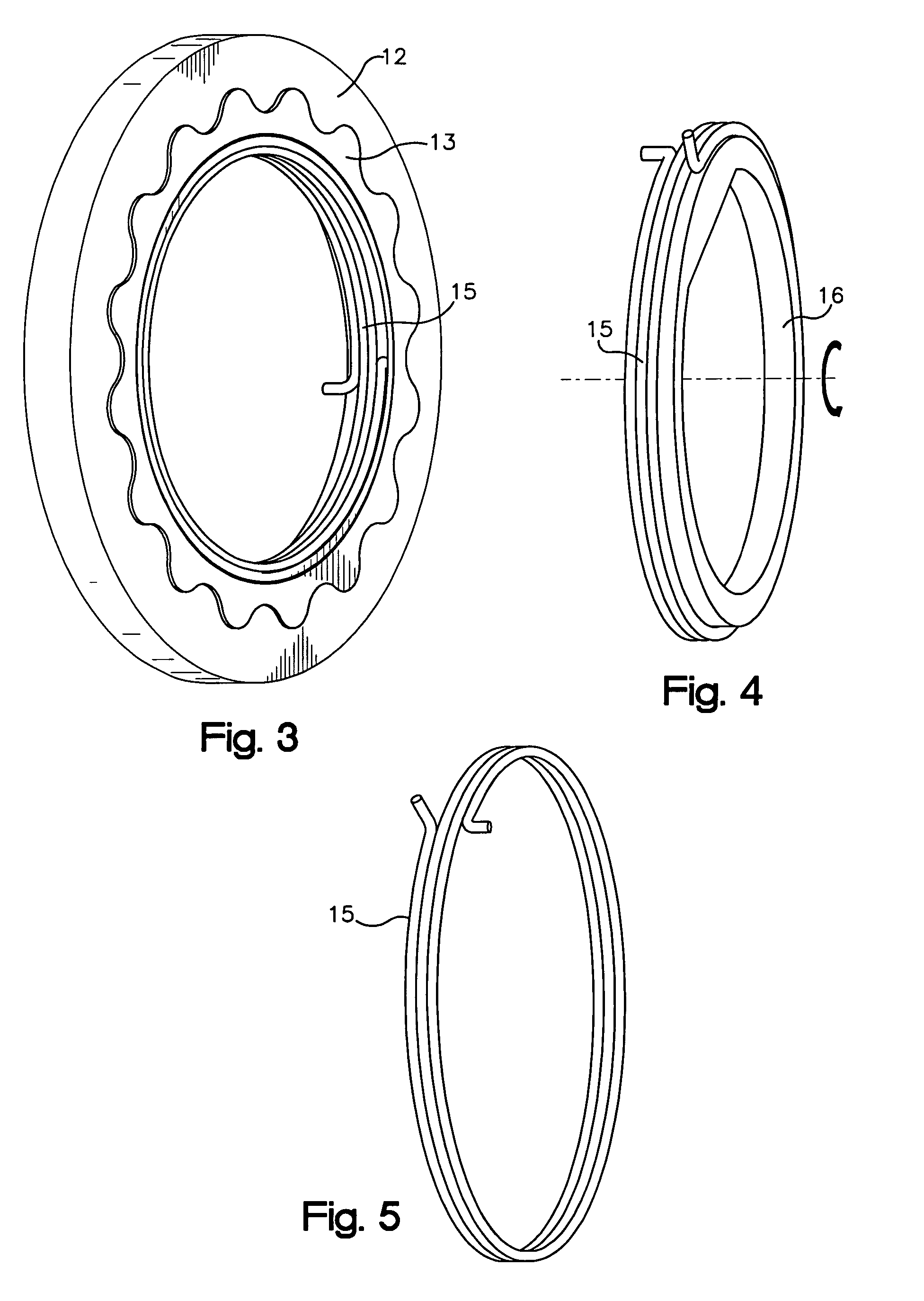

Device for controlling parasitic losses in a fluid pump

InactiveUS20050249622A1Reduce parasitic lossImprove life expectancyOscillating piston enginesRotary piston pumpsClutchEngineering

A device for reducing parasitic loss of a fluid pump is accomplished by connecting the power supply driveshaft to the drive pump element through a clutch element. The clutch element engages the drive pump element and frictionally engages the driveshaft so that at or above a predetermined fluid pressure, the clutch element releases the driveshaft so the driveshaft rotates within the clutch element thereby halting the pumping action of the pump. When the fluid pressure drops below a predetermined fluid pressure, the clutch element reengages the driveshaft to resume the pumping action.

