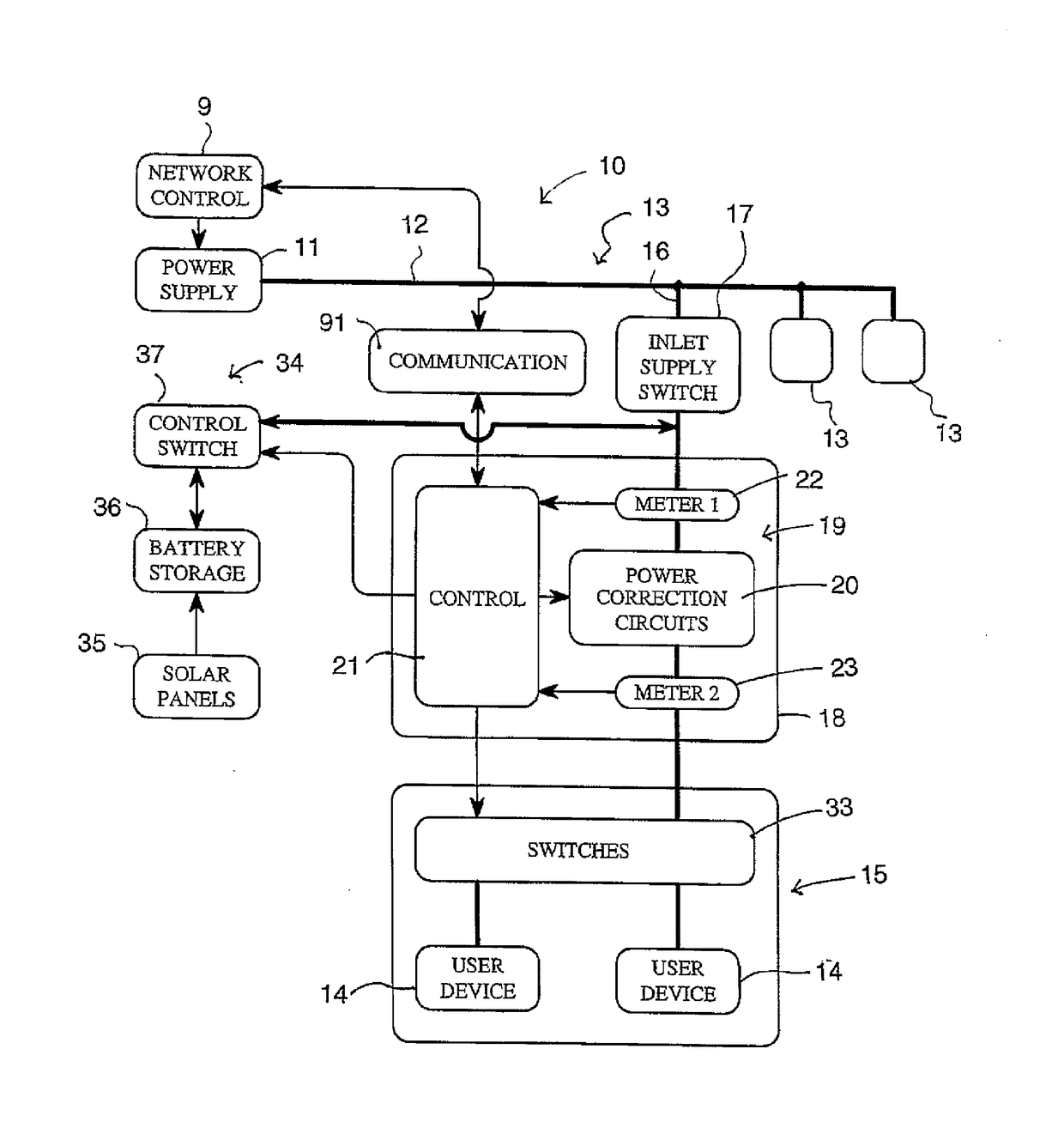

Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

55results about How to "Reduce torsional stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

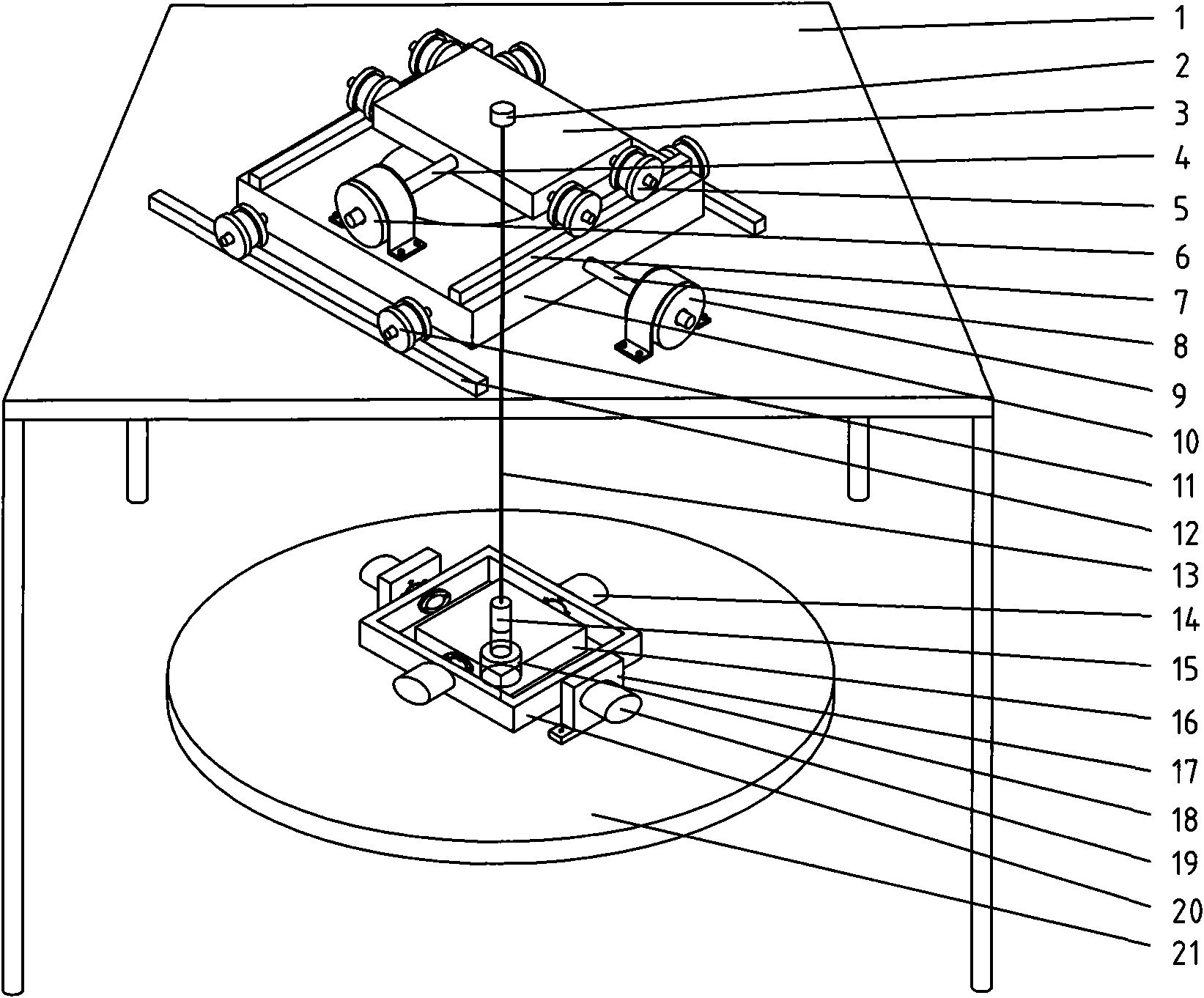

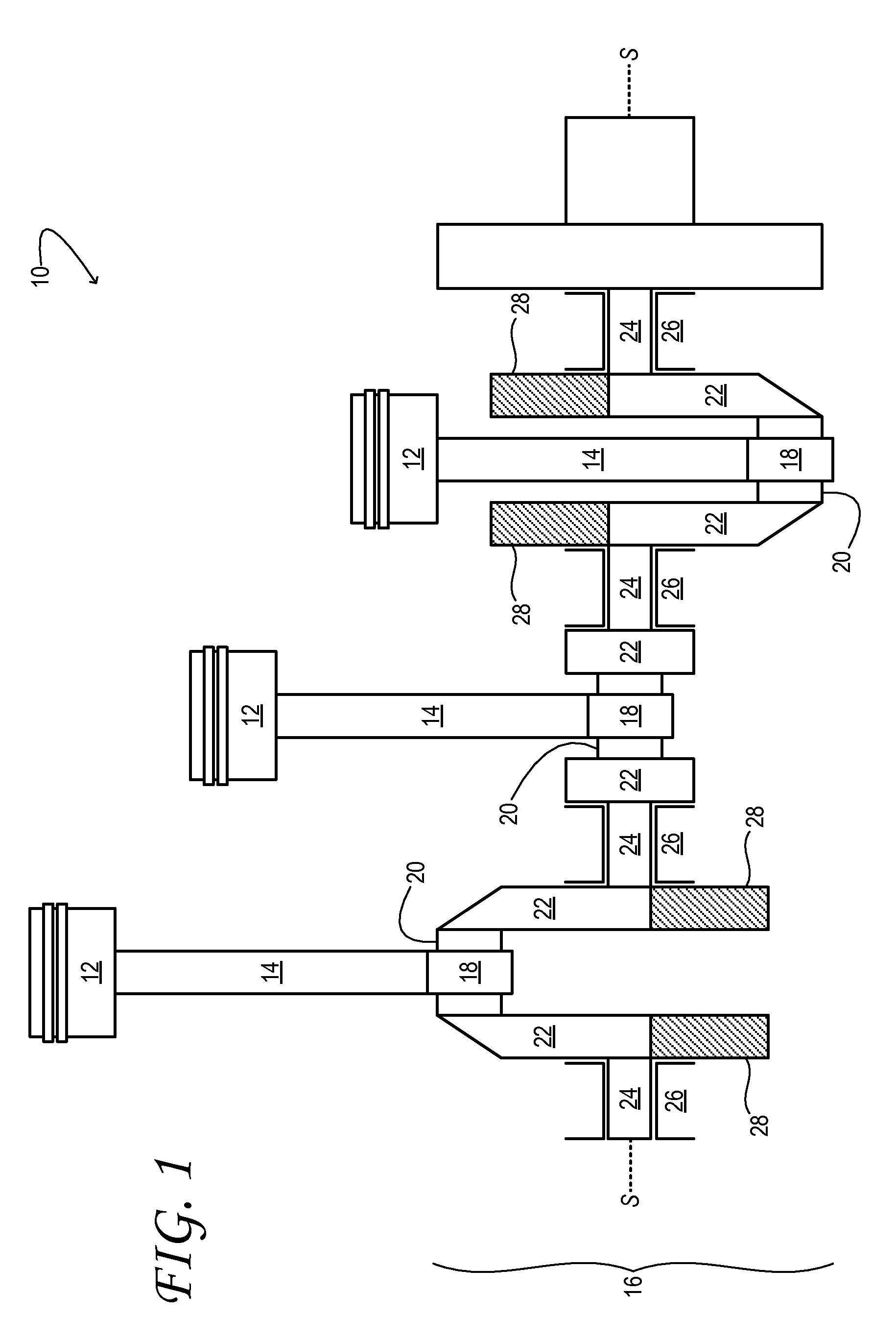

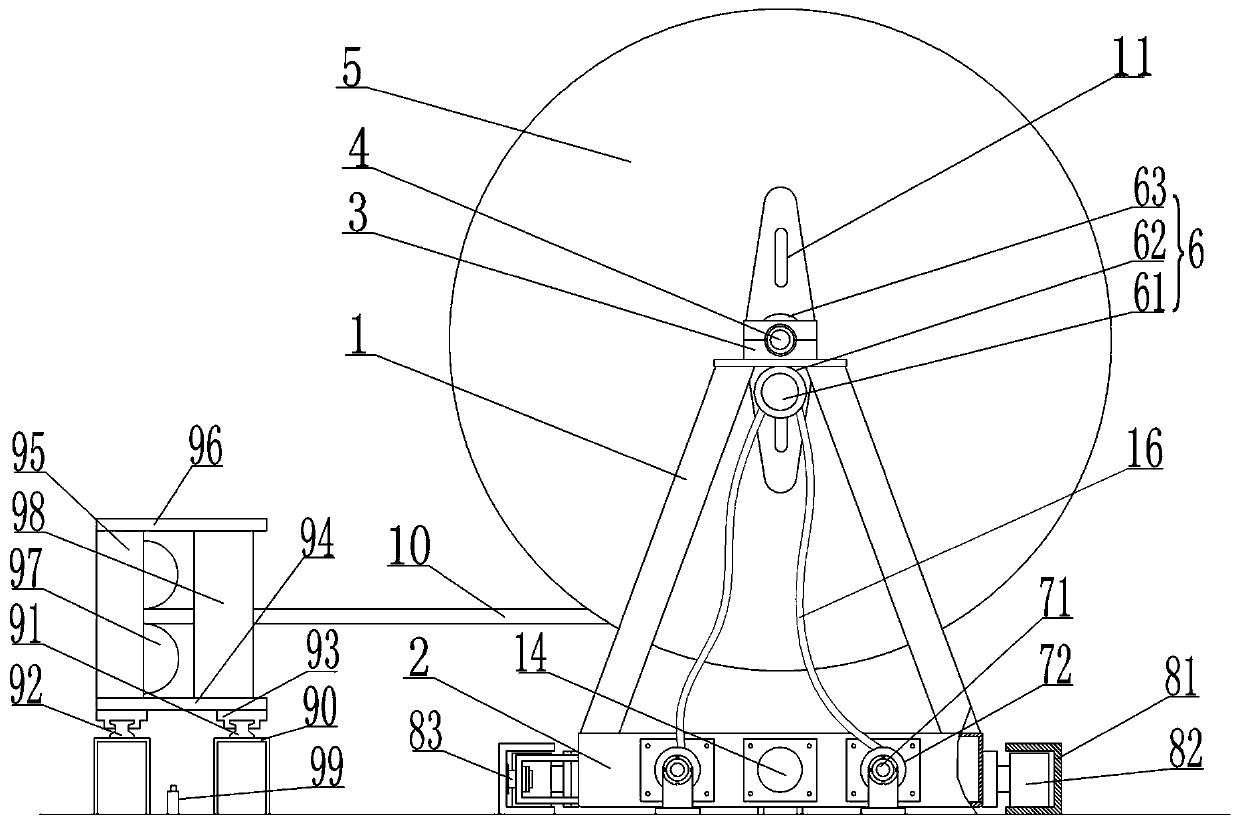

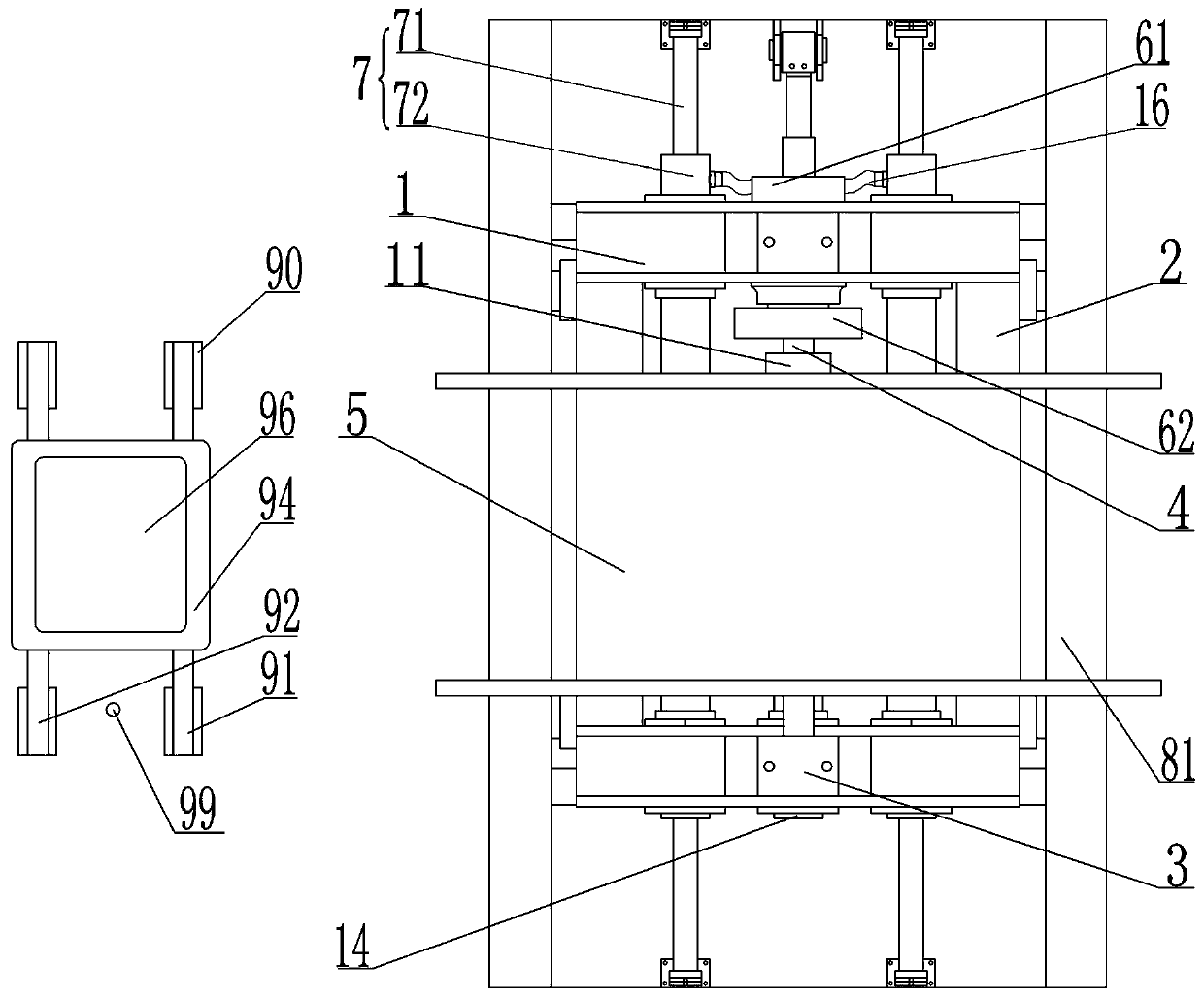

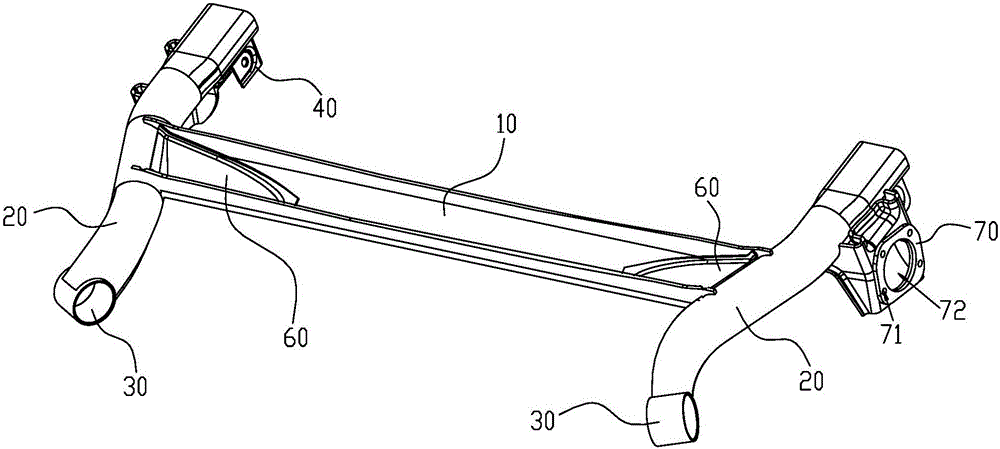

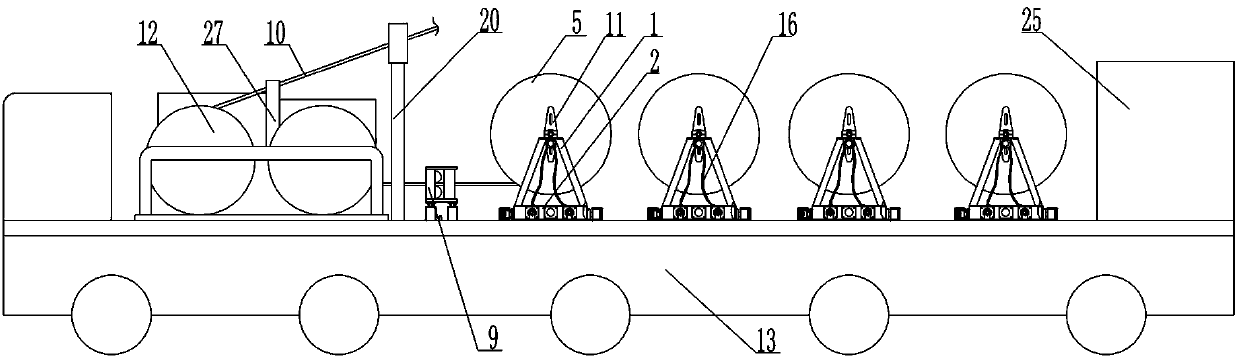

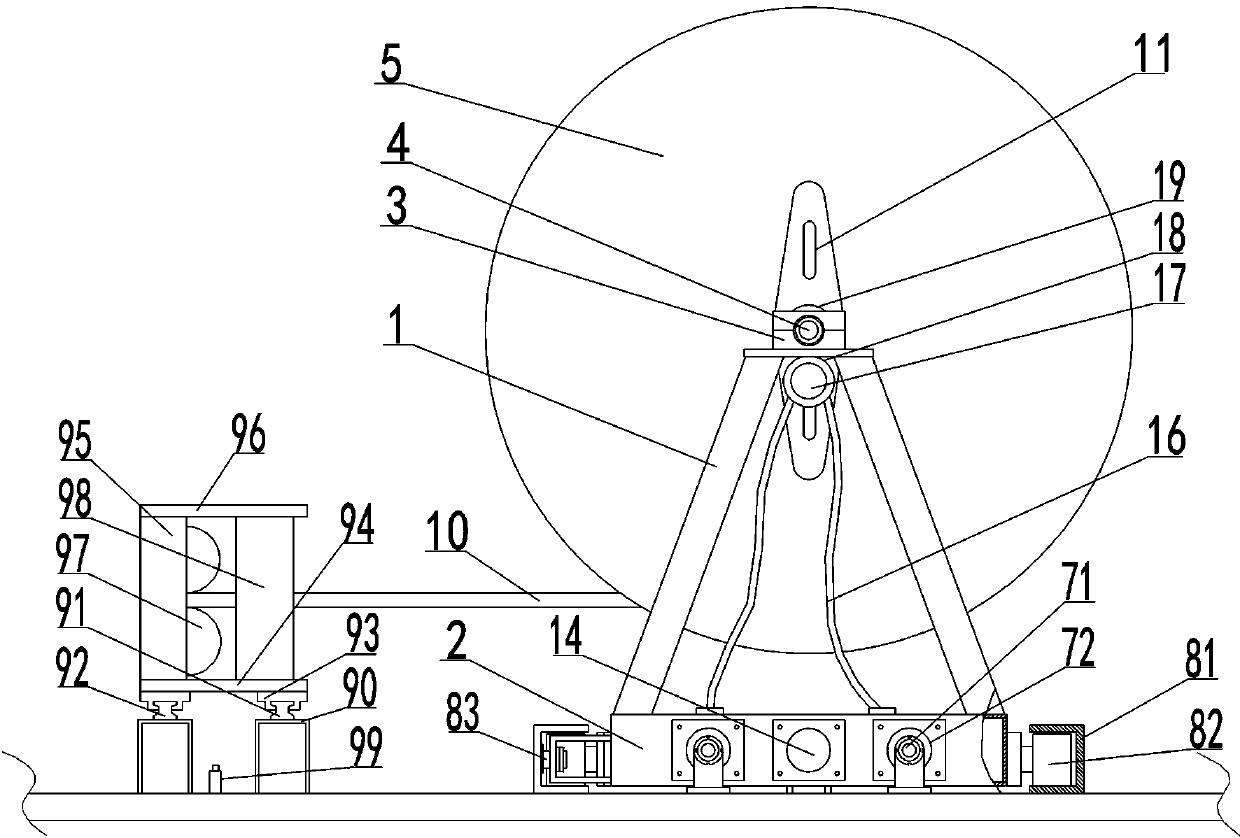

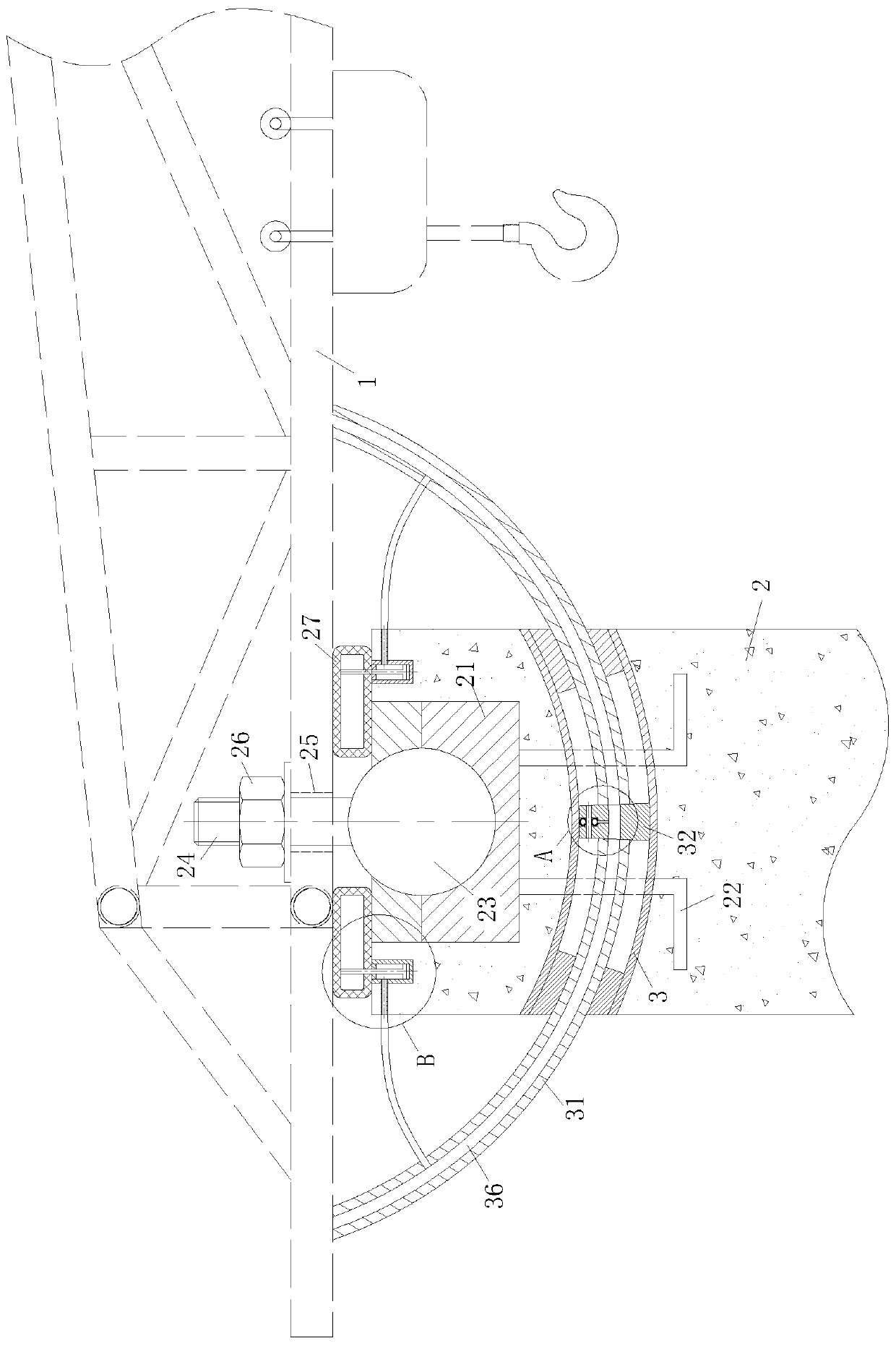

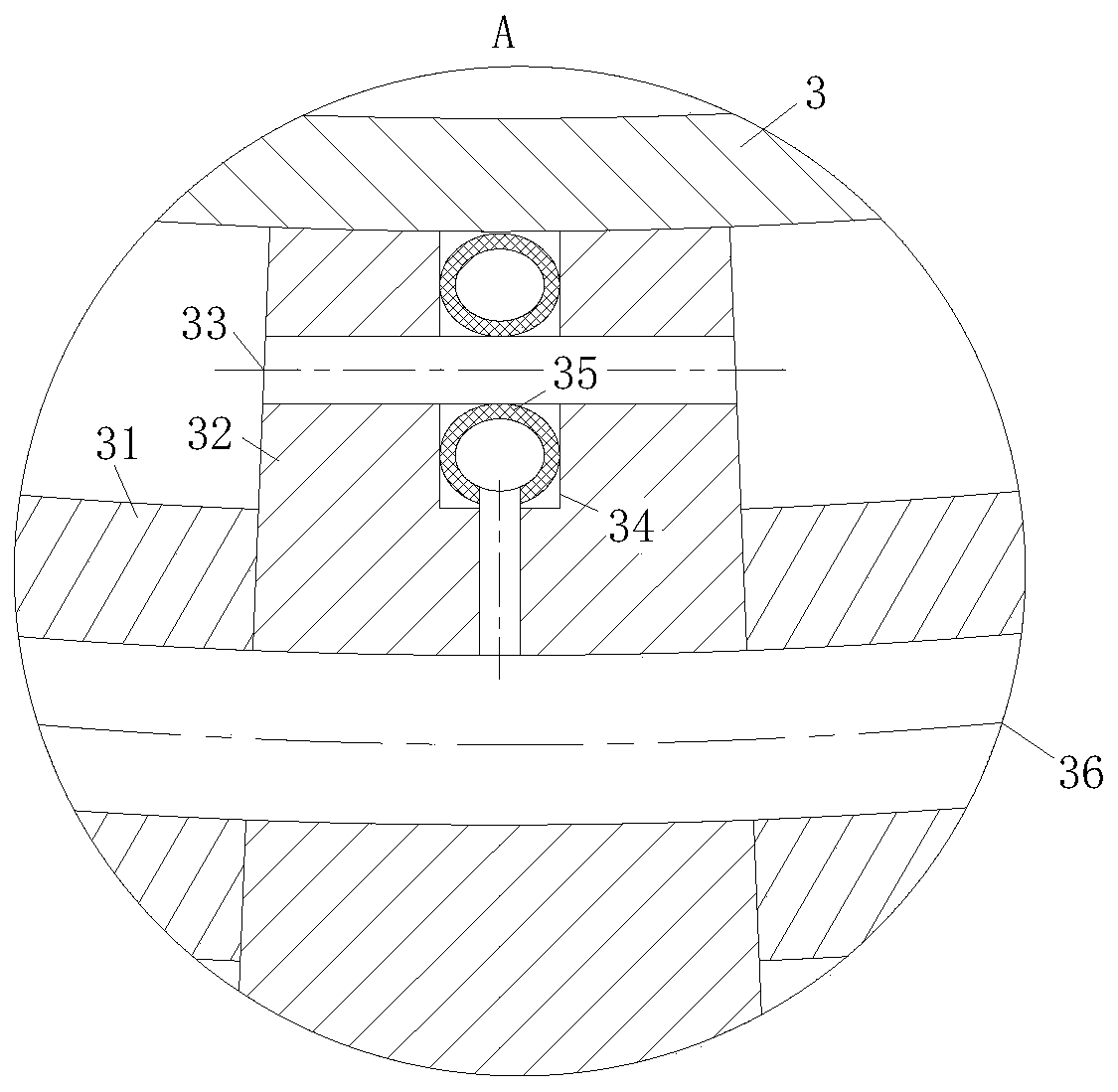

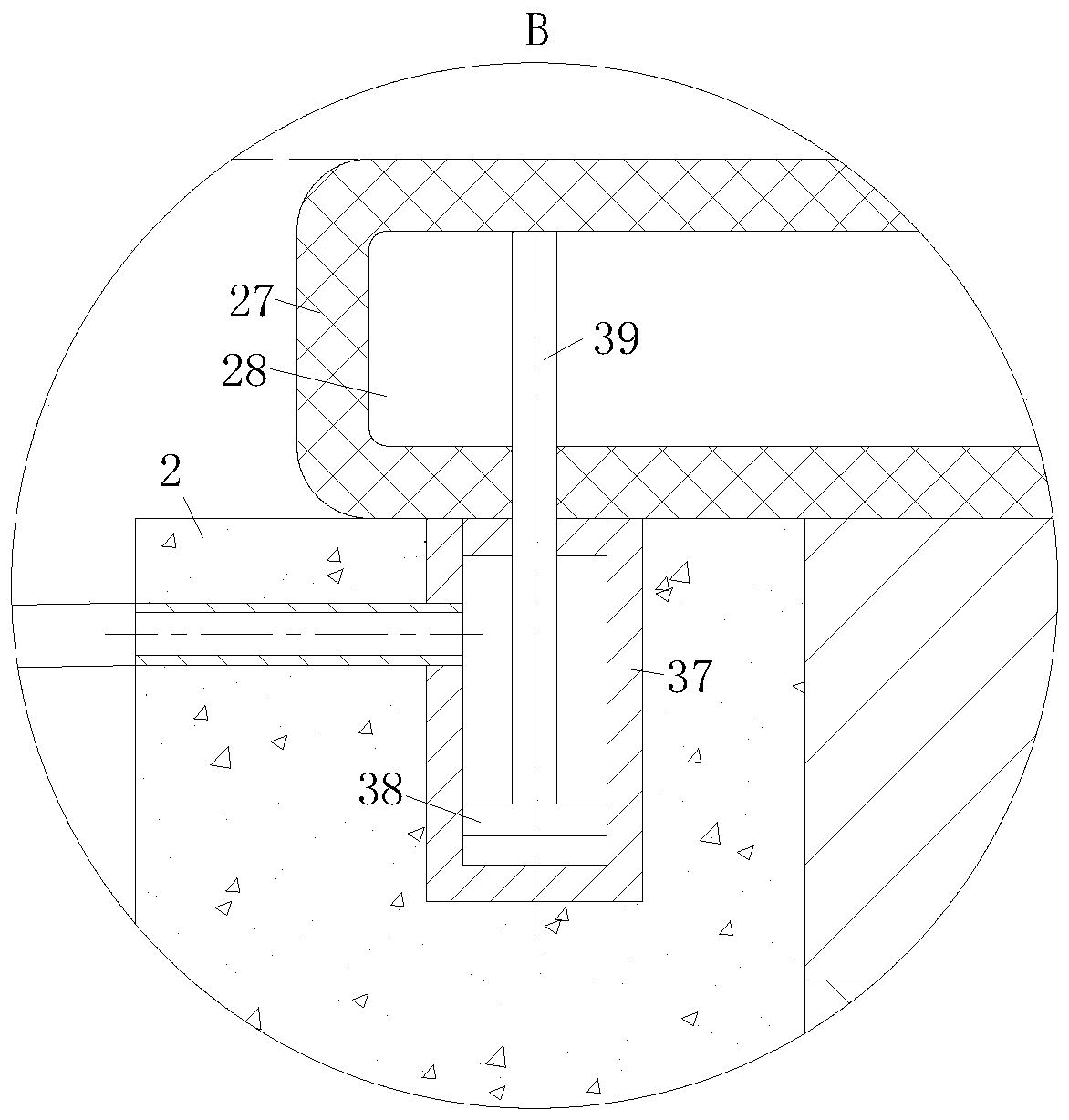

Ground simulation test device for space vehicle

InactiveCN101596940ASimple structureLow costCosmonautic condition simulationsFlight vehicleEngineering

