Low-construction trolley for wire rope hoist

A hoist and wire rope technology, which is applied to motor vehicles, traveling mechanisms, clockwork mechanisms, etc., can solve the problems of hoisting rope wear, trolley bumping movement, wear and scratches, etc., and achieve the reduction of bending moment and drift reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

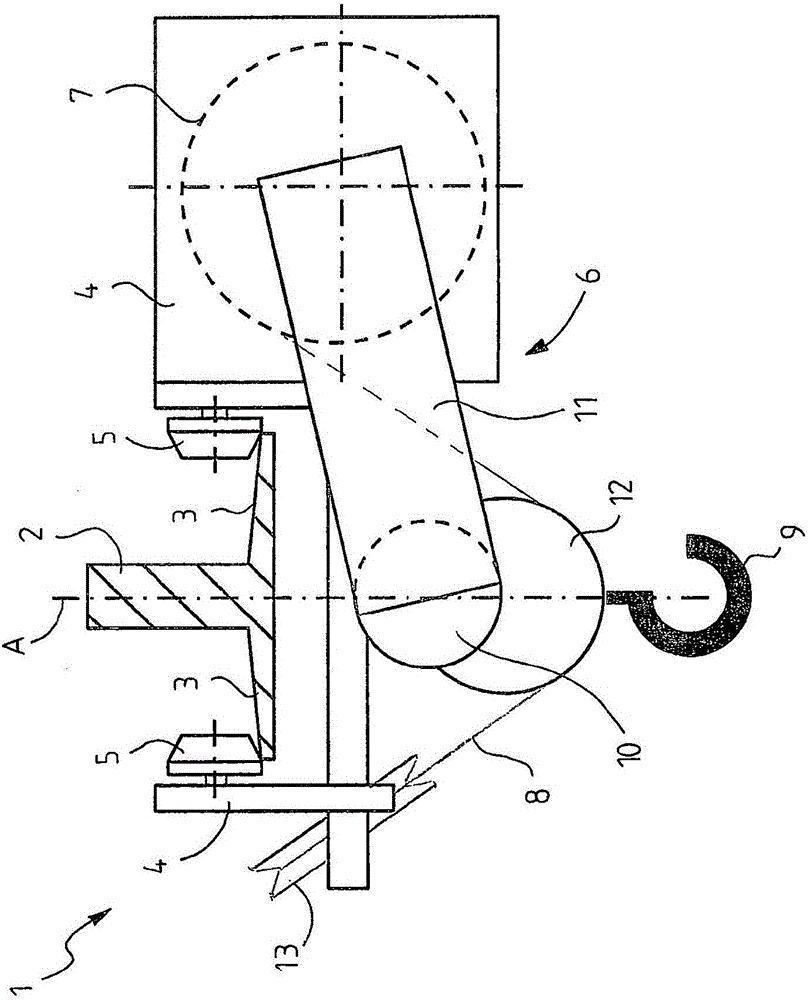

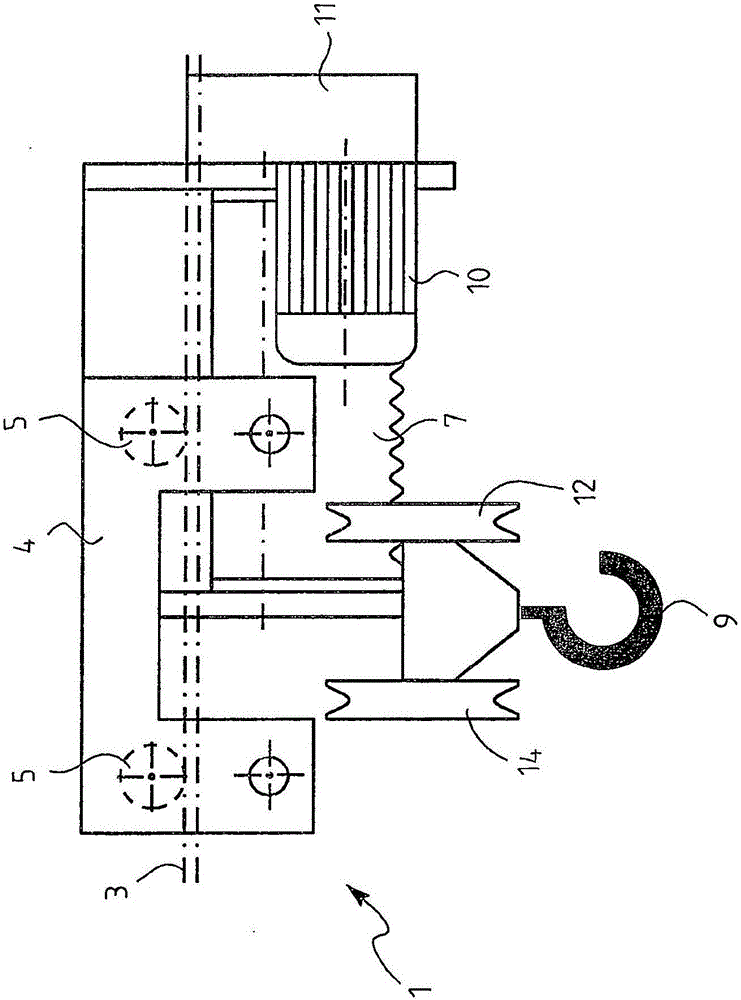

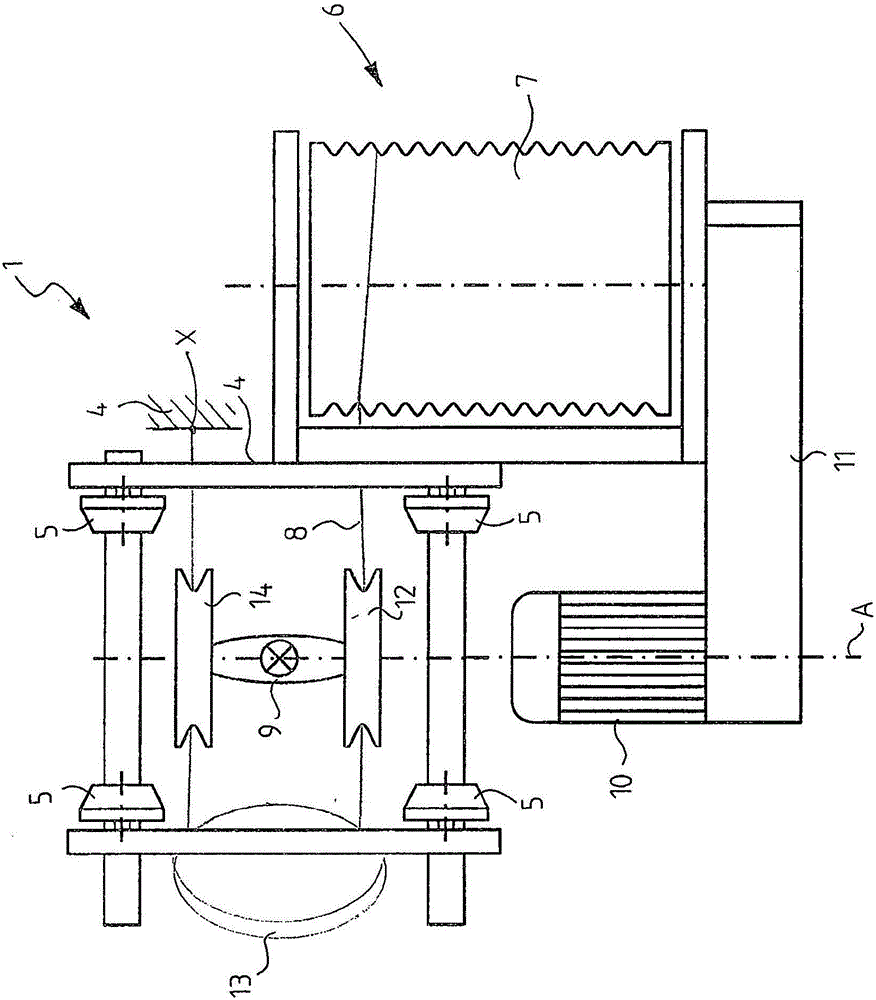

[0028] With reference to the attached drawings, first of all reference is made to Figures 1 to 3 , like here, it can be seen that a low-structure trolley 1 for a wire rope hoist is arranged to run along a horizontal beam or the lower flange 3 of a guide rail 2 . The guide rail 2 usually establishes the main support of the bridge crane or is included in the bridge crane as the lowest part of the main support of the bridge crane.

[0029] The trolley 1 is shown by means of a simplified functional diagram showing only the components required for the understanding of the invention.

[0030] The trolley 1 includes a trolley frame 4 , support wheels 5 and a lifting mechanism 6 .

[0031] Support wheels 5 are attached to the trolley frame 4 and are arranged to run on the upper surface of the lower flange 3 of the guide rail 2 on both longitudinal edges of the guide rail 2, and at least some of said support wheels are to make the platform Car 1 moves the driven wheels. The actuato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com