Owner:METALDYNE LLC

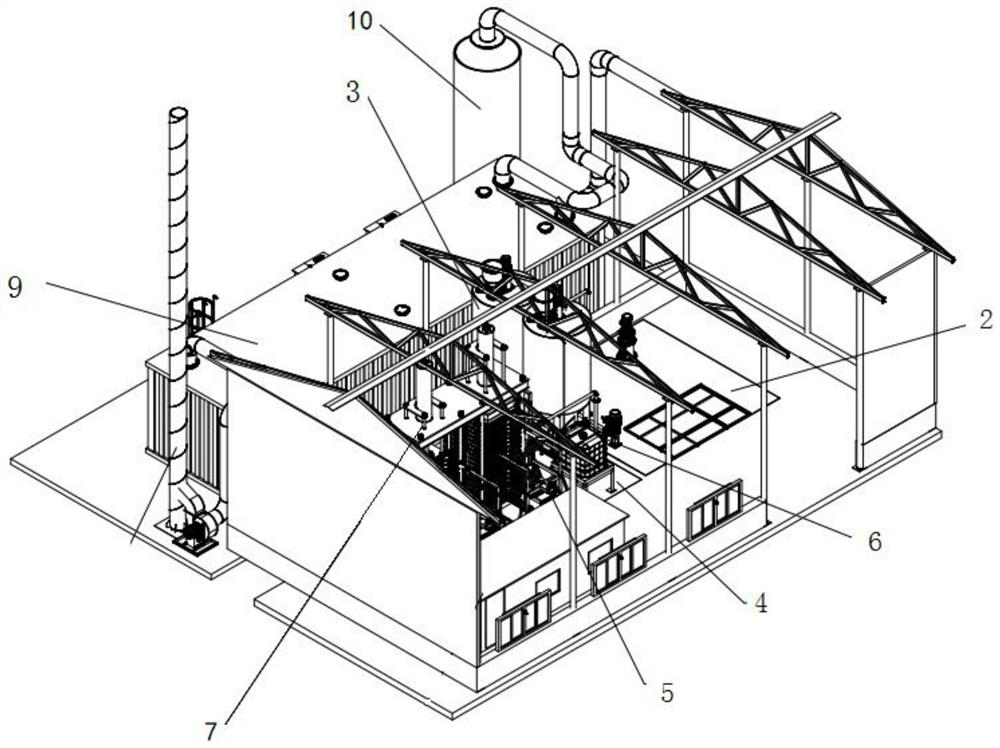

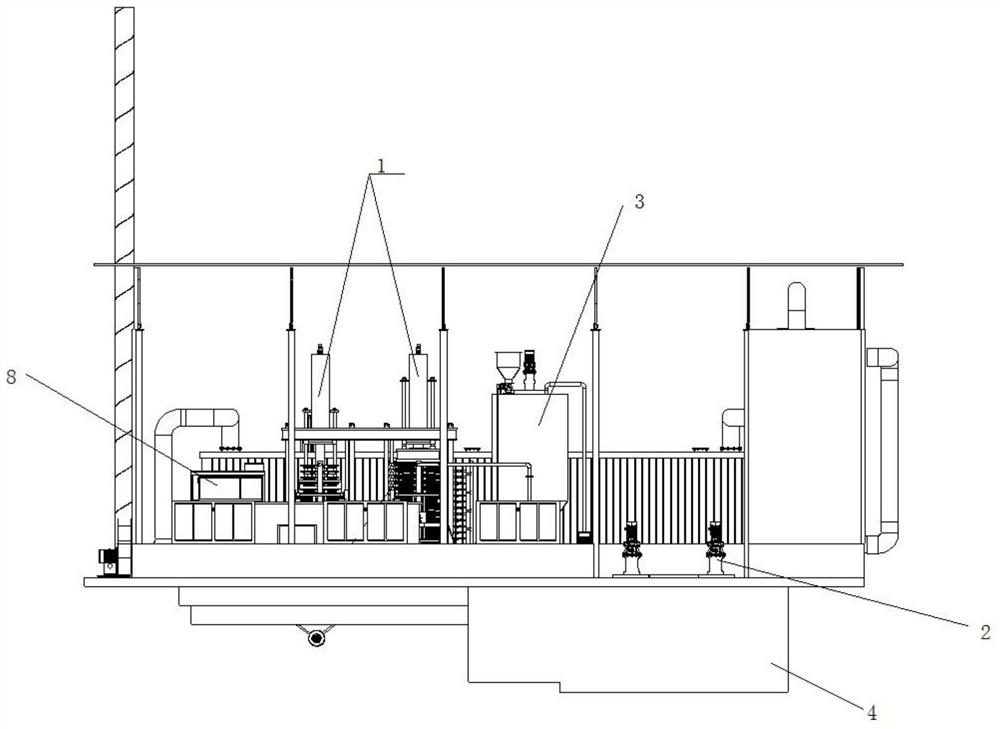

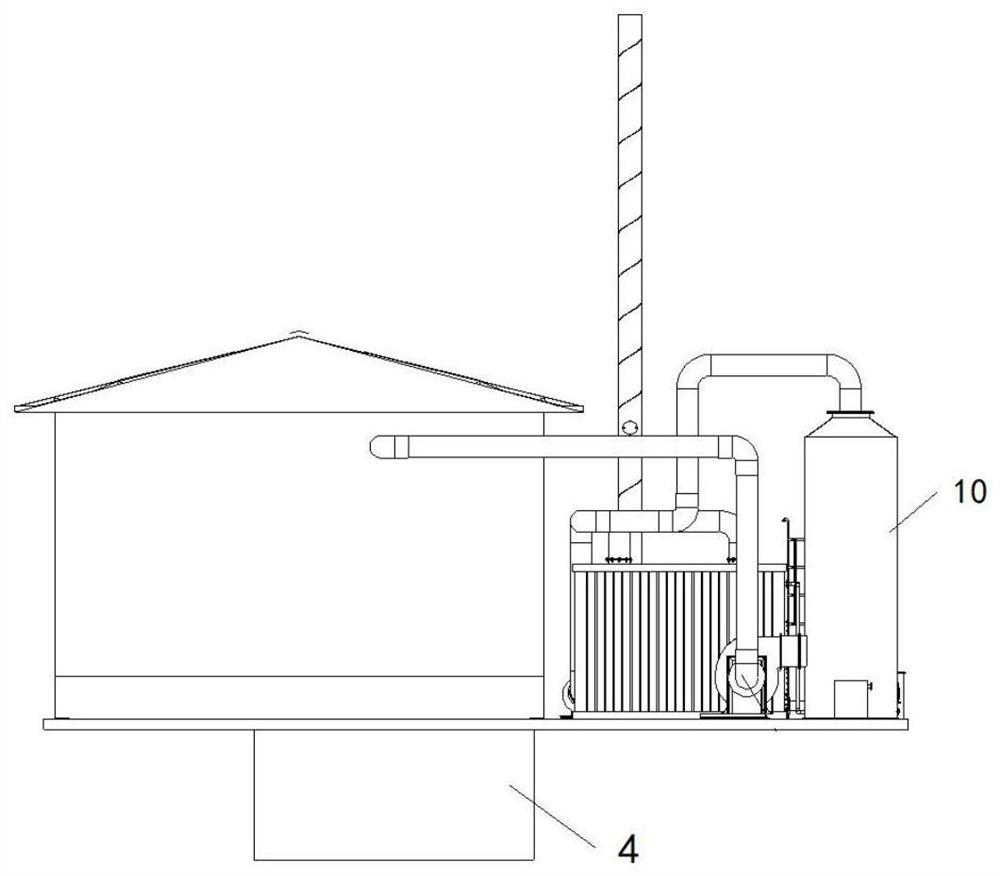

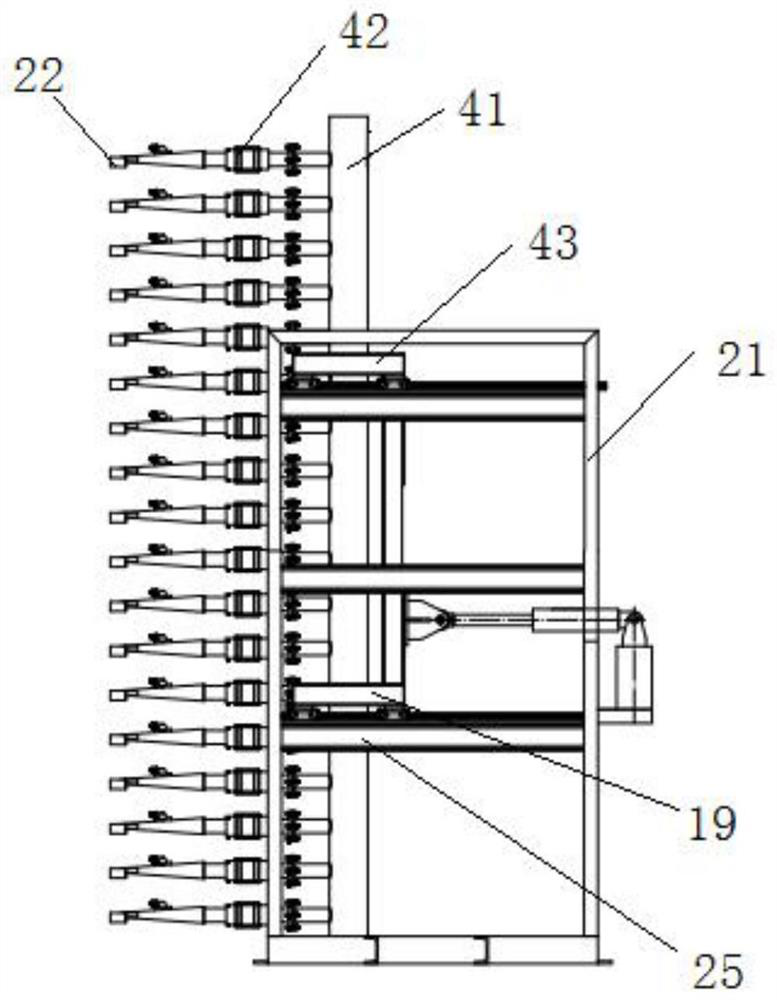

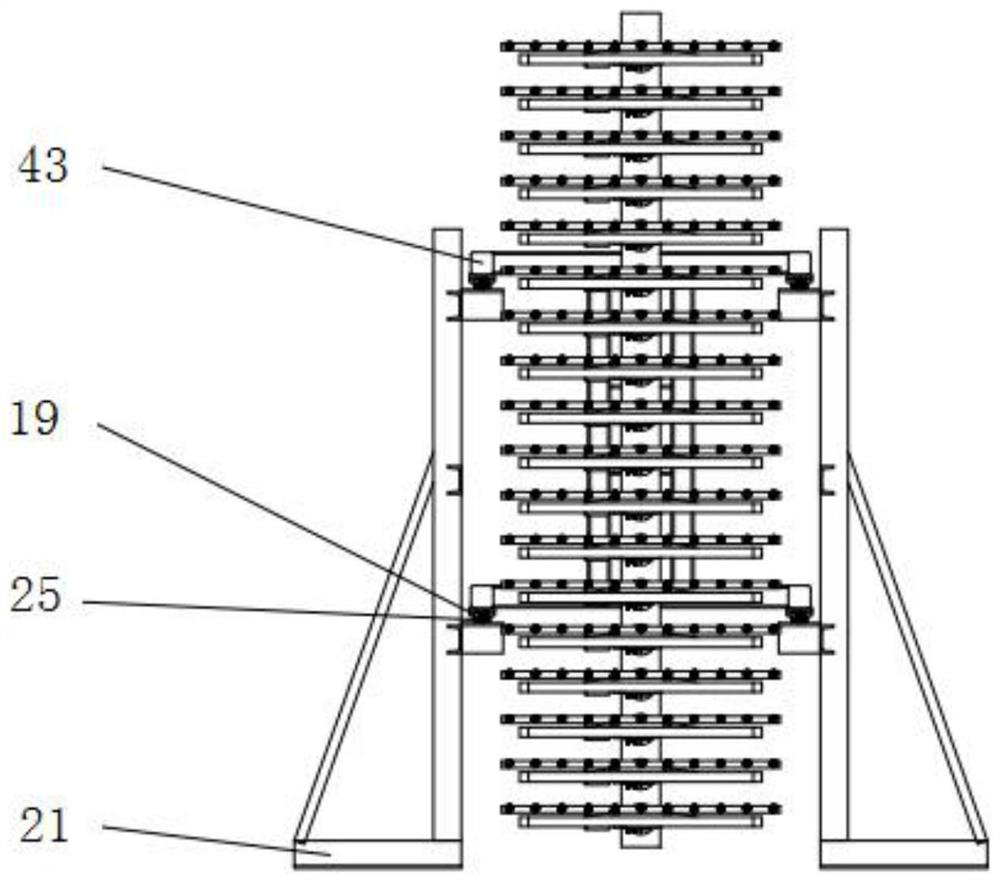

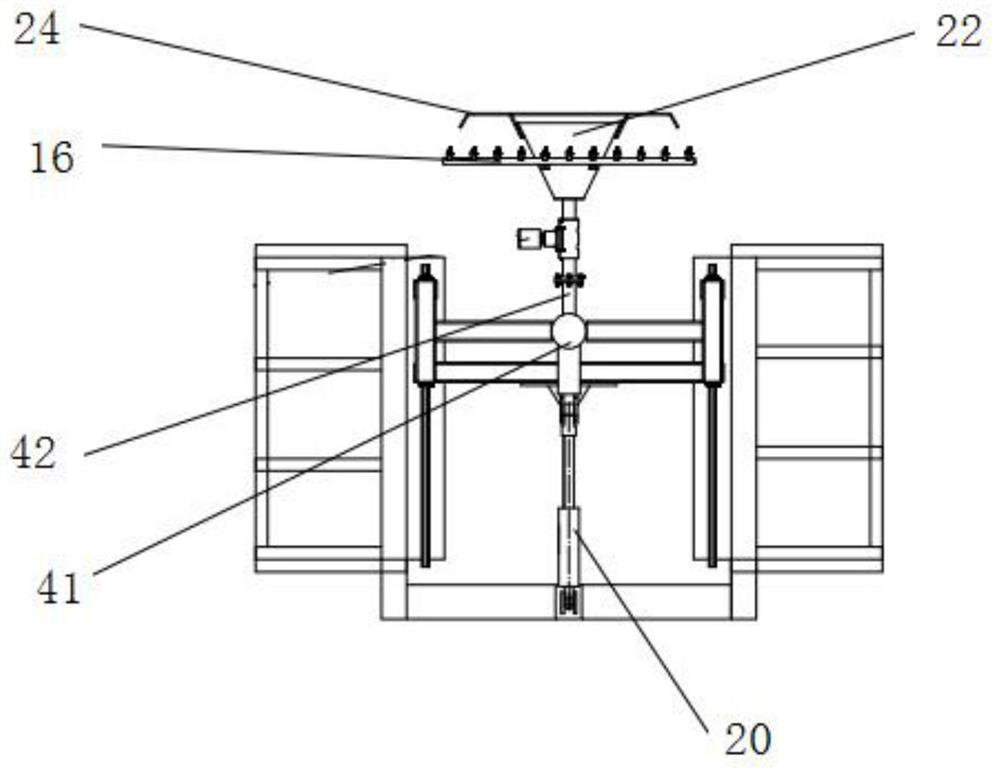

Full-automatic solid-liquid separation system suitable for sludge treatment

PendingCN111925097AImprove mud output efficiencyImprove dehydration rateSludge treatment by de-watering/drying/thickeningDispersed particle separationSludgeProcess engineering

The invention discloses a full-automatic solid-liquid separation system suitable for sludge treatment. The full-automatic solid-liquid separation system comprises a material pretreatment system and asludge distribution filter pressing device. The material pre-treatment system comprises a sludge stirring bin which is used for accommodating and stirring cloth materials to be stirred; one or more conditioning tanks which are communicated with the sludge stirring bin and provided with an automatic conditioner feeding device; the sludge distribution filter pressing device comprises one or more sludge distributors, wherein inlets of the sludge distributors are communicated with the corresponding conditioning tanks; a filter press which is arranged beside the distribution outlet of the sludge distributor and comprises one or more filter pressing devices, wherein the number of the filter pressing devices is the same as that of the sludge distributors, the filter pressing devices are arrangedon the distribution side of the sludge distributor in a one-to-one correspondence mode, and each filter pressing device comprises a filter pressing assembly, a lifting mechanism and a press machine. The effects of high solid-liquid separation sludge discharge speed, high dehydration rate, low requirement on filter cloth and small occupied area of the filter pressing system are achieved.

Owner:聂麒曌

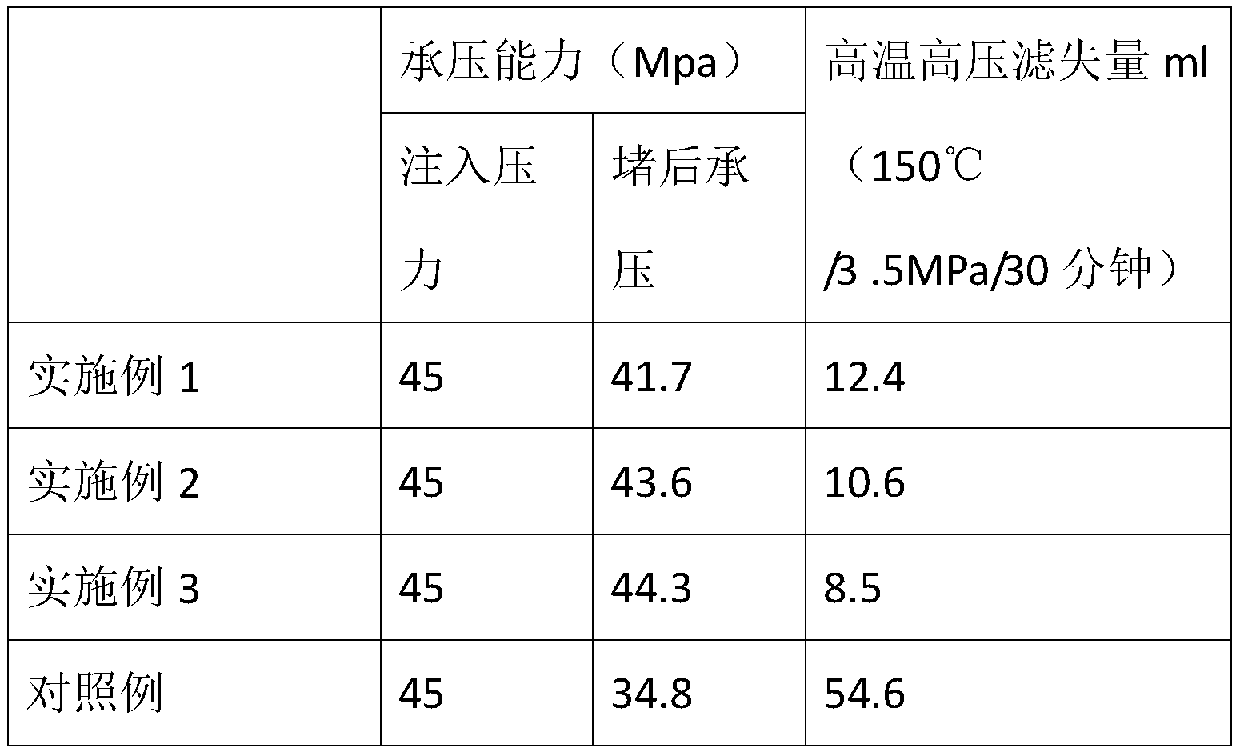

Oil-soluble latex blocking agent and preparation method thereof

InactiveCN109762542AImprove the blocking effectPrevent openingDrilling compositionSolubilityAntioxidant

The invention discloses an oil-soluble latex blocking agent and a preparation method thereof. The oil-soluble latex blocking agent is prepared from the following components in parts by mass: 30-60 parts of monomer butadiene, 35-60 parts of monomer styrene, 15-35 parts of alkyl acrylate, 3-15 parts of glycidyl acrylate, 1.5-3 parts of an emulsifying agent, 100-120 parts of deionized water, 0.16-0.35 part of a molecular weight modifier, 0.02-0.04 part of an antioxidant, 5-12 parts of extending oil, 0.1-0.4 part of an initiating agent, 0.01-0.025 part of a chelating agent and 0.1-0.5 part of a chain terminator. The oil-soluble rubber latex blocking agent has suitable solubility and mobility, a blocking layer can be rapidly formed, and shortening of a construction period is facilitated; and meanwhile, the oil-soluble rubber latex blocking agent has good resident and pressure bearing capacity, the blocking layer formed by the blocking agent has a good blocking effect towards a micro-crack,the pressure bearing property is good, the crack is prevented from opening, and the stability of a well wall of an oil well is ensured.

