Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

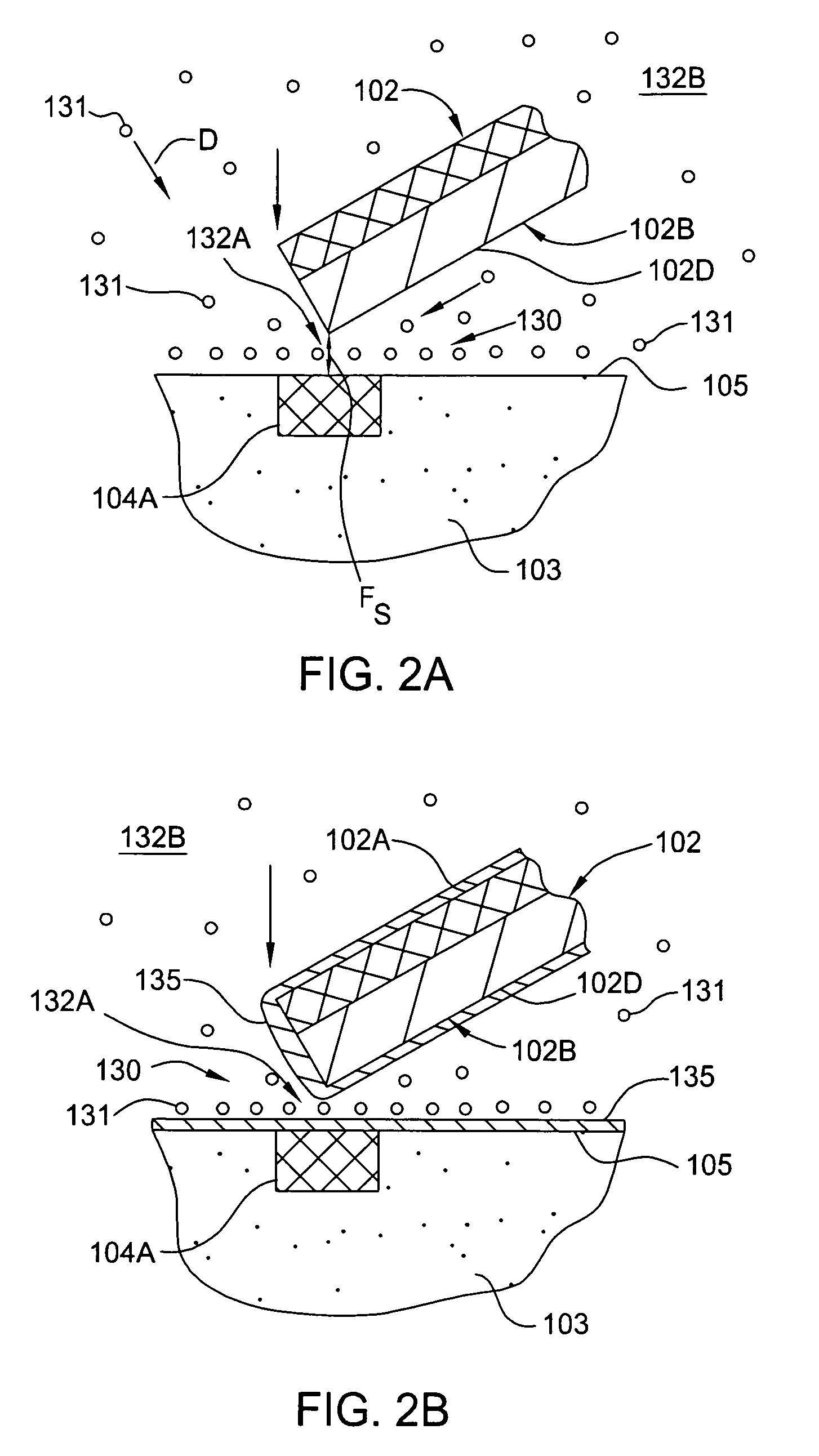

179results about How to "Reduce static friction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

