Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Reduce safety accidents" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

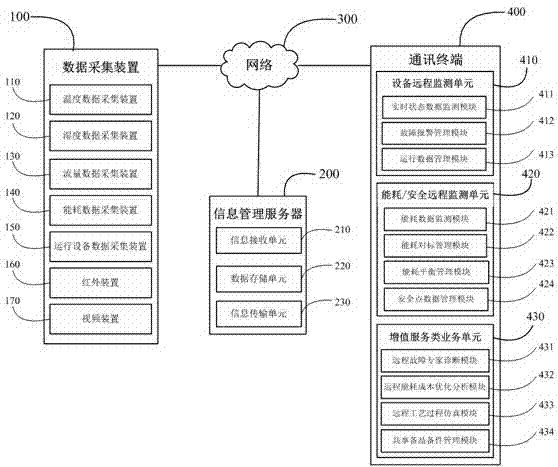

Remote monitoring and controlling system

InactiveCN103034213ATo achieve the effect of energy saving and emission reductionSimple processEnergy industryTotal factory controlMonitoring systemIndustrial equipment

The invention relates to a remote monitoring and controlling system, in particular to a remote monitoring system for industrial equipment. The remote monitoring and controlling system comprises a data collecting device, an information management server, a communication terminal and a network. The data collecting device is used for collecting data of the monitored equipment and transmitting the data to the information management server or the communication terminal. The information management server is used for receiving, storing and processing the data from the data collecting device and transmitting the data to the communication terminal. The communication terminal is used for receiving and displaying the data of the data collecting device and the data of the information management server. The network is used connecting the data collecting device, the information management server and the communication terminal. The remote monitoring and controlling system can not only carry out remote monitoring, failure warning, energy conservation statistics and data analysis to the industrial equipment, but also maintain, repair and preserve the industrial equipment.

Owner:WUHAN BEIDOU RUIHUA TECH

Precaution analysis system for distribution line and analysis method

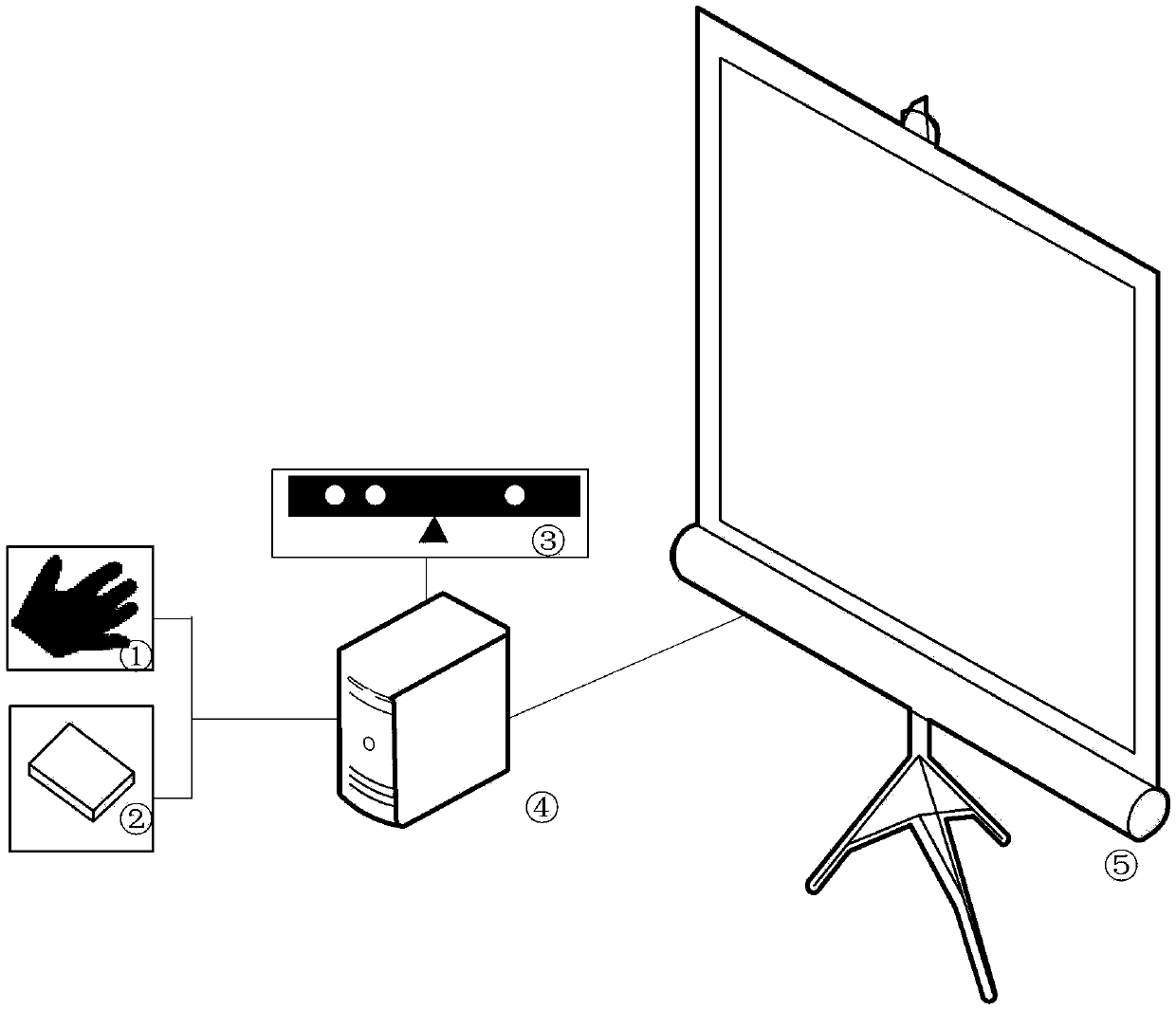

InactiveCN104700679AImprove the quality of trainingImprove production safety levelCosmonautic condition simulationsSimulatorsHuman bodySomatosensory system

The invention discloses a precaution analysis system for a distribution line and an analysis method. The analysis system and analysis method are characterized by comprising gloves, a vibrator, a somatosensory device, a host machine and a display screen; the host machine is respectively connected with the gloves, the vibrator, the somatosensory device, and the display screen; the gloves are data gloves and internally provided with a temperature sensor and a humidity sensor which are used for sensing hand temperature and humidity data; the vibrator generates an impulse vibrating signal when wrong operation is happened, stimulates trainees and enhances the training effect; the somatosensory device catches movement action of human body, and displays corresponding operation action of a virtual person on the display screen. The precaution analysis system can realize interactively, lively and vividly staff safety training, and improve the electrical safety production knowledge and skill training quality.