Owner:青岛科凯达橡塑有限公司 +1

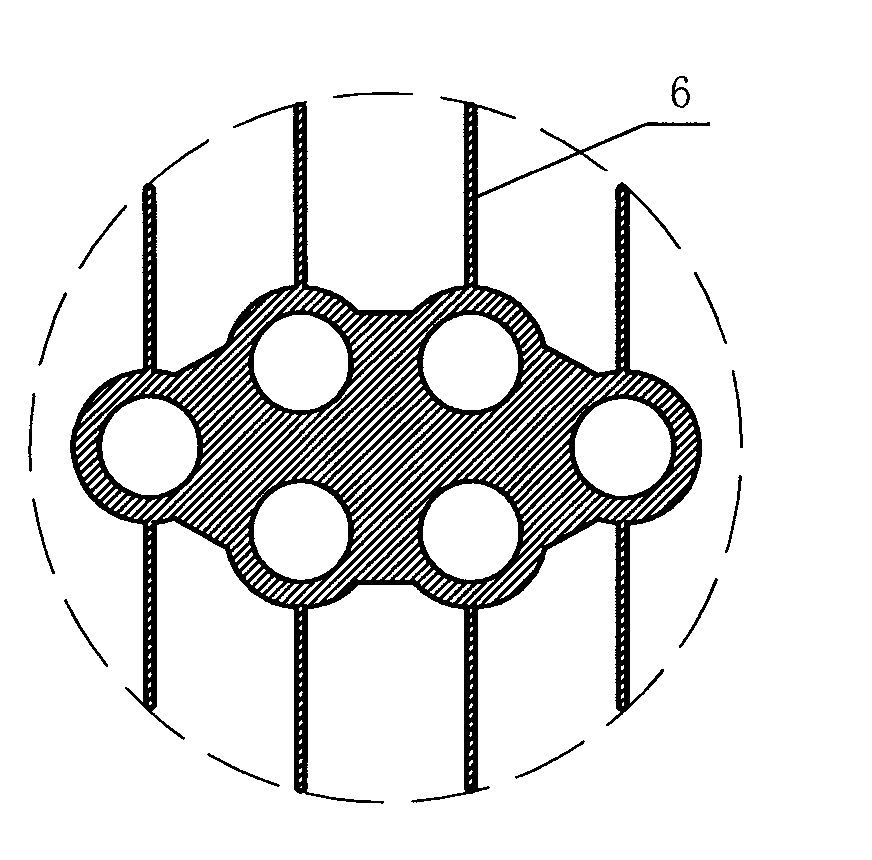

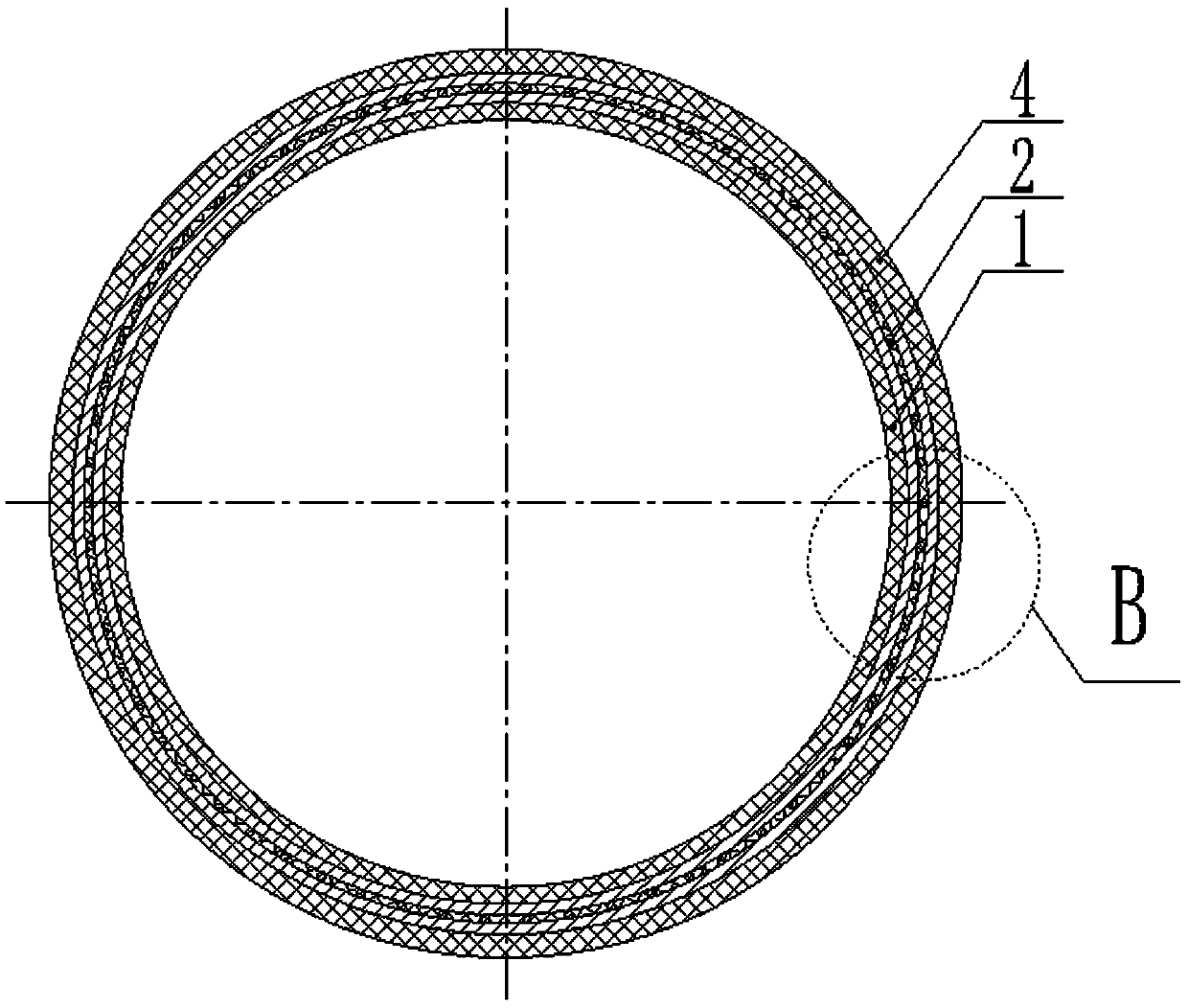

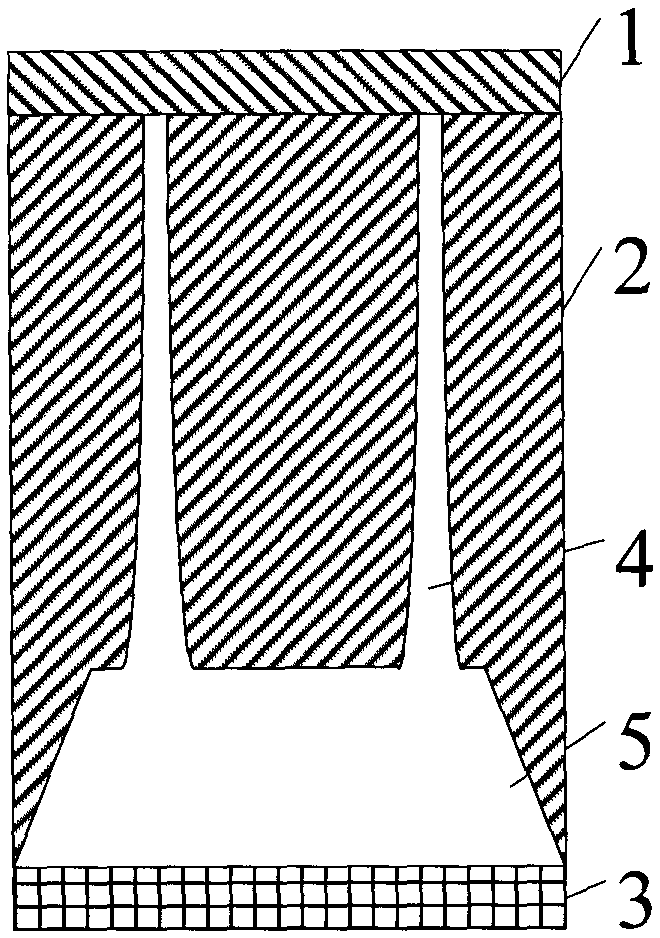

Multi-layer framework reinforced plastic composite pipe

PendingCN111219542AImprove pressure bearing capacityIncrease wall thicknessRigid pipesPipe protection against damage/wearPipeMesh grid

The invention discloses a multi-layer framework reinforced plastic composite pipe which comprises a pipe body formed through the extrusion molding technology, wherein at least two layers of reinforcedframeworks are fixed between the inner wall and the outer wall of the pipe body through the extrusion molding technology and comprise at least one of a reinforced framework A or a reinforced framework B; the reinforced framework A comprises a plurality of longitude lines arranged in the circumferential direction of the pipe body; the longitude lines extend in the axial direction of the pipe body,are spirally wound through latitude lines in the axial direction of the pipe body, and are fixed through welding; the longitude lines and the latitude lines are steel wires; and the reinforced framework B is a continuous integrated grid structure. The multi-layer framework reinforced plastic composite pipe can improve the pipe loading capacity and organically combines high rigidity of steel withnon-corrosibility of plastic; the pipe with relative smaller wall thickness can meet the pressure using requirement, and the excellent characteristics of the plastic pipe are also kept. The multi-layer framework reinforced plastic composite pipe is suitable for the technical field of performance reinforcement of the composite pipe during the production process of plastics-steel composite pipes.

Owner:HUACHUANG TIANYUAN IND DEVING

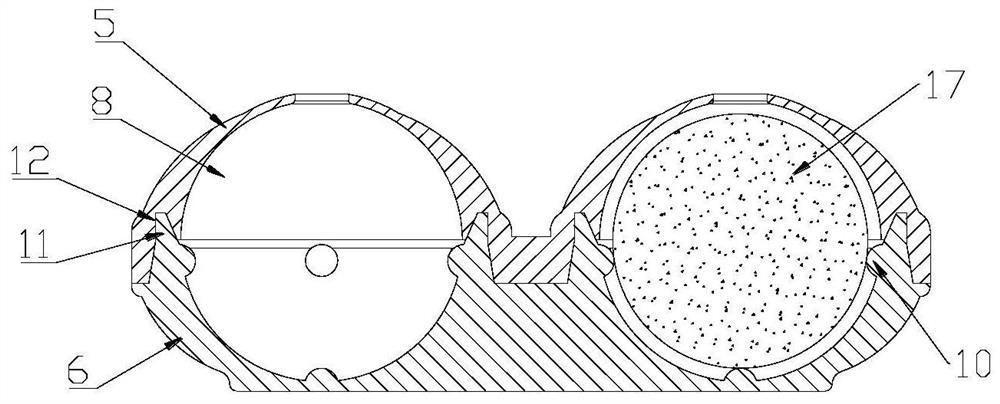

Multilayer material combined cavity anechoic tile

InactiveCN105620697AImprove low-frequency sound absorption performanceMature materials and workmanshipSound producing devicesUnderwater vesselsPhysicsAdhesive

The invention relates to a multilayer material combined cavity anechoic tile which consists of a surface layer, a punching layer and a base layer, wherein mixed type cavity structures consisting of circular-table-shaped cavities and horn-shaped cavities are arranged in the punching layer in an arrayed manner; a punching rate of the circular-table-shaped cavities is 10-20%; a punching rate of the horn-shaped cavities is 1-2%; each mixed type cavity structure consists of one circular-table-shaped cavities and two to six horn-shaped cavities; the surface layer is made of sound transmission polyurethane elastomer; the punching layer is made of polyurethane double-layer compound foam sound absorption material; the base layer is made of butyl rubber matched with the impedance of a housing of an underwater navigation vehicle; and the surface layer, the punching layer and the base layer are glued through an adhesive sequentially, and are subjected to integrated cold-press moulding.