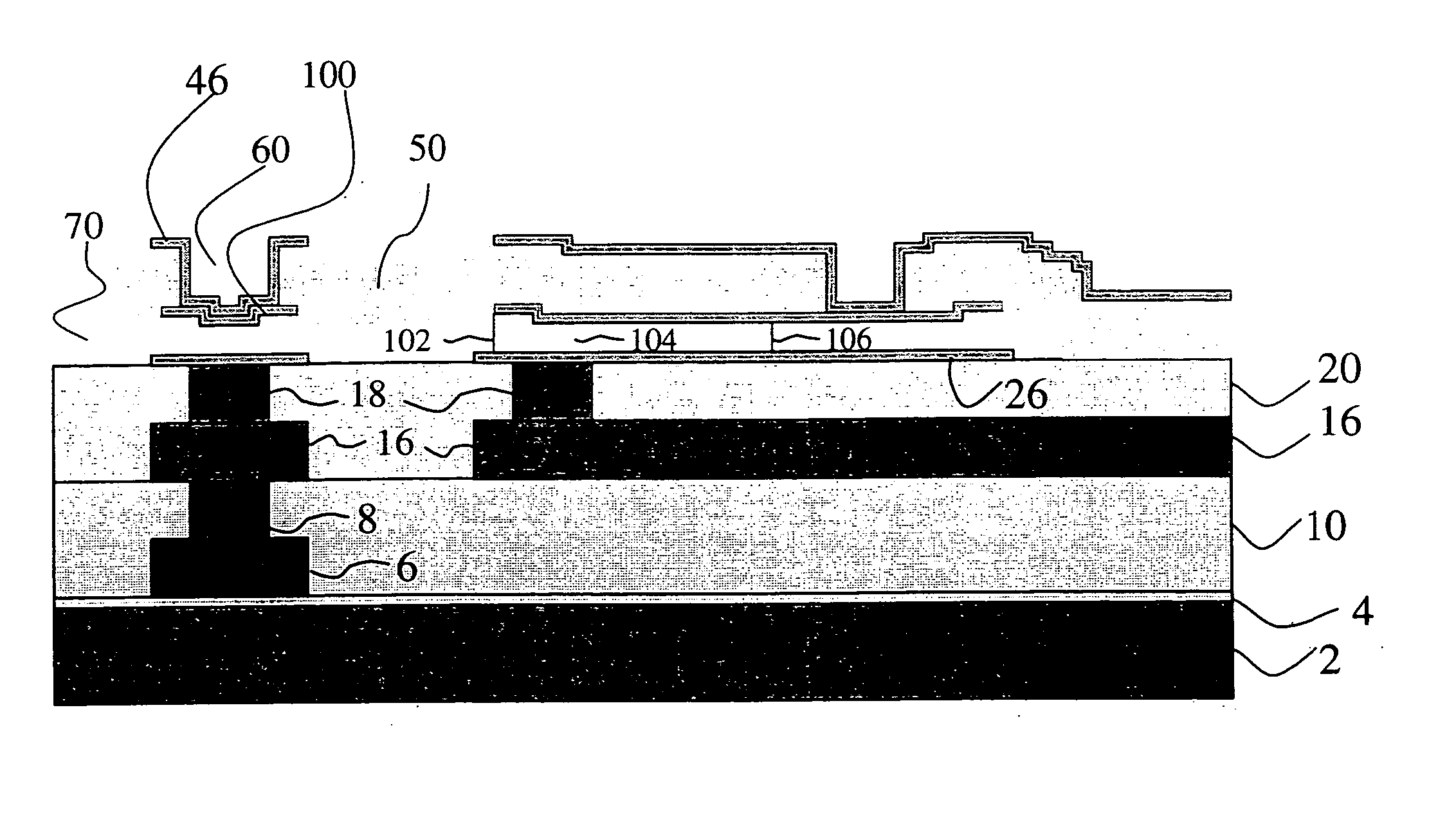

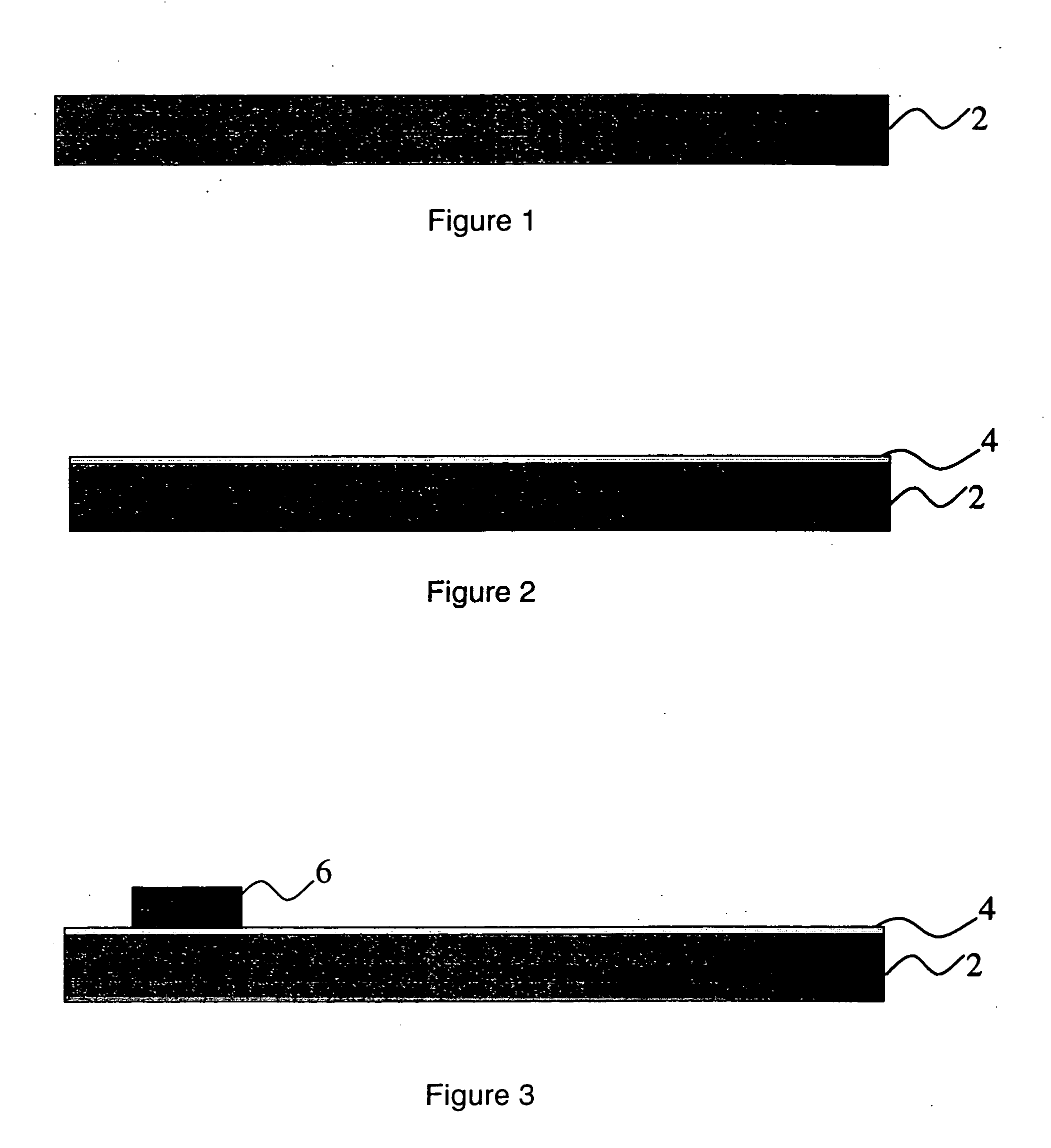

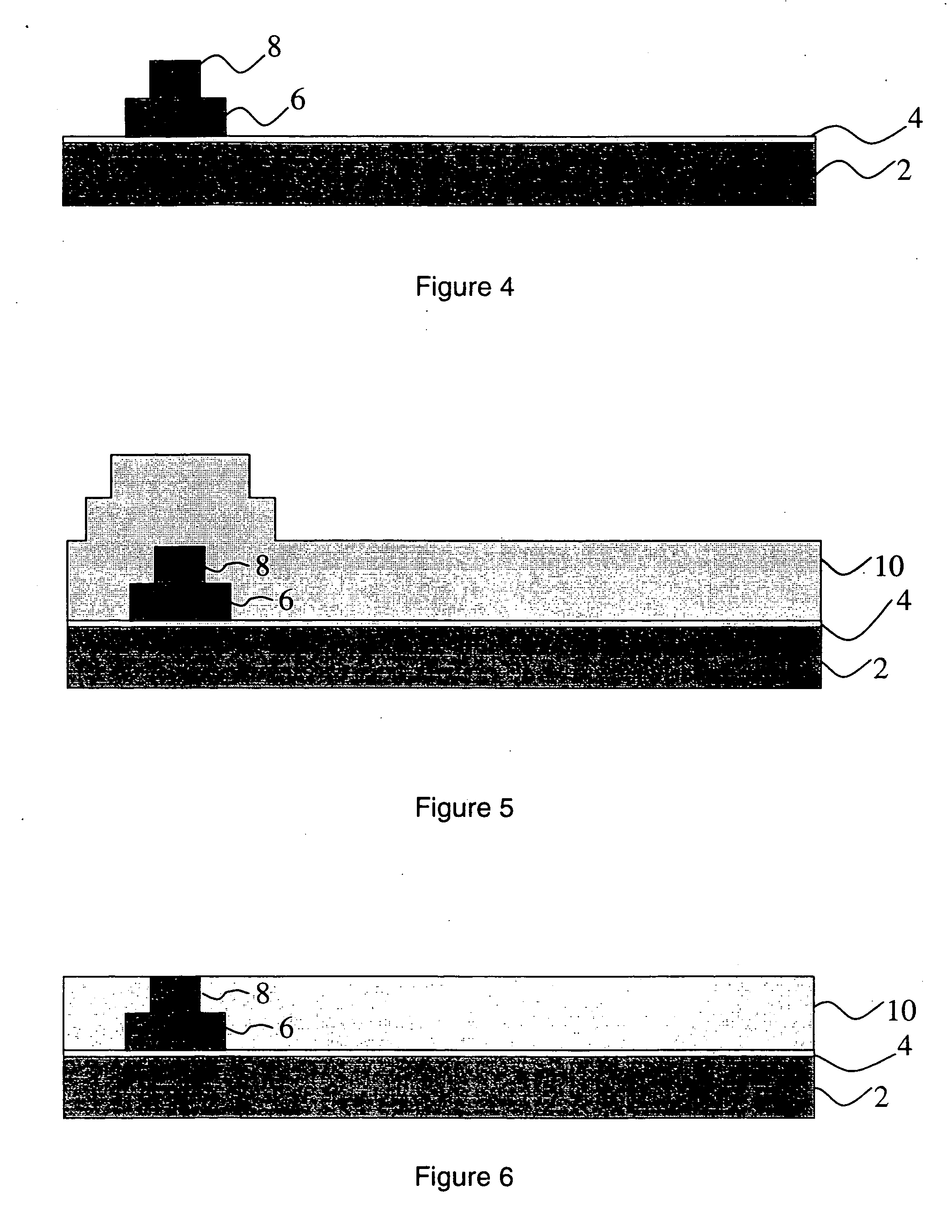

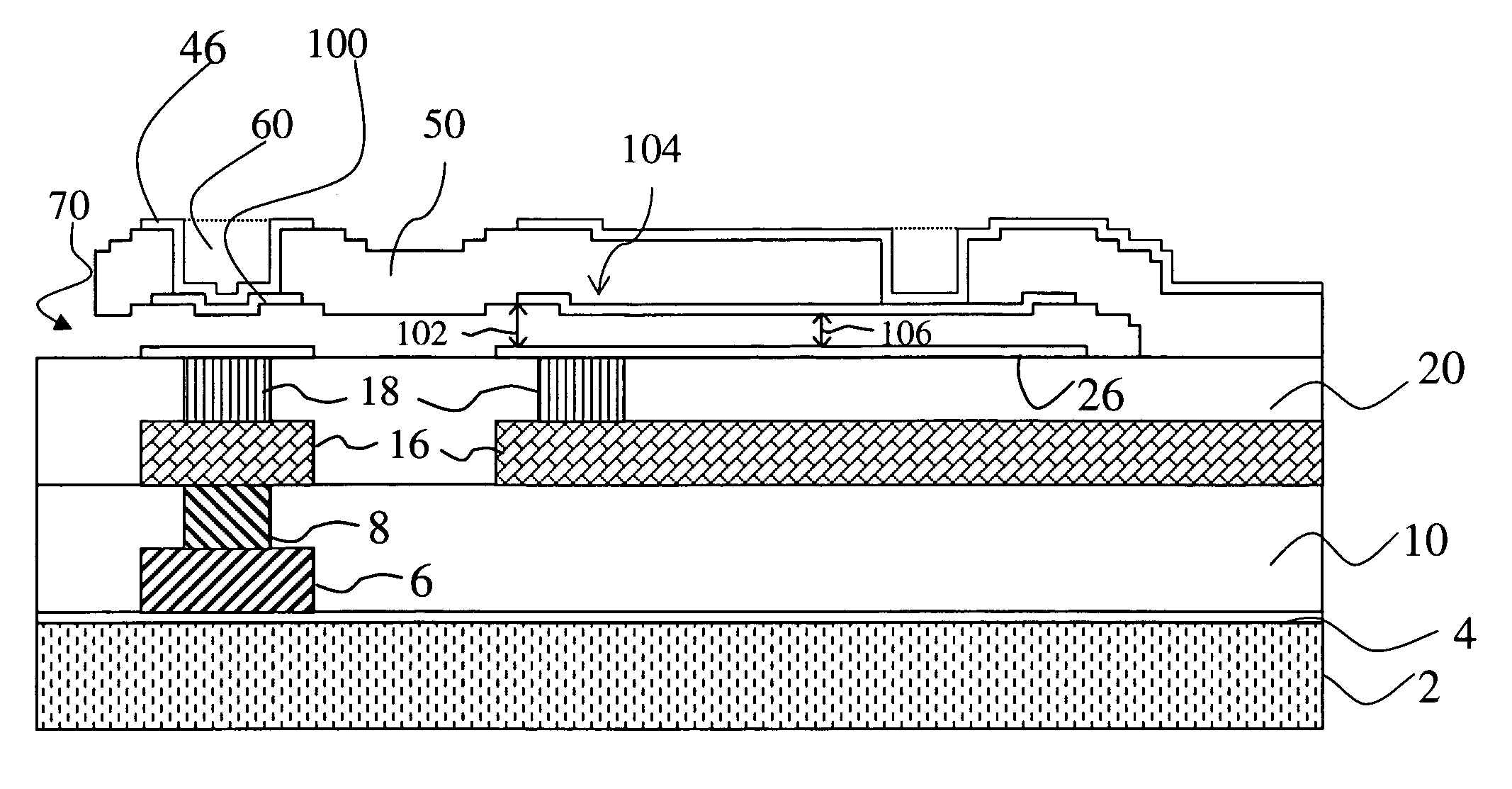

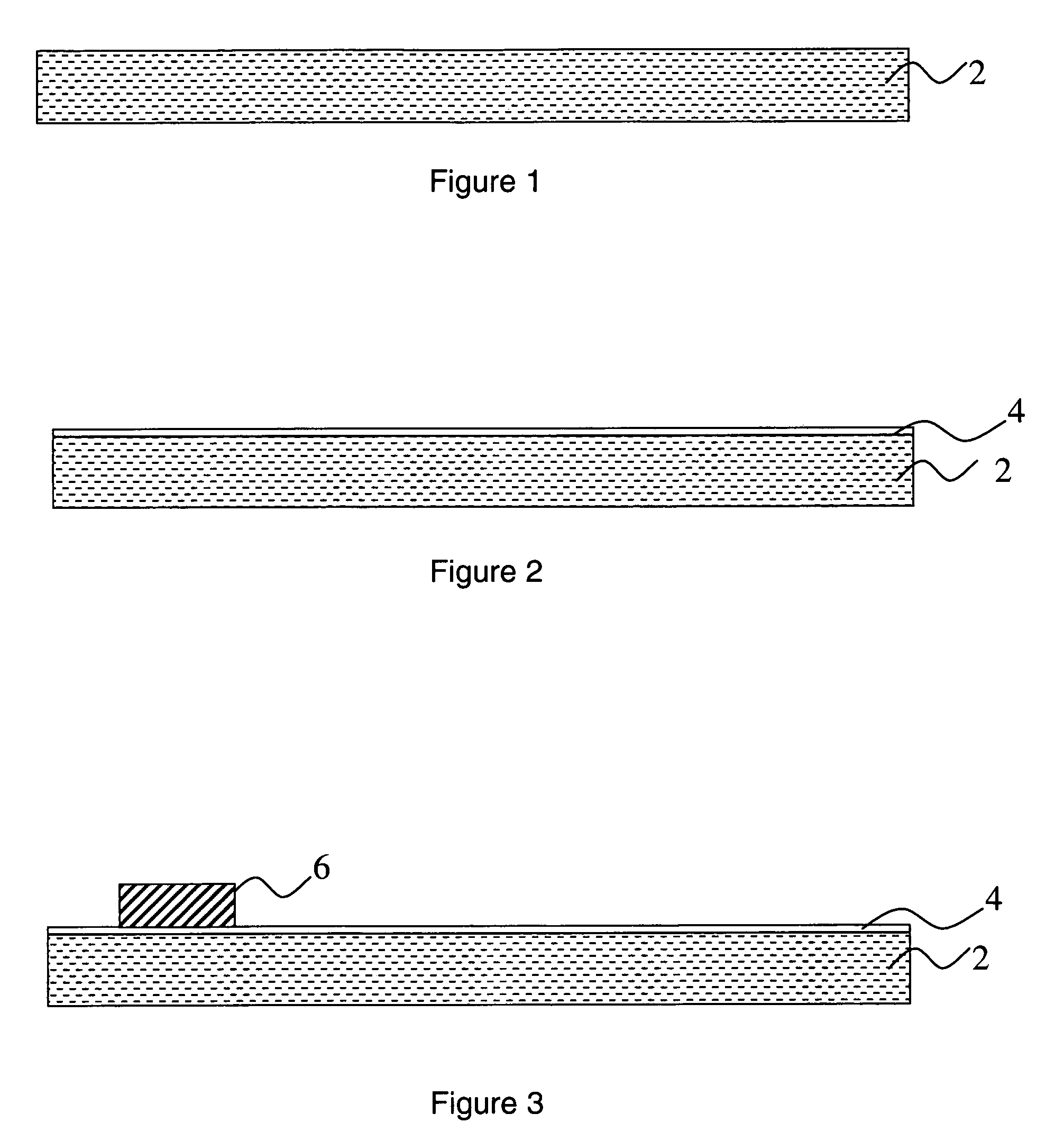

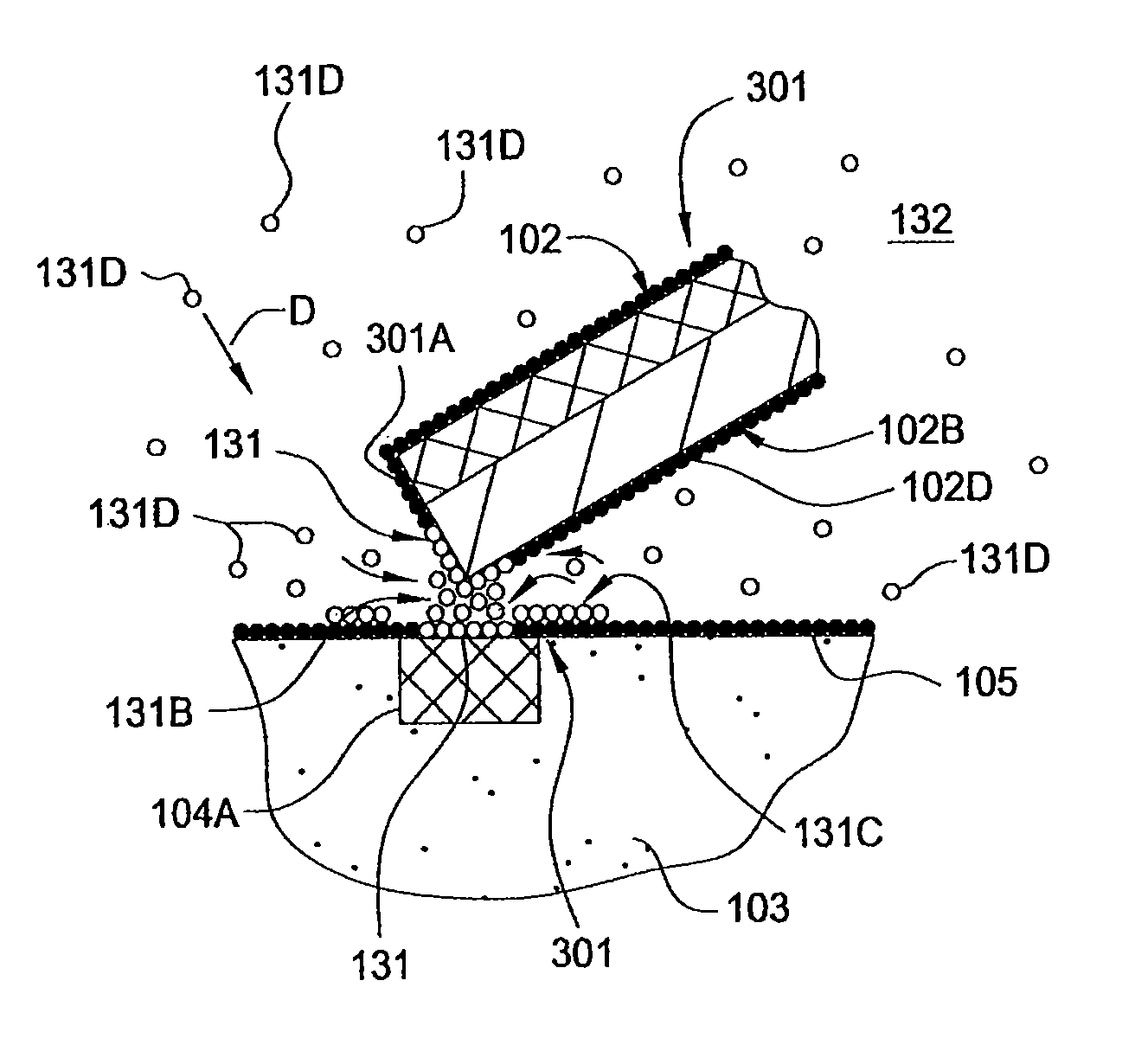

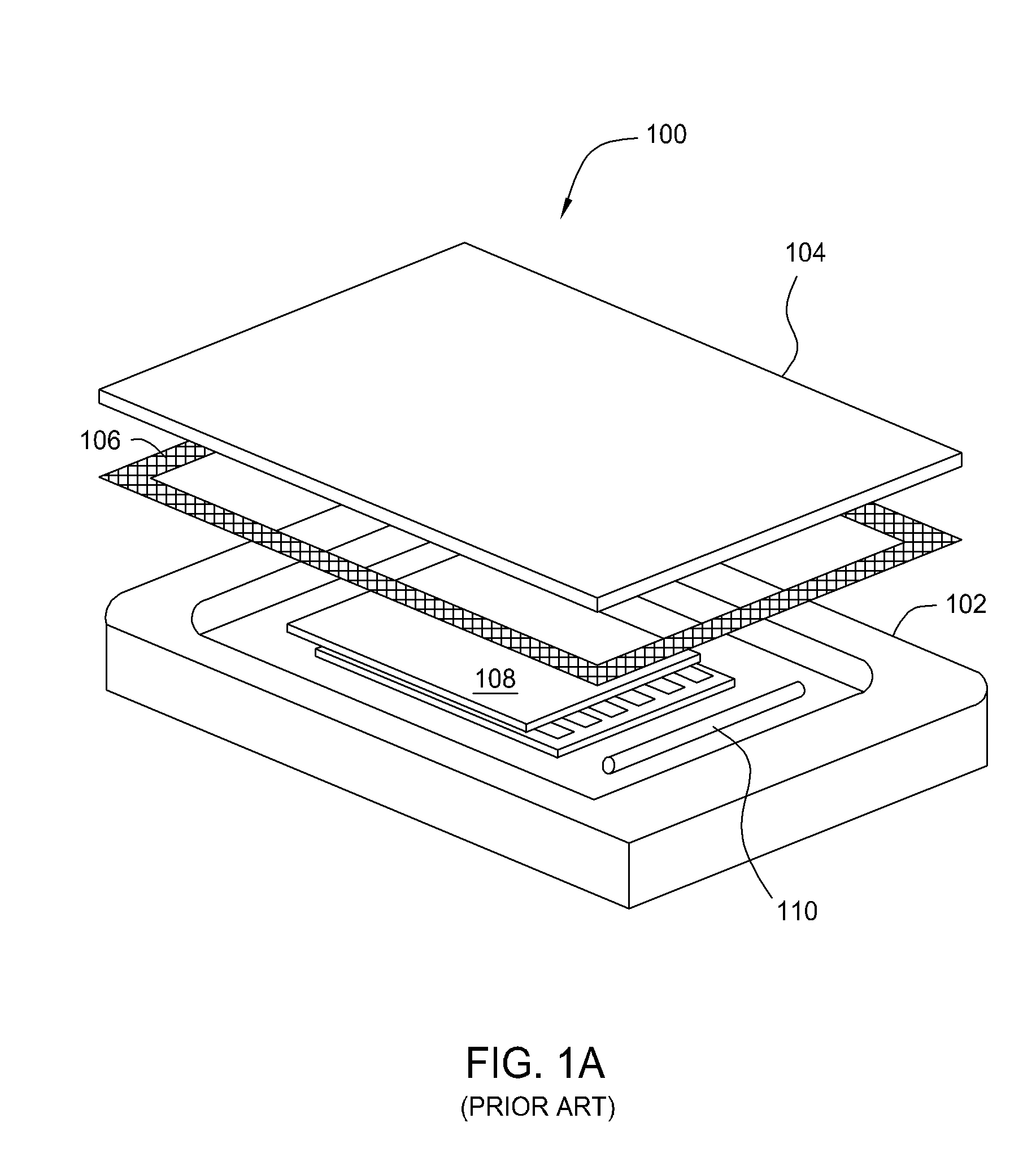

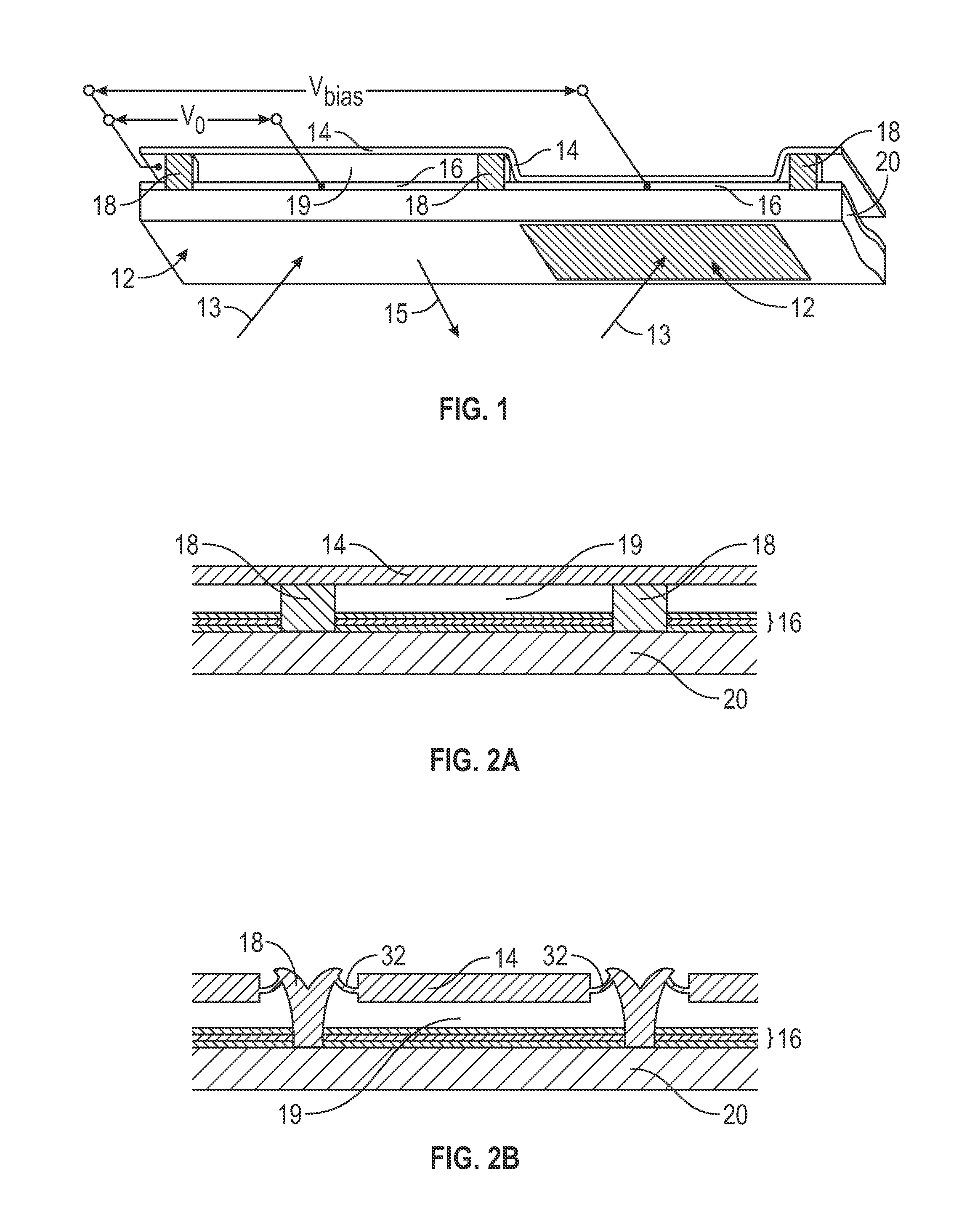

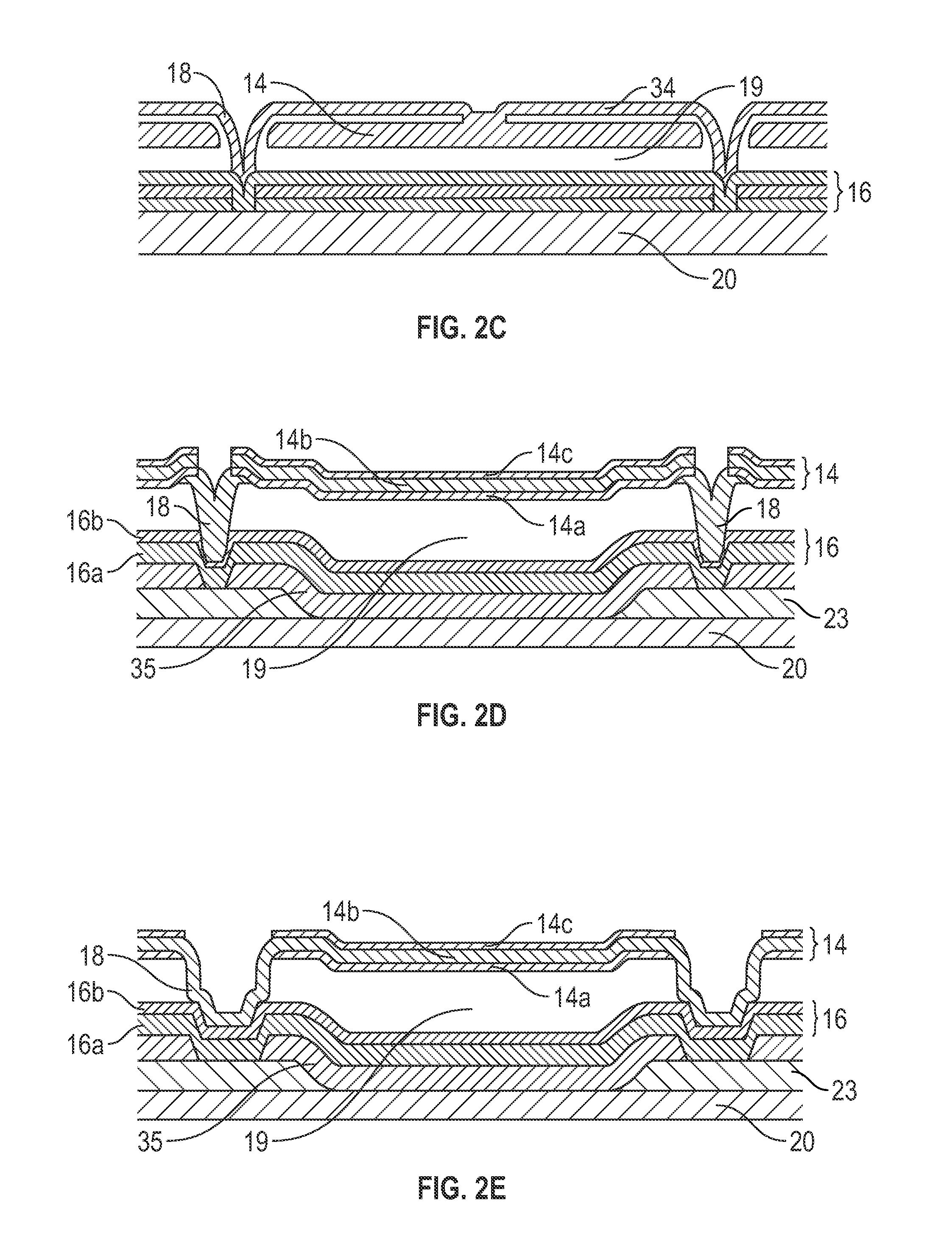

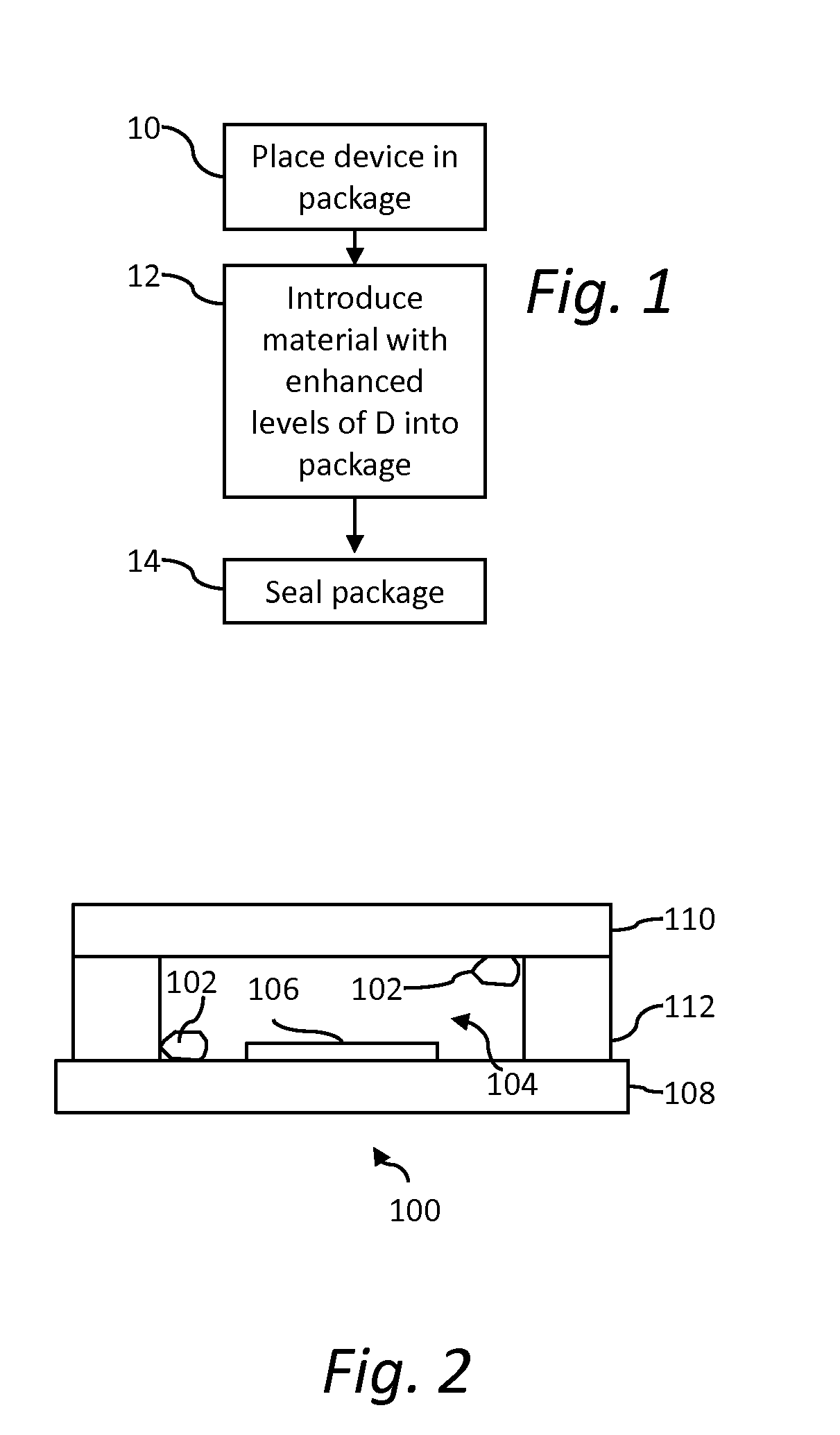

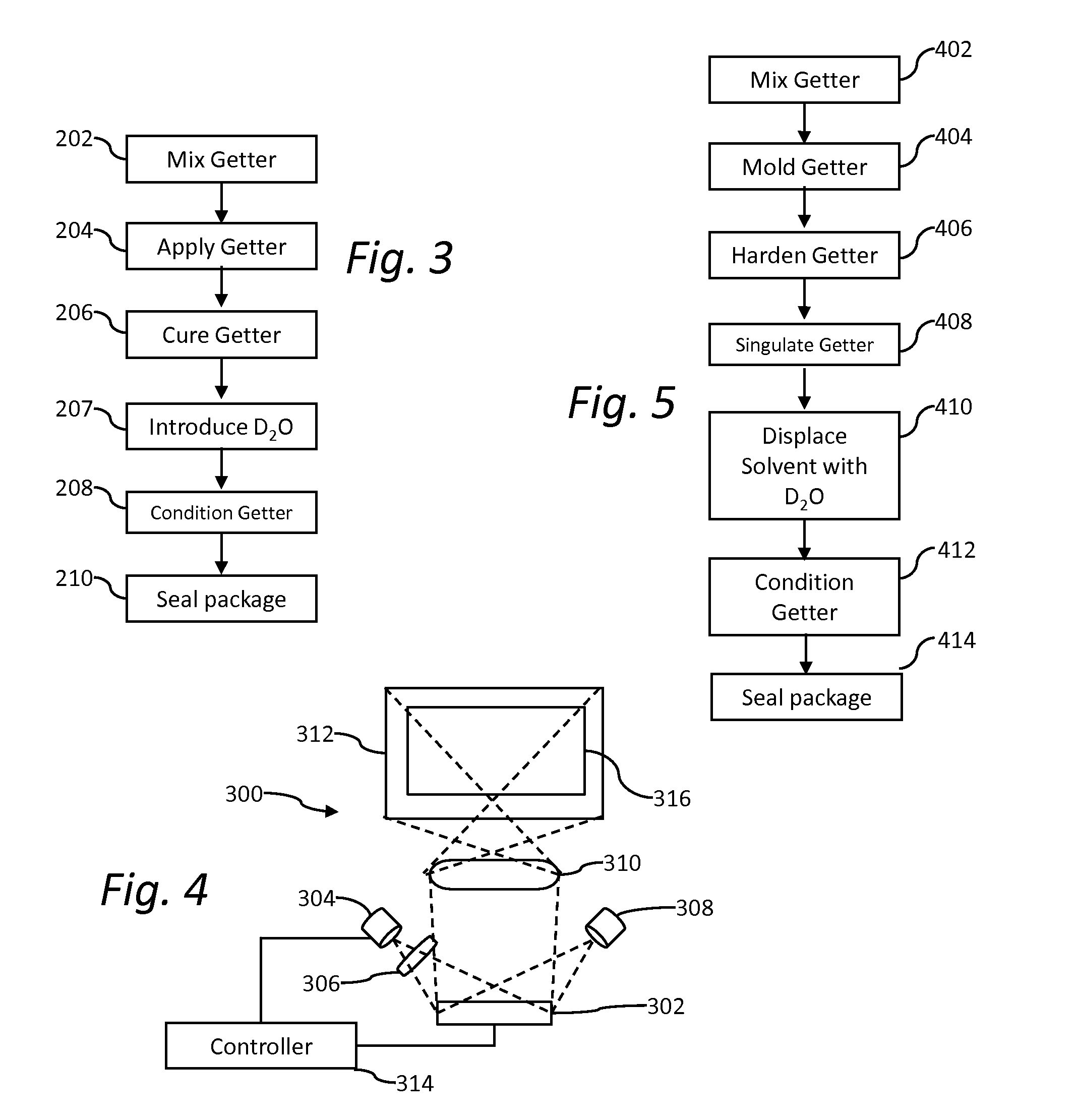

Methods for manufacturing fluid-filled mems displays

InactiveUS20080283175A1Improve performanceReduce static frictionHollow inflatable ballsHollow non-inflatable ballsDisplay deviceEngineering

This invention relates to methods of manufacturing fluid-filled MEMS displays, where the fluid is sealed in the display assembly and substantially surrounds the moving components of the display to reduce the effects of stiction and to improve the optical and electromechanical performance of the display.

Owner:SNAPTRACK

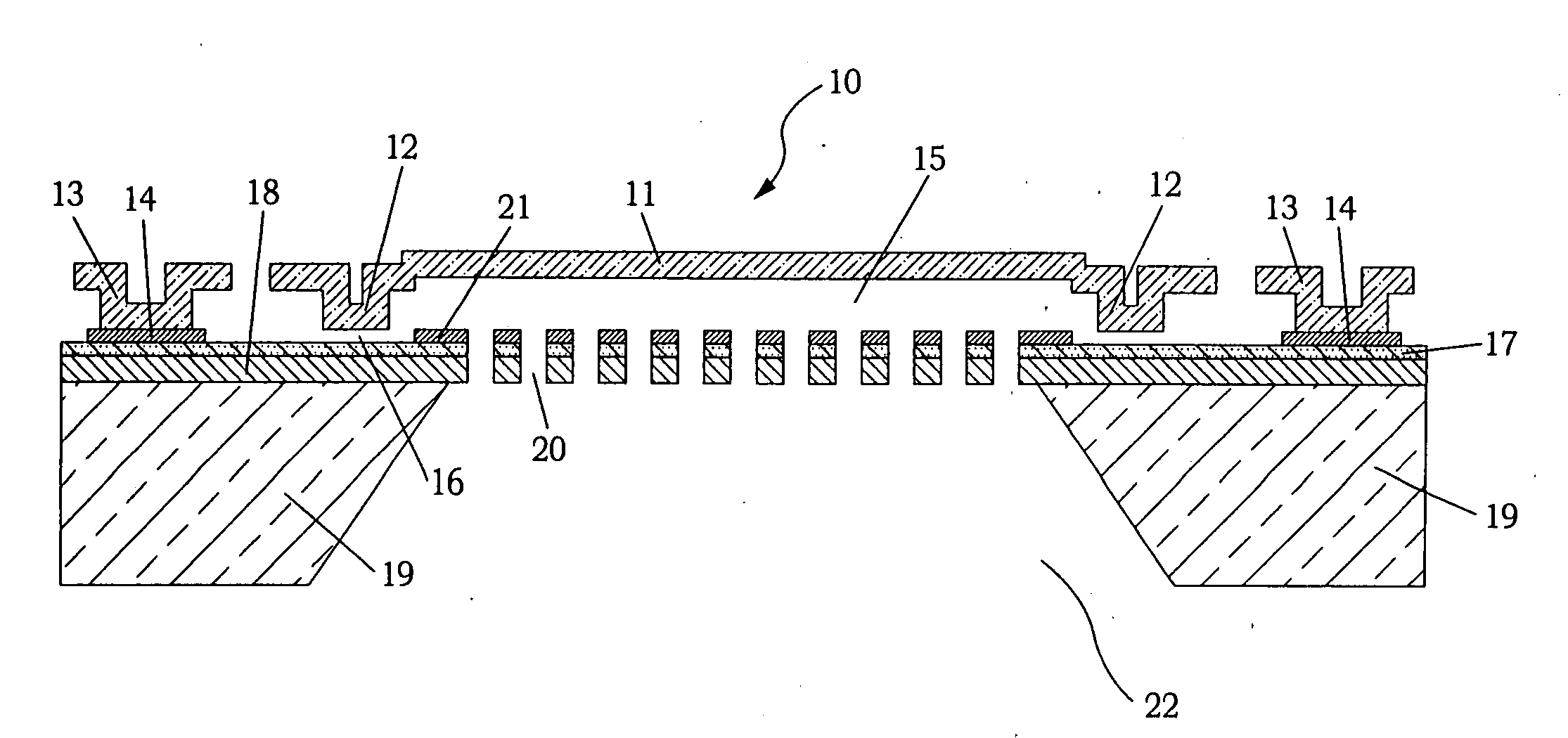

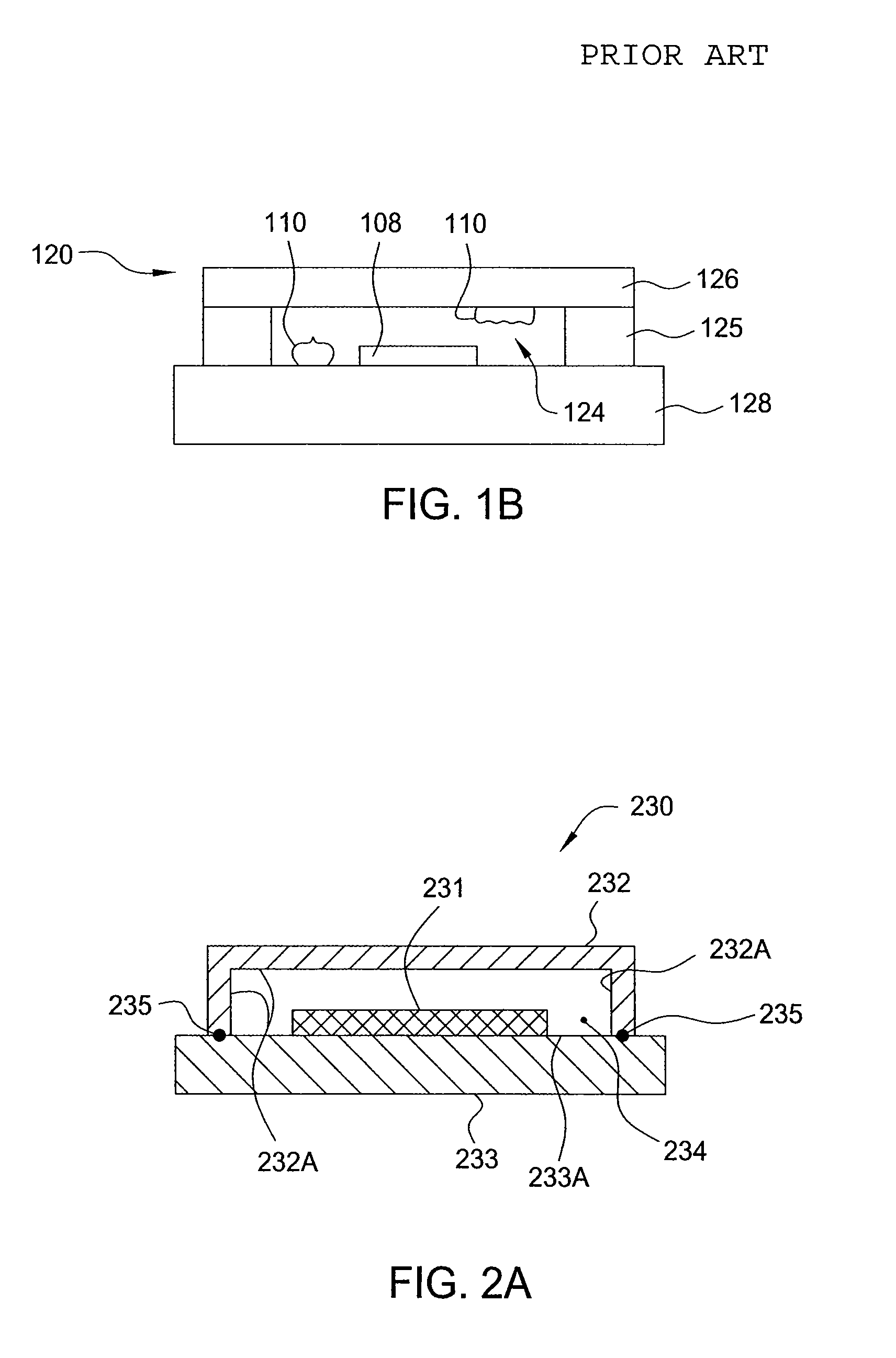

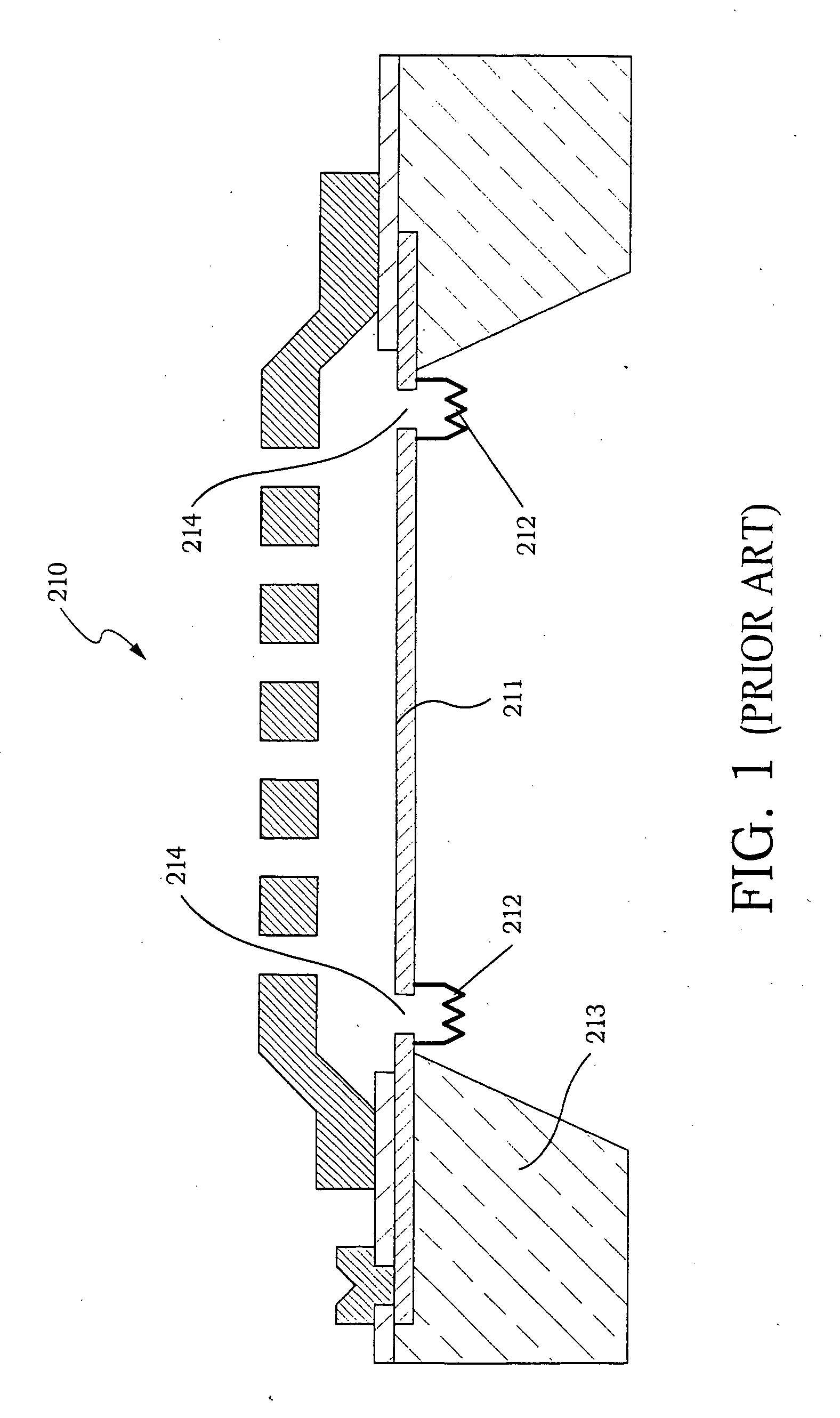

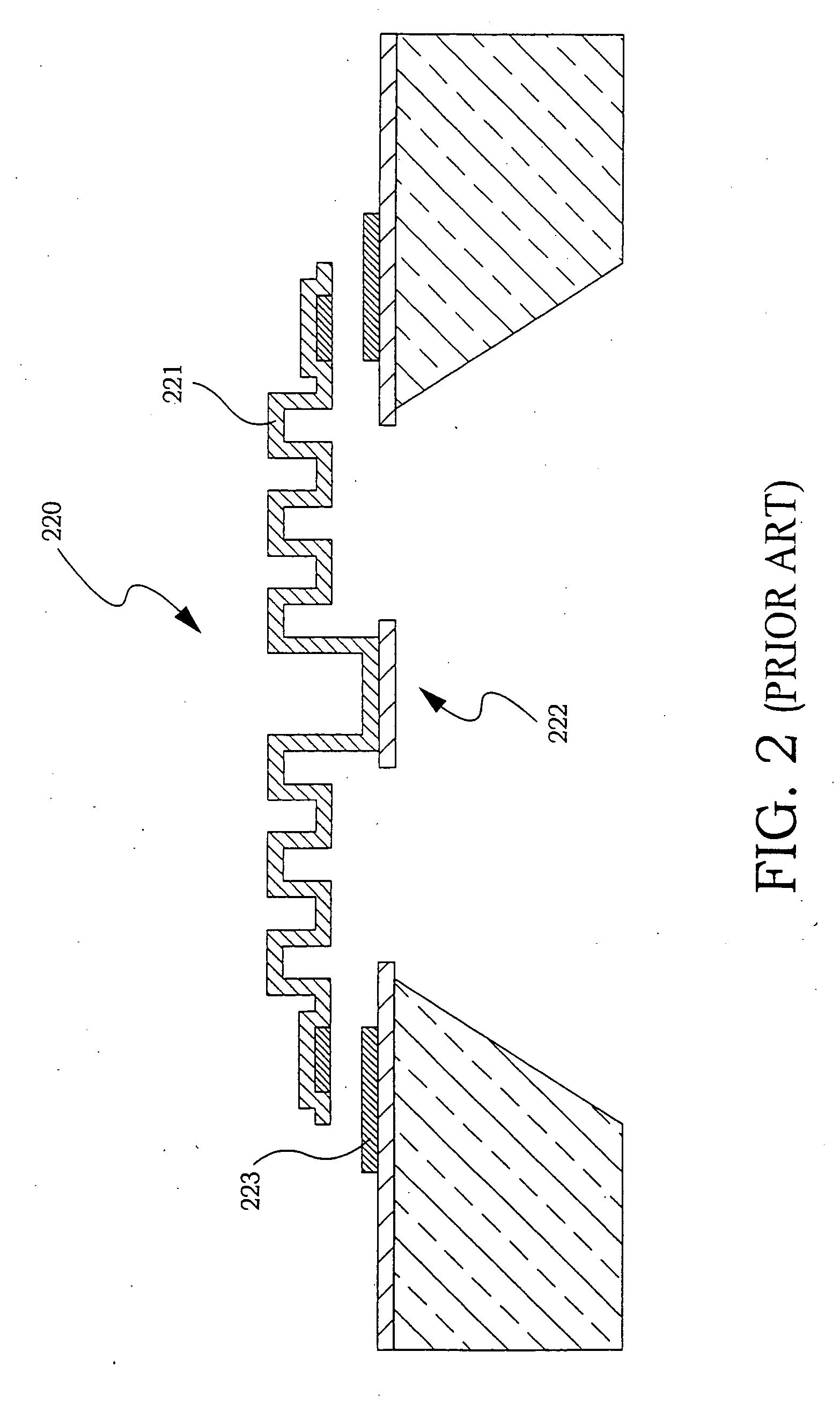

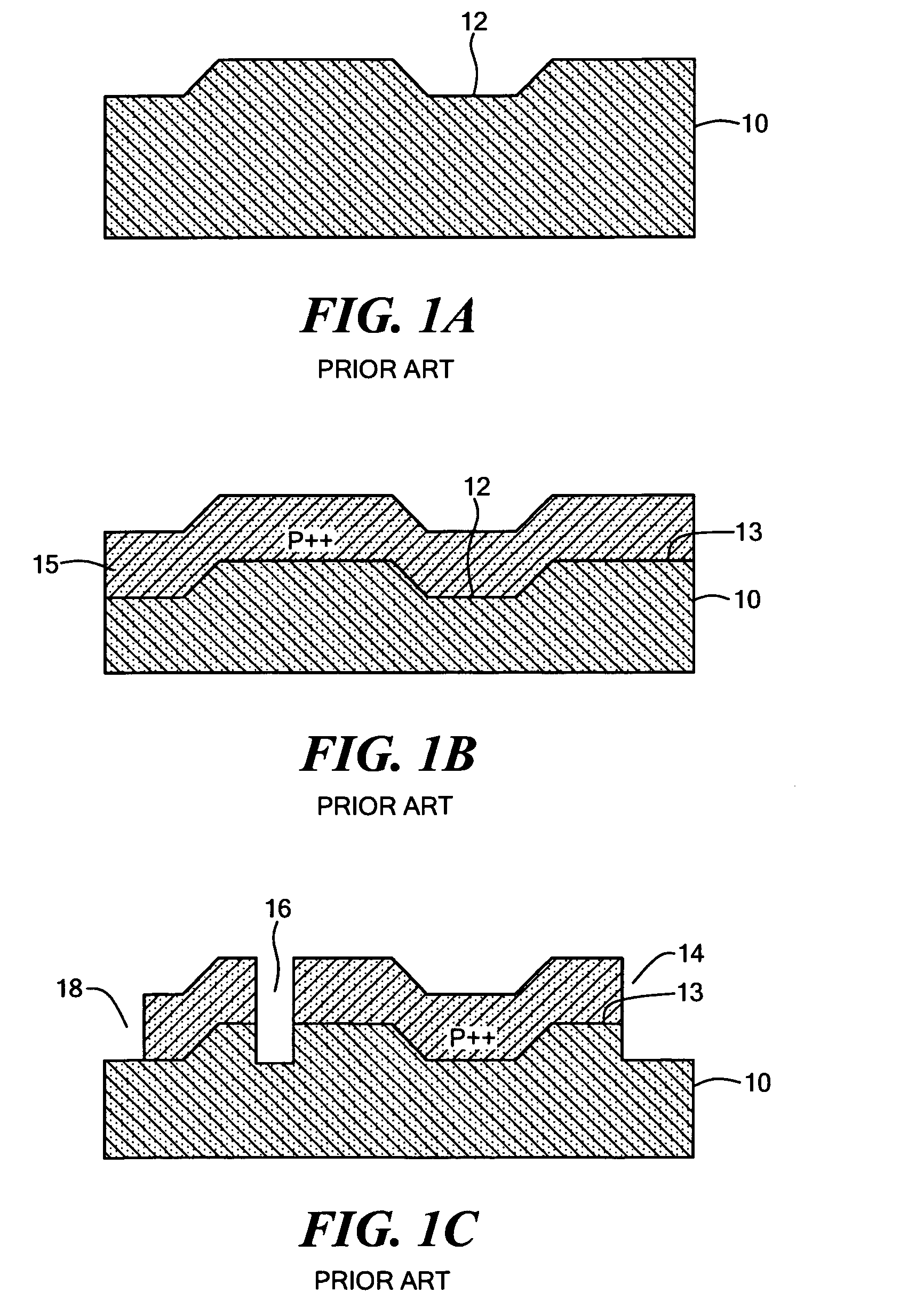

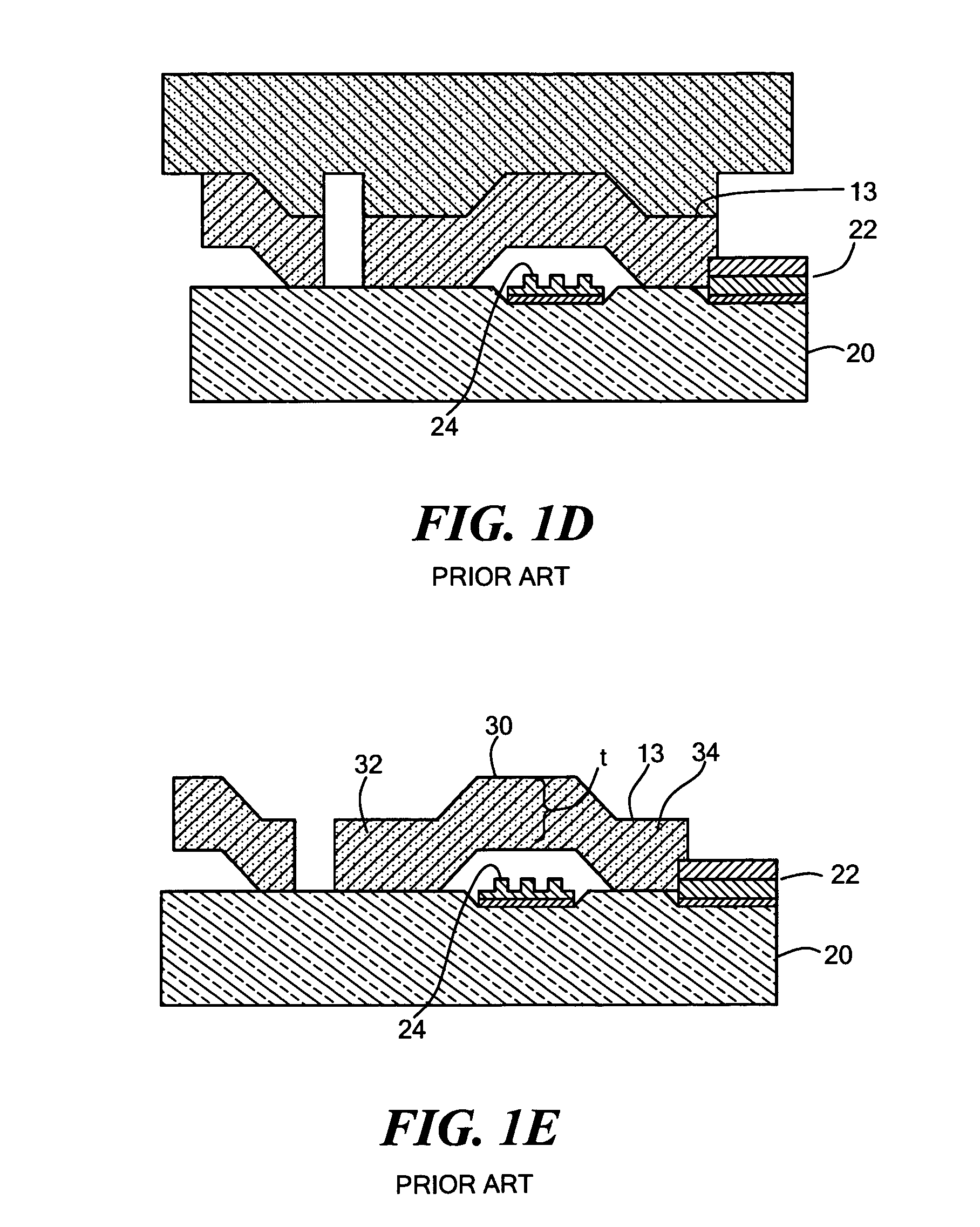

Recessed electrode for electrostatically actuated structures

InactiveUS20050048687A1Reduce the starting voltageReduce gap distanceElectrostatic/electro-adhesion relaysWave amplification devicesEmbedded systemVoltage

The present invention relates to micro-electro-mechanical systems (MEMS). The present invention relates to a design feature that allows lower actuation voltage for electrostatically actuated structures (i.e., switches or mirrors). The present invention further relates to a method for fabricating such a design that allows lower actuation voltage.

Owner:WISPRY INC

Recessed electrode for electrostatically actuated structures

InactiveUS7064637B2Reduce the starting voltageReduce gap distanceElectrostatic/electro-adhesion relaysElectrostrictive/piezoelectric relaysStictionVoltage

An electro-statically actuated switch having a reduced gap distance between electrodes for reducing actuation voltage is provided. The invention provides more reliable electro-statically actuated switches. The invention provides a micro-electro-mechanical system (MEMS) that includes a recessed, movable electrode. The invention provides electro-statically actuated switches that reduce the likelihood of stiction and beam deformation and that allows lower actuation voltage for electrostatically actuated structures such as switches and mirrors. A method for fabricating such a design is provided that allows lower actuation voltage.

Owner:AAC TECH PTE LTD

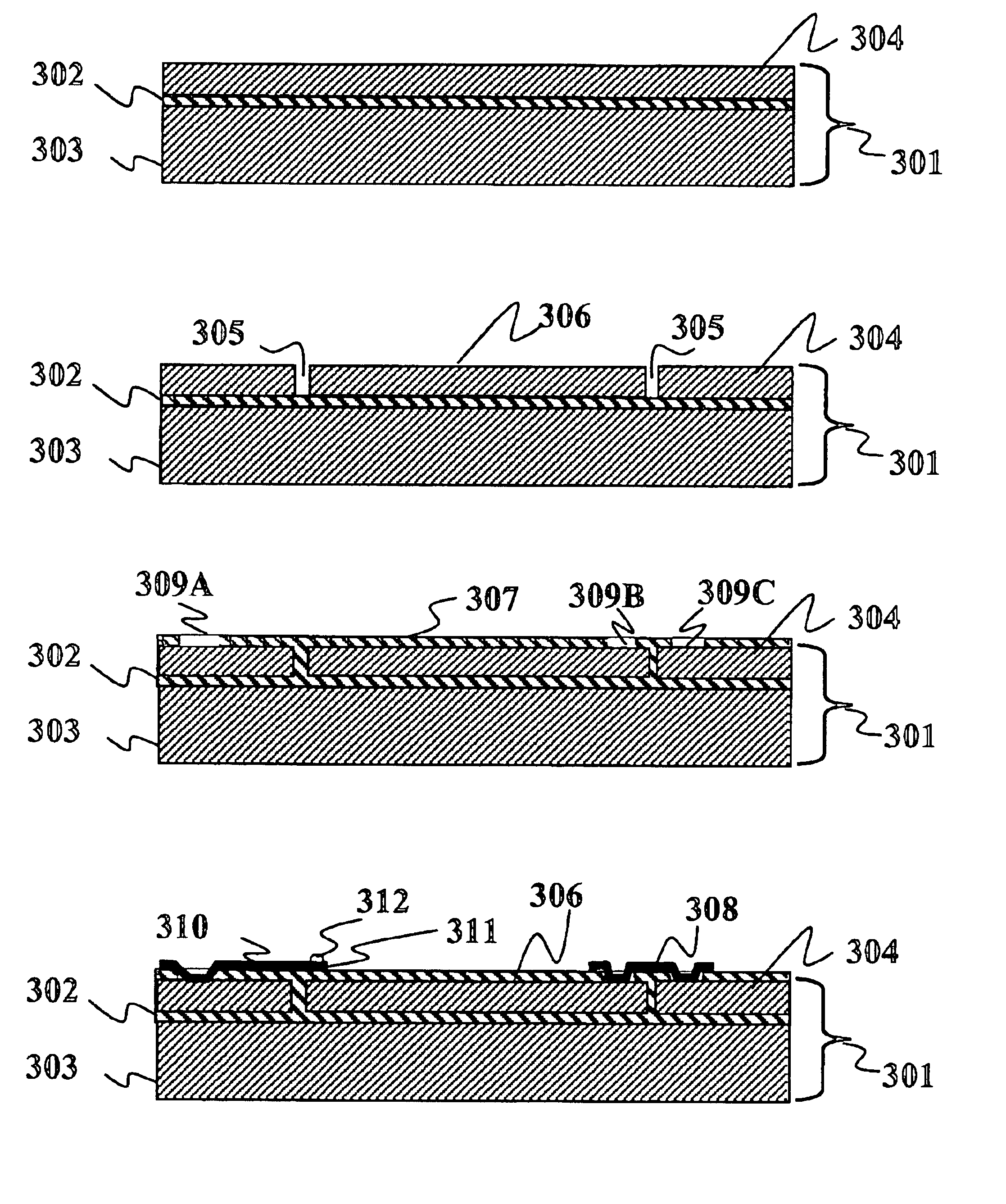

Miniature condenser microphone and fabrication method therefor

ActiveUS20060210106A1Cost reductionMinimize impactPiezoelectric/electrostrictive microphonesPiezoelectric/electrostriction/magnetostriction machinesPressure sensitiveElectrically conductive

An acoustic pressure type sensor fabricated on a supporting substrate is disclosed. The acoustic sensor is fabricated by depositing and etching a number of thin films on the supporting substrate and by machining the supporting substrate. The resulting structure contains a pressure sensitive, electrically conductive diaphragm positioned at a distance from an electrically conductive fixed electrode. In operation, the diaphragm deflects in response to an acoustic pressure and the corresponding change of electrical capacitance between the diaphragm and the fixed electrode is detected using an electrical circuit. Two or more such acoustic sensors are combined on the same supporting substrate with an interaural flexible mechanical connection, to form a directional sensor with a small surface area.