Owner:JINZHOU ELECTRIC POWER SUPPLY COMPANY OF STATE GRID LIAONING ELECTRIC POWER SUPPLY +1

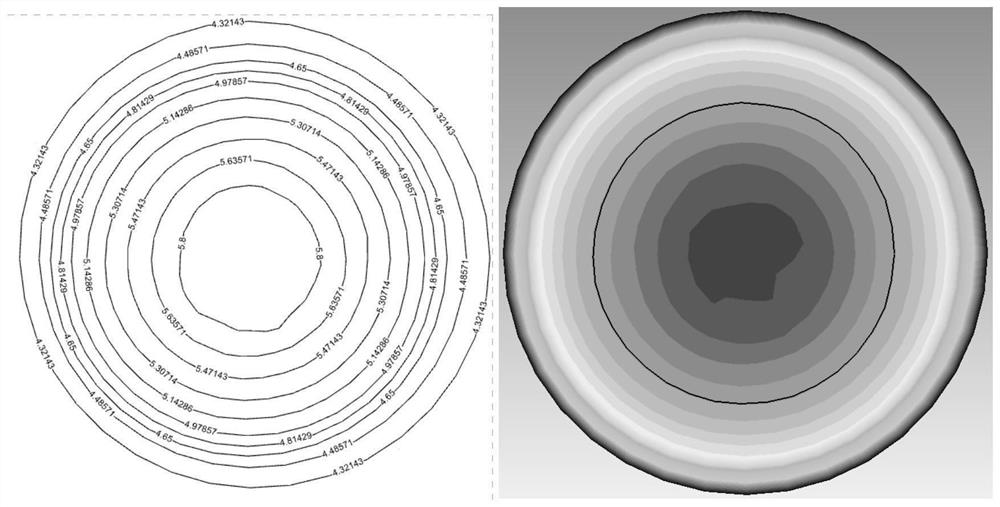

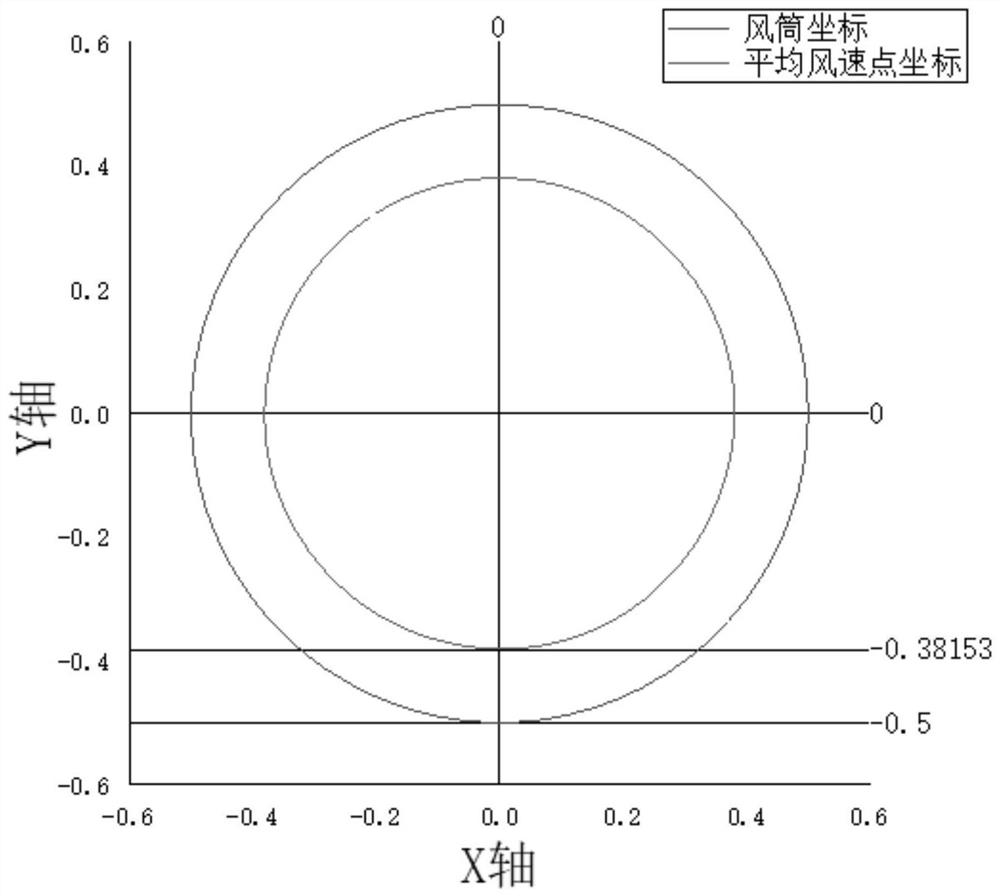

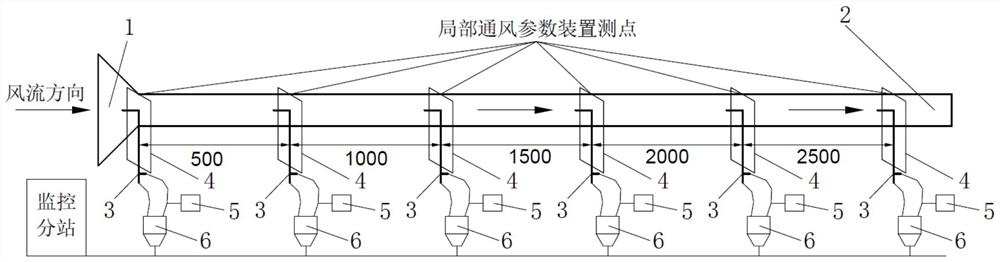

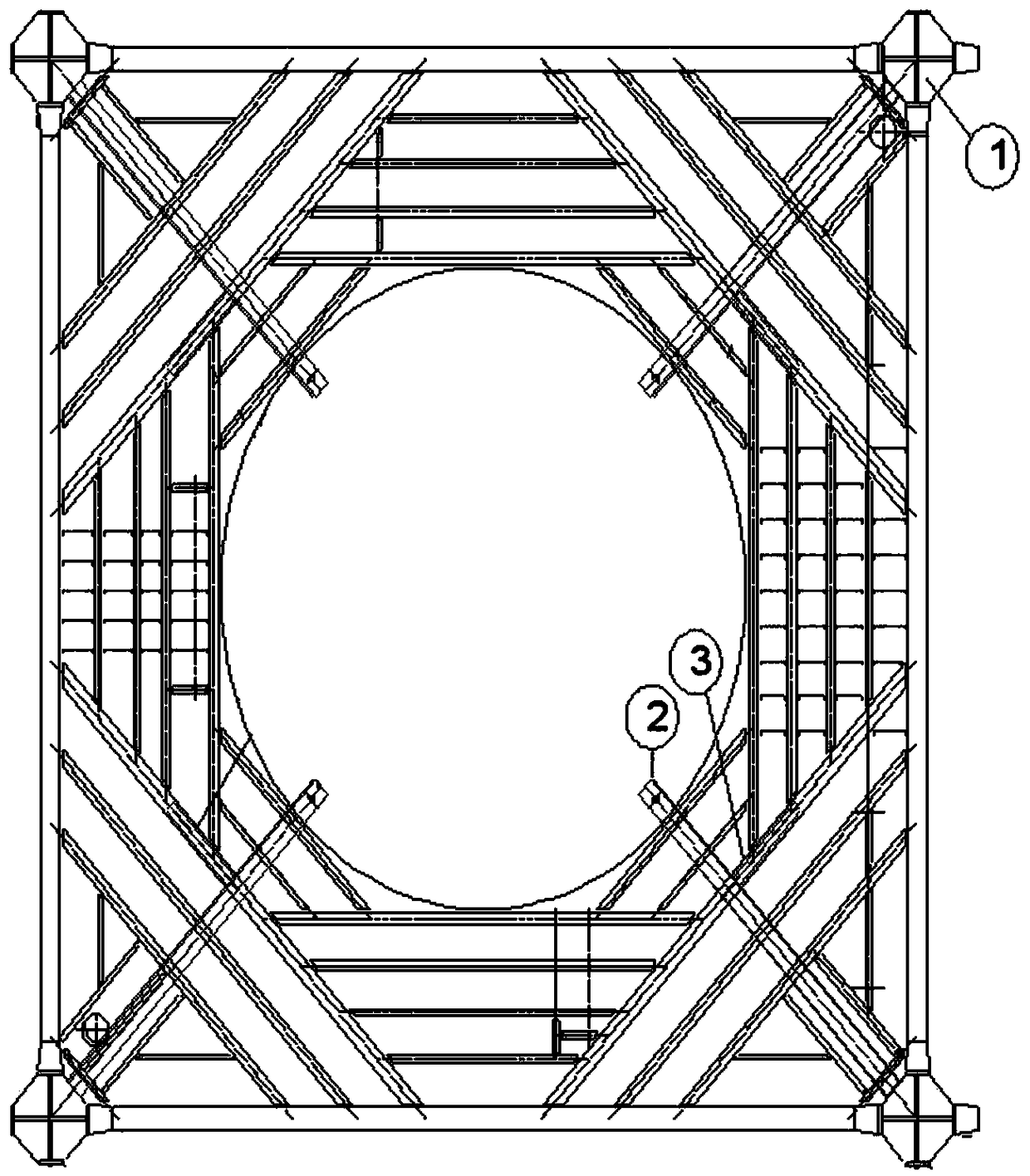

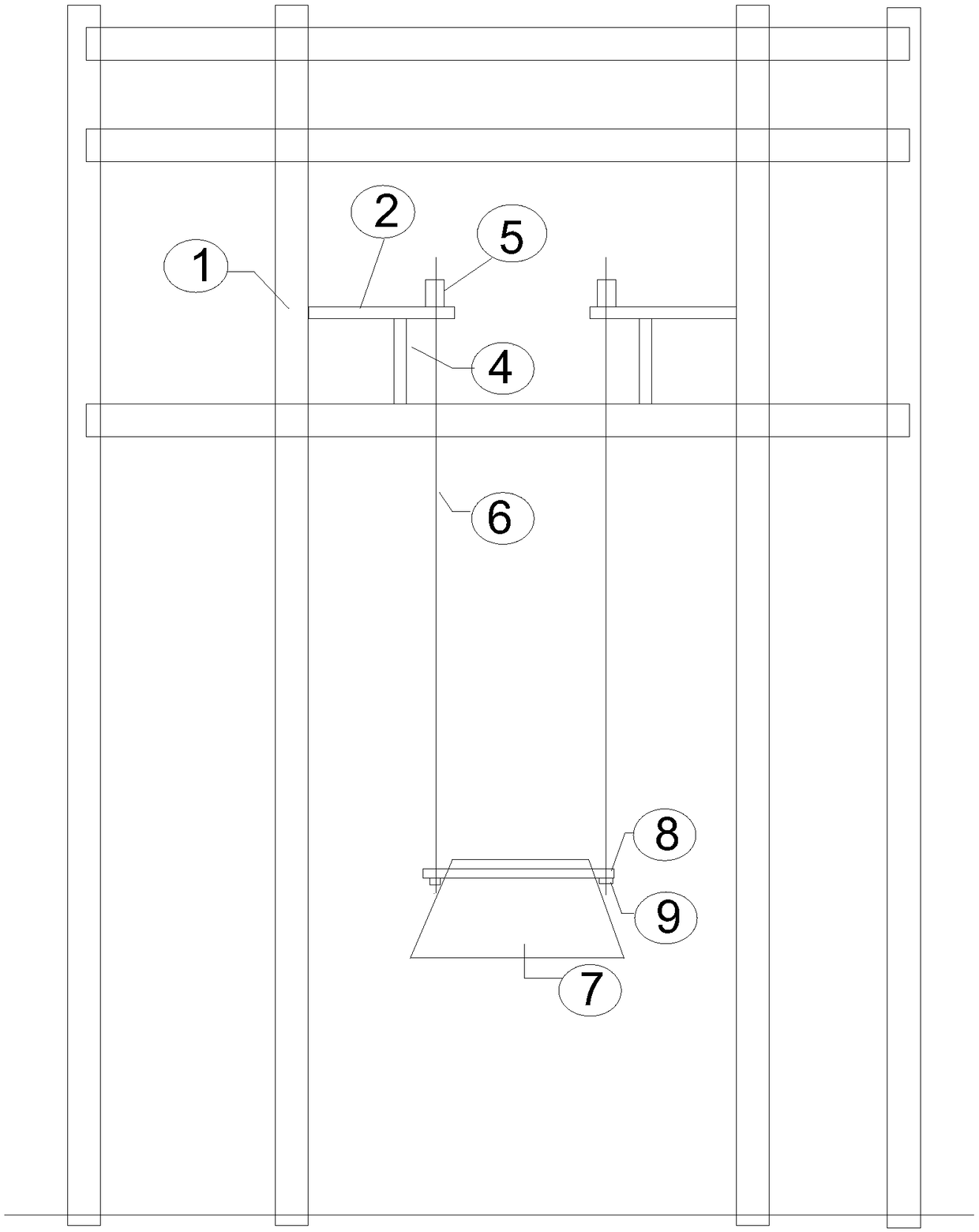

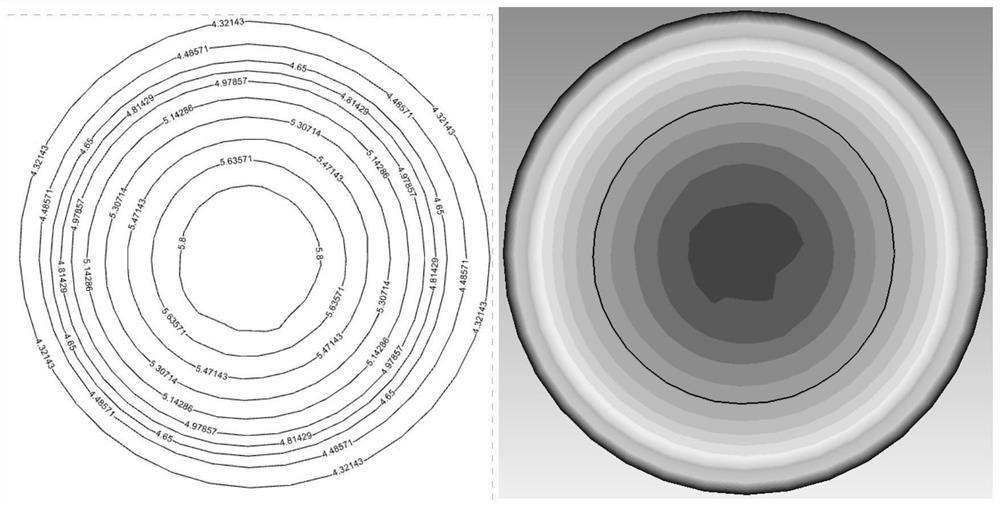

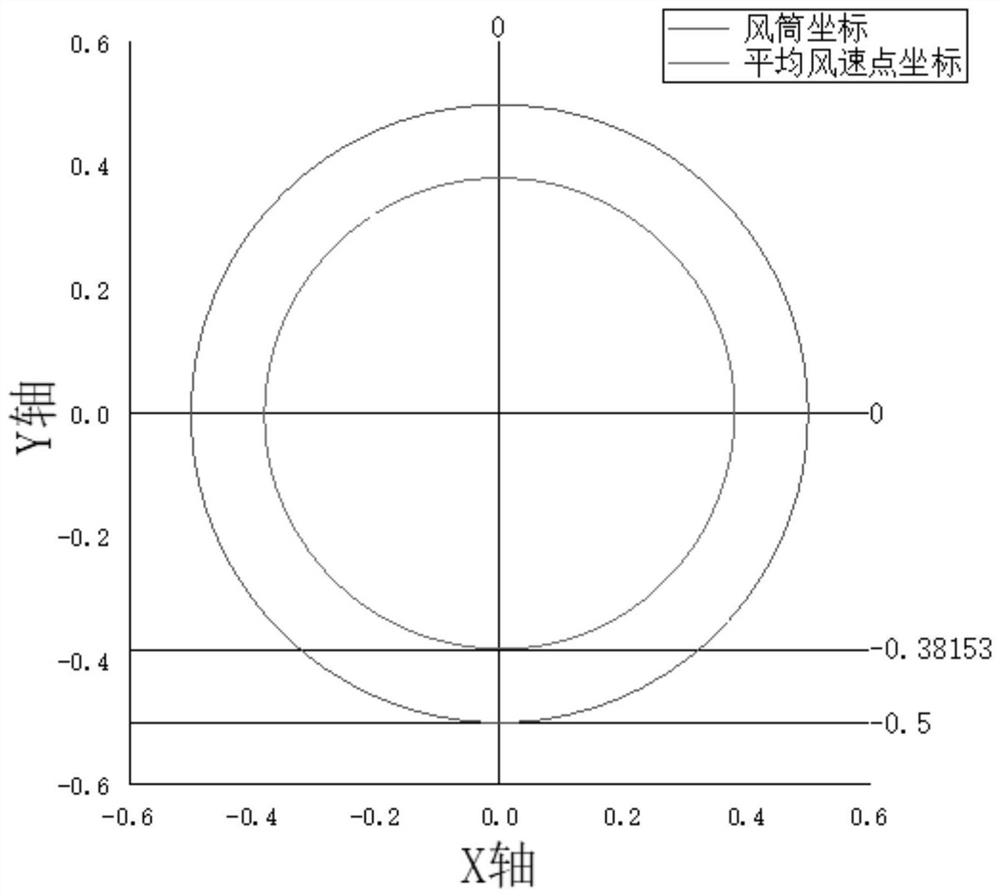

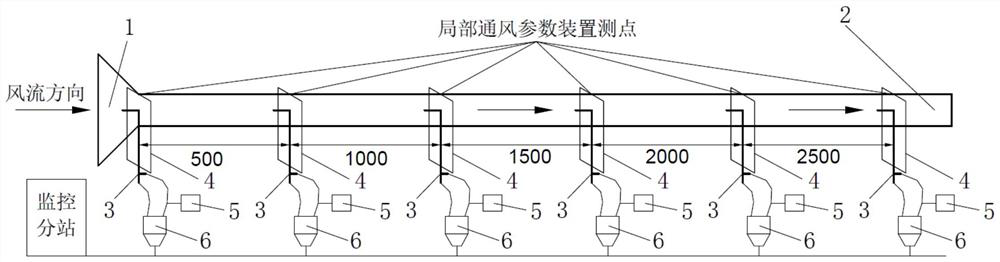

Coal mine local ventilation parameter accurate monitoring and abnormity early warning system and method

ActiveCN112177661AReduce wind and production stop accidentsEnsure safe productionMining devicesFluid speed measurement using pressure differenceEarly warning systemVisual monitoring

The invention discloses a coal mine local ventilation parameter accurate monitoring and abnormity early warning system and method. The system is composed of an air duct air volume accurate monitoringand analysis module, a local ventilation system power consumption analysis module, an air volume supply and demand matching analysis module and a ventilation fault research and judgment early warningmodule. The air volume accurate measuring, monitoring and analysis module comprises various sensors and monitoring substations, and local air volume accurate monitoring is achieved by optimally arranging air volume measuring points of an air duct and calculating and verifying kinetic energy of monitoring speed pressure. The ventilation system power consumption analysis module comprises a local ventilation resistance parameter monitoring and wind pressure on-way loss model and is used for realizing visual monitoring and resistance abnormity early warning of local resistance. The air volume supply and demand matching analysis module predicts fan adjustment according to the air volume data and advanced simulation of air volume supply and demand, and establishes a local ventilation air volumesupply and demand matching model. The ventilation fault research and judgment early warning module extracts a characteristic sample and precursor information of a local ventilation fault state according to the monitored multivariate environmental parameters to realize development situation research and judgment early warning of the local ventilation state.

Owner:徐州中矿科光机电新技术有限公司

Pushing segmented hydraulic synchronous lifting assembling method for furnace shell of blast furnace

InactiveCN109468420AReduce in quantityReduce safety accidentsBlast furnace componentsBlast furnace detailsIndustrial systemsEngineering

The patented technology is mainly used for achieving the problems that an industrial system blast furnace is pushed for replacement of a furnace body, when a blast furnace body structure is pushed forrapid replacement of the new furnace body, the structural stability of a blast furnace body framework structure is not affected to the largest degree, structure detachment is reduced for pushing thefurnace body, and the replacement time is saved. A method is suitable for overhauls and replacement of the furnace body structure of the high-capacity blast furnace, and the problems that the replacement period of the furnace shell of the blast furnace is long, and the idling period is long are solved.

Owner:MCC TIANGONG GROUP

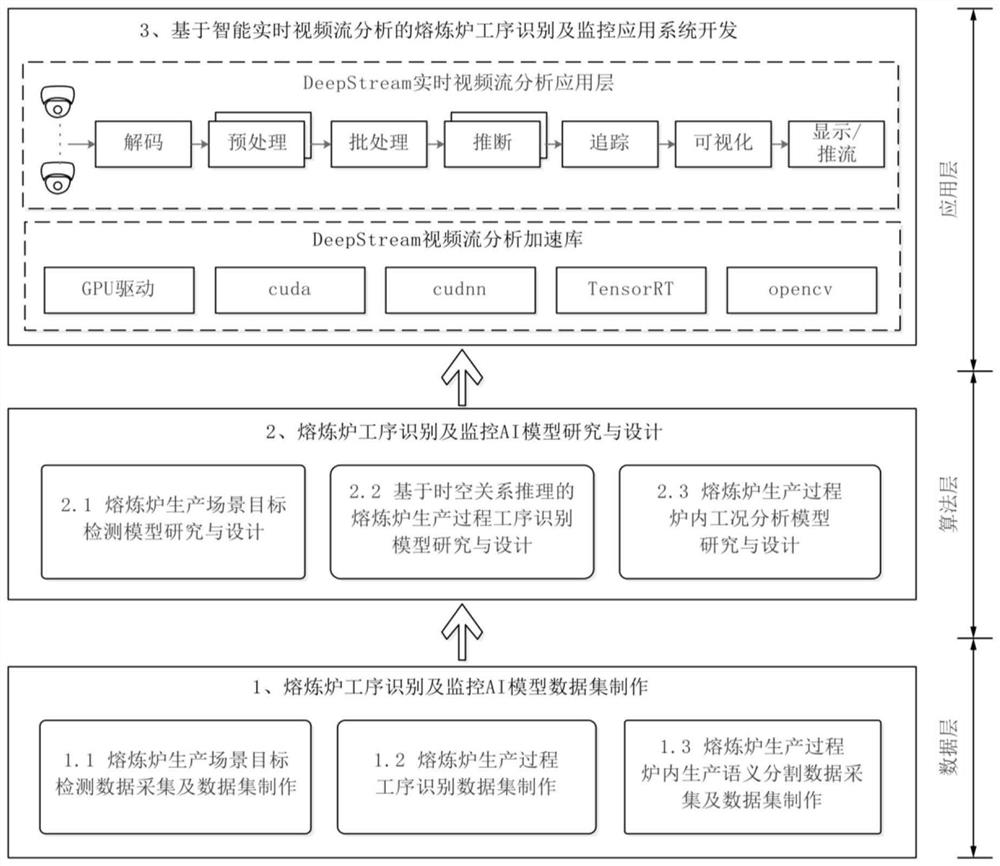

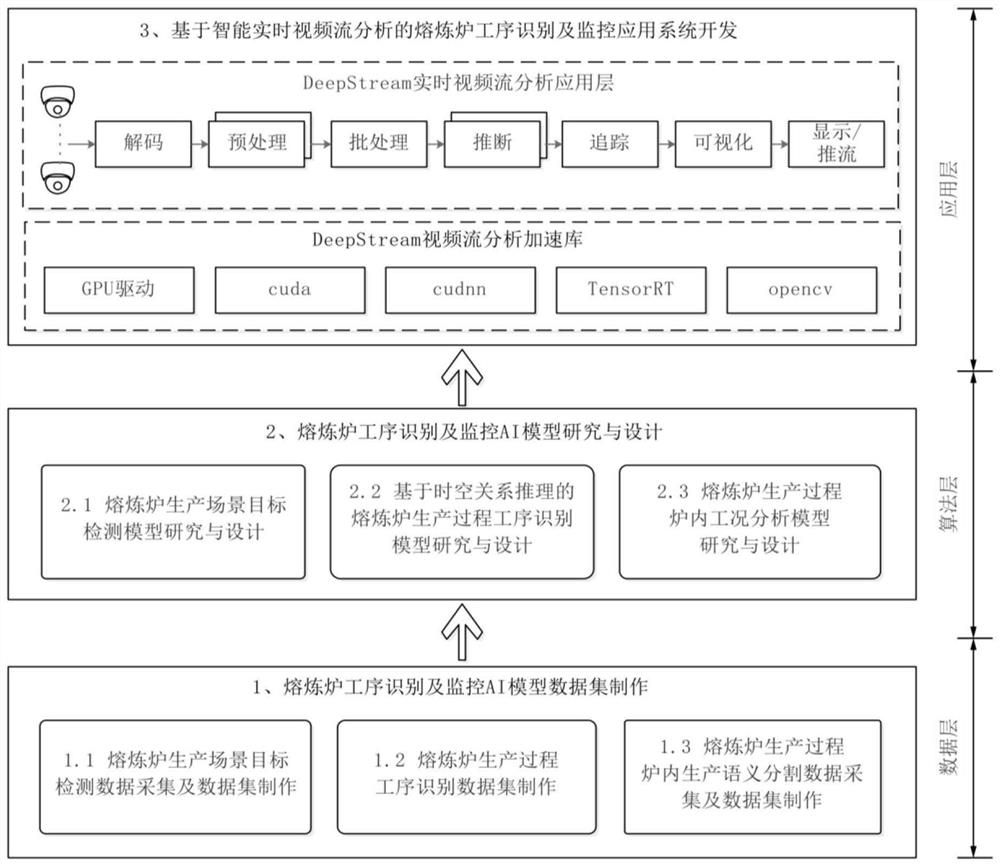

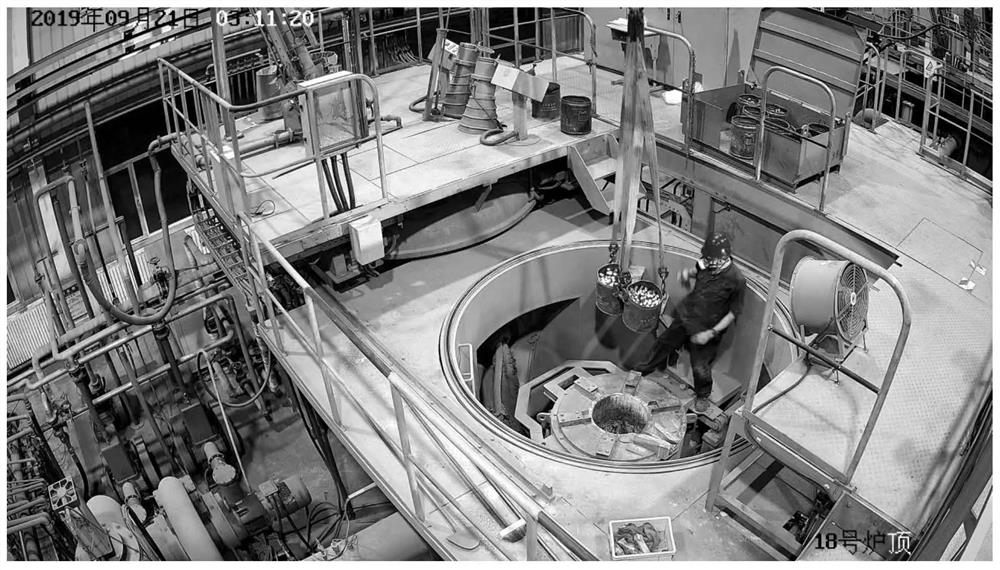

Magnetic material preparation process identification and monitoring system based on artificial intelligence

ActiveCN113033492AImprove yieldImprove yield rateCharacter and pattern recognitionResourcesBatch processingAlgorithm

The invention discloses a magnetic material preparation process identification and monitoring system based on artificial intelligence, and belongs to the technical field of identification and monitoring. The invention aims to solve the problems of low monitoring efficiency and low accuracy due to the fact that the existing magnetic material preparation process depends on manual judgment. The system comprises a data layer, an algorithm layer and an application layer. The data layer is used for storing identification and monitoring data of a magnetic material preparation process; the algorithm layer carries out actual magnetic material preparation process identification and monitoring inference according to a rare earth magnetic material preparation process identification and monitoring AI model; the application layer adopts a DeepStream-based real-time video stream analysis framework, under the support of a DeepStream video analysis acceleration library, multi-channel videos are subjected to the steps of decoding, preprocessing, batch processing, neural network inference, tracking, visualization, display and stream pushing, and real-time detection of working procedures and real-time monitoring of violation work are achieved based on the algorithm layer. The system is mainly applied to identification and monitoring of the magnetic material preparation process.