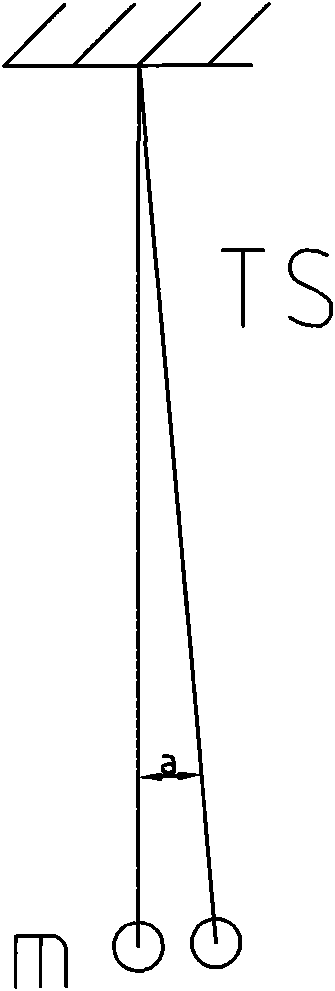

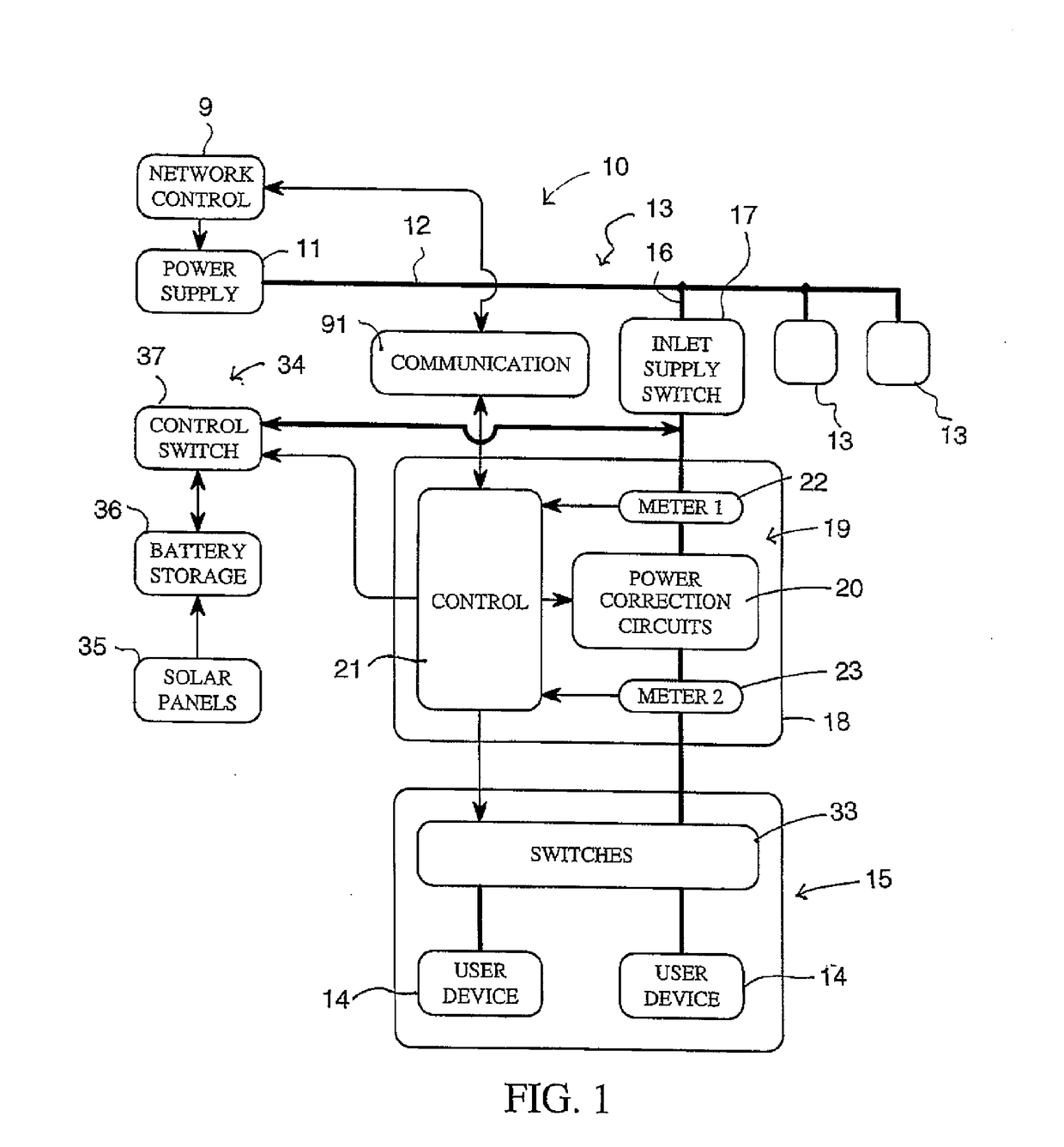

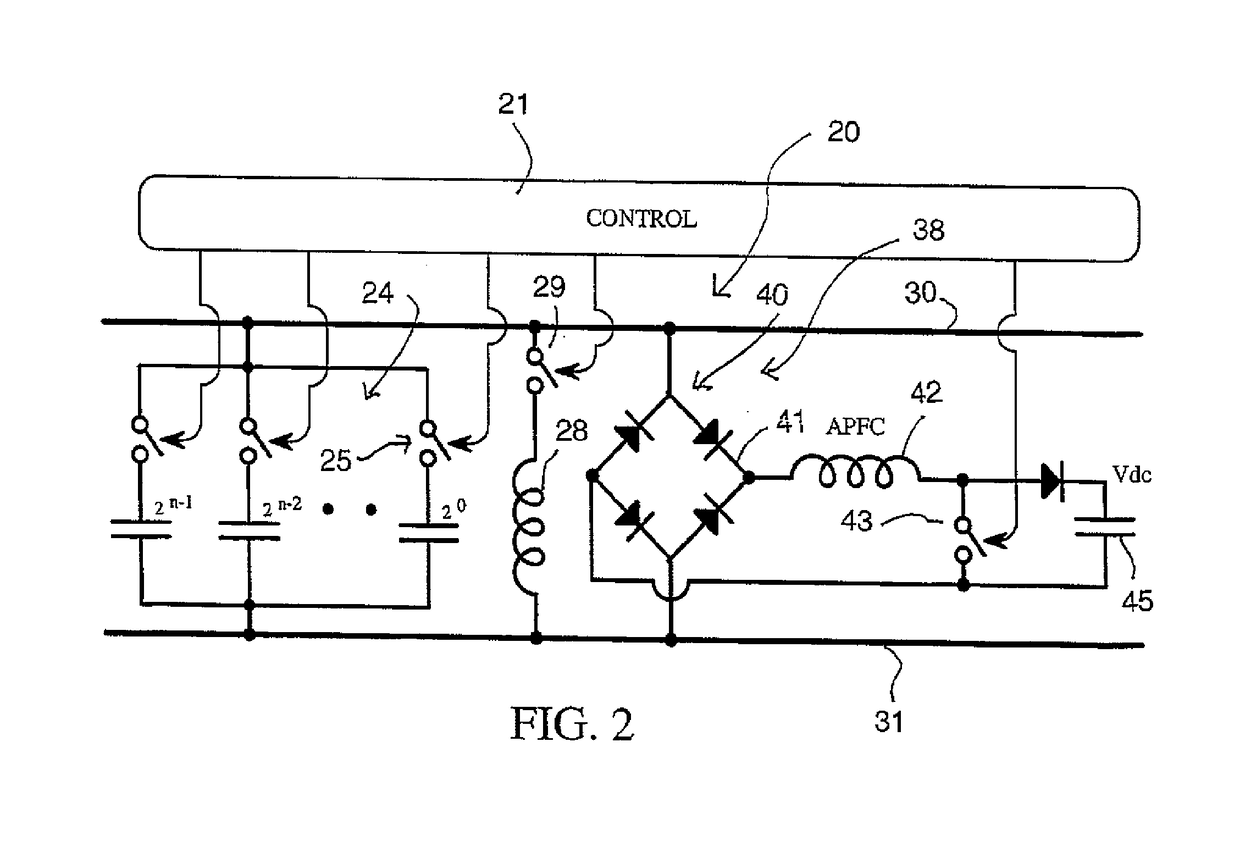

The invention relates to a test device, in particular to a ground simulation test device for space vehicle. The test device is characterized in that a driving mechanism is arranged above a support platform 1 and a space vehicle simulation mechanism is arranged below the support platform 1. One end of a flexible rope 13 is connected with the driving mechanism, and the other end is connected with a space vehicle simulator 21 by a three-axle table. One end of the flexible rope is fixedly connected with an upper trolley 3 on the support platform 1 at a flexible rope fixed point 2, and the other end of the flexible rope 13 is connected with a three-axle table inner shaft 15. A suspension corner formed by rotating motion of the space vehicle is eliminated, so as to cause suspension to be closed to an angle equilibrium position all the time, thus reducing suspension torsion stress; and meanwhile the method also can eliminate that suspension deviates a gravitational equilibrium position caused by translation motion of the space vehicle, so as to cause the suspension to be closed to the gravitational equilibrium position all the time, thus reducing suspension restoring force and ensuring disturbing force of the space vehicle simulator to be minimum.

Owner:葛升民

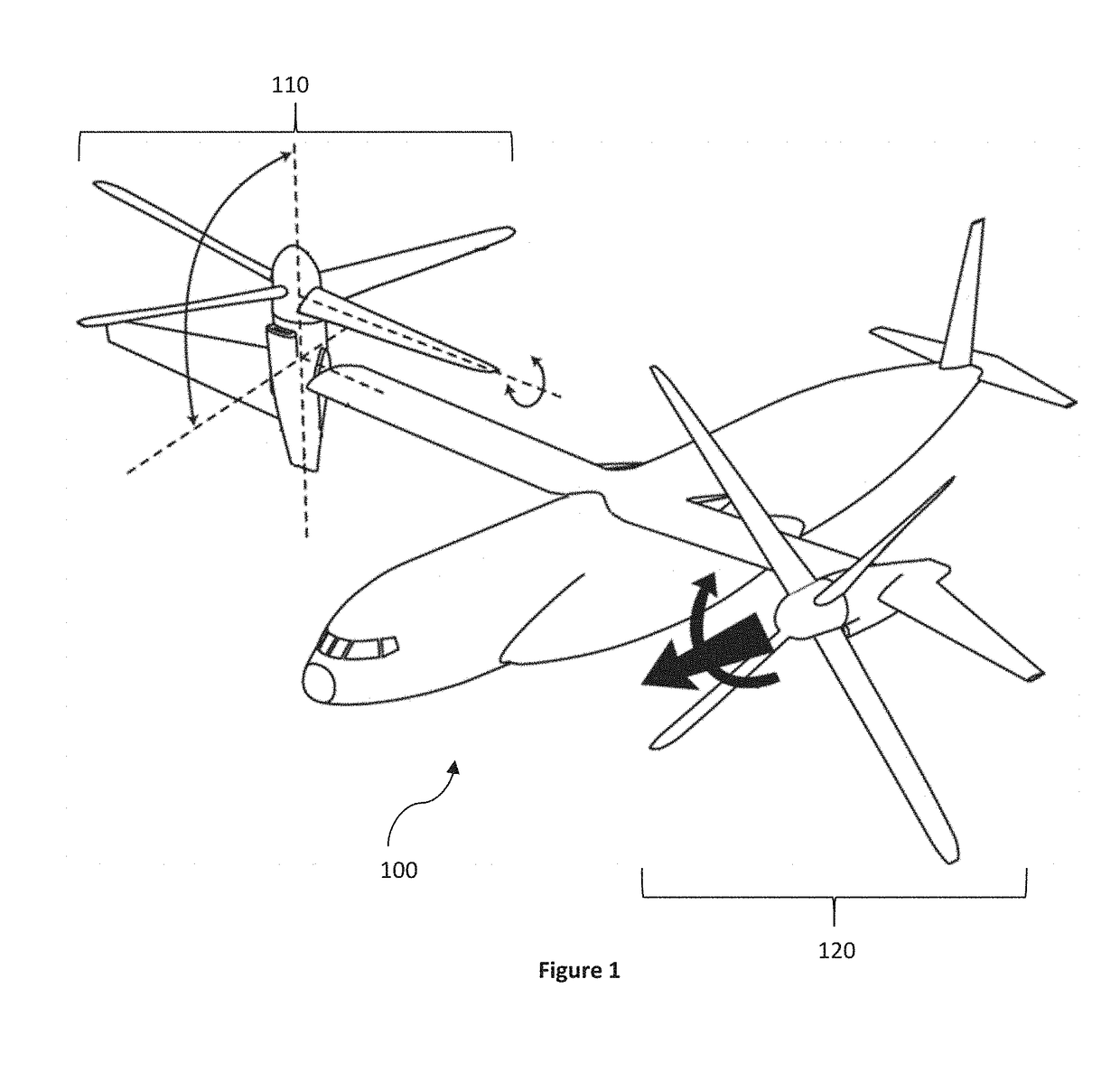

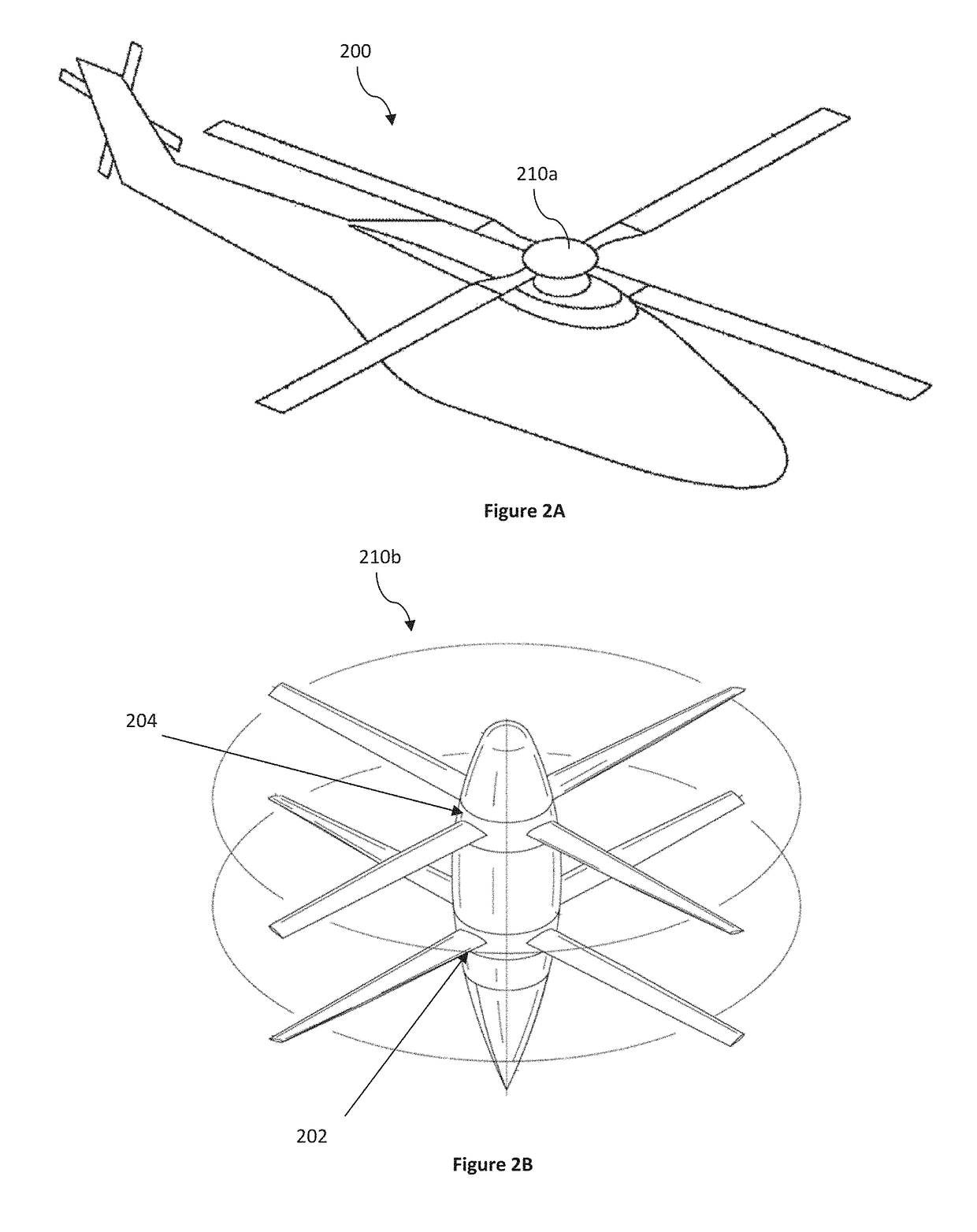

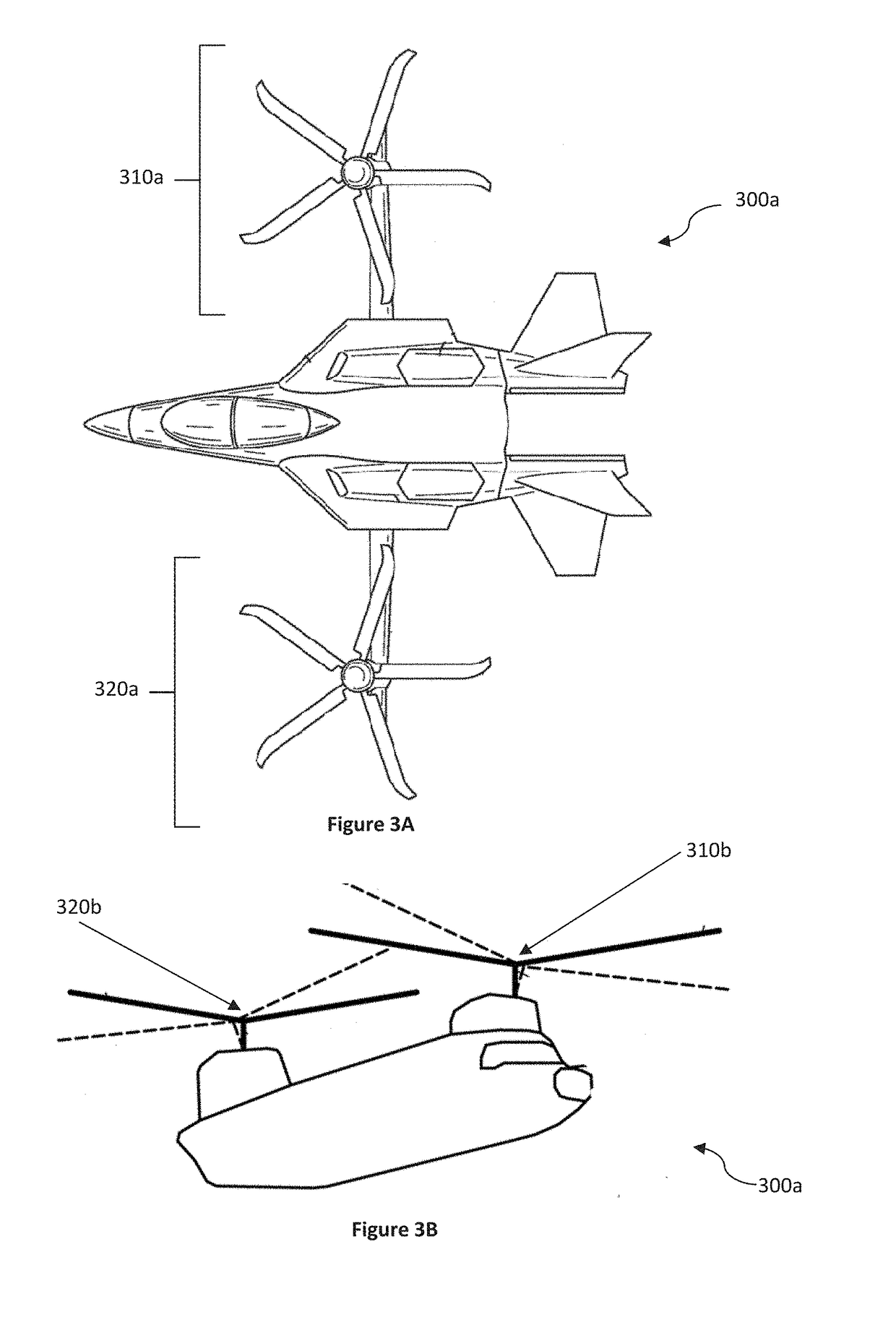

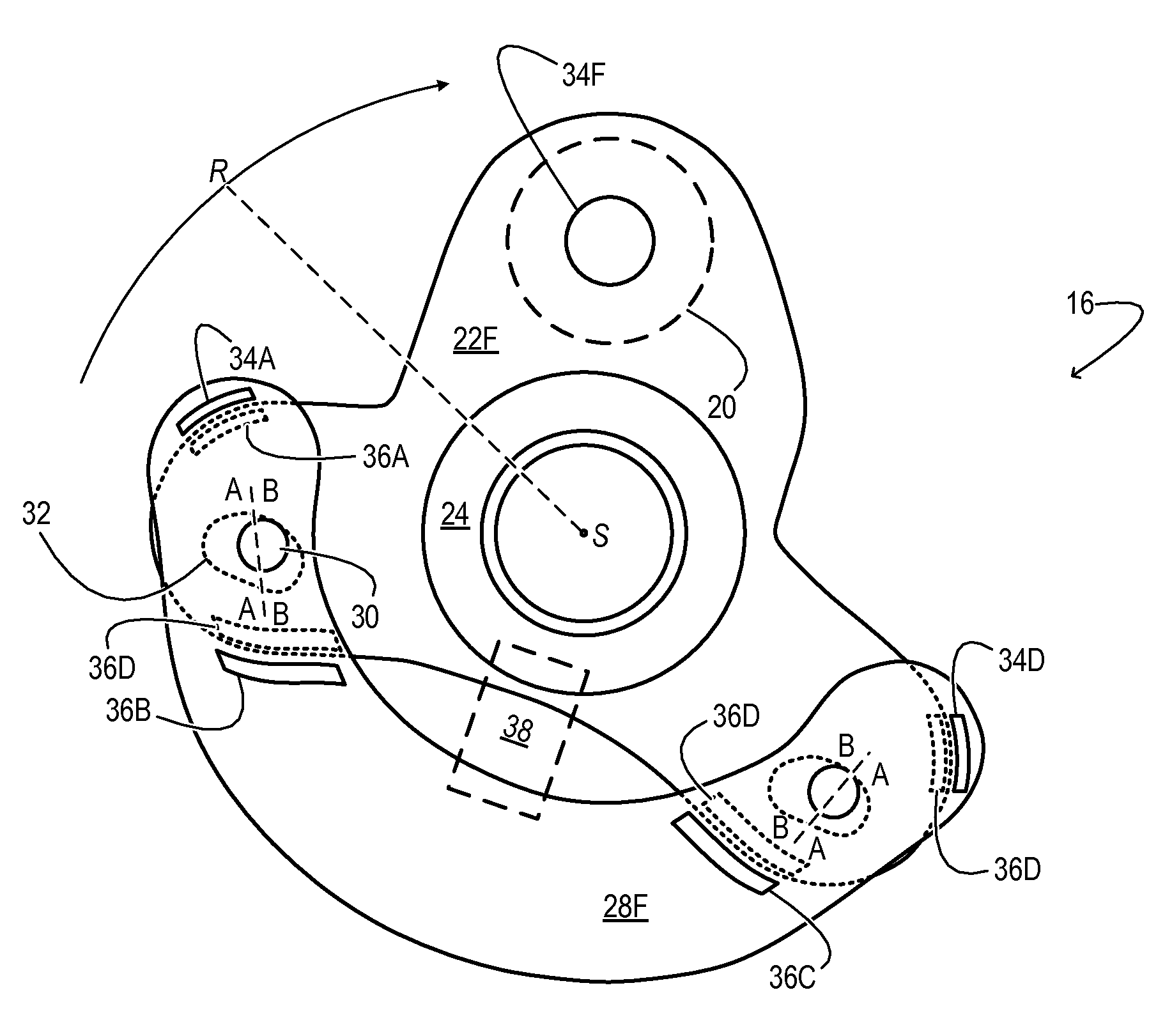

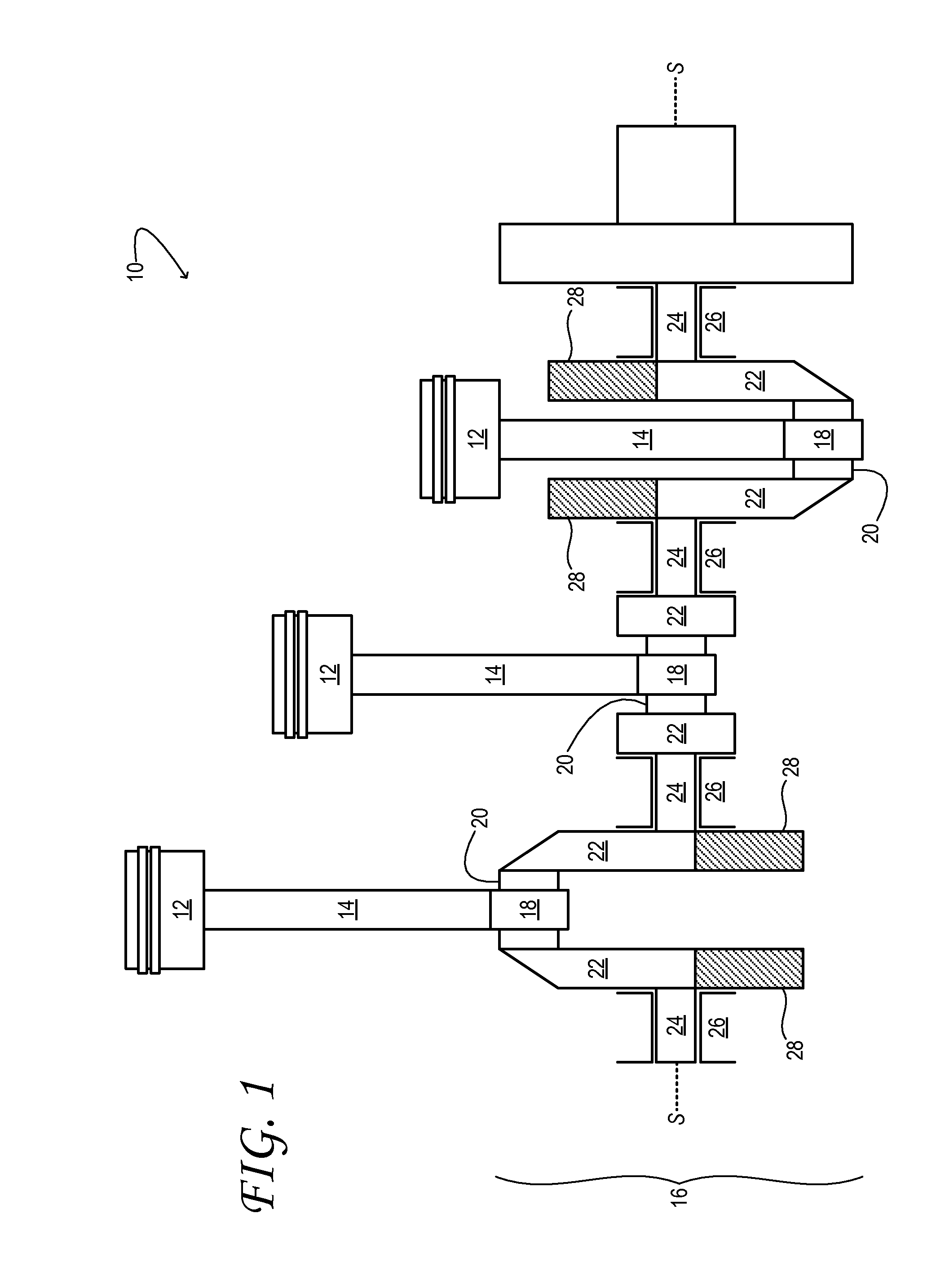

Use of individual blade control on a propeller or rotor in axial flight for the purpose of aerodynamic braking and power response modulation

ActiveUS20180346111A1Improve aircraft flight dynamicsImproving aerodynamic brakingGas turbine type power plantsWing lift eficiencyAerodynamic dragDrive shaft

Systems and methods are contemplated for favorably improving flight dynamics of aircraft, including enhanced aerodynamic braking and improved flight maneuverability. Air braking systems selectively position a first set of blades at a negative thrust pitch to product a net negative thrust across first and second sets of blades, while balancing torque of the drive shafts to zero. First and second sets of IBC blades can be driven by the same shaft or torque-linked shafts. Flight maneuver systems operate a powerplant at a high power mode, and dissipate the energy from the high power output by positioning a first set of IBC blades at a low efficiency pitch while maintaining constant thrust. As increased or rapid flight maneuverability is required, the first set of blades is positioned toward a high efficiency pitch to instantly increase thrust to the aircraft without requiring a related increase in energy output from the powerplant.

Owner:KAREM AIRCRAFT INC

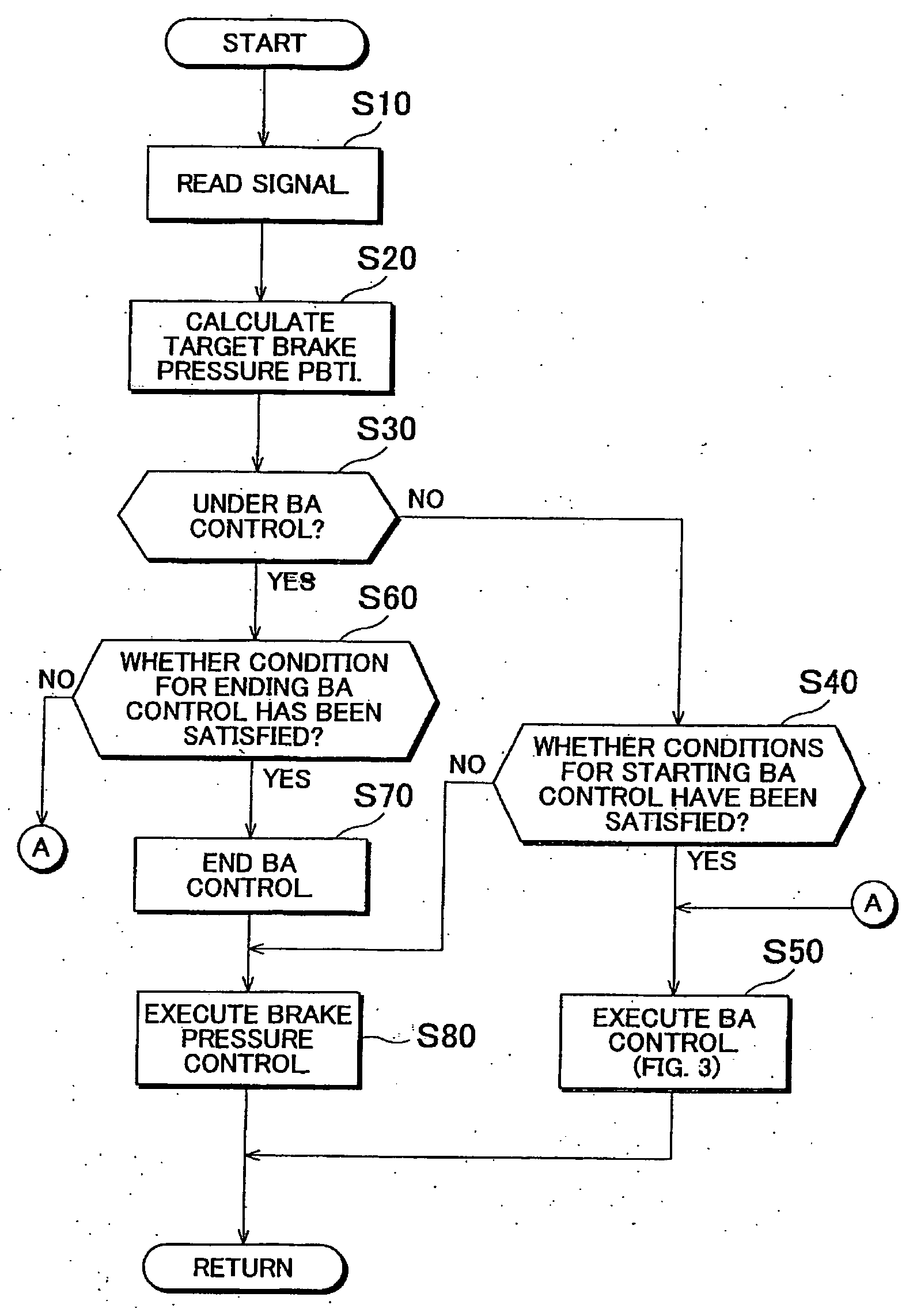

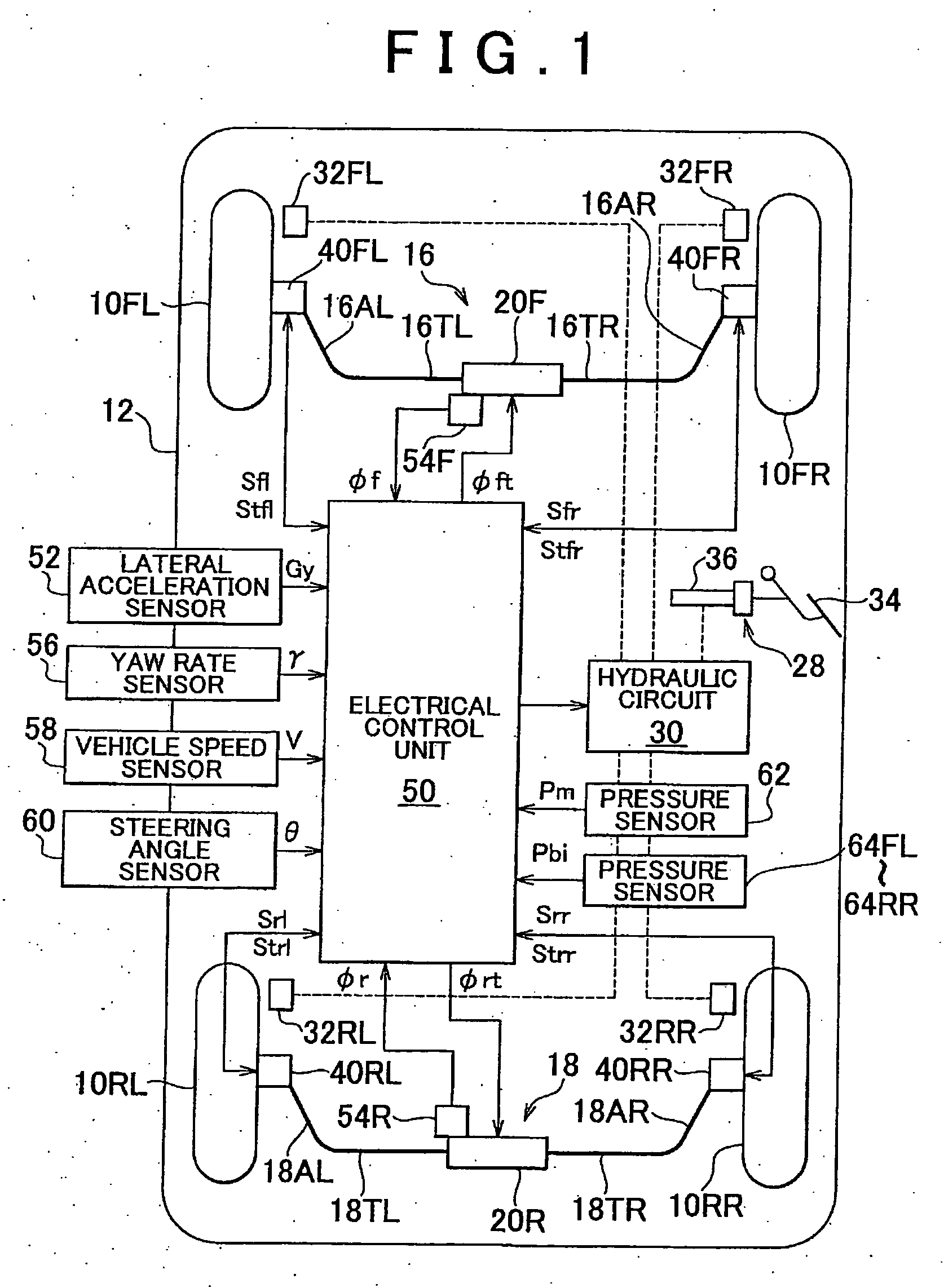

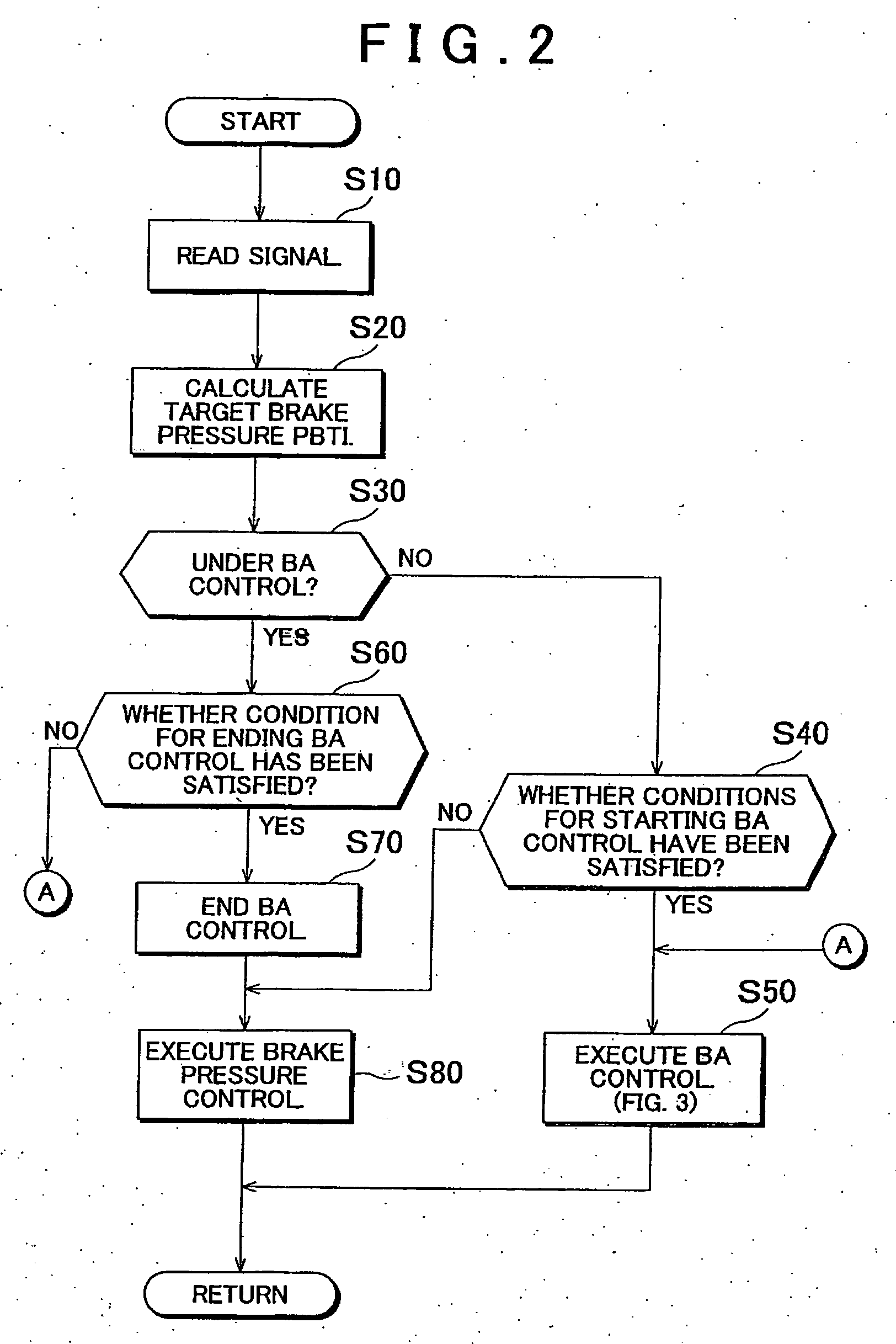

Vehicle drive control system and method

InactiveUS20070124051A1Turn the vehicle easilyAdditional componentBrake system interactionsAnalogue computers for trafficControl systemEmergency situations

A drive control system for a vehicle includes a braking force control mechanism that controls braking forces on the wheels of the vehicle according to a braking operation, a steering characteristic control mechanism that varies the steering characteristic of the vehicle, a determination portion that determines whether an emergency steering operation is likely to de performed when hard braking is being applied, and a main control portion that controls the steering characteristic control mechanism so as to vary the steering characteristic of the vehicle to increase oversteering component of the vehicle if the determination portion determines that an emergency steering operation is likely to be performed.