Owner:FOR NAT RES INITIATIVES

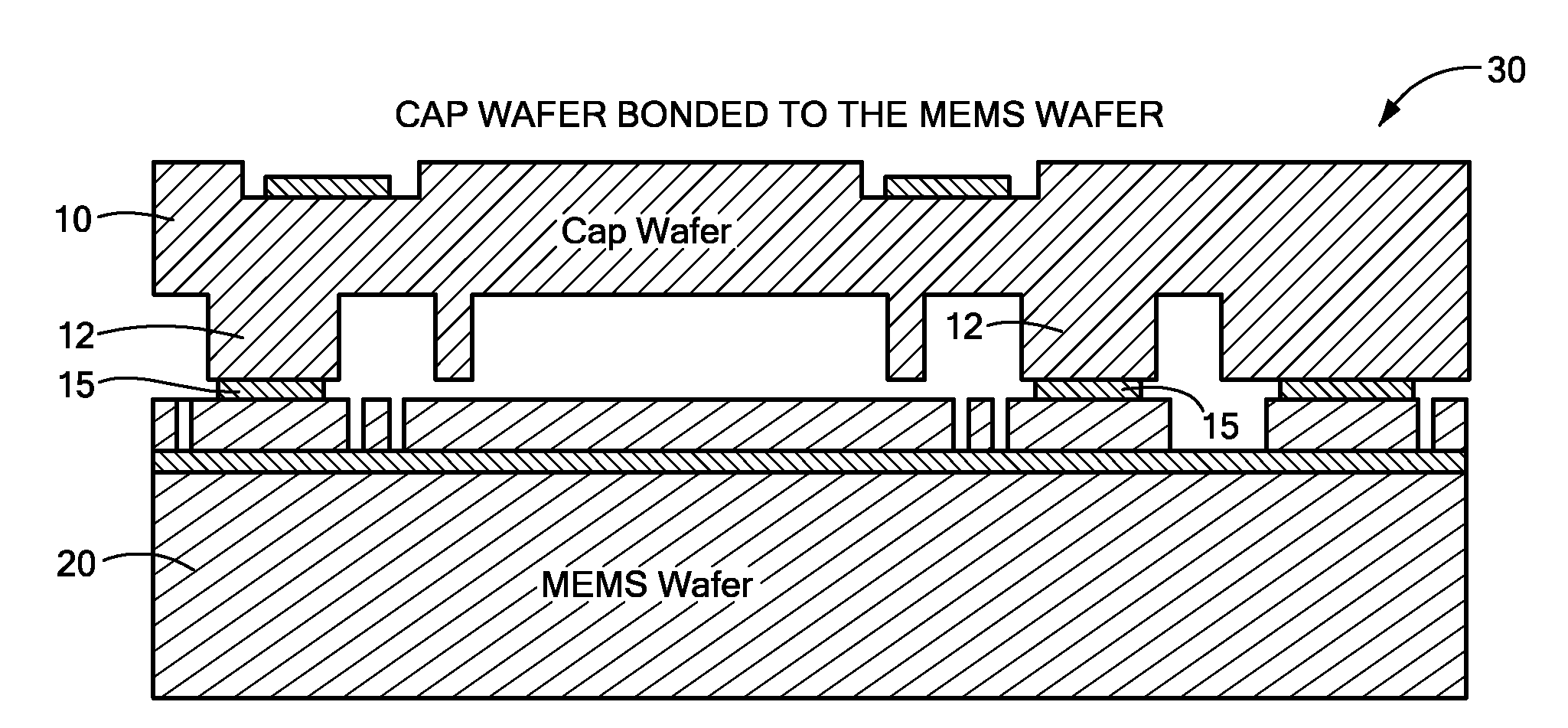

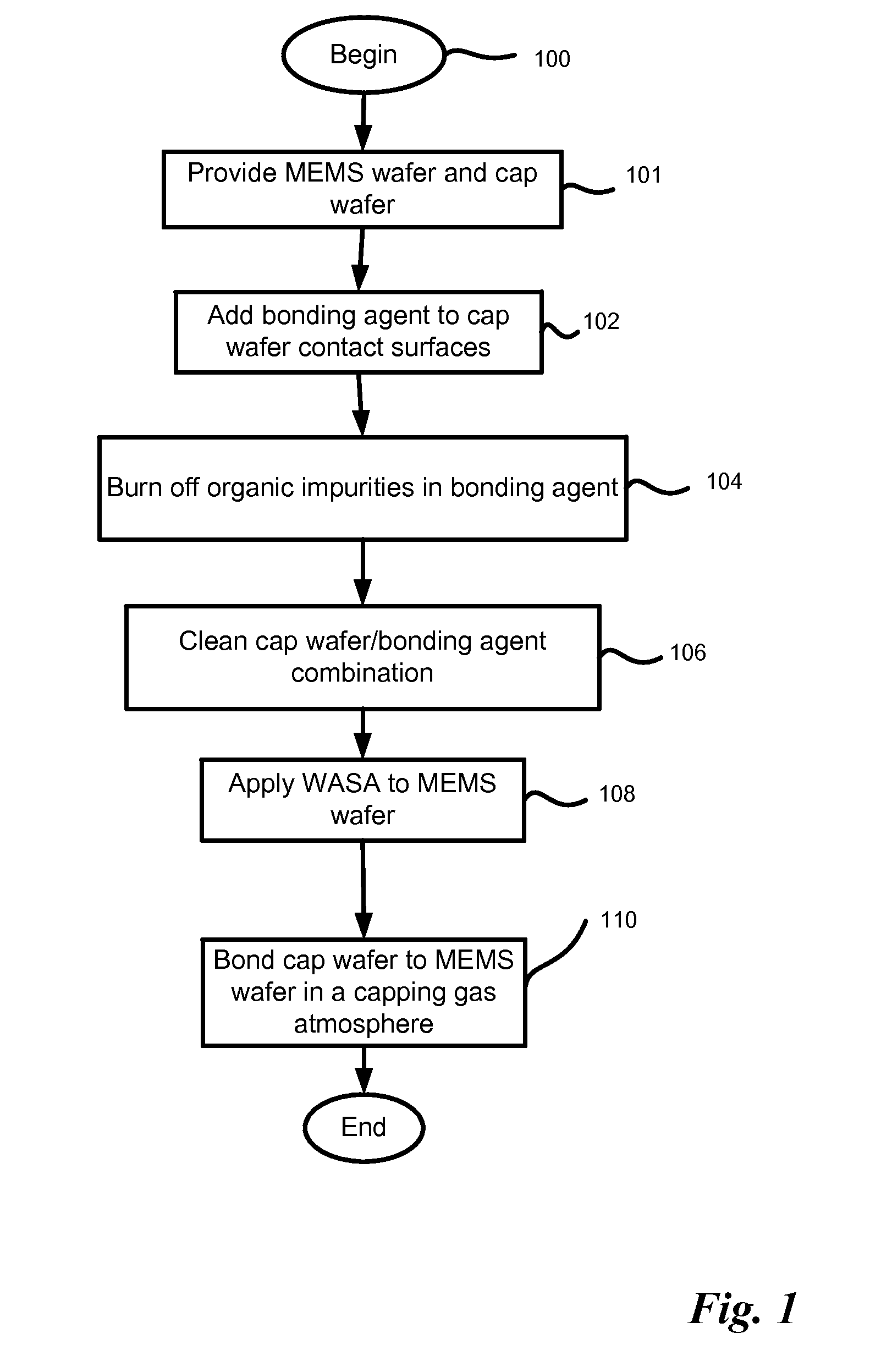

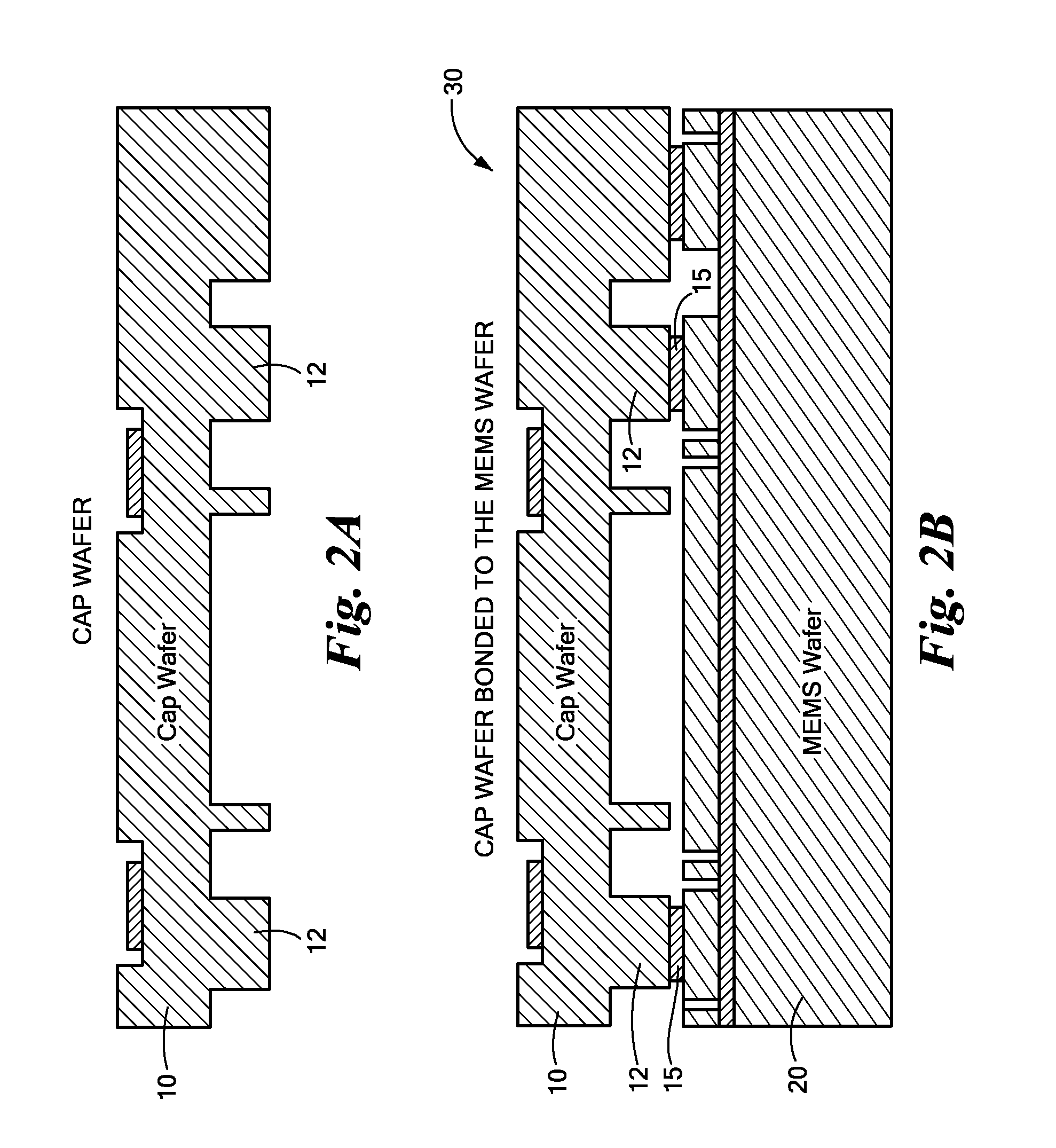

Method for Capping a MEMS Wafer

ActiveUS20090294879A1Reduce static frictionSemiconductor/solid-state device detailsSolid-state devicesNeonEngineering

A method for capping a MEMS wafer to form a hermetically sealed device. The method includes applying a glass bonding agent to the cap wafer and burning off organic material in the glass bonding agent. The cap wafer / glass bonding agent combination is then cleaned to reduce lead in the combination. The cleaning is preferably accomplished using an oxygen plasma. The MEMS device is coated with a WASA agent. The cap wafer is then bonded to the MEMS wafer by heating this combination in a capping gas atmosphere of hydrogen molecules in a gas such as nitrogen, argon or neon. This method of capping the MEMS wafer can reduce stiction in the MEMS device.

Owner:ANALOG DEVICES INC

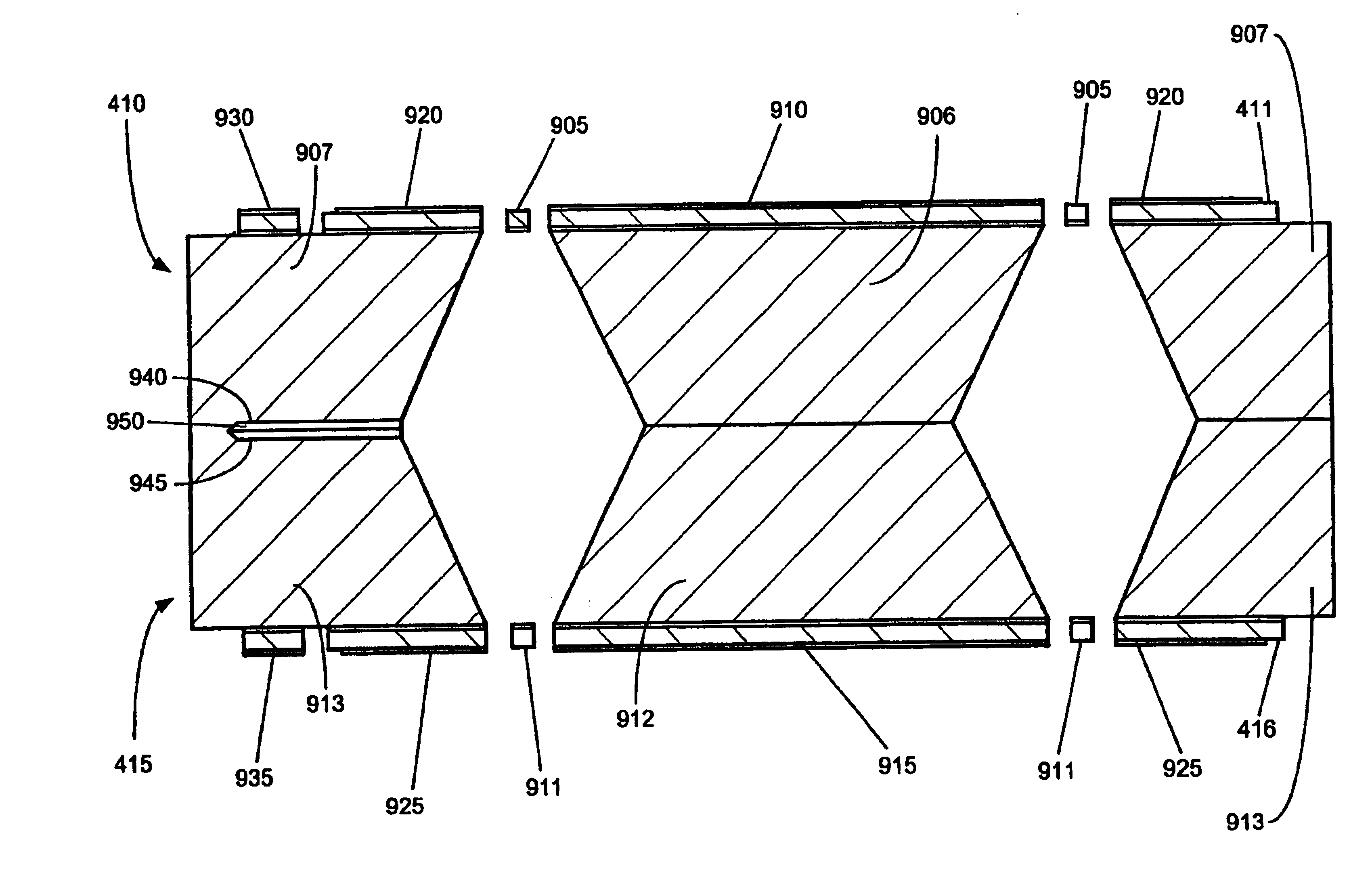

Sensor design and process

InactiveUS6871544B1Reduce static frictionReliable measurementAcceleration measurement using interia forcesSemiconductor/solid-state device manufacturingAccelerometerEngineering

An accelerometer (305) for measuring seismic data. The accelerometer (305) includes an integrated vent hole for use during a vacuum sealing process and a balanced metal pattern for reducing cap wafer bowing. The accelerometer (305) also includes a top cap press frame recess (405) and a bottom cap press frame recess (420) for isolating bonding pressures to specified regions of the accelerometer (305). The accelerometer (305) is vacuum-sealed and includes a balanced metal pattern (730) to prevent degradation of the performance of the accelerometer (305). A dicing process is performed on the accelerometer (305) to isolate the electrical leads of the accelerometer (305). The accelerometer (305) further includes overshock protection bumpers (720) and patterned metal electrodes to reduce stiction during the operation of the accelerometer (305).

Owner:INPUT OUTPUT INC

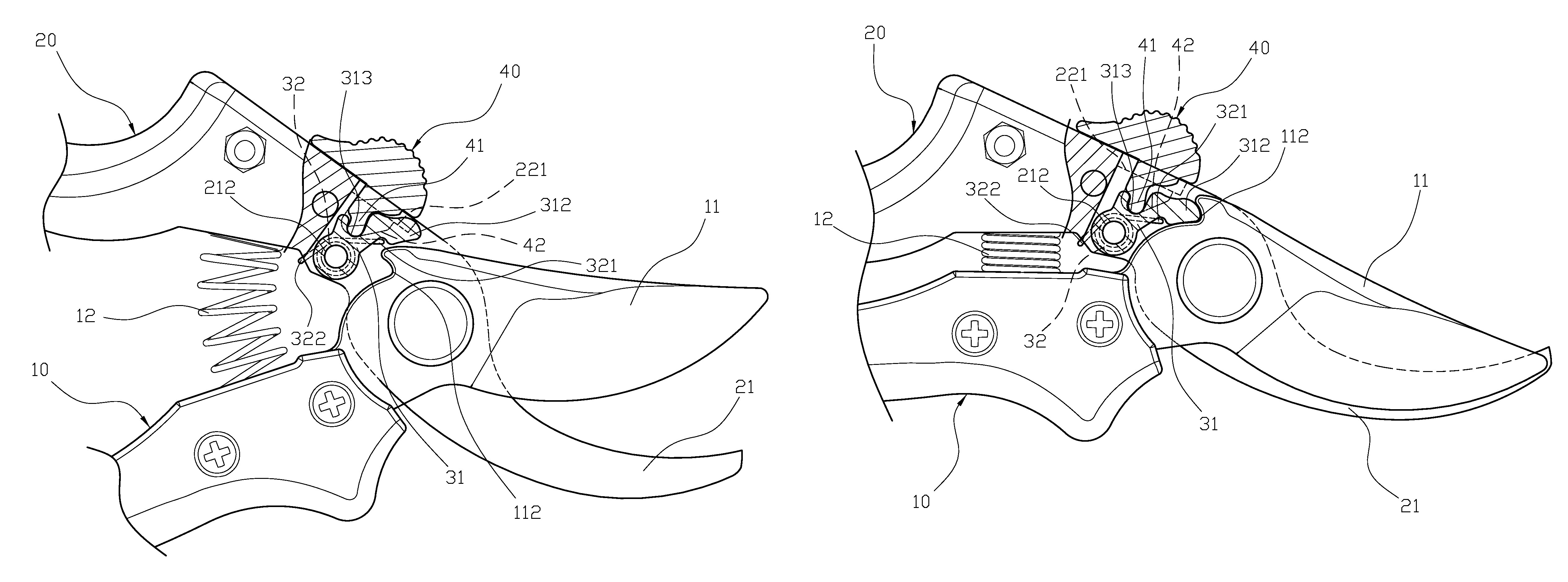

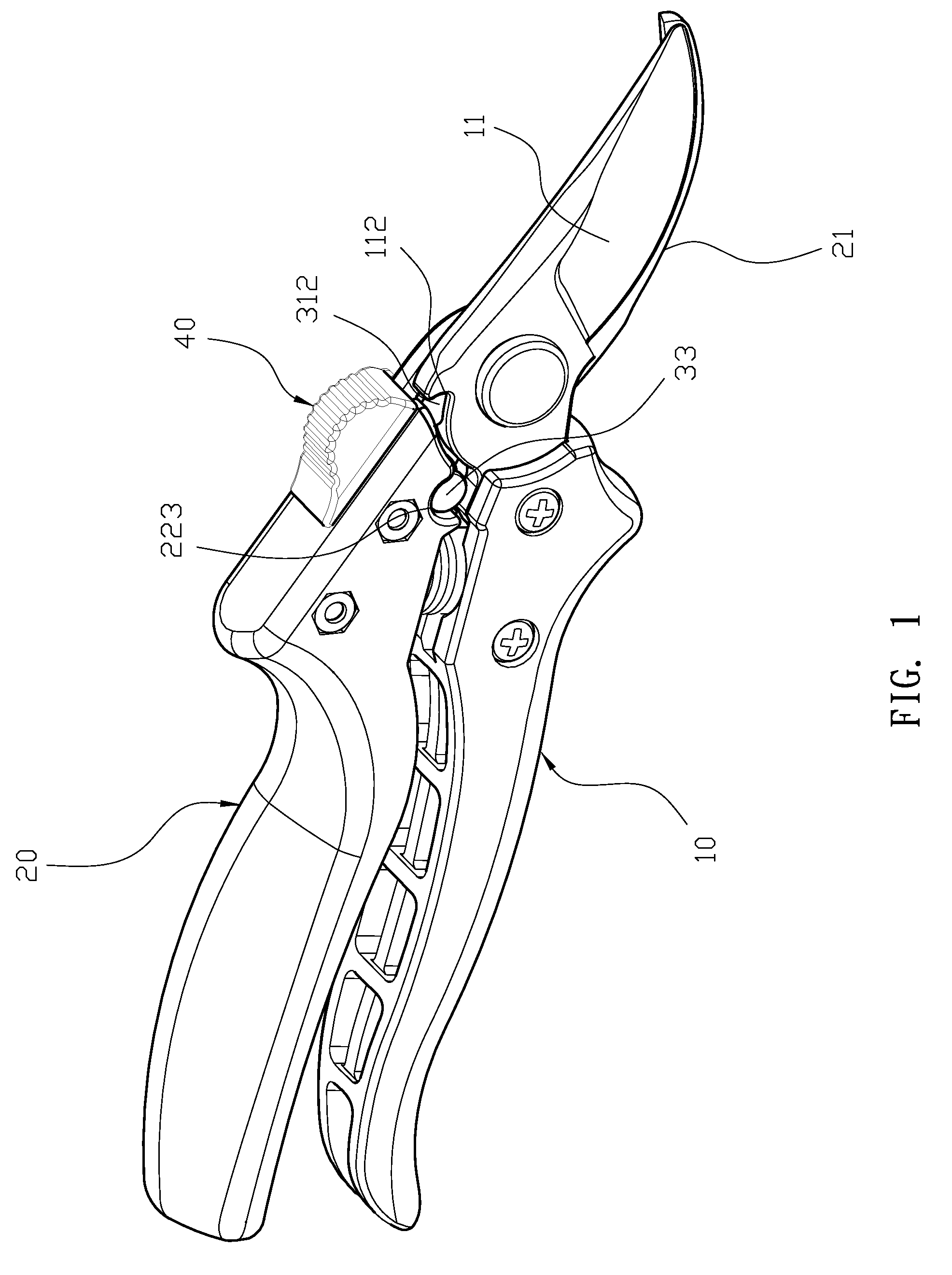

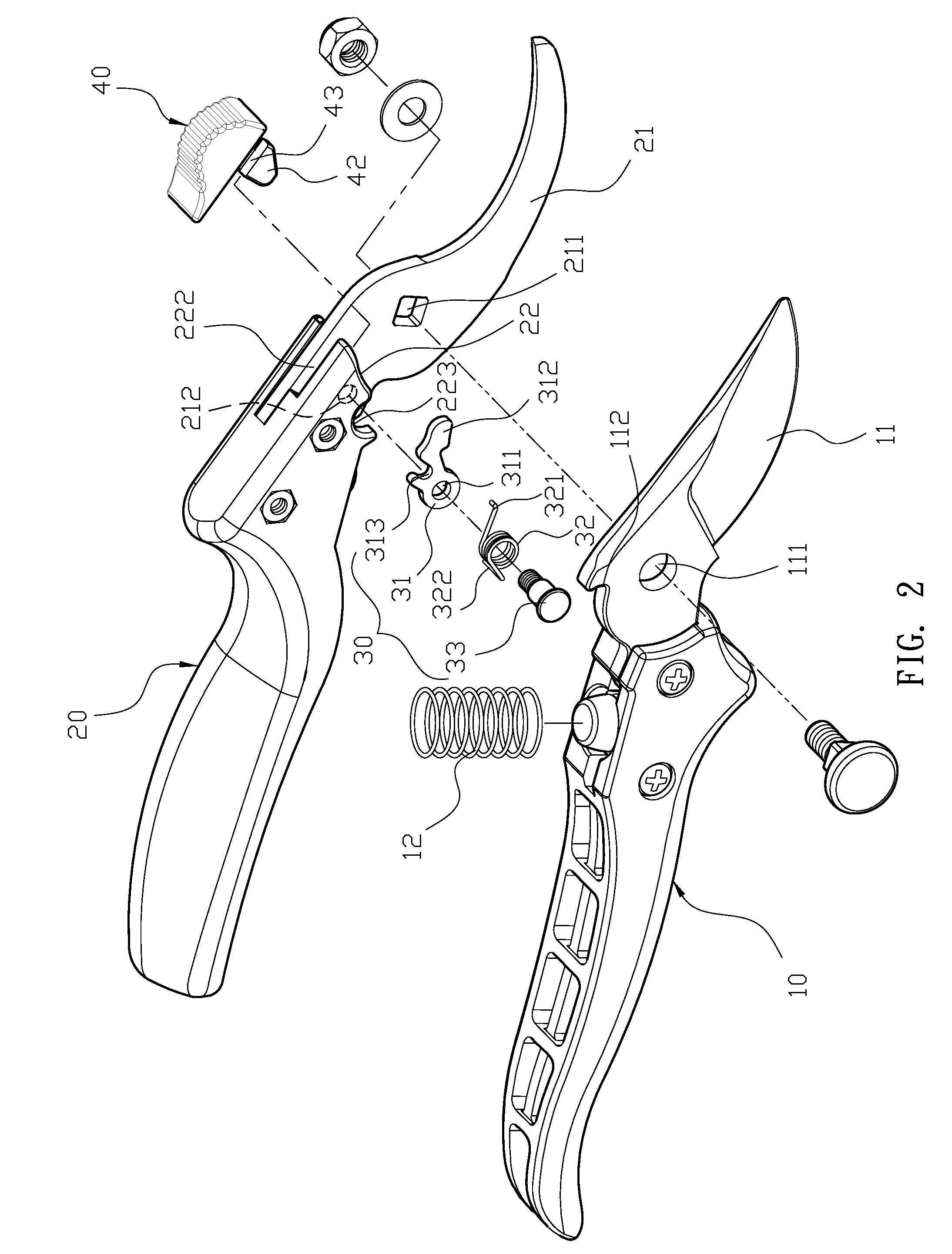

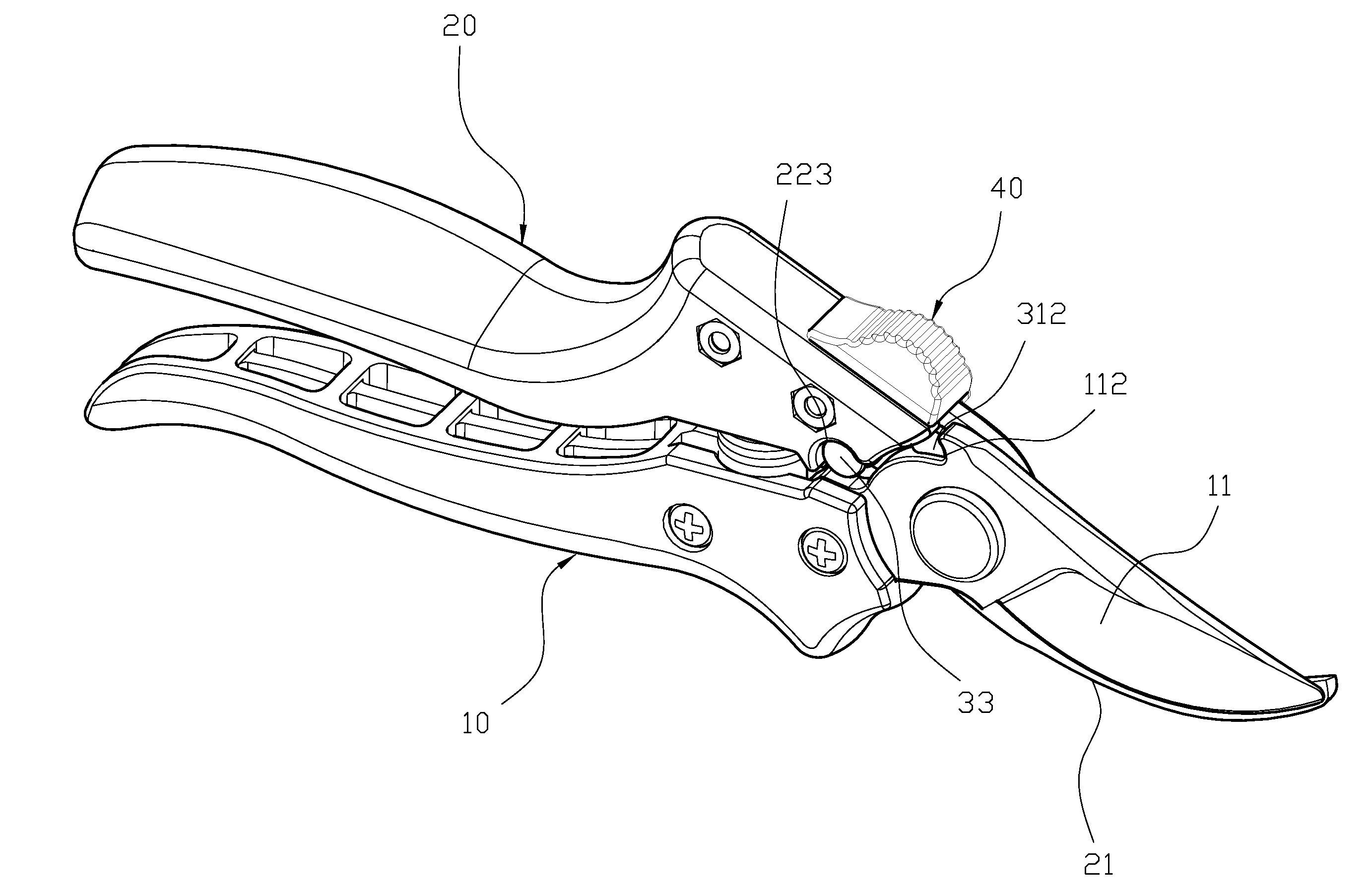

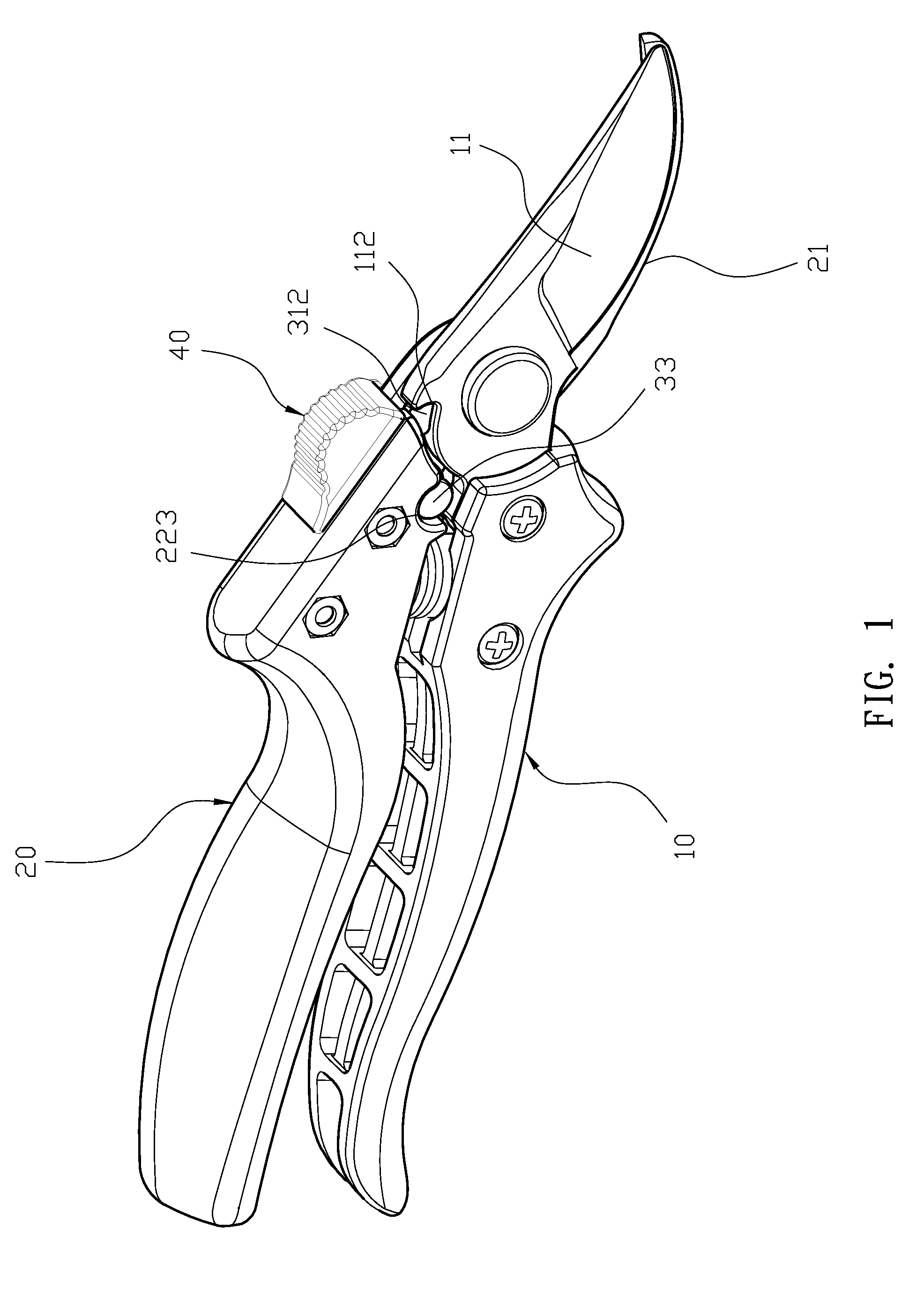

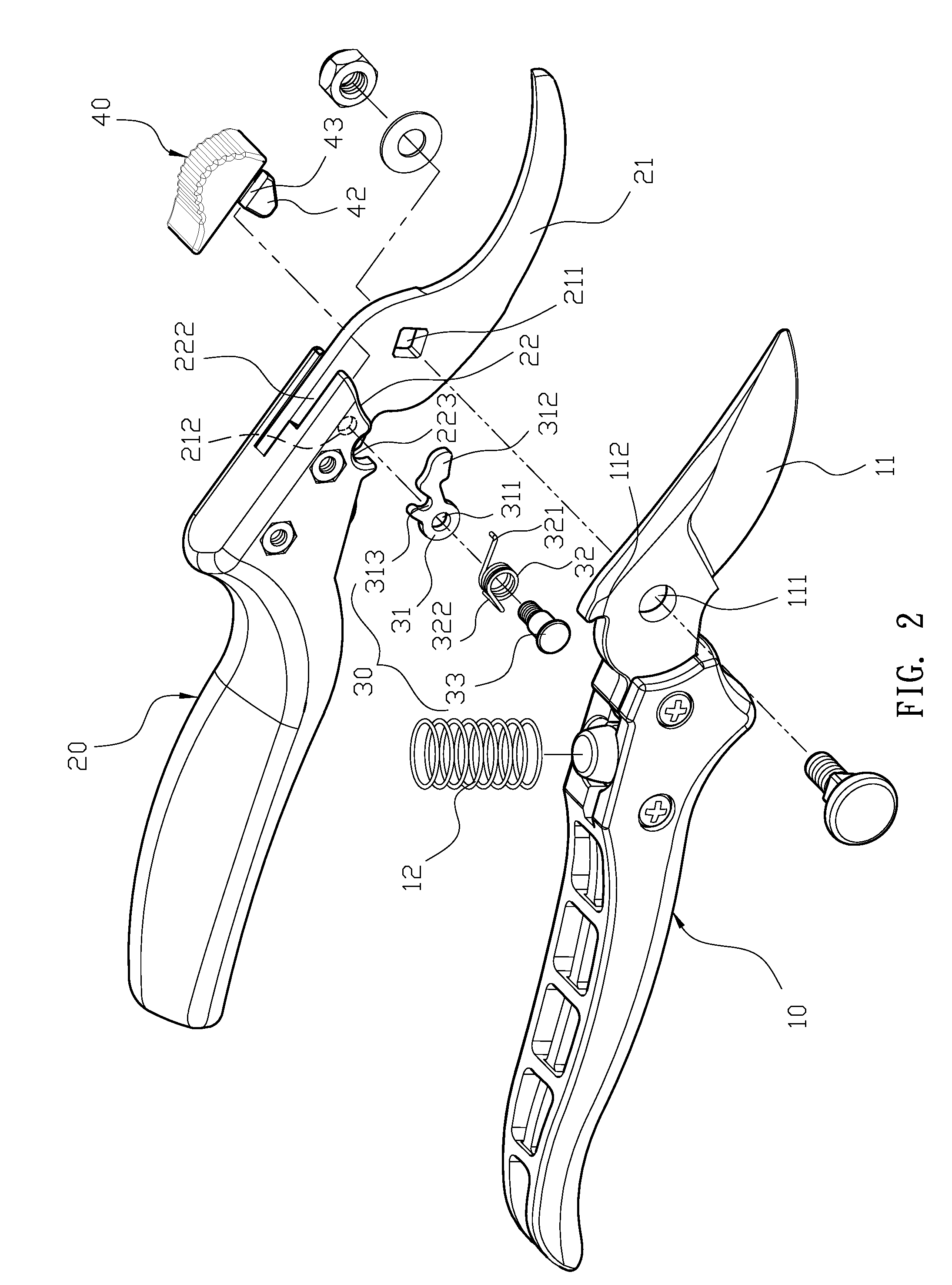

Garden shears

A pressing handle is connected to a moveable blade having a hook-shaped engaging slot near the outer edge of an aperture to which a gripping handle fixed blade is pivoted. A containment space is formed by the junction of the gripping handle and a side of the fixed blade. The containment space has an arc-shaped opening, and the fixed blade has a positional aperture at a position corresponding to the opening. An end of an engaging member has an axle aperture and another end forms an engaging end, with a concave region formed between the two ends. A positioning pin passes through the engaging member and a torsion spring and is attached to the positional aperture. A push button-shaped body has a tongue at its lower end, an edge of which extends as a stop, and the tongue and the stop are both slidably mounted in the containment space.