Owner:内蒙古海洋工信科技有限责任公司 +1

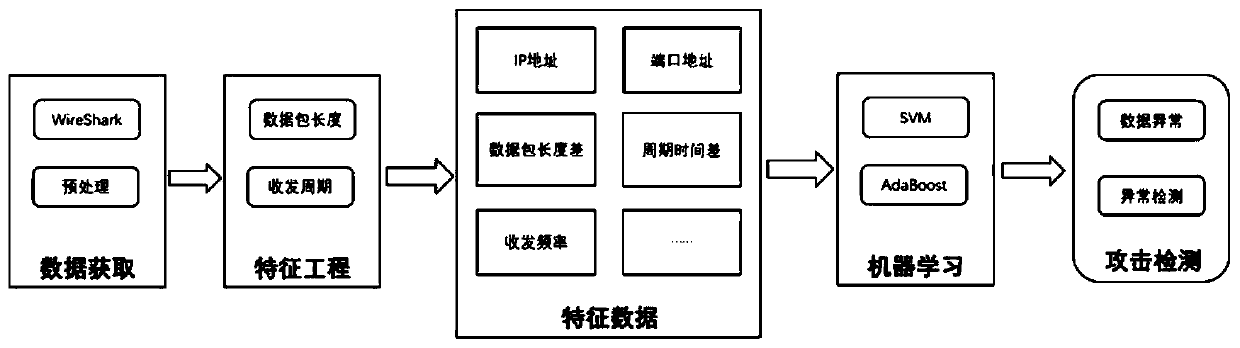

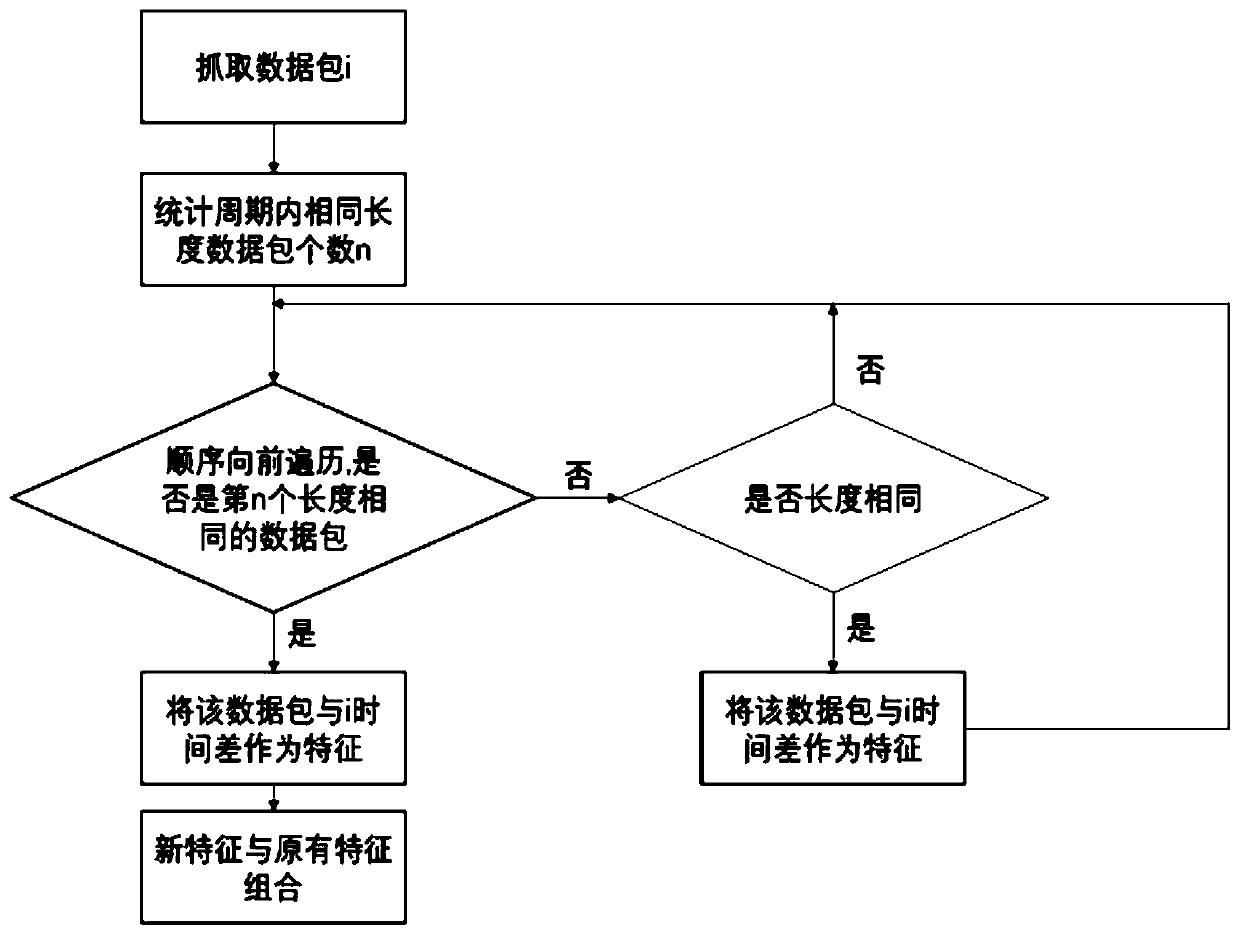

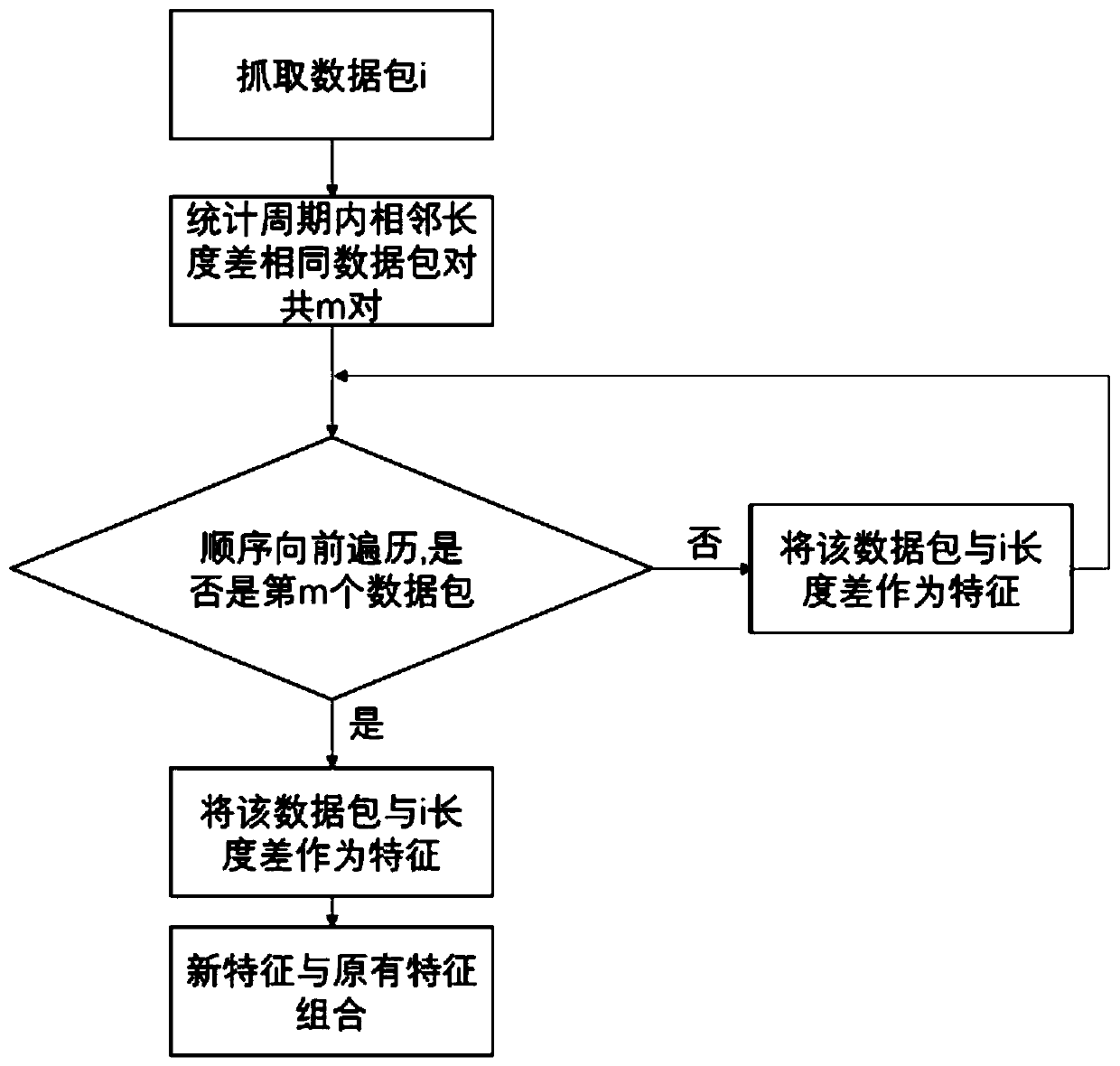

Machine learning-based attack detection method for non-analyzable network data feature selection

ActiveCN111314310AReduce safety accidentsAccurate detectionCharacter and pattern recognitionMachine learningFeature basedEngineering

The invention discloses a machine learning-based attack detection method for non-analyzable network data feature selection. The method is composed of three parts of data acquisition preprocessing, feature extraction and construction and attack detection model establishment and detection based on machine learning. The data preprocessing part is used for carrying out numeralization on network data;the feature extraction and construction part completes construction of data features based on data packet period and length information on the basis of deep analysis of industrial control network attacks. The modeling part is used for establishing an industrial control network attack detection model based on a machine learning classification method. According to the invention, attack forms such asre-amplification flow attack and man-in-the-middle attack in the industrial control system network can be accurately detected in real time, and safety accidents and economic losses caused by the safety accidents are reduced.