Owner:TOYOTA JIDOSHA KK

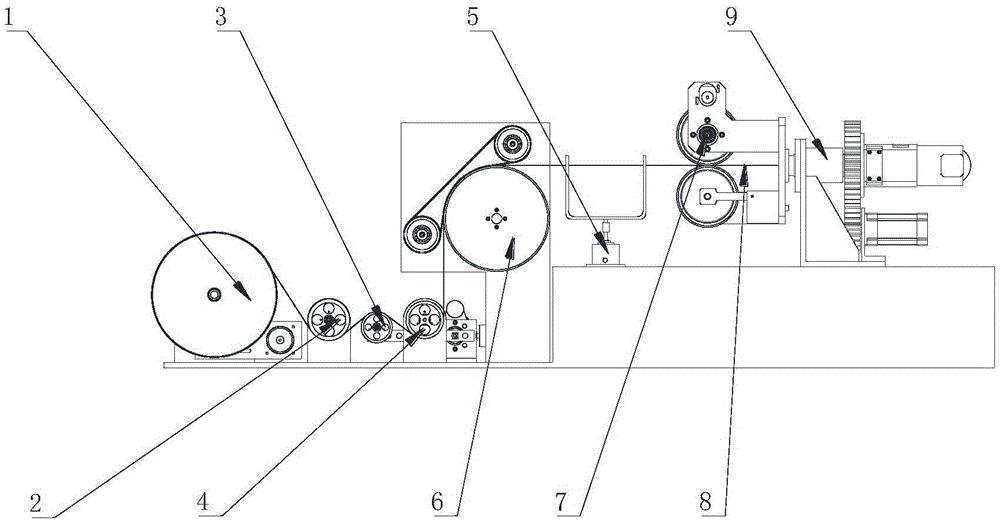

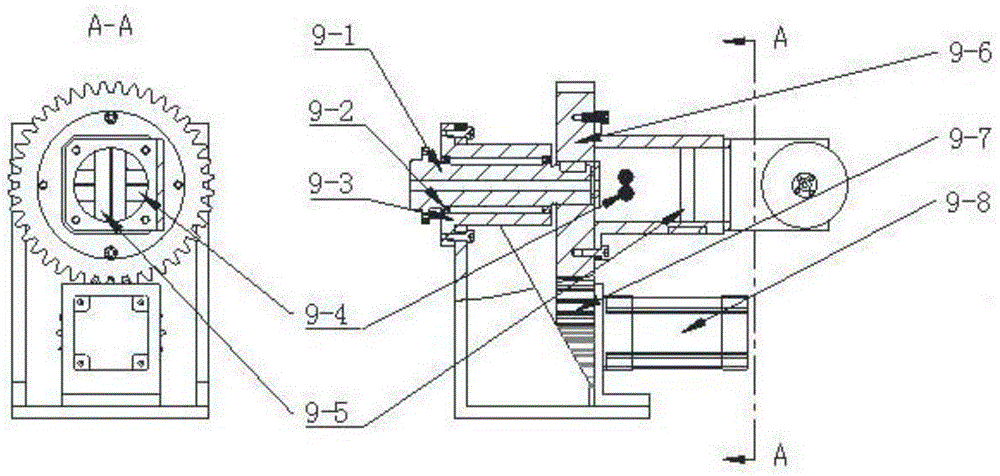

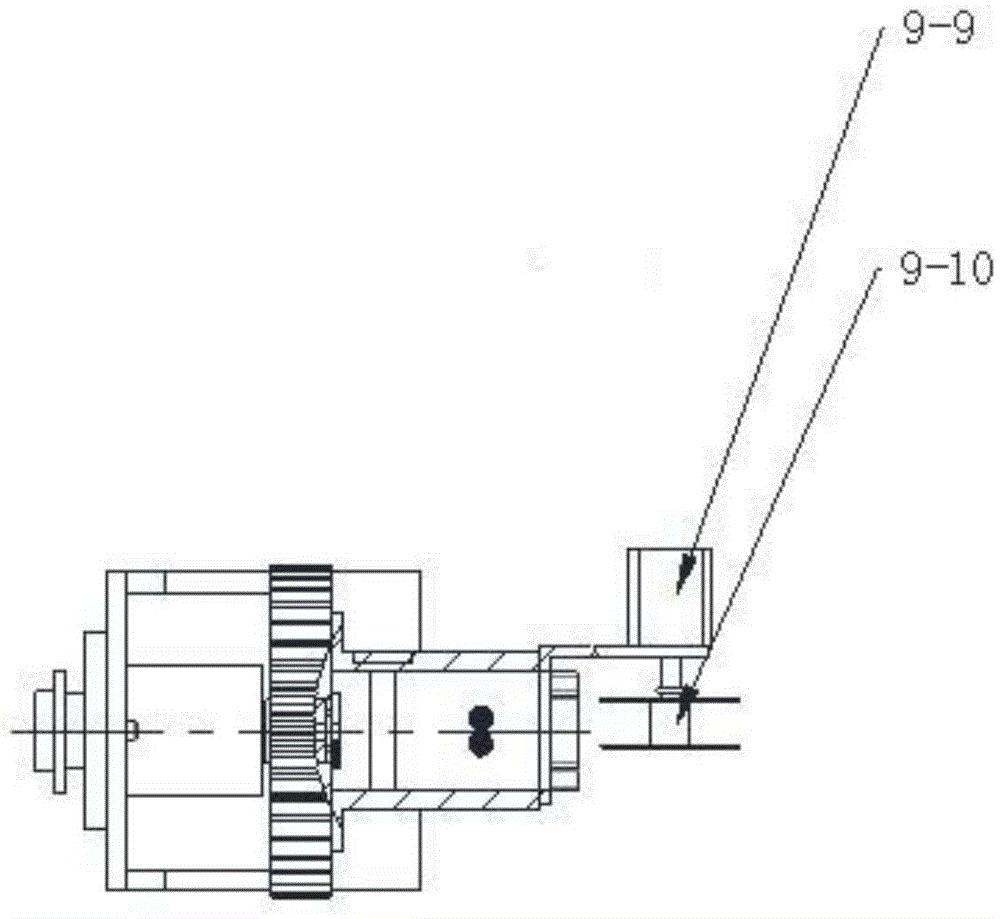

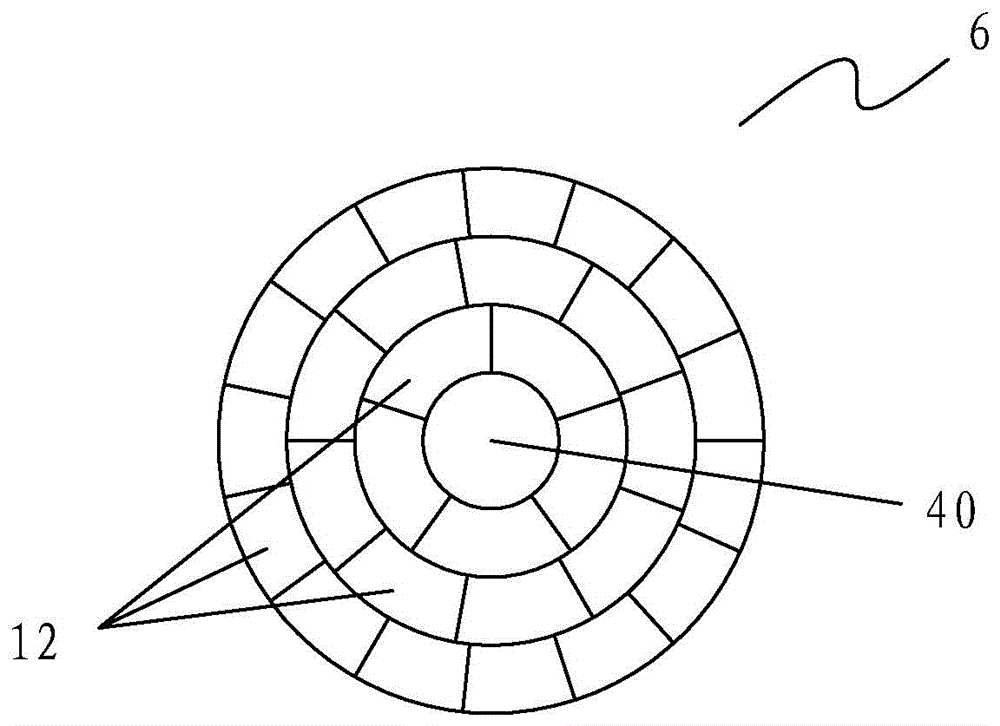

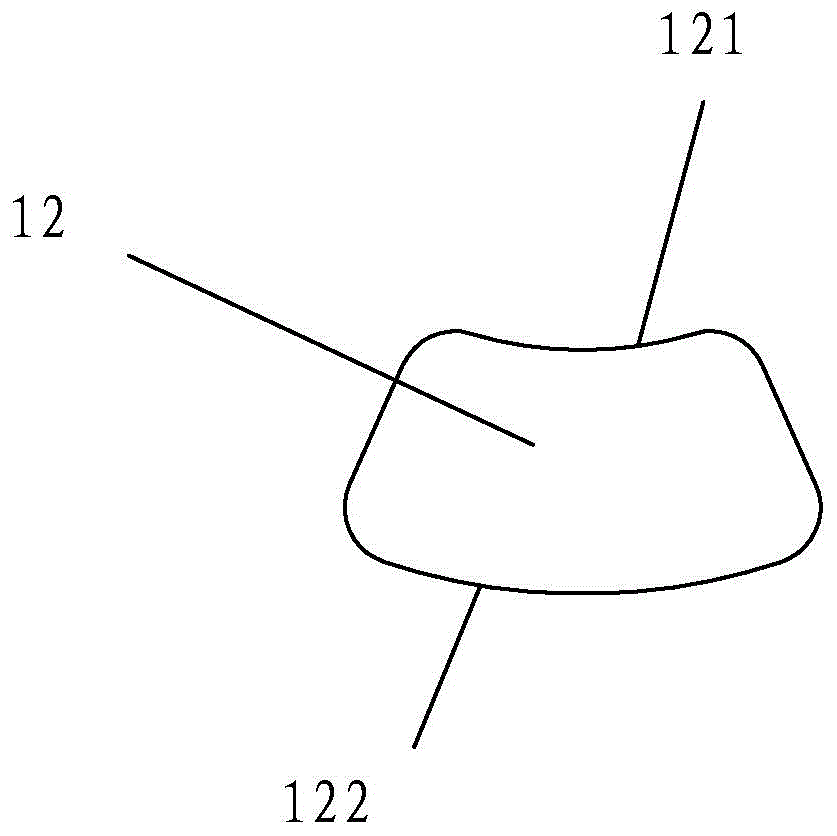

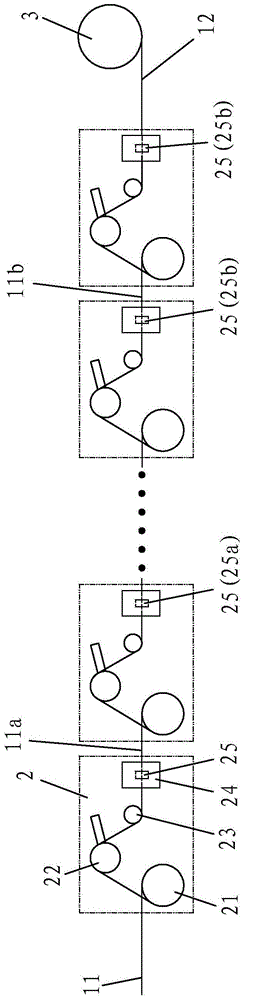

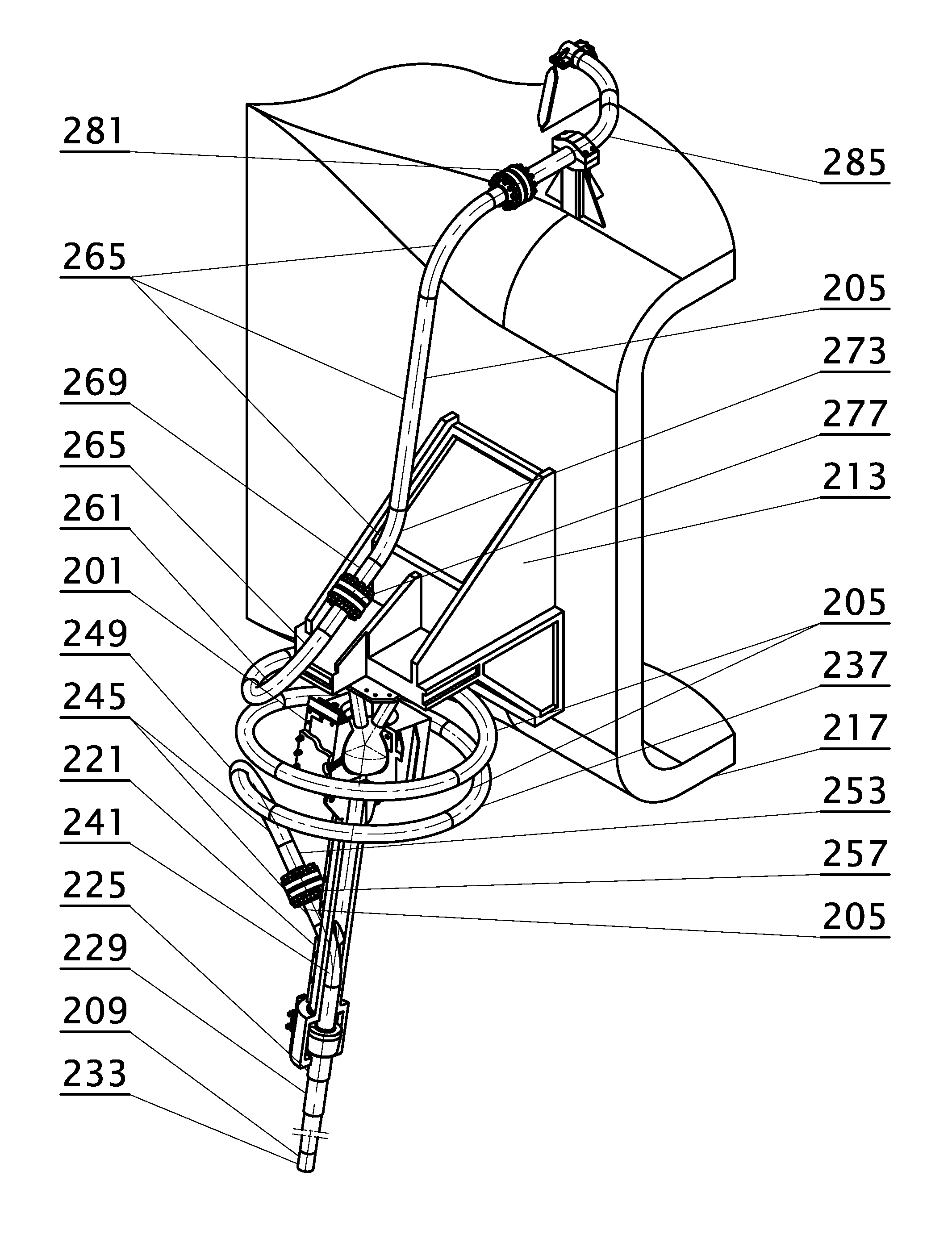

Optical fiber untwisting device

ActiveCN105621157AReduce torsional stressReduced concentricity requirementsMeasurement devicesFilament handlingFiberGyroscope

The invention discloses an optical fiber untwisting device. An optical fiber guided out of an optical fiber traction assembly passes through an optical fiber twisting detecting unit, an optical fiber winding and clamping assembly and an optical fiber untwisting assembly which are arranged in sequence and is wound around the interior a fiber winding disc in the optical fiber untwisting assembly. The optical fiber untwisting assembly comprises a rotary driving motor, a transmission mechanism and the fiber winding disc. The rotary driving motor is connected with an angle sensor and rotates according to a feedback signal given by the angle sensor. The optical fiber winding and clamping assembly is driven by the transmission mechanism to rotate synchronously and connected with the transmission mechanism through a flange face. The optical untwisting device can overall untwist the whole long optical fiber, torsional stress existing in the optical fiber is reduced, the magnetic sensitivity problem of a fiber-optic gyroscope is solved, and the precision of the fiber-optic gyroscope is improved. In addition, by means of the optical fiber untwisting technology, the influence of eccentricity of an insulated single wire on characteristic impedance can be eliminated, and the requirement for the concentricity of the insulated single wire can be reduced.

Owner:武汉光谷长盈通计量有限公司

Method for preparing aluminium alloy trapezoidal conductor

InactiveCN105023651AStable structureImprove bindingCable/conductor manufactureElectrical conductorMaterials science

The invention provides a method for preparing an aluminium alloy trapezoidal conductor, and includes: a drawing step in which a non-sliding wire drawing machine to draw trapezoidal single wires, uses an aluminium alloy rod material as wires to perform paying off, the aluminium alloy rod material passes through each drawing group in sequence and is drawn into trapezoidal single wires, and the trapezoidal single wires are rolled by a wire coil; a stranding step in which a frame type stranding machine is used to strand a trapezoidal conductor, in a stranding process of the frame type stranding machine, a center line of the trapezoidal single wires is guaranteed to be toward a core wire through a directional disc, then the trapezoidal single wires are pre-twisted, a pre-twisting direction is opposite to a rotation direction of the frame type stranding machine, and then each trapezoidal single wire and the core wire converge in the position of a molding device, thereby completing stranding, and forming a stranded conductor. The trapezoidal single wires drawn according to the method have stable structures and smooth and clean surfaces, and wires are not easy to break in a drawing process. The trapezoidal conductor formed by stranding has relatively small torsional stress, and has relatively good surface quality since compacting treatment is not needed, and a filling coefficient can be higher than 0.96.

Owner:福建锦鸿线缆有限公司

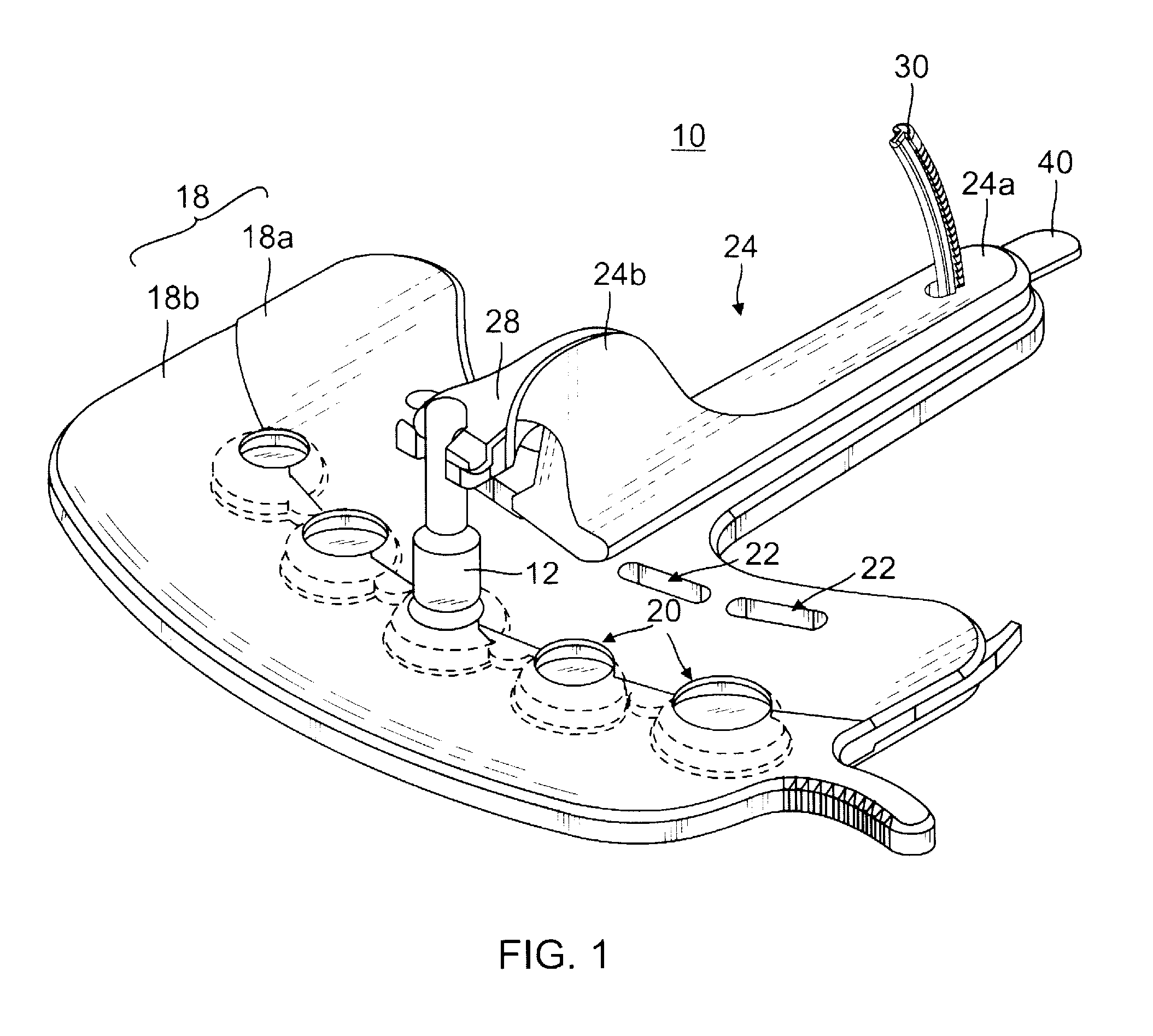

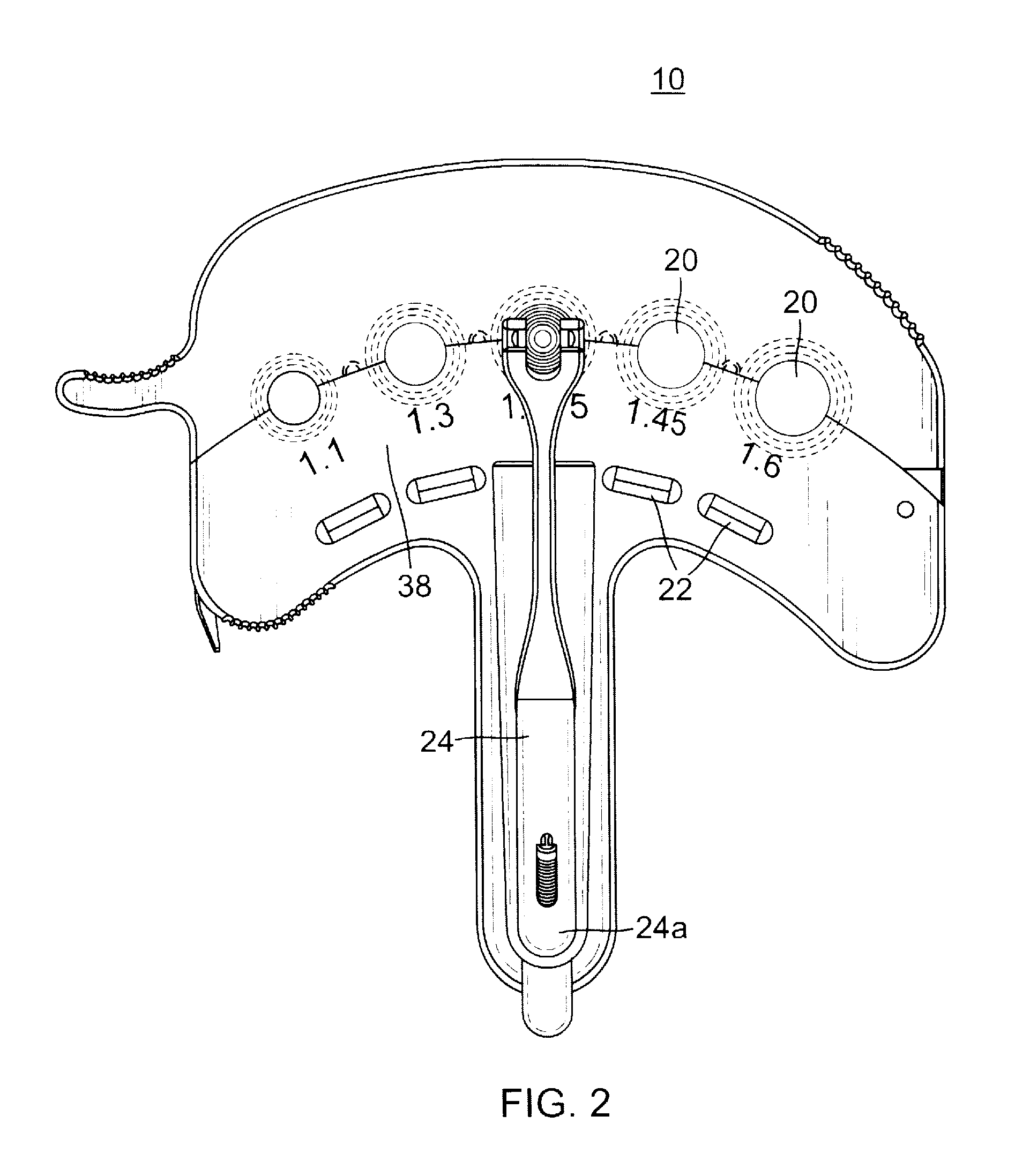

Circumcision Clamp and Surgical Kit

A circumcision clamp and surgical kit including a rod having a bell-shaped member at a first end for receiving the head of a penis and an engagement structure at an opposing end; a base including: two hinged arms. wherein when closed the arms include at least three upwardly tapered apertures aligned along an arc and having unequal diameters, wherein each upward taper is complementary to the bell-shaped member, at least three fulcrum recesses aligned along an arc and in radial alignment with the at least three apertures; a lever including: a proximal end in radial alignment with the at least three apertures and the at least three fulcrum recesses, a distal end including a fulcrum foot complementary to the at least three fulcrum recesses and adapted for engagement with the engagement structure of the rod; and an adjustment structure for raising and lowering an engaged rod by pivoting the lever at one of the at least three fulcrum recesses.