Owner:HO CHENG GARDEN TOOLS

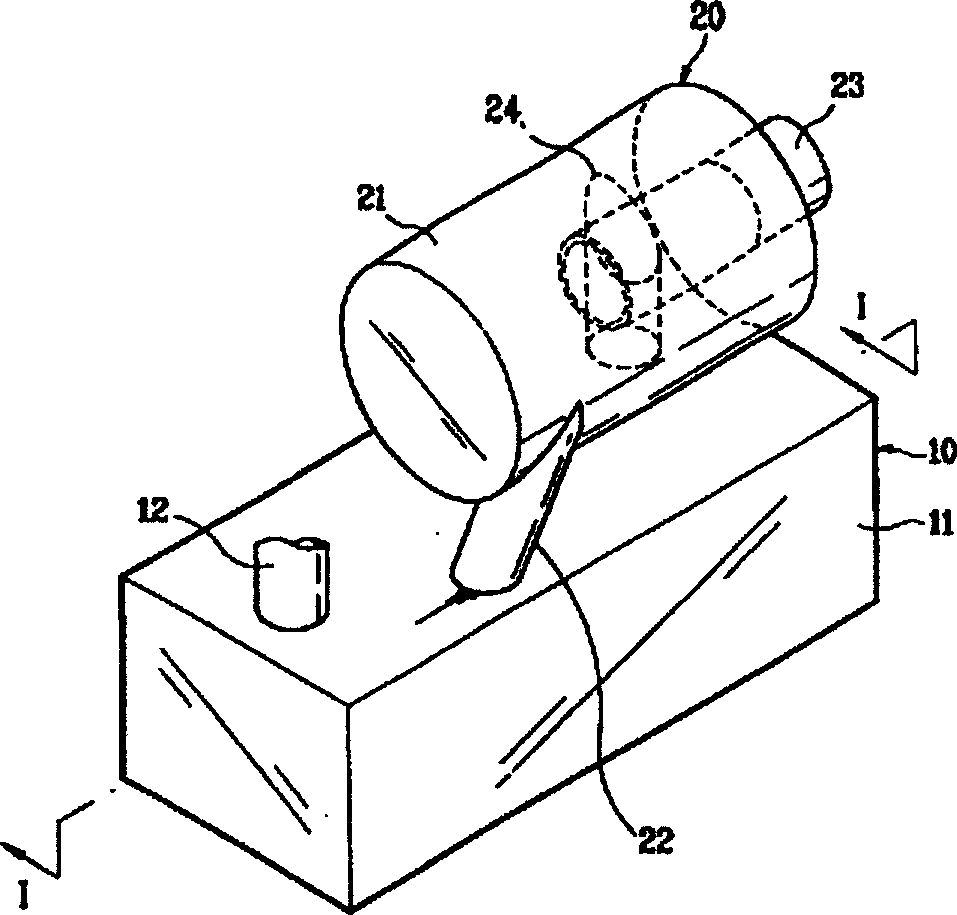

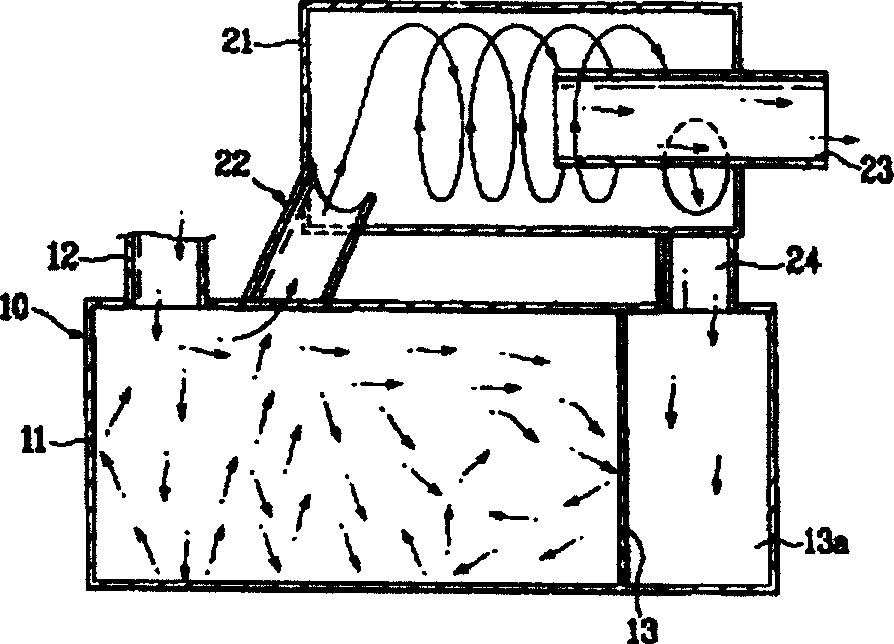

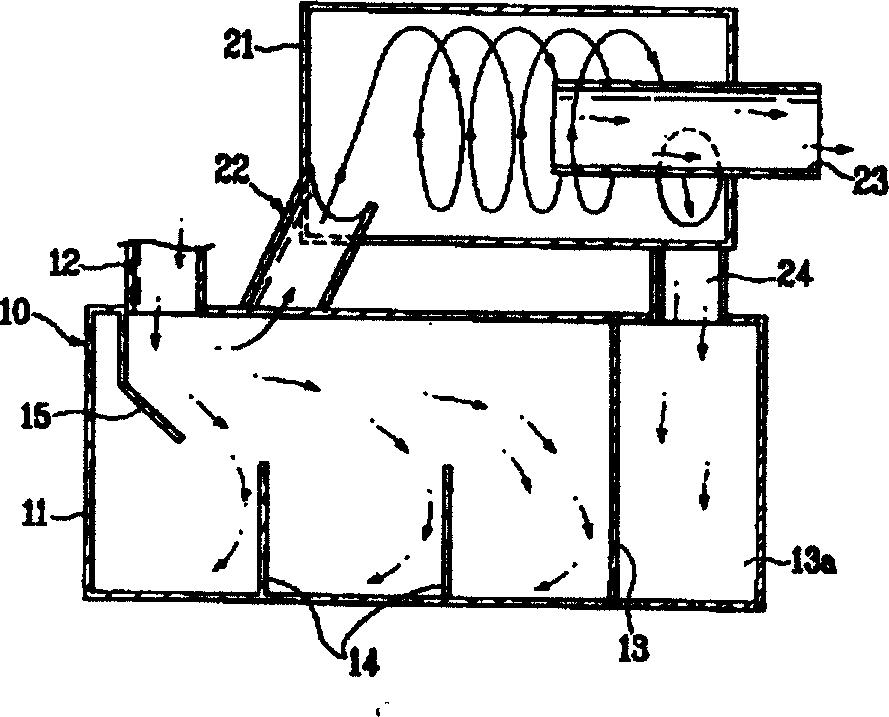

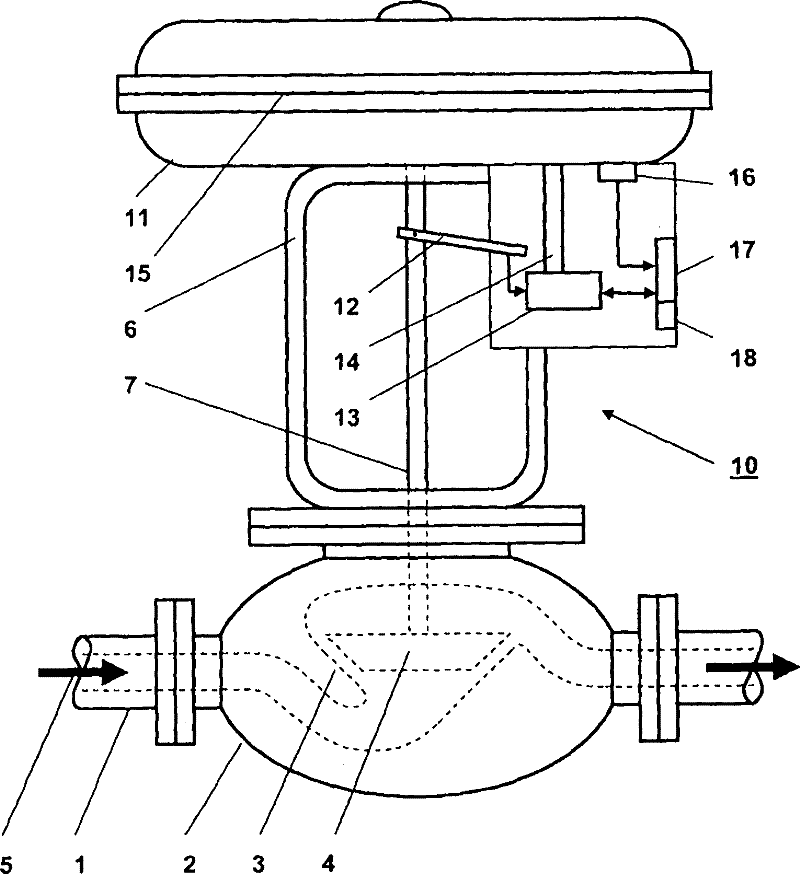

Cyclone dust-collector for vacuum cleaning

InactiveCN1212095CReduced leakage to the second dust collectorImprove dust collection effectSuction filtersDispersed particle separationEngineeringCentrifugal force

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Device having reduced friction properties

InactiveUS20120263936A1Reduce coefficient of frictionReduce adhesionMaterial nanotechnologyFilm/foil adhesivesEngineeringSurface plate

A device, in particular a cover panel for a display device or a monitor auxiliary panel or a surface for input devices, includes a substrate and a coating applied onto the substrate. The coating has a surface having a coefficient of friction in the range between approximately 0.01 and 0.12, in particular between approximately 0.02 and 0.1, or between approximately 0.03 and 0.09.

Owner:SCHOTT AG

Low breakout friction energized gasket

InactiveUS20110272892A1Reduce stictionReduce static frictionEngine sealsEngineeringMechanical engineering

A mechanical seal typically includes gaskets as secondary seals therein. An improved gasket is provided which has a U cup design wherein the gasket is formed with a first spring-energized groove which opens radially and has a deflectable sealing wall which is deflectable axially, and includes a second spring-energized groove which is canted at an angle relative to the axial and radial directions wherein the groove defines a sealing leg which is deflectable at an angle relative to the axial and radial directions. A support ring supports the canted sealing leg along the major extent thereof wherein an end portion of the canted sealing leg is disposed for sealing contact with an axially-extending component surface.

Owner:FLOWSERVE MANAGEMENT CO

Self assembled micro anti-stiction structure

InactiveUS6859577B2Reduce static frictionOvercome disadvantagesDecorative surface effectsOptical articlesOptical switchEngineering

A method and apparatus are described for reducing stiction in a MEMS device having a movable element and a substrate. The method generally comprises providing the substrate with an anti-stiction member and interposing the anti-stiction member between the moveable element and the substrate. The apparatus generally comprises an anti-stiction member that is interposable between the moveable element and the substrate. Another embodiment of the invention of the invention is directed to a MEMS device, comprising: a substrate, a moveable element moveably coupled to the substrate, and an anti-stiction member that is interposable between the moveable element and the substrate. A further embodiment of the invention is directed to an optical switch having one or more moveable elements moveably coupled to a substrate, and an anti-stiction member that is interposable between at least one of the moveable elements and the substrate. The anti-stiction member may be in the form of a flexible cantilevered structure that overhangs the moveable element. Actuating the moveable element causes the anti-stiction member to flex and snap into place between the moveable element and the substrate. An additional embodiment of the invention is directed to a method of fabricating a MEMS device. The method proceeds by providing a silicon-on-insulator (SOI) substrate; defining a moveable element from a device layer of the SOI substrate; and depositing a flexible material over the device layer and the moveable element. One or more portions of the flexible material overhang the moveable element, whereby the flexible material forms one or more anti-stiction members.

Owner:ANALOG DEVICES INC

Method of operating a micromechanical device that contains anti-stiction gas-phase lubricant

InactiveUS7372615B2Extended service lifeReduce static frictionMaterial nanotechnologyMicroscopesDiffusionGas phase

One embodiment of an micromechanical device includes a first contact surface, a moveable component having a second contact surface, where the second contact surface interacts with the first contact surface during device operation, and a gas-phase lubricant disposed between the first contact surface and the second contact surface, where the gas-phase lubricant is adapted to reduce stiction-related forces between the first contact surface and the second contact surface. One advantage of the disclosed device is that a gas-phase lubricant has a high diffusion rate and, therefore, is self-replenishing, meaning that it can quickly move back into a contact region after being physically displaced from the region by the contacting surfaces of the device during operation. Consequently, the gas-phase lubricant is more reliable than conventional solid or liquid lubricants in preventing stiction-related device failures.

Owner:MIRADIA INC

Garden shears

InactiveUS20110023309A1Reduce static frictionReduce frictionSecateursMetal working apparatusTorsion springPush-button

A pressing handle is connected to a moveable blade having a hook-shaped engaging slot near the outer edge of an aperture to which a gripping handle fixed blade is pivoted. A containment space is formed by the junction of the gripping handle and a side of the fixed blade. The containment space has an arc-shaped opening, and the fixed blade has a positional aperture at a position corresponding to the opening. An end of an engaging member has an axle aperture and another end forms an engaging end, with a concave region formed between the two ends. A positioning pin passes through the engaging member and a torsion spring and is attached to the positional aperture. A push button-shaped body has a tongue at its lower end, an edge of which extends as a stop, and the tongue and the stop are both slidably mounted in the containment space.

Owner:HO CHENG GARDEN TOOLS

Preferentially deposited lubricant to prevent anti-stiction in micromechanical systems

InactiveUS7723812B2Reduce static frictionIncrease chanceMaterial nanotechnologySemiconductor/solid-state device detailsGas phaseEngineering

Embodiments of the present invention generally relate to a device that has an improved usable lifetime due to the presence of a lubricant that reduces the likelihood of stiction occurring between the various moving parts in an electromechanical device. Embodiments of the present invention also generally include a device, and a method of forming a device, that has one or more surfaces or regions that have a volume of lubricant disposed thereon that acts as a ready supply of “fresh” lubricant to prevent stiction occurring between interacting components found within the device. In one aspect, components within the volume of lubricant form a gas or vapor phase that reduces the chances of stiction-related failure in the formed device. In one example, aspects of this invention may be especially useful for fabricating and using micromechanical devices, such as MEMS devices, NEMS devices, or other similar thermal or fluidic devices.

Owner:MIRADIA INC

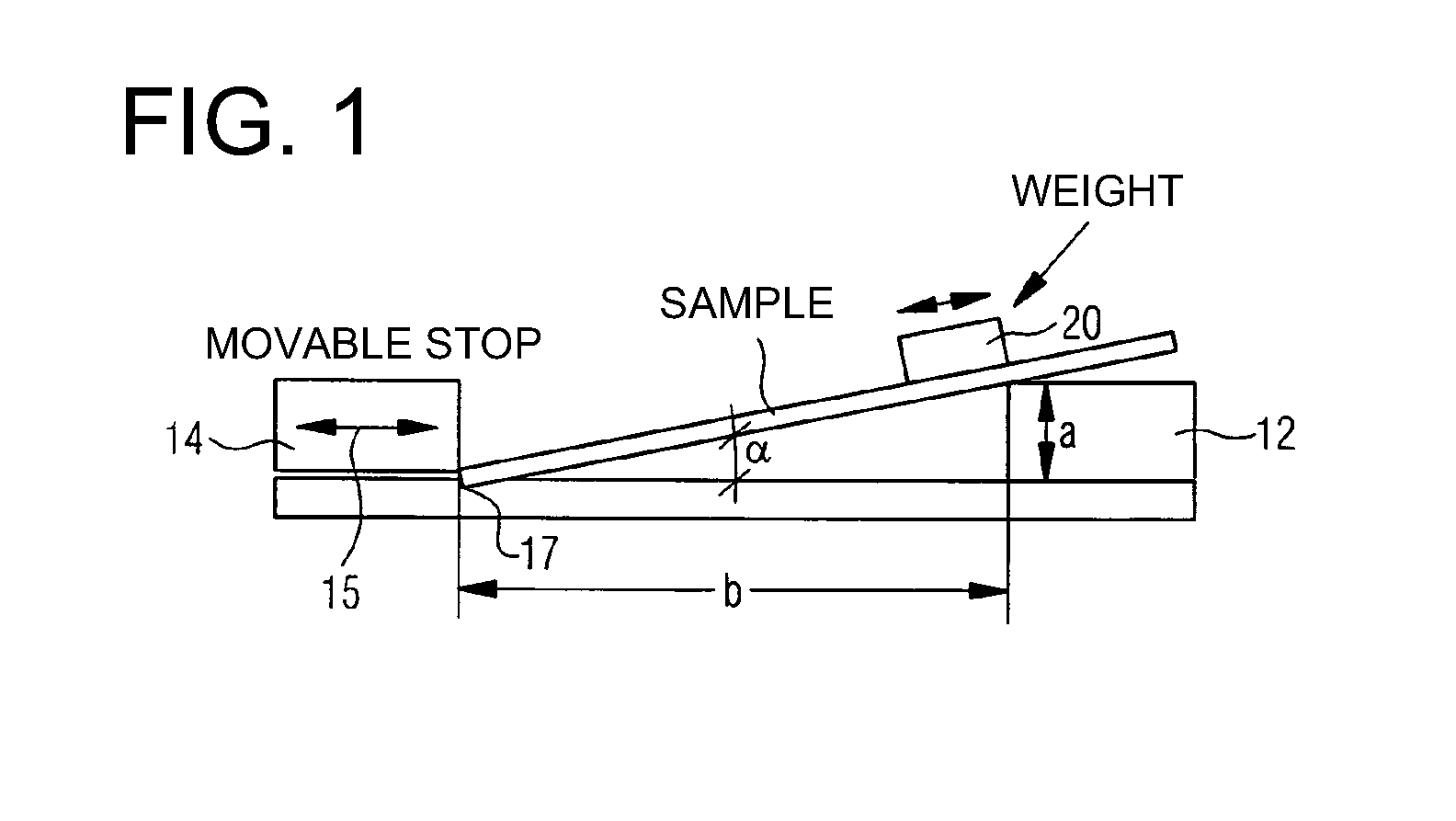

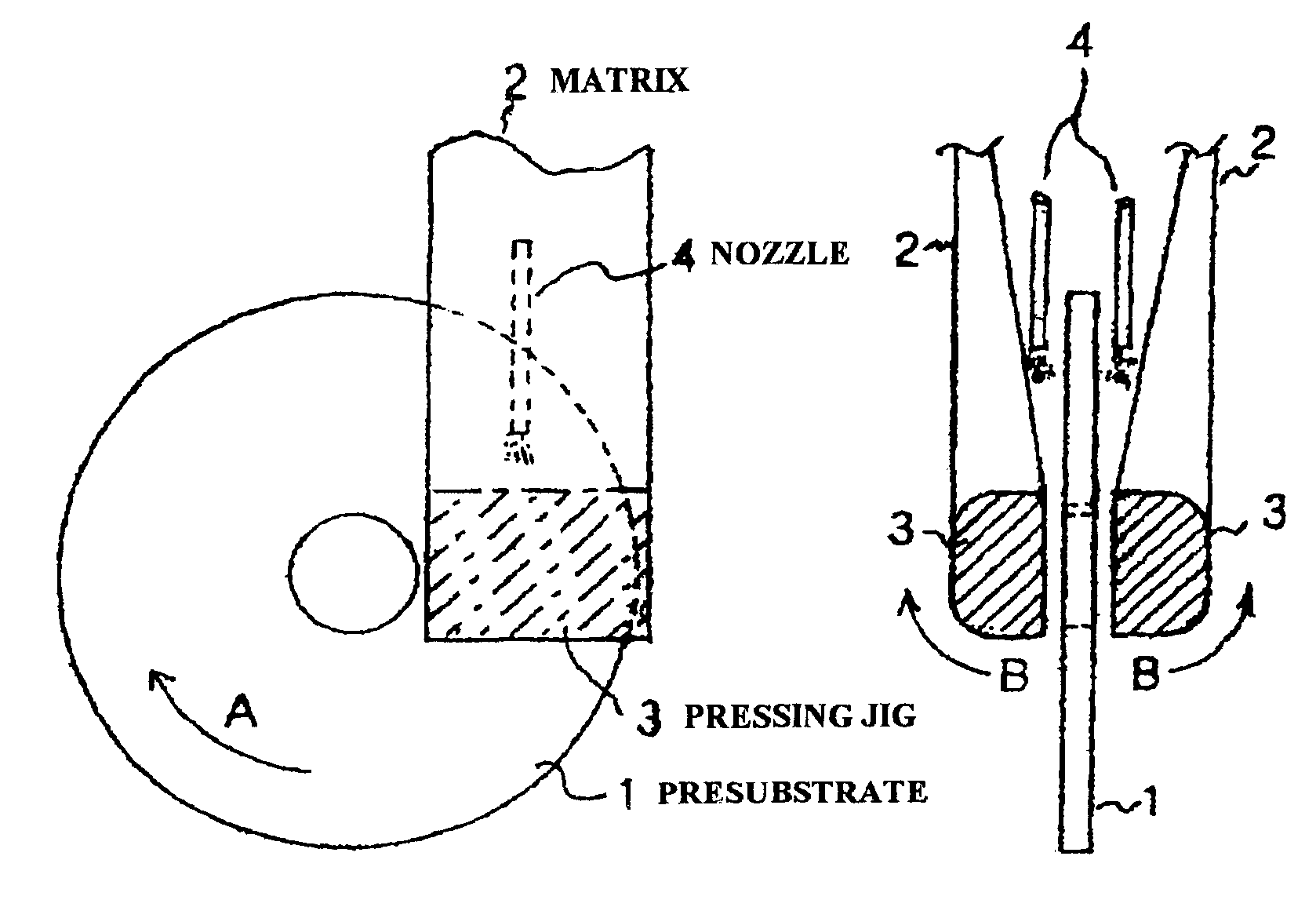

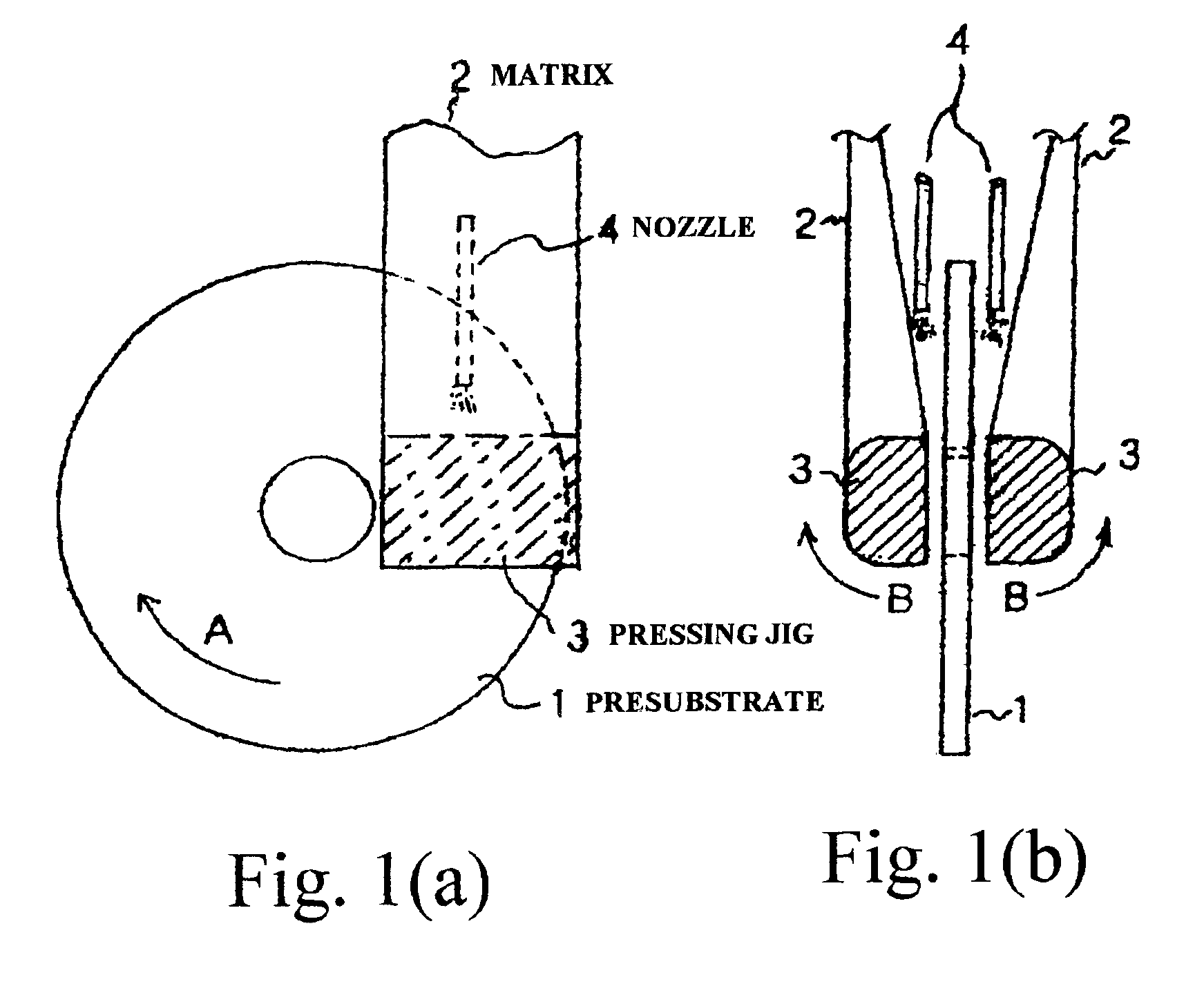

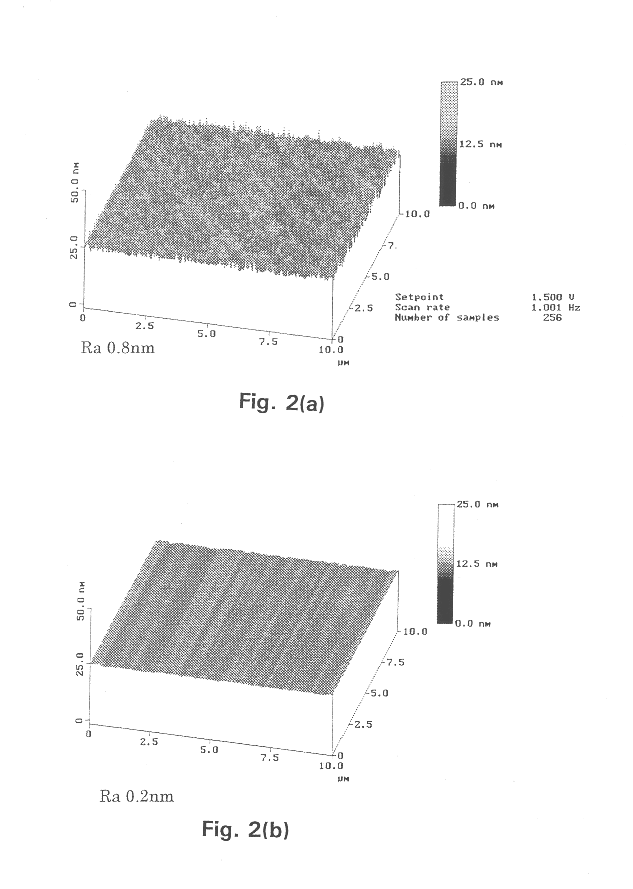

Substrate for magnetic recording medium, manufacturing method thereof, and magnetic recording medium

InactiveUS6632547B2Increased surface roughness accuracyImproved machine characteristicPolishing machinesRevolution surface grinding machinesSingle processContact pressure

A slowly advancing tape-shaped matrix is pressed into contact with a surface of a rapidly rotating non-magnetic substrate for a magnetic recording medium. An abrasive slurry is added to the matrix. The area contact rate between the matrix and the surface, as well as the contact pressure per unit area between the matrix and the surface are regulated to both polish and slightly roughen the surface in a single process. In the case of a glass presubstrate, the glass is chemically strengthened before being surface-treated.< / PTEXT>

Owner:FUJI ELECTRIC CO LTD

Anti-stiction gas-phase lubricant for micromechanical systems

InactiveUS7580174B2Reduce static frictionExtended service lifeMaterial nanotechnologyPiezoelectric/electrostriction/magnetostriction machinesGas phaseEngineering