Owner:ZHEJIANG UNIV

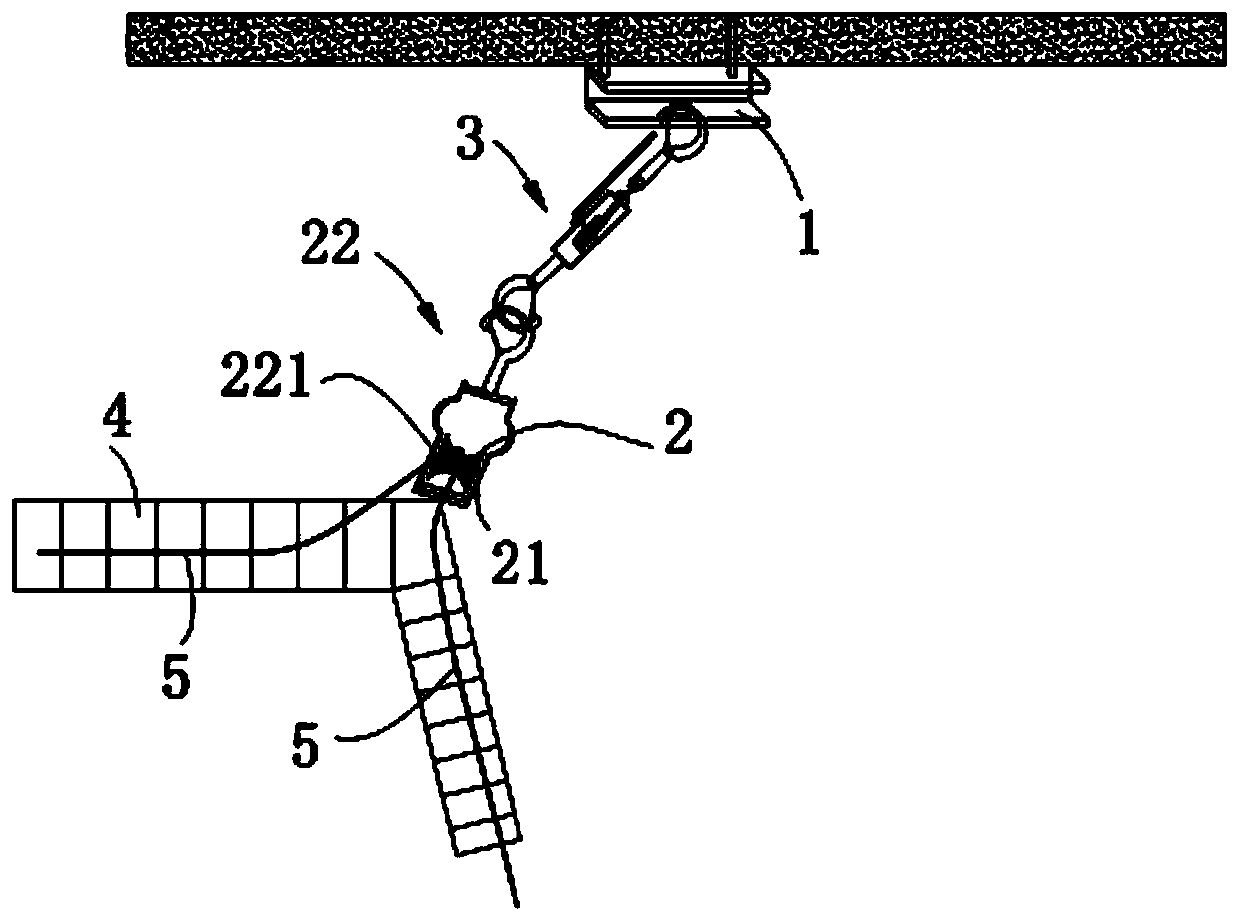

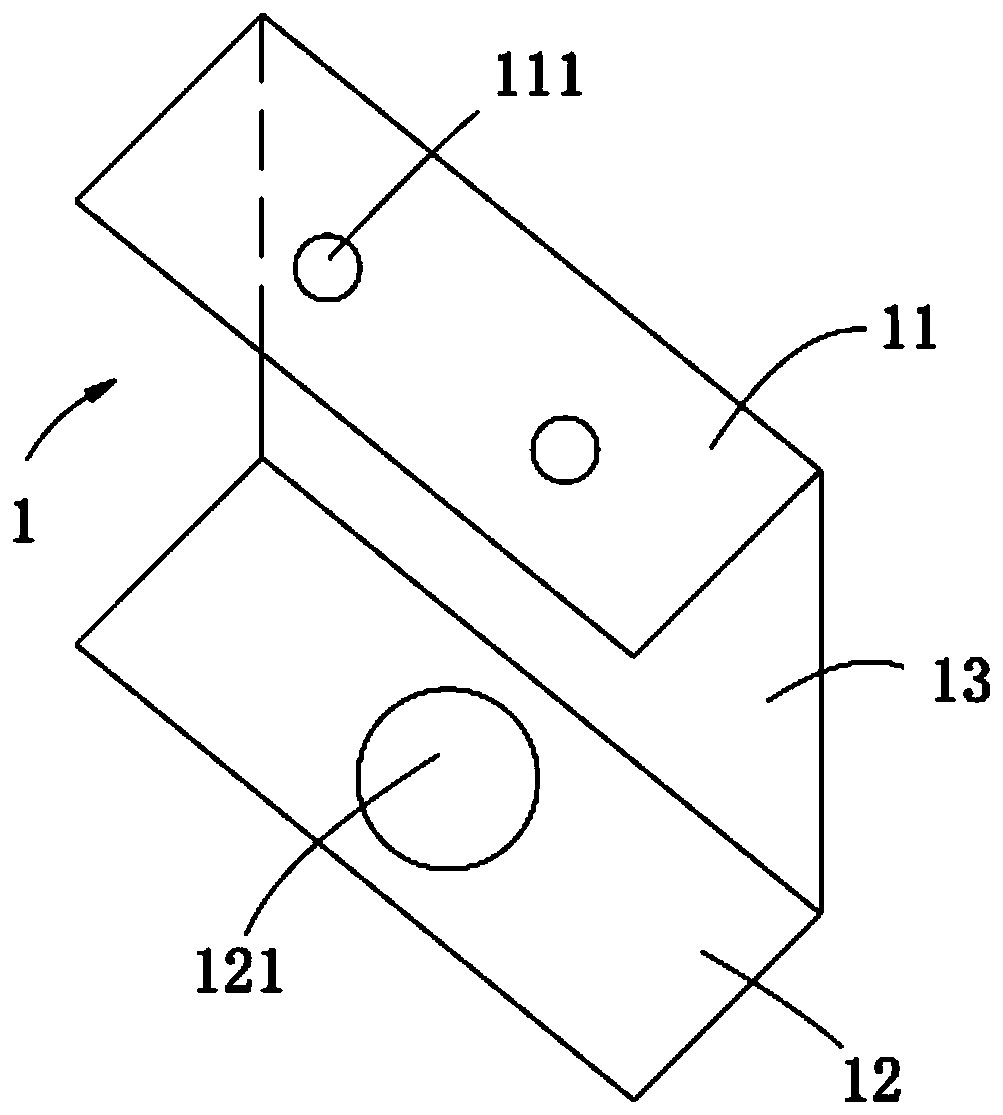

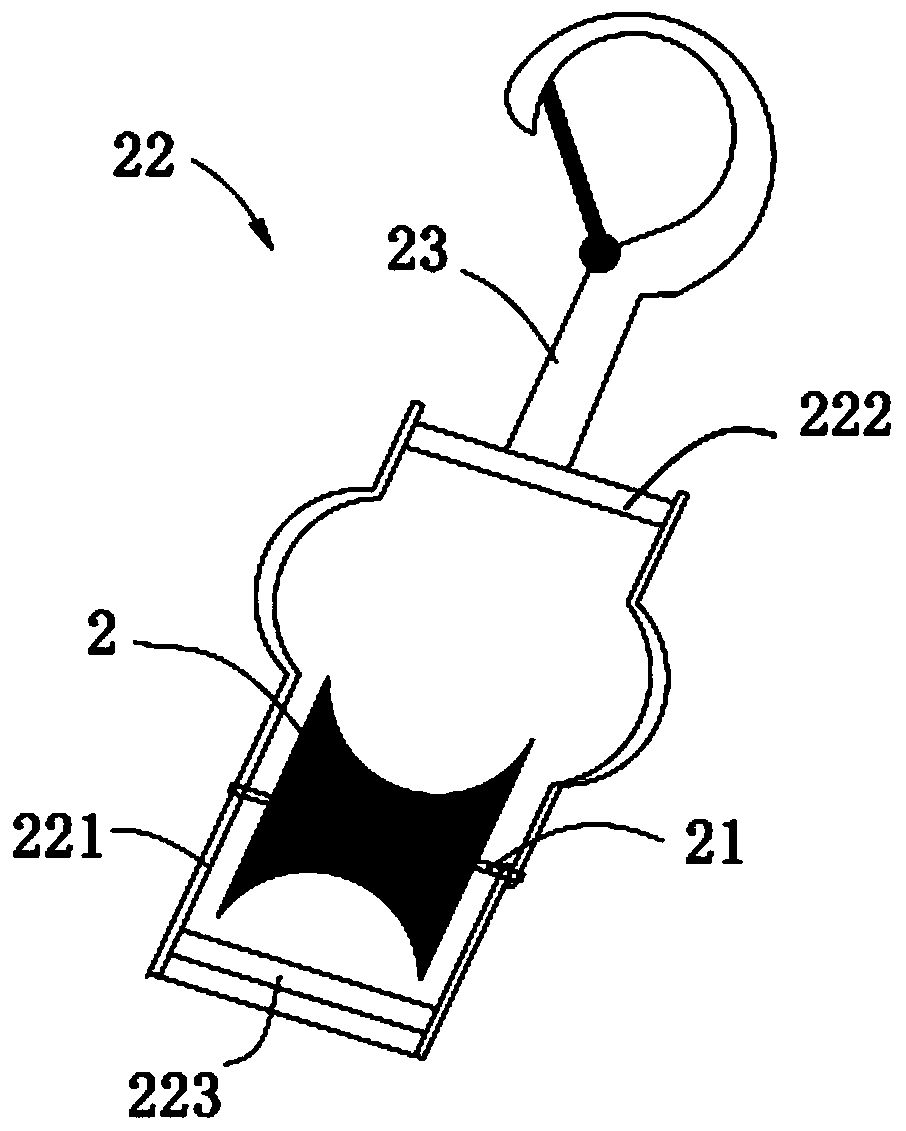

Adjustable combined corner pulley device and adjusting method

ActiveCN110838695AReduce safety accidentsReduce the difficulty of workers' operationPhotovoltaic energy generationApparatus for laying cablesBlock and tackleControl theory

The invention provides an adjustable combined corner pulley device and an adjusting method. The laying device comprises a positioning mounting seat, corner pulleys and a length-adjustable length adjusting piece, wherein the corner pulleys are rotatably mounted on the side plates on the two sides of a pulley support through a rotating shaft, and the rotating shaft is detachably connected with the side plates; and the length adjusting piece is detachably connected between the mounting base and the pulley support. Cable laying positions at the corners can be prevented from being overlapped to theinner sides of the corners, cable laying is ensured to be standard and tidy, safety accidents caused by uneven stress of the bridge are reduced, the operation difficulty of workers is lowered, and the cable laying efficiency is improved; the cable can be conveniently separated from the pulley support, and the defect that a pulley block is difficult to detach after the cable is laid in the prior art is overcome.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

Construction process of tool type steel lattice column lifting frame for high-altitude integral lifting large-span integral assembling welding ball net frame

InactiveCN112031176AReduce the difficulty of assemblyPrecise positioningBuilding constructionsSocial benefitsLong span

The invention discloses a construction process of a tool type steel lattice column lifting frame for high-altitude integral lifting large-span integral assembling welding ball net frame. The construction process comprises the following steps of (1) net frame construction; and (2) integral lifting of a pulling rod of the net frame. The process has the advantages of being convenient to operate, highin construction speed, excellent in quality, capable of saving labor and the like, the requirements for energy conservation and environmental protection are met, and no safety and quality problems occur in the construction process. According to the construction method, a traditional net frame lifting construction method is technically innovated, an advanced construction method is provided for building construction, and good social benefits are achieved.

Owner:青岛中筑置业有限公司

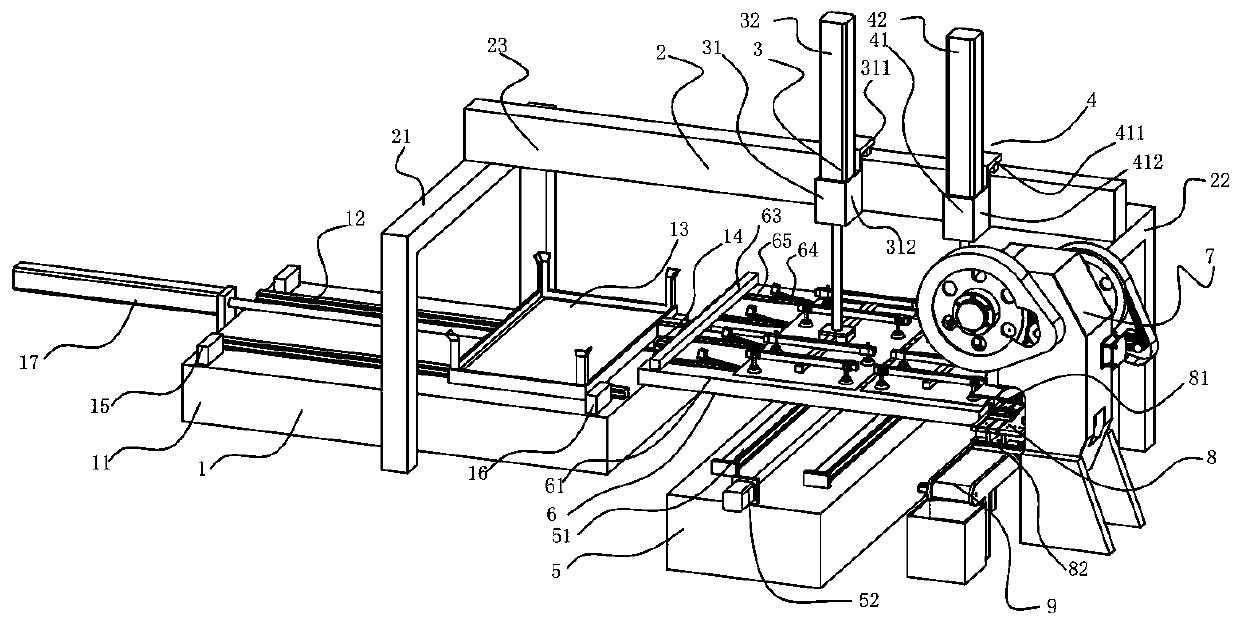

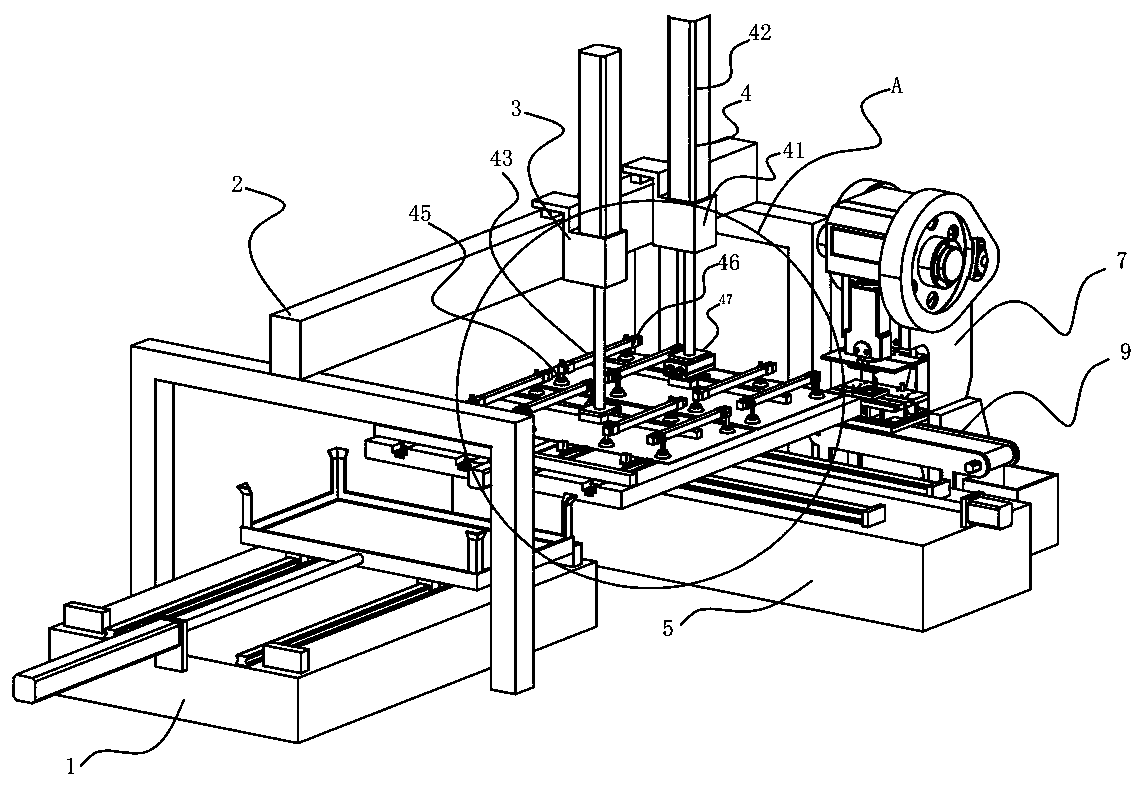

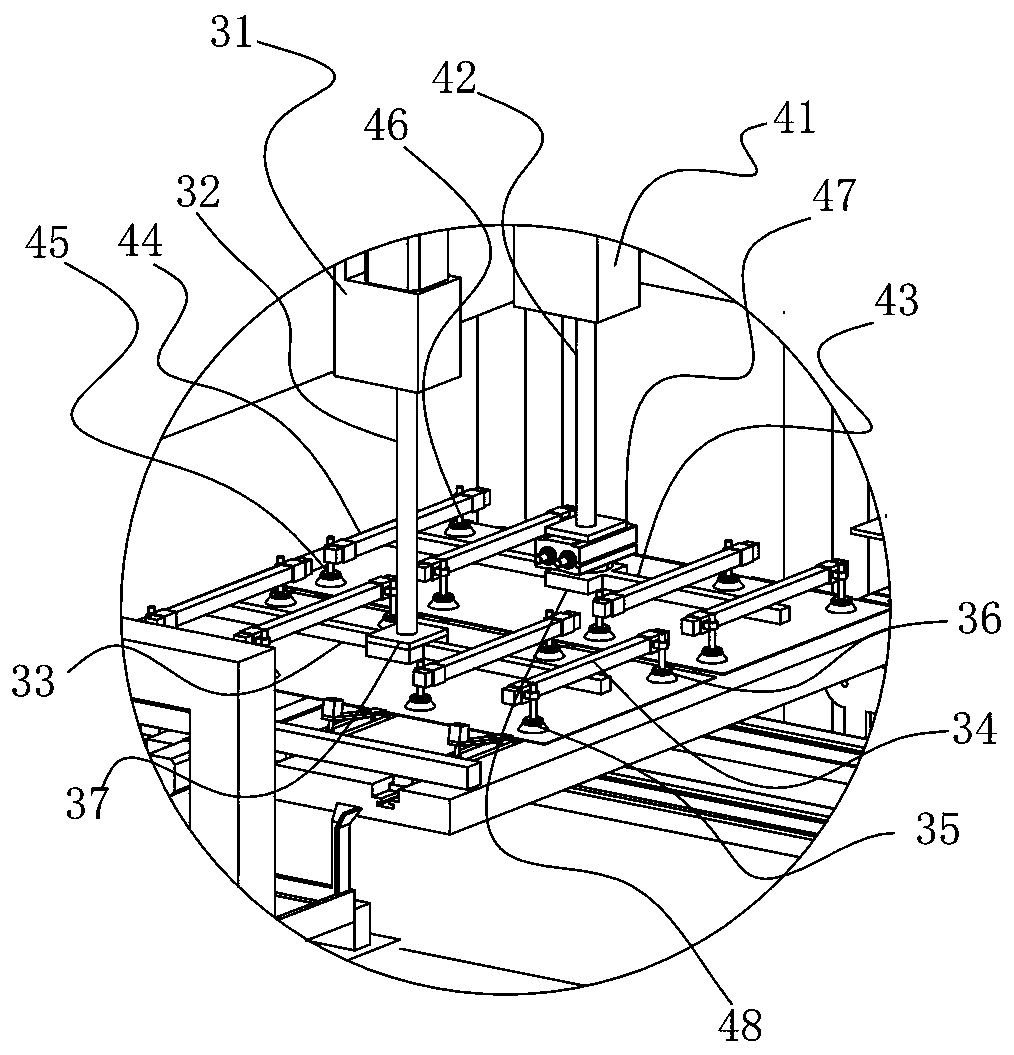

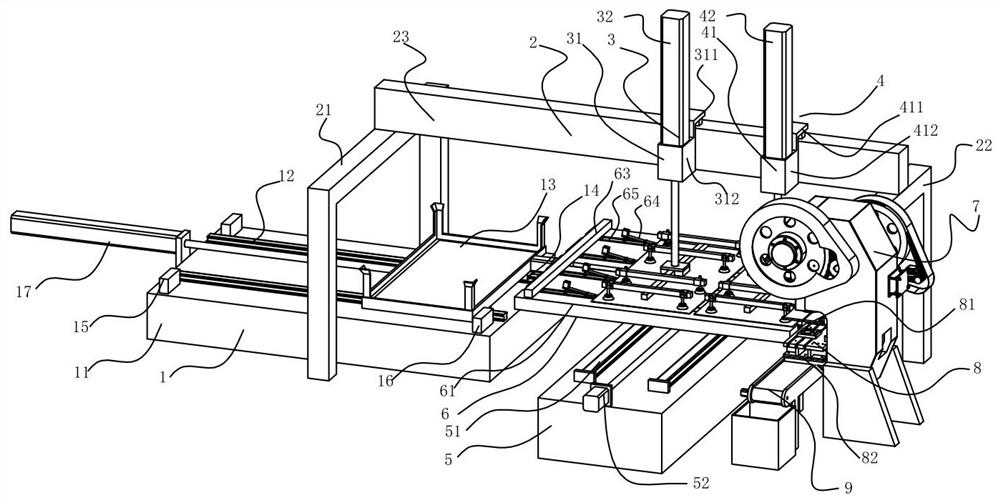

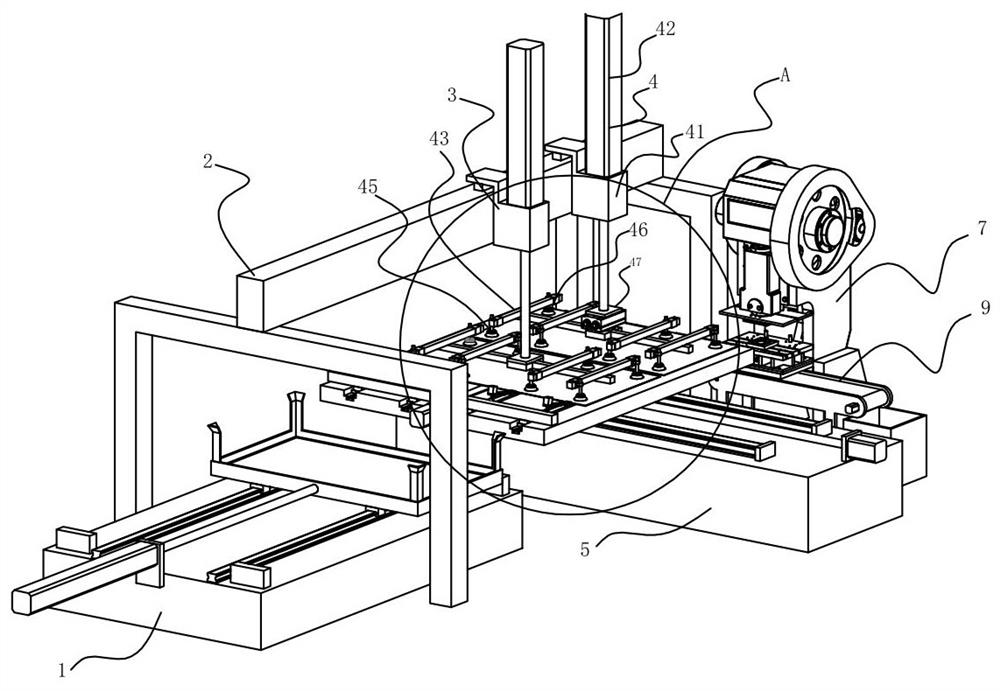

Automatic blanking assembly line

ActiveCN111589935AImprove work efficiencyReduce safety accidentsMetal-working feeding devicesPositioning devicesAssembly lineMaterials processing

The invention relates to an automatic blanking assembly line, and belongs to the technical field of assembly lines. According to the main scheme, the automatic blanking assembly line comprises a movable-type material placement platform assembly, a portal frame assembly, a material conveying assembly capable of horizontally moving on the portal frame assembly, a first supporting platform, a material processing platform arranged on the first supporting platform in a matched mode, a pressing machine arranged on the material processing platform, a tool assembly arranged in the pressing machine, and a finished material product conveying device arranged under the tool assembly; the tool assembly comprises a movable tool assembly body arranged on a pressing machine movable block and a fixed toolassembly body arranged on a pressing machine fixed seat; and the movable tool assembly body is connected with a guiding rod assembly of the fixed tool assembly body through a guiding sleeve assembly.The automatic blanking assembly line has the functions that a finished product is cut out, and meanwhile waste materials can be cut, thus the labor cost is reduced, and the production efficiency is improved.