Owner:MANSOUR KARIM

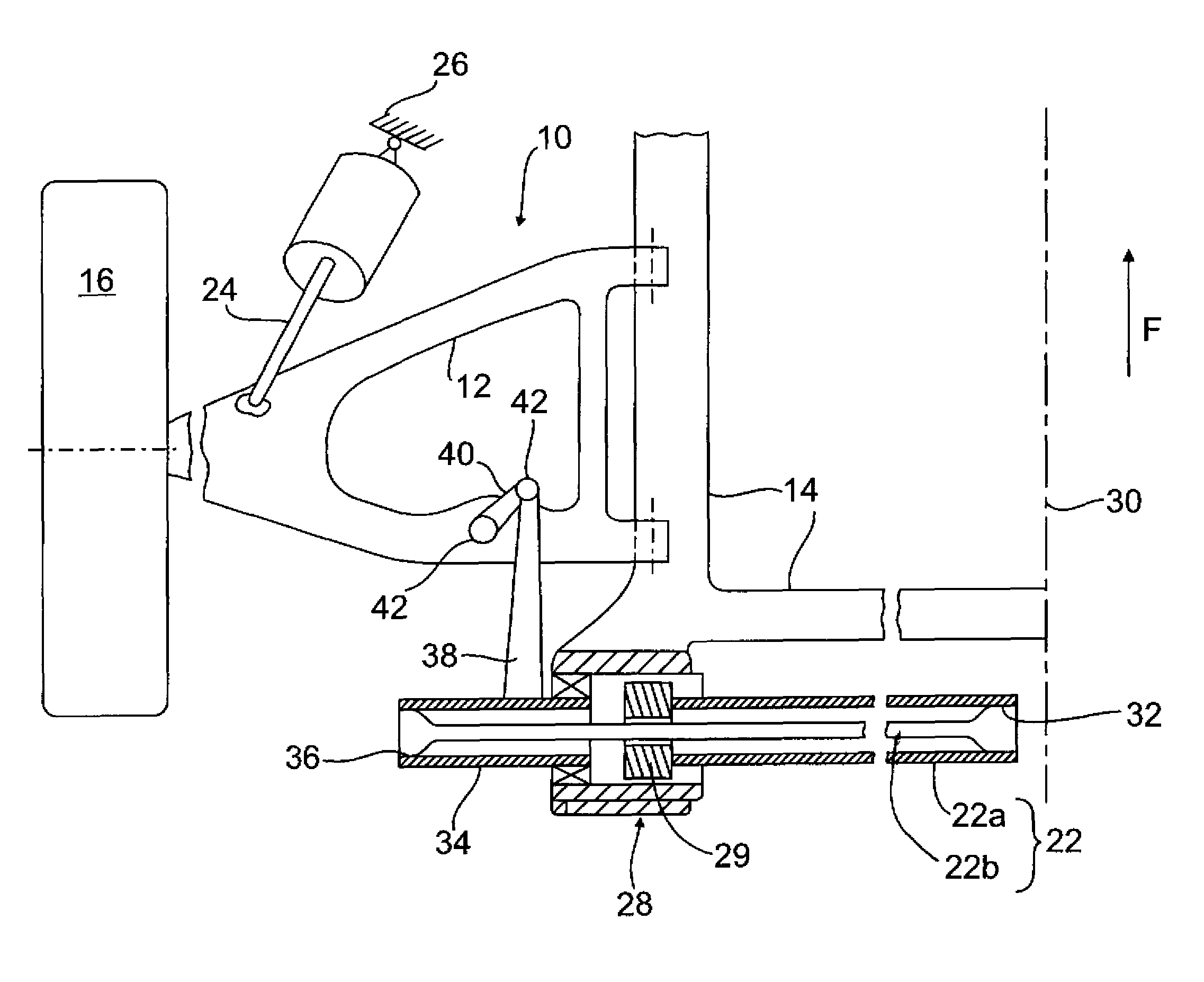

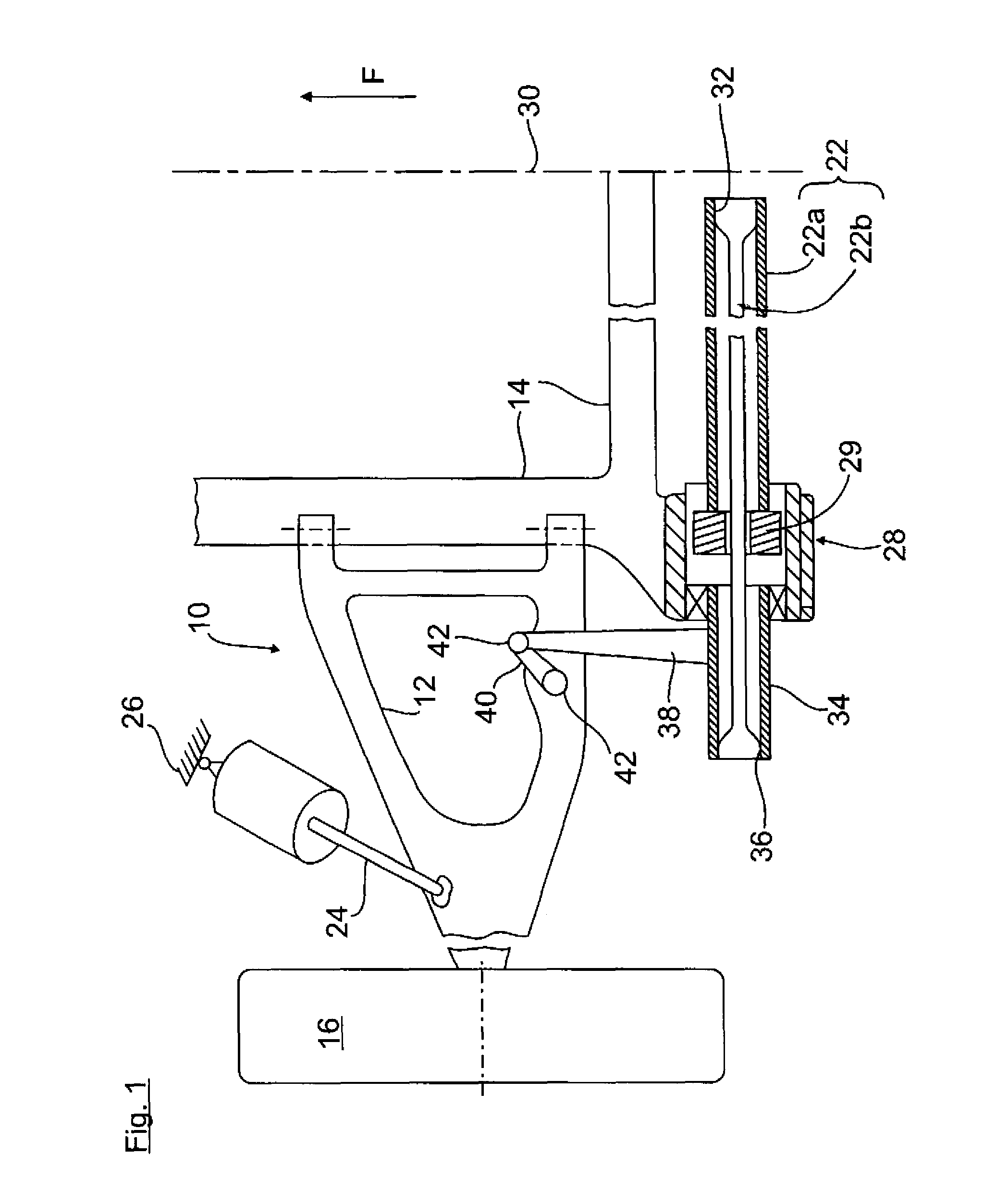

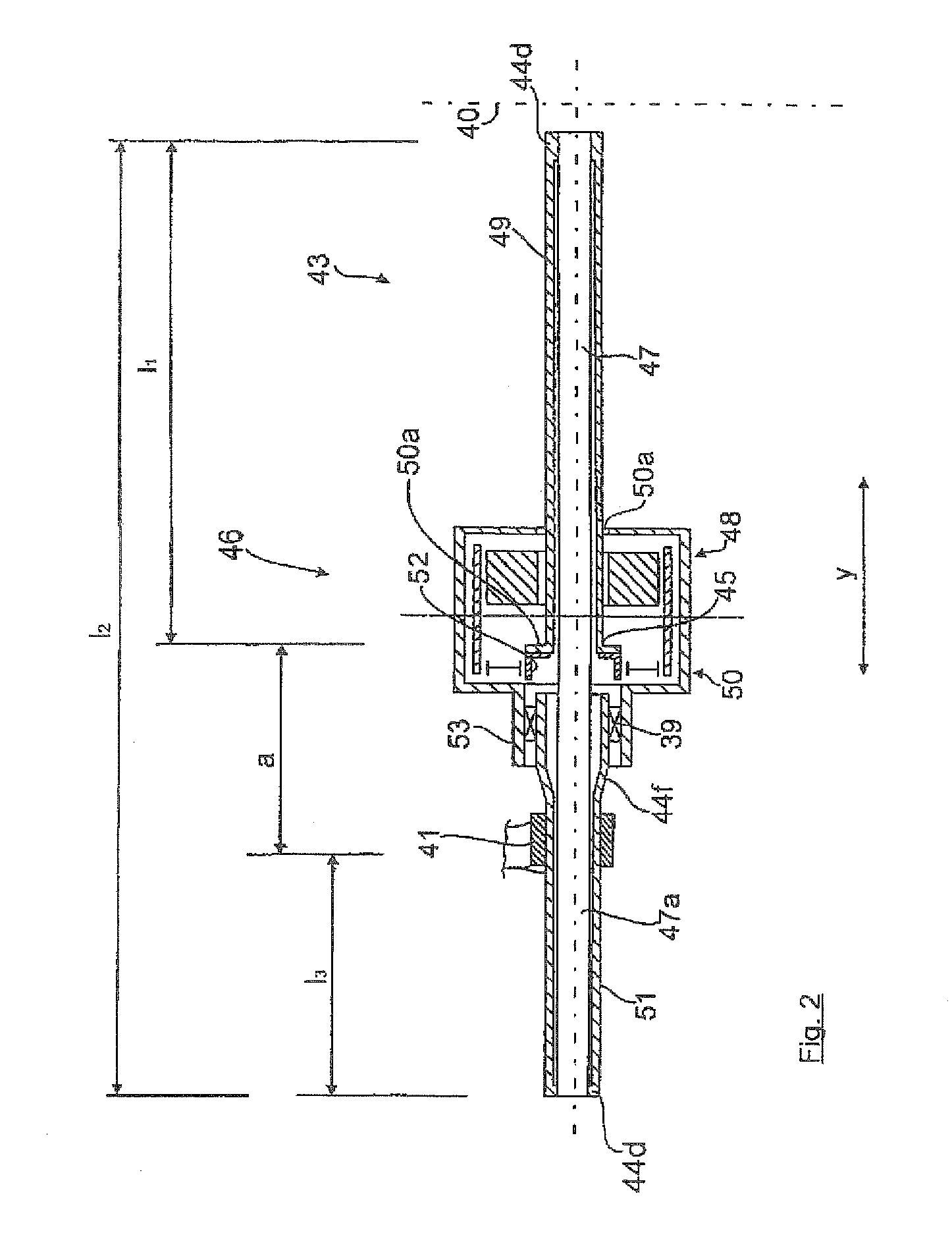

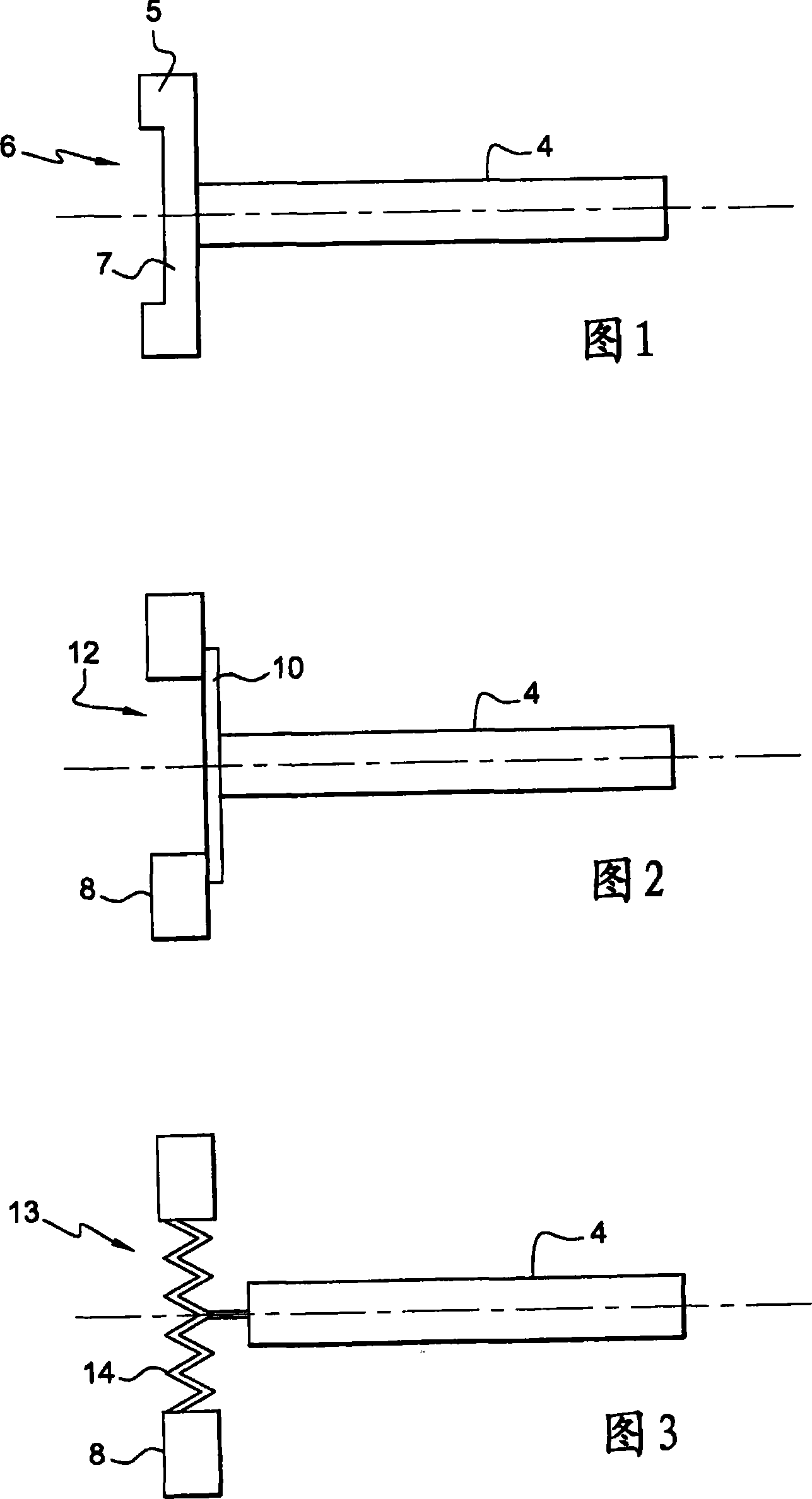

Suspension arrangement for a wheel suspension of a motor vehicle

ActiveUS8562009B2Reduce the spring rateReduce torsional stressInterconnection systemsResilient suspensionsMobile vehicleEngineering

A suspension arrangement for a wheel suspension of a motor vehicle includes an output lever hinged directly or indirectly to a wheel control element and configured as a flexible spring of defined spring rate. A transverse torsion-bar spring acts on the output lever, with an actuator adjusting a pretension of the torsion-bar spring.

Owner:AUDI AG

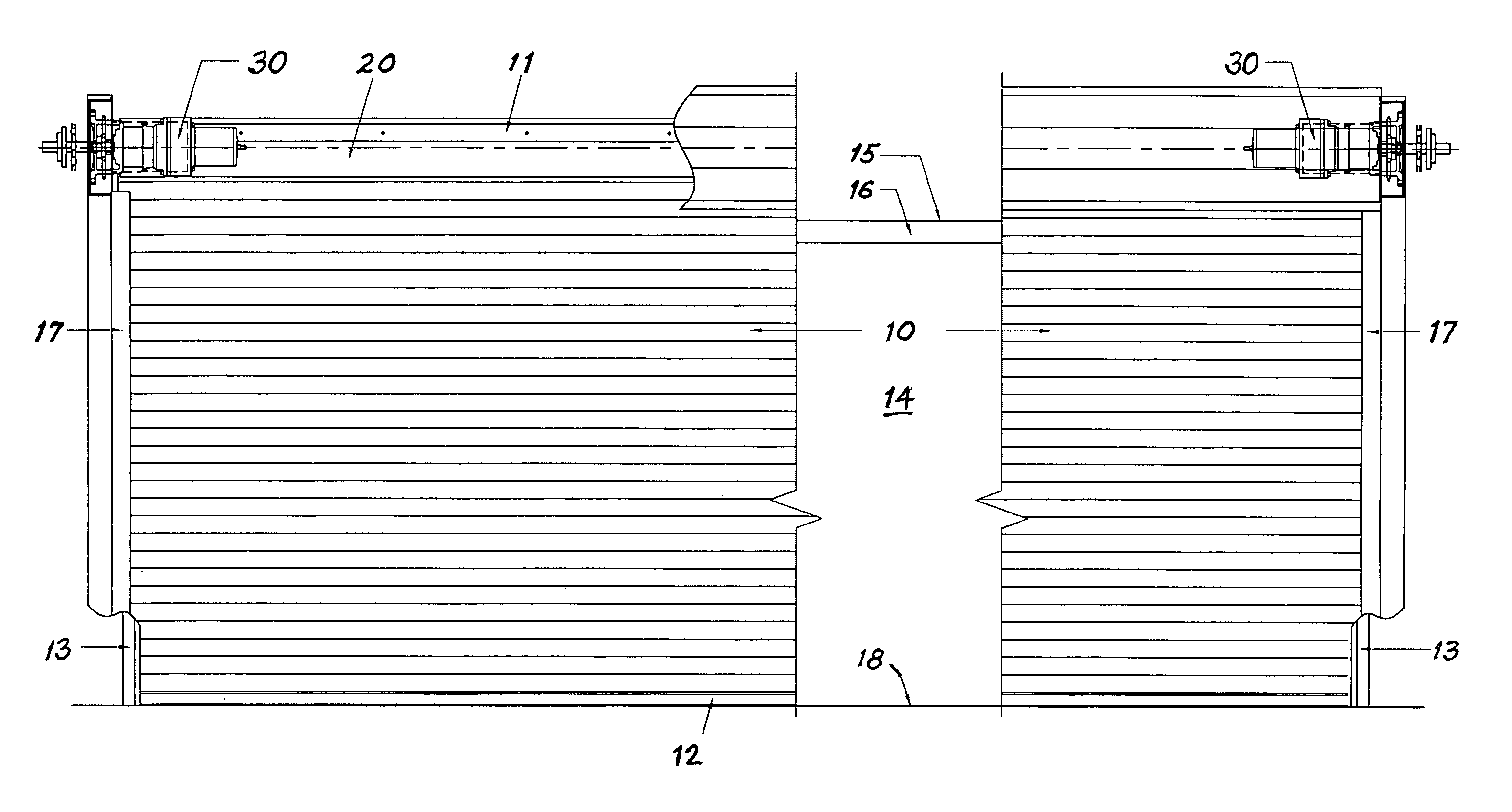

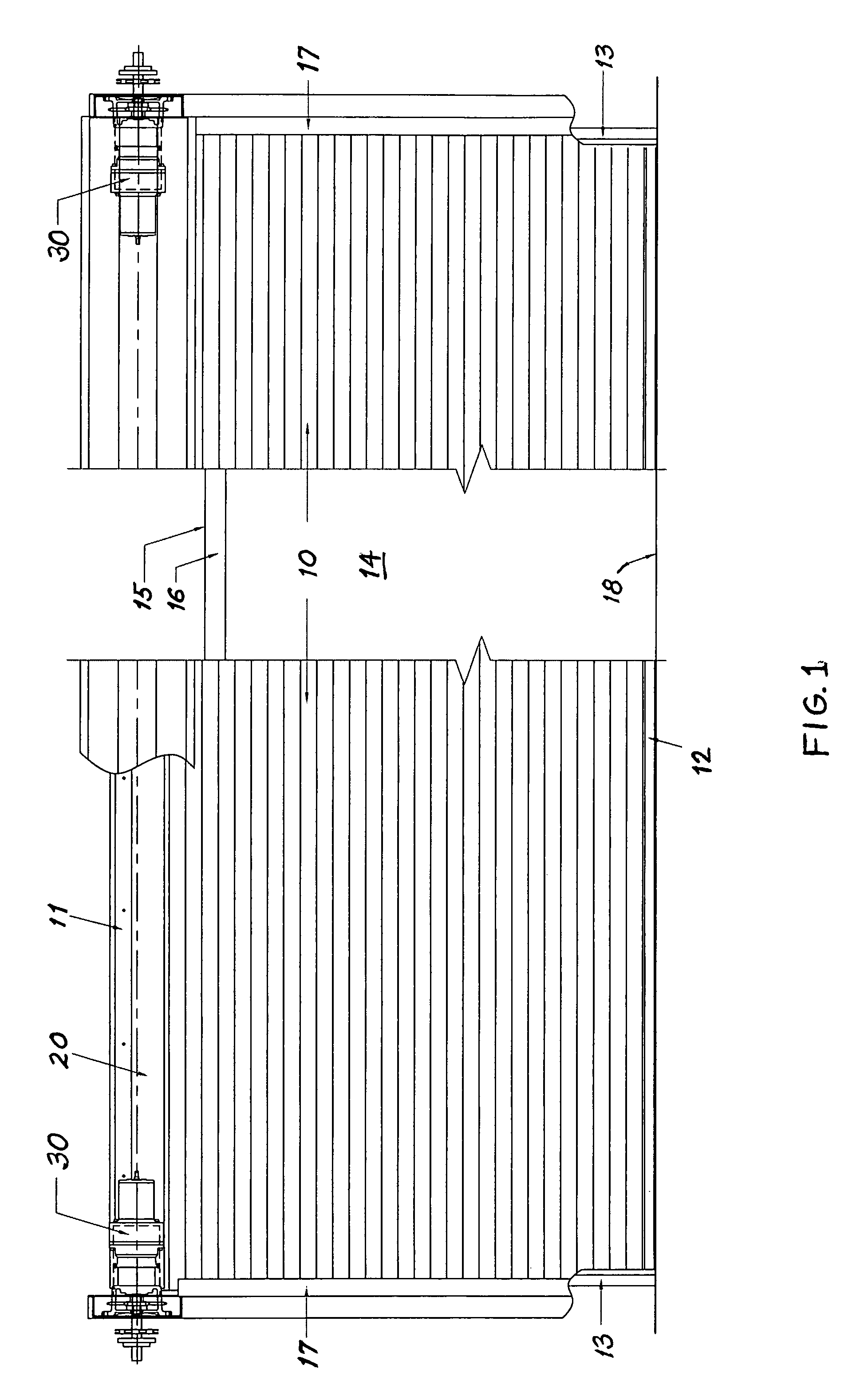

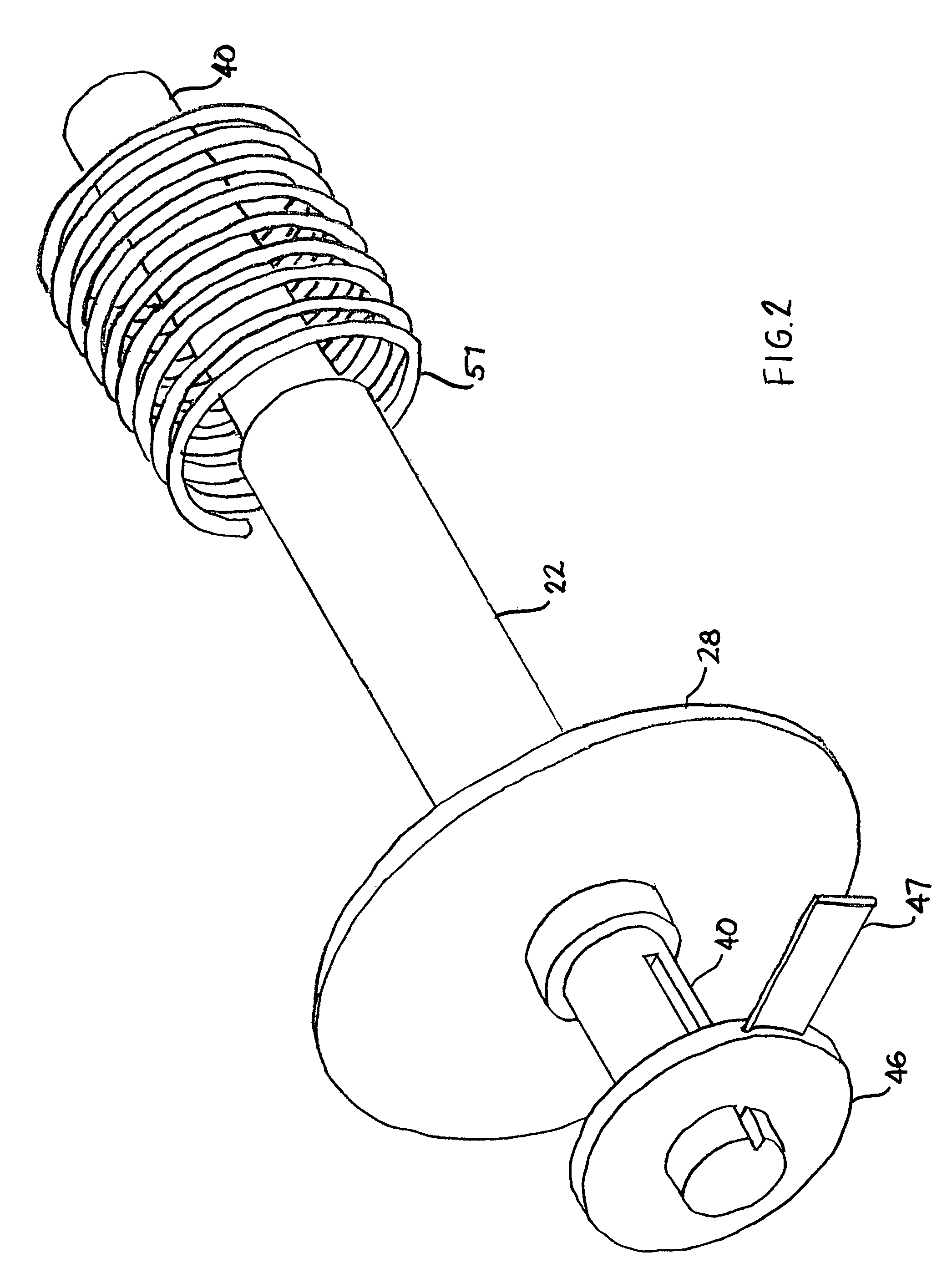

Two-motor drive arrangement for a roller curtain

ActiveUS8453707B2Reduce componentsLow voltage requirementScreensDoor/window protective devicesMotor driveDrive shaft

A drive arrangement for a roller curtain covering an opening defined by a frame includes a drum mounted horizontally across one side of the opening, a pair of hollow drive shafts fixed against rotation in opposite ends of the drum, and a pair of coaxial tension shaft portions fixed to the frame and received through respective hollow drive shafts. At least one coil spring is associated with each tension shaft portion, each spring having a first end fixed to a tension shaft portion and a second end fixed to the drum. A pair of drive motors are operatively connected to respective hollow drive shafts for synchronously rotating the drive shafts in order to coil a roller curtain on the drum.

Owner:MCKEON ROLLING STEEL DOOR

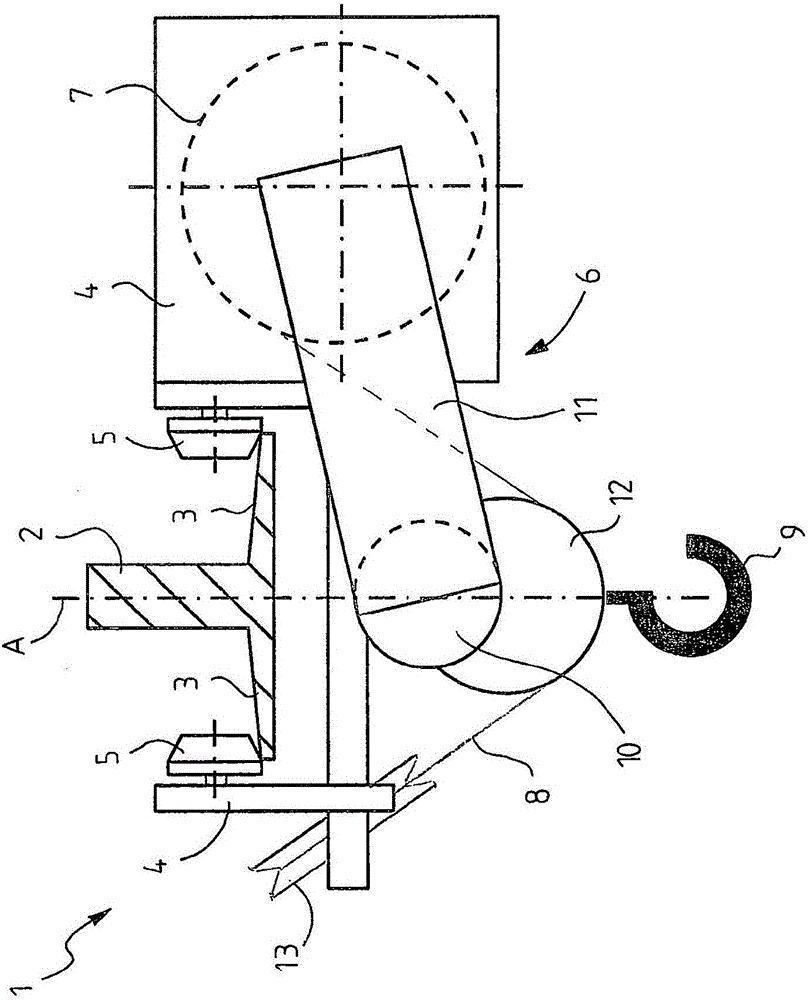

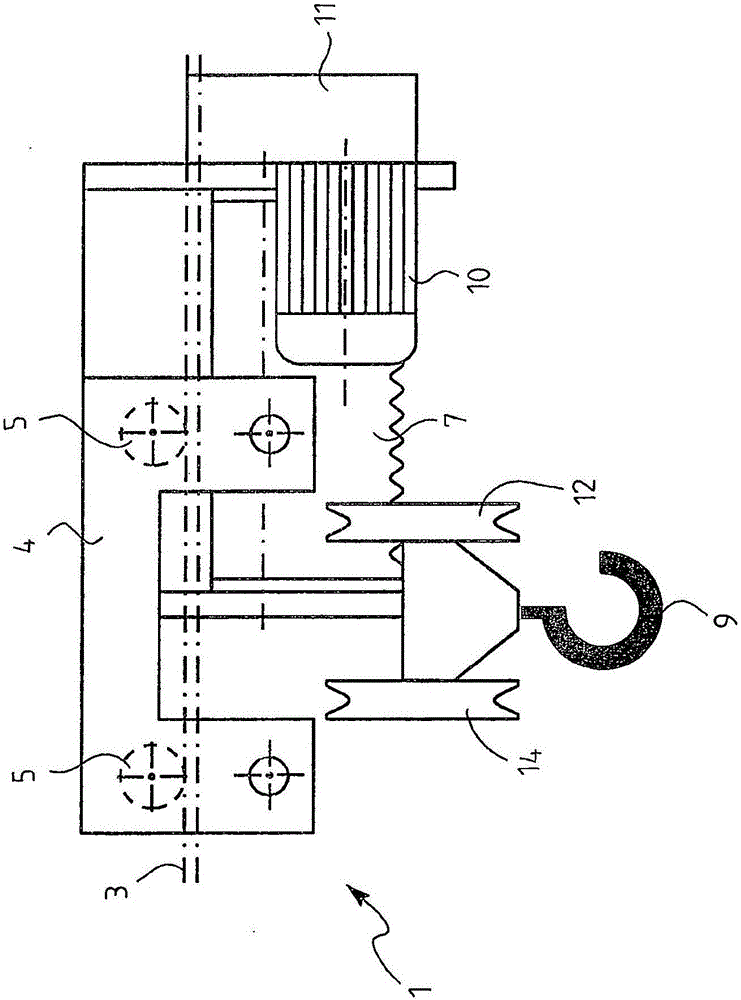

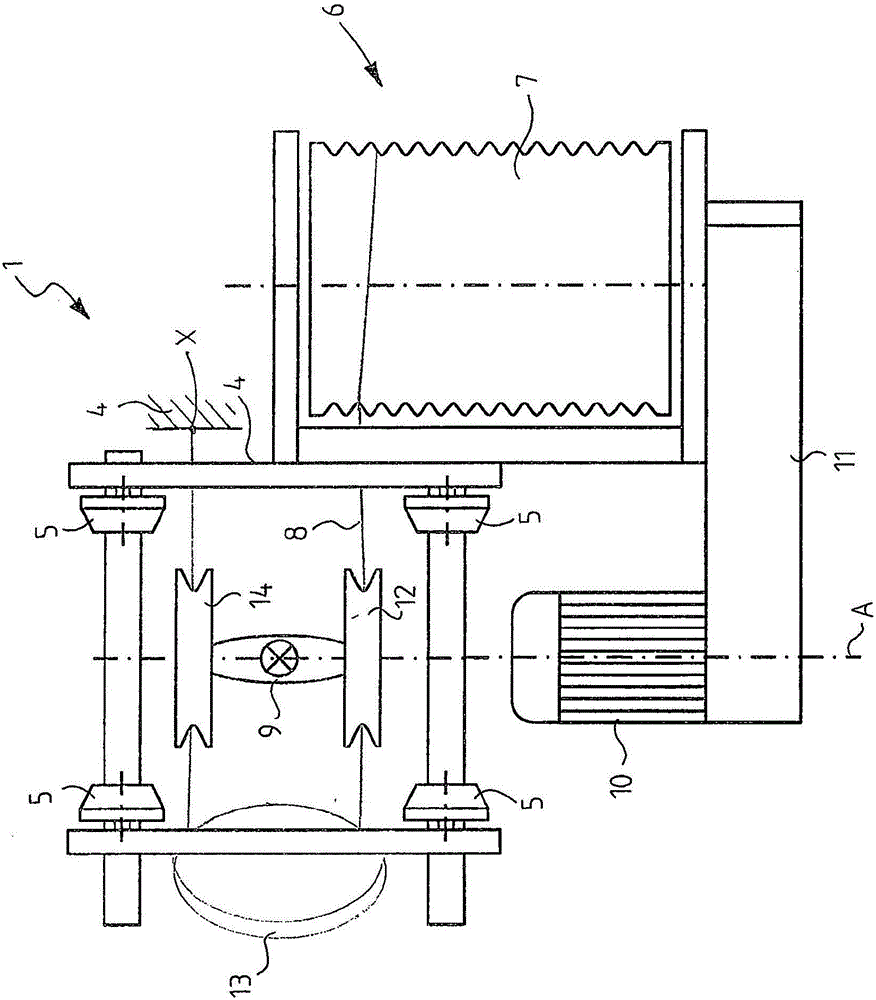

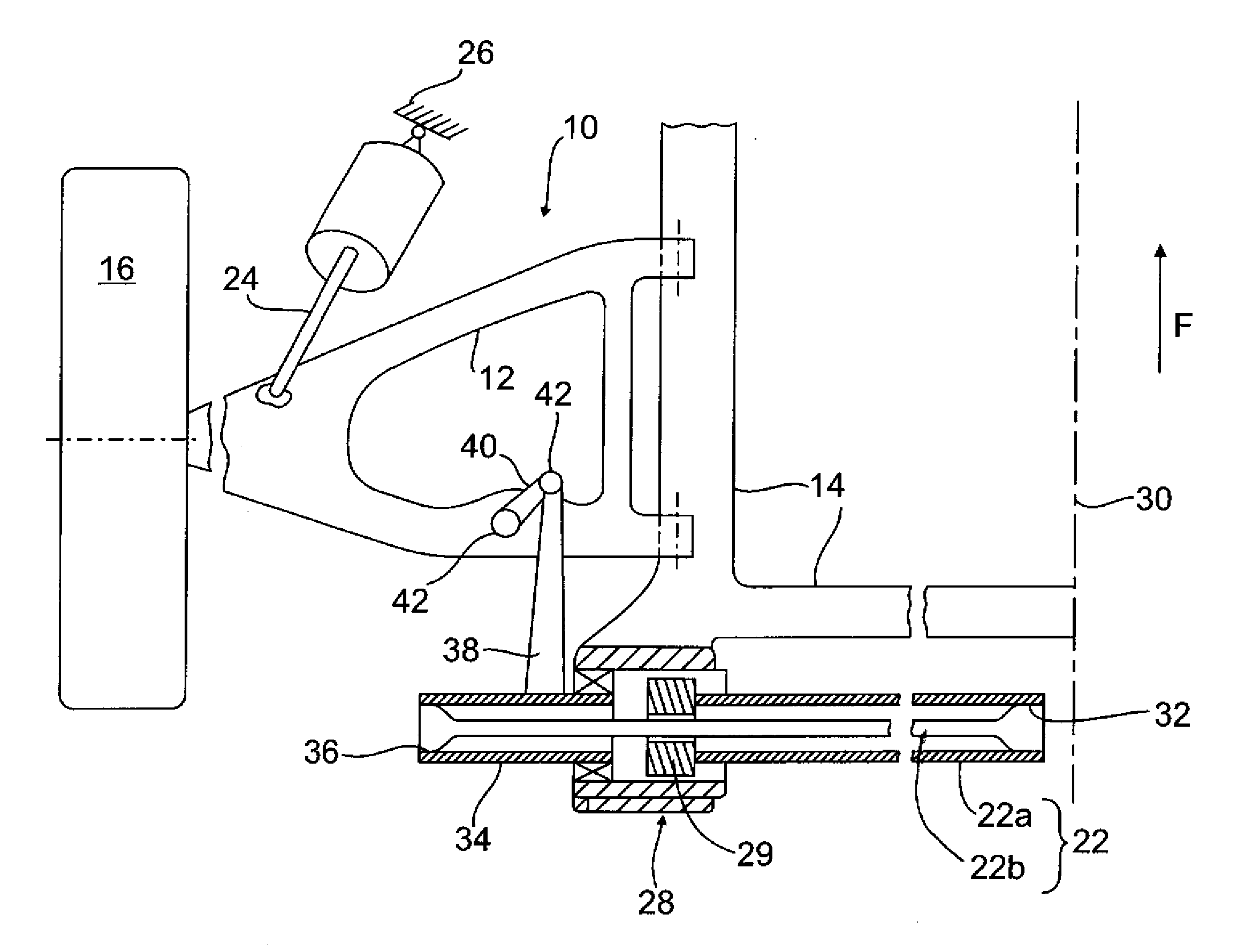

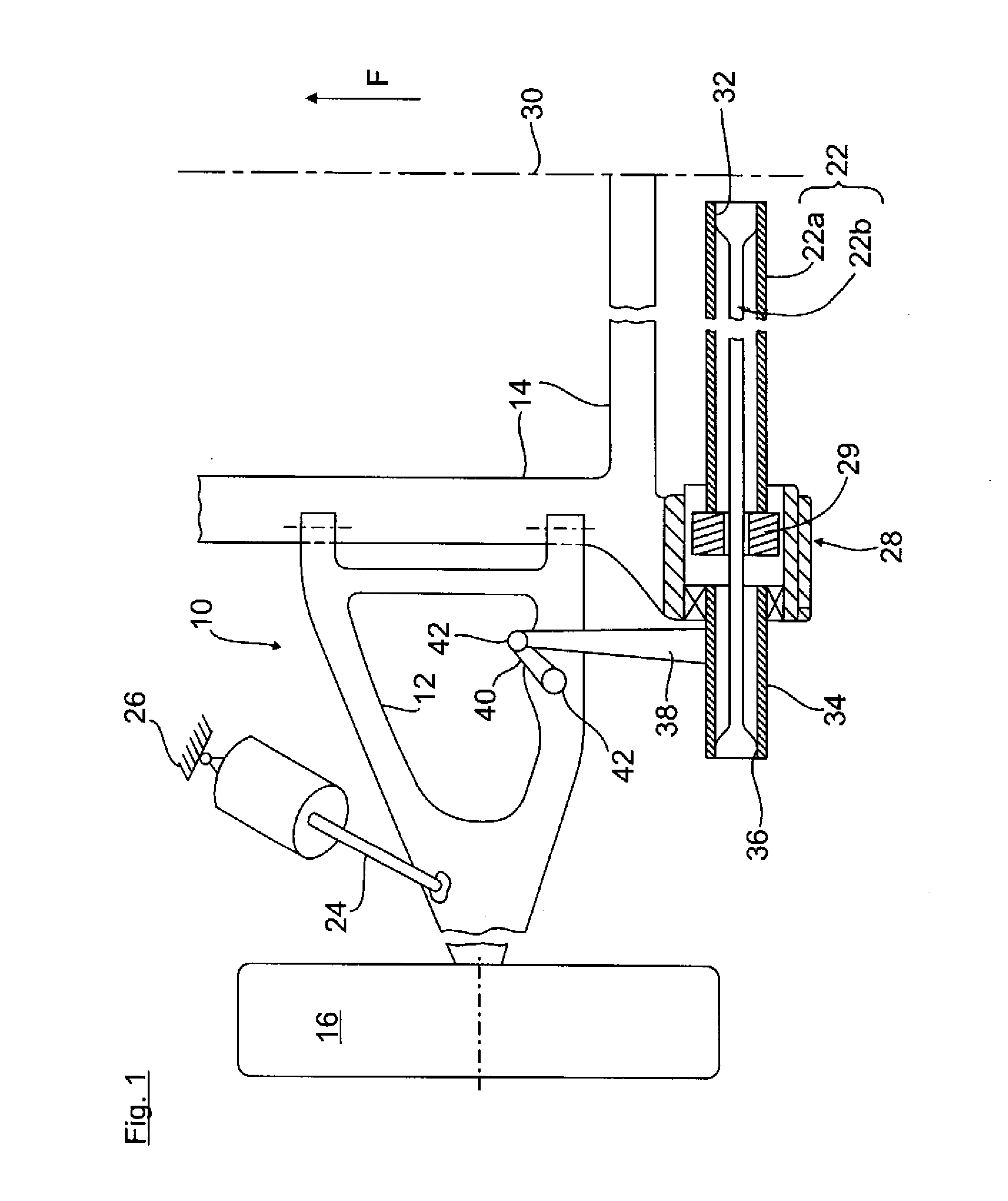

Low-construction trolley for wire rope hoist

ActiveCN105939955ANo risk of crossoverReduce torqueTrolley linesTrolley cranesVertical planeClassical mechanics

The invention relates to a low-construction hoist (1) for a wire rope hoist, arranged to move along a lower flange (3) of a horizontal beam or rail (2), whereby the trolley (1) comprises a trolley frame (4); bearing wheels (5), which are fixed to the trolley body and arranged to move on the upper surface of the lower flange (3) of the rail, a hoisting mechanism (6) comprising a rope drum (7) for a hoisting rope (8), a hoisting member (9) in cooperation with the hoisting rope for hoisting a load, and a hoisting motor (10) for driving the rope drum; whereby the rope drum is supported to a first side of the trolley frame so that the axle of the rope drum is parallel to the rail, and the hoisting member is arranged to move under the rail; whereby the hoisting rope (8) is led from the rope drum (7) to a fixing point (X; Z) in the trolley frame (4) through at least a rope pulley arrangement (12, 14) of the hoisting member (9), whereby the fixing point (X) of the hoisting rope (8) to the trolley frame (4) is located in the longitudinal direction of the trolley (1) outside the end of the rope drum (7), or outside the vertical plane which is transverse in relation to the rail or beam (2) and passing through the end of the rope drum.

