Method and air-operated valve for determining wear condition of valve through pressure sensing

A pressure and valve technology, applied in the field of moving and/or stopping, which can solve problems such as equipment or vehicle failure, reduce measurement errors and eliminate adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

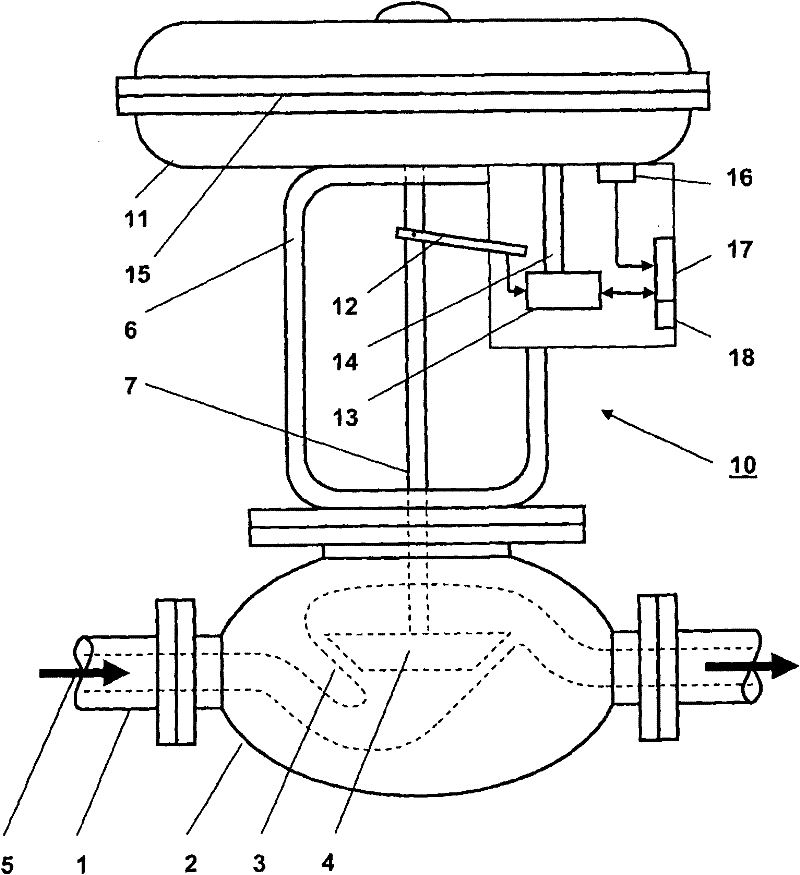

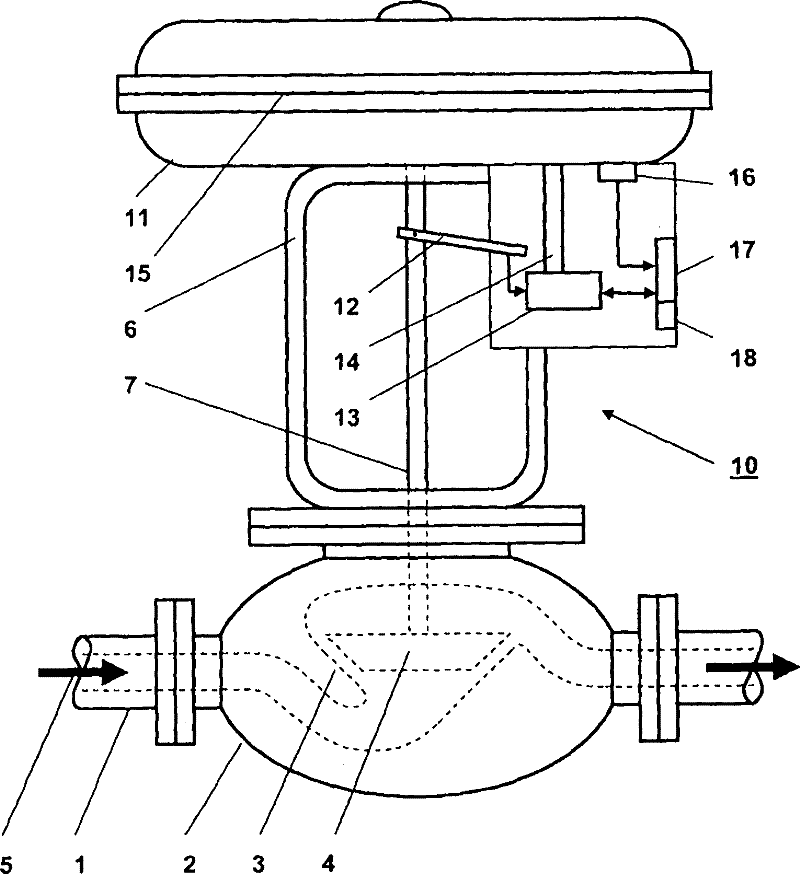

[0025] according to figure 1 , a process valve is arranged in the fragmented line 1 of a process technology device not shown further. The treatment valve has in its interior a closing body 4 which cooperates with the valve seat 3 for controlling the amount of treatment medium 5 flowing through. The closing body 4 is driven linearly by the pneumatic adjustment drive 10 via the lifting rod 7 . The pneumatic adjustment drive 10 is connected to the valve housing 2 of the treatment valve via the yoke 6 . A digital positioner with a positioner 13 is arranged on the yoke 6 . The lift of the lift rod 7 is reported to the position controller area via the position recorder 12 . The detected lift is compared in the positioning controller 13 with a predetermined setpoint value, and the pneumatic actuating drive 10 is actuated as a function of the determined actuating deviation. The pneumatic actuating drive 10 includes a pilot valve arrangement in the area of the positioning control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com