Owner:宁波景升明诚汽车科技股份有限公司

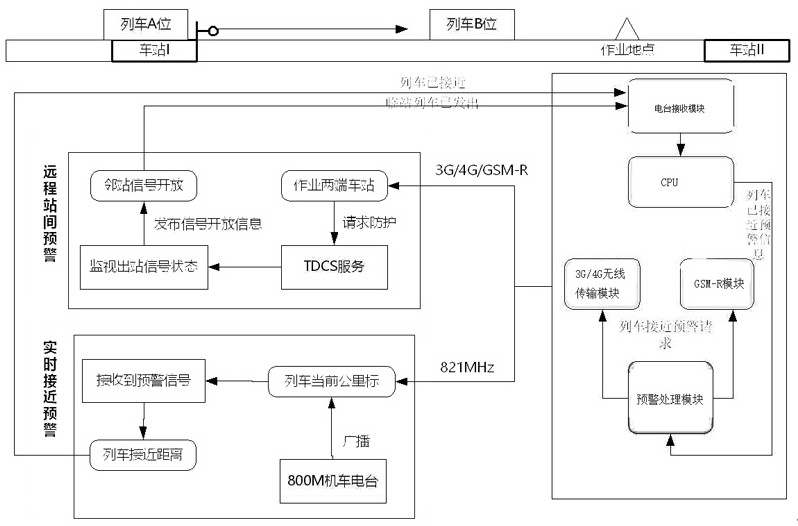

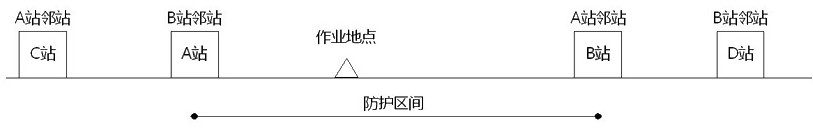

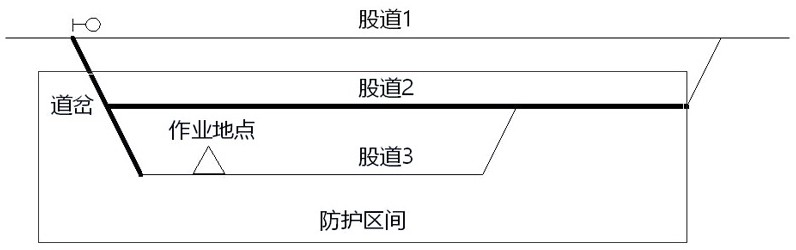

A train approach early warning method and system based on train-ground signal fusion

ActiveCN110979400BEffective warningReliable early warningRailway signalling and safetyEmbedded systemTransport engineering

Owner:HENAN THINKER TRACK TRAFFIC TECH RES INST

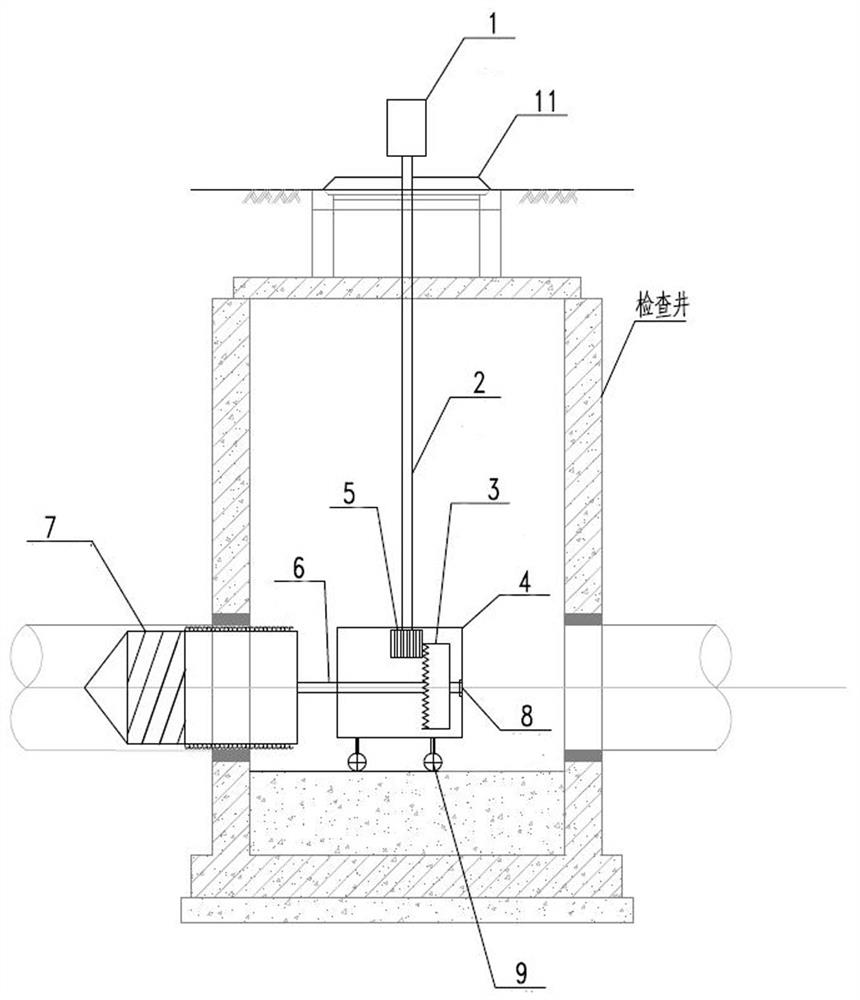

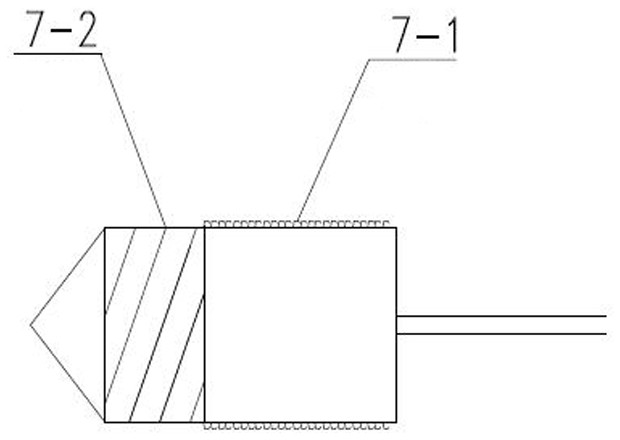

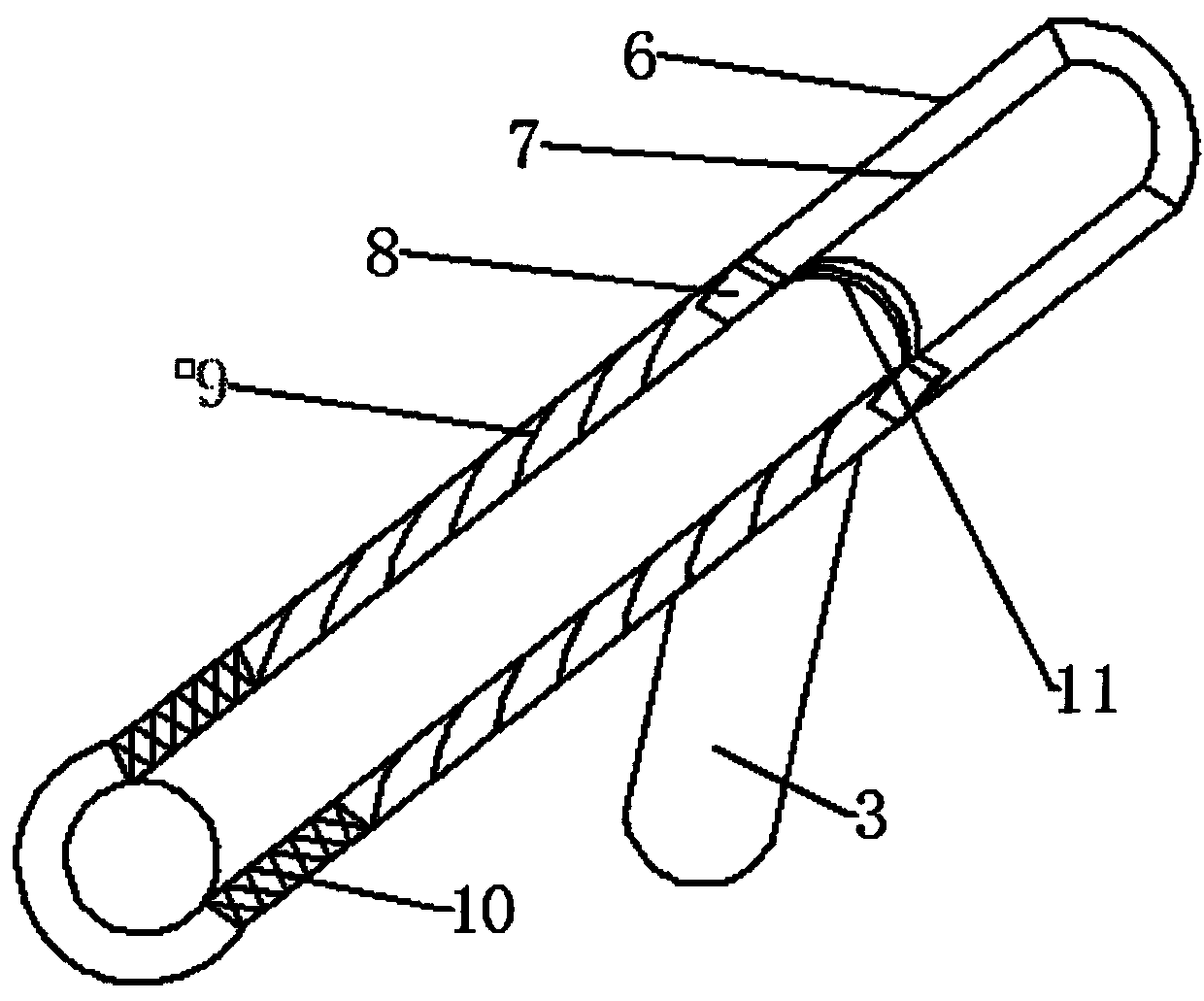

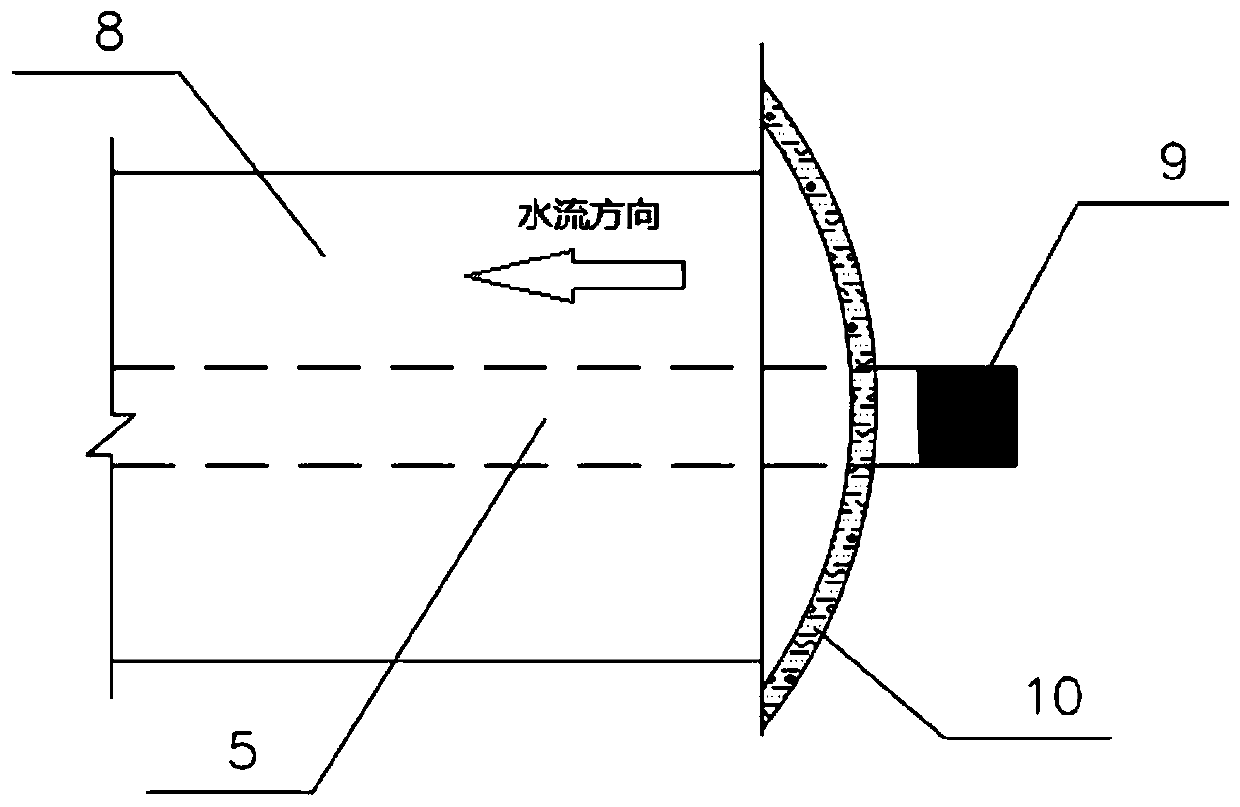

Sewage pipeline plugging system suitable for high-water-level operation and use method

PendingCN113309211AGuarantee personal safetyReduce safety accidentsSewer systemsMunicipal sewagePulley

The invention relates to a sewage pipeline plugging system suitable for high-water-level operation and a use method. According to the technical scheme, the system comprises a desilting device used for cleaning an inlet of a sewage pipeline, an air bag plugging device and an air bag mounting device. The air bag plugging device is provided with an air bag and used for plugging a sewage pipeline inlet cleaned by the desilting device through the air bag; the air bag mounting device is used for remotely mounting the air bag to the part of the sewage pipeline inlet; and the air bag mounting device is provided with a vertical telescopic mechanism, the lower end of the vertical telescopic mechanism is connected with two parallel transverse rods perpendicular to the axial direction of the vertical telescopic mechanism, the distance between the two transverse rods is matched with the diameter of a sewage pipeline, a pulley I is mounted at the outer end of each transverse rod, and a pulley II is mounted at the inner end of each transverse rod. The air bag is arranged between the two transverse rods of the air bag mounting device and connected with two traction ropes, and the two traction ropes are sequentially wound around the pulleys I and the pulleys II on the transverse rods on the two sides respectively and then extend upwards along the vertical telescopic mechanism to be connected with a traction mechanism. The plugging system is suitable for the technical field of municipal sewage pipeline plugging.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

Integrated working partition chamber of powder forming machine

The invention discloses an integrated working partition chamber of a powder forming machine. The integrated working partition chamber of the powder forming machine comprises a plurality of partition surfaces and a partition part formed by mutually connecting the partition surfaces, the partition part divides the surrounding space into an internal space and an external space, and the internal space is used for containing the powder forming machine. The working space of the powder forming machine and the environment space where the powder forming machine is located are isolated through the partition part in the physical space, the safety performance of equipment is improved through isolation, the probability of safety production accidents is reduced, the influence of noise generated when the powder forming machine works on the surrounding space is reduced, meanwhile, the working partition chamber has a more attractive shape, and the comfort degree of the working environment of a production workshop can be improved.

Owner:宁波汇众粉末机械制造有限公司

An automatic unloading assembly line

ActiveCN111589935BImprove work efficiencyReduce safety accidentsMetal-working feeding devicesPositioning devicesAssembly lineMaterials processing

The invention relates to an automatic unloading assembly line, which belongs to the technical field of assembly lines. Its main scheme includes a mobile material placement table assembly, a gantry assembly, a material conveying assembly that can move horizontally on the gantry assembly, a first support platform, a material processing platform that is set on the first support platform, and a material processing platform that is arranged on the first support platform. The press of the platform, the cutter assembly arranged in the press, and the finished material conveying device arranged directly under the cutter assembly; the cutter assembly includes a movable cutter assembly arranged on the movable block of the press and a fixed The cutter assembly; the movable cutter assembly is connected with the guide rod assembly of the fixed cutter assembly through the guide sleeve assembly; it has the function of cutting finished products and cutting waste materials at the same time, thereby reducing labor costs and improving production efficiency.