Owner:NAVAL UNIV OF ENG PLA

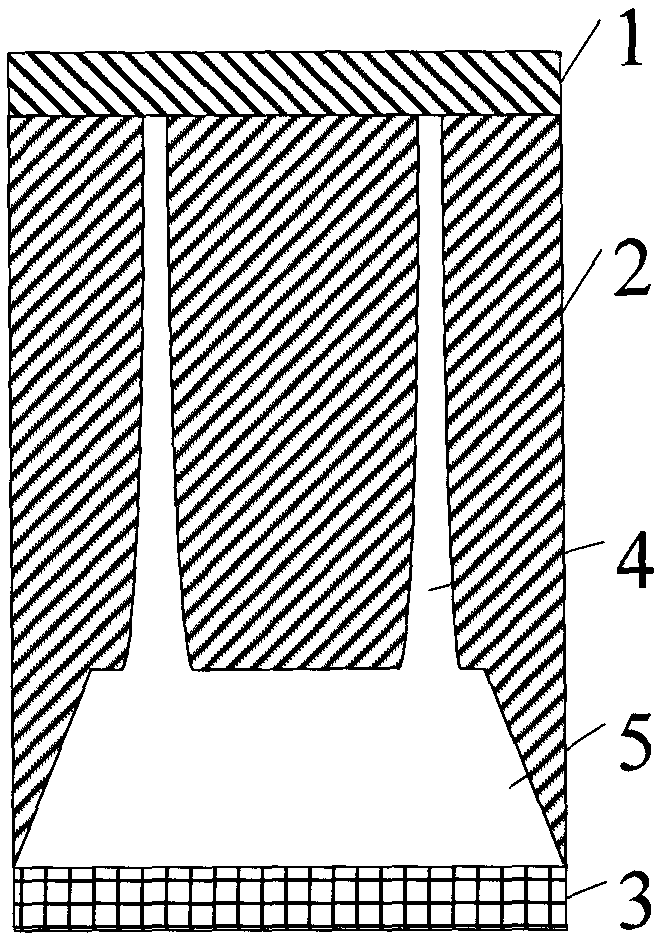

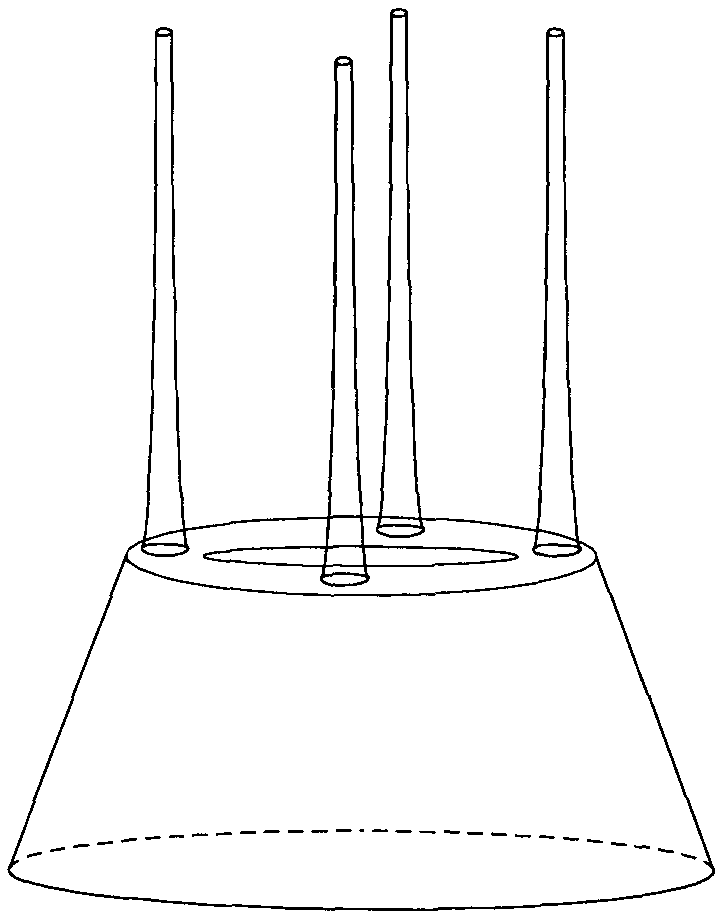

Chemical grouting sealing device and method for underground formation sealing

The invention discloses a chemical grouting isolation device for downhole formation sealing, which comprises a relay container, the input end of the relay container is provided with a manual pump, and the output end of the relay container is connected with a grouting pipe through a throttle valve , the output end of the relay container is also equipped with a pressure gauge for detecting the pressure of the output end of the relay container, and a spray plug is set at the set position underground, and the spray plug at each set position is controlled by self-operated segmental pressure The valve communicates with the grouting section where the grouting pipe is located underground. Also disclosed is a chemical grouting sealing method for underground formation sealing. The invention has no damage to the casing, and easily realizes multi-layer isolation; the volume expansion rate is larger, and the downhole sealing adaptability is better, and the grouting operation at different depths can be realized through different injection pressure values of a grouting pipe at the wellhead.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

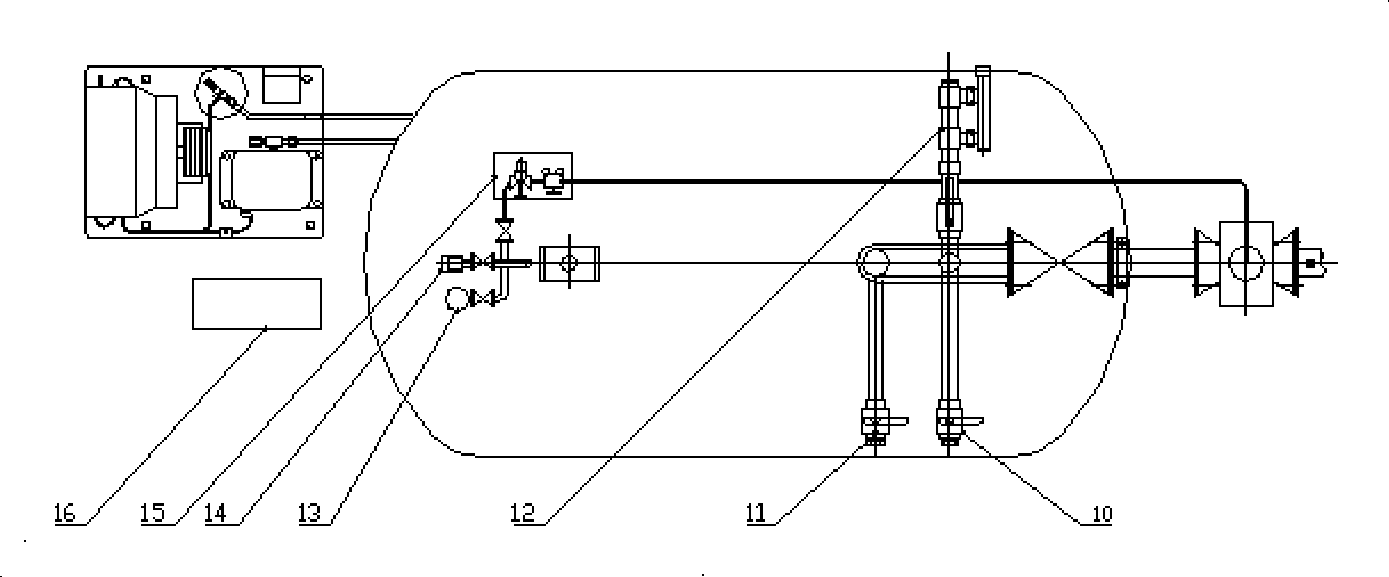

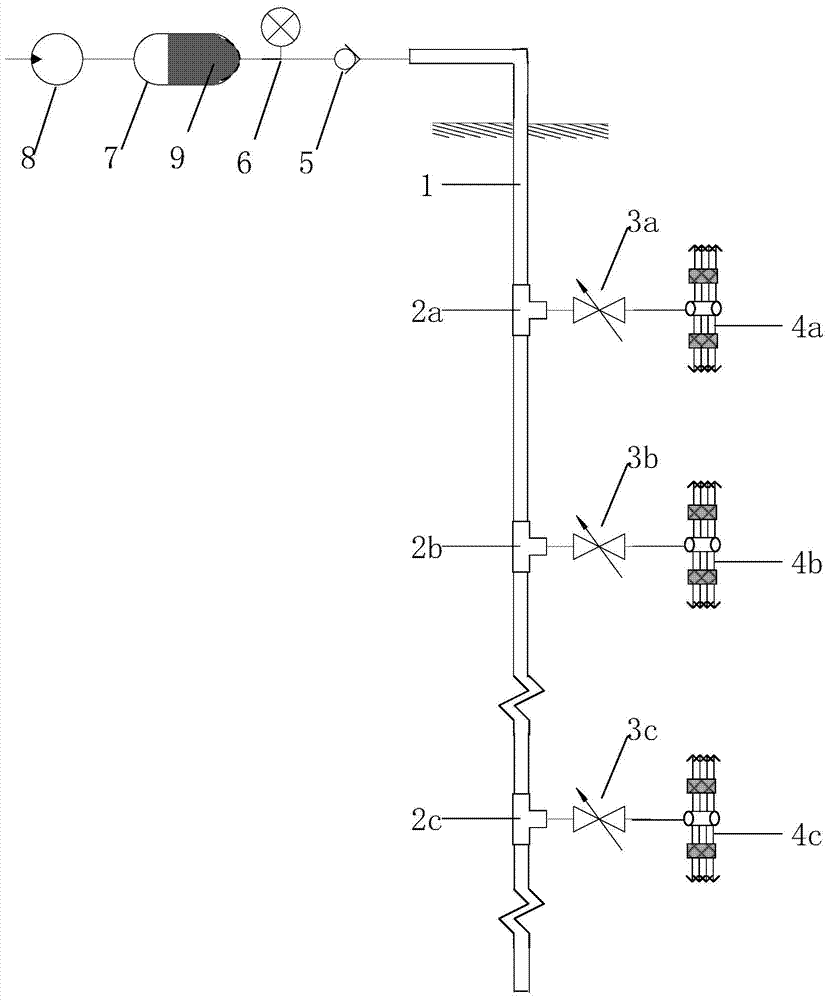

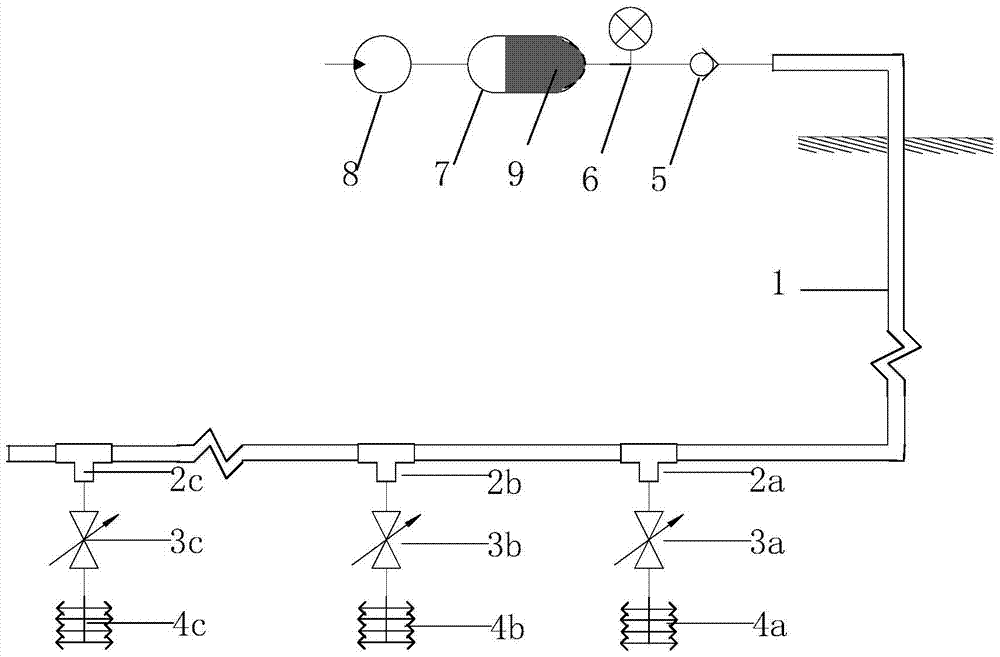

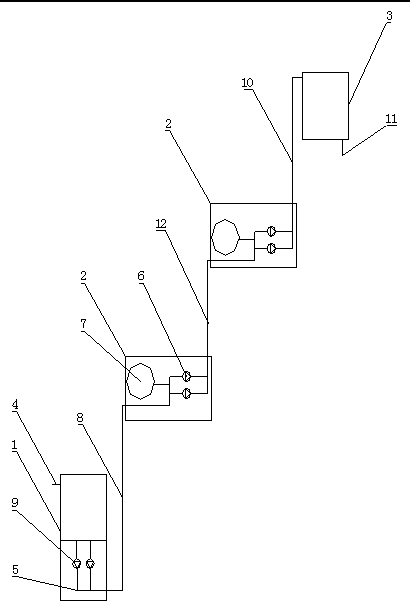

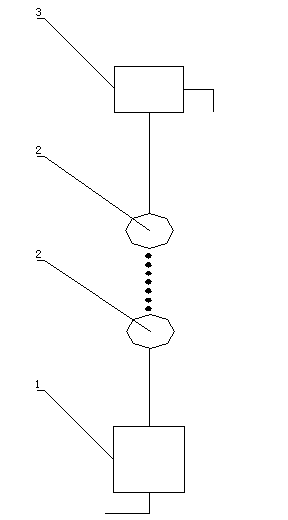

High-rise pressure-superposed water supply equipment

InactiveCN103382732AReduced pressure capacityReduce labor intensityWater supply tanksWater sourceHigh rise

High-rise pressure-superposed water supply equipment is provided with an underground pressurizing device, a plurality of medium pressurizing devices and a roof reserve tank, wherein the underground pressurizing device is connected with the medium pressurizing devices through a pipeline; the medium pressurizing devices are connected with the roof reserve tank through a pipeline, and can be arranged for step-by-step pressurizing according to the height of a building; the underground pressurizing device is provided with a connector connected with a water source (tap water); the roof reserve tank is provided with a water supply connector. The pressure configuration of the underground booster pump group is only required to meet the requirement of the height of the medium pressurizing devices, and is pressurized to the roof reserve tank step by step through the medium pressurizing devices, so that the loading capacity of the whole water supply connecting pipeline is reduced effectively, and workers' labor intensity, equipment investment and occupied area are reduced.

