Composite wallboard structure of impact-resistant foam metal composite material for aircraft manufacturing

A foam metal and aircraft manufacturing technology, applied in the fuselage bulkhead, fuselage insulation, etc., can solve the problems of poor impact resistance and sound insulation performance, affecting the comfort of cabin members, and heavy structural weight, etc., to achieve good deformation and Energy absorption performance, improve low-frequency sound absorption effect, and improve the effect of sound insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

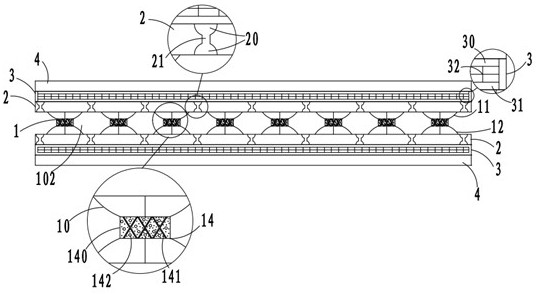

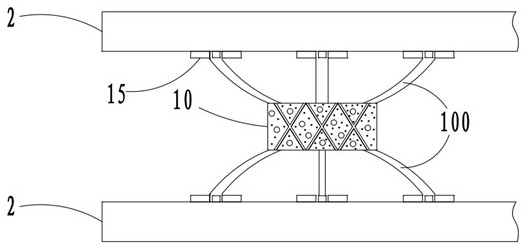

[0035] like figure 1 , 2 As shown, a composite wall panel structure of an impact-resistant foam metal composite material for aircraft manufacturing includes a sound-absorbing core material 1, a transition connecting layer 2 arranged at the upper and lower ends of the sound-absorbing core material 1, and a transition connecting layer 2 on the transition connecting layer 2 away from the absorbing material. The glass fiber protective layer 3 connected on one side of the acoustic core material 1, and the outer skin 4 connected with the glass fiber protective layer 3 on the side away from the transition connecting layer 2;

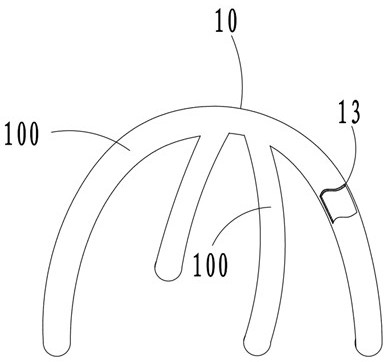

[0036] The sound-absorbing core material 1 includes a first substrate layer 11 and a second substrate layer 12 formed by 30 umbrella-shaped hollow tube frames 10 arranged in a matrix. The first substrate layer 11 and the second substrate layer 12 are symmetrically distributed up and down and each The opening of the umbrella-shaped hollow pipe frame 10 faces th...

Embodiment 2

[0045] What this embodiment records is the preparation method of the open-cell aluminum foam in Example 1, comprising the following steps:

[0046] S1. Use a supersonic gas atomizing furnace to prepare aluminum alloy powder, and use an ultrasonic vibrating screen to sieve to obtain a powder with a particle size of -100 mesh;

[0047] S2, place the above-mentioned aluminum alloy powder and sodium chloride particles in a mixer in a ratio of 1:5 by weight, and mix and stir for 2h at a rate of 450r / min to obtain a mixture;

[0048] S3. Put the mixture into an aluminum casing, and use a vacuum pump to degas until the degree of vacuum is less than 5×10 - 3 Pa, and then, under the conditions of a temperature of 450 ° C and a pressure of 120 MPa, using a hot isostatic pressing machine for hot isostatic pressing for 2 hours to obtain a hot compact;

[0049] S4, take out the hot compact from the mold of the hot isostatic press, and at room temperature, use ultrasonic cleaning for 2 ho...

Embodiment 3

[0054] What is described in this example is also the preparation method of the open-cell aluminum foam in Example 1. The difference between this example and Example 2 is that the parameters are different, which specifically includes the following steps:

[0055] S1. Use a supersonic gas atomizing furnace to prepare aluminum alloy powder, and use an ultrasonic vibrating screen to sieve to obtain a powder with a particle size of 200 meshes;

[0056] S2, place the above-mentioned aluminum alloy powder and sodium chloride particles in a mixer in a ratio of 1:5 by weight, and mix and stir at a rate of 480r / min for 2.5h to obtain a mixture;

[0057] S3. Put the mixture into an aluminum casing, and use a vacuum pump to degas until the degree of vacuum is less than 5×10 - 3 Pa, and then, under the conditions of a temperature of 480 ° C and a pressure of 140 MPa, a hot isostatic pressing process is performed for 3 hours using a hot isostatic pressing machine to obtain a hot compact; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com