Owner:宁波景升明诚汽车科技股份有限公司

A system and method for accurate monitoring and abnormal early warning of local ventilation parameters in coal mines

ActiveCN112177661BRealize optimized layoutEnsure ventilation safetyMining devicesFluid speed measurement using pressure differenceVisual monitoringAir volume

The invention discloses a system and method for accurate monitoring and abnormal early warning of local ventilation parameters in coal mines. The system consists of an accurate monitoring and analysis module of air volume of a fan, a power consumption analysis module of a local ventilation system, an analysis module of air volume supply and demand matching, and a ventilation failure research and early warning module. composition. Accurate measurement of air volume The monitoring and analysis module includes various sensors and monitoring sub-stations. By optimizing the arrangement of air duct air volume measurement points and monitoring the kinetic energy calculation and verification of velocity pressure, accurate monitoring of local air volume is realized; the power consumption analysis module of the ventilation system includes local ventilation Resistance parameter monitoring and wind pressure loss model along the way realize visual monitoring of local resistance and early warning of abnormal resistance; air volume supply and demand matching analysis module predicts fan adjustment based on air volume data and advanced simulation of air volume supply and demand, and establishes a matching model of local ventilation air volume supply and demand; ventilation The fault research, judgment and early warning module extracts the characteristic samples and precursor information of the local ventilation fault state based on the monitored multivariate environmental parameters, and realizes the research, judgment and early warning of the development trend of the local ventilation state.

Owner:徐州中矿科光机电新技术有限公司

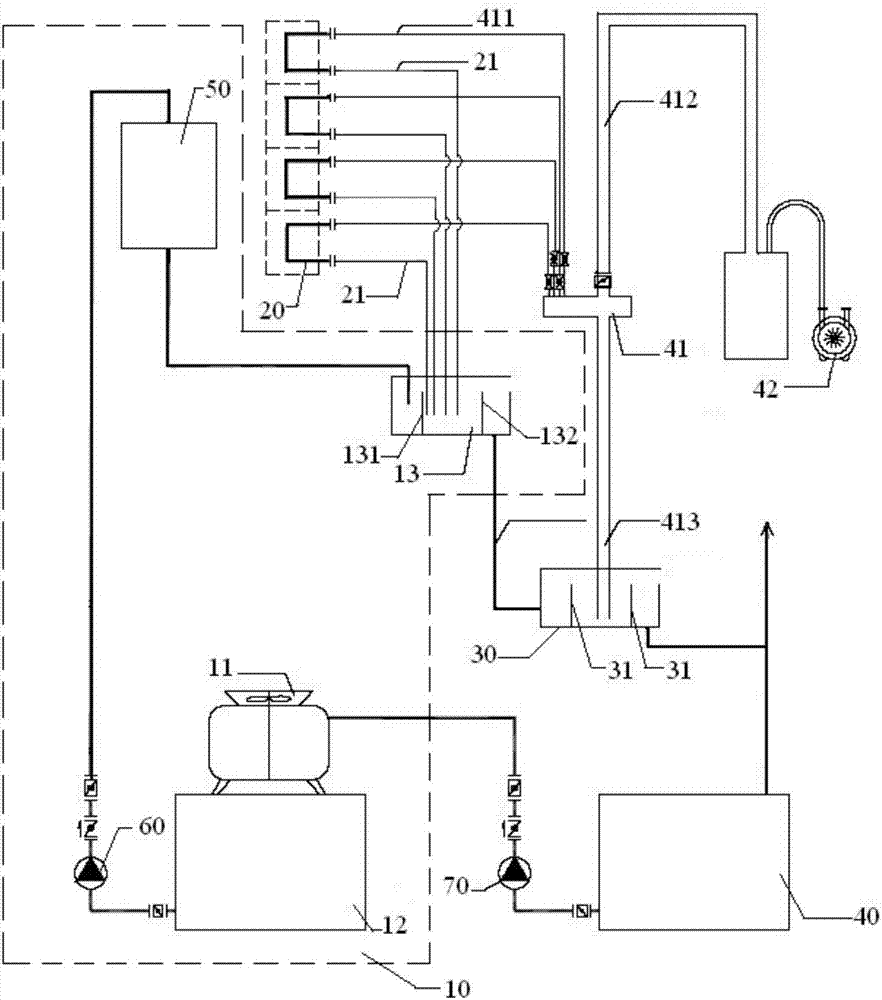

cooling system

ActiveCN105651057BNo or very little spillageReduce safety accidentsFurnace cooling arrangementsSiphonHeight difference

A cooling system comprises a refrigerant supply unit (10), a cooling unit (20) used for cooling a to-be-cooled object, a liquid seal groove (30) and a refrigerant recycling unit (40). The cooling unit (20) communicates with the refrigerant supply unit (10) through a refrigerant input pipe (21). The refrigerant recycling unit (40) comprises a refrigerant recycling pipe set (41) and a vacuum pump set (42). The refrigerant recycling pipe set (41) comprises a refrigerant recycling branch pipe (411), a vacuum pipe (412) and a siphon (413), all of which communicate with one another through the same port. The vacuum pump set (42) is connected with the vacuum pipe (412). The refrigerant recycling branch pipe (411) communicates with the cooling unit (20). The siphon (413) communicates with the liquid seal groove (30). The horizontal plane where the refrigerant supply unit (10) is located is higher than the horizontal plane where the liquid seal groove (30) is located. Due to the fact that a certain height difference exists between the refrigerant supply unit (10) and the liquid seal groove (30), cooling water in the refrigerant supply unit (10) can overcome resistance of a pipeline and enters the liquid seal groove (30) by itself. Due to the fact that the whole cooling system is in negative pressure, when the cooling unit is fractured, a refrigerant cannot overflow or hardly overflows, and accordingly production accidents caused by refrigerant overflow can be better reduced.

Owner:CHINA ENFI ENGINEERING CORPORATION

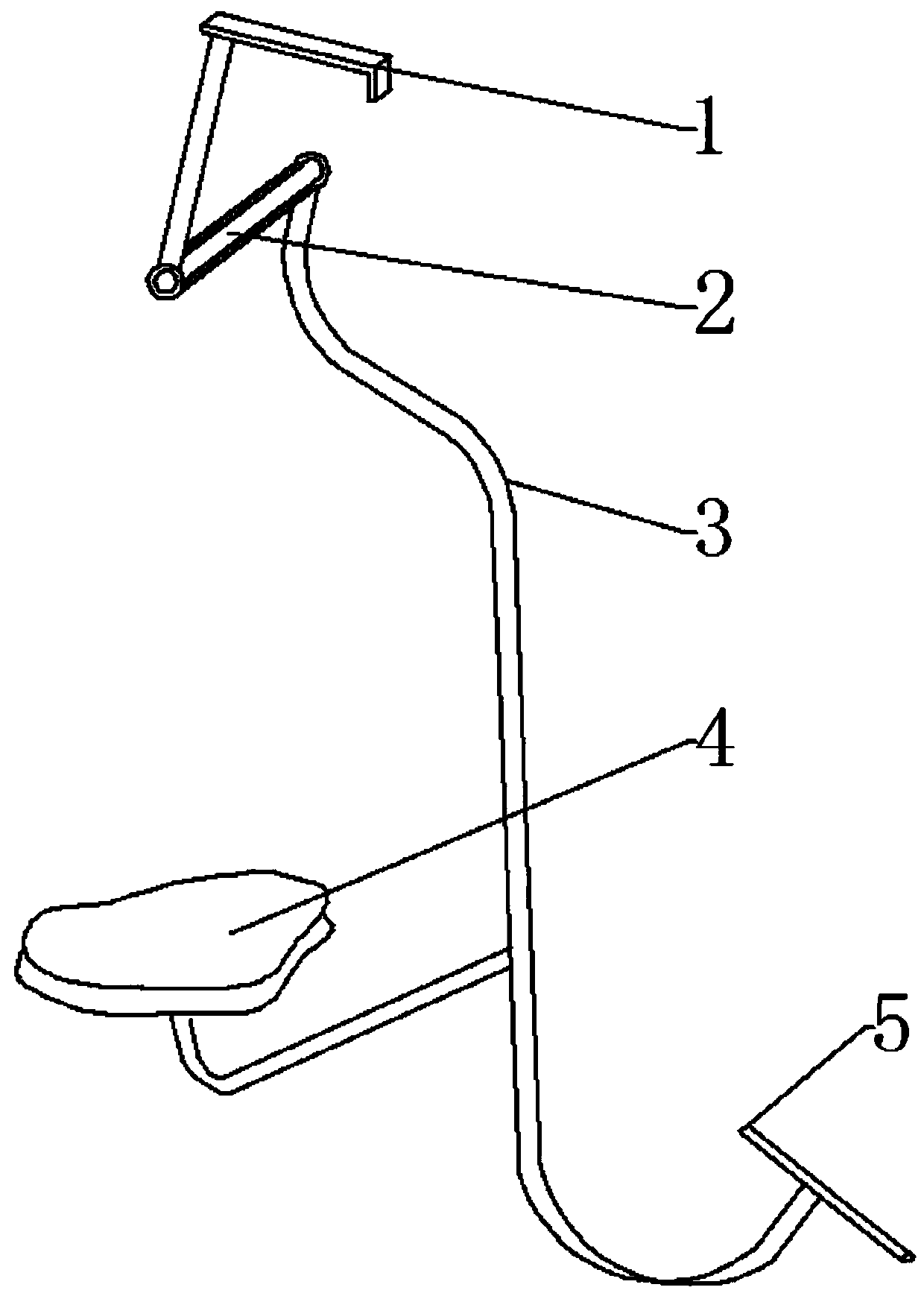

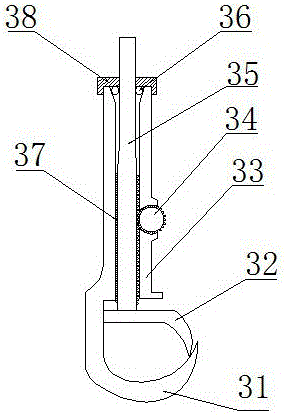

Mining overhead man-riding device capable of sliding and self-adapting

InactiveCN110920639AReduce psychological burdenReduce safety accidentsRope railwaysSelf adaptiveIndustrial engineering

The invention discloses a mining overhead man-riding device capable of sliding and self-adapting. The overhead man-riding device is mainly composed of a hanging plate, a hanging rod, a seat and a footrest lever. A telescopic sliding rod device is arranged at the upper part of the hanging rod. A telescopic sliding rod is a sleeve device with an upward angle and a telescopic automatic reset function; a supporting frame is composed of an inner barrel and an outer barrel, the outer barrel is fixedly connected with an upper hanging rod, a lower hanging rod can slide in the inner barrel under the action of a lantern ring, a check block is arranged on the lantern ring, a spring acts on the check block to enable the lower hanging rod to reset, and an elastic block is further arranged on the lowerportion where the outer barrel is connected with the inner barrel. When a miner uses the monkey vehicle, the telescopic sliding rod drives the hanging rod to move downwards, the acceleration of the hanging rod is reduced, and the miner can better adapt to taking a monkey vehicle. The overhead man-riding device is simple and safe in structure and practical and novel in function, especially can effectively overcome the fear when a person takes the overhead man-riding device for the first time, and has good social and economic benefits.

Owner:HENAN POLYTECHNIC UNIV

A method for replacing and repairing the connecting plate of copper cross-arm electrode cable

ActiveCN105666030BIncrease security risksSimple replacement and repair processWelding/soldering/cutting articlesWelding apparatusCouplingEngineering

Owner:GUANGDONG GUANGDONG SHAOGANG ENG TECH

An ultra-high temperature and ultra-high pressure gas boiler and its auxiliary equipment installation method

ActiveCN112146078BImprove installation accuracyGuaranteed installation accuracyFluid heatersBoiler supporting/setting arrangementsAir preheaterUltra high pressure

Owner:ANSHAN NORTHEAST CONSTR ARCHITECTURAL ENG

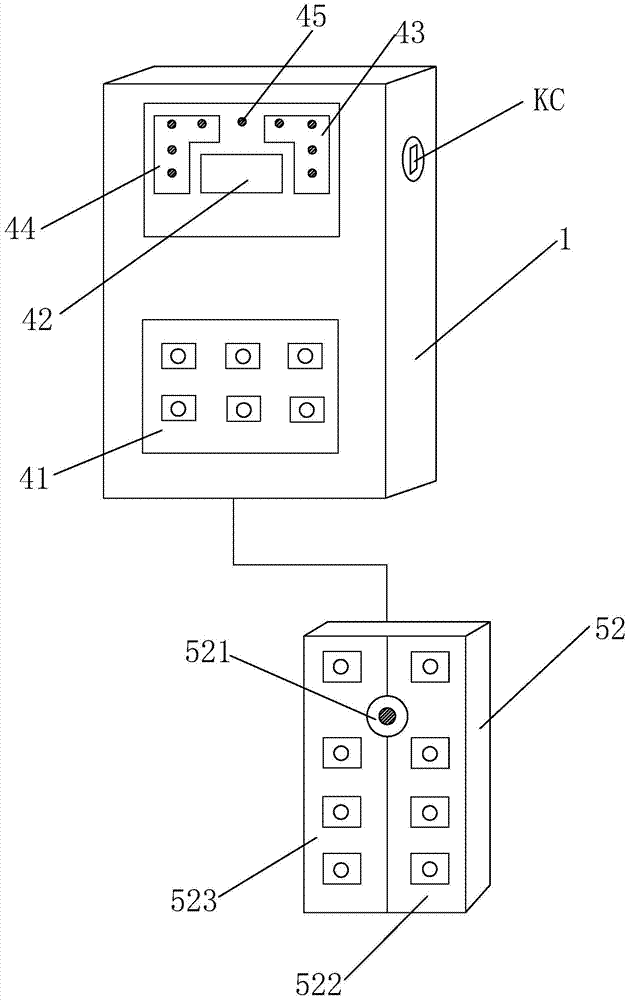

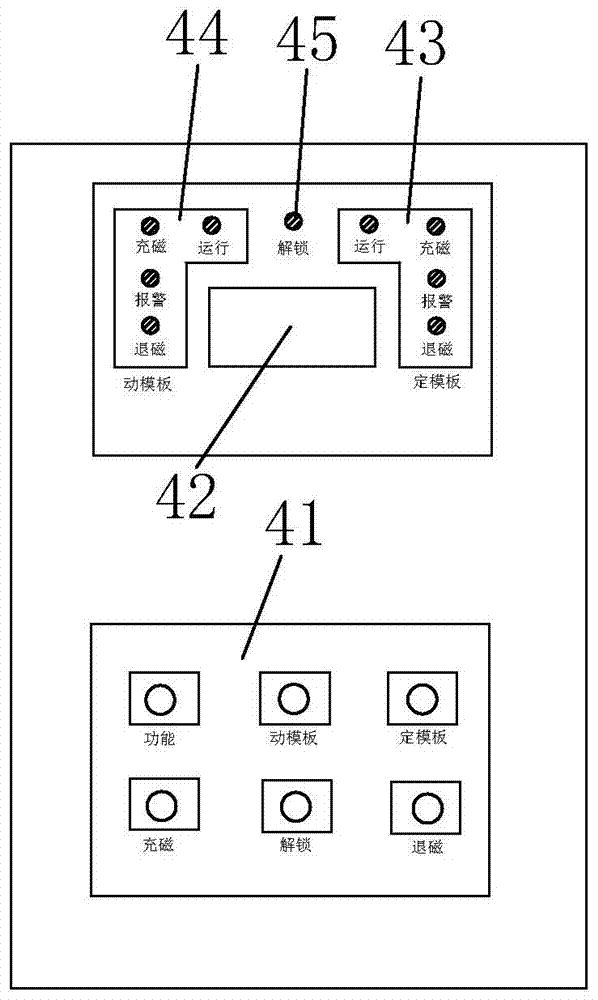

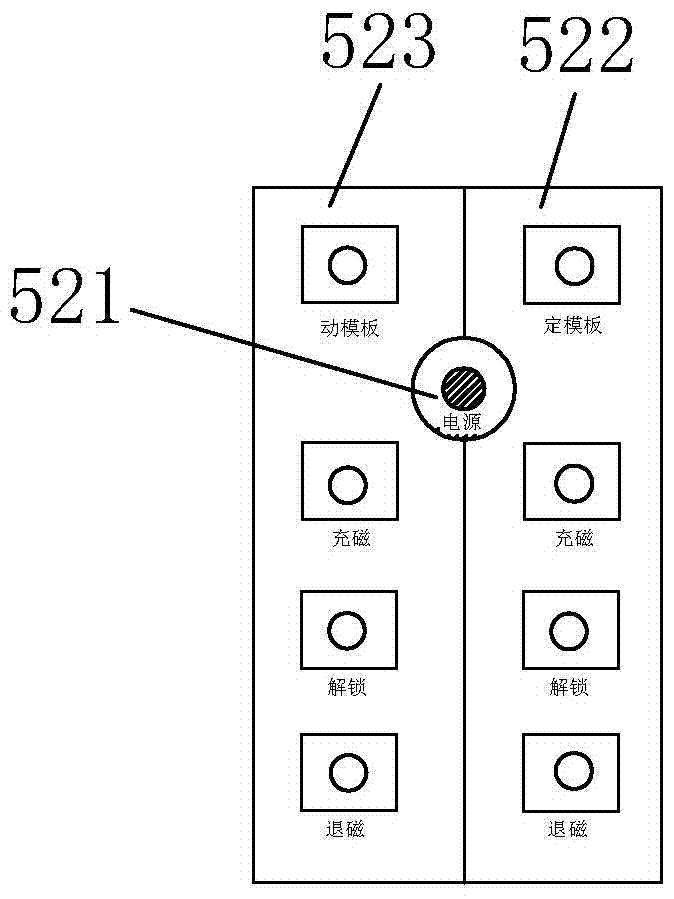

An electro-permanent magnet chuck control device for quick die change

ActiveCN104330988BImplement real-time monitoringAvoid damageProgramme control in sequence/logic controllersMagnetic tension forceElectricity

The invention discloses an electric permanent magnetic chuck control device capable of quick mold changing, comprising a fixed controller, a fixed template, and a moving template. The fixed controller is electrically connected with the fixed template and the moving template. The front of the fixed controller is provided with a button control panel, a digital display, fixed template status indicating lamps, moving template status indicating lamps, and an unlocking state indicating lamp. The fixed controller is electrically connected through wires with a proximity switch sensor, a temperature sensor, a magnetic sensor, a magnetic induction coil, a magnetic injection molding machine injection platform proximity switch, an injection molding machine power supply, and a mobile controller. The side of the fixed controller is provided with a power supply key switch. The electric permanent magnetic chuck control device has good magnetic suction performance, and mold installation can be carried out without screws. The security level is high, and the occurrence of production safety accidents is greatly reduced. The time for mold changing is reduced. The production efficiency is improved.