Owner:MIRADIA INC

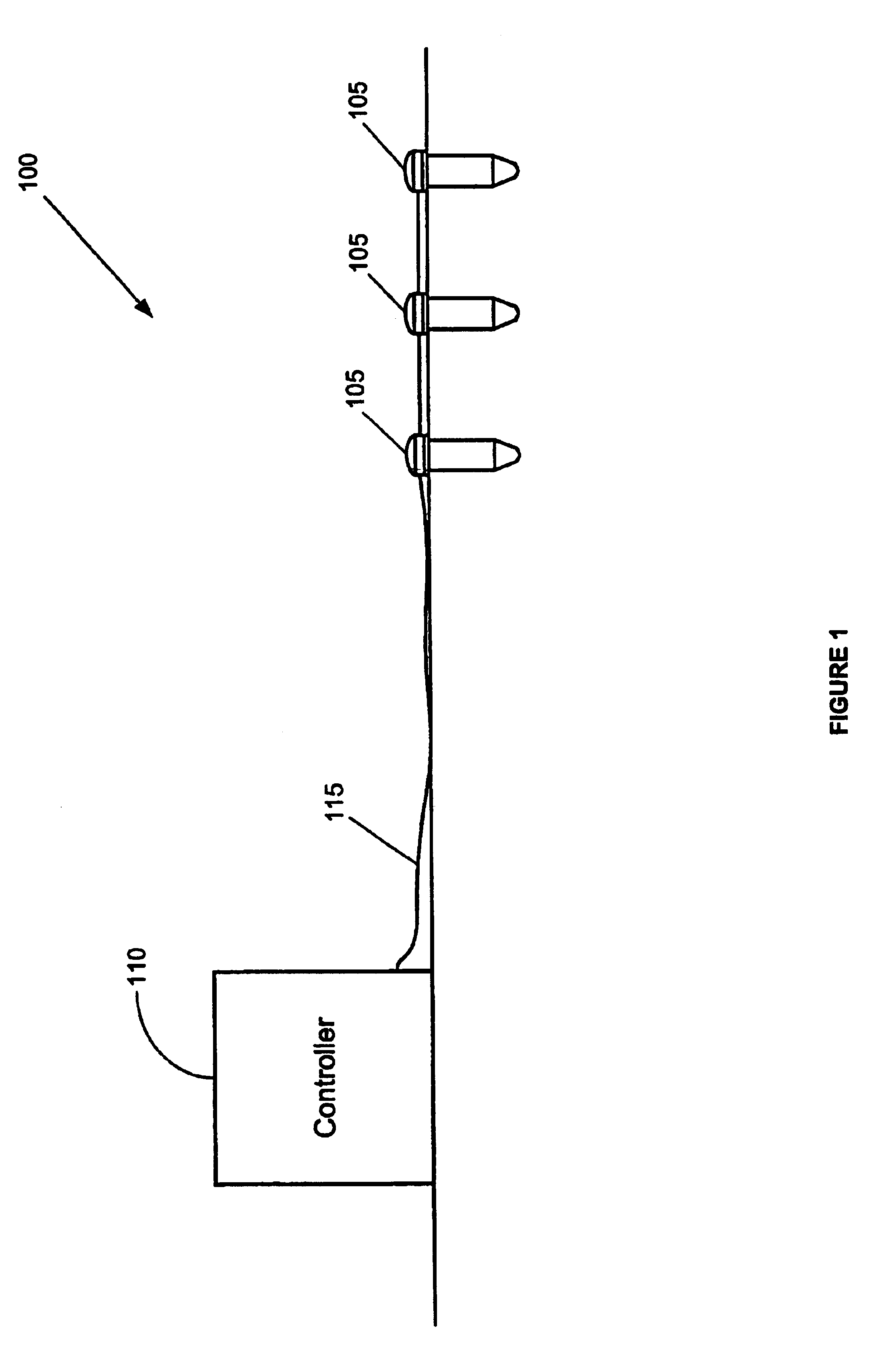

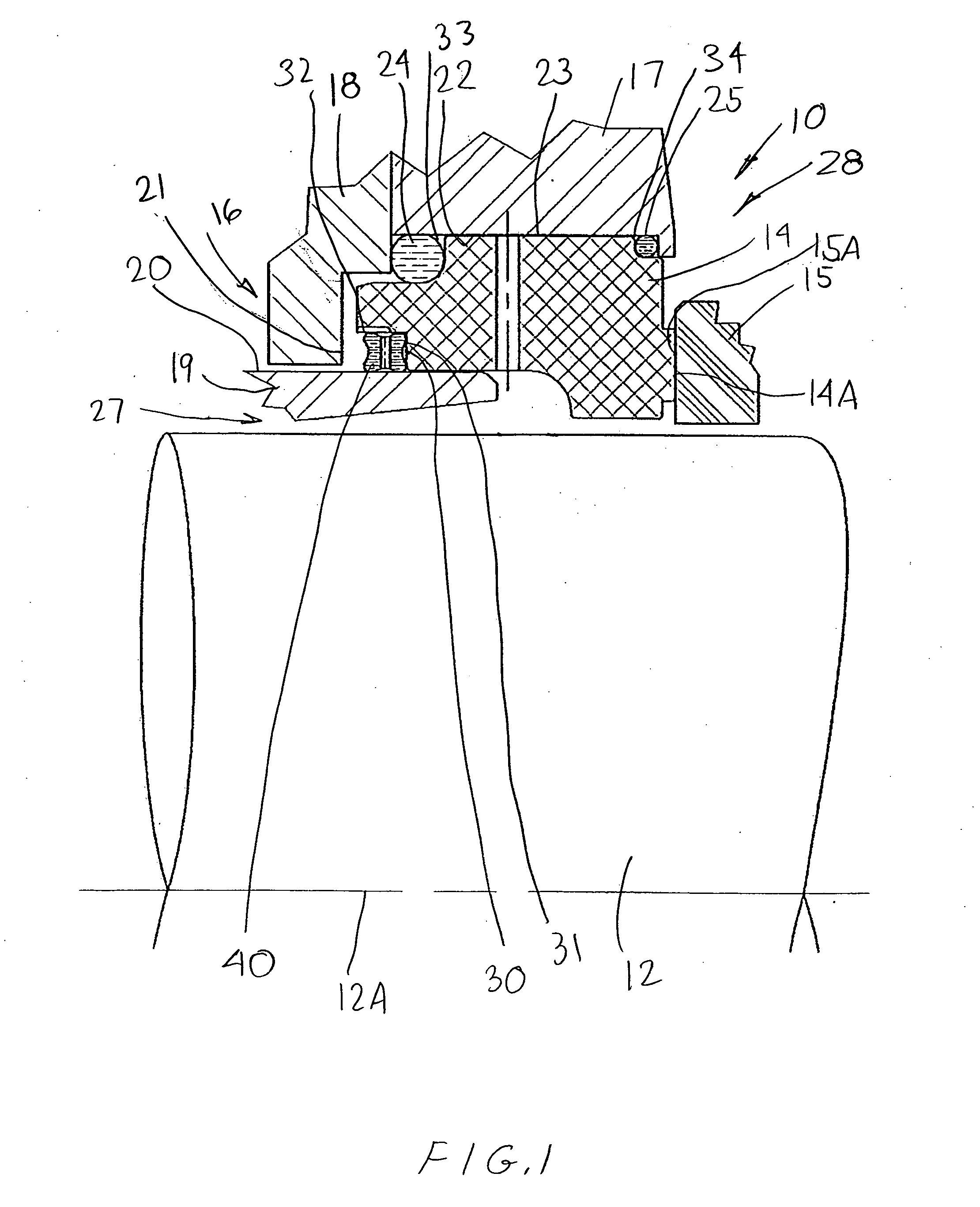

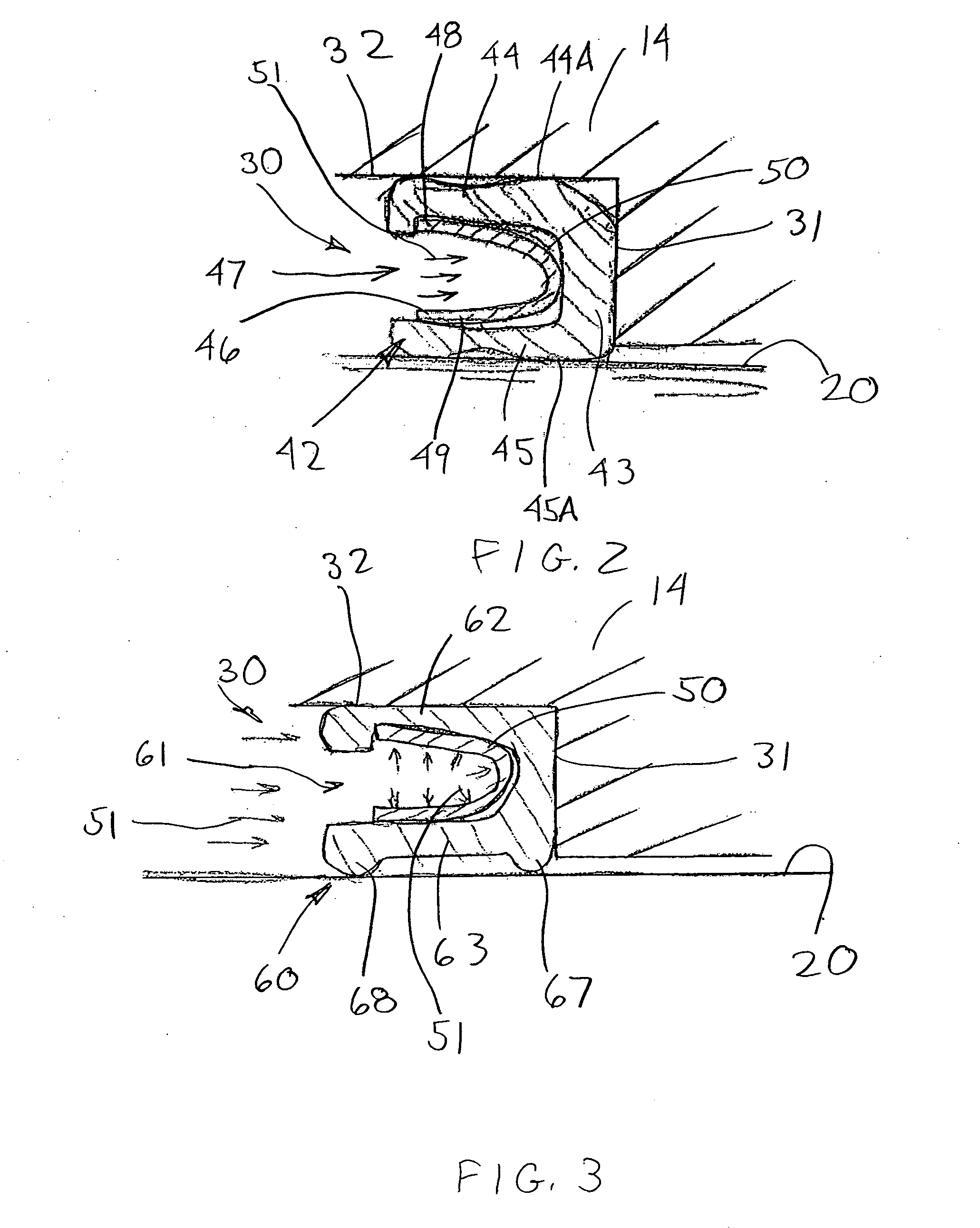

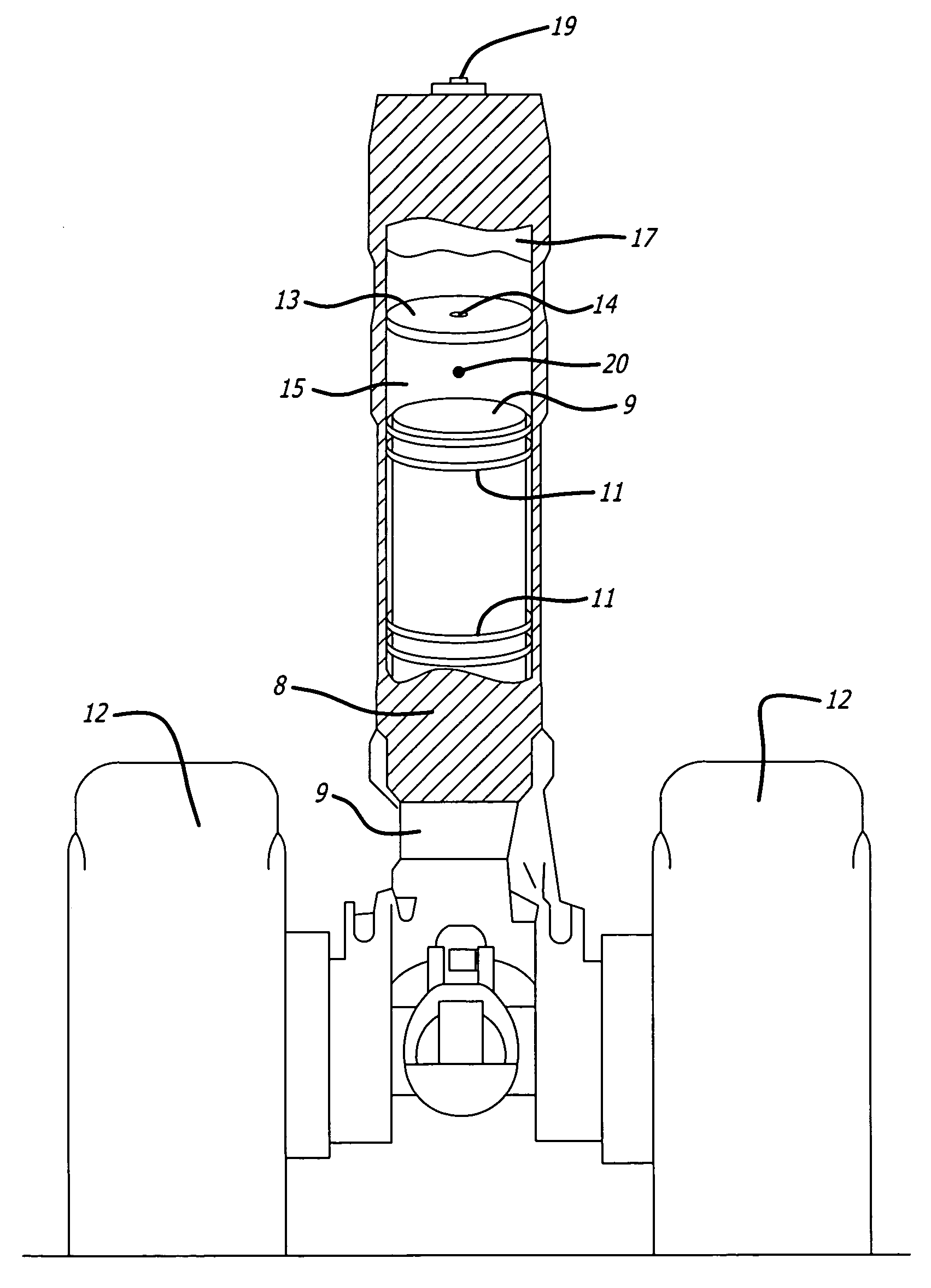

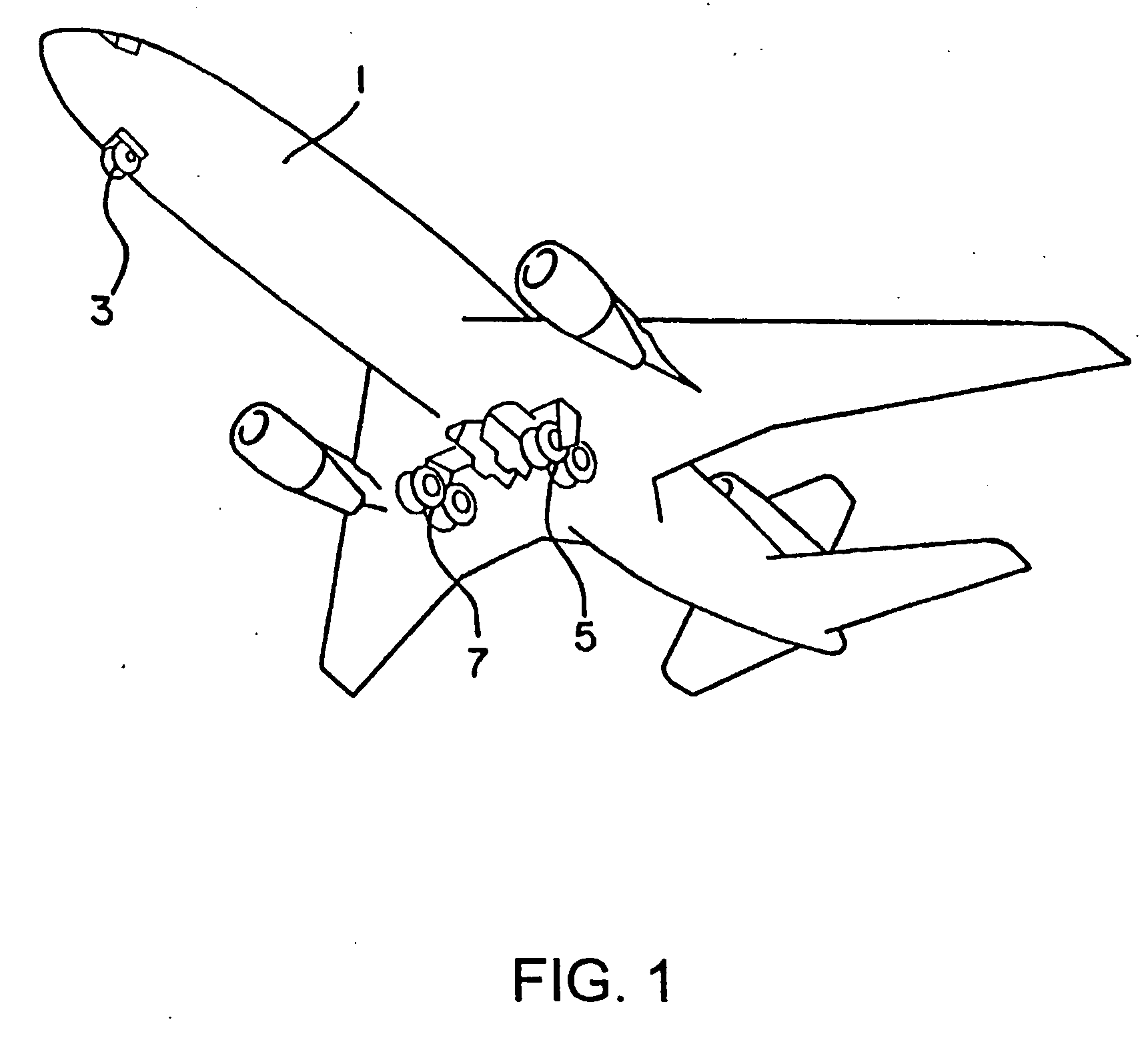

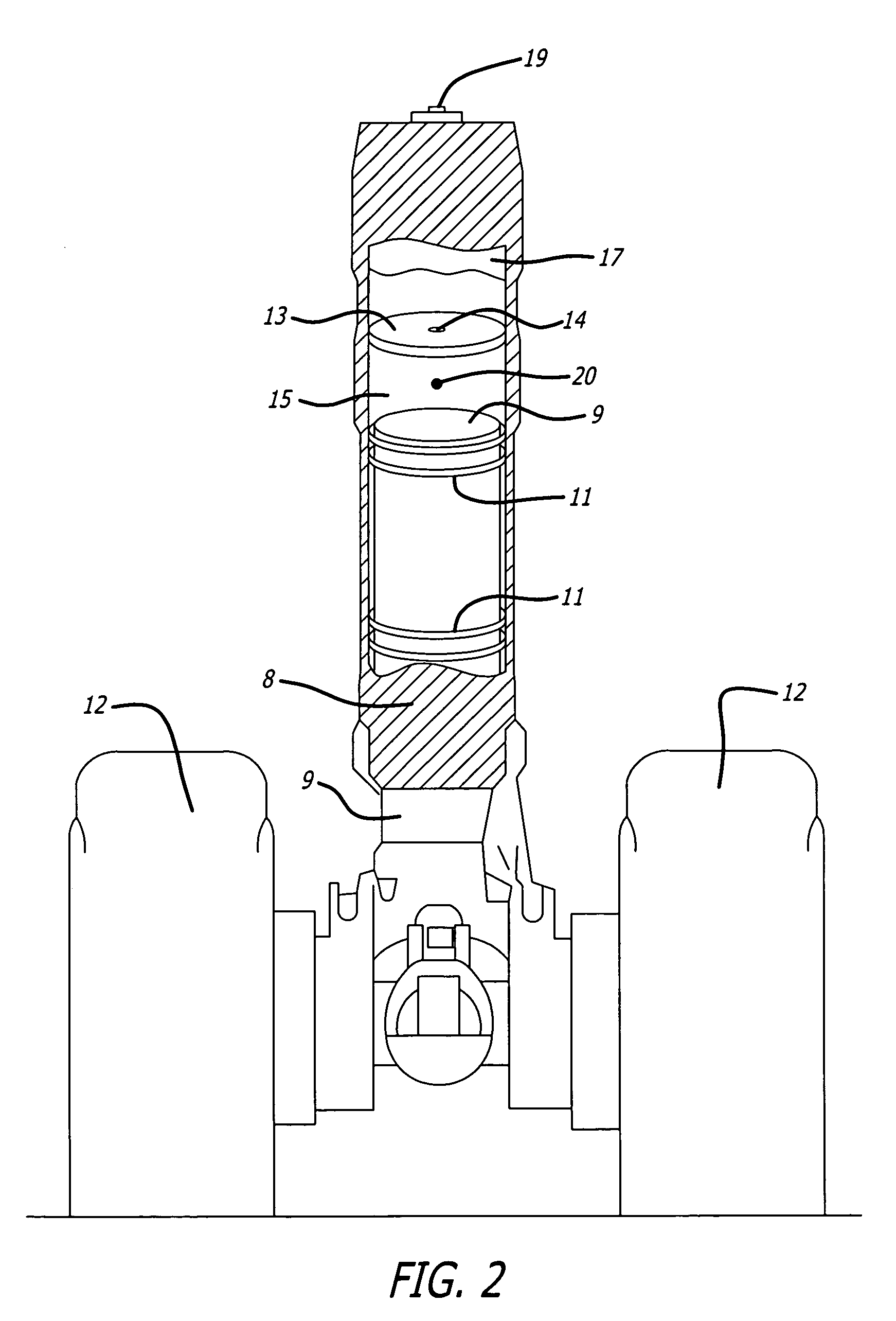

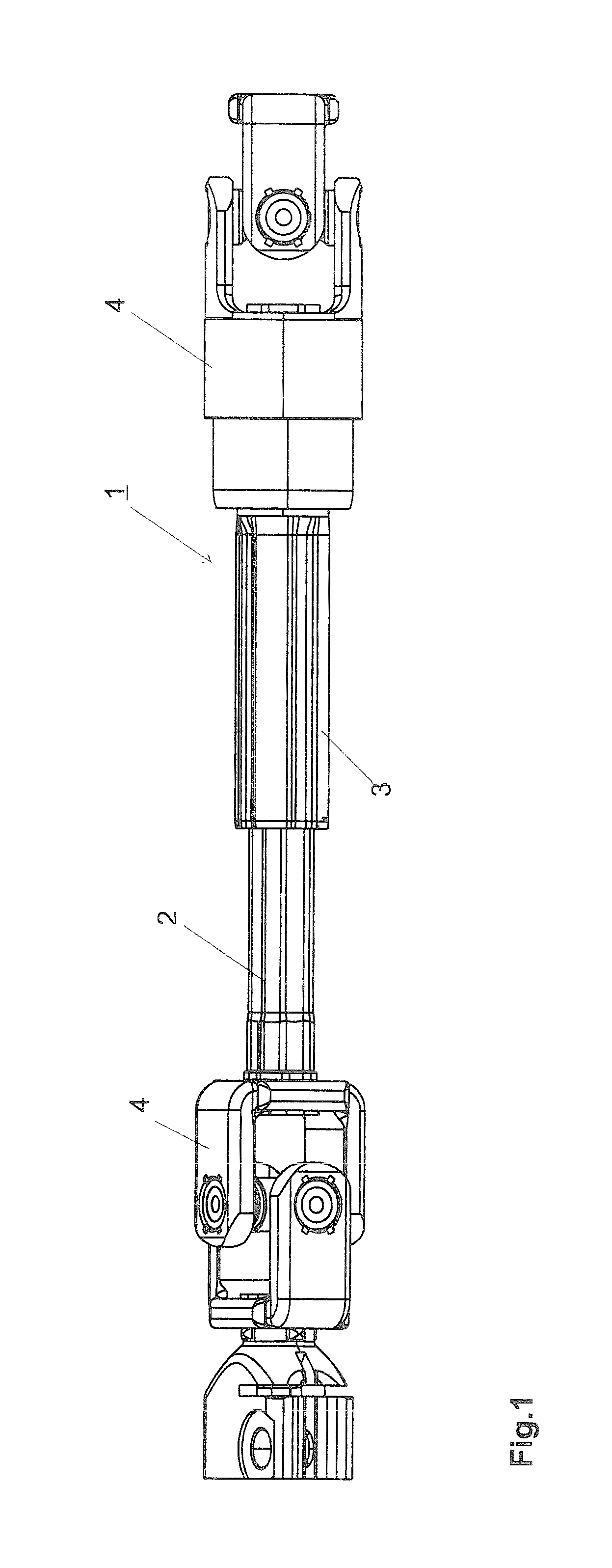

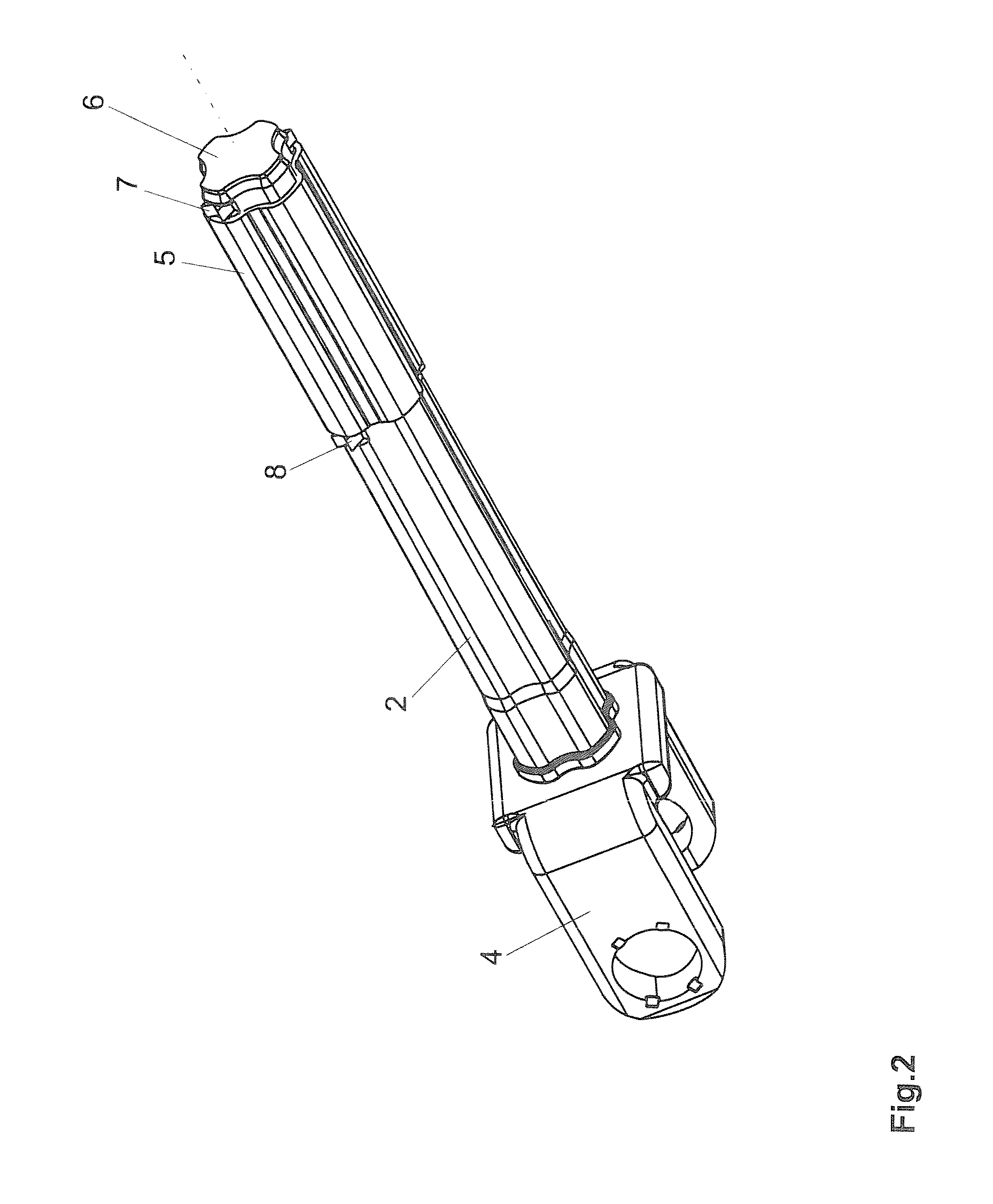

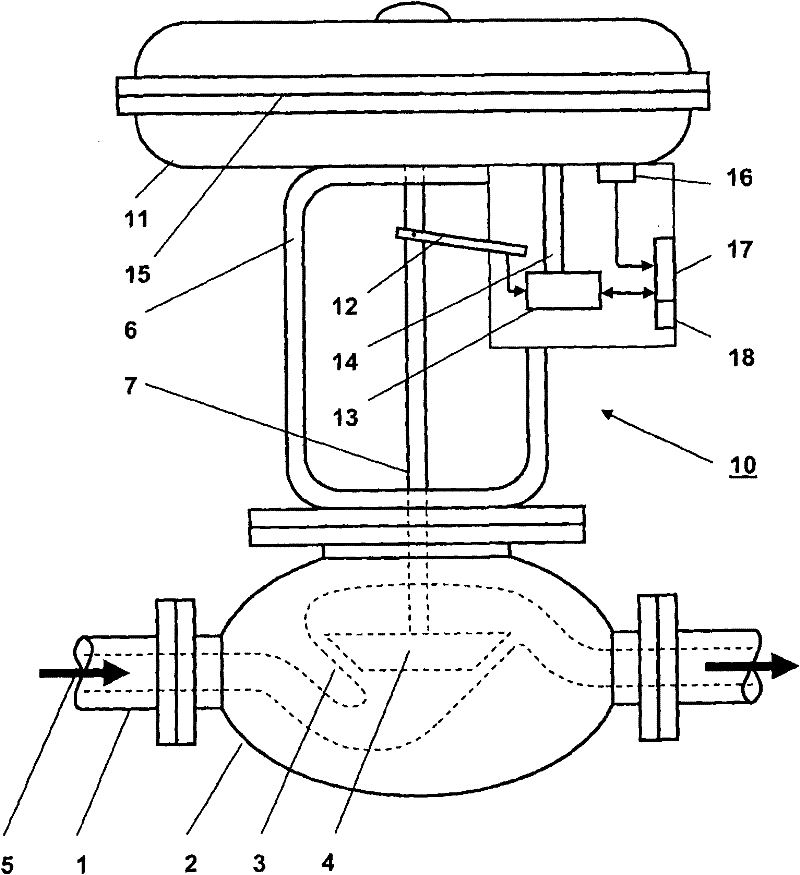

Rotating seal for anti-stiction of hydraulic struts

InactiveUS20060220918A1Reduce and eliminate stictionMinimizing aircraft movementAlarmsAircraft components testingDistortionFluid level

An onboard system for use in measuring, computing and displaying the weight and center-of-gravity for aircraft, while keeping aircraft movement to a minimum. Pressure sensors are mounted in relation to each of the landing gear struts. A motor and rotating seal are configured into each strut and are activated by a computer / controller, while landing gear strut pressures are monitored in the determination of strut stiction. The computer / controller calculates the stiction of each landing gear strut and compensates for the pressure distortions caused by landing gear strut stiction. Additional features include reducing strut stiction, measuring landing gear strut fluid levels, monitoring landing gear strut health, weight adjustments for external ice and de-icing fluids, weight adjustments for wind, monitoring aircraft landing gear strut movement.

Owner:CRANE CO

Boron nitride antistiction films and methods for forming same

InactiveUS20140043216A1Reduce static frictionStatic indicating devicesSpecial surfacesBoron nitrideStiction

This disclosure provides systems, methods and apparatuses for providing a boron nitride layer in a cavity of an optical electromechanical systems (EMS) device. The boron nitride layer can be deposited, for example using ALD, after removal of the sacrificial layer to define an EMS cavity. The boron nitride layer may reduce stiction between a first and second electrode structure of the EMS device.

Owner:SNAPTRACK

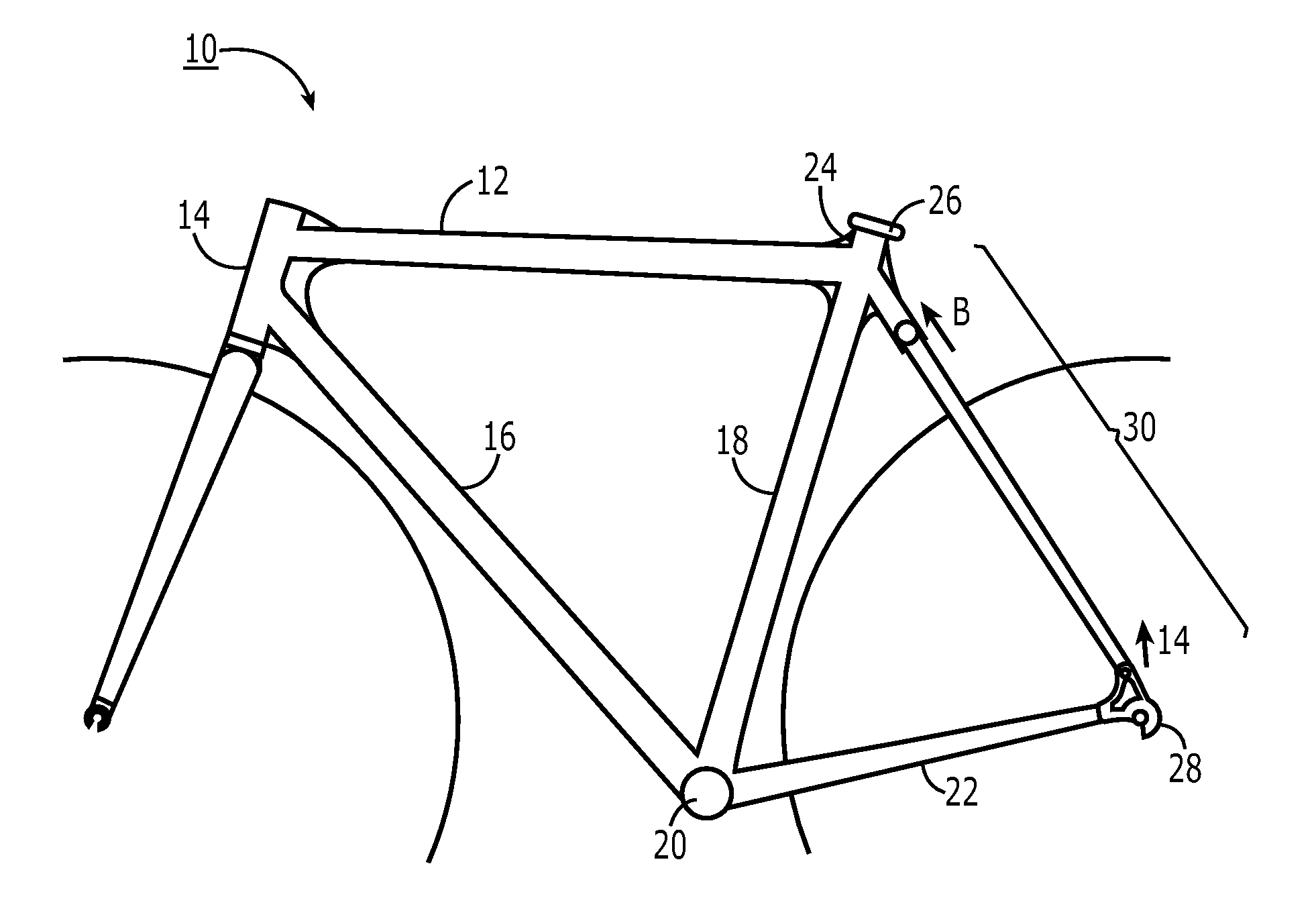

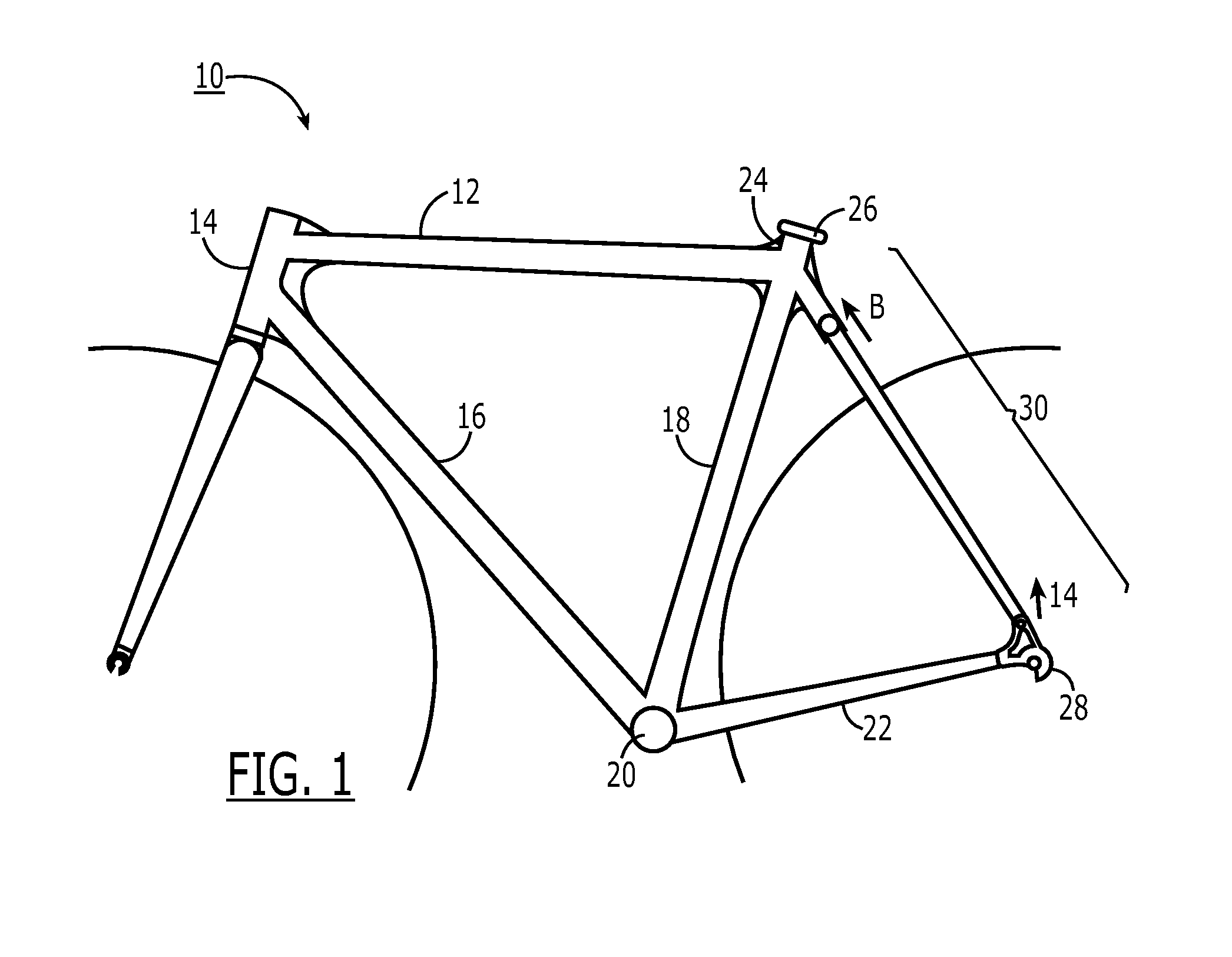

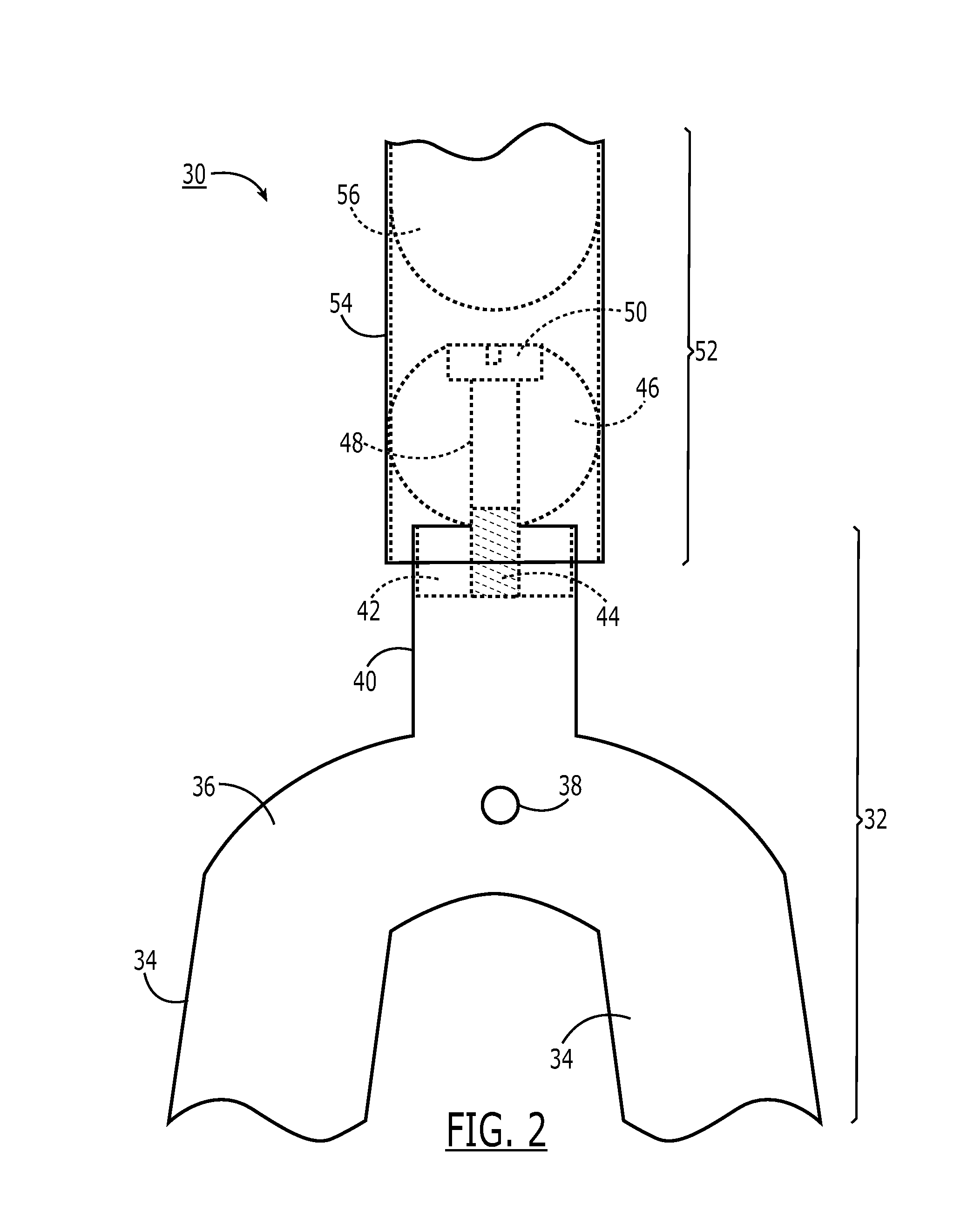

Simplified rear suspension for a bicycle or the like

InactiveUS7591475B1Large force rangeReduce static frictionPassenger cyclesChildren cyclesTerrainEngineering

A simplified rear suspension for a bicycle or the like comprises a wishbone seatstay structure. The wishbone structure is provided with a first extension extending toward the seat junction. A low friction guide component, for example a spherical element, is provided at the distal end of the extension. A second extension is provided at the seat junction, with a hollow interior for receiving the guide component. The guide component slides with little friction and play within the hollow interior. A stop member may also be provided within the hollow interior, stopping travel of the guide component under load. Motion of the rear wheel (via dropout) relative to the main frame (e.g., from the terrain) is translated into motion of the guide component within the hollow interior. The chainstays, in a pivotless arrangement, provide a moment which acts as a spring, resisting the motion of the dropouts and providing shock absorption and / or damping for improved ride and control.