Owner:SHANGHAI PANDA MACHINEGRP CO LTD

Laminated soft package button battery

PendingCN111244380AReduce the risk of explosionReduced pressure capacitySmall-sized cells cases/jacketsButton batteryEngineering

The invention belongs to the technical field of batteries in particular to a laminated soft-package button battery. The battery comprises a first packaging film, a second packaging film and a laminated bare battery cell packaged between the first packaging film and the second packaging film, wherein a positive pole lug and a negative pole lug are led out of the laminated bare battery cell, the positive pole lug is conductively connected with the inner surface of the first packaging film, the negative pole lug is conductively connected with the inner surface of the second packaging film, and conductive areas are arranged on the outer surfaces of the first packaging film and the second packaging film. Compared with the prior art, the mode that a positive tab and a negative tab are led out of a packaging film by a conventional soft package button battery is avoided, the risk of explosion of the battery is reduced, and the safety is high.

Owner:HUIZHOU LIWINON NEW ENERGY TECH CO LTD

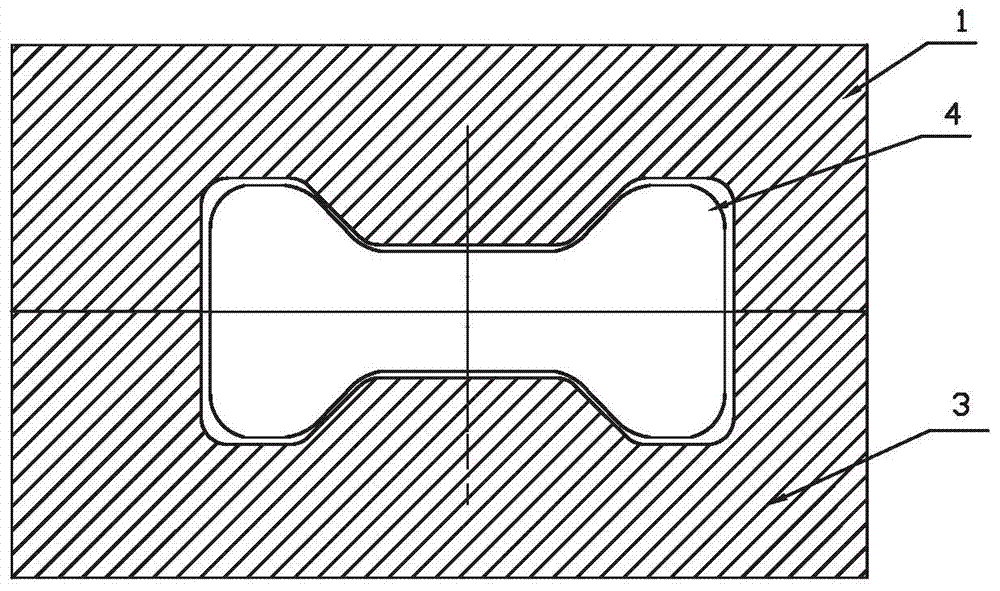

A method for forming an internal high-pressure forming die for forming a stepped pipe fitting

Owner:DALIAN DESIGN INST CO LTD CHINA FIRST HEAVY IND +1

Sludge distribution filter pressing device

PendingCN111921239AImprove mud output efficiencyImprove dehydration rateSludge treatmentFiltration separationSludgeProcess engineering

The invention discloses a sludge distributing and filter pressing device which comprises a sludge distribution machine and a filter press which are matched to work, wherein the sludge distribution machine comprises a sludge distribution main pipe, a plurality of sludge distribution branch pipes and a movable supporting mechanism; the filter press is arranged beside a distribution outlet of the sludge distribution machine and comprises a filter pressing assembly, a lifting mechanism and a press machine. The effects of high solid-liquid separation sludge discharge speed, high dehydration rate, low requirement on filter cloth and small occupied area of the filter pressing sludge distribution device are achieved.