Owner:李锵华

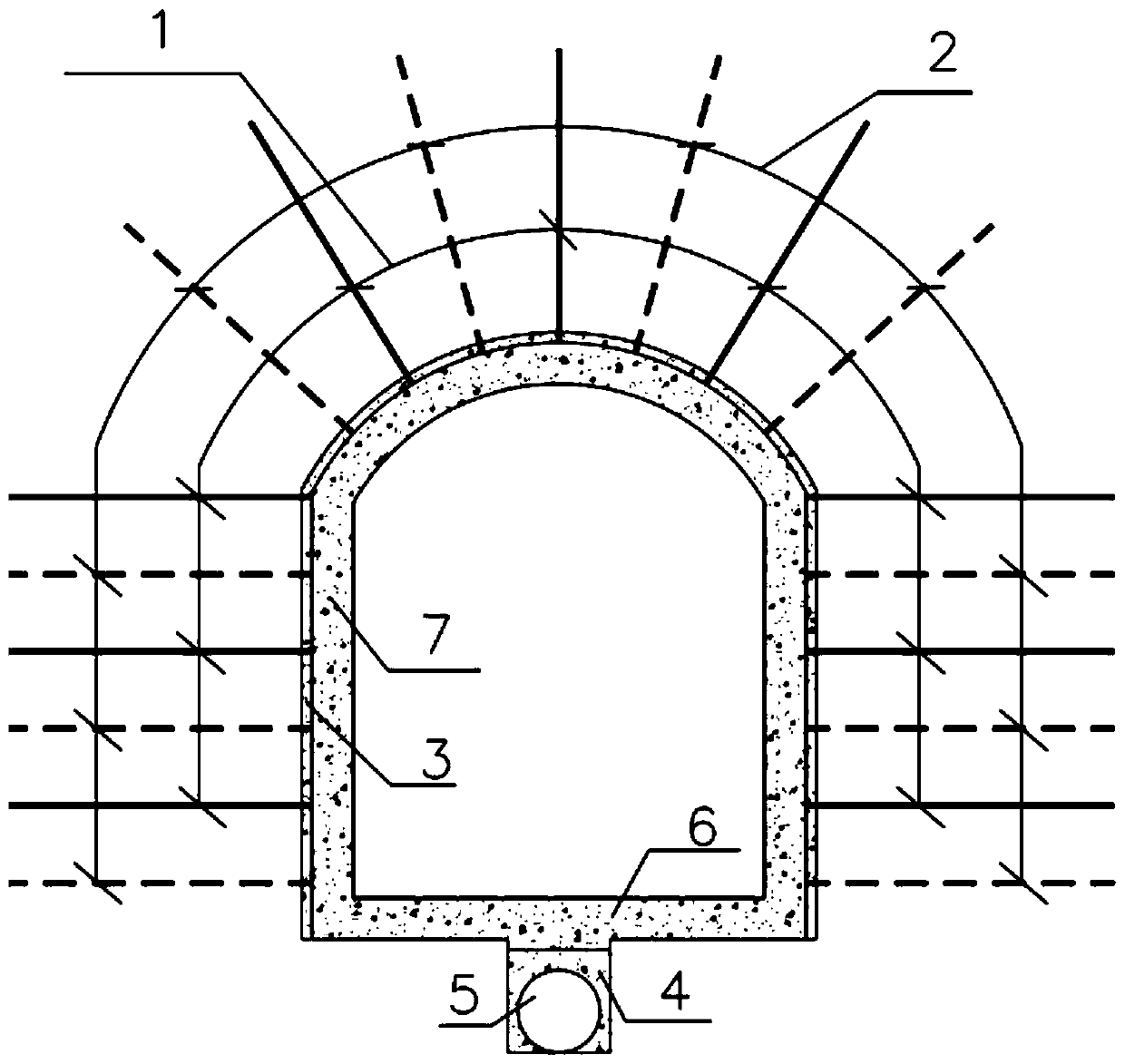

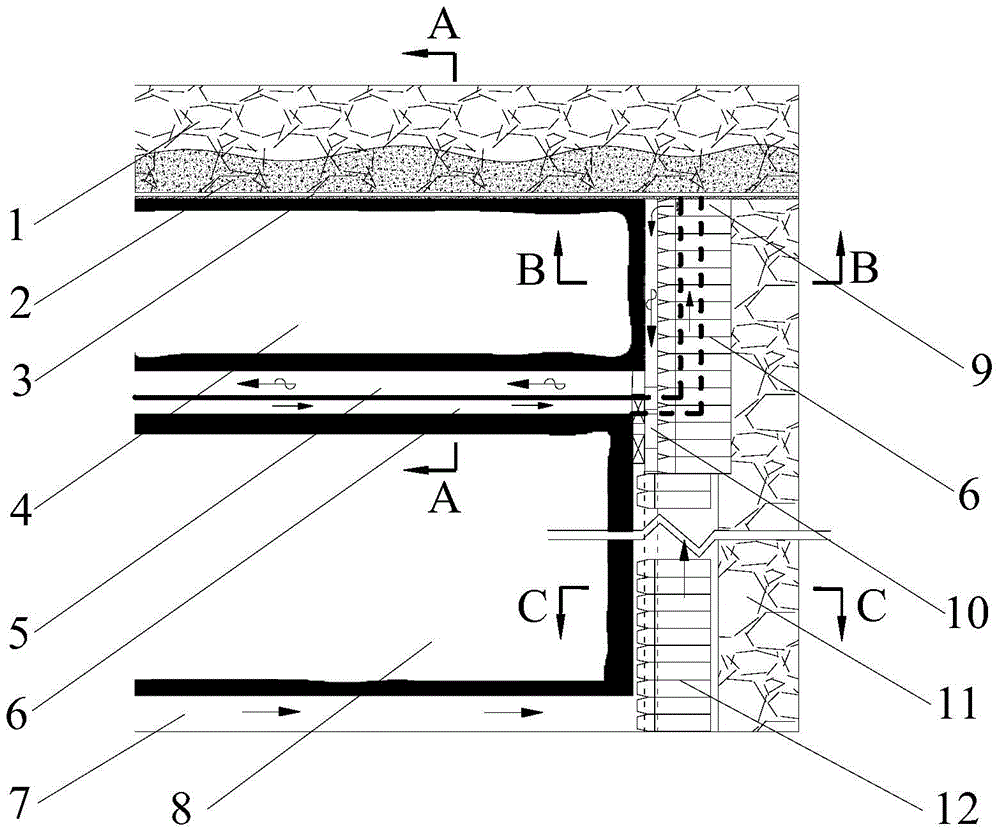

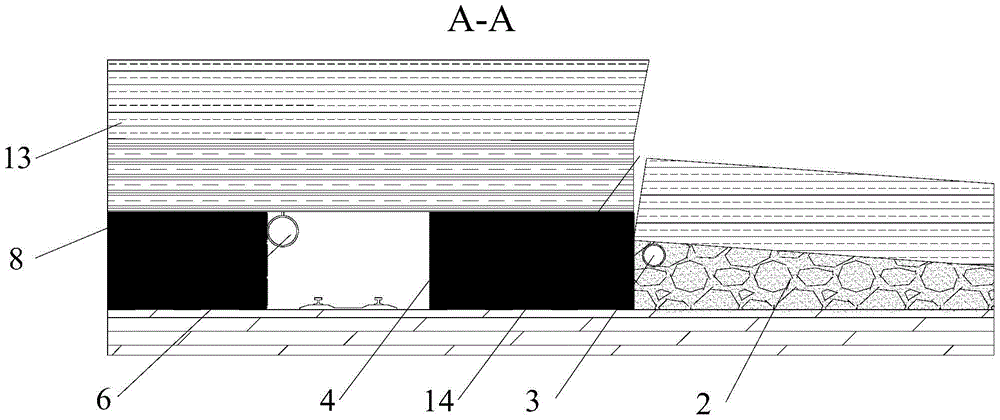

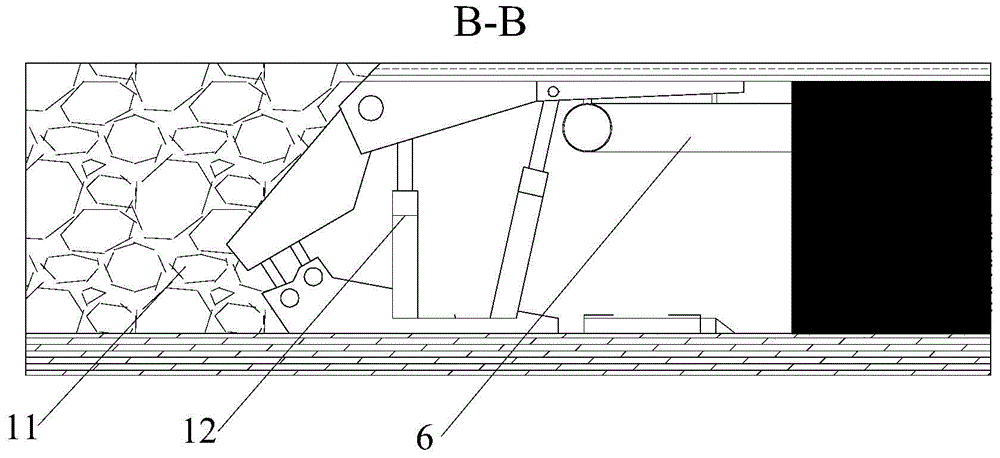

A repairable drainage tunnel, construction method and repair method

ActiveCN107829407BIncreased durabilityEasy maintenanceUnderground chambersArtificial water canalsWater flowPipe

Owner:POWERCHINA ZHONGNAN ENG

Identification and monitoring system of magnetic material preparation process based on artificial intelligence

ActiveCN113033492BImprove yieldImprove yield rateCharacter and pattern recognitionResourcesBatch processingAlgorithm

A magnetic material preparation process identification and monitoring system based on artificial intelligence belongs to the technical field of identification and monitoring. The present invention solves the problems of low monitoring efficiency and low accuracy in the existing magnetic material preparation process relying on manual judgment. The invention includes a data layer, an algorithm layer and an application layer; the data layer stores the data for identifying and monitoring the preparation process of magnetic materials; the algorithm layer identifies and monitors the actual magnetic material preparation process according to the AI model for identifying and monitoring the preparation process of rare earth magnetic materials. ;The application layer adopts the real-time video stream analysis framework based on DeepStream. With the support of the DeepSteam video analysis acceleration library, the multi-channel video goes through the steps of decoding, preprocessing, batch processing, neural network inference, tracking, visualization, display, and streaming. The algorithm layer realizes real-time detection of processes and real-time monitoring of illegal operations. The invention is mainly applied to the identification and monitoring of the magnetic material preparation process.

Owner:内蒙古海洋工信科技有限责任公司 +1

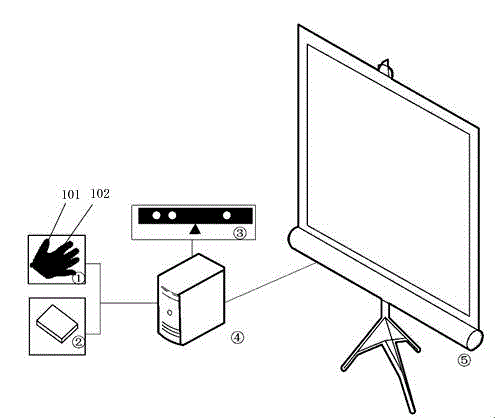

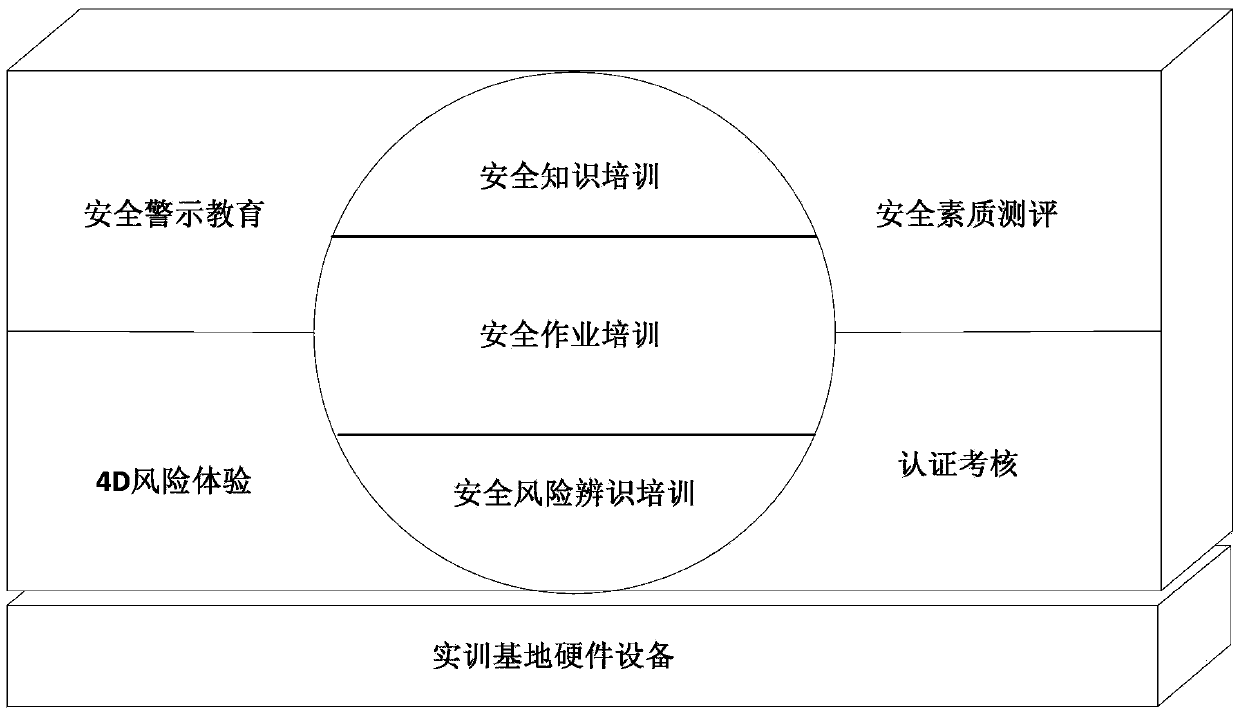

An interactive power safety training system and its training method

ActiveCN102842258BImprove the quality of trainingImprove production safety levelEducational modelsCognitionMotion sensing

The invention discloses an interactive electric power safety training system and a training method thereof. The training system comprises a glove (1), a stimulating source (2), motion-sensing equipment (3), a host computer (4) and a display screen (5). The host computer (4) is respectively connected with the glove (1), the stimulation source (2), the motion-sensing equipment (3) and the display screen (5). The glove (1) brings true experience to training staff. The interactive electric power safety training system can achieve interactive, vivid and realistic staff safety training, and enables a training way to change from book dogmatic abstract passive mode study to virtual and realistic combination specific active mode study, and from cognition training to experience sense. Moreover, the interactive electric power safety training system improves training quality of electric power safety production knowledge and skills and plays an important part in assisting in promoting company safety production level.

