Multilayer material combined cavity anechoic tile

A technology of multi-layer materials and sound-absorbing tiles is applied in the field of vibration reduction and noise reduction, which can solve the problems of poor sound absorption effect and narrow sound reduction frequency band, and achieve the effects of improving low-frequency sound absorption performance, reducing cost, and reducing complexity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and specific embodiment the invention is further introduced:

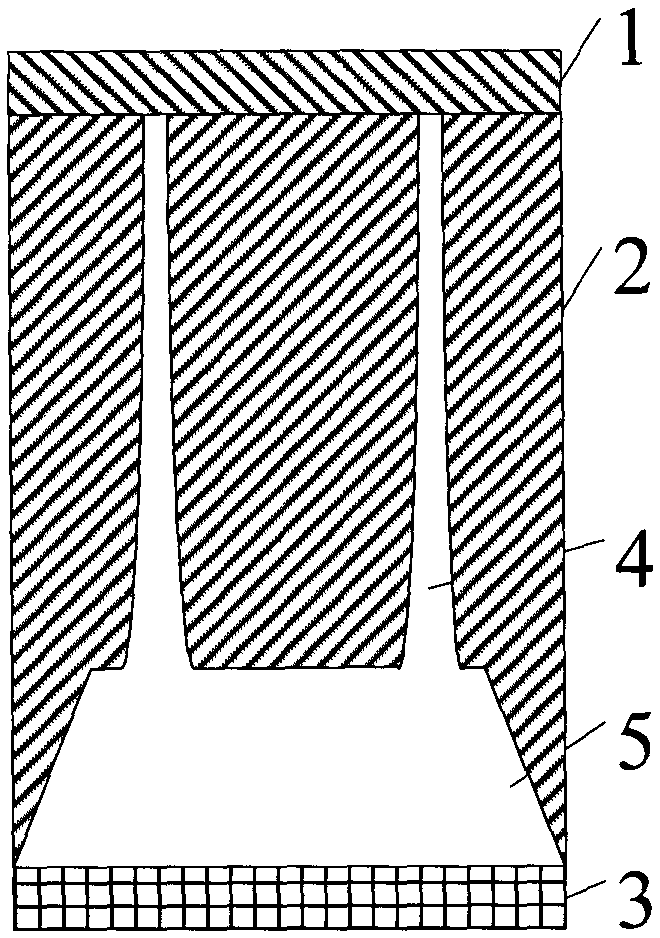

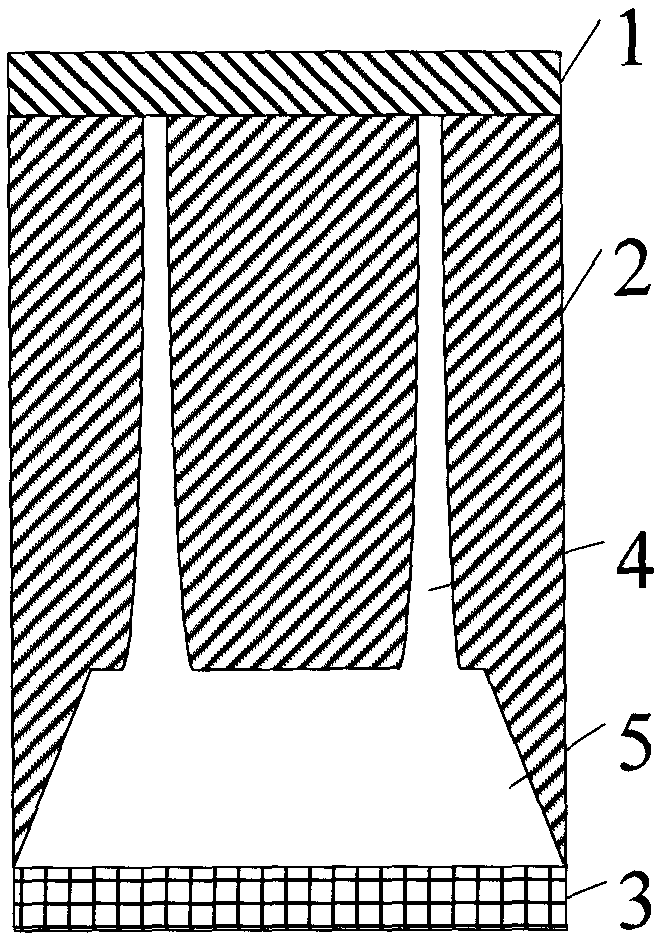

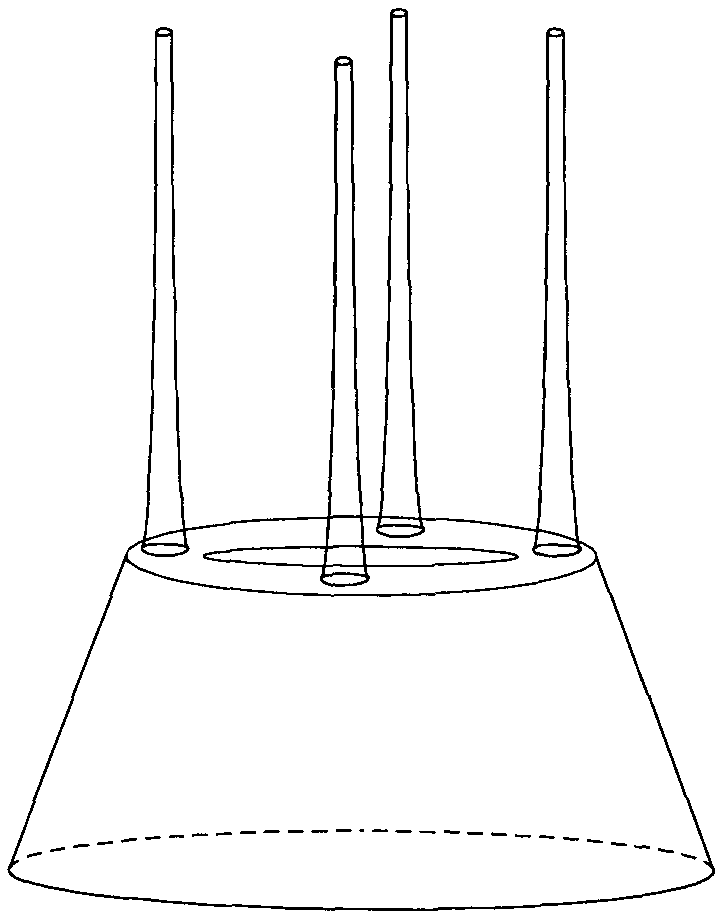

[0024] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a multi-layer material composite cavity sound-absorbing tile includes a surface layer 1, a perforated layer 2, and a base layer 3. Wherein, the surface layer 1 is in contact with the medium water, and the surface layer 1 adopts a sound-transmitting polyurethane elastomer. When the sound wave enters, because the acoustic impedance of the sound-transmitting polyurethane elastomer matches the acoustic impedance of the water, the enemy's active sonar sound waves can Maximize the incidence and reduce the reflection of sound waves. The perforated layer 2 is made of polyurethane double-layer composite foam sound-absorbing material, and the incident sound wave converts the sound wave energy into heat energy and dissipates it through the combined cavity and the waveform conversion and energy dissipa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com