Concrete upright column steel truss

A technology of concrete columns and steel trusses, applied in the field of building construction, can solve problems such as potential safety hazards, speed up bolt fatigue, bolt fracture, etc., and achieve the effects of reducing torsional stress, reducing safety hazards, and preventing breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

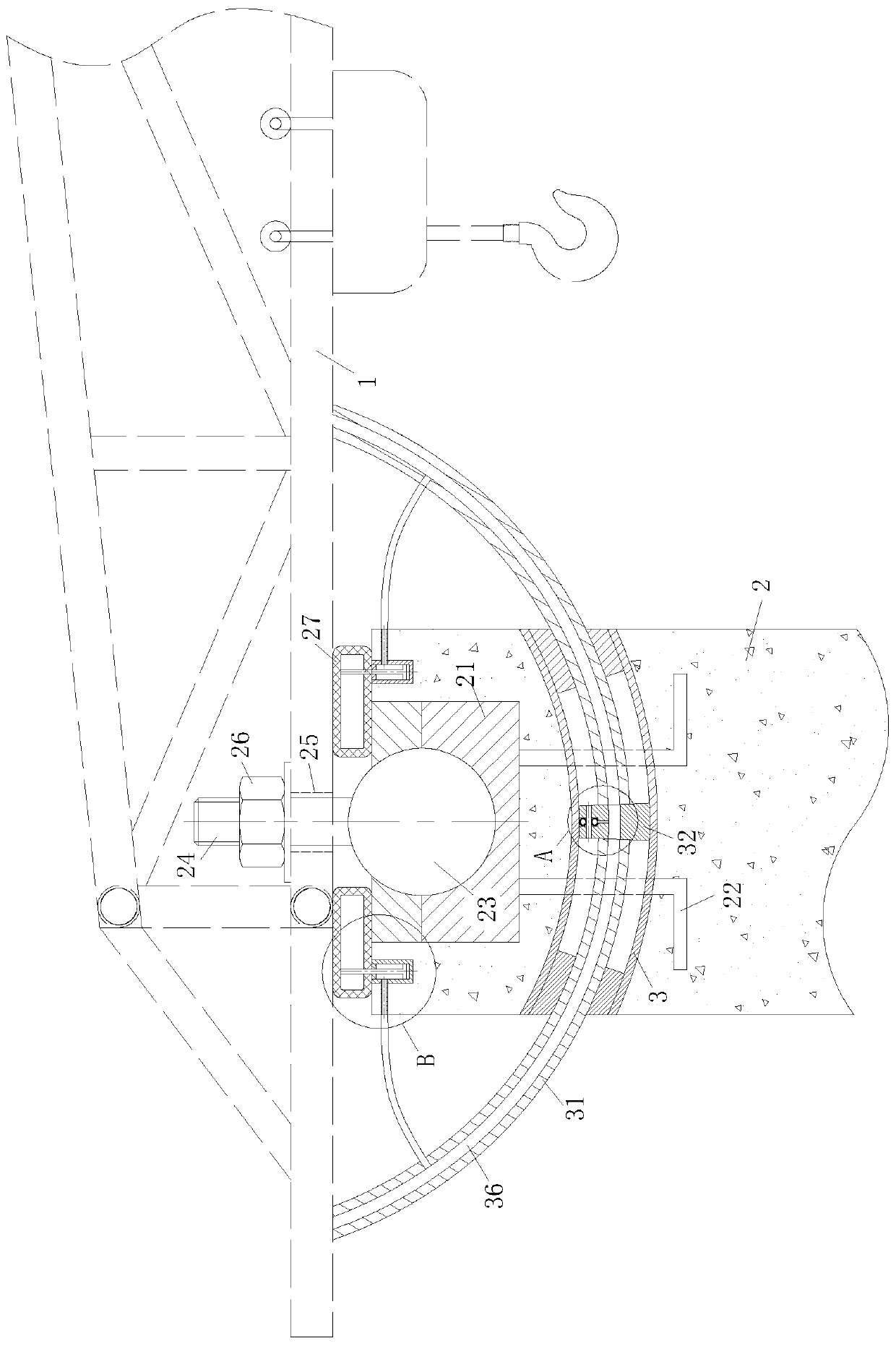

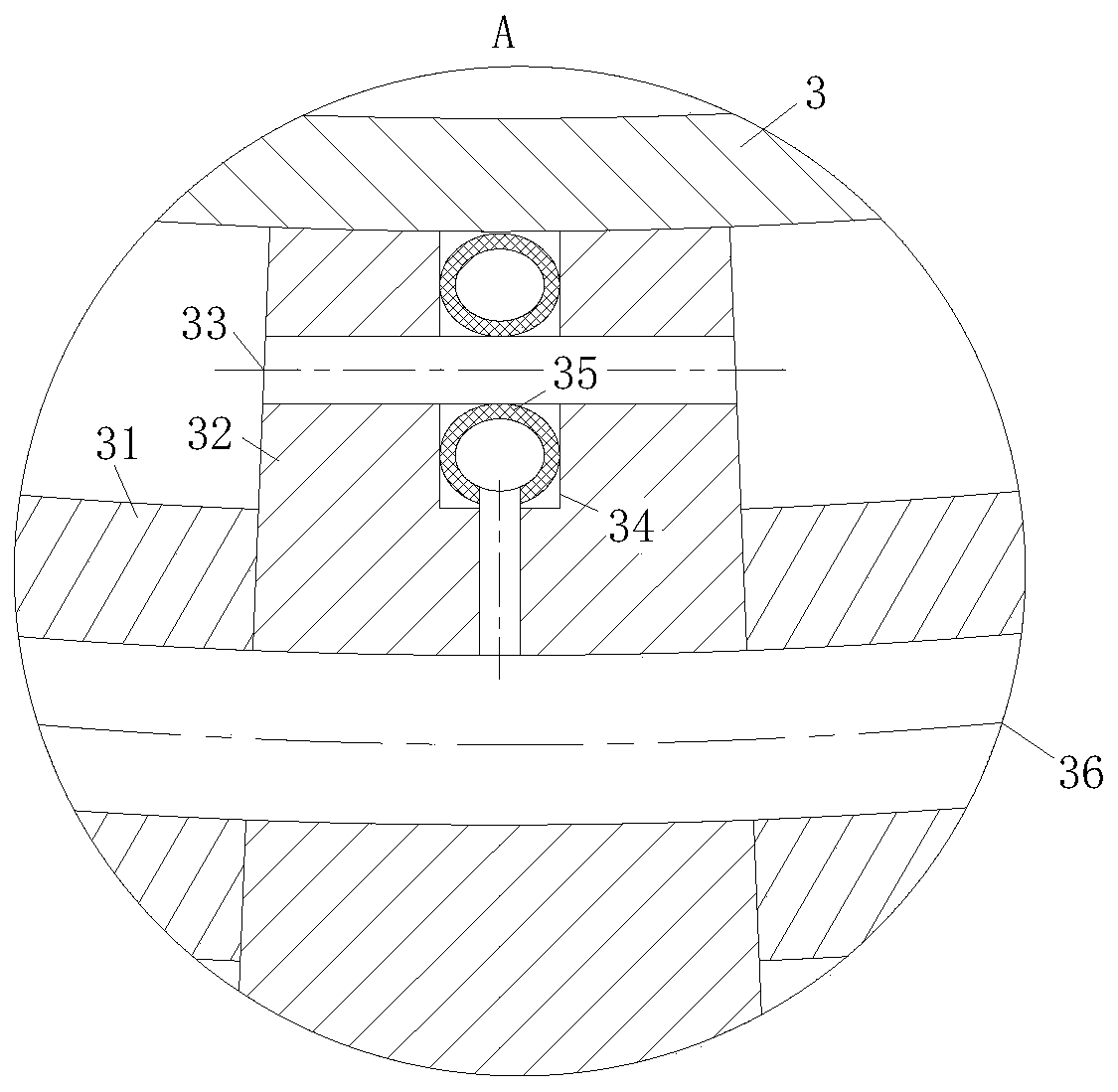

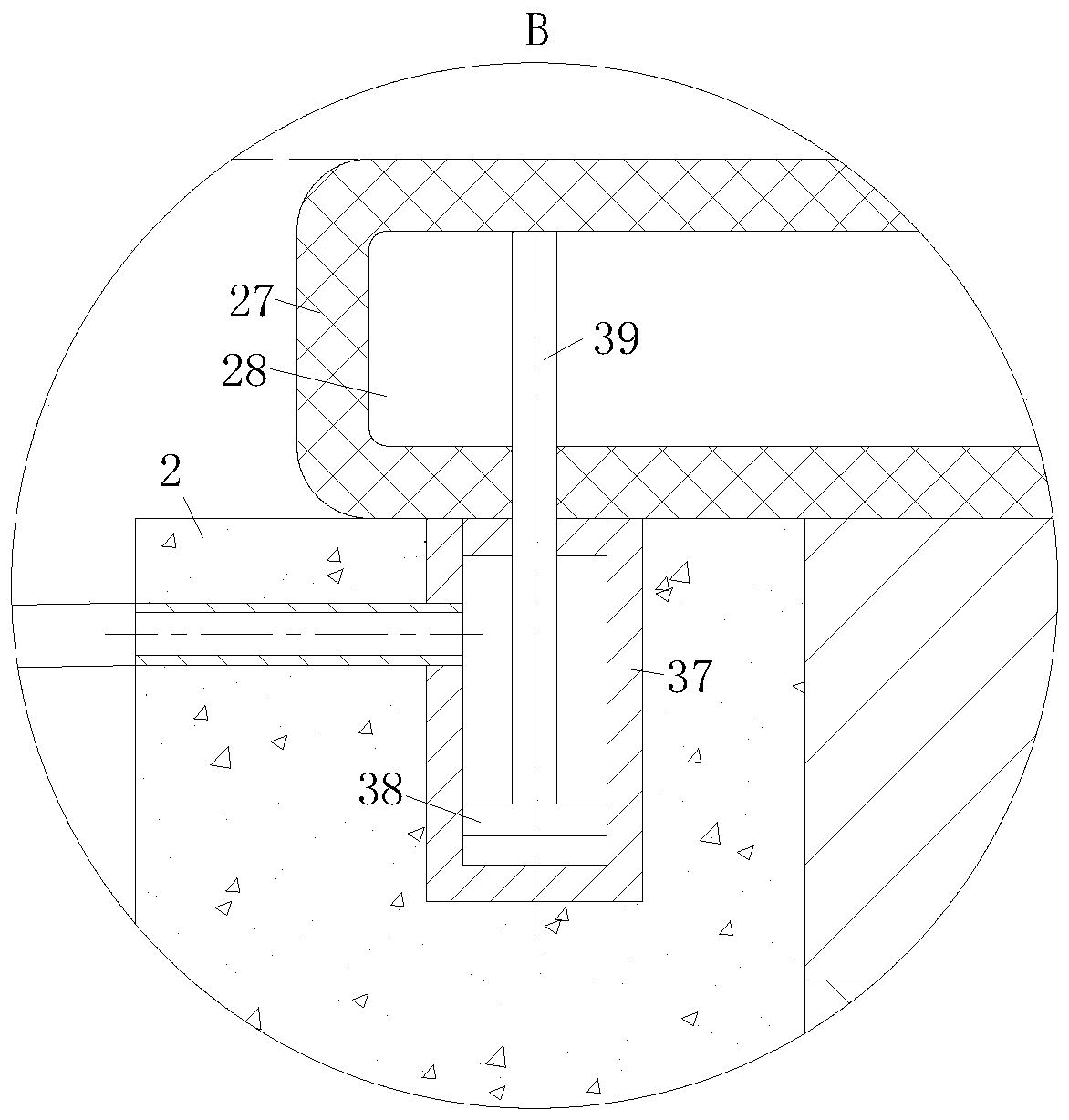

[0023] As an embodiment of the present invention, the part where the No. 1 piston head 32 contacts the piston cylinder 3 is provided with a sealing groove 34, and an air bag 35 is provided in the sealing groove 34; A set of air cylinders 37 are provided below the rubber pad, and the rodless cavity of the cylinder 37 is connected to the air duct 36 through a pipe; the cylinder 37 is slidably connected with the No. 2 piston head 38, The second piston rod 39 fixedly connected to the second piston head 38 extends out of the cylinder 37; the end of the second piston rod 39 located outside the cylinder 37 is inserted into the cavity 28 in the rubber gasket 27, and the second piston rod 39 The top of the cavity 28 is fixedly connected; when the rubber washer 27 deforms following the deformation of the steel frame 1 to disperse the pressure of the steel frame 1 on the column 2, the rubber washer 27 expands on one side and pulls the No. 2 piston rod 39 at its corresponding position. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com