Owner:KONECRANES GLOBAL

Pendulum-absorber brake

InactiveUS9068617B2Avoid excessive vibrationAvoid vibrationSelf acting brakesShaftsEngineeringPendulum

Owner:FORD GLOBAL TECH LLC

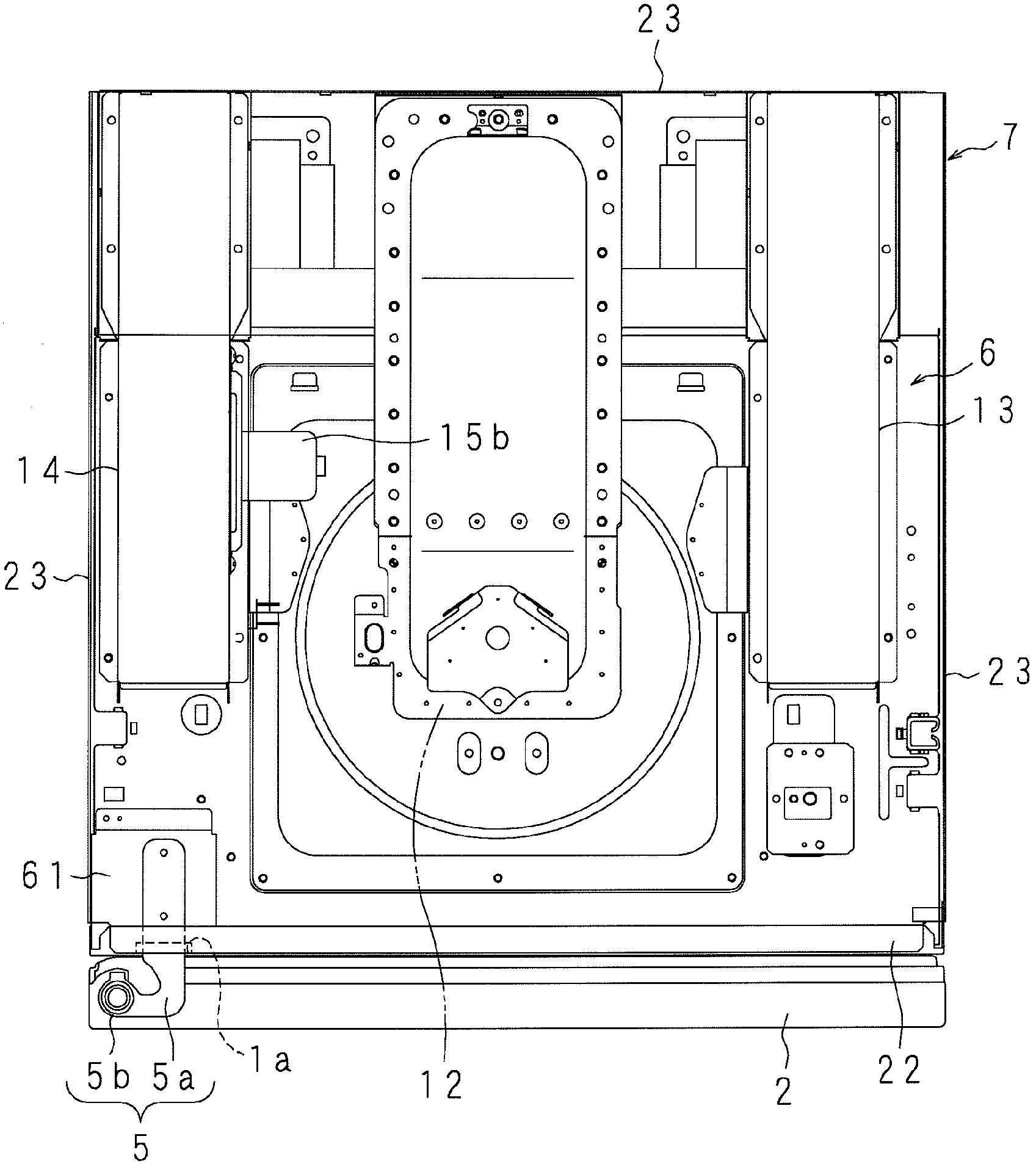

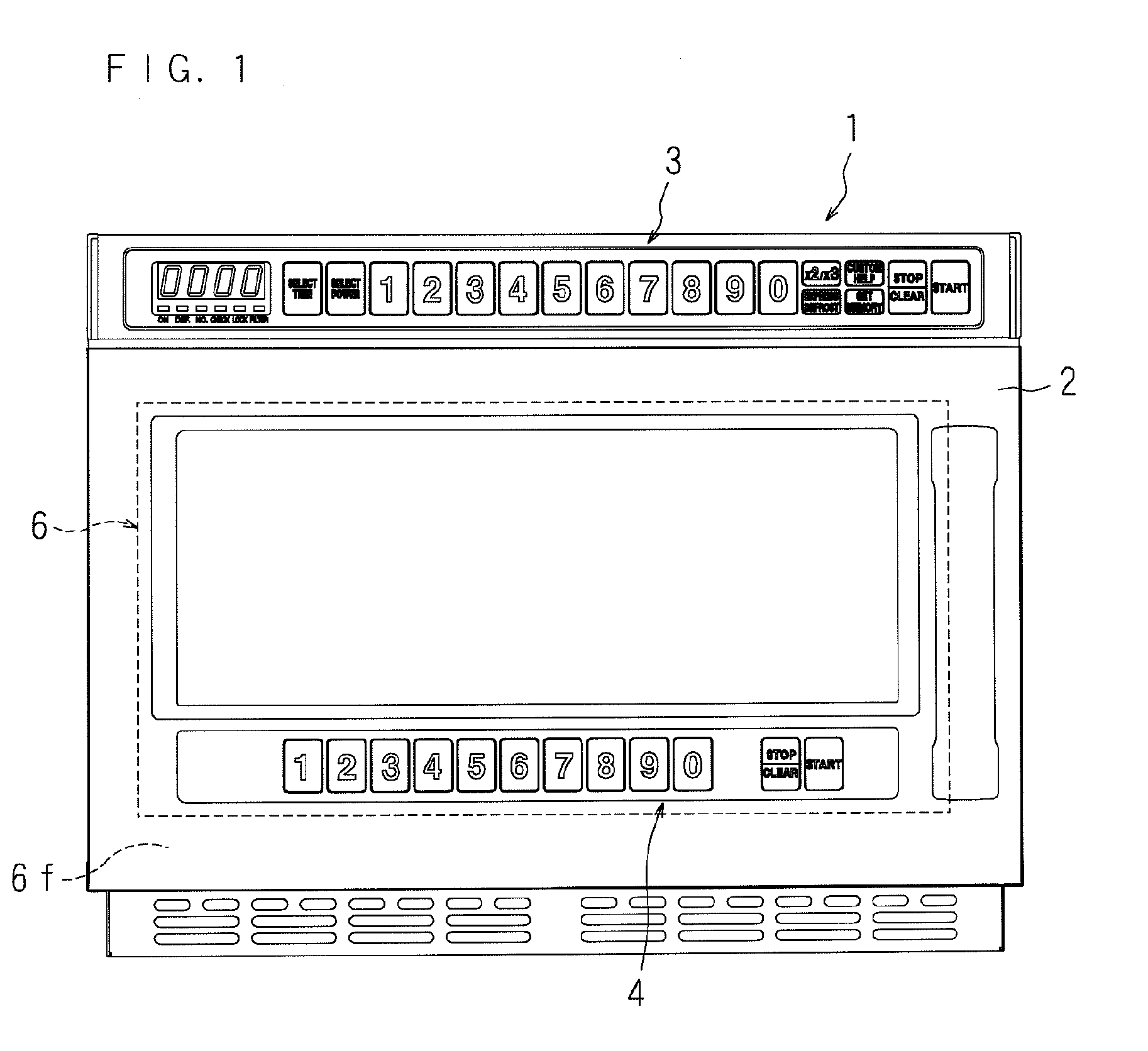

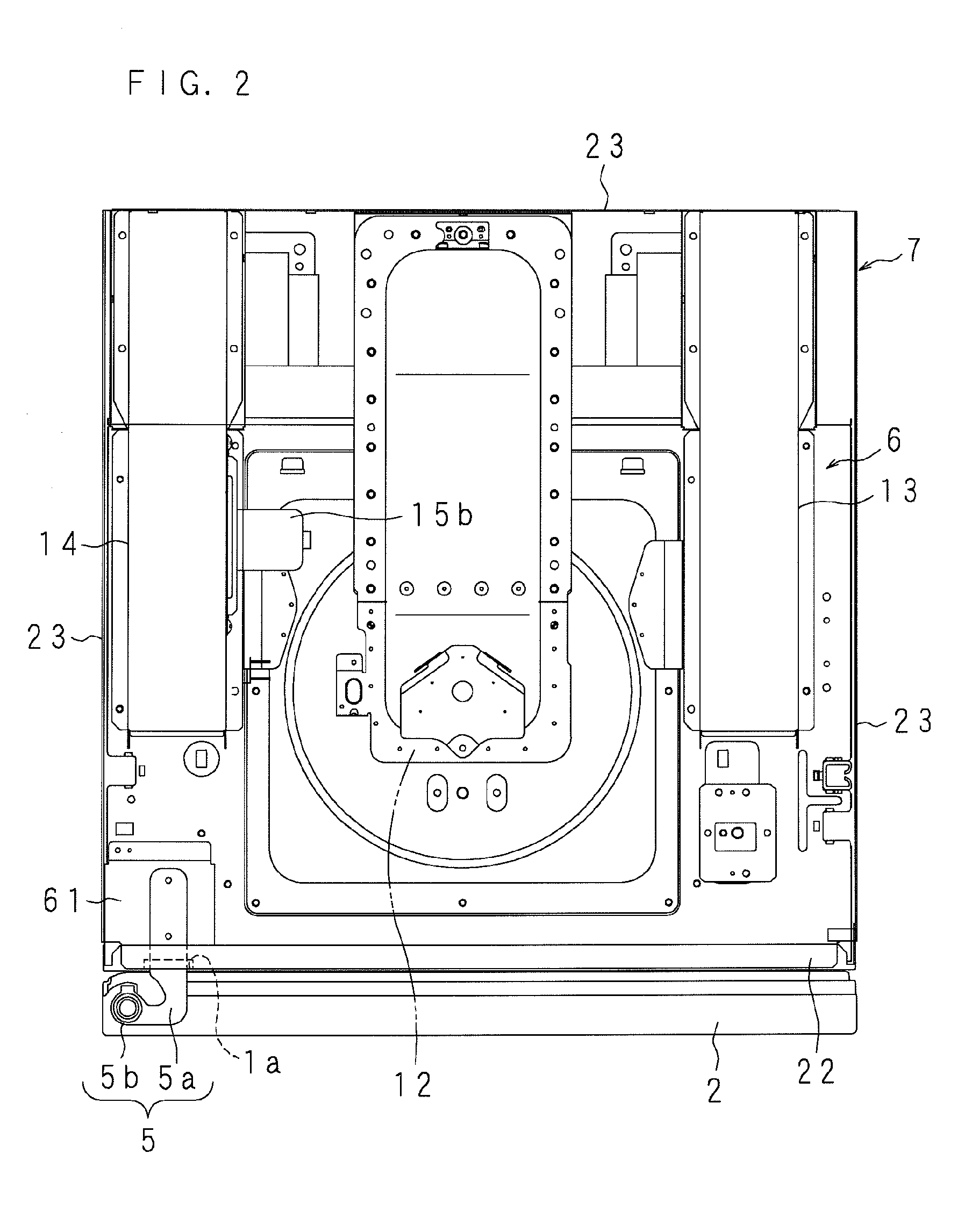

Cooking device

Multicore electric wires 31 for connecting an operation key sheet 4a and a control section of an oven body are loosely inserted into a hinge shaft 5b in a cylindrical shape and a door pipe 30 in a cylindrical shape having a length exceeding a half of the height of a door 2, and the door pipe 30 guides the electric wires 31 along the axial direction of the hinge shaft 5b. When the door 2 is opened / closed, torsional stress caused in the electric wires 31 are dispersed over the electric wires 31 disposed correspondingly to the length of the door pipe 30.

Owner:SHARP KK

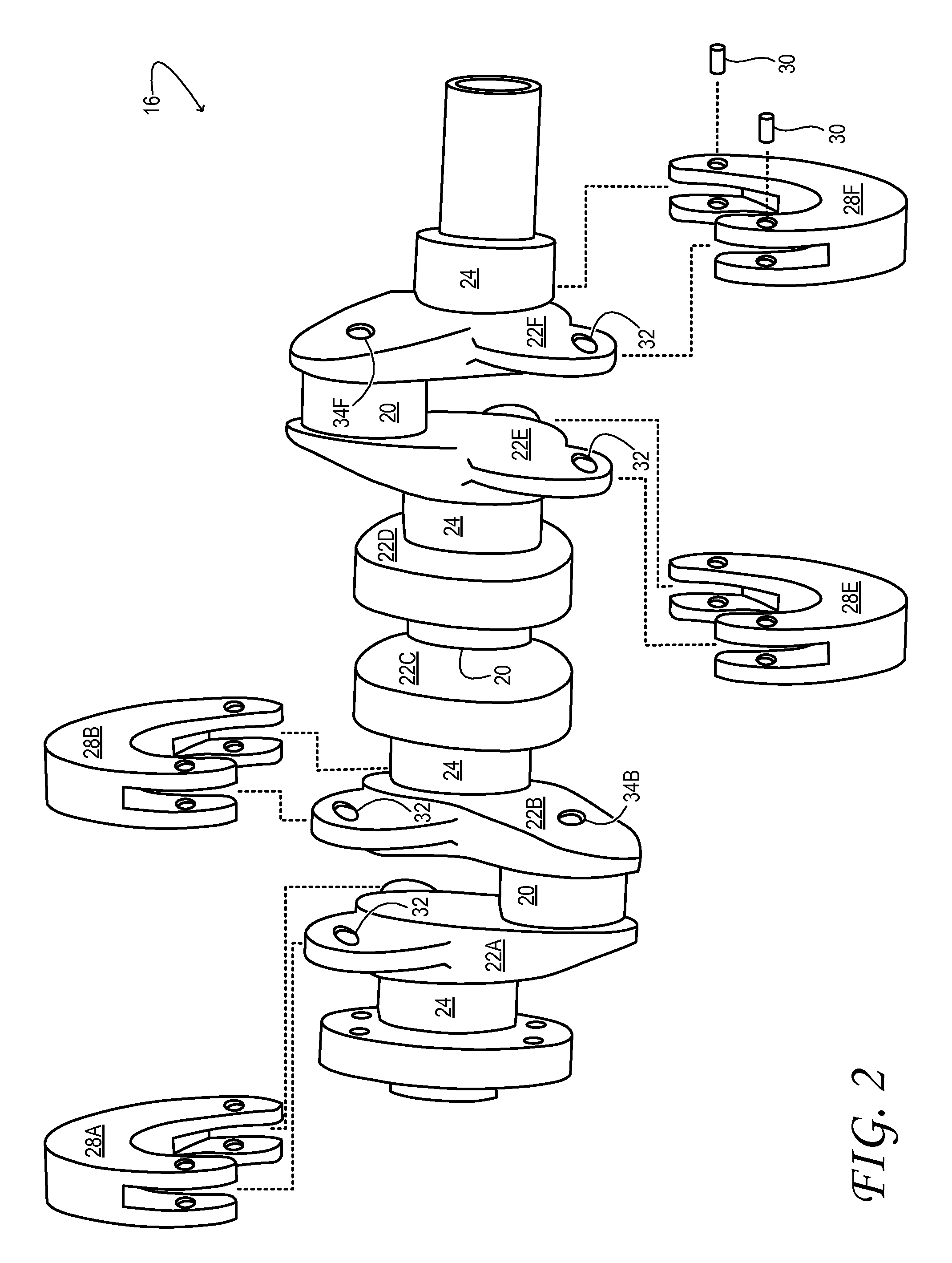

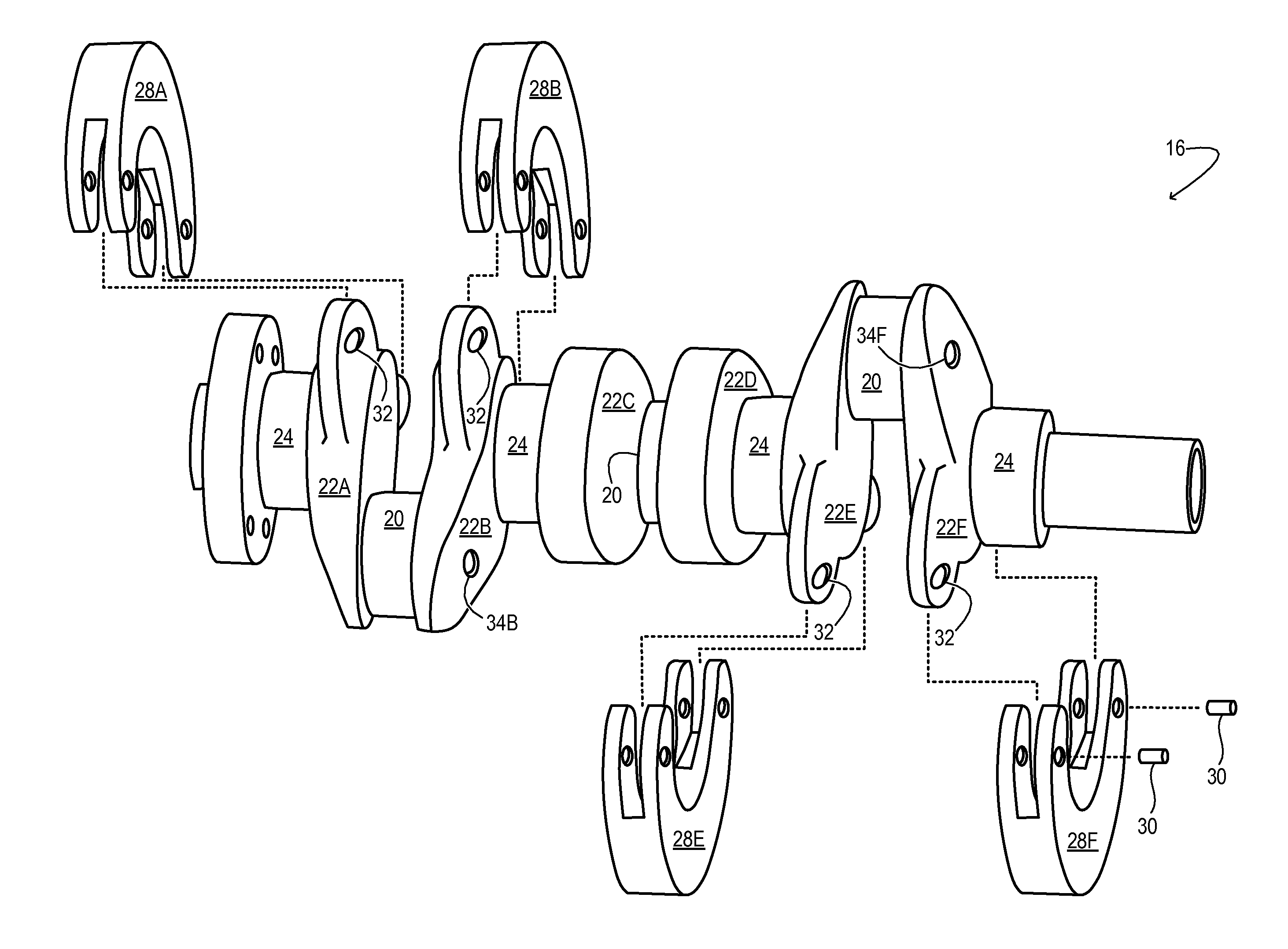

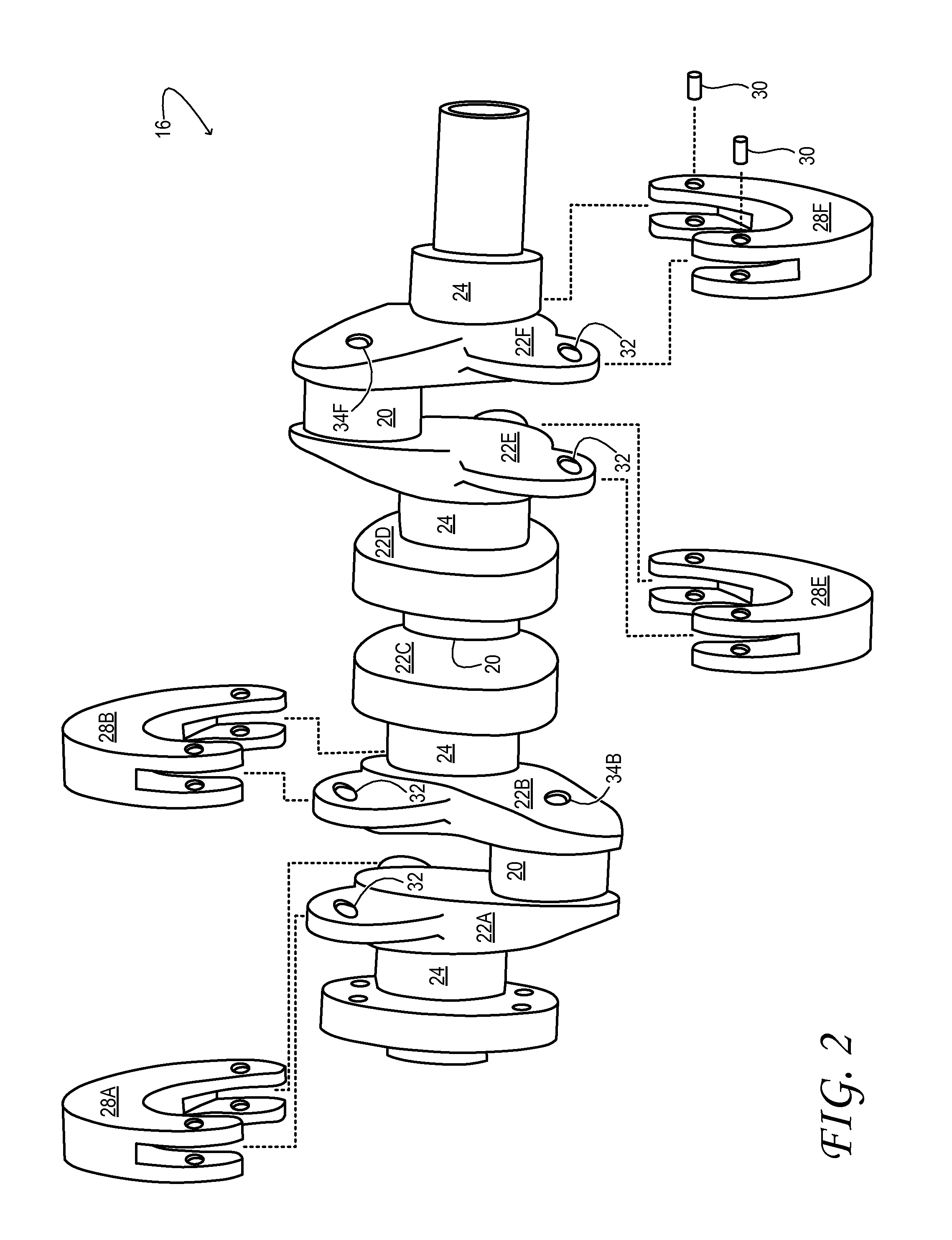

Pendulum-absorber brake

InactiveUS20140196568A1Avoid excessive vibrationAvoid vibrationRotating vibration suppressionSelf acting brakesEngineeringCrankshaft

A crankshaft comprising a cheek, a torsion-absorbing pendulum pivotally coupled to the cheek, and a rotational speed actuated brake to oppose motion of the pendulum relative to the cheek. The brake is configured to provide greater opposition to the motion at lower rotational speeds than at higher rotational speeds.