Owner:聂麒曌

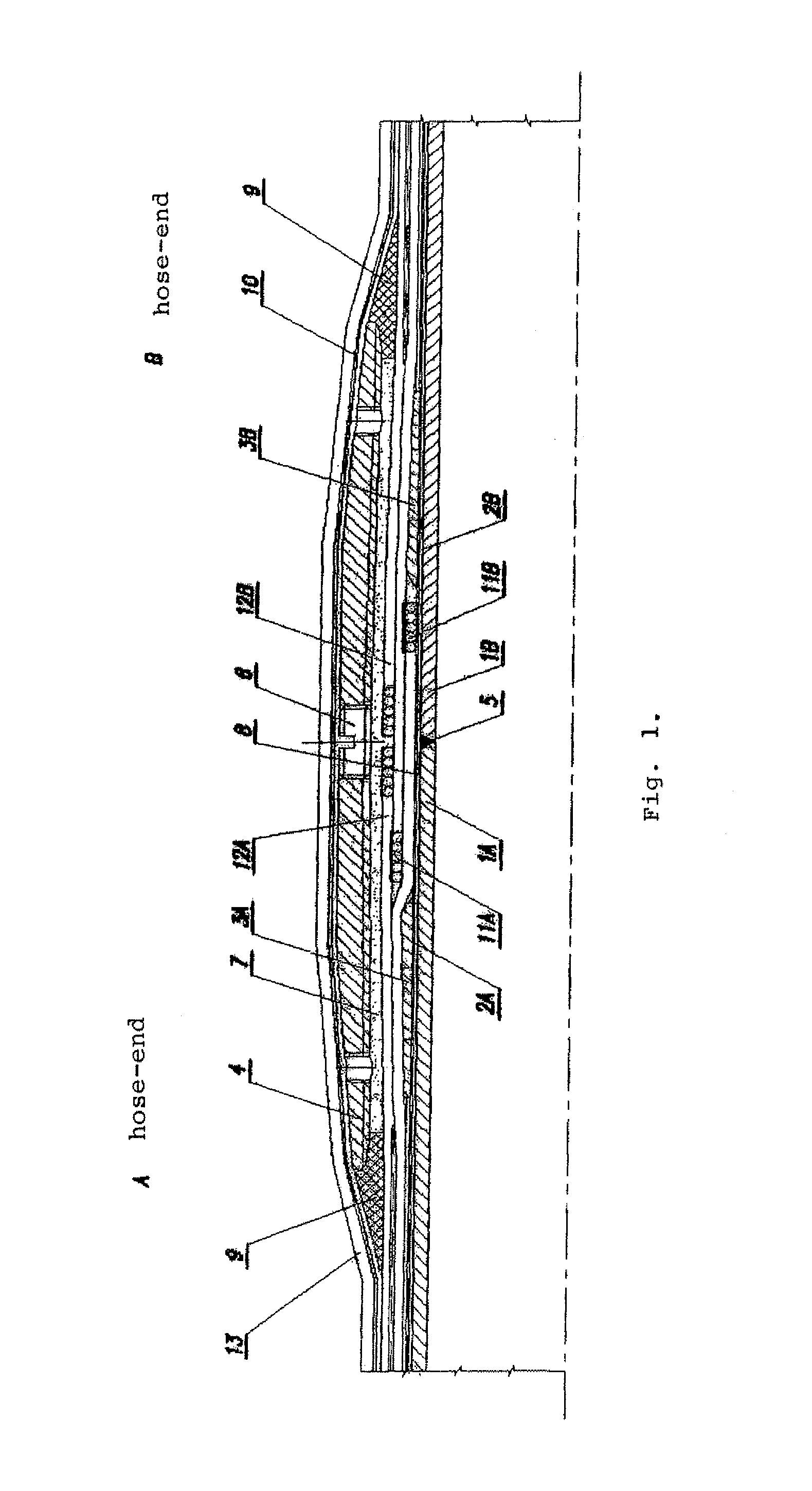

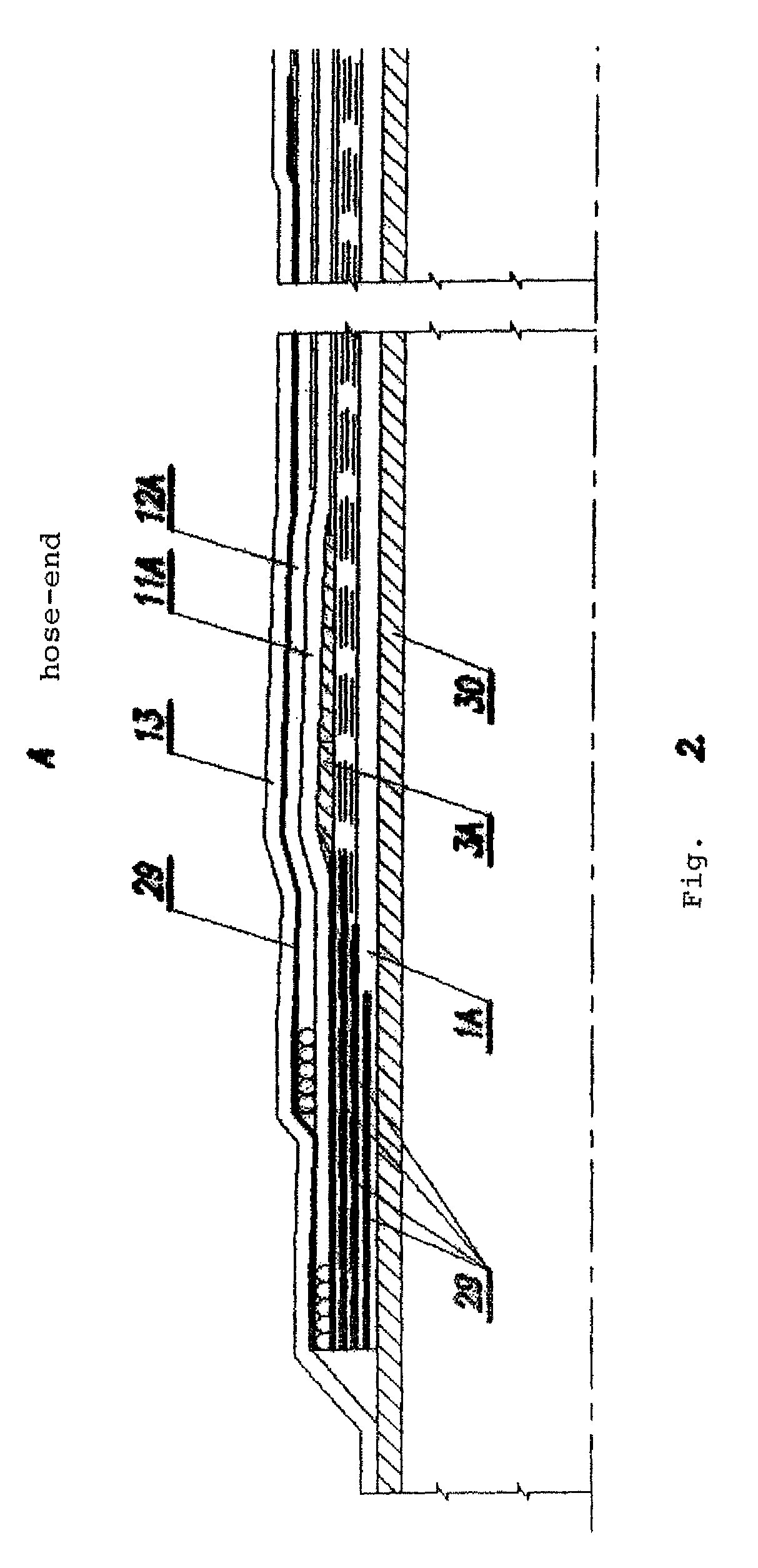

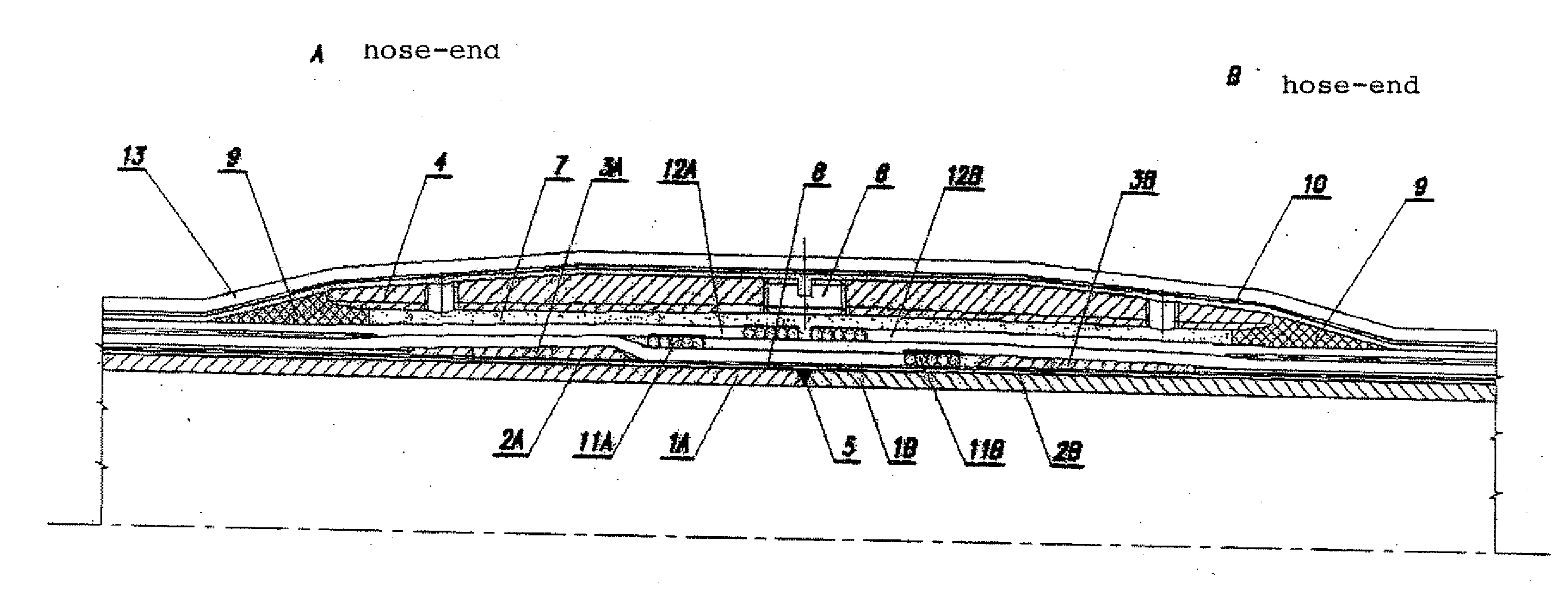

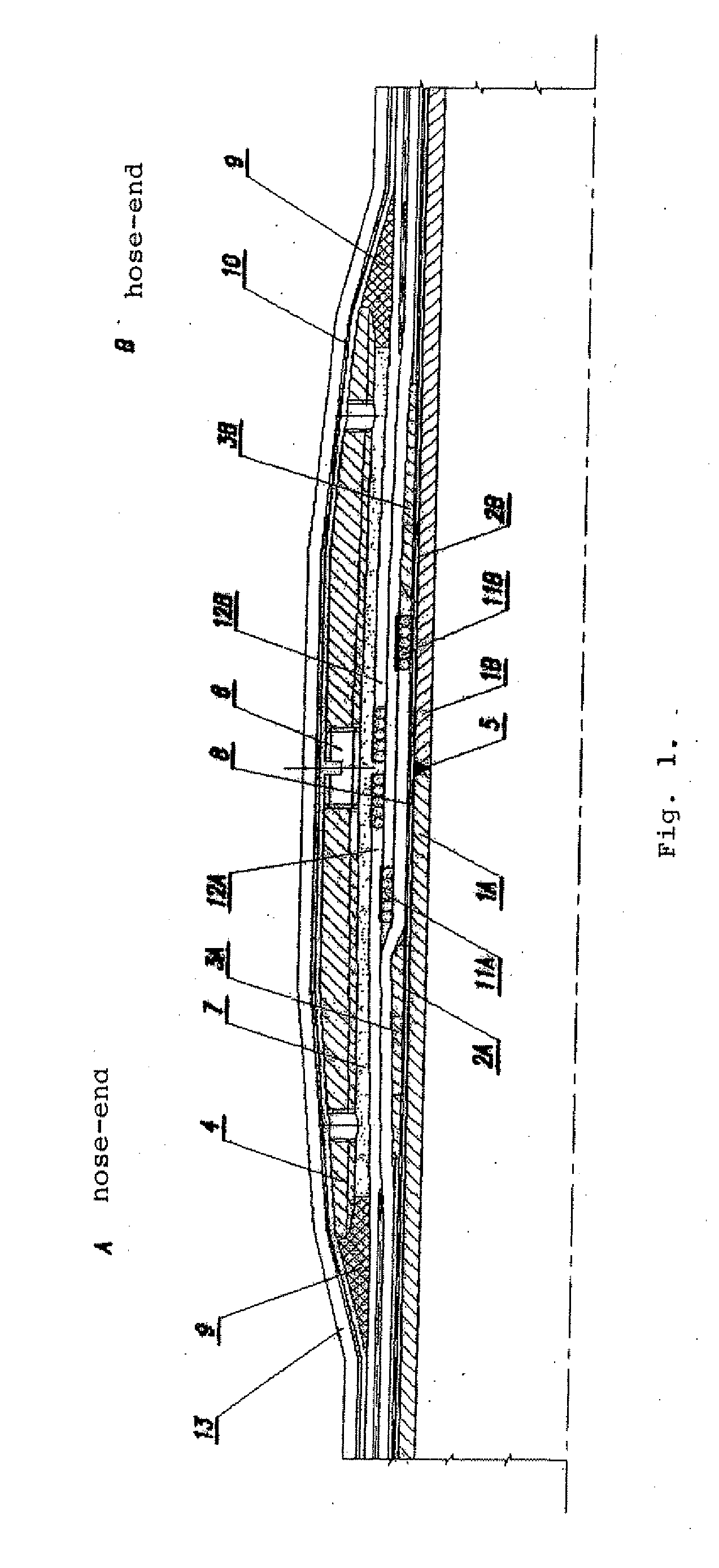

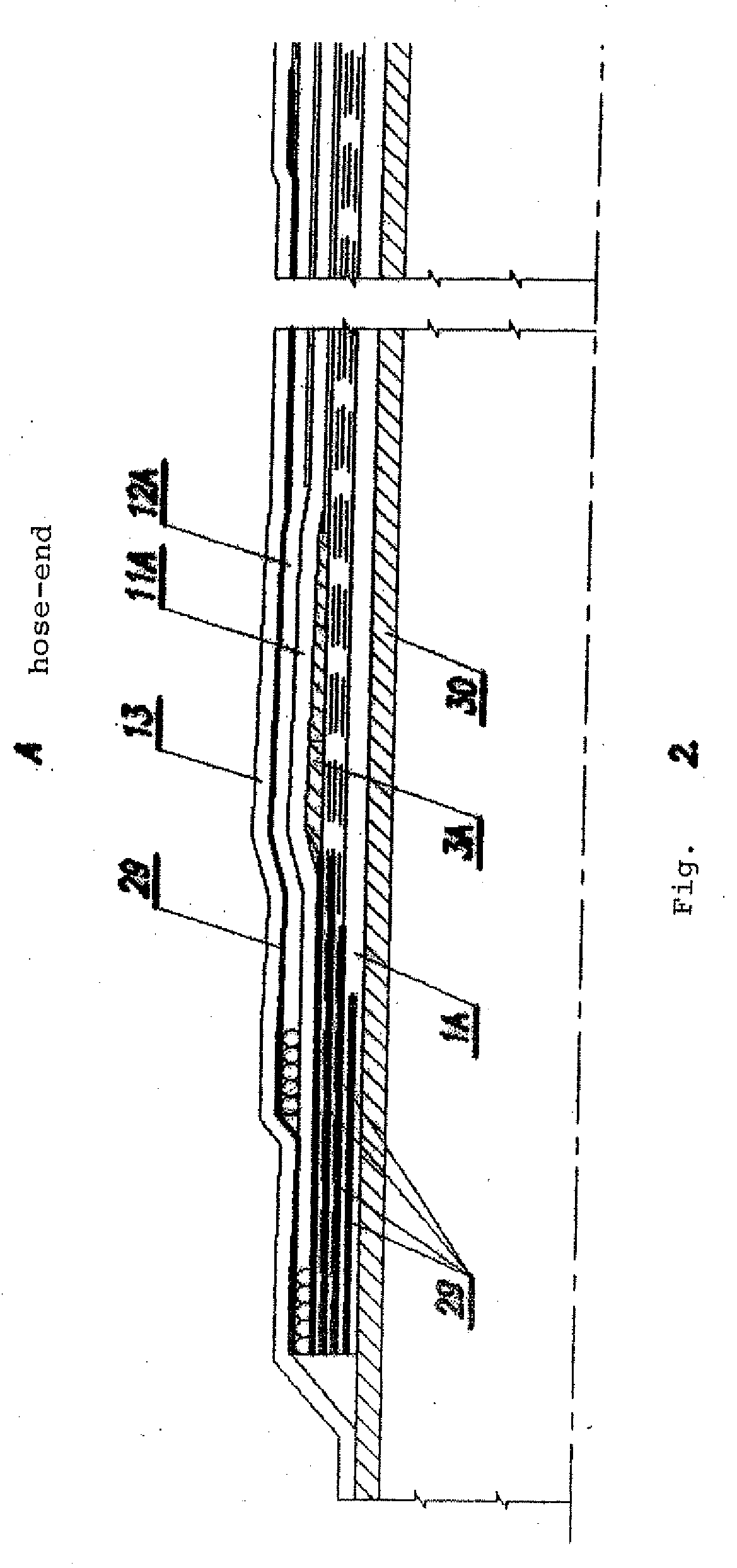

Spliced long-length hose and method for splicing hoses

ActiveUS7967030B2Reduced pressure capacityMinimal lengthFilament handlingFlexible pipesEngineeringAdhesive materials

Owner:PHOENIX RUBBER GUMIIPARI KFT SZEGED

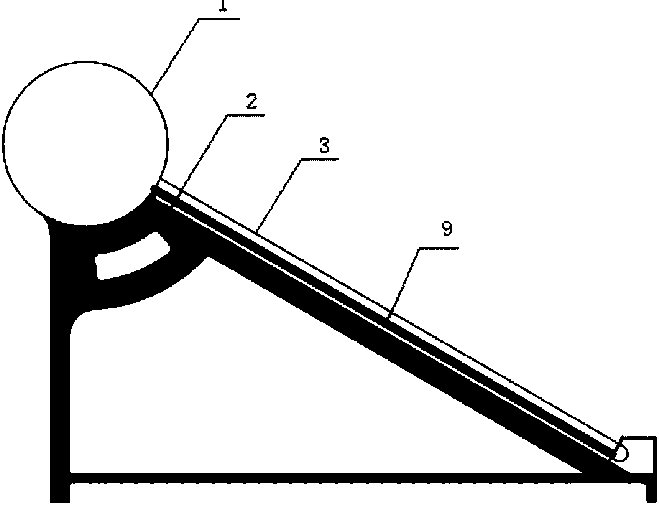

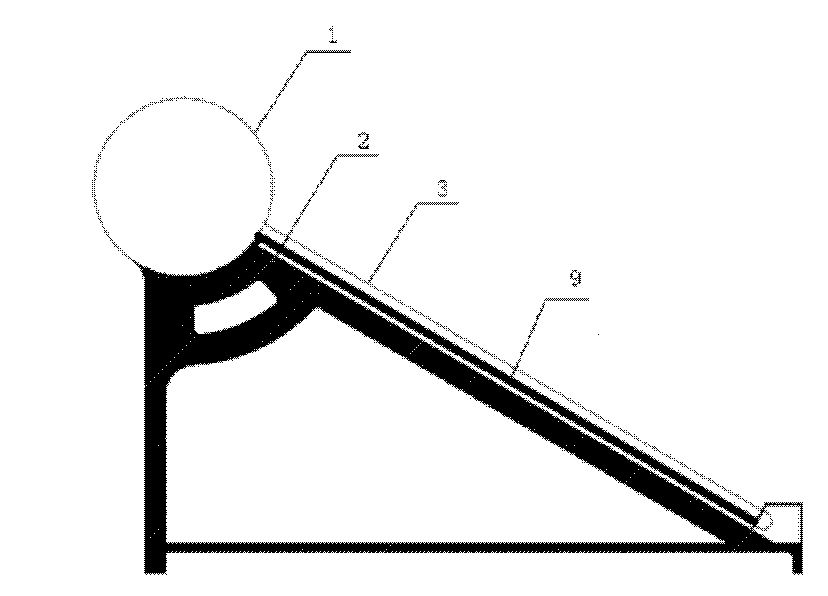

All-glass vacuum tube type solar water heater with pressure-proof inner containers