Owner:CALFEE CRAIG

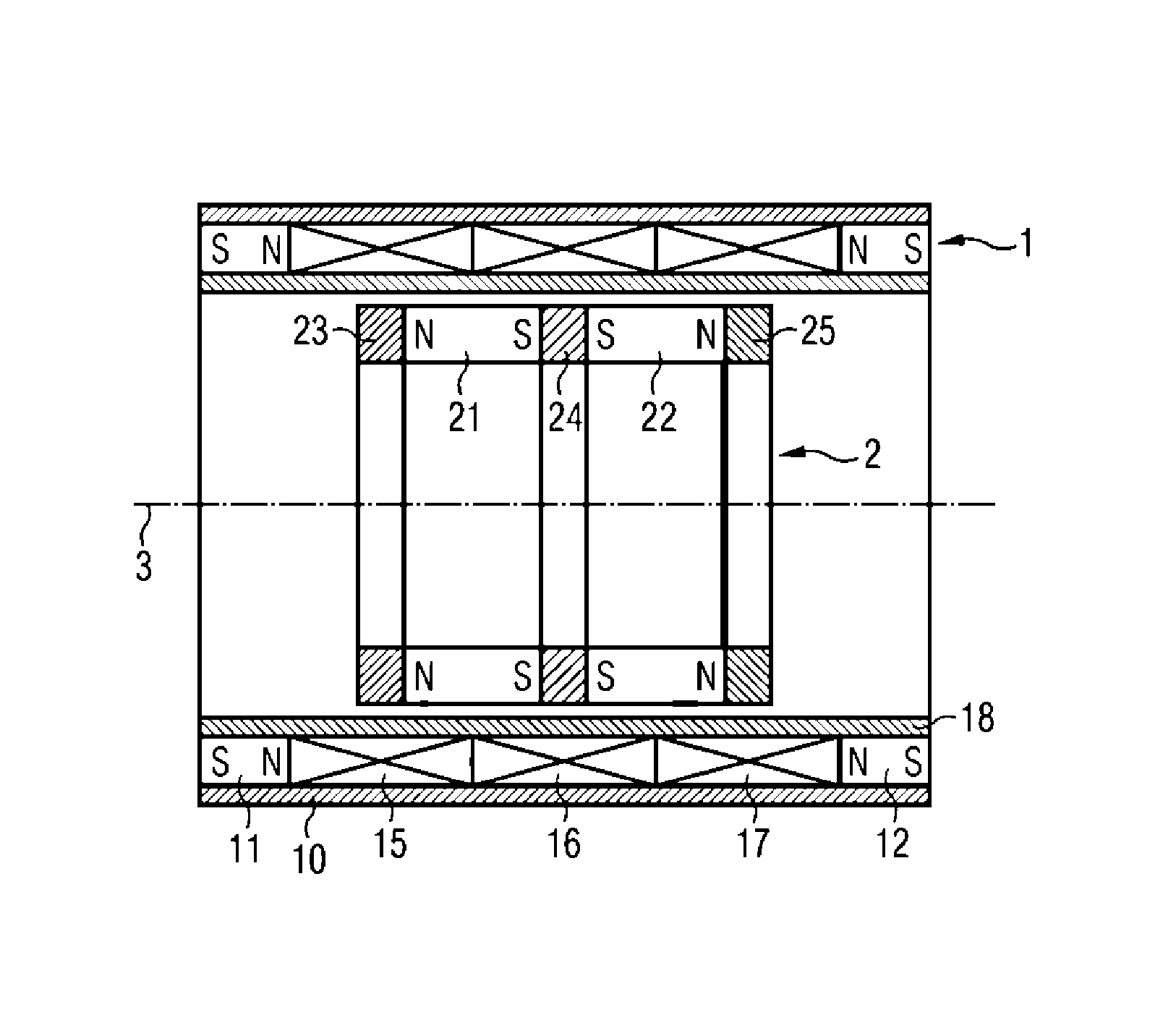

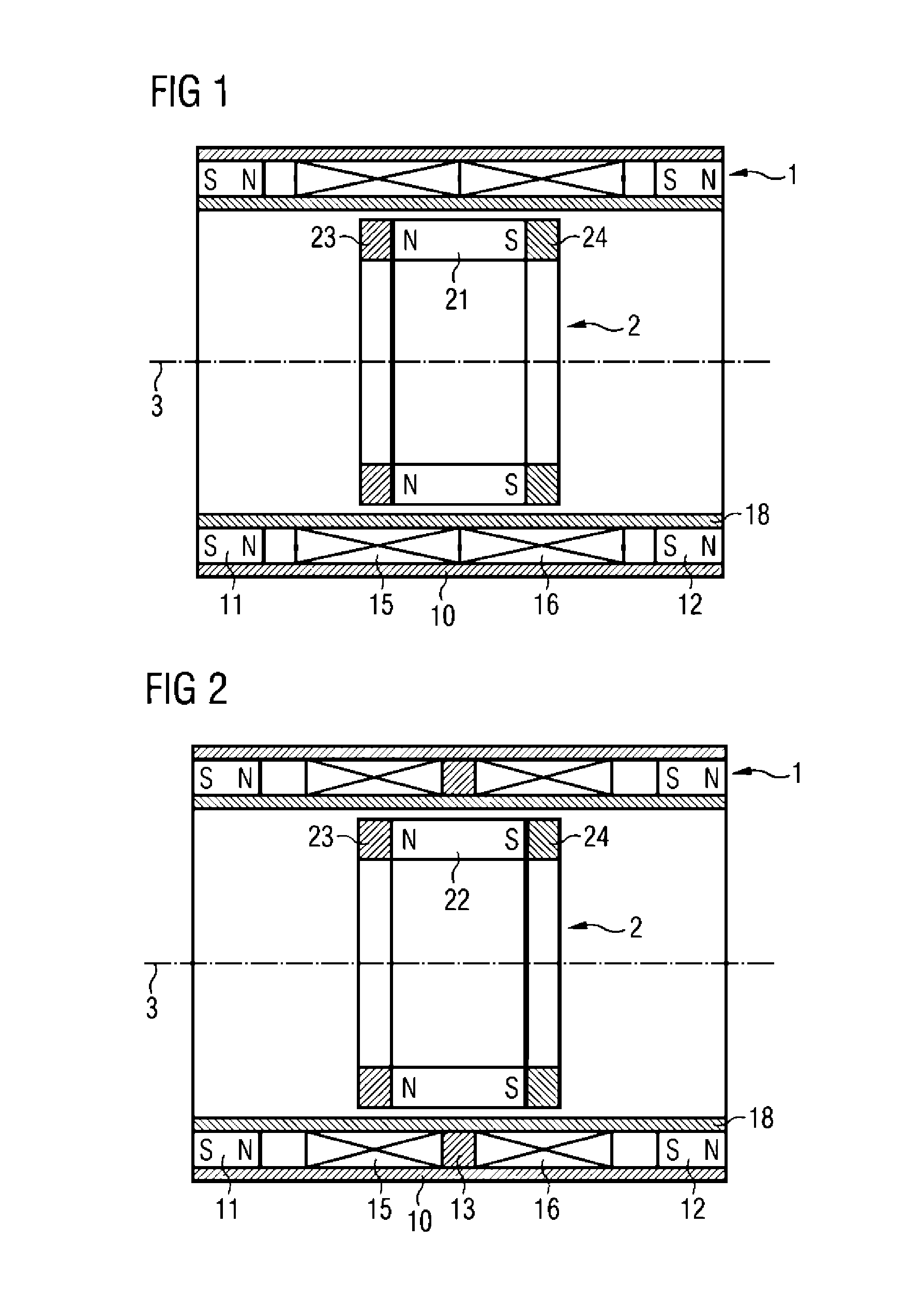

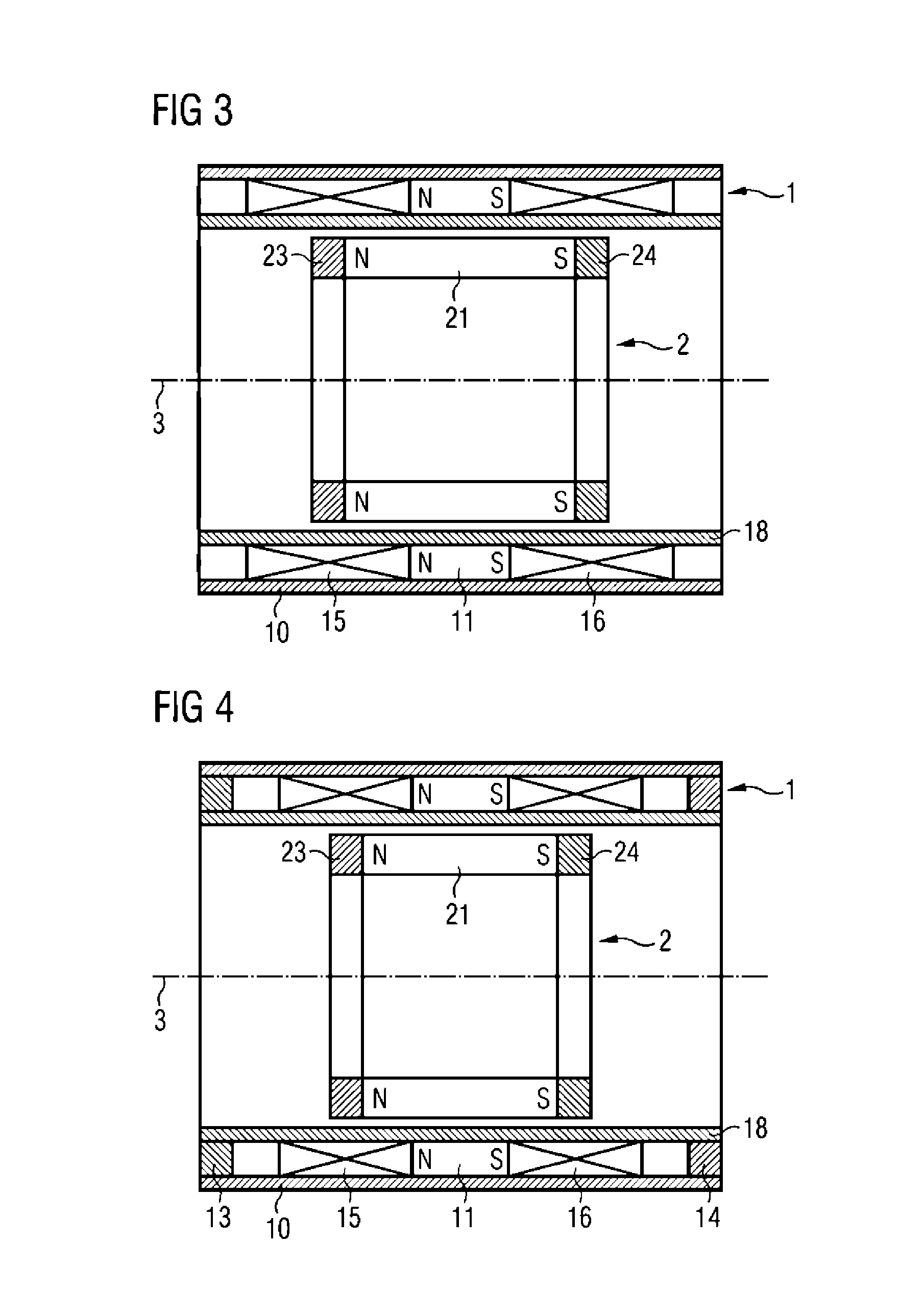

Linear motor with permanent-magnetic self-holding

A linear motor for optical systems, for example, endoscopes, is described. The motor has a stator with a magnetic guiding member and two adjacently disposed coils which are energized in opposite directions. Furthermore permanent magnets polarized in opposite directions and in the axial direction are provided on both sides of the pair of coils. The armature of the motor has a permanent magnet which is polarized in the opposite direction to the permanent magnet of the stator and is connected to a pole piece at each end. The pole pieces are arranged so that in the rest position each pole piece lies at the centre of one of the coils. By applying current to the coil, the armature can be displaced from a rest position in the longitudinal direction.

Owner:KARL STORZ GMBH & CO KG

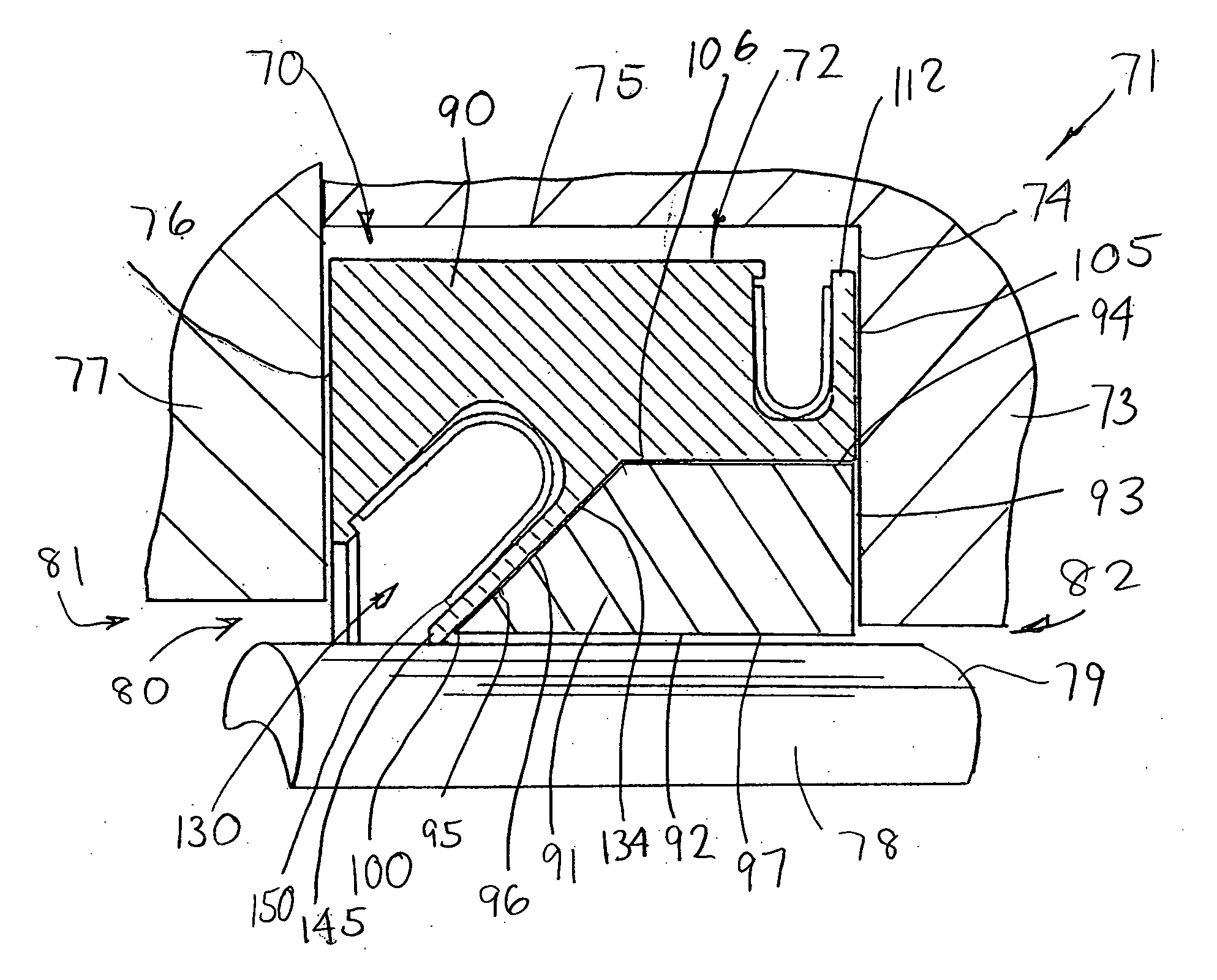

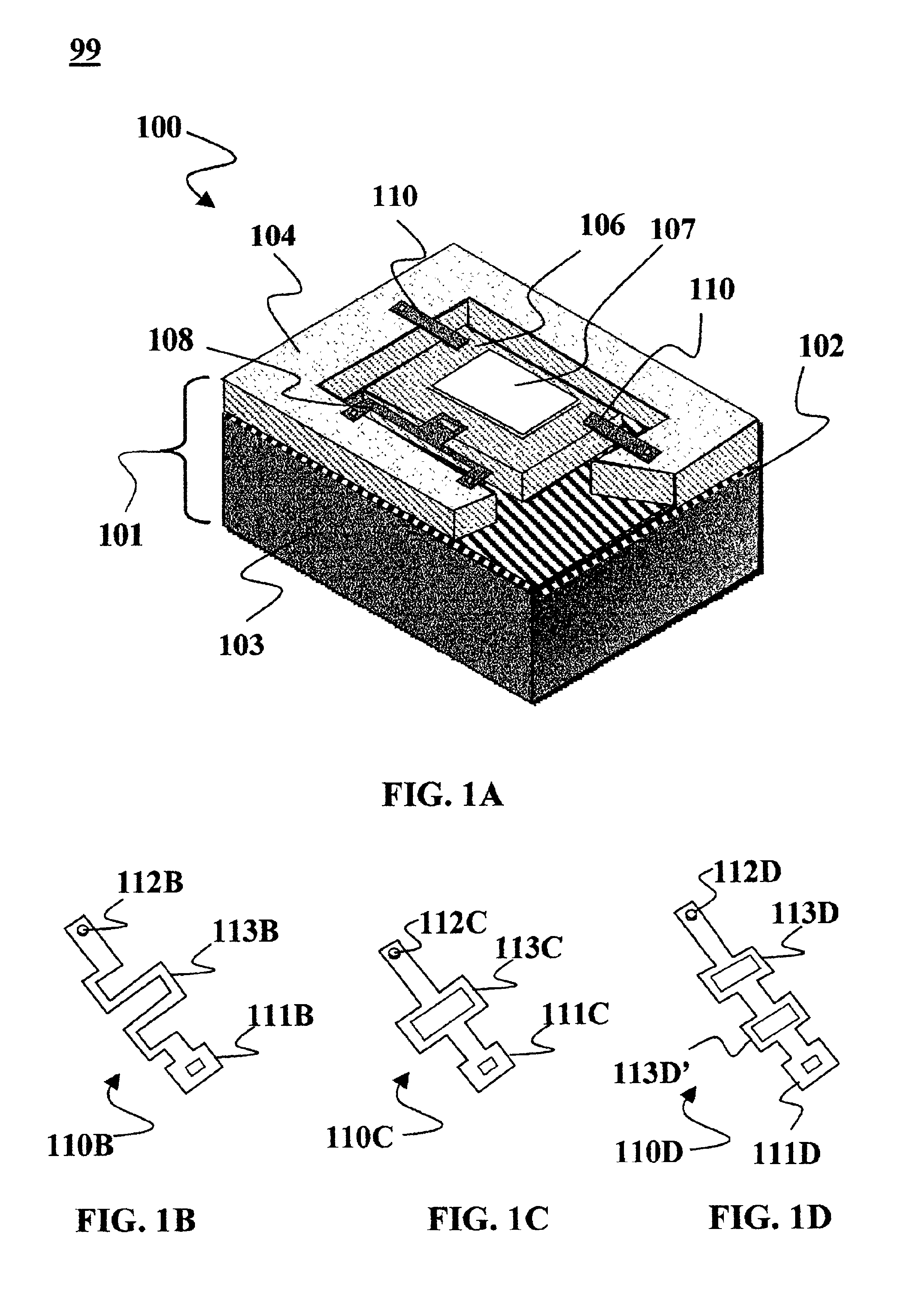

Integrated CMOS/MEMS microphone die

The claim invention is directed at a MEMS microphone die fabricated using CMOS-based technologies. In particular, the claims are directed at various aspects of a MEMS microphone die having anisotropic springs, a backplate, a diaphragm, mechanical stops, and a support structure, all of which are fabricated as stacked metallic layers separated by vias using CMOS fabrication technologies.

Owner:KNOWLES ELECTRONICS INC

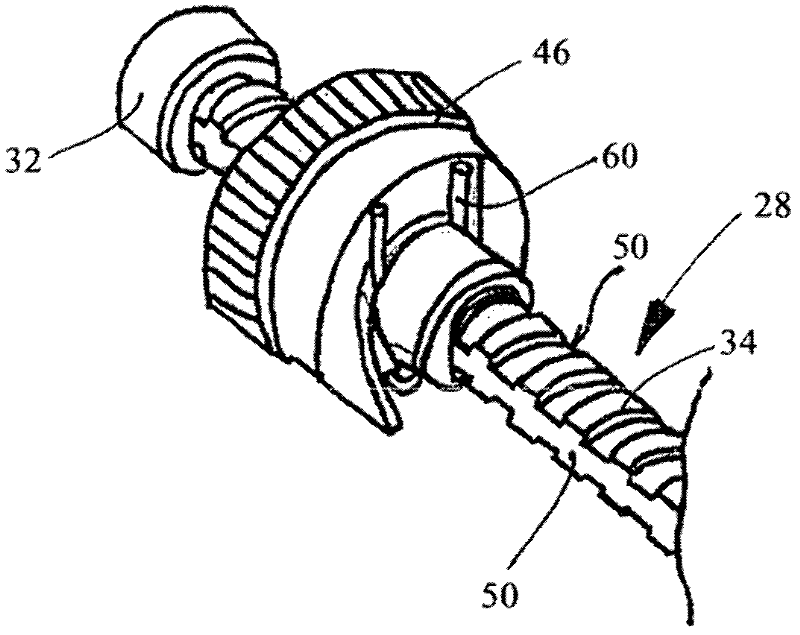

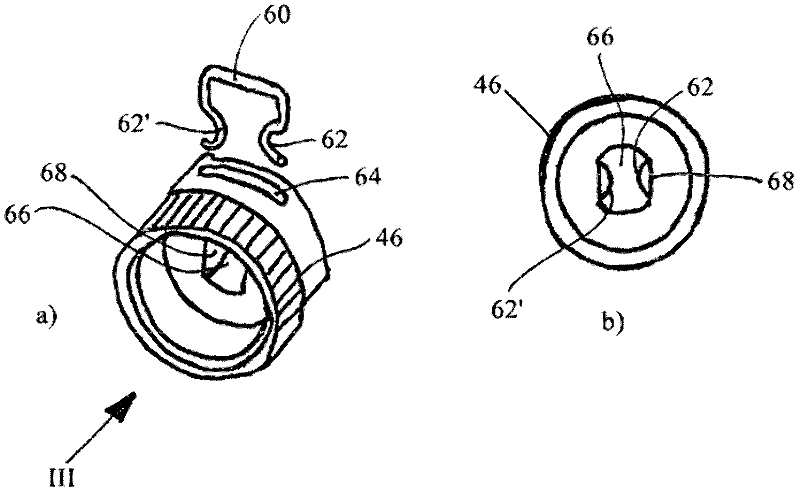

Injection device with holding means to prevent unintentional movements of piston rod

ActiveCN102238974AImprove the display effectAvoid formingAmpoule syringesMedical devicesAxial displacementEngineering

The invention relates to a injection device, comprising a housing being adapted to receive in its proximal housing portion a container with an injection fluid and to receive in its distal housing portion a dose setting and injection mechanism, wherein the mechanism includes a piston rod (28) being axially displaceable with respect to the housing for dispensing injection fluid from the container, wherein the piston rod (28) has an outer thread (34) and is arranged torque proof with respect to the housing, dose setting means comprising a threaded element, which threaded element has an inner thread being in engagement with the outer thread (34) of the piston rod (28), is designed so that its axial position relative to the housing is changeable and is rotatable relative to the piston rod (28) and relative to the housing during setting of an injection dose, wherein the dose setting means are designed such that the threaded element is held in torque proof manner relative to the piston rod (28) and to the housing during the injection of the beforehand set injection dose in such a manner that the threaded element and the piston rod (28) are axially displaceable together with respect to the housing, wherein the mechanism (26) further comprises holding means (60; 160) being in contact with the piston rod (28) and being designed such that the axial displacement of the piston rod (28) can be substantially immobilized during use of the device except for the dispensing of the injection dose. It is proposed according to the invention that the holding means (60; 160) are axially fixed with respect to the housing.

Owner:SANOFI AVENTIS DEUT GMBH

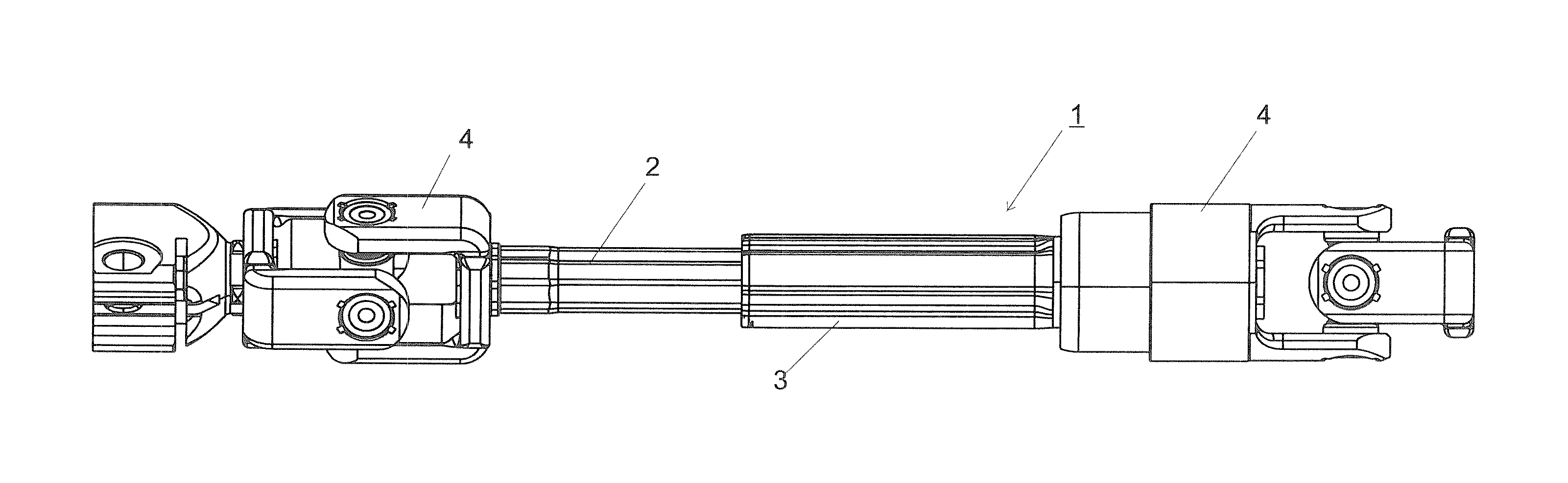

Antifriction bushing

ActiveUS20120165106A1Improve propertiesReduce expenditureClutchesYielding couplingFiberCarbon fibers

An antifriction bushing is provided for the bearing of a telescopable steering spindle having an inner spindle and an outer spindle which are disposed coaxially with respect to one another and displaceably with respect to one another and for the torque transmission have a cross section differing from circular. Between the outer spindle and the inner spindle, an interspace is provided for receiving the antifriction bushing consisting of a thermoplastic synthetic material or comprising such material. The bushing includes an inner surface and an outer surface, and consists of a mixture comprising the material PEEK and additionally at least one of the materials PTFE at a volume fraction of up to maximally 15% and / or graphite at a volume fraction of up to maximally 15% and / or carbon fibers at a volume fraction of up to maximally 40%.

Owner:THYSSENKRUPP PRESTA AG

Reduced stiction and mechanical memory in MEMS devices

ActiveUS20100025832A1Reduces bonding vibrational constant for bondStatic frictionSemiconductor/solid-state device detailsSolid-state devicesHydrogenEngineering