Owner:FORD GLOBAL TECH LLC

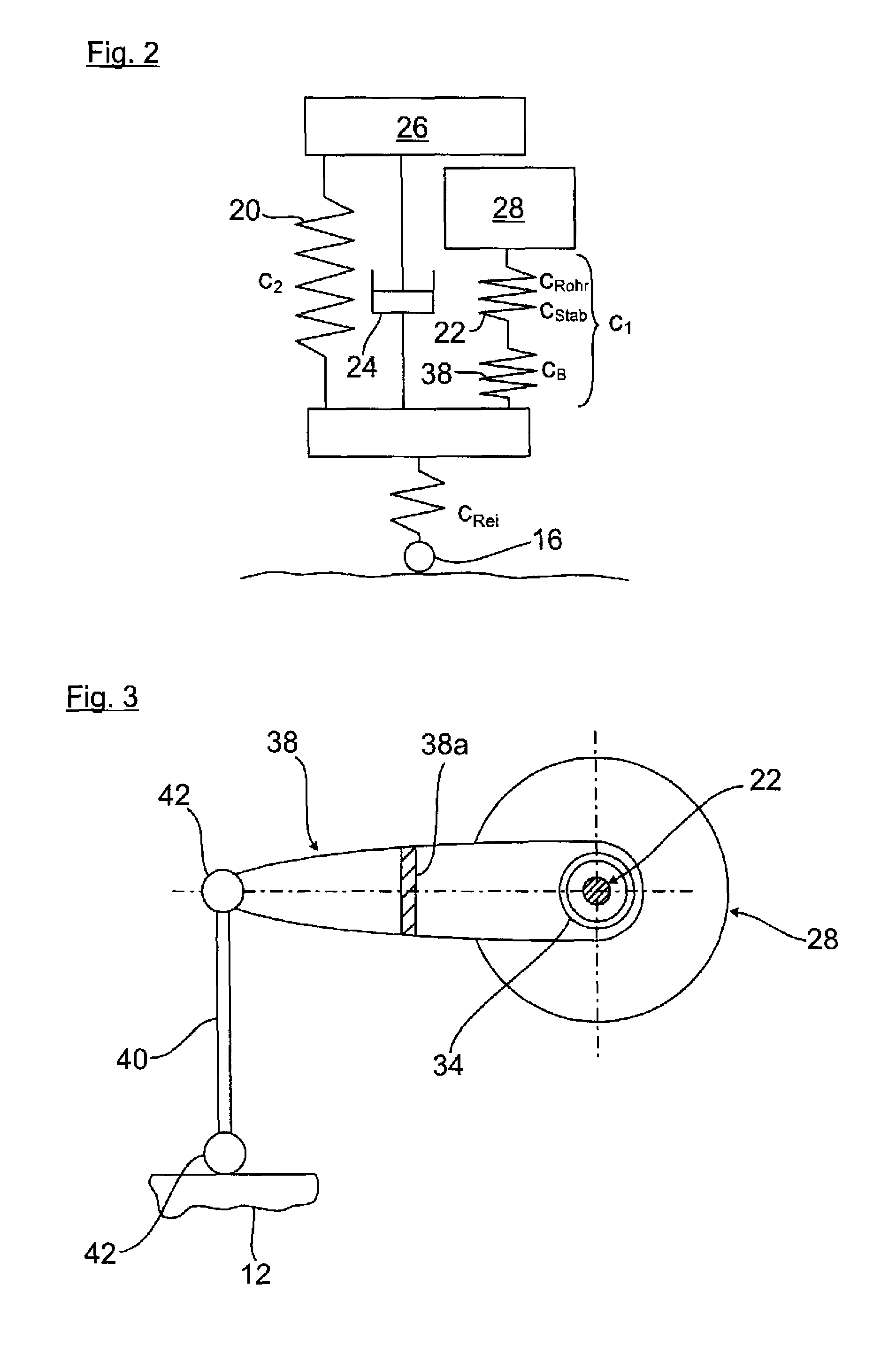

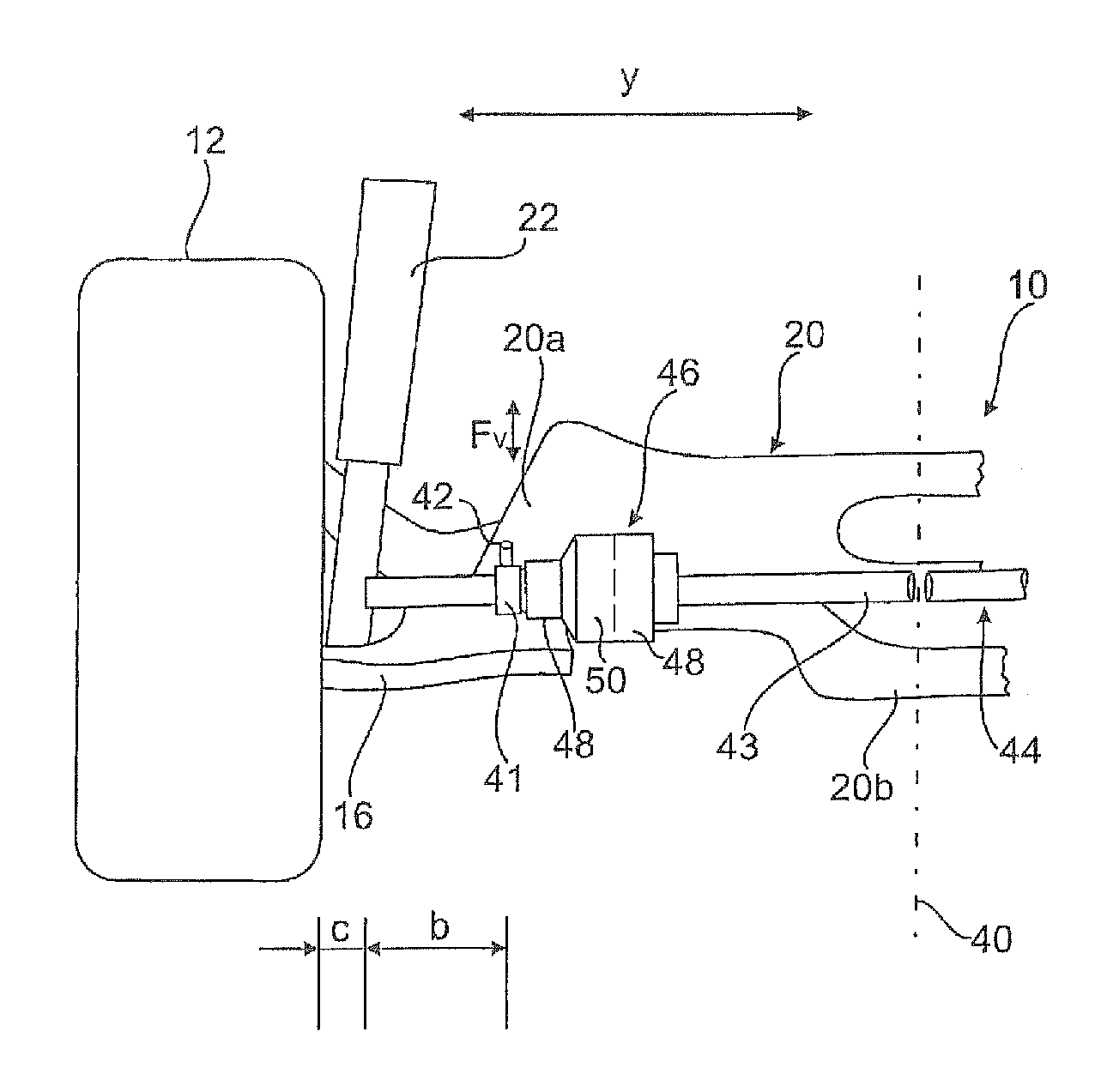

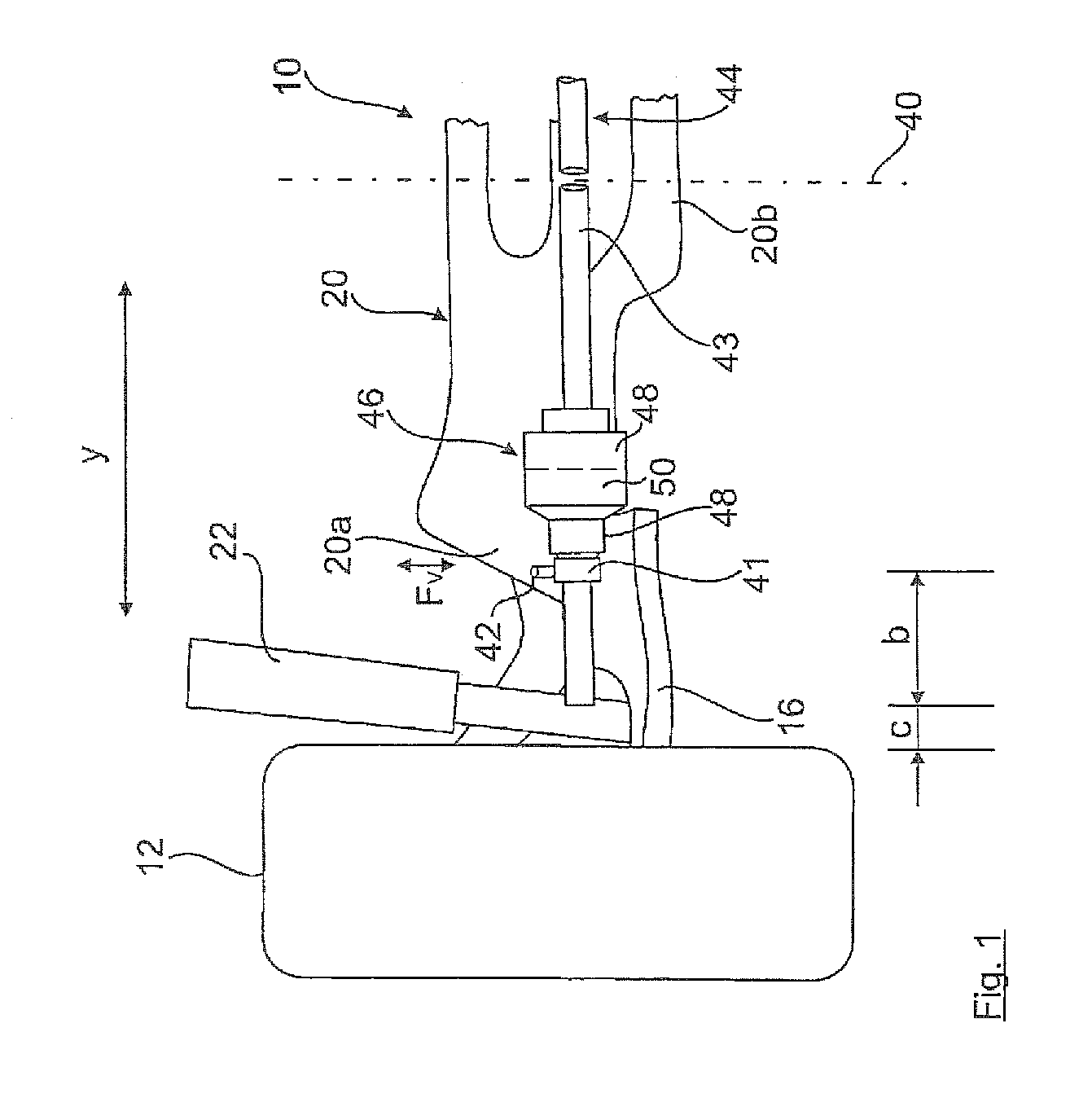

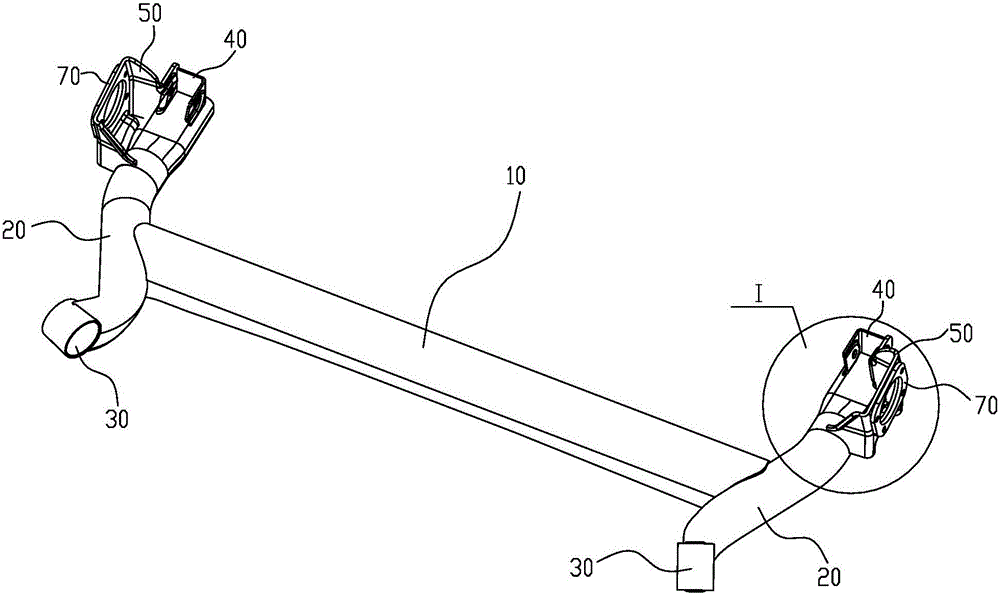

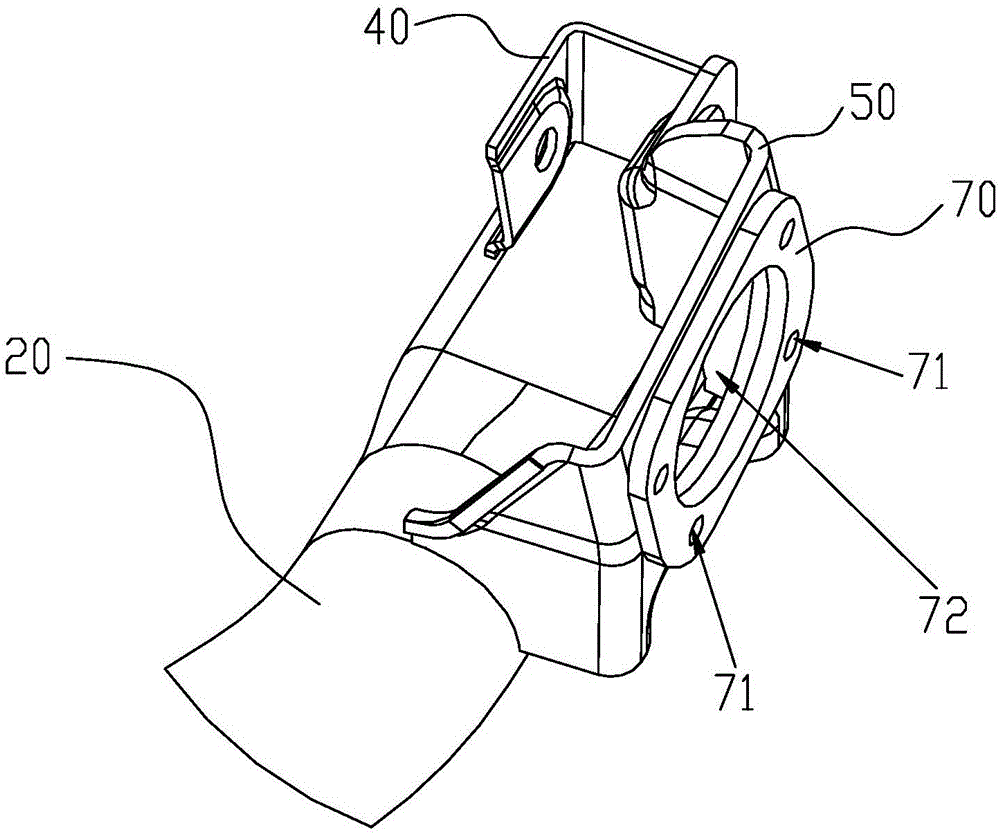

Arrangement of a stabilizer on a wheel suspension for motor vehicles

ActiveUS8616569B2Adds “yieldability”Reduce torsional stressInterconnection systemsResilient suspensionsActuatorMotorized vehicle

The invention relates to an arrangement of a stabilizer (44), which is configured in two parts, on a wheel suspension for a motor vehicle, characterized in that the stabilizer parts (43) thereof can be rotated relative to one another in the same or opposite direction by means of an associated motor / gear unit (46). Each stabilizer part (43) comprises a hollow-cylindrical outer torsion bar (49) whose end on the gear side (45) is connected to a gear output (50a) and whose end distal from the gear is connected for drive purposes to an inner torsion bar (47) which is guided through the hollow-cylindrical outer torsion bar (49) and out of the end (45) on the gear side of the hollow-cylindrical outer torsion bar. The inner torsion bar (47) is directly or indirectly connected to an output lever (41) which is articulated on a wheel suspension element (16). According to the invention, the gear (50) of the motor / gear unit is disposed with its gear output (50a) between the actuator motor (48) and the output lever (41) in the transverse direction of the vehicle (y).

Owner:AUDI AG

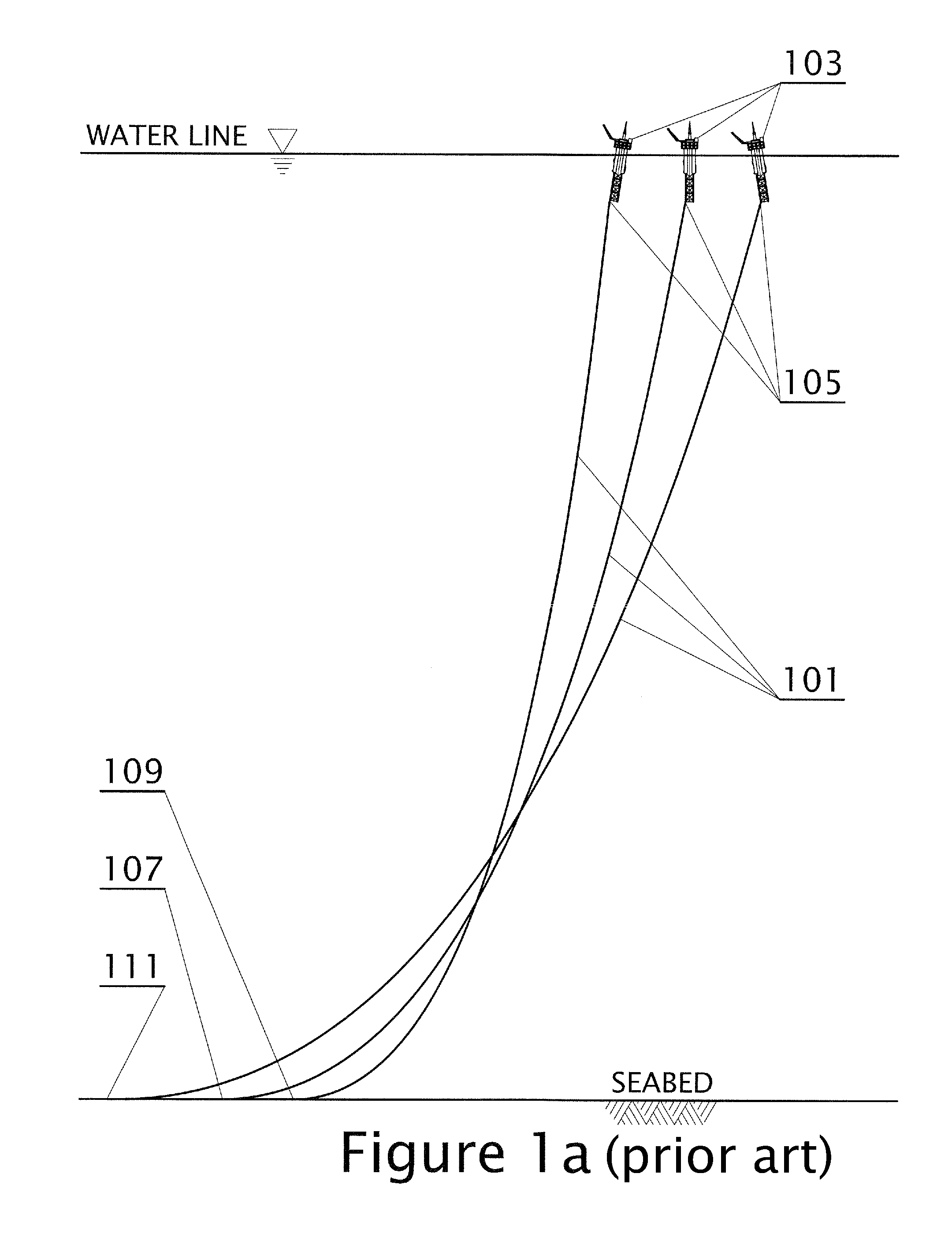

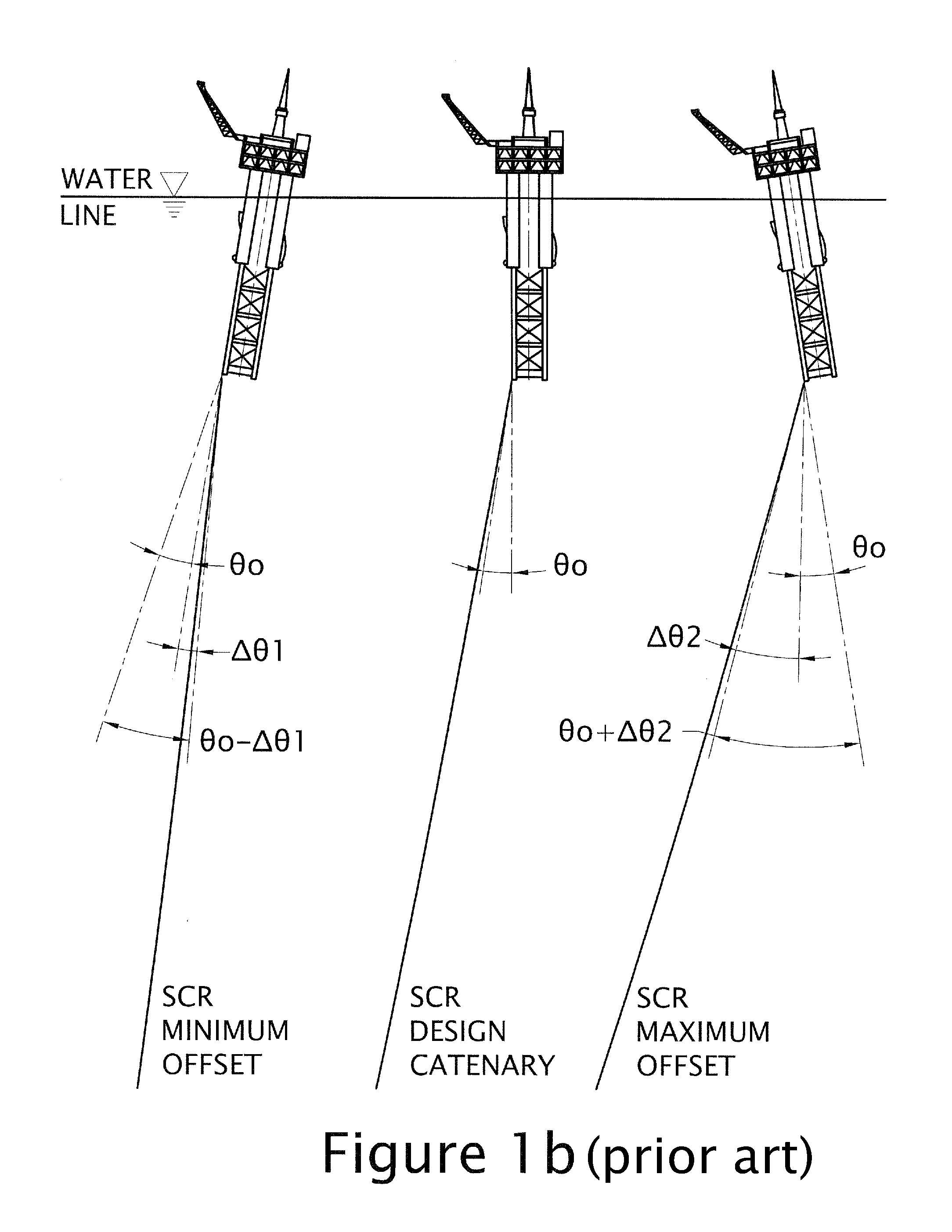

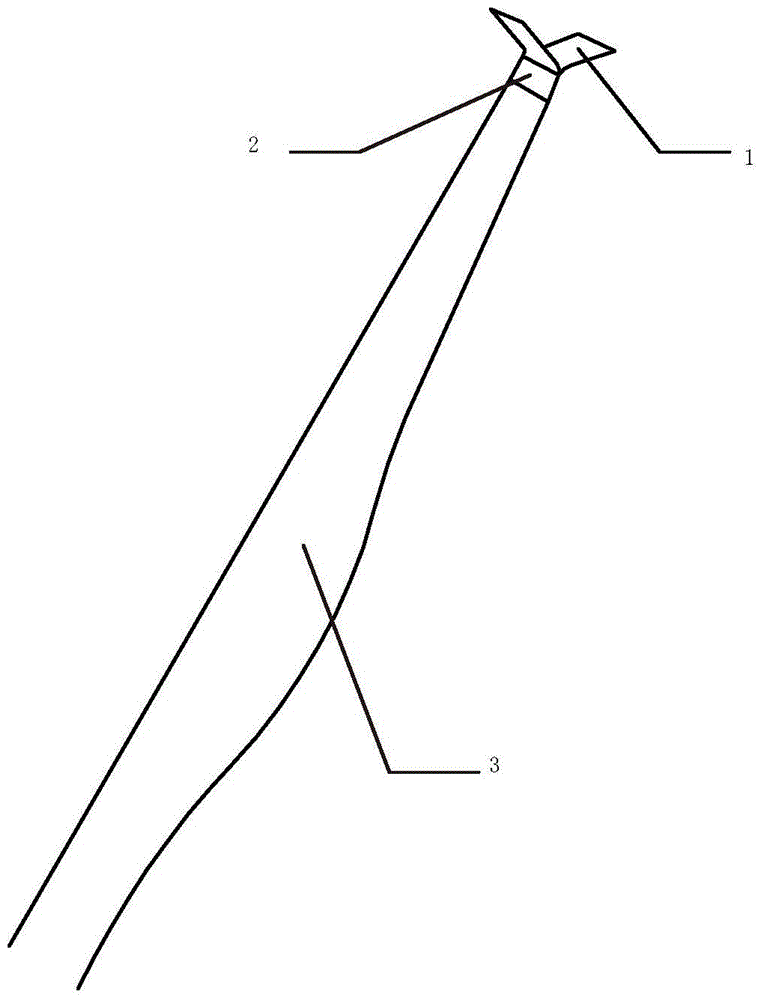

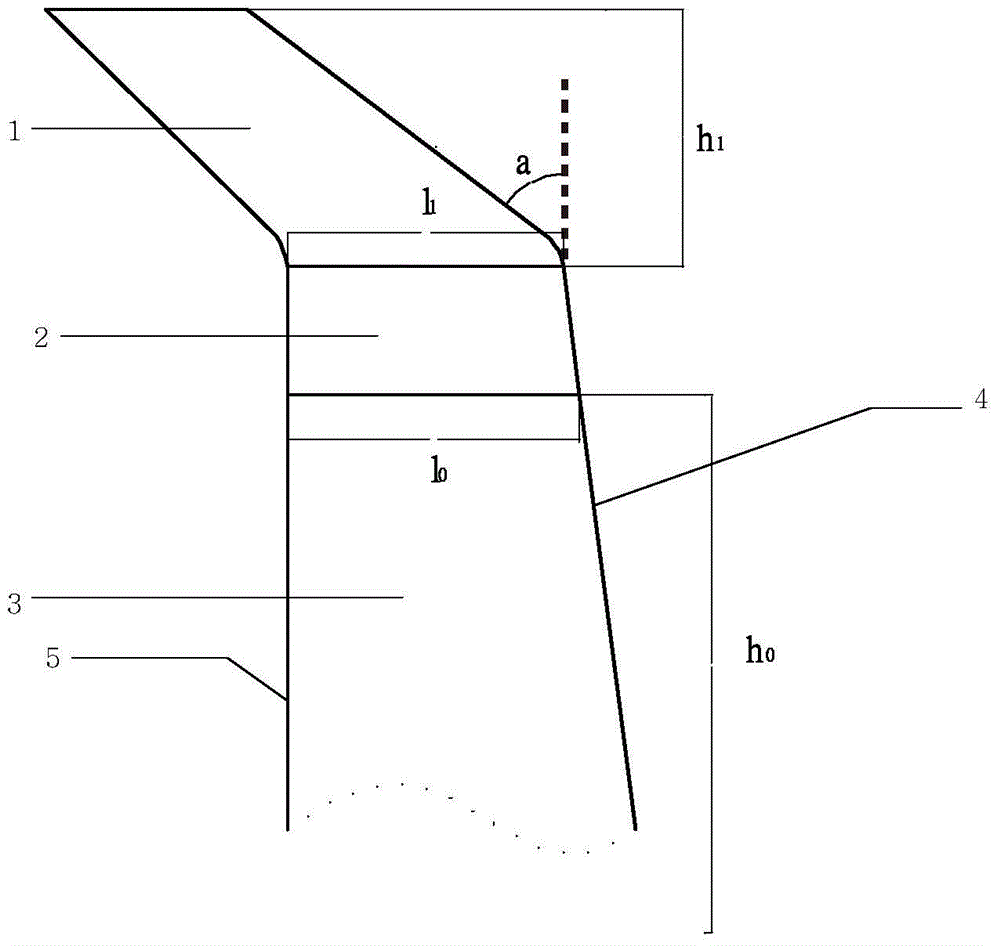

Flexible hang-off arrangement for a catenary riser

Flexible hang-off arrangement is provided for a catenary riser suspended from an offshore or inshore platform, which includes floating or fixed platforms, vessels or / and buoys. The bending loads in the top segments of the said riser are reduced by incorporating a pivot at the riser hang-off. Pressure containing welded, bolted, rolled or swaged pipe spools transfer fluids, including hydrocarbons between the riser and the platform. Along significant spool lengths the tangents to the center lines of said spools are orthogonal to and offset from the tangent to the center line of the riser at the hang-off. The said pressure containing spools include arbitrary looped, spiral and helicoidal designs that are subject to torsion.

Owner:SEAHORSE EQUIP

Phosphorization bolt friction coefficient stabilizer and preparation method thereof

The invention relates to a phosphorization bolt friction coefficient stabilizer and a preparation method thereof. The stabilizer comprises the following components in percentage by mass: 10%-20% of base oil, 6%-15% of fatty acid, 8%-12% of triethanolamine, 1%-2% of emulsifying agent, 0.5%-1% of bactericide, 3%-5% of silicone oil and 48%-60% of purified water, wherein various machine oils and spindle oils are selected as the base oil. The preparation method of the stabilizer comprises the following steps of: firstly adding a design amount of base oil, fatty acid and silicon oil to a container, adding the purified water for dissolving, then sequentially adding the triethanolamine, the emulsifying agent, the bactericide and a defoaming agent according to proportioning, stirring, dissolving and filling a volumetric flask, thus the phosphorization bolt friction coefficient stabilizer can be used. The phosphorization bolt friction coefficient stabilizer has good capacity of resisting oxidation, acid gas, discoloration and dampness; a lubricating film formed on the surface of a phosphating film stabilizes the friction coefficient of a fastener to be in the range of 0.06-0.09; and the friction coefficient of phosphorization bolts is controlled in the range of 0.075+ / -0.015, thus the effects of controlling the friction coefficient very well and resisting corrosion are achieved.

Owner:十堰达克罗涂覆工贸有限公司

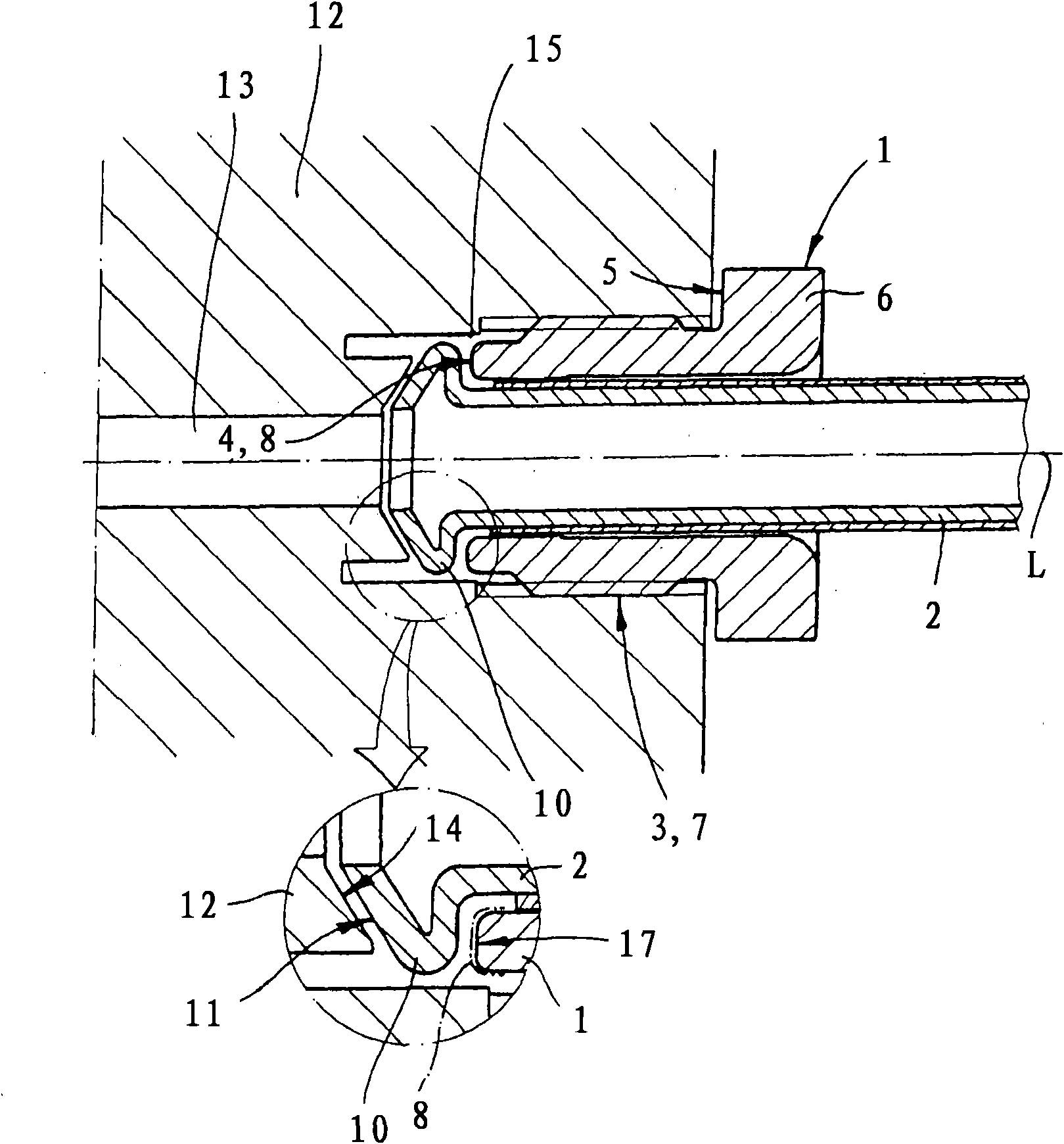

Screwing element and pipe connection device for attaching pipes

ActiveCN101608722APrevent disengagementReduce torsional stressJoints with sealing surfacesNutsScrew threadCoefficient of friction

A threaded component for connecting piping employed on motor vehicles includes a thread formed thereon and at least one unthreaded, contacting surface. A first coating having a first coefficient of friction is disposed on at least a portion of the thread, and a second coating having a second coefficient of friction is disposed on at least a portion of the unthreaded, contacting surface(s) of the threaded component. The first coefficient of friction is greater than the second coefficient of friction. In an embodiment an anti-corrosion coating is provided between the coatings and the component.

Owner:TI AUTOMOTIVE HEIDELBERG

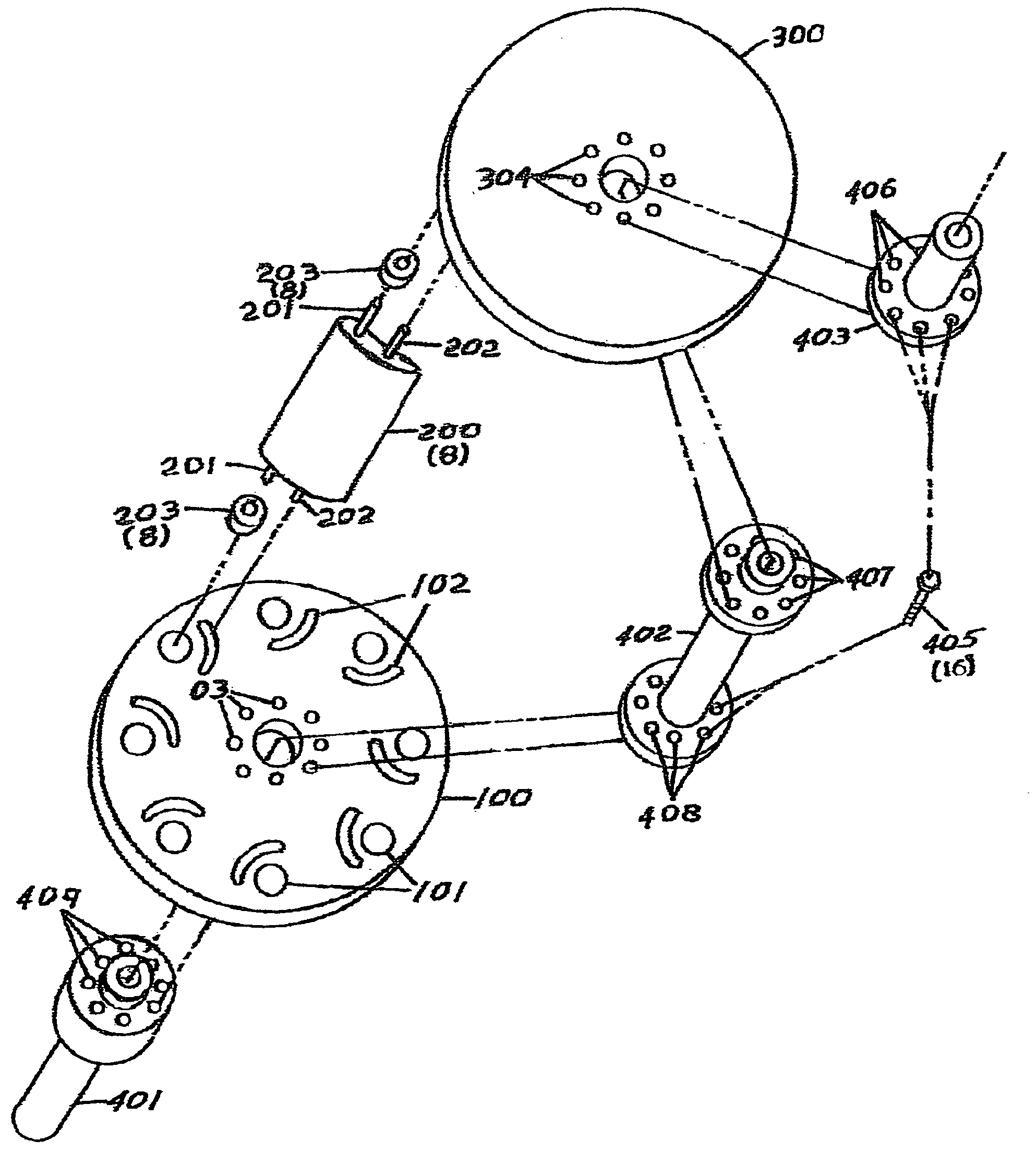

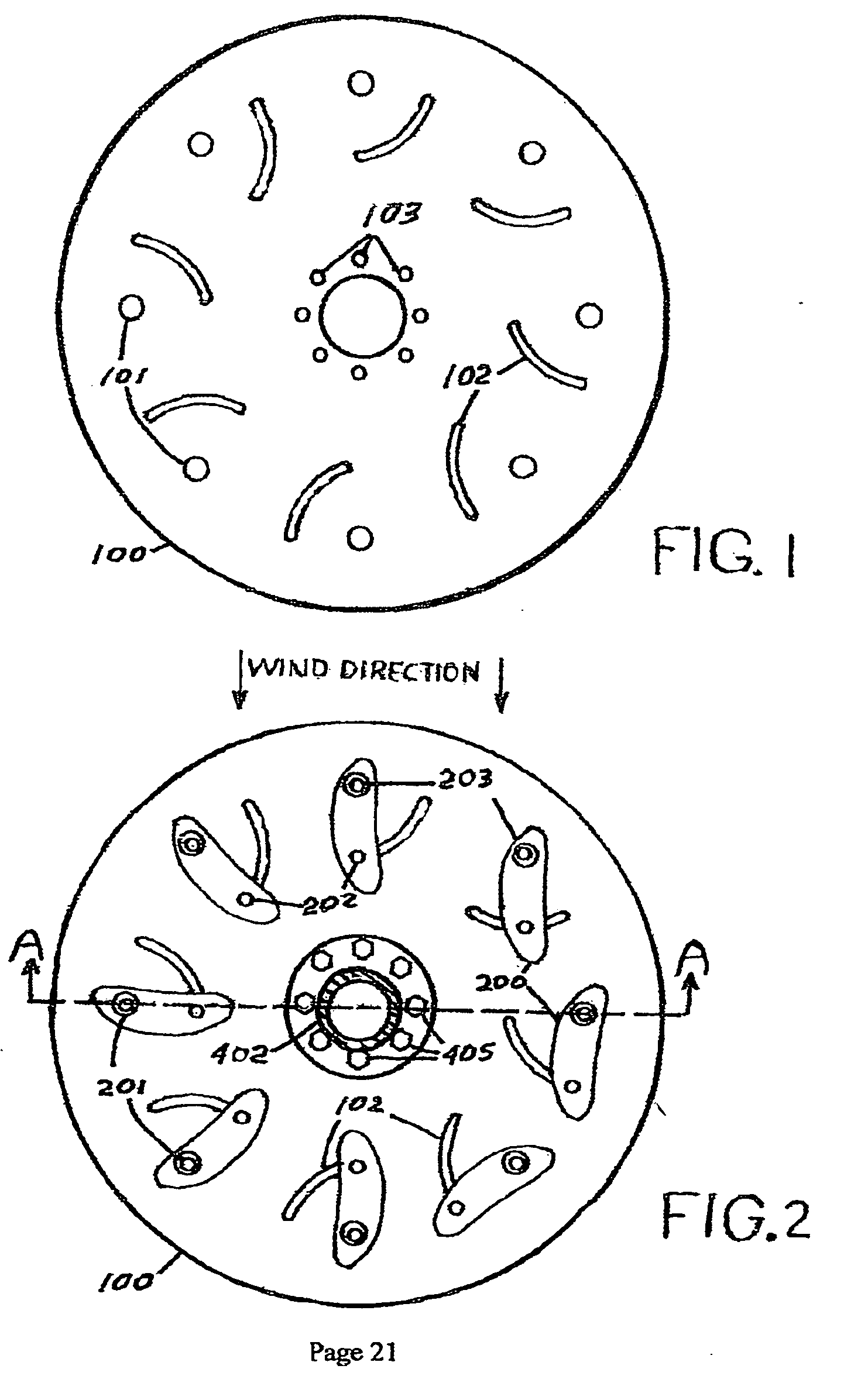

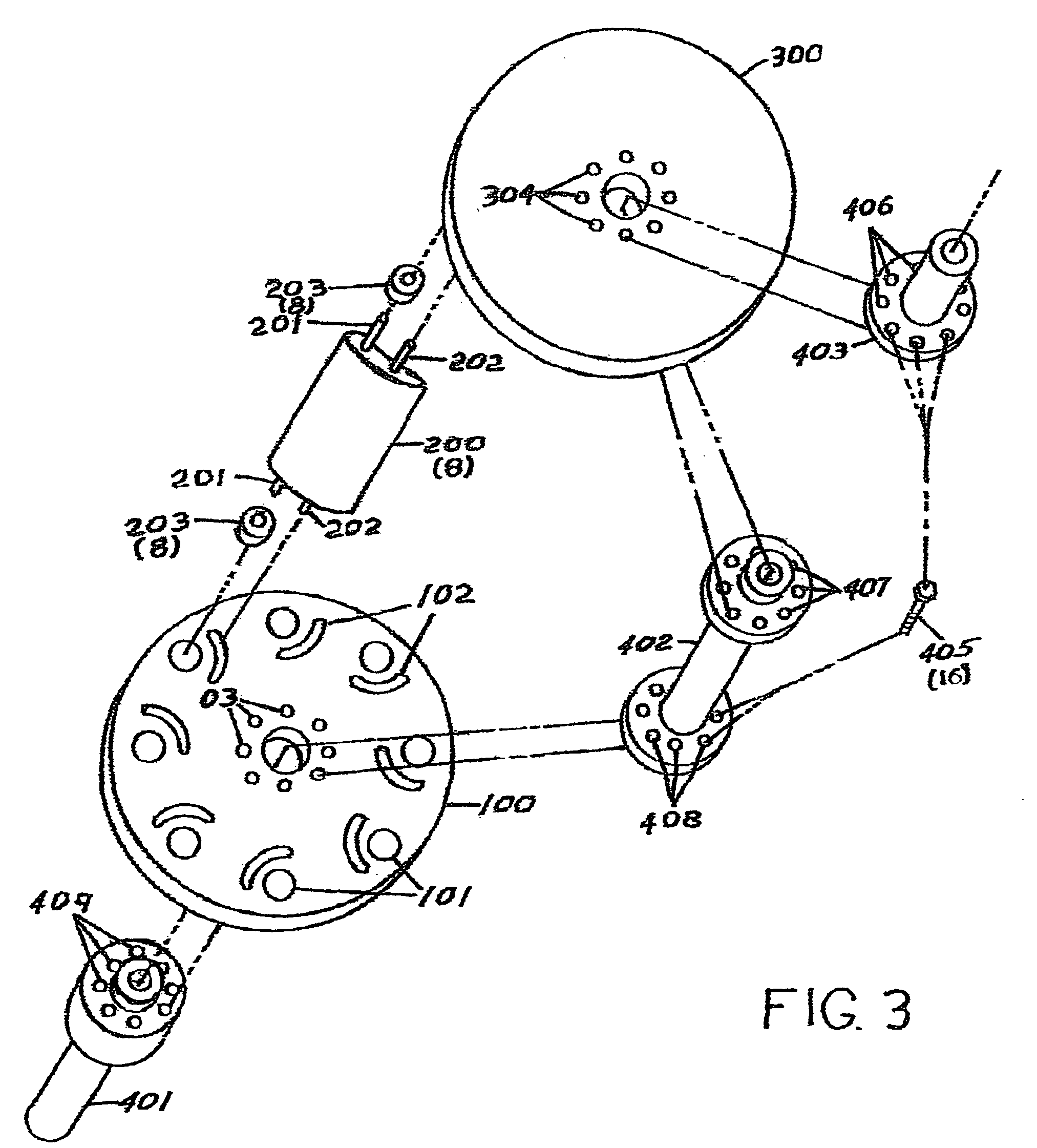

Advanced vertical shaft wind turbine power generator

InactiveUS20100202883A1Robust structureReduce torsional stressPropellersWind motor controlTurbineWind force

A design for a scalable advanced design vertical shaft wind turbine power generator which incorporates a superior symmetrical blade configuration and a unique blade mounting approach which utilizes aerodynamic forces to provide wide changes in blade positions o optimize efficiency and eliminates the need for expensive mechanical control devices while minimizing manufacturing, operational and maintenance costs.