InactiveCN101666550AGood elasticity and flexibilityLow priceSolar heating energySolar heat devicesSolar waterThermal efficiency

The invention relates to an all-glass vacuum tube type solar water heater with a pressure-proof inner containers, belonging to the technical field of solar equipment and comprising an insulating pressure-proof water tank, a steel frame and a plurality of double-glass vacuum heat-collecting tubes, wherein the insulating pressure-proof water tank is fixed on the steel frame, the outer part thereof is provided with an insulating layer, and the bottom part thereof is provided with a connecting port; the upper ends of the double-glass vacuum heat-collecting tubes are positioned in the insulating layer of the insulating pressure-proof water tank, the lower ends thereof are fixedly connected with the steel frame, and the inner parts thereof are provided with containers; the upper ends of the containers are fixedly connected with a connecting port of the insulating pressure-proof water tank by a sealing device, and the lower ends thereof are closed; the containers comprise stainless steel foils and elastic heat-proof rubber sheets, wherein the stainless steel foils are shaped like an arc-shaped barrel and are attached to one side of a heat-absorbing surface of each double-glass vacuum heat-collecting tube; and the elastic heat-proof rubber sheets are positioned at openings of the inner sides of the stainless steel foils and are fixedly connected with the stainless steel foils in a sealing manner. The all-glass vacuum tube type solar water heater has high heat-collecting efficiency, good safety and strong pressure-proof capability.

Owner:SHANGHAI JIAO TONG UNIV

Bus mounting and fixing device

InactiveCN103915796AIncrease widthIncreased load-bearing capacityOpen bus-bar installationsWork safetyTransverse beam

The invention discloses a bus mounting and fixing device which comprises a load-bearing support and pressure-bearing components. The load-bearing support comprises a transverse beam and a supporting arm, and a load-bearing member is arranged in the transverse beam. Each pressure-bearing component is in an L shape, a square channel is arranged in each pressure-bearing component, and the pressure-bearing components are arranged on the two sides of the supporting arm and at corner positions in a sleeved mode when used. A plurality of pressure-bearing strips are arranged on the outer side of the upper end of each pressure-bearing component, two sets of pressure-bearing members are arranged on the surfaces of the corner positions of each pressure-bearing member, the pressure-bearing members are embedded inside the pressure-bearing components through welding, and each pressure-bearing member is in a W shape formed by a first pressure-bearing plate, a second pressure-bearing plate, a third pressure-bearing plate and a fourth pressure-bearing plate. The bus mounting and fixing device can effectively improve the pressure-bearing performance of the support in the transverse direction and the longitudinal direction and can effectively improve the load-bearing performance the technical problem that the corner positions of the support are easy to damage due to overlarge stress can be solved, safe using of the support is guaranteed, and enterprise production work safety is guaranteed.

Owner:JIANGSU JIANGCHENG ELECTRIC

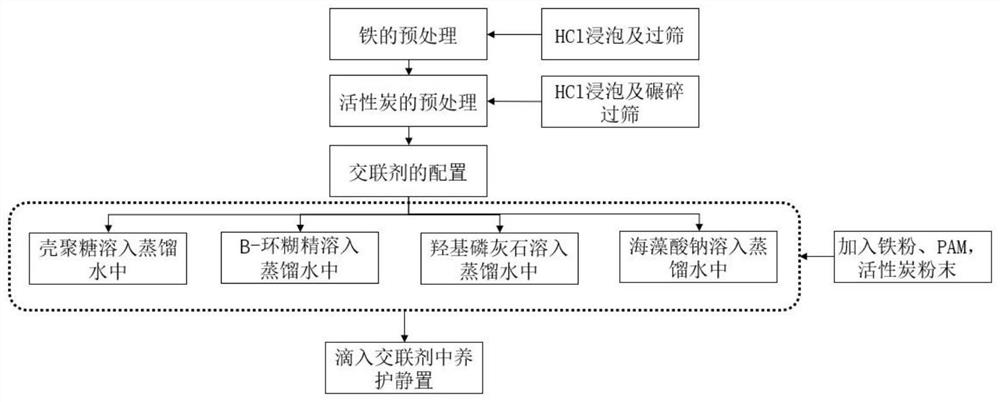

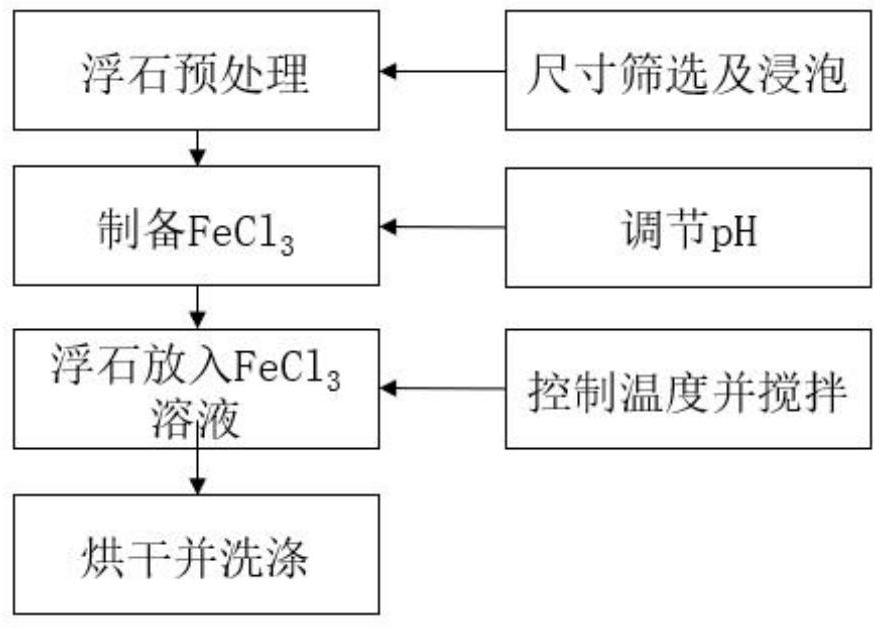

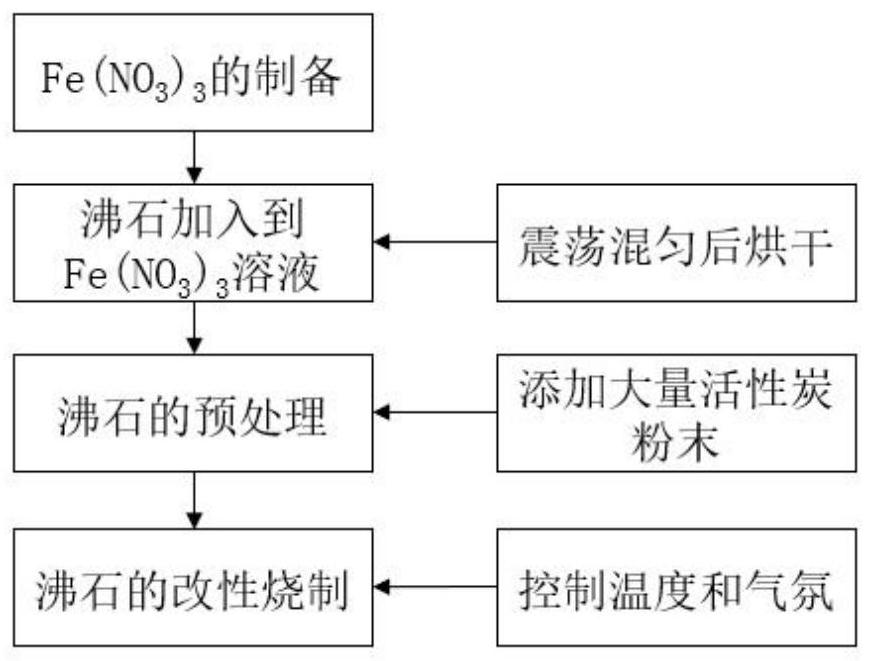

Method for removing multiple heavy metals in underground water by matching modified iron filler with modified zeolite and modified pumice stone

PendingCN114132985ANot easily affected by fillersSmall removal effectWater contaminantsWater/sewage treatment by sorptionCyclodextrinZerovalent iron

The invention discloses a method for removing multiple heavy metals in underground water by matching modified iron filler with modified zeolite and modified pumice stone, and belongs to the field of underground water treatment. The method comprises the following steps: preparing zero-valent iron, FeCl3 of which the pH is adjusted, pumice stones with different sizes, activated carbon, zeolite, sodium alginate, chitosan, beta-cyclodextrin and hydroxyapatite. Zero-valent iron is pretreated in HCl, then sodium alginate, chitosan, beta-cyclodextrin, hydroxyapatite and other materials are added for modification preparation, and finally four different fillers are prepared. The pumice is calcined in a tubular furnace so as to load zero-valent iron. And the pumice is mixed with FeCl3 so as to load iron. Finally, the pumice stone, the modified iron filler and the zeolite are combined and filled. According to the sequence of the small-size pumice stone, the medium-size pumice stone, the mixture of the modified iron filler, the large-size pumice stone and the zeolite, the small-size pumice stone and the medium-size pumice stone. According to the modified material and the combined filling process, the efficiency of removing the heavy metals in the water can be remarkably improved.