Owner:TEXAS INSTR INC

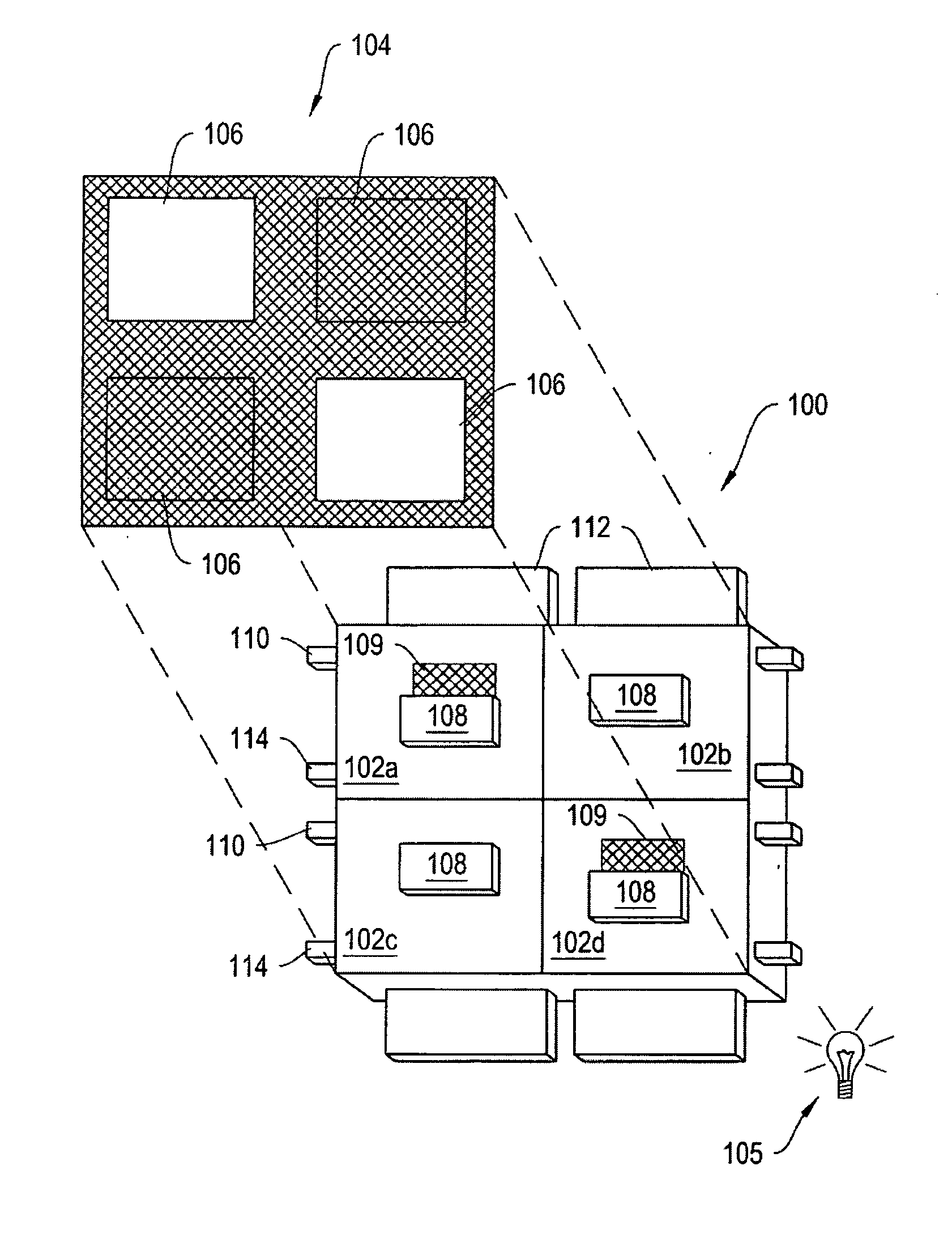

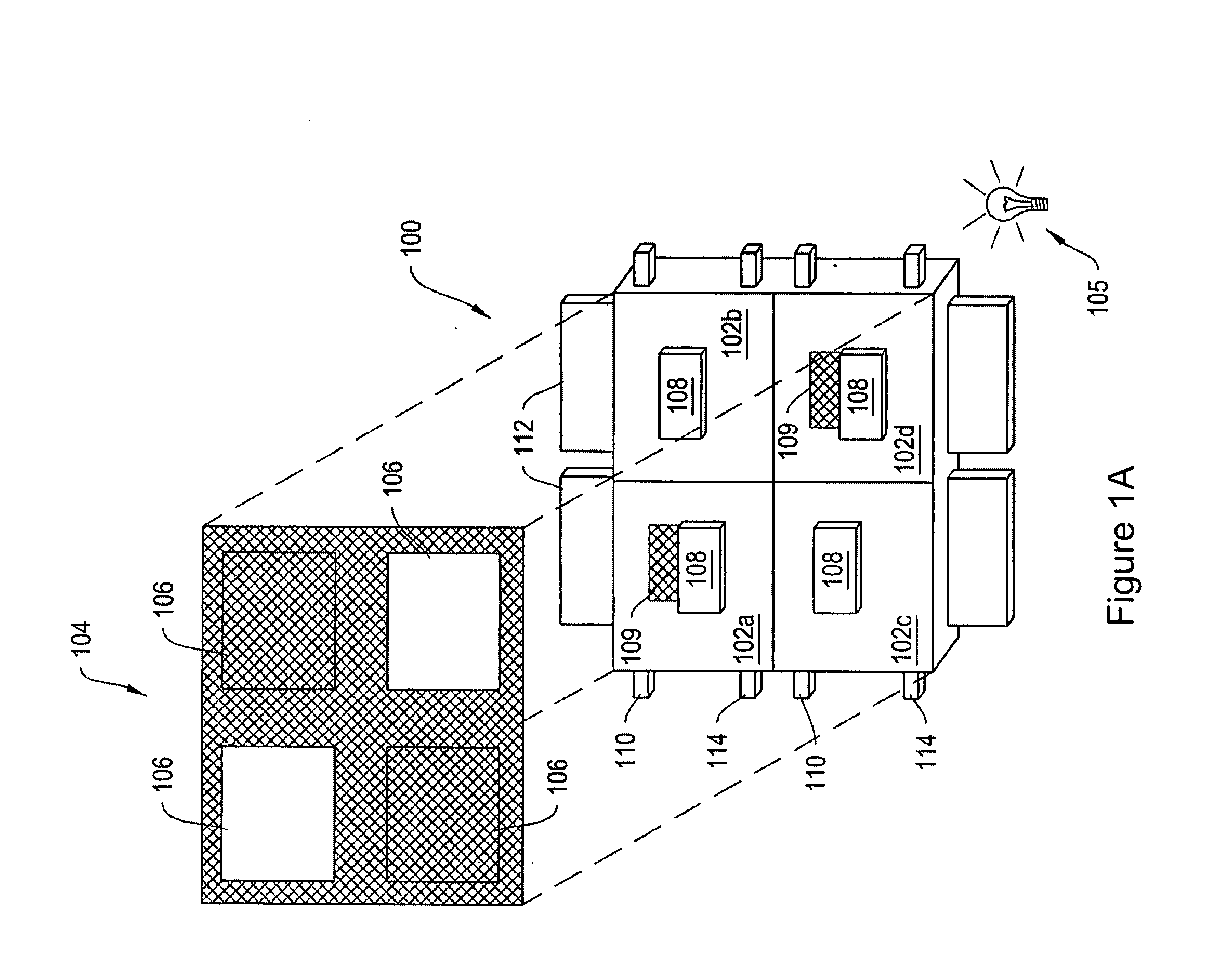

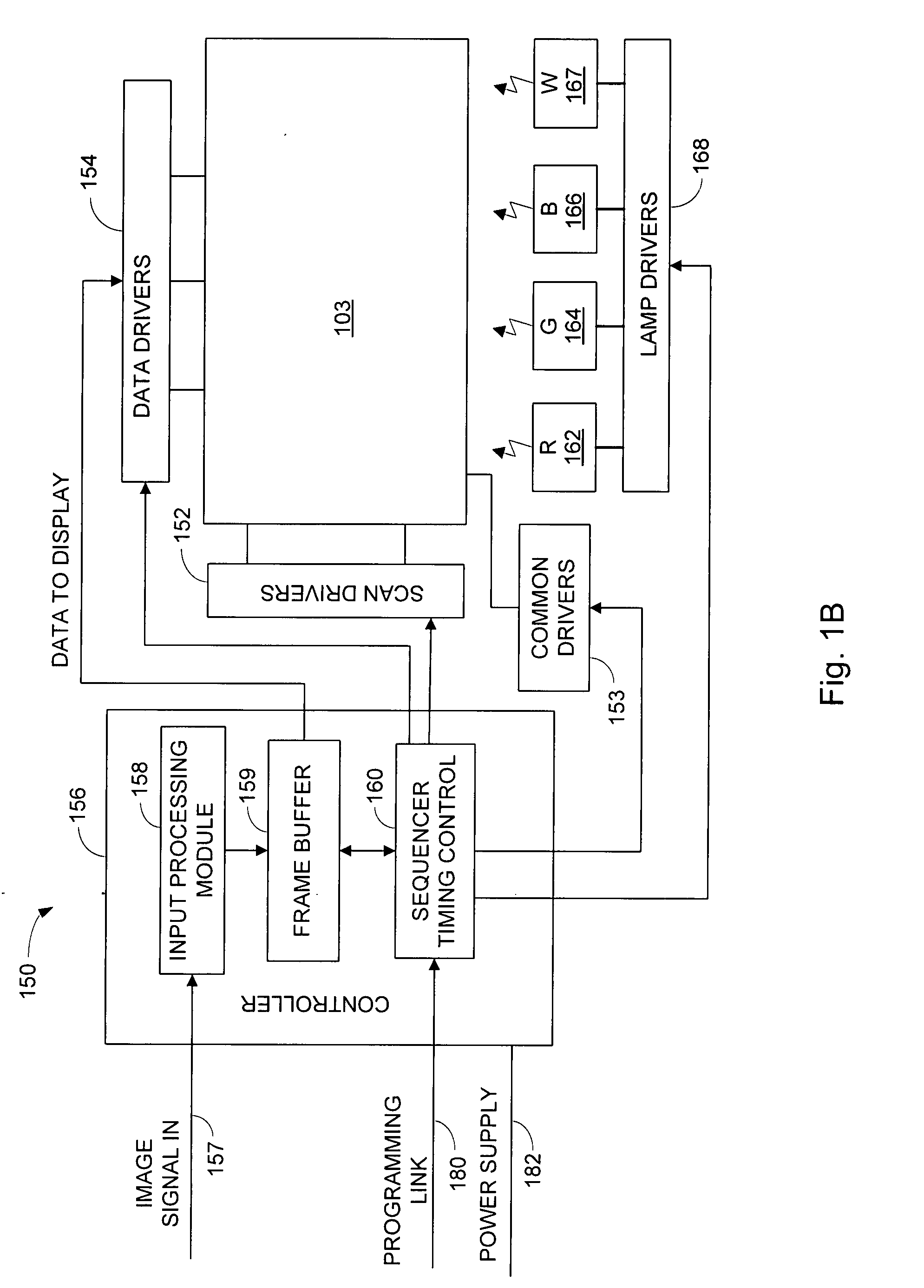

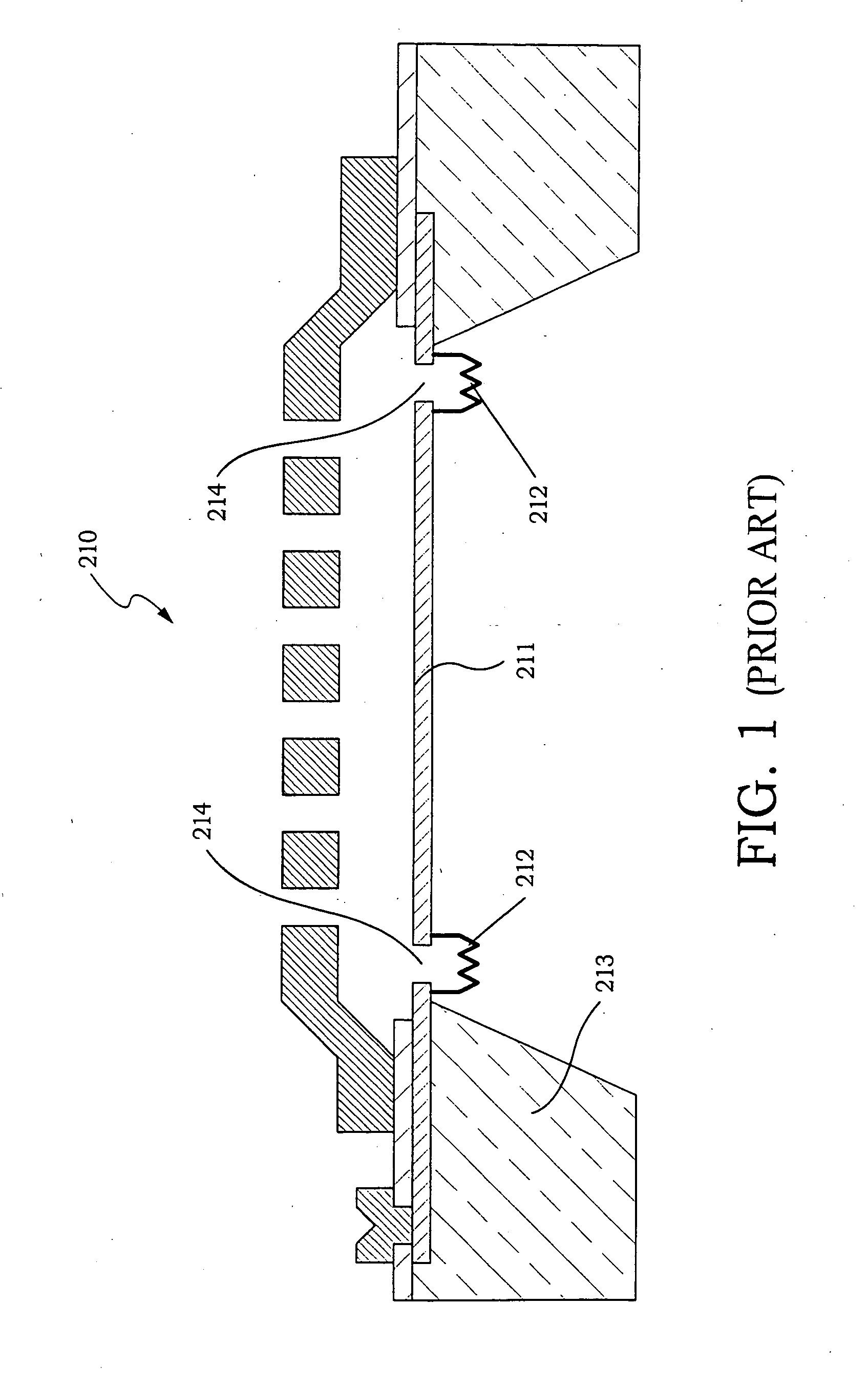

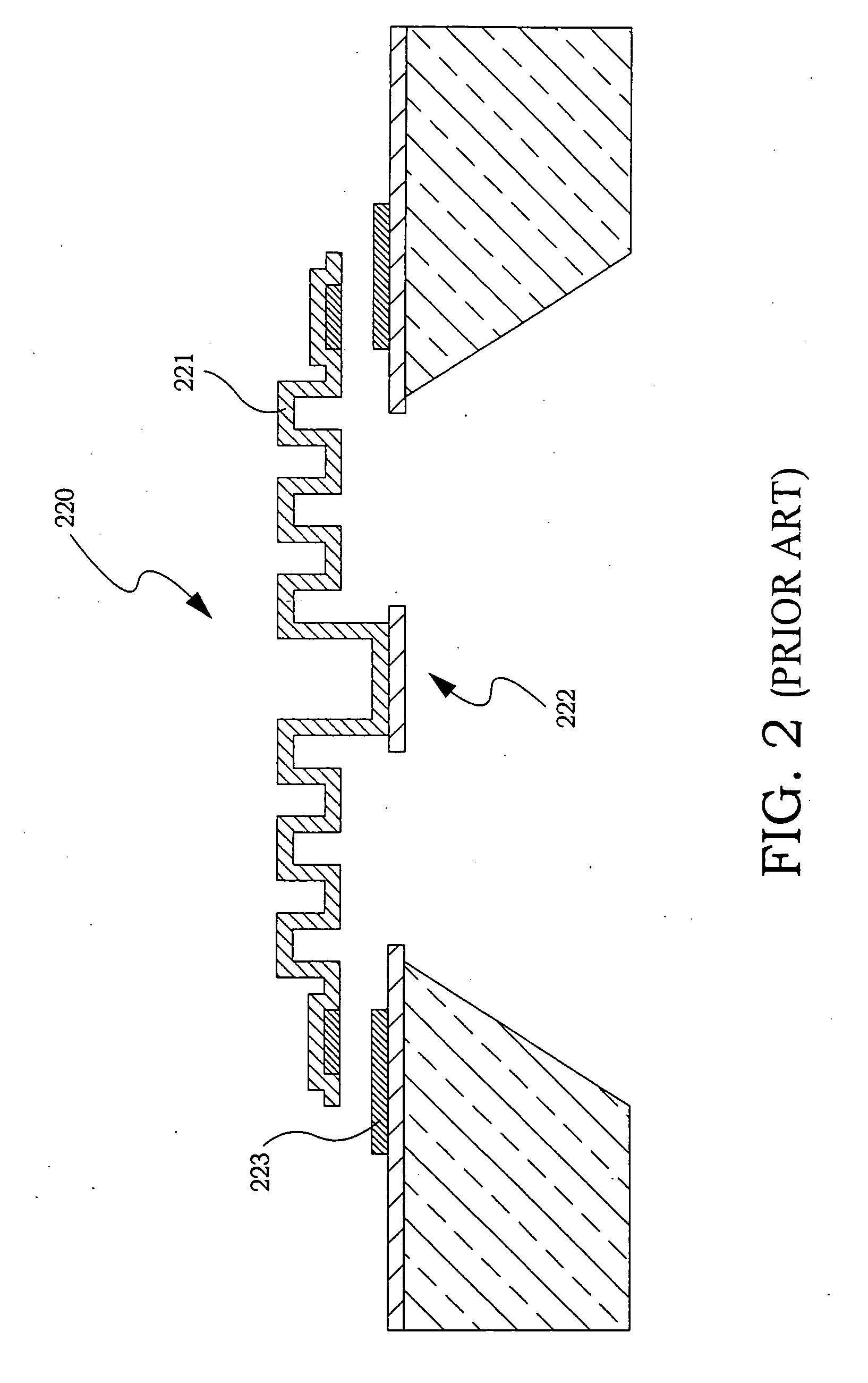

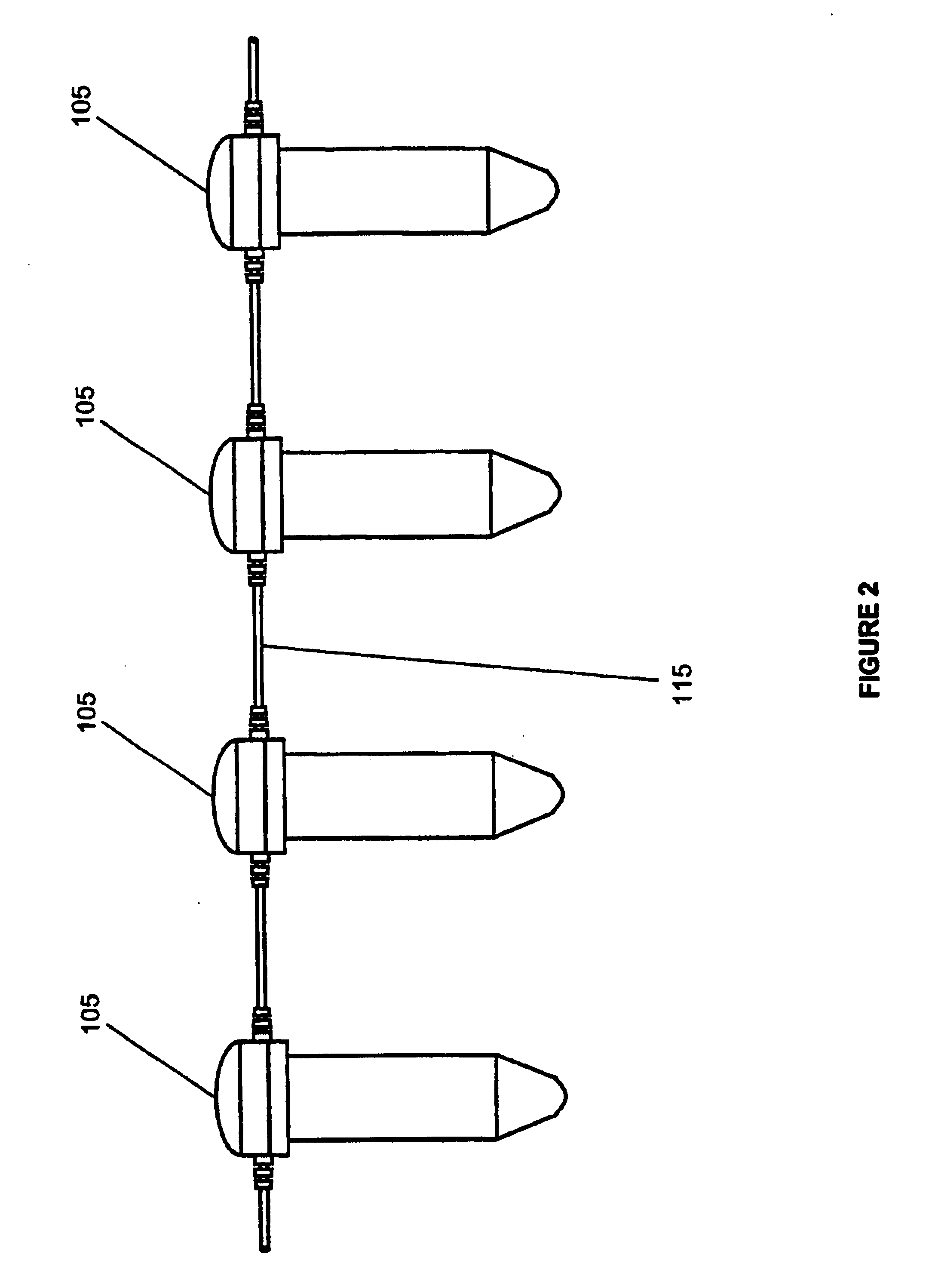

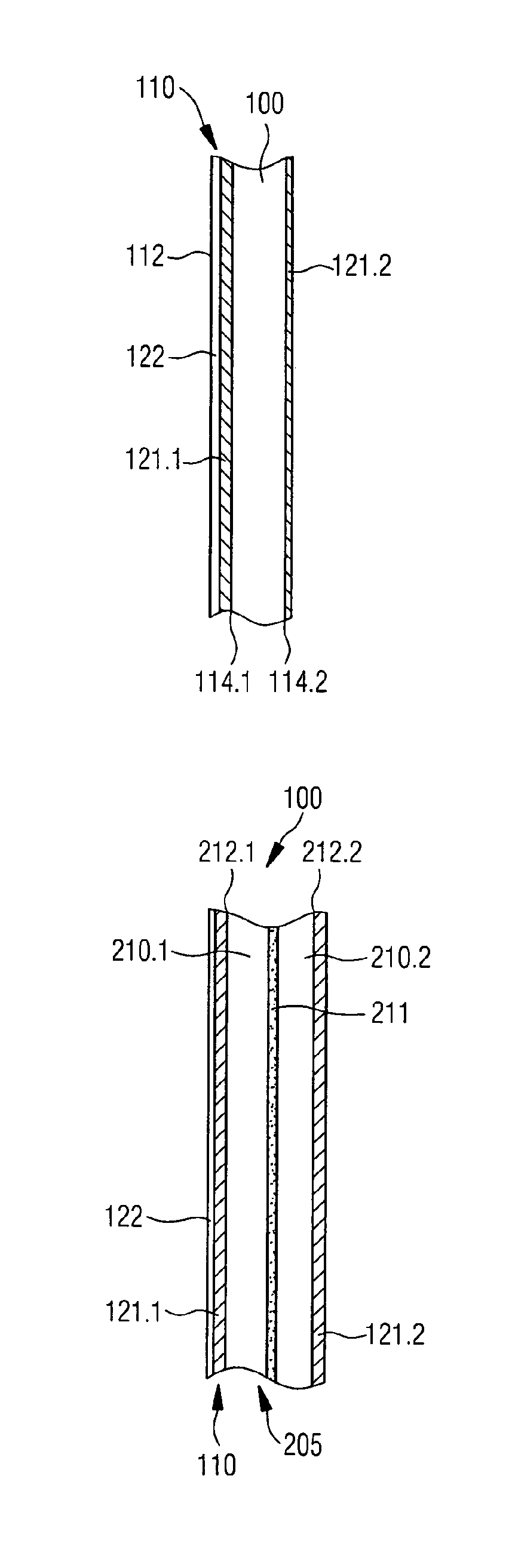

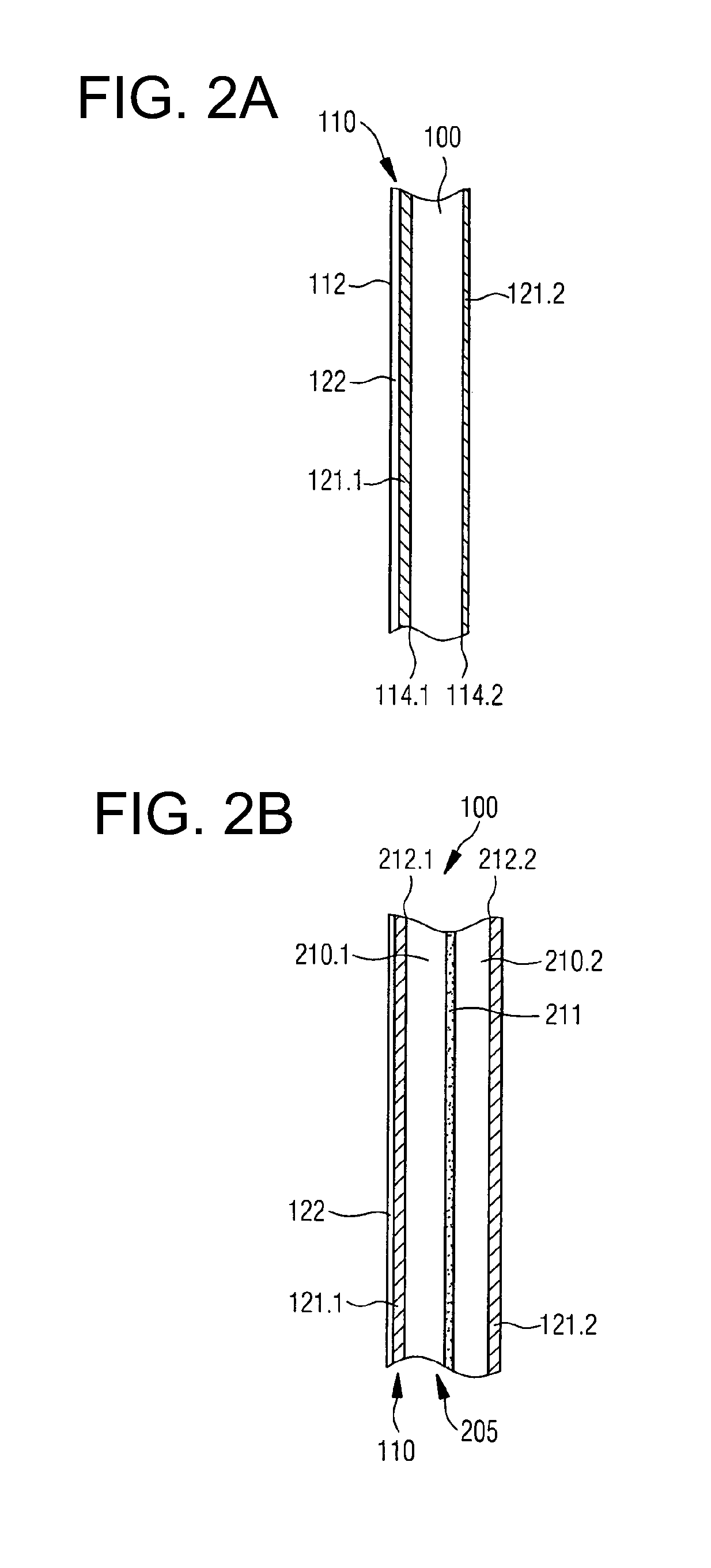

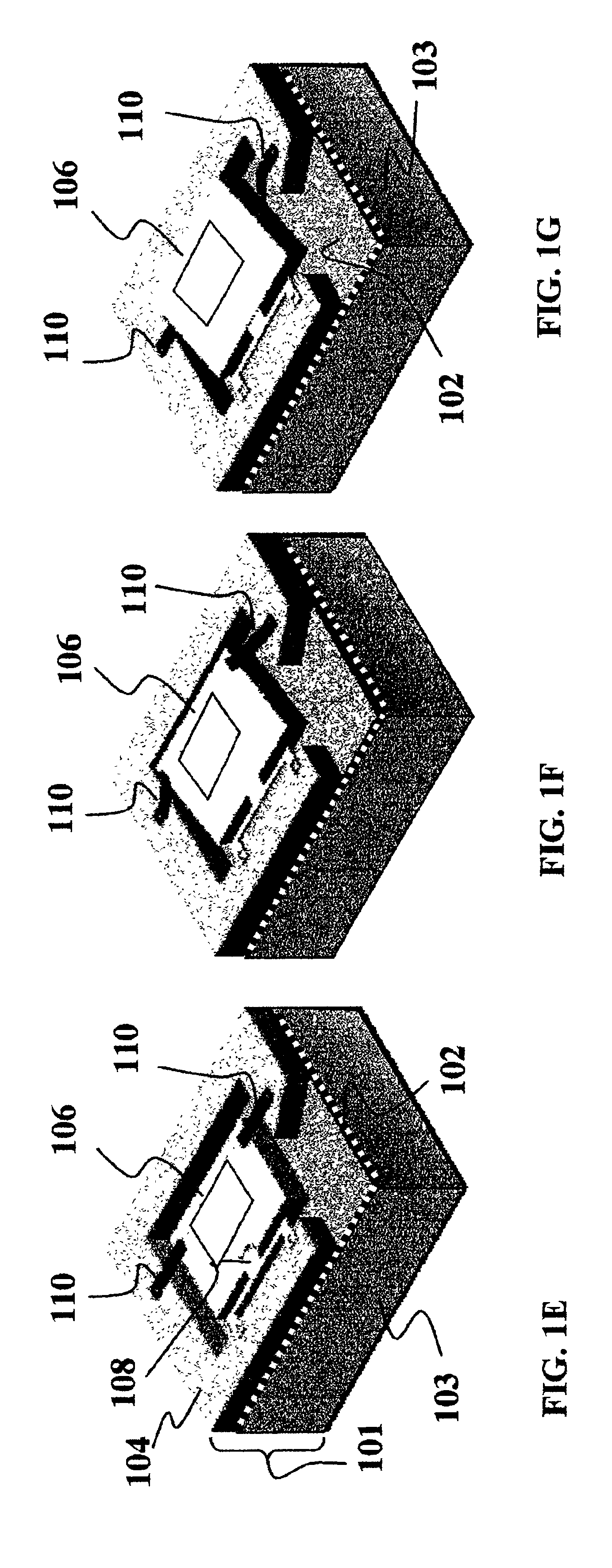

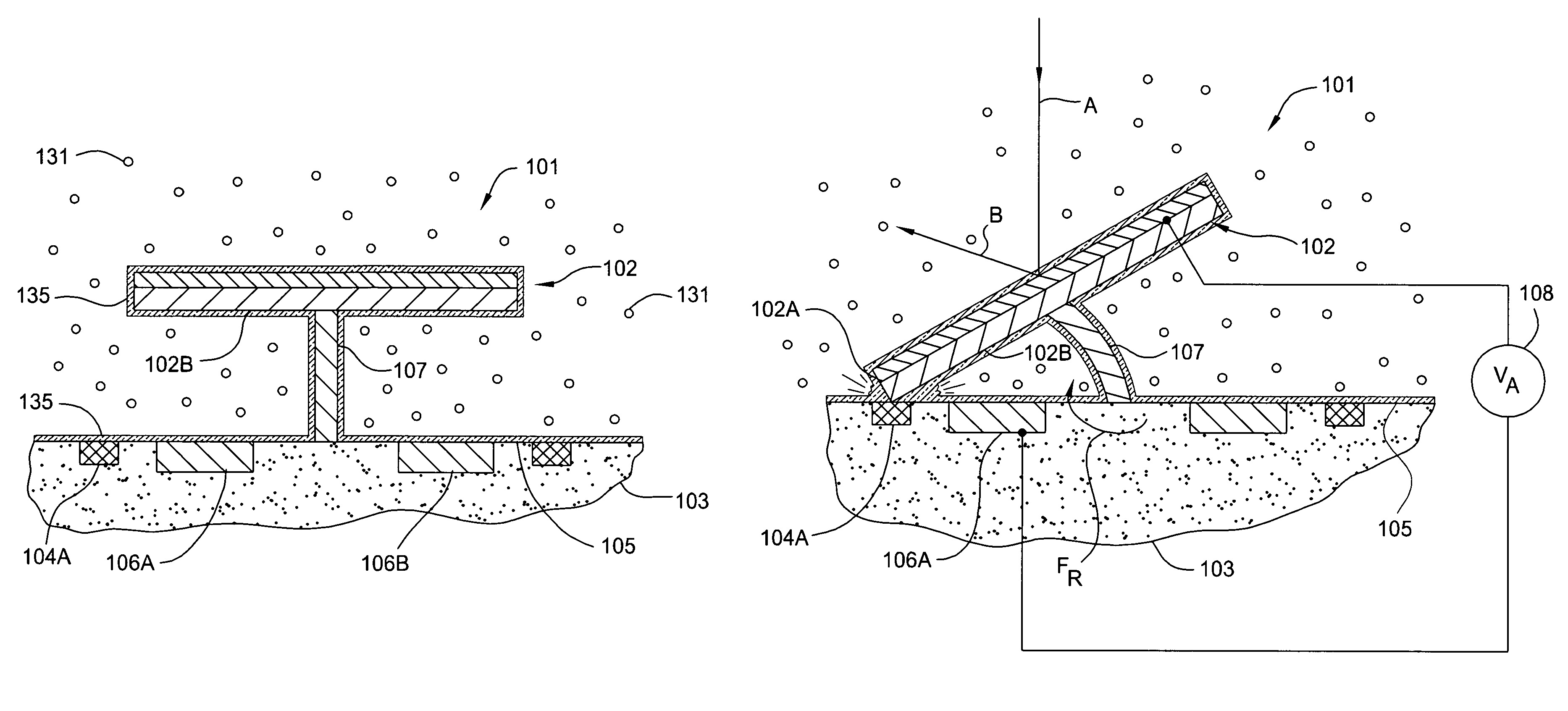

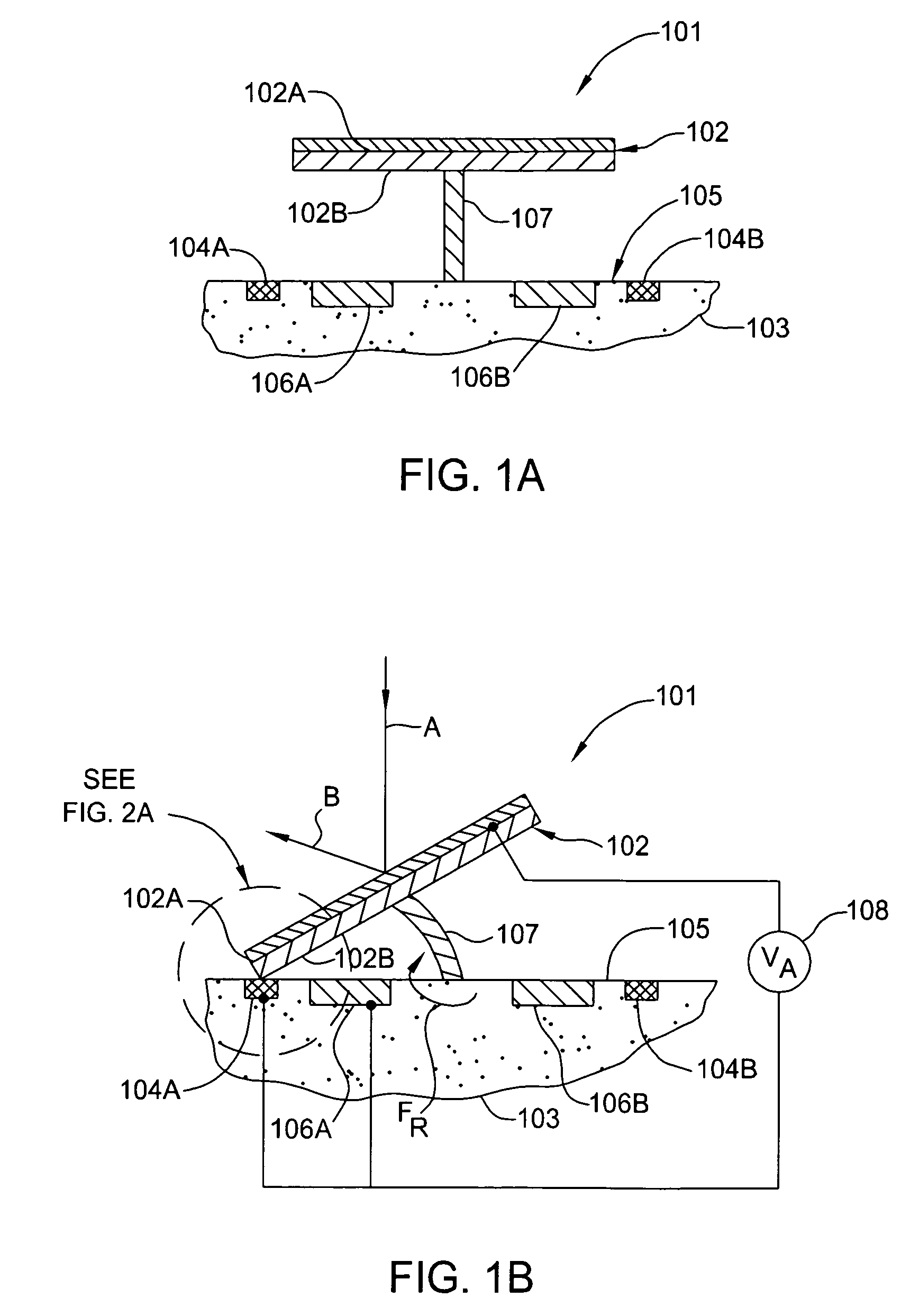

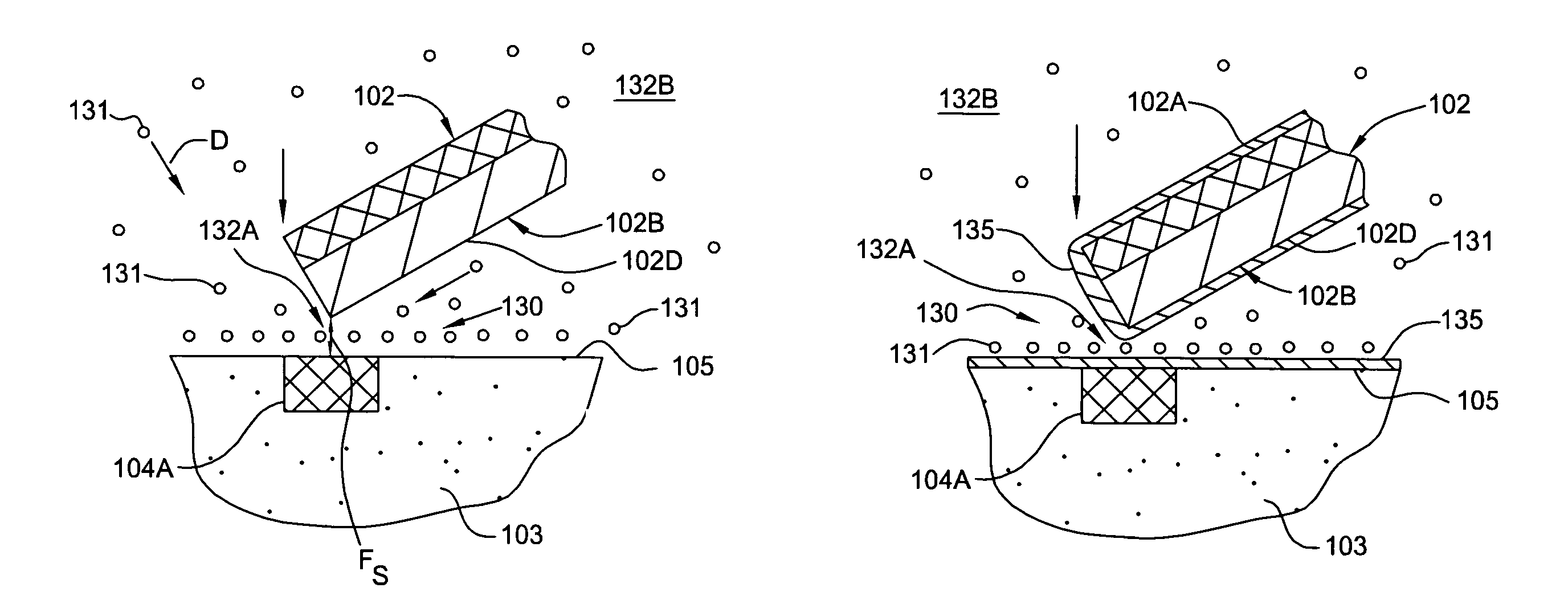

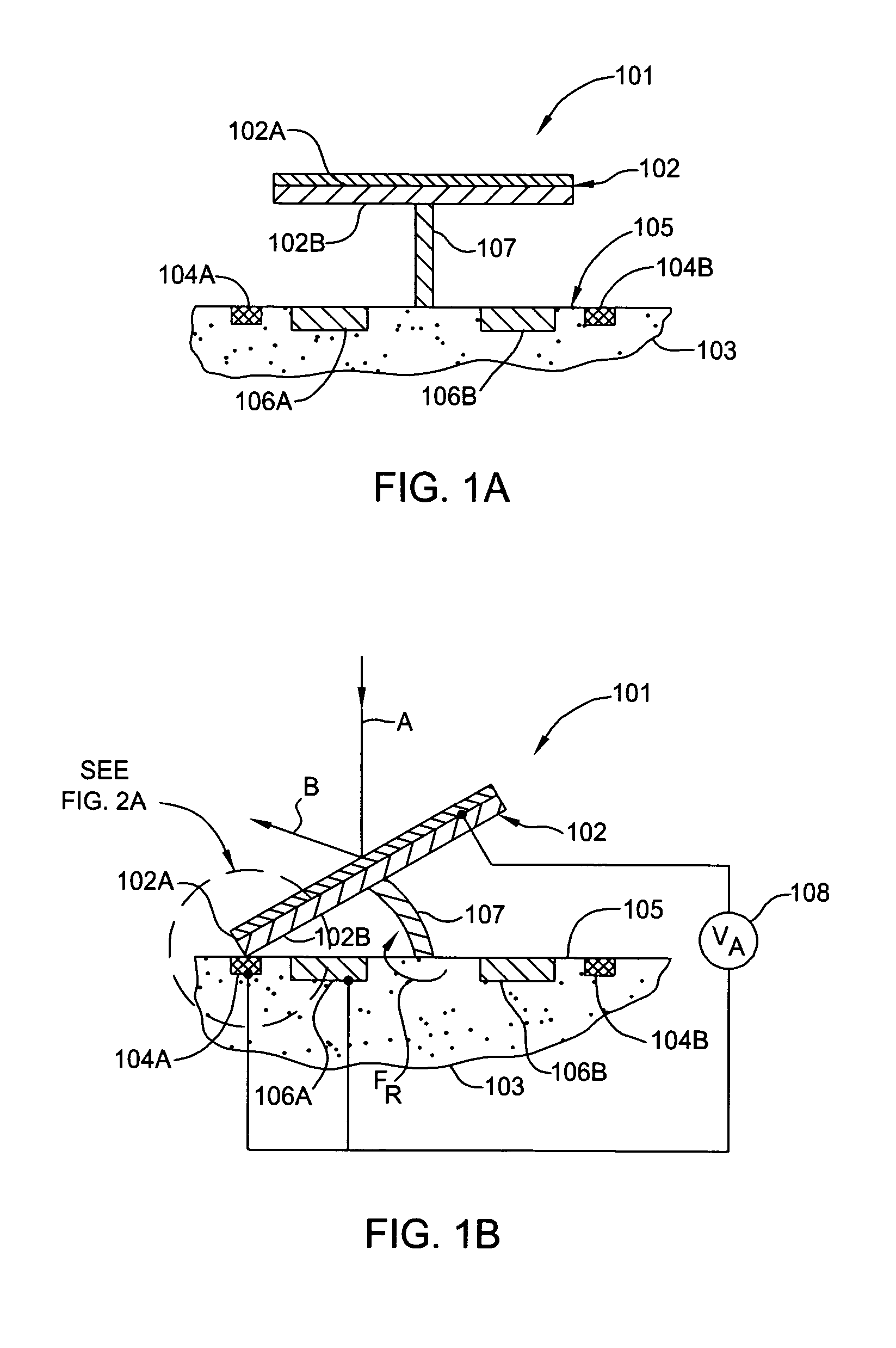

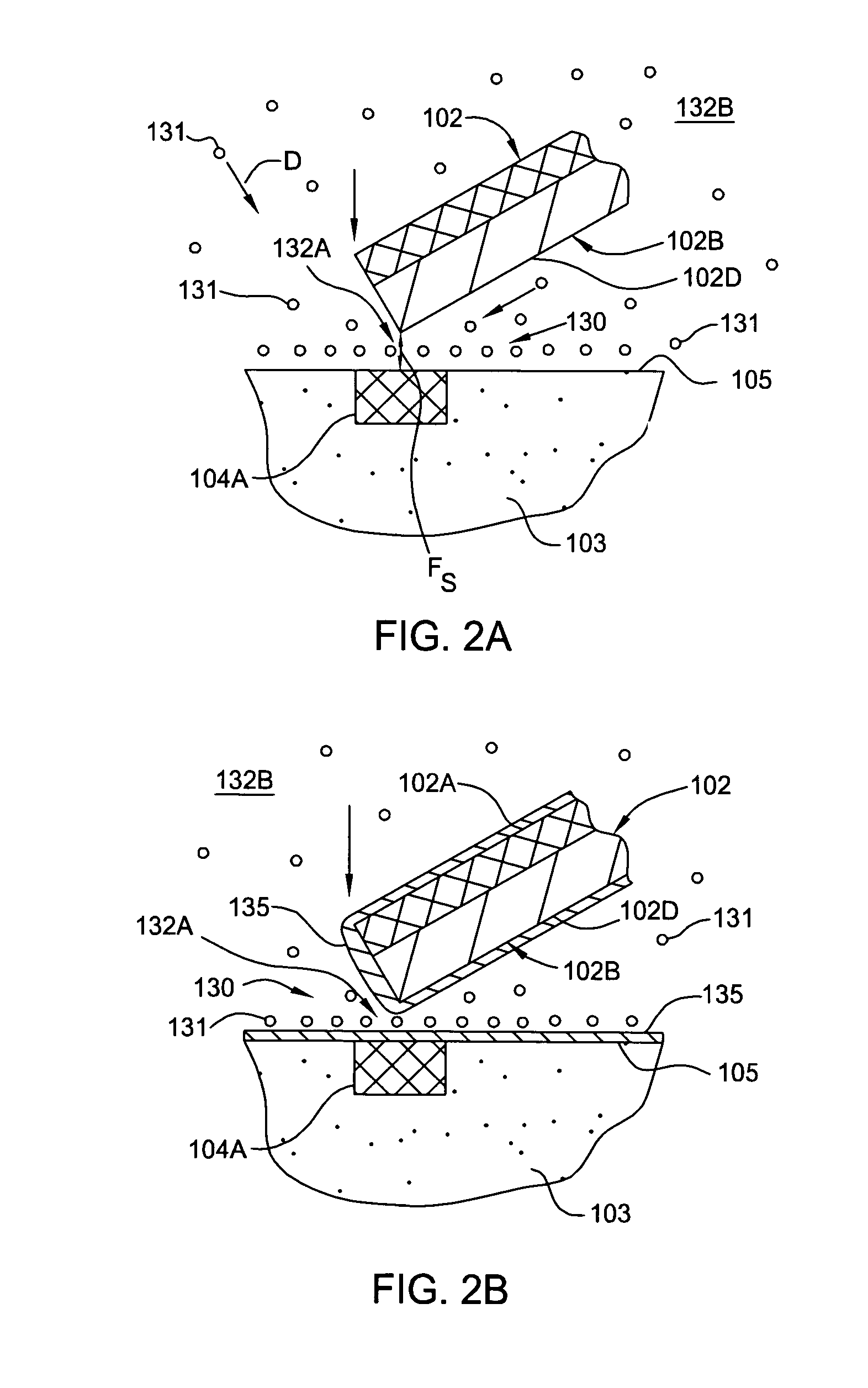

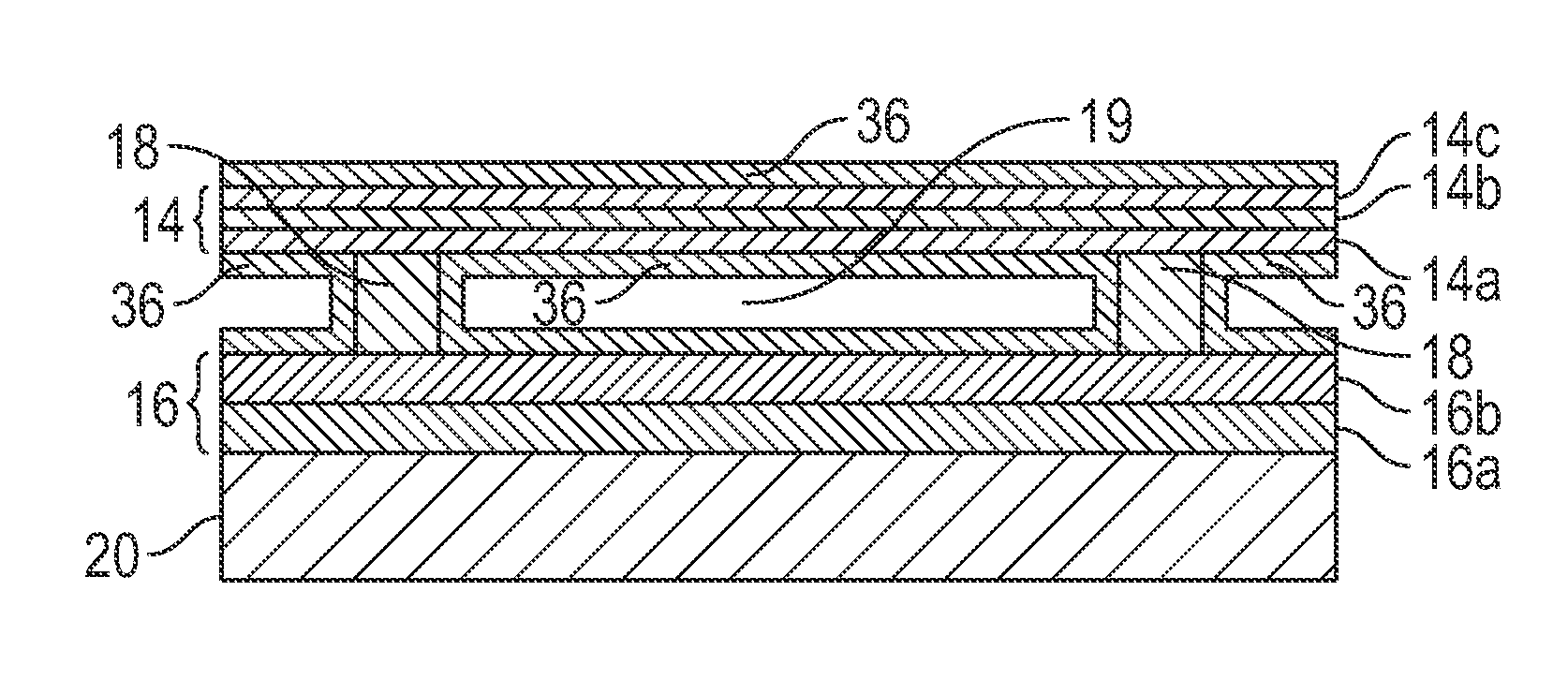

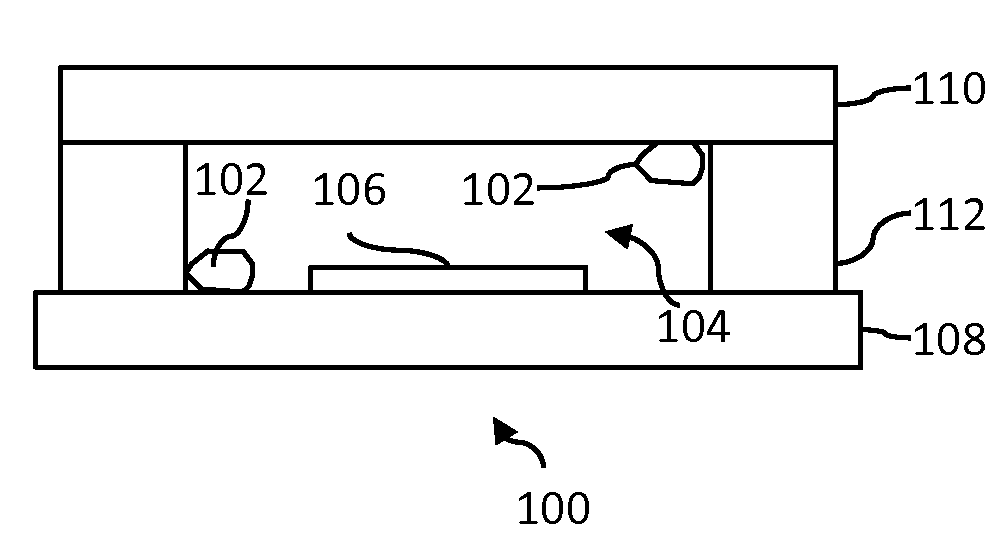

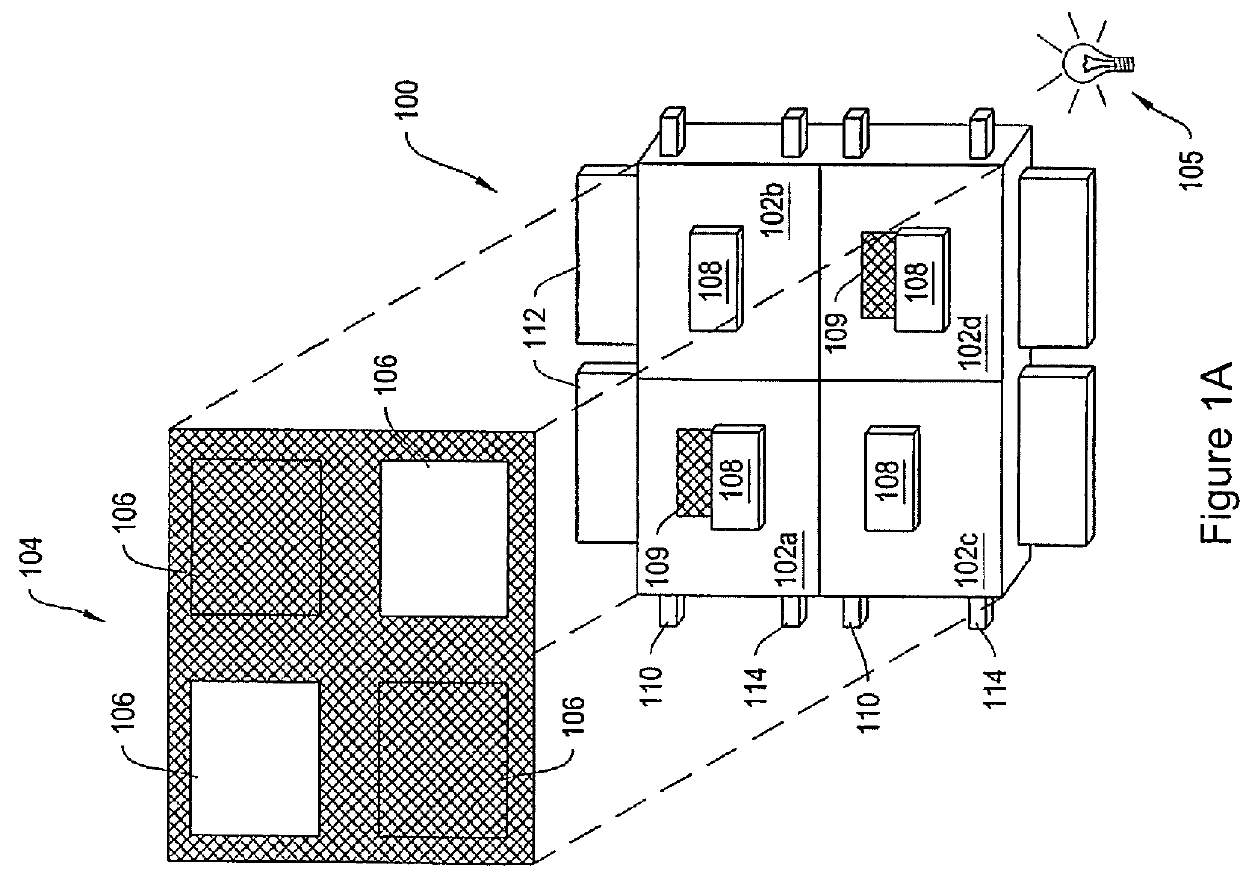

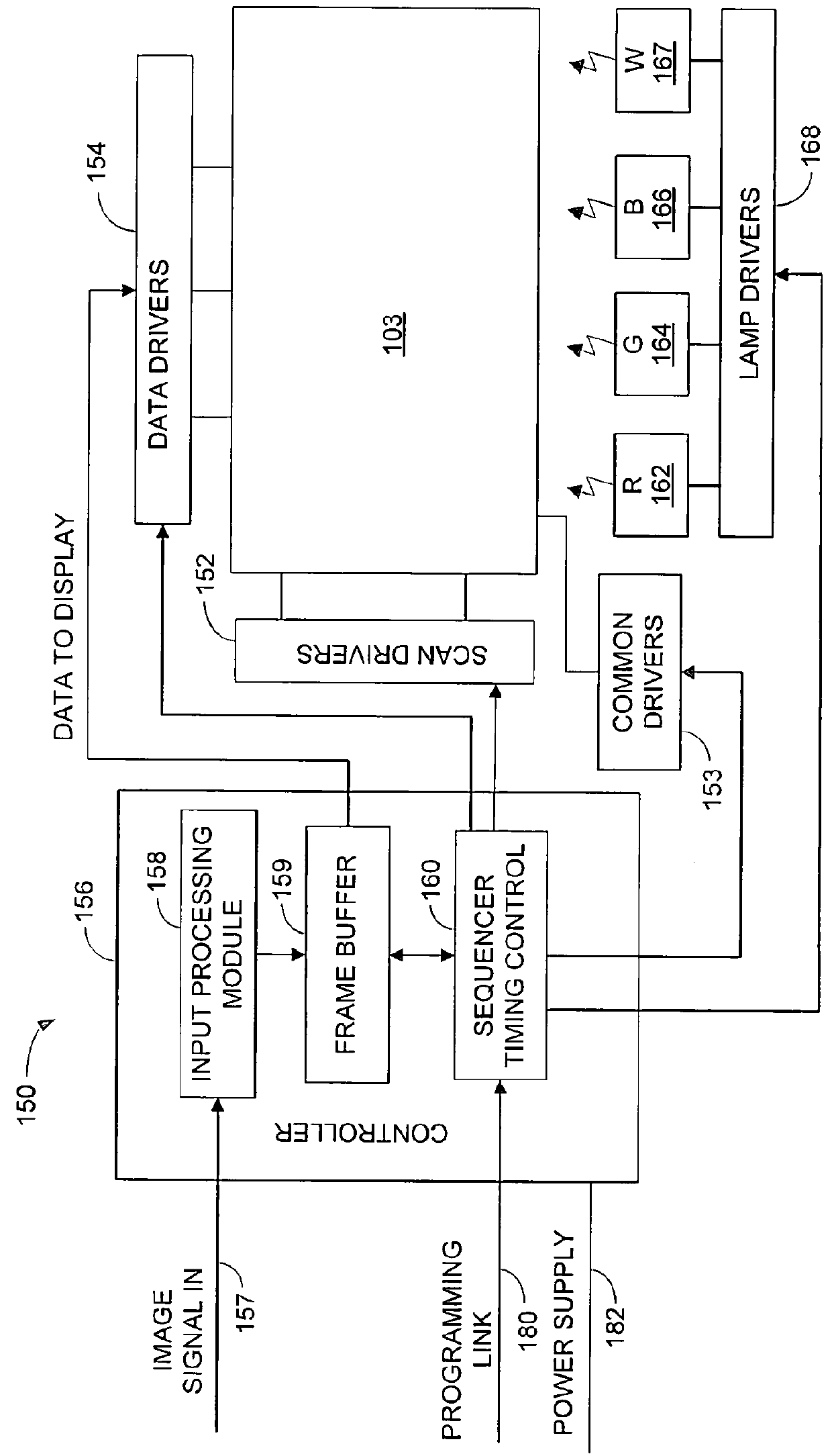

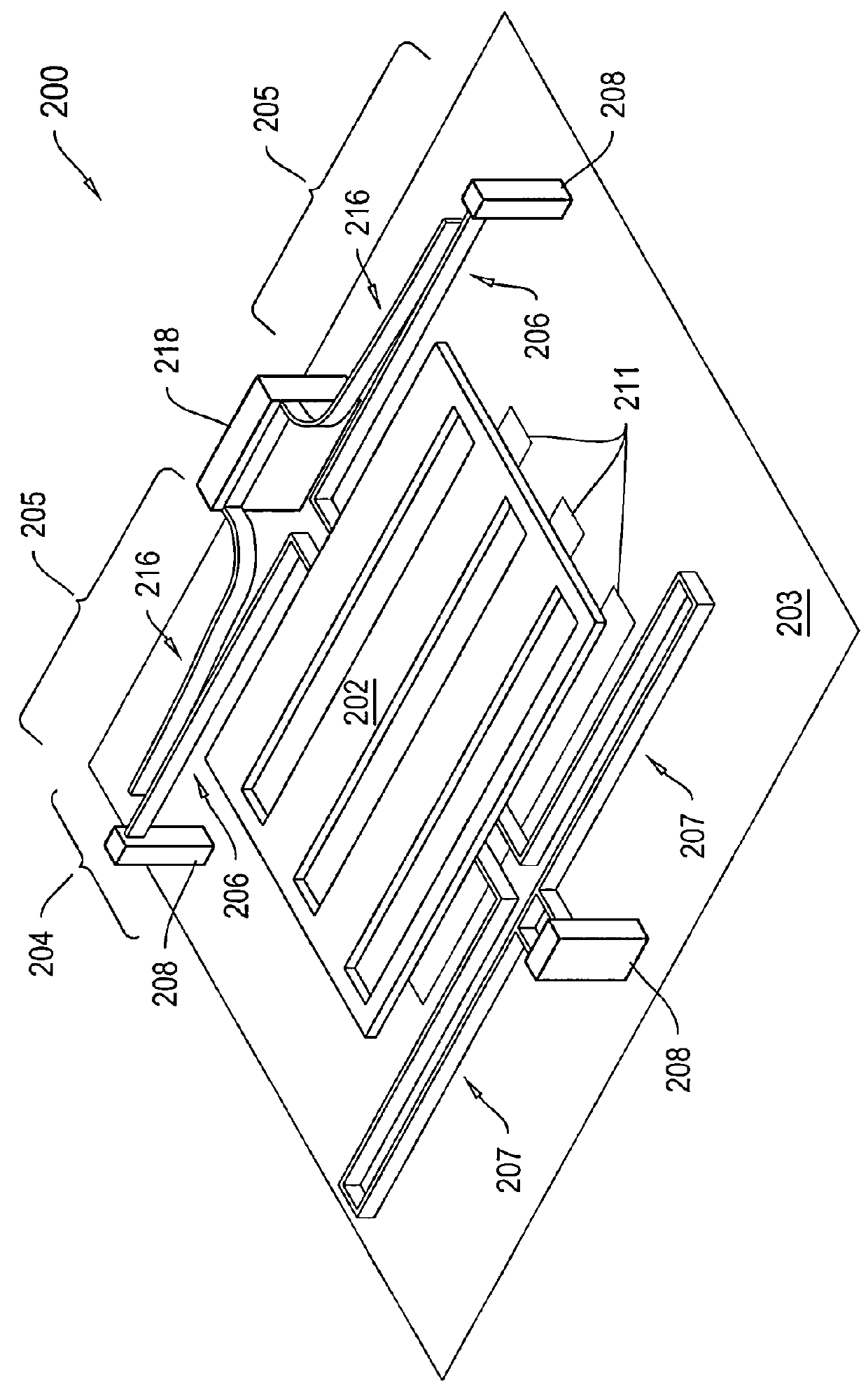

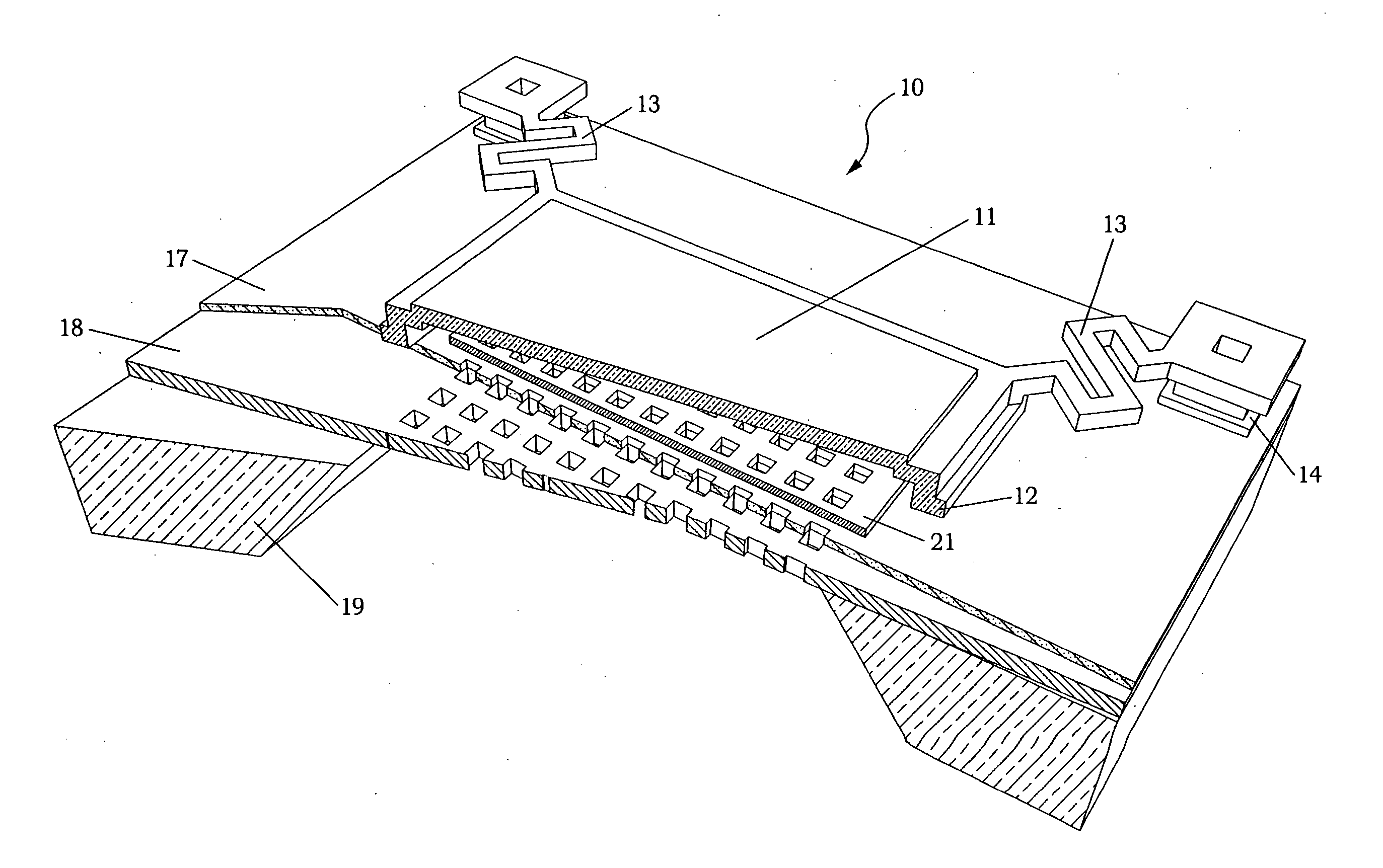

Alignment methods in fluid-filled MEMS displays

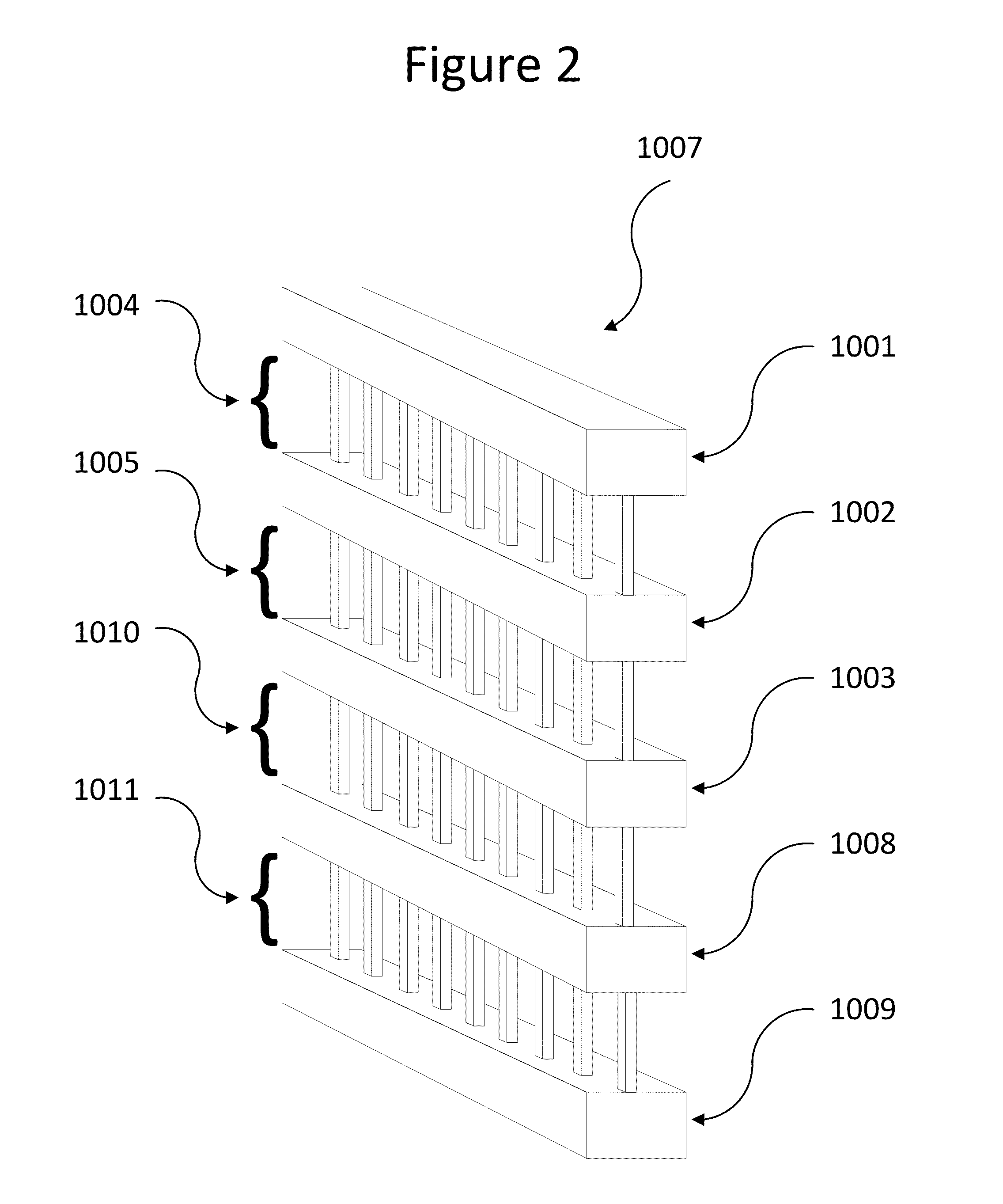

InactiveUS9229222B2Improve performanceReduce static frictionPrecision positioning equipmentStatic indicating devicesEngineeringStiction

This invention relates to MEMS display apparatus and methods for assembly thereof that include a plurality of light modulators having components substantially surrounded in a liquid that reduces the effects of stiction and improves the optical and electromechanical performance of the display apparatus. The invention also relates to methods for aligning components of a MEMS display to establish a correspondence between the plurality of light modulators and a plurality of apertures to regulate the transmission of light through the apparatus.

Owner:SNAPTRACK

Miniature condenser microphone and fabrication method therefor

InactiveUS20060215858A1Minimize impactReduce manufacturing costPiezoelectric/electrostrictive microphonesSemiconductor electrostatic transducersCapacitanceEngineering

An acoustic pressure type sensor fabricated on a supporting substrate is disclosed. The acoustic sensor is fabricated by depositing and etching a number of thin films on the supporting substrate and by machining the supporting substrate. The resulting structure contains a pressure sensitive, electrically conductive diaphragm positioned at a distance from an electrically conductive fixed electrode. In operation, the diaphragm deflects in response to an acoustic pressure and the corresponding change of electrical capacitance between the diaphragm and the fixed electrode is detected using an electrical circuit. Two or more such acoustic sensors are combined on the same supporting substrate with an interaural flexible mechanical connection, to form a directional sensor with a small surface area.

Owner:FOR NAT RES INITIATIVES

Display substrate, method of manufacturing the same and display panel having the same

ActiveUS20120293852A1Reduce static frictionSemiconductor/solid-state device manufacturingLiquid/solution decomposition chemical coatingEngineeringElectrode