Owner:DALEY III JOSEPH A +1

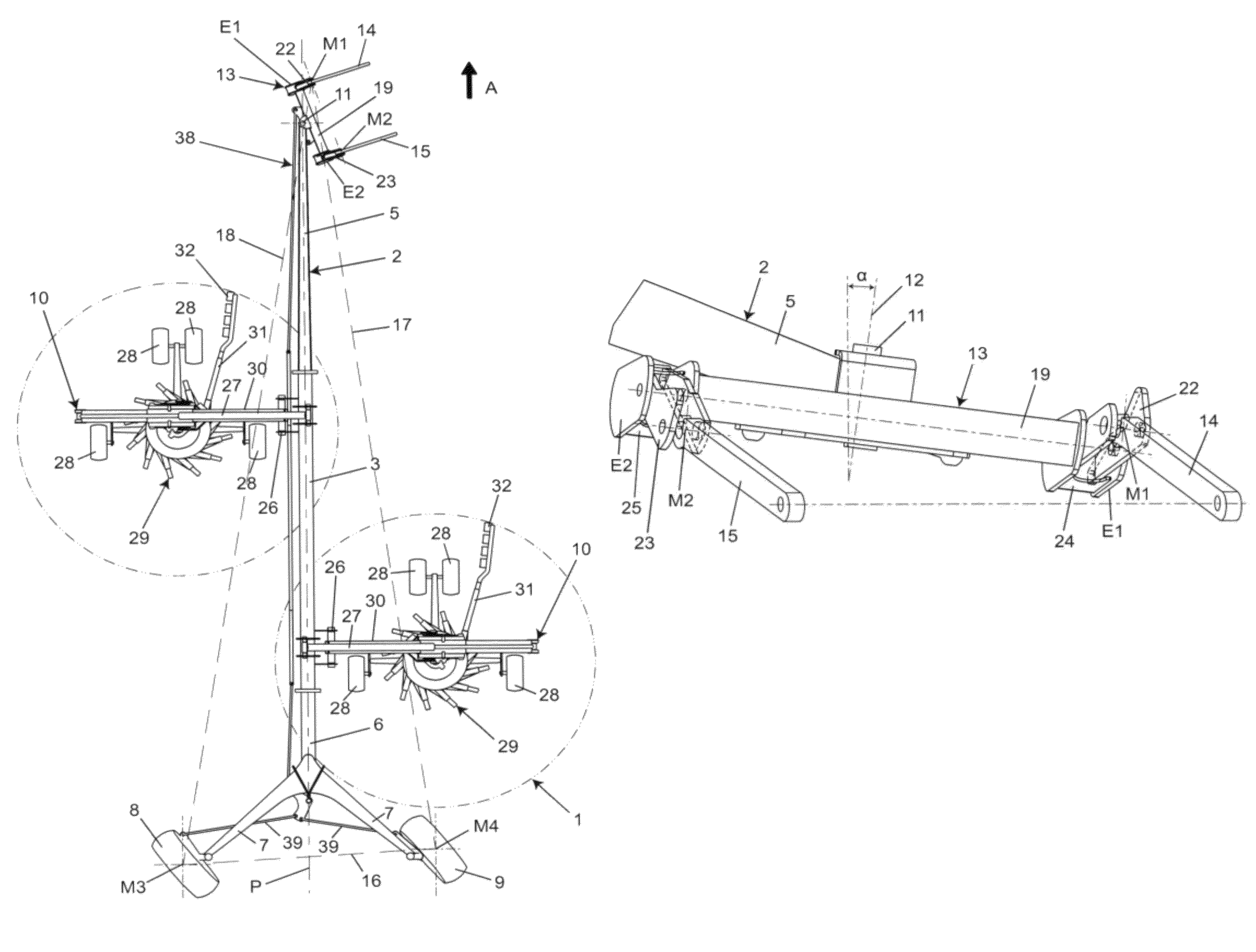

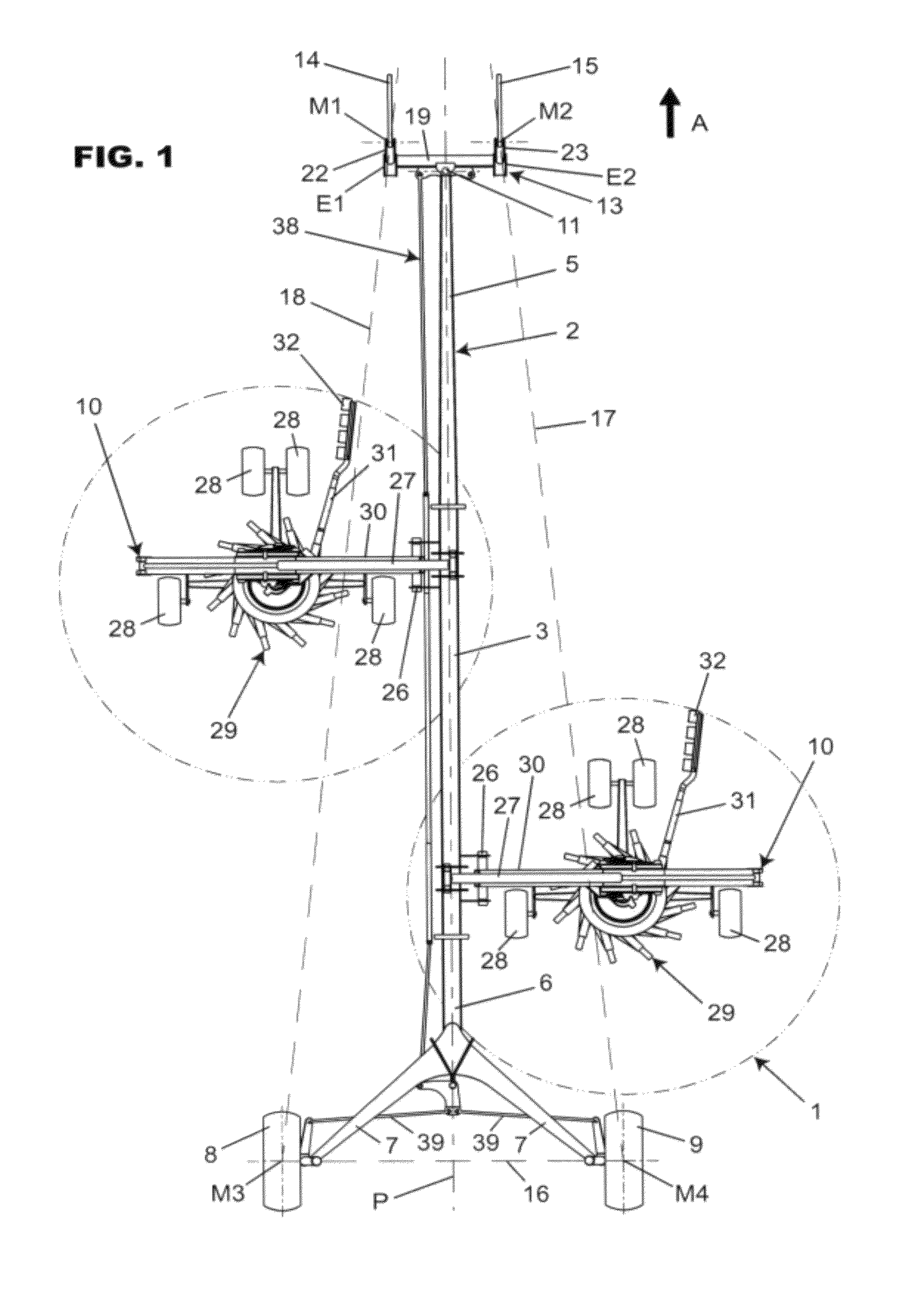

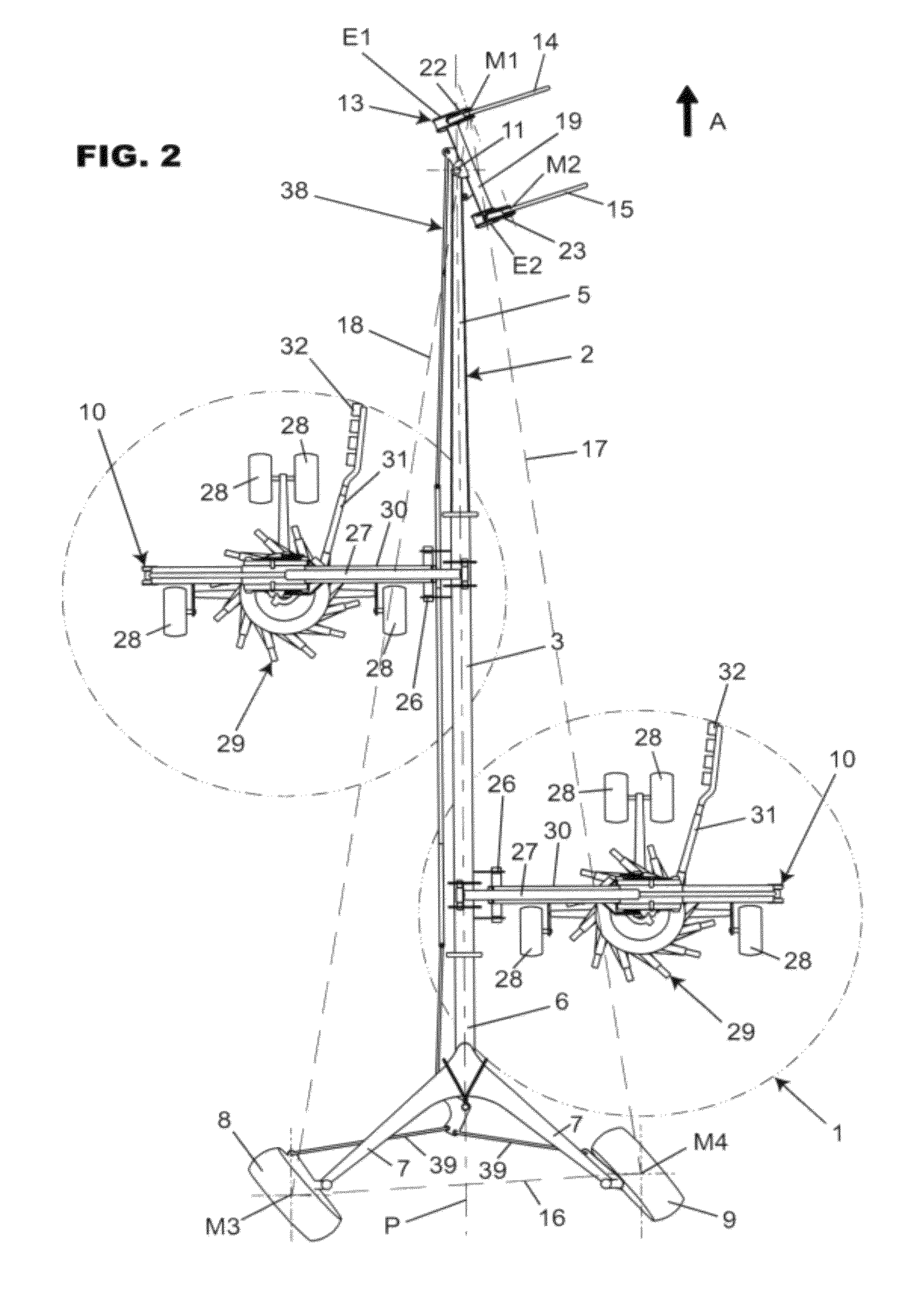

Haymaking machine provided with a hitching device with an inclined pivoting axis

An agricultural haymaking machine intended to be hitched to the lower arms of a tractor comprises a frame supported on the ground by wheels and at least one work device connected to the frame, the frame being in its front part in pivoting connection with a hitching device configured to be connected to the two lower arms, the center of gravity of the machine being situated between the wheels and the hitching device. According to the invention, the projection of the axis of the pivoting connection, on a plane which is substantially vertical and substantially parallel to the direction of advance, has an inclination towards the direction of advance following a direction of the ground upward.

Owner:KUHN SA

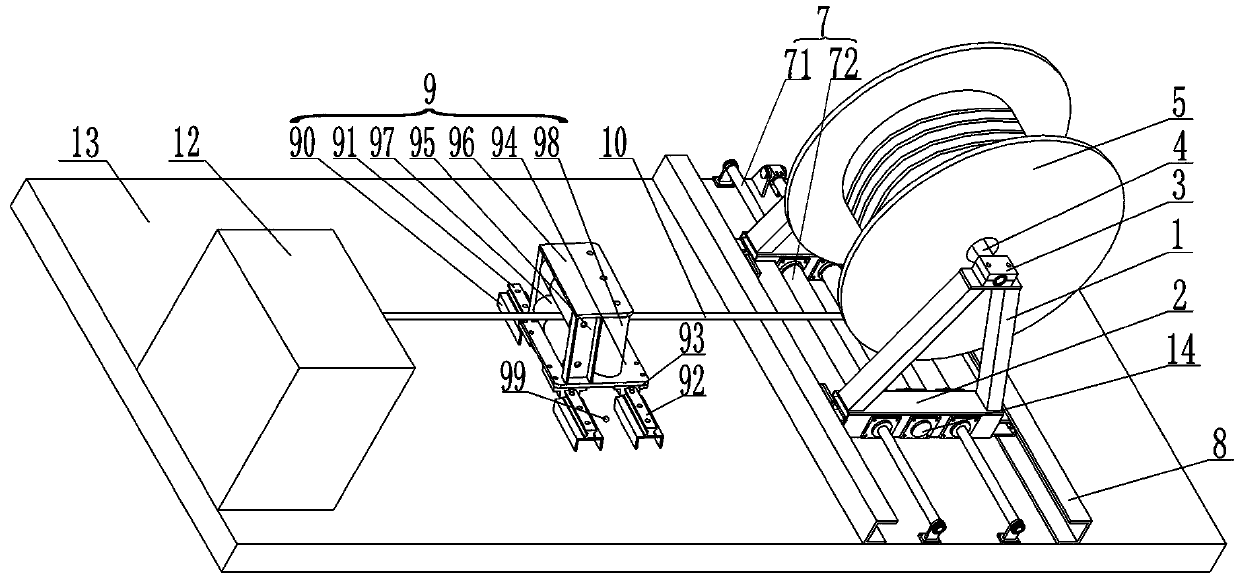

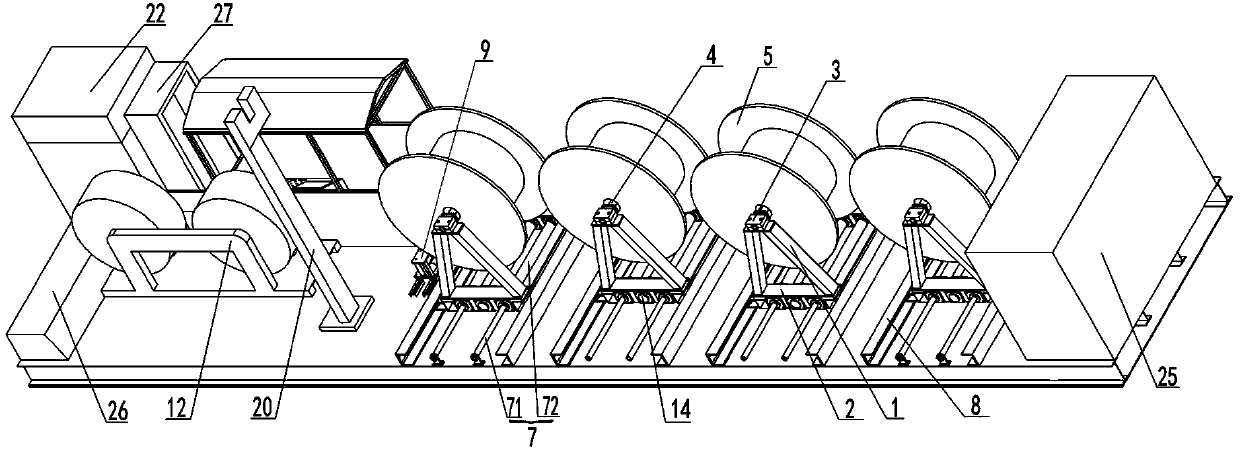

Constant-tension pay-off device

PendingCN111532894AConstant tensionStable tensionFilament handlingTrolley linesControl theoryWire wrap

The invention discloses a constant-tension pay-off device and belongs to the technical field of railway bearing conductor erection. The constant-tension pay-off device comprises a support, a rotary shaft rotationally connected to the support, and a winding device which is fixedly arranged on the rotary shaft and used for winding a bearing conductor. The support is connected to a car body, used forbearing the support, in a sliding mode through sliding rail devices. Moving devices and driving devices are fixedly arranged on the support, the moving devices enable the support to move along the sliding rail devices, the driving devices are used for driving the rotary shaft to rotate and provide tension for the winding device, and the force application direction of the driving devices is opposite to the pay-off direction of the winding device. The constant-tension pay-off device further comprises a guide device used for detecting the position of the bearing conductor and providing an actuating signal for the moving devices, and a control device. The constant-tension pay-off device provided by the invention is high in automation degree can be automatically aligned with a tension application device during paying-off, the tension is constant and can be automatically adjusted, friction between the bearing conductor and the ground and dragging are reduced during paying-off, the service life is long, dismounting and mounting are convenient, guiding is stable, and the device is applicable to all pay-off devices.

Owner:CHINA CREC RAILWAY ELECTRIFICATION BUREAU GRP

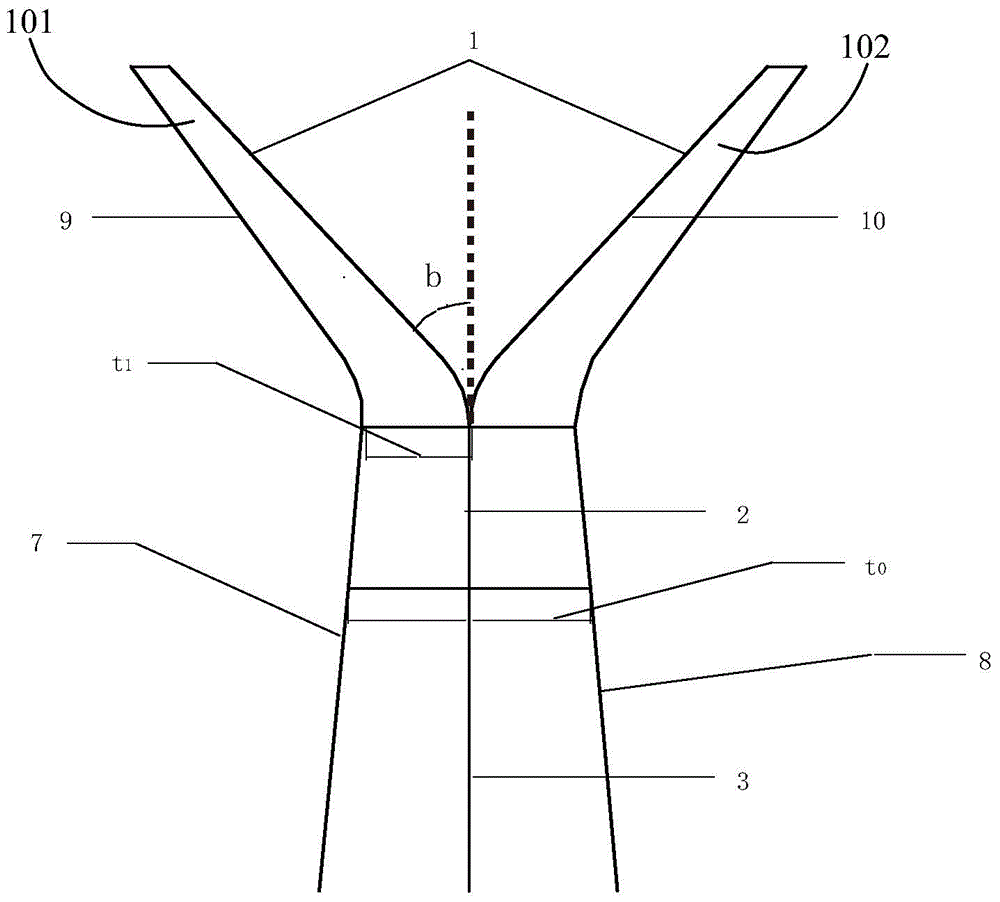

Novel wind turbine blade

InactiveCN104863791AImproved aerodynamic layoutReduce intensityMachines/enginesEngine componentsTurbine bladeUltimate tensile strength

The invention provides a novel wind turbine blade which comprises a main blade body, a blade tip extension segment and symmetrical little wings. The blade tip extension segment is connected with the main blade body and the symmetrical little wings respectively. The chord length of the blade tip extension segment is in smooth transition from the blade tip chord length to the little wing root chord length. The symmetrical little wings comprise the first little wing and the second little wing. The first little wing and the second little wing are symmetrical to each other. Both the first little wing and the second little wing are provided with lifting airfoils. Both the suction surface of the first little wing and the suction surface of the second little wing face a wind turbine body. The novel wind turbine blade has the advantages that the blade tip vortex is reduced, the blade stress is balanced, the pneumatic efficiency of the wind turbine is improved, the blade root waving moment is lowered, the requirement for the strength level of all components of the wind turbine is lowered, the reliability degree of the components of the wind turbine is increased, and the power generation cost of the wind turbine is reduced.

Owner:SHANGHAI JIAO TONG UNIV +1

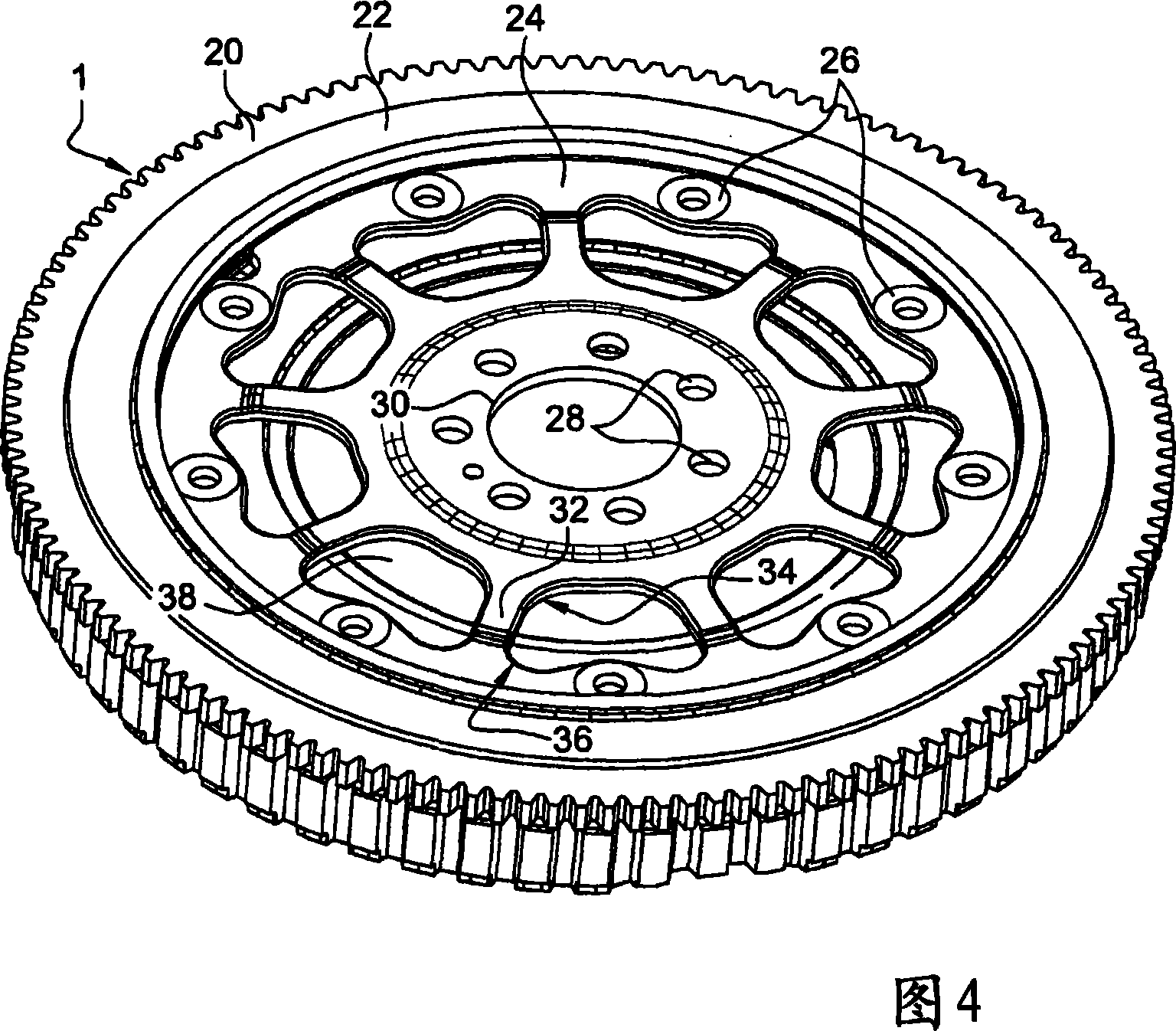

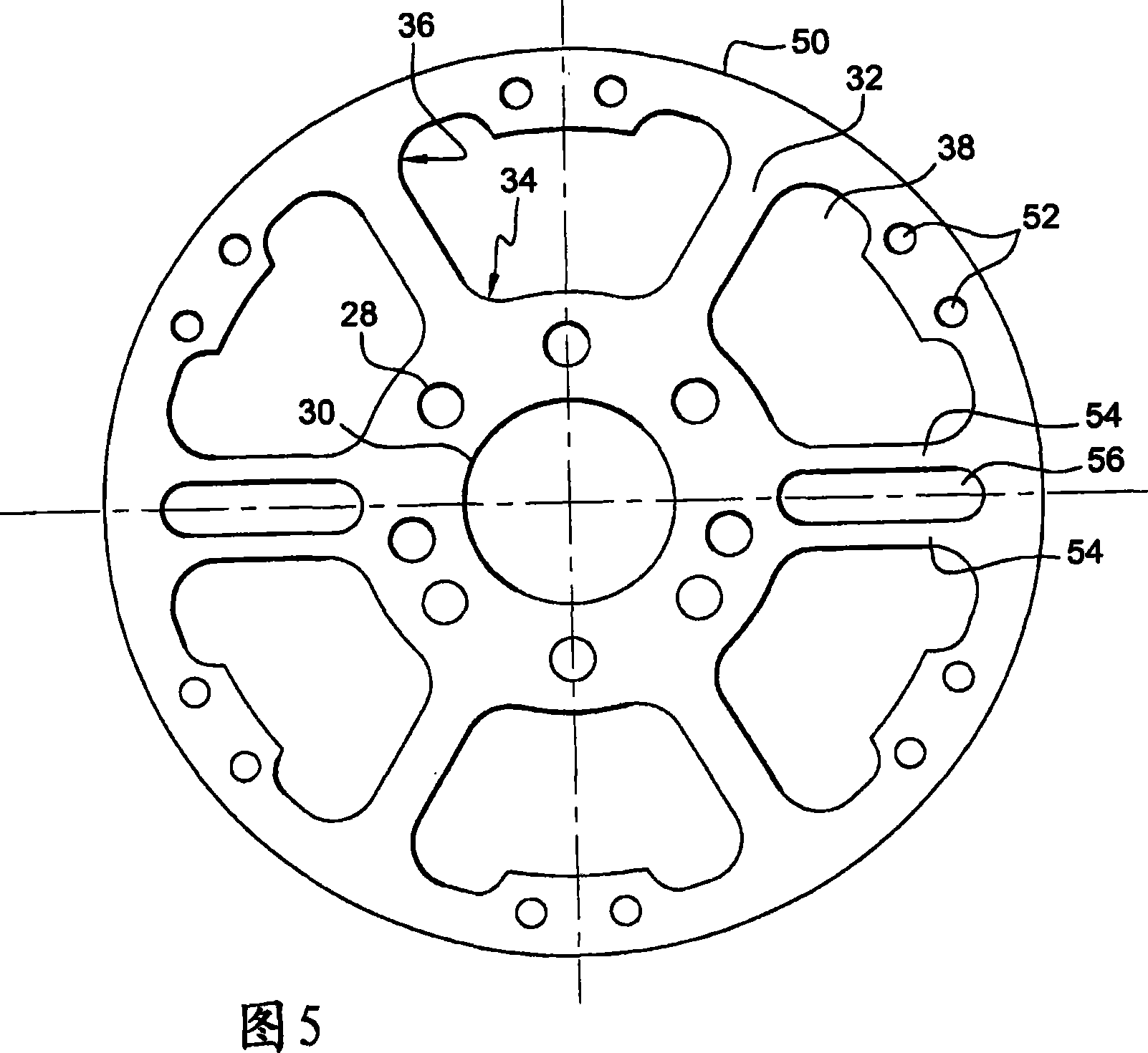

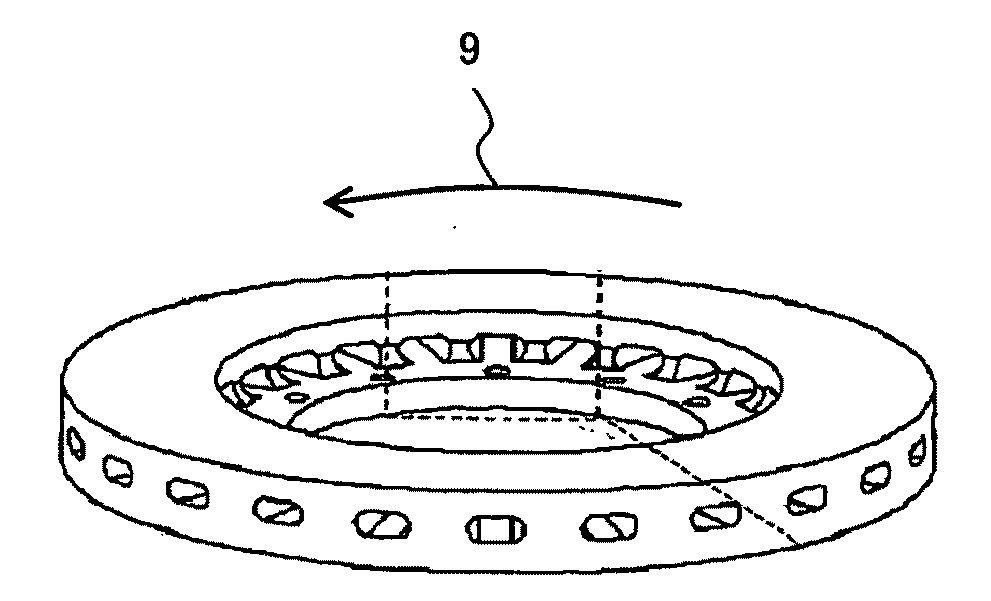

Flywheel for internal combustion engine

ActiveCN101099051AReduce torsional stressHigh natural torsional frequencyYielding couplingVibration suppression adjustmentsExternal combustion engineFlywheel

The invention relates to a flywheel (1) for an internal combustion engine comprising a rotating annular flywheel mass (22) which is fixed to one end of the engine crankshaft (4) by a connecting means (14) having a torsional stiffness of less than that of the crankshaft (4) alone, such that the natural torsional frequency of the crankshaft (4) fixed to the flywheel (1) is reduced, but still greater than the first frequency generated by successive combustion events in the cylinders of the engine.

Owner:VALEO EMBRAYAGES SAS

Suspension arrangement for a wheel suspension of a motor vehicle

ActiveUS20120256387A1Reduce the spring rateReduce torsional stressInterconnection systemsResilient suspensionsEngineeringActuator

A suspension arrangement for a wheel suspension of a motor vehicle includes an output lever hinged directly or indirectly to a wheel control element and configured as a flexible spring of defined spring rate. A transverse torsion-bar spring acts on the output lever, with an actuator adjusting a pretension of the torsion-bar spring.