Owner:HARBIN INST OF TECH

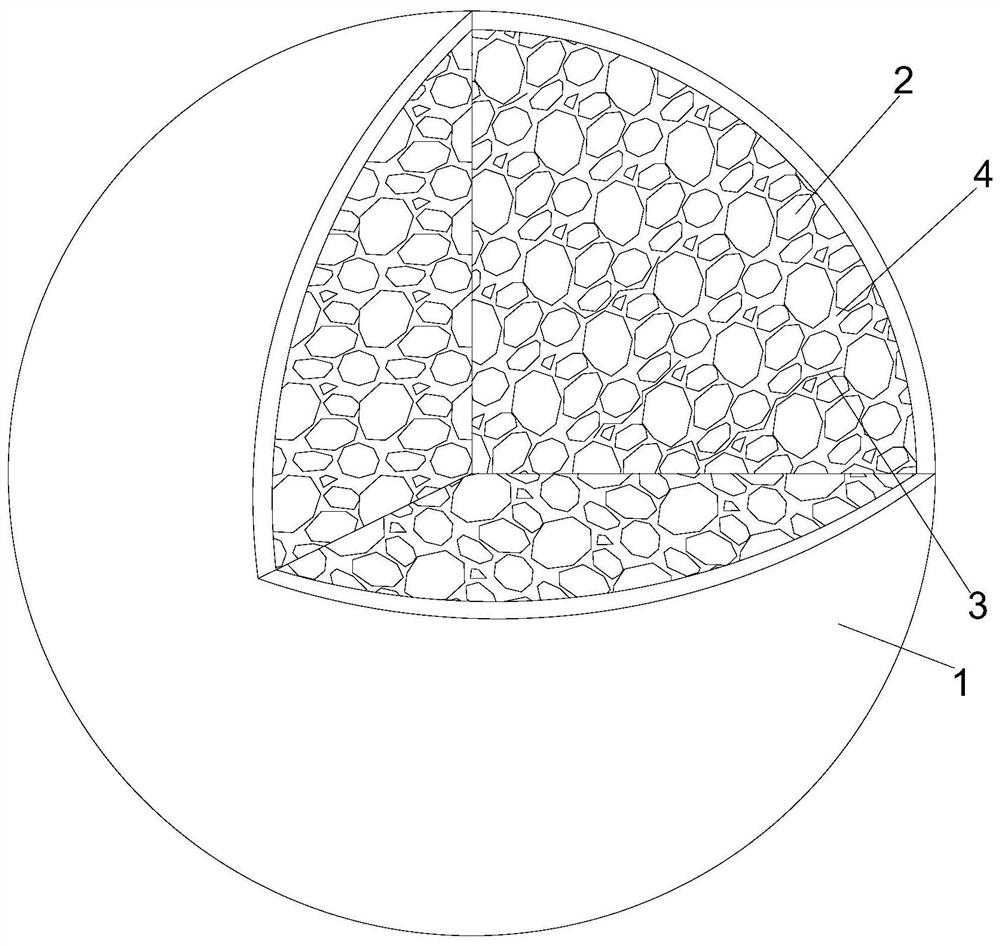

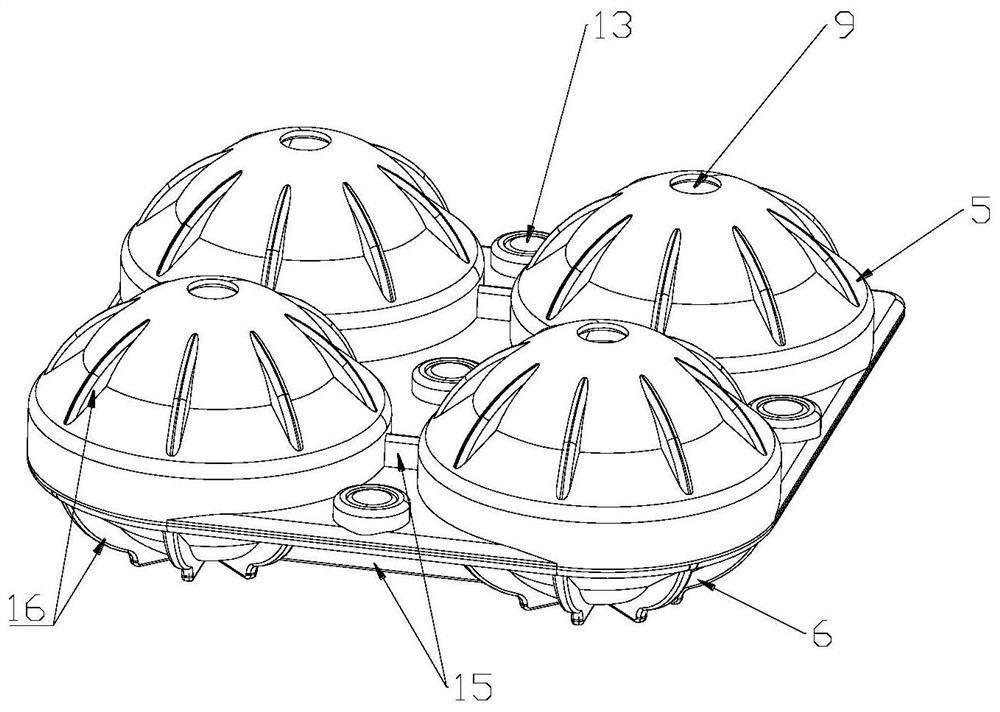

Drilling leaking stoppage small ball and preparation method thereof

ActiveCN113863892APlugging safetyQuick plugDrilling compositionSealing/packingGlass fiberEngineering

The invention discloses a drilling leaking stoppage small ball and a preparation method thereof, and belongs to the technical field of drilling construction. The drilling leaking stoppage small ball comprises a shell and framework particles, wherein the shell is filled with the framework particles. Gaps between the framework particles and the shell are filled with glass fibers and PVC factice. The framework particles comprise stones. The length of the glass fibers is larger than the particle size of the framework particles. The contradiction that when an inert material is used for leaking stoppage, large particles are prone to bridging but cannot enter the gaps, and small particles are prone to entering but are difficult to bear pressure is solved, the large particles can enter the gaps, stay in the gaps and bear pressure, and the purpose of safe, rapid, simple and reliable leaking stoppage is achieved.

Owner:四川省地质矿产勘查开发局四0三地质队

Spliced long-length hose and method for splicing hoses

ActiveUS20080047625A1Reduced pressure capacityEasy to produceFilament handlingFlexible pipesEngineeringAdhesive materials

A long-length hose spliced from two or more hoses containing an inner sealing layer, at least two spirally laid reinforcing plies, and a cover. A liner forming the inner sealing layer is formed by leak-tight splicing of liners of hoses to be spliced and the reinforcing plies are embedded into filling / adhesive material inside of a rigid outer sleeve, at the location of the splicing.

Owner:PHOENIX RUBBER GUMIIPARI KFT SZEGED

Method for testing pressure bearing capacity of oil well cement lightening admixture

InactiveCN109556956AEasy to operateReduced pressure capacityMaterial strength using tensile/compressive forcesMaterial weighingParaffin oilsProficiency testing

The invention discloses a method for testing pressure bearing capacity of an oil well cement lightening admixture. The method comprises the following steps: pouring a mixed liquid of water and a lightening admixture into a plastic bag; putting the plastic bag into a thickening pulp cup; adding paraffin oil into the thickening pulp cup along the inner wall of the thickening pulp cup, and putting the thickening pulp cup into a pressurization thickening instrument; performing a pressurization test on the thickening instrument; standing for two hours, separating floating materials and sedimented materials and drying; and calculating the pressure bearing capacity of the oil well cement lightening admixture by virtue of mass of the obtained floating materials and sedimented materials. The methodfor testing the pressure bearing capacity of the oil well cement lightening admixture is easy to operate, the actual pressure bearing capacity of a lightening material is evaluated by testing breakage rates of the lightening material under different pressure conditions, then low-density cement paste with high pressure bearing capacity is prepared, stable performance and density of the cement paste as well as cement strength are guaranteed, well cementation construction safety is guaranteed, and well cementation quality is improved.

Owner:CNPC BOHAI DRILLING ENG

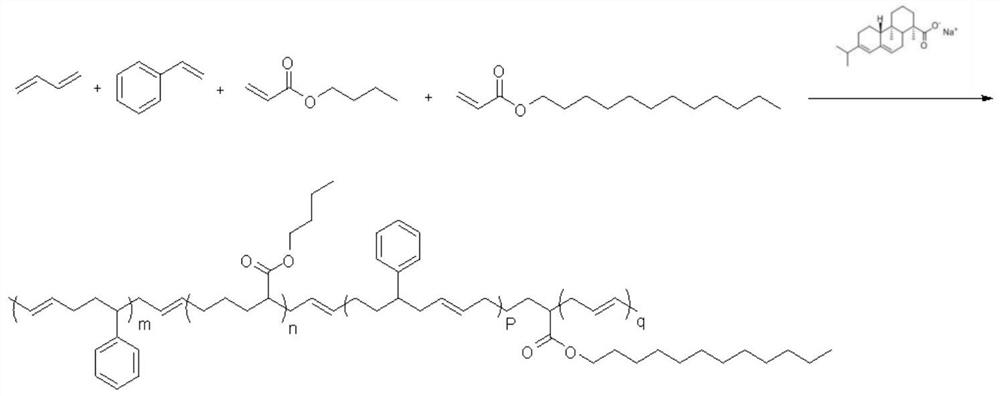

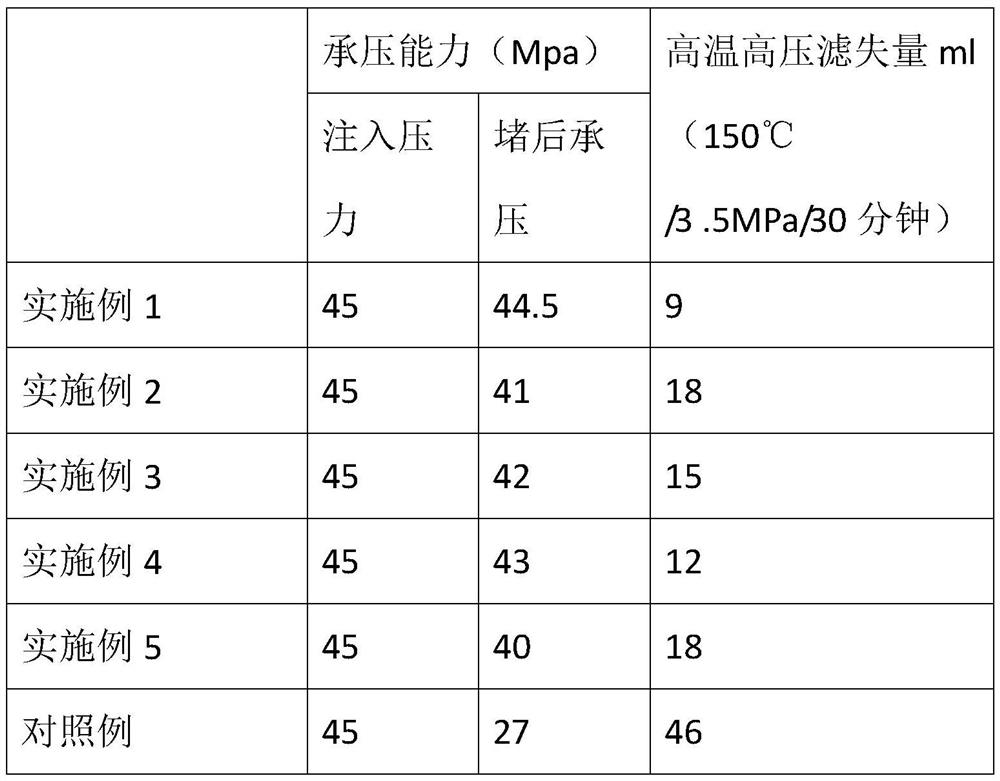

A kind of gas-soluble sealing emulsion and preparation method thereof

ActiveCN109824826BImprove the blocking effectImprove pressure resistanceDrilling compositionComponents of crude oilMaterials science

The invention discloses an aerosol sealing emulsion and a preparation method thereof. The sealing agent is mainly prepared from the following components in parts by mass: 60-90 parts of butadiene monomer, 25-90 parts of styrene monomer 55 parts, 3-15 parts of butyl acrylate, 3-15 parts of lauryl acrylate, 1.5-3 parts of emulsifier, 100-120 parts of deionized water, 0.16-0.35 parts of molecular weight regulator, 0.02-0.04 parts of antioxidant , 5-12 parts of extender oil, 0.1-0.4 parts of initiator, 0.01-0.025 parts of chelating agent, and 0.1-0.5 part of chain terminator. The gas-soluble sealing emulsion of the present invention forms a plug for formation water, and at the same time has good retention and pressure bearing capacity, reduces the water content, improves the extraction efficiency of natural gas, has a good plugging effect on micro-cracks, and prevents cracks Open to ensure the stability of the well wall of the gas well, and can quickly dissolve in shale gas, natural gas, and coalbed methane, and be discharged with the gas and liquid, forming a fast gas path without damage to the underground rock formation.

Owner:青岛科凯达橡塑有限公司

All-glass vacuum tube type solar water heater with pressure-proof inner containers

InactiveCN101666550BAvoid bursting under pressureEnsure safetySolar heating energySolar heat devicesSolar waterArchitectural engineering

The invention relates to an all-glass vacuum tube type solar water heater with a pressure-proof inner containers, belonging to the technical field of solar equipment and comprising an insulating pressure-proof water tank, a steel frame and a plurality of double-glass vacuum heat-collecting tubes, wherein the insulating pressure-proof water tank is fixed on the steel frame, the outer part thereof is provided with an insulating layer, and the bottom part thereof is provided with a connecting port; the upper ends of the double-glass vacuum heat-collecting tubes are positioned in the insulating layer of the insulating pressure-proof water tank, the lower ends thereof are fixedly connected with the steel frame, and the inner parts thereof are provided with containers; the upper ends of the containers are fixedly connected with a connecting port of the insulating pressure-proof water tank by a sealing device, and the lower ends thereof are closed; the containers comprise stainless steel foils and elastic heat-proof rubber sheets, wherein the stainless steel foils are shaped like an arc-shaped barrel and are attached to one side of a heat-absorbing surface of each double-glass vacuum heat-collecting tube; and the elastic heat-proof rubber sheets are positioned at openings of the inner sides of the stainless steel foils and are fixedly connected with the stainless steel foils in a sealing manner. The all-glass vacuum tube type solar water heater has high heat-collecting efficiency, good safety and strong pressure-proof capability.

Owner:SHANGHAI JIAO TONG UNIV

A kind of concrete recycling process and concrete formula

The invention relates to a concrete regeneration process and a concrete formula. The process comprises the following steps: step 1, pretreatment; step 2, impurity filtration; step 3, impurity adsorption; step 4, screening treatment; step 5, crushing treatment; and step 6, drying and collection. Various raw materials adopted in the scheme meet an environmentally-friendly concept, and in the raw materials, materials such as mineral powder, fly ash and mineral admixture are waste materials, and the process belongs to waste utilization and reasonable application of resources; recycled aggregate has the characteristics of high porosity, large water absorption rate and the like, and therefore the recycled concrete is a porous material; and human walking ways do not have high requirements on load-bearing capacity, and therefore the recycled concrete can be used through casting molding.

Owner:国泷集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com