A display substrate includes a base substrate, a micro shutter, a first driving electrode, a second driving electrode, and a plurality of anchors. The micro shutter includes a flat portion having at least one opening, a main concave portion adjacent to the opening and extending in from the flat portion to a first depth, and at least one sub-concave portion extending in from a bottom surface of the main concave portion to second depth. The first driving electrode is connected to a first side of the micro shutter. The second driving electrode is connected to a second side of the micro shutter. The second side is positioned opposite to the first side. The anchors fix the first and second driving electrodes on the base substrate.

Owner:SAMSUNG DISPLAY CO LTD

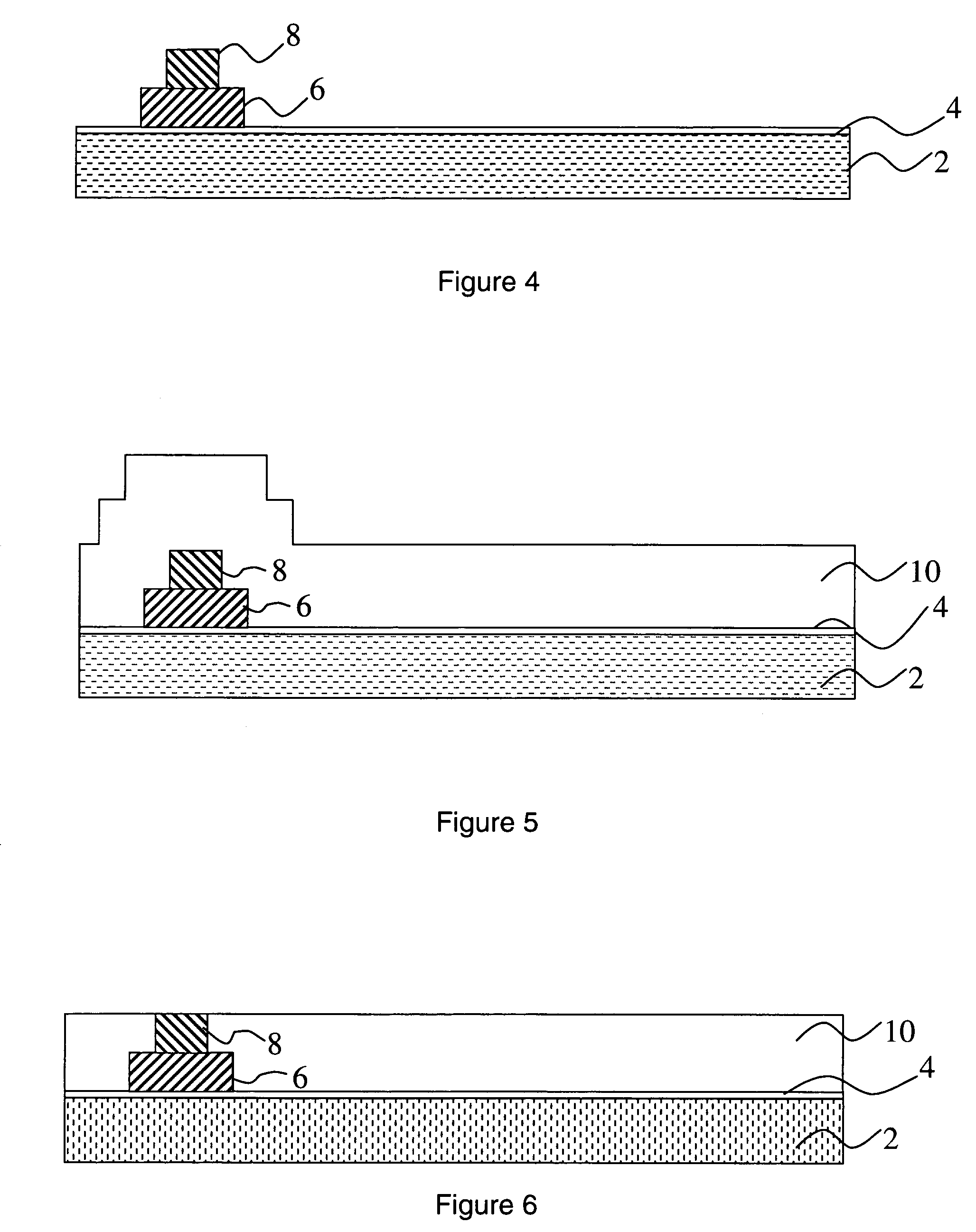

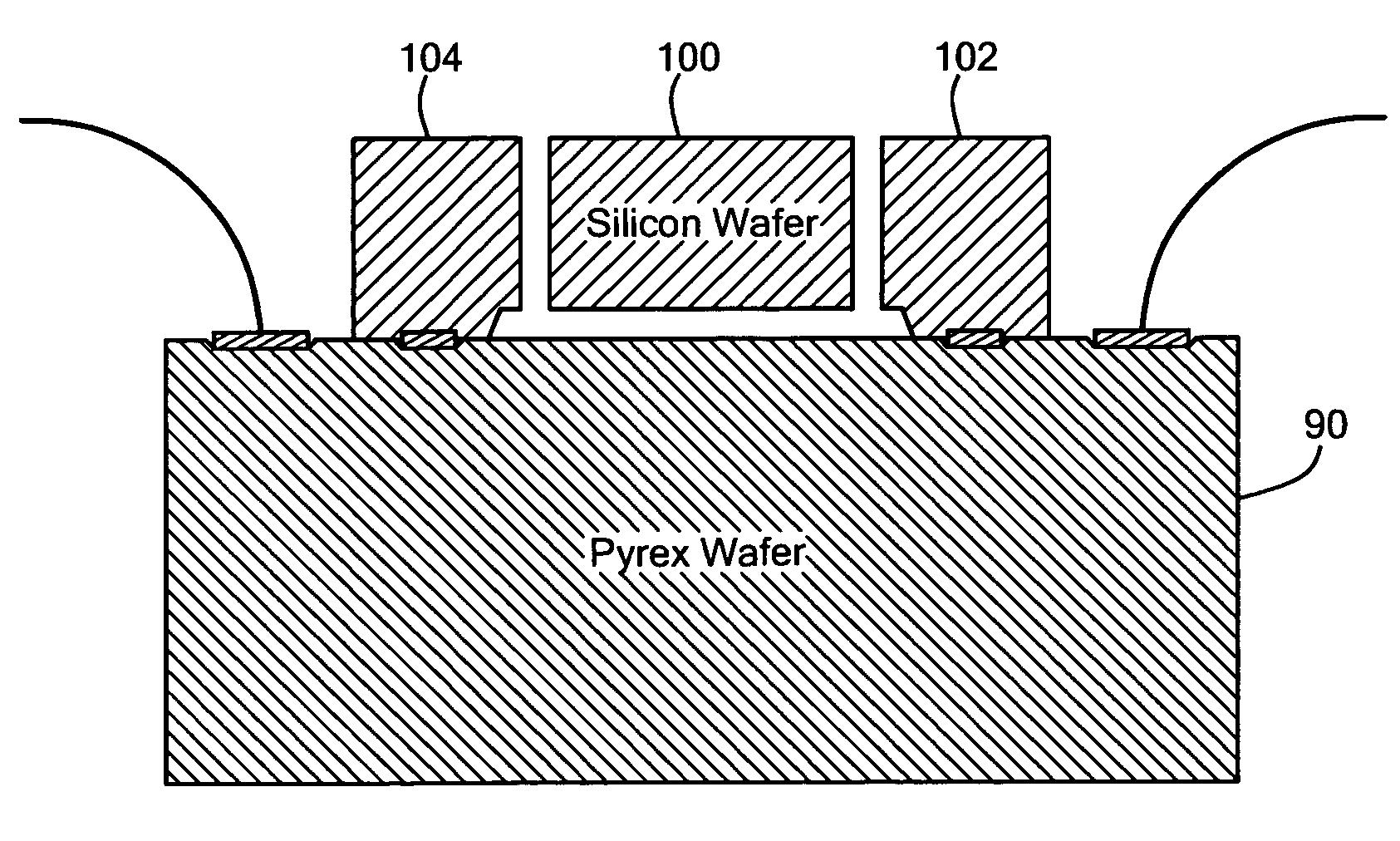

Method for fabricating micro-mechanical devices

ActiveUS7300814B2Reduce misalignmentLow costSolid-state devicesSemiconductor/solid-state device manufacturingPatterned substrateElectrical and Electronics engineering

A method of fabricating micro-mechanical devices. A mesa is etched in a homogeneous wafer. The wafer is bonded to a patterned substrate with the mesa defining device elements suspended above the substrate. A portion of the wafer is removed until a desired device thickness is achieved. Discrete elements of the device are then formed by performing a structural etch on the remaining wafer material.

Owner:CHARLES STARK DRAPER LABORATORY

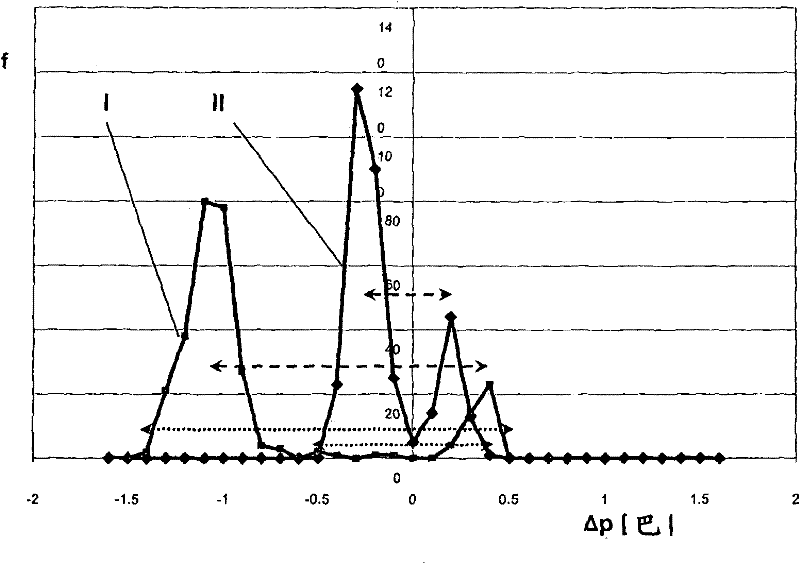

Method and air-operated valve for determining wear condition of valve through pressure sensing

InactiveCN101749296AReduce adverse effectsReduce measurement errorValve arrangementsFluid-pressure actuator testingStatic frictionEngineering

Owner:ABB TECH AG

Electronic throttle control simulation experiment system

InactiveCN101739862AContinuous currentGood low speed characteristicsProgramme controlComputer controlMicrocontrollerControl signal

The invention relates to an electronic throttle control simulation experiment system. The overseas research of the electronic throttle control system (ETCS) has over twenty-year history, the products prepared by manufacturers are beginning to be put on the market largely and the current generation of the electronic throttle products has been launched. The system of the invention comprises a control circuit, wherein the control circuit comprises a signal acquiring and processing circuit, a MCU, a power drive circuit, a DC motor control driver, an accelerator pedal position sensor (PPS) and an electronic throttle position sensor (TPS); the accelerator pedal position sensor and the electronic throttle position sensor are used to separately input the accelerator pedal control signal and feed back the throttle position signal, the A / D converter of the MCU converts an input analog signal to a digital signal, after the control algorithm calculates control quantity, the control signal is output from a high-speed outlet (HSO) and an I / O port, the DC motor driver outputs the power drive signal to control the rotation of the DC motor, thus realizing the control of the opening of the throttle. The invention is used in the electronic throttle.

Owner:HEILONGJIANG INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com