Owner:AUDI AG

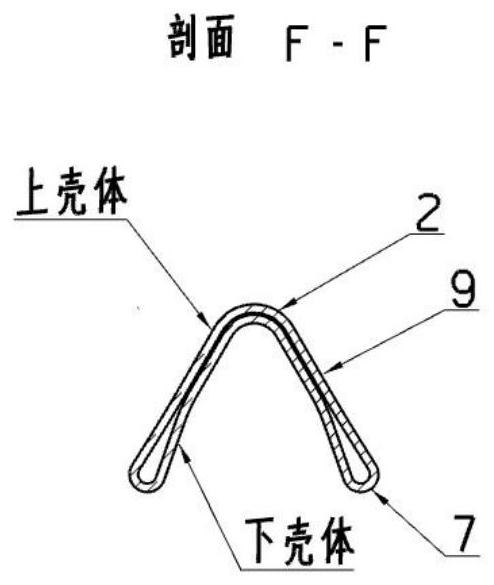

Rear torsion beam structure of automobile

ActiveCN105774462AReduce torsional stressGuaranteed torsional rigidity requirementsInterconnection systemsEngineeringShock absorber

The invention discloses a rear torsion beam structure of an automobile. The rear torsion beam structure comprises a transverse beam, wherein longitudinal beams are respectively arranged at two ends of the transverse beam; a lining sleeve is arranged at one end of each longitudinal beam; a shock absorber bracket is arranged at the other end of each longitudinal beam; hub brackets are arranged at the positions close to the shock absorber brackets on the bodies of the longitudinal beams; the transverse sectional surface of the transverse beam takes the shape of an inverted U; the cross section area of the transverse beam is gradually increased from the middle to two ends in a symmetric manner. Due to the adoption of the transverse beam of which the transverse sectional surface is U-shaped, torsion stress can be dispersed, the adjusting difficulty of torsion rigidity can be greatly reduced, and thus development and design of products can be facilitated; meanwhile, as the torsion stress of the transverse beam is mainly concentrated at two ends, and the middle of the transverse beam is relatively slightly stressed, both the requirement on the torsion rigidity of the transverse beam can be ensured and the space occupied by the transverse beam can be effectively reduced due to adoption of a variable cross section structure which has a small middle and large two ends of the transverse beam, and thus other automobile parts around the transverse beam fittings can be arranged conveniently.

Owner:CHERY AUTOMOBILE CO LTD

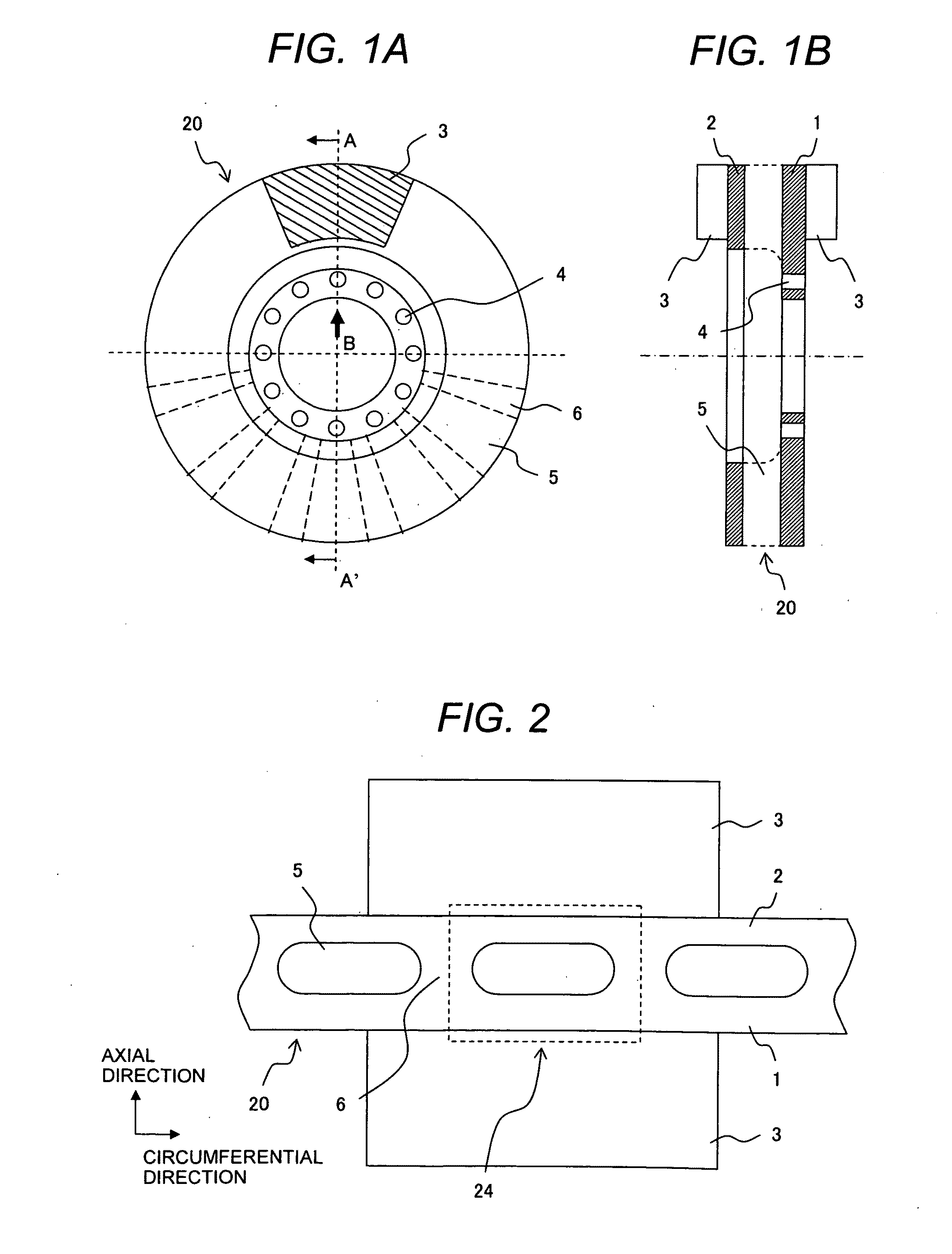

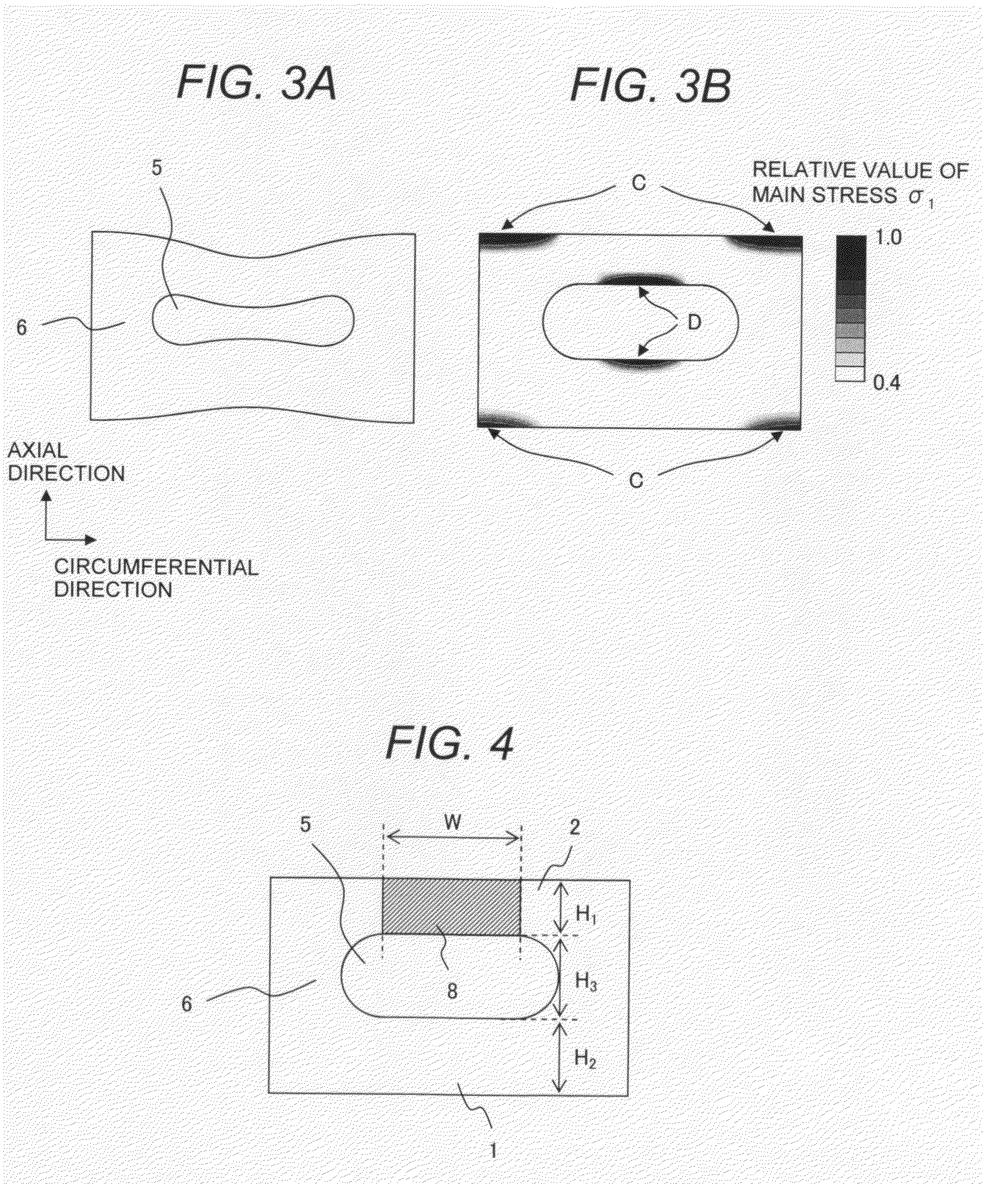

Disc rotor for disc brake

InactiveUS20090294228A1Large radiusTorque stress is largeBraking discsBrake arrangement with pressed braking surfaceBrake torqueEngineering

A disc rotor for a disc brake with a vent hole shape which has an inner peripheral corner with a larger radius to reduce stress generated by braking torque and suppresses an increase in stress generated by pad pressure. The disc rotor includes a first sliding part connected to a bell housing, a second sliding part located parallel to, and spaced in an axle direction from, the first sliding part, a plurality of ribs circumferentially spaced between the sliding parts, and vent holes formed by the ribs and the sliding parts. The inner peripheral shape of each of the vent holes has at least two arc shapes with different curvature radii at an end perpendicular to the disc rotor's rotation direction. The smallest curvature radius is 2 mm or more. An arc curvature radius on the first sliding part side is larger than that on the second sliding part side.

Owner:HITACHI CHEM CO LTD

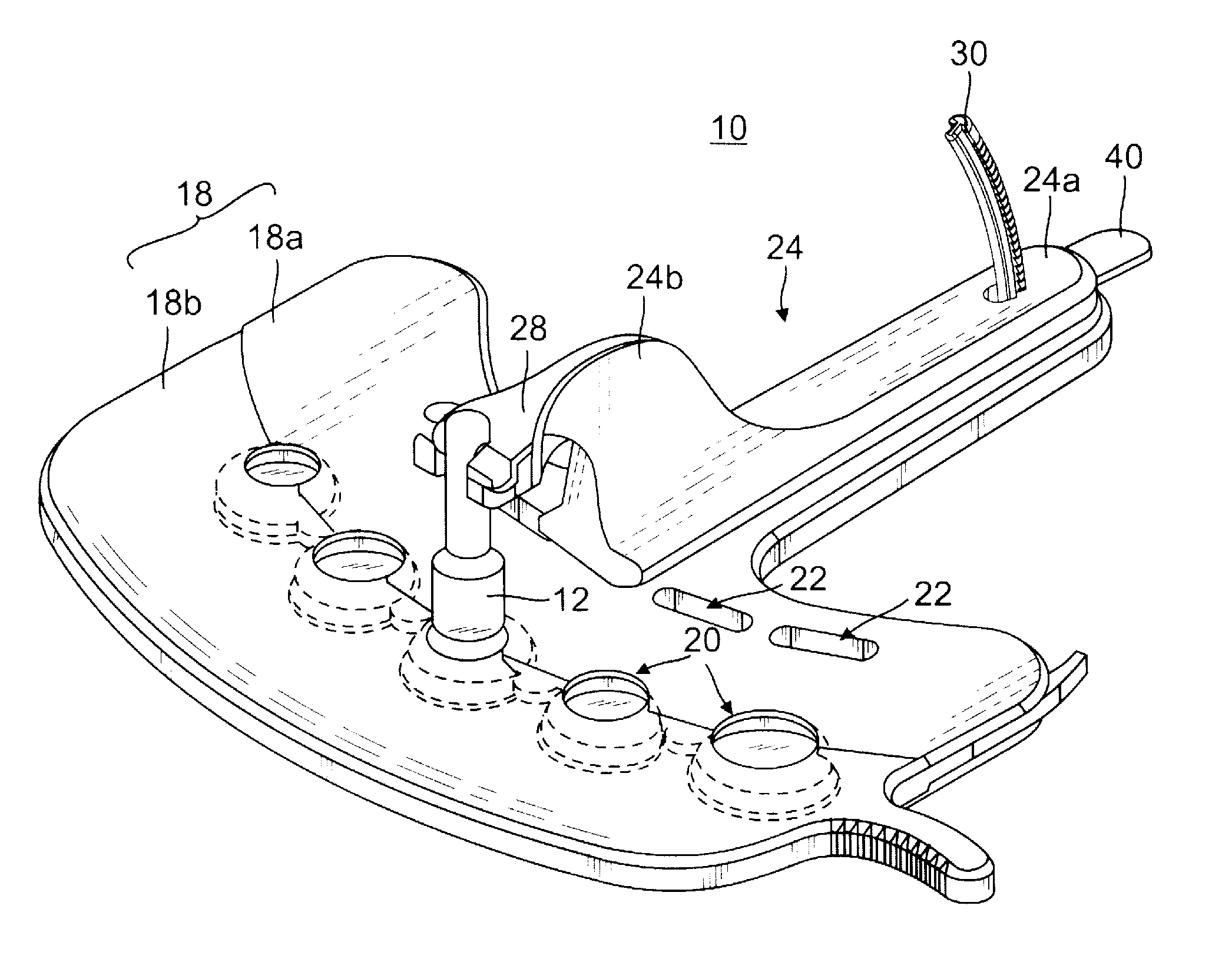

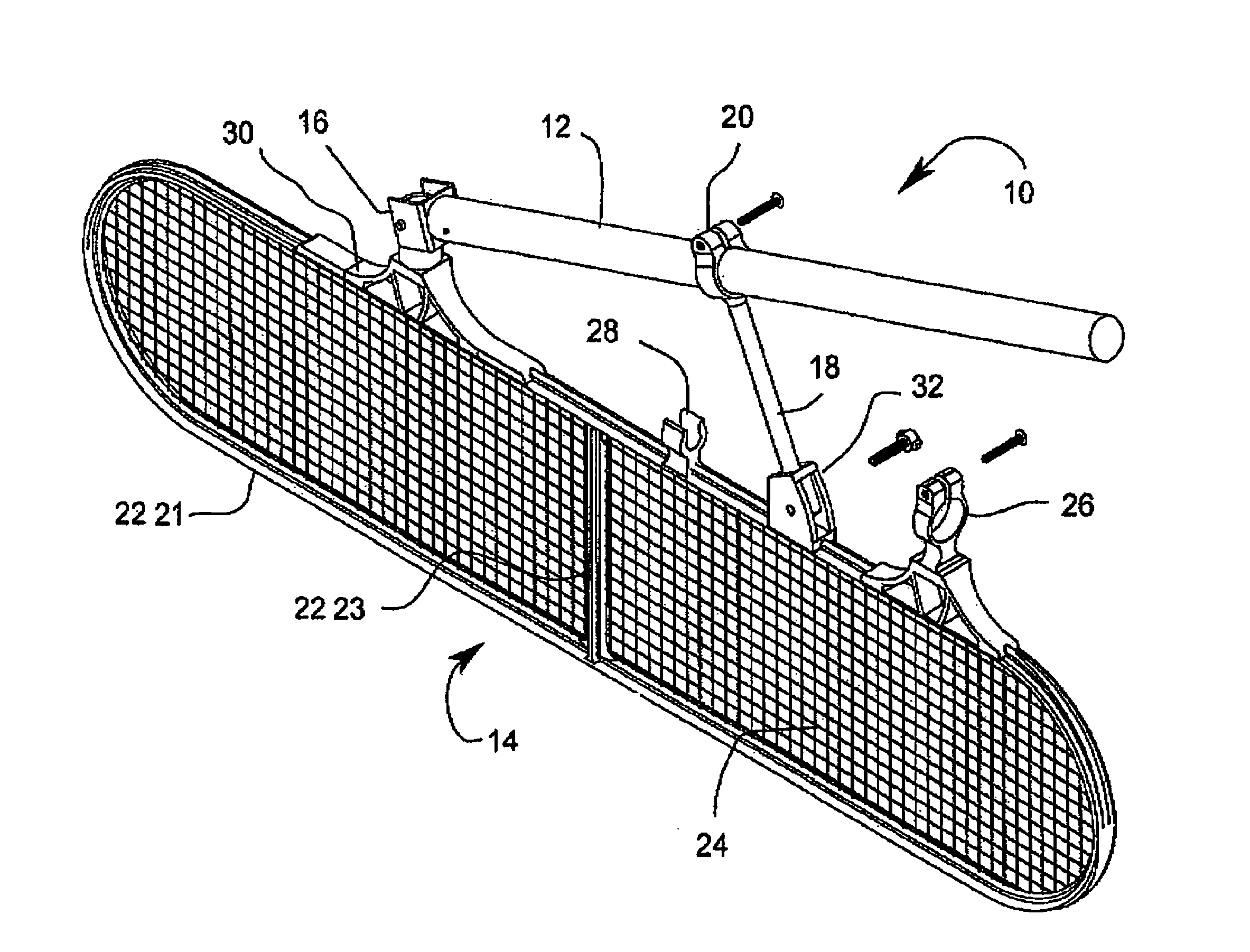

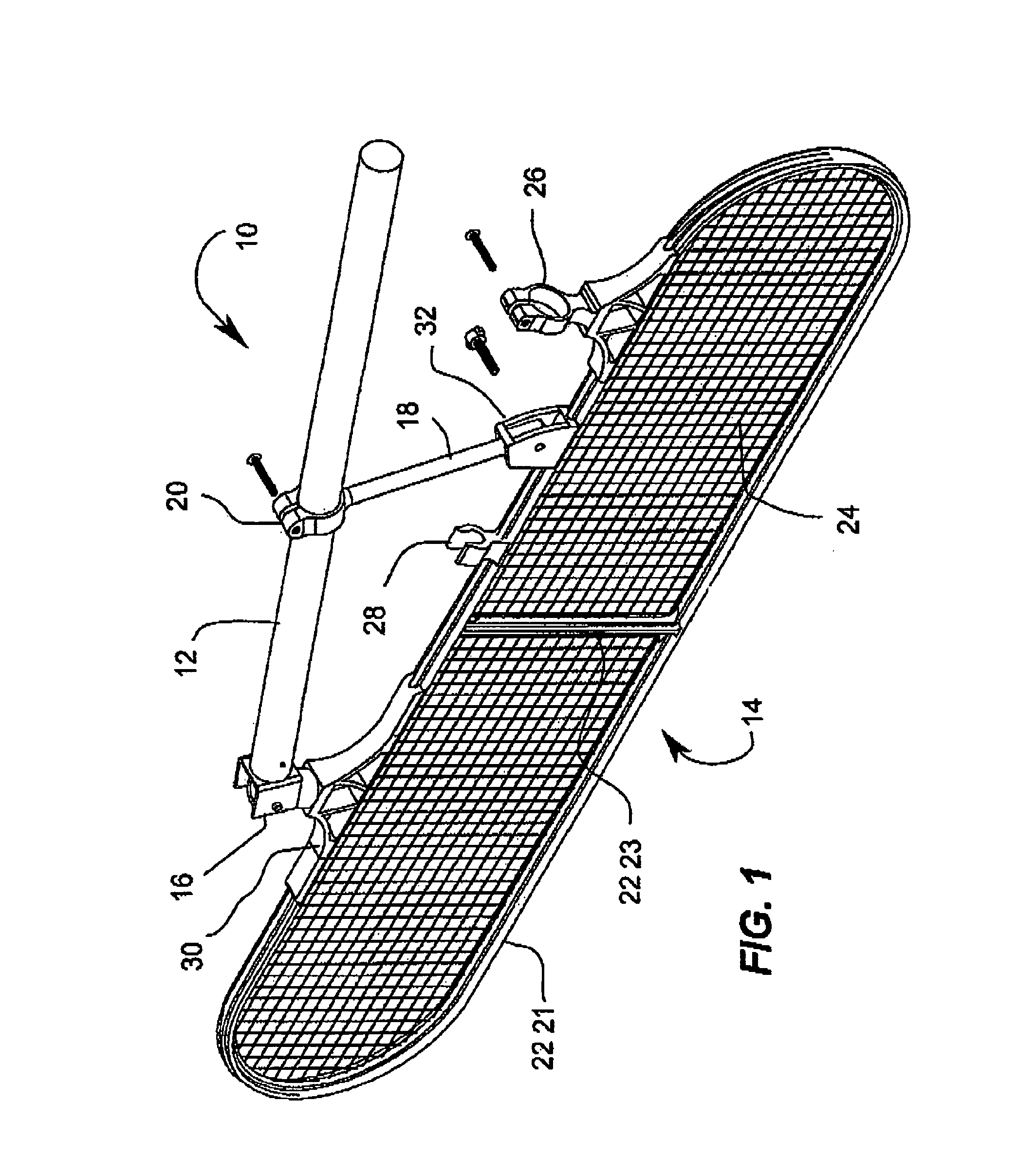

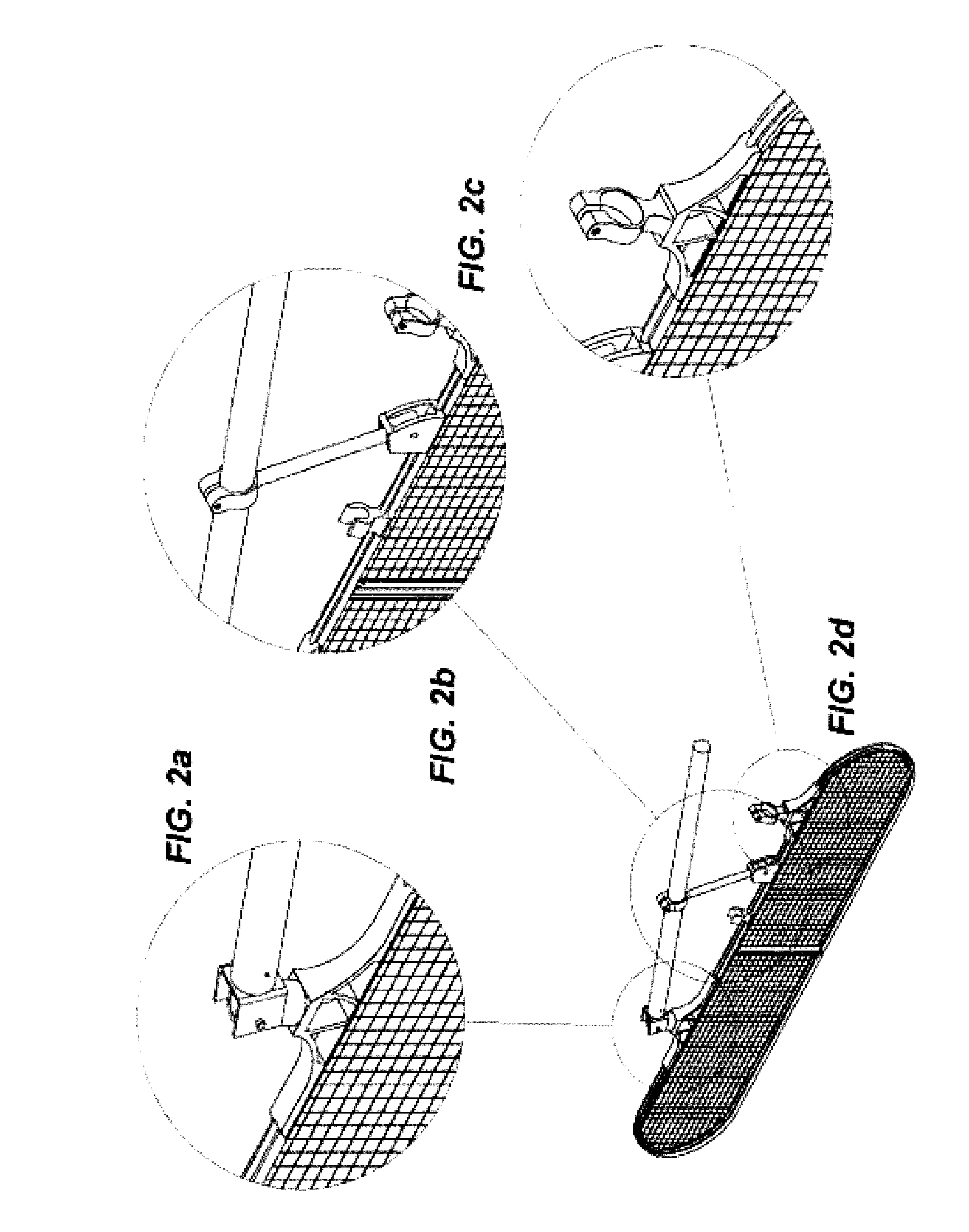

Multiple orientation pool skimming net with three-point leveraging configurations

ActiveUS9528288B2Reduce undue warping of a net memberReduce torsional stressWater/sewage treatmentGymnasiumAcute angleEngineering

An improved pool skimming net apparatus has a net member including a frame and a net held by the frame. The frame has parallel elongated top and bottom frame portions, an elongated handle member pivotally attached to the top frame portion by an articulated joint member, an elongated retainer member pivotally attached to the top frame portion at a distance from the articulated joint member, a handle clamp member attached to a distal end of the retainer member and adapted to releasably hold a portion of the handle member, and a secondary handle clamp member fixedly attached to the top frame portion at a distance from the articulated joint member and adapted to releasably hold a portion of the handle member, such that when the handle member is held by the handle clamp member an acute angle is formed between the handle member and the top frame portion.

Owner:FLEURY LUC

Catenary constant tension pay-off car

PendingCN111532893AReduce tensionQuality improvementFilament handlingTrolley linesHydraulic motorHydraulic cylinder

The invention discloses a catenary constant tension pay-off car, comprising a pay-off device fixedly arranged on a road flat car and penetrated through bearing wires in sequence, a guiding device, a tension applying device, a wire column and a control device. A slide rail device and a hydraulic cylinder for moving a bracket along the slide rail device are fixedly arranged on the road flat car. A hydraulic motor is fixedly arranged on the bracket, and the direction of force applying when the hydraulic motor provides tension for a winding device is opposite to the direction of paying-off of thewinding device. The control device comprises a generator set and a hydraulic control assembly; the hydraulic control assembly comprises a signal control assembly and an oil storage device, a hydraulicoil pump and an integrated valve group connected in sequence. The pay-off car has a high degree of automation, the modularization is achieved, the size is small, constant tension is ensured, and thetension is automatically adjusted according to actual conditions during the working process. In addition, the quality of winding is ensured, the service life is long, the disassembly and assembly areconvenient, the orientation is stable, the energy is saved, the emission is reduced, the environmental pollution is low, and the pay-off car is suitable for all catenary pay-off cars.

Owner:CHINA CREC RAILWAY ELECTRIFICATION BUREAU GRP

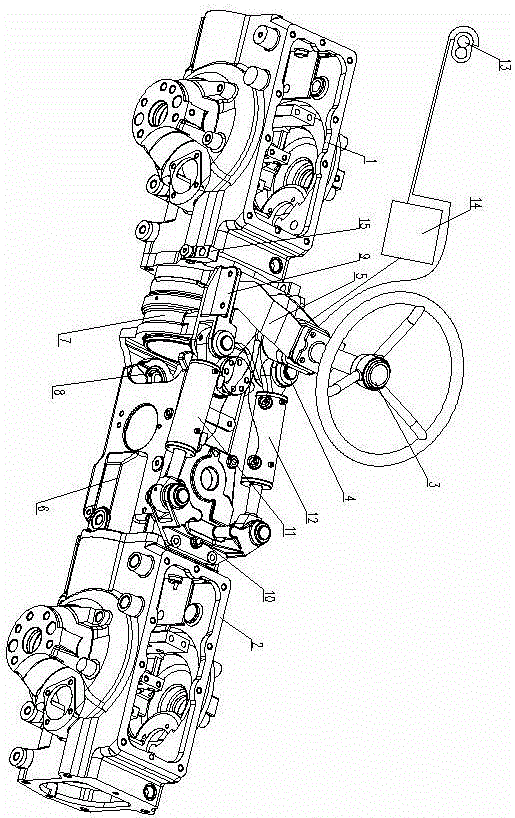

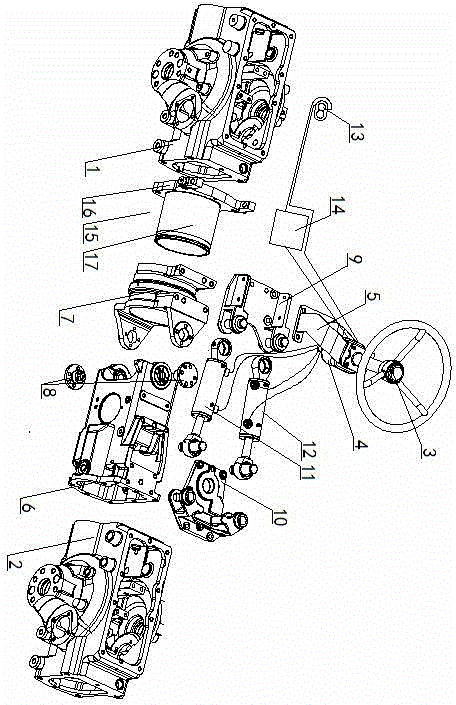

Articulated steering mechanism for use on tractor

PendingCN106741162ACompact structureIngenious designFluid steeringSteering for vehicles in tandemSteering wheelGreenhouse

The invention discloses an articulated steering mechanism for use on a tractor; the articulated steering mechanism comprises a front transmission box (1), a rear transmission box (2) and a steering wheel (3); a steering mechanism connected with the front transmission box (1) and the rear transmission box (2) is arranged between the front transmission box (1) and the rear transmission box (2), and a steering push mechanism connected with the steering mechanism is disposed on the upper end face of the steering mechanism; the steering wheel (3) is connected with the upper end face of one end of the steering push mechanism through a hydraulic steering gear (4) and a steering wheel mount (5), and the steering push mechanism is connected with a hydraulic system through the hydraulic steering gear (4). The articulated steering mechanism has the advantages of compact structure, ingenious design, and good reliability of use, may be used to provide small steering radius, good steering flexibility and good maneuverability for a tractor, and is effective to operate in hilly areas, vegetable greenhouses and orchards.

Owner:CHONGQING ZONGSHEN GENERAL POWER MACHINE

Concrete upright column steel truss

The invention belongs to the technical field of building construction, and particularly relates to a concrete upright column steel truss. The steel truss comprises a steel frame, an upright column made of reinforced concrete is arranged on the lower portion of the steel frame, and a hoisting trolley is arranged on the steel frame. An installation base is pre-buried in the top of the upright column, and an L-shaped pre-buried steel bar is arranged at the bottom of the installation base. A joint ball is rotationally connected with the interior of the installation base, a bolt is fixedly connected to the top of the joint ball, and the bolt penetrates through an installation hole in the steel frame and is connected with a nut. The steel frame continuously expands and retracts to drive the boltand the joint ball to rotate in the installation base when the temperature difference of day and night is violently changed. The torsion stress borne by the bolt is reduced while it is ensured that the steel frame reliably installs the upright column, the situation that the bolt bears repeated torsion stress for a long time and is broken is prevented, and the potential safety hazard that the steel frame falls off is reduced.

Owner:枣庄旗胜建设集团有限公司

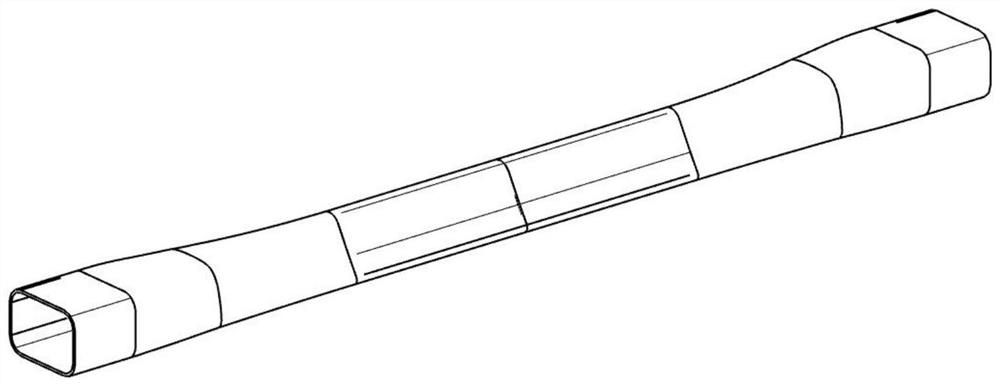

Multi-Conduit Coiled Tubing Assembly Including Pivotal Clamping Members

ActiveUS20170321497A1Great flexingAvoid changePipe supportsBatteries circuit arrangementsCoiled tubingCatheter

In a coiled tubing assembly for use in a wellbore, the tubing assembly uses longitudinally spaced apart clamping members to clamp two or more coiled tubing members alongside one another. Each clamping member includes a clamping portion extending circumferentially about each coiled tubing member so as to be rotatable in relation thereto, and a connecting portion joined between the clamping portions. A longitudinal positioning element is fixed relative to one of the tubing members in association with each clamping member such that the clamping member remains pivotal relative to the positioning element and the tubing members upon which it is fixed. The longitudinal positioning element thus only restricts the respective clamping assembly in the longitudinal direction along the tubing members without restricting relative twisting between the tubing members.

Owner:GENERAL ENERGY RECOVERY INC

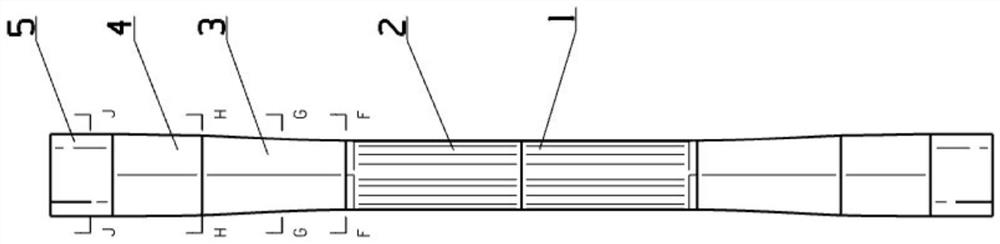

Torsion beam in passenger vehicle rear axle assembly

PendingCN111873746AIncreased longitudinal stiffnessIncrease lateral stiffnessInterconnection systemsManufactured materialStructural engineering

The invention discloses a torsion beam in a passenger car rear axle assembly, and the torsion beam comprises a beam body and a weld joint; the beam body is a bilaterally symmetrical variable cross-section hollow pipe beam and is formed by cold stamping forming and quenched-tempered heat treatment of a high-strength steel round pipe. The weld joint is located near a circular bead of an upper shellof a rectangular area of a torsion beam port and extends to the waist line position of the upper shell in the length direction, the port area is in a rectangular pipe shape subjected to rounding treatment, and the section structure of the middle area is in an inverted V shape formed by folding a closed curve. According to the invention, the high-strength steel seamless welding circular tube is used as a raw material of the torsion beam, so the production cost is greatly reduced compared with a V-shaped opening beam; the forming quality and the production efficiency of the product are improved;meanwhile, the modeling of the torsion beam is optimized through CAE simulation, so the longitudinal rigidity, the lateral rigidity and the roll rigidity of torsion can be effectively improved, the torsion stress of the torsion beam is effectively reduced, and the fatigue durability is improved.

Owner:湘潭地通汽车制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com