Owner:CHINA ELECTRIC POWER RES INST +2

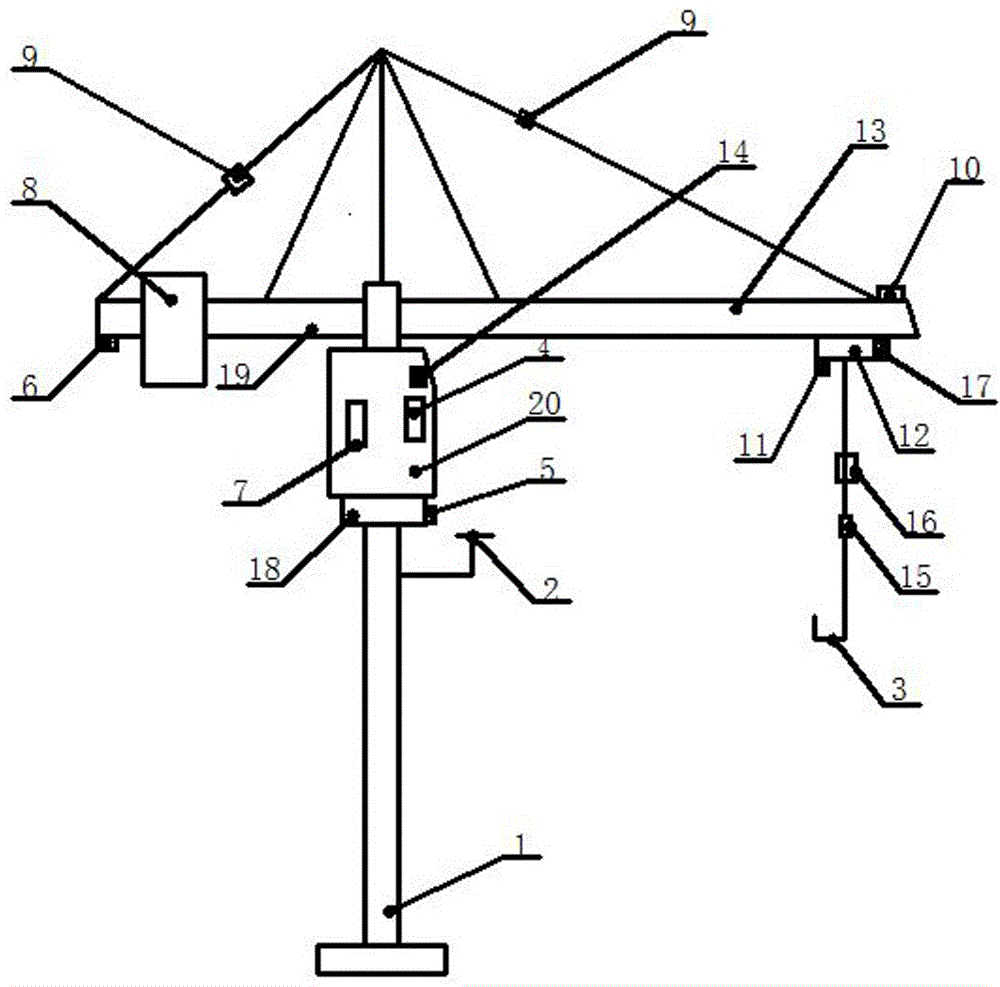

Safety monitoring tower crane

The invention discloses a safety monitoring tower crane. The tower crane is provided with a cab and a balancing weight. The cab is provided with a master controller, a displayer and an alarming device. The tower crane is provided with a rotation mechanism and an amplitude-change trolley. Tension sensors comprise the front tension sensor and the rear tension sensor which are mounted on a front stay cord and a rear stay cord correspondingly. A wind speed sensor is arranged in the middle of a tower body. A weight sensor is arranged on a lifting cord. A height sensor is arranged on the amplitude-change trolley. Speed sensors are arranged on the amplitude-change trolley and the lifting cord correspondingly. An angle sensor is arranged on the rotation mechanism. A temperature sensor is arranged at one end of a weight arm. An electrostatic sensor is arranged on a cargo boom. The tower crane can detect the working conditions of the tower crane and the field temperature and detect whether dangers exist around or not, so that accidents are reduced, and control over the tower crane by operators is facilitated.

Owner:SICHUAN TUOJIANG CRANE EQUIP

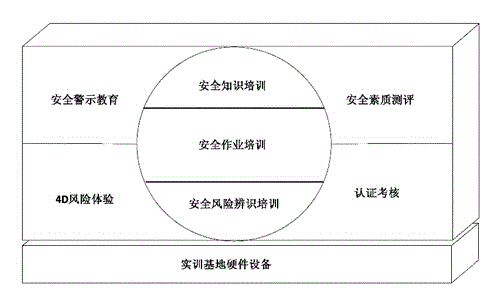

Electric power safety warning training system and training method thereof

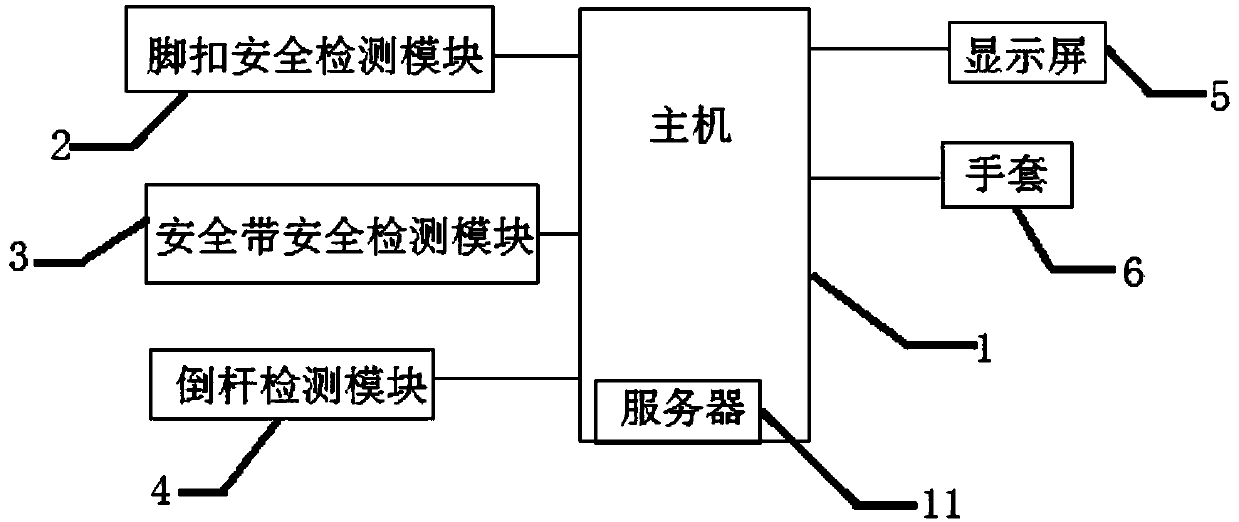

InactiveCN109637281AMobilize enthusiasmImprove securityTeaching apparatusElectric power systemSafety control

The invention discloses an electric power safety warning training system and a training method thereof. The system comprises a foot buckle safety detection module, a safety belt safety detection module, an inverted rod detection module, a host machine, a display screen, and gloves, wherein the foot buckle safety detection module, the safety belt safety detection module, the inverted rod detectionmodule, the gloves and the display screen are all connected with the host machine; the host machine comprises a server, the server comprises a safety interactive training system; and the electric power safety warning training method comprises the following steps that: step a, the electric power safety warning training system is started; and step b, training personnel logs on the safety interactivetraining system and enters a safety control measure module to carry out three times of training and examination, if the training is not qualified, the training personnel exits the system, and otherwise, the safety interactive training system carries out training performance evaluation and display. By the adoption of the electric power safety warning training system and the training method thereof, occurrence of safe production accidents can be reduced; learning interest and enthusiasm of students are mobilized to an utmost extent; and the training effect is greatly enhanced.

Owner:国网浙江台州市路桥区供电有限公司

Power Insulation Clamp

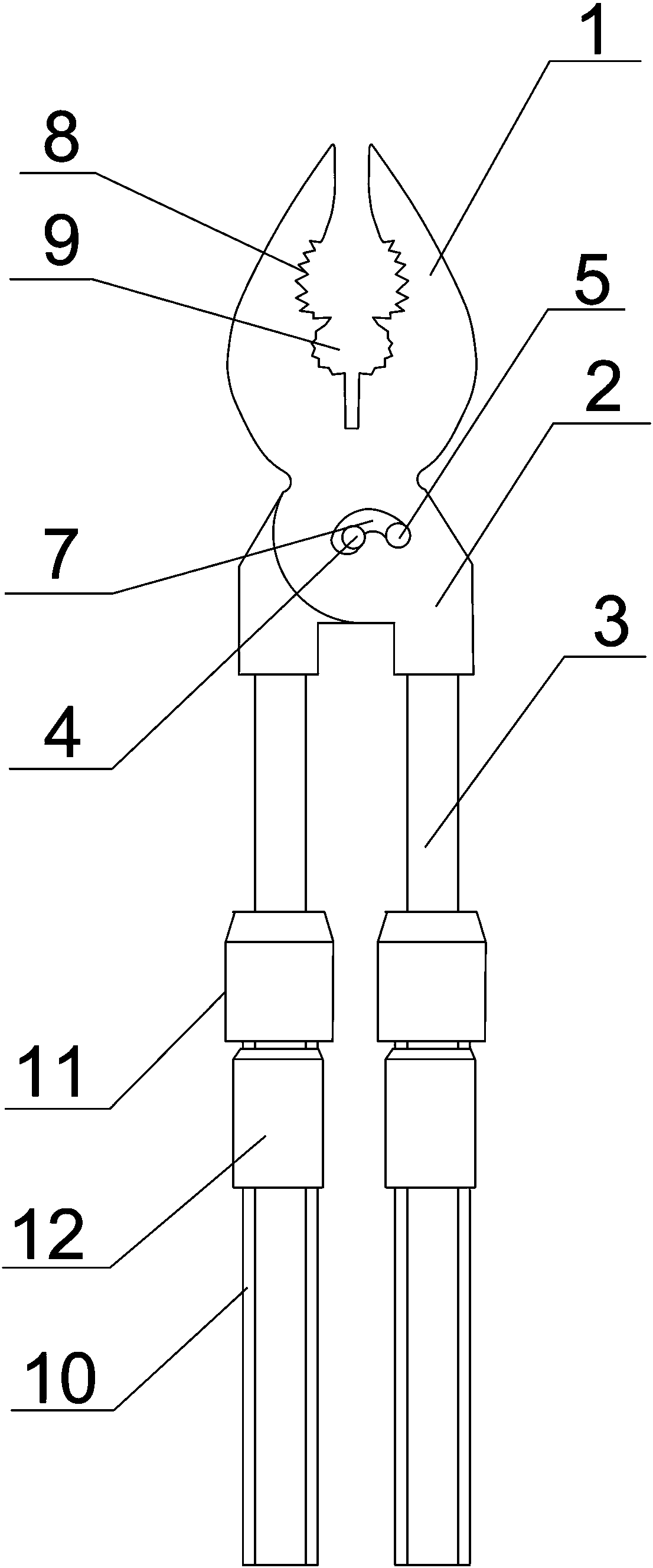

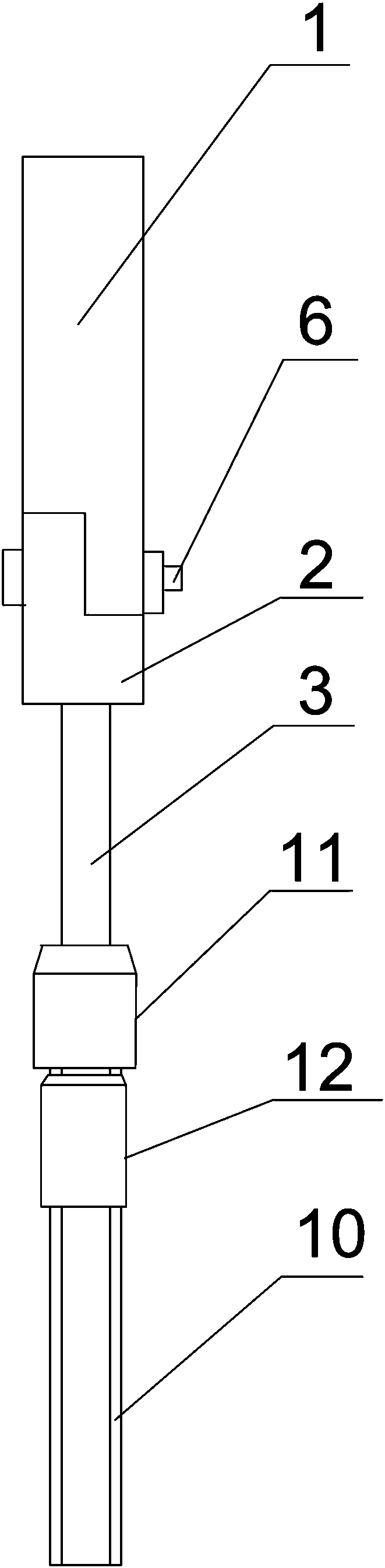

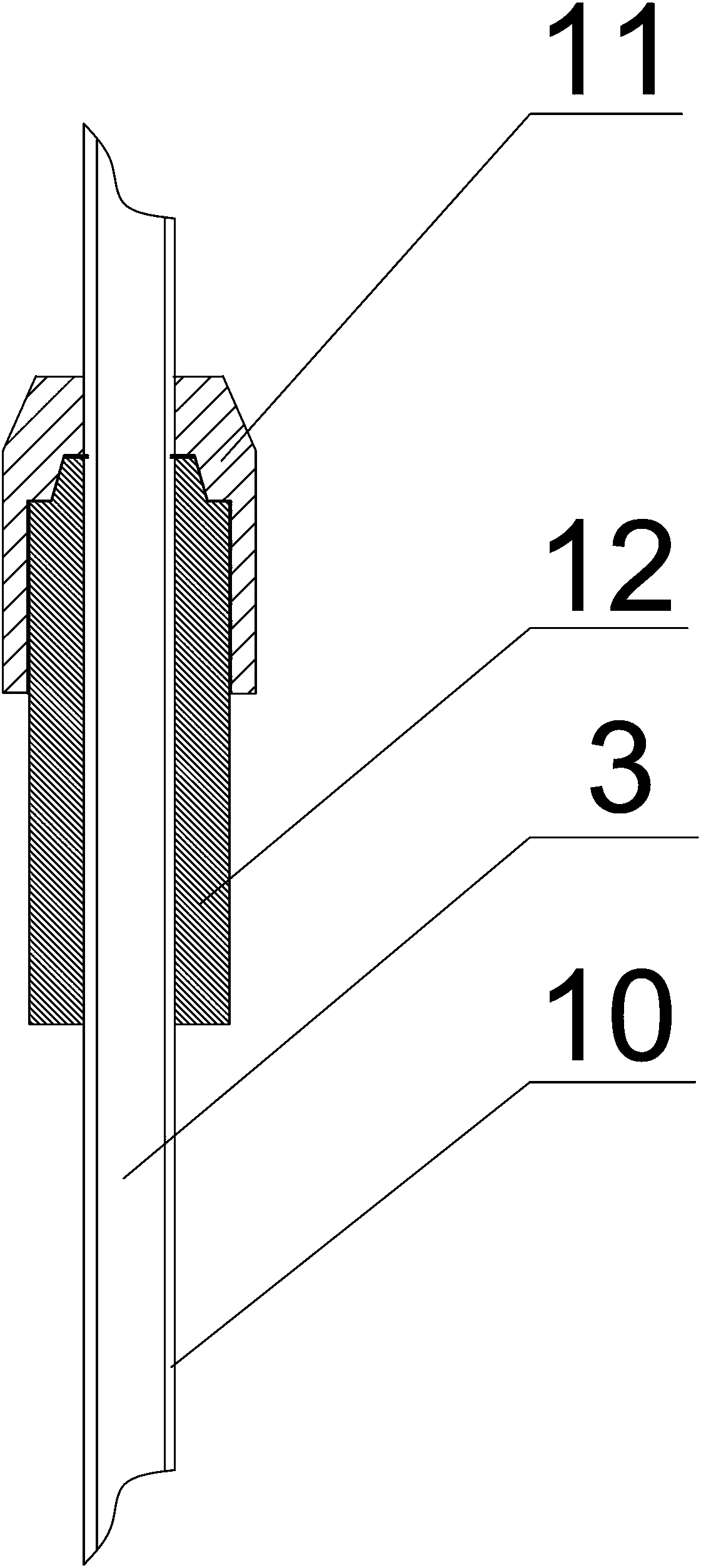

InactiveCN106272134BIncrease bite forceWon't fallPliersMetal-working hand toolsBite force quotientWhole body

The invention discloses an electric insulating pliers, which comprises two pliers bodies and a connecting mechanism. The pliers bodies include successively connected pliers mouths, pliers jaws and pliers handles. The pliers mouths and pliers jaws are integrally formed. The pliers handle is fixedly connected with the pliers jaw; the two pliers bodies are connected together by a connection mechanism arranged at the center of the pliers body, the connection mechanism includes a main connection hole, a secondary connection hole and a connection shaft, the main connection hole and Slide grooves are arranged between the auxiliary connecting holes. The invention solves the problems of insufficient bite force and poor insulation performance of the jaws of the existing insulating clamps.

Owner:NANYANG POWER SUPPLY COMPANY OF STATE GRID HENAN ELECTRIC POWER

A Coal Mining Method for F-shape Sections Realizing Coal Pillar Coal Mining

InactiveCN105240012BHigh recovery rateExtended service lifeUnderground miningSurface miningCoal pillarPressure increase

The invention discloses an F-type section coal-mining method allowing commingled mining of coal pillars. The method is specific mainly to the problem of technical methods for stoping of sectional protective coal pillars. A working face is divided into two parts, one part is a solid coal stoping face, and the other part is a coal pillar stoping face. Hydraulic supports are spread in the whole working face. Air from the solid coal stoping face is discharged from an intake roadway via a return roadway during a mining process. The coal pillar stoping face uses local ventilators, air is pressed from the intake roadway into the coal pillar face through flexible air pipes, and the air is returned via the return roadway. During stoping of an upper section, major factures are given to a main roof over a coal wall by pre-blasting, , the basic roof breaks at this position after stoping, and thus pressure increase in close-to-gob areas caused by rotation of the main roof is decreased. In addition, a filled wall which is formed by means of filling and the like isolates an upper section gob area and a lower section coal pillar stoping face, and thus roof fall and side spanning accidents caused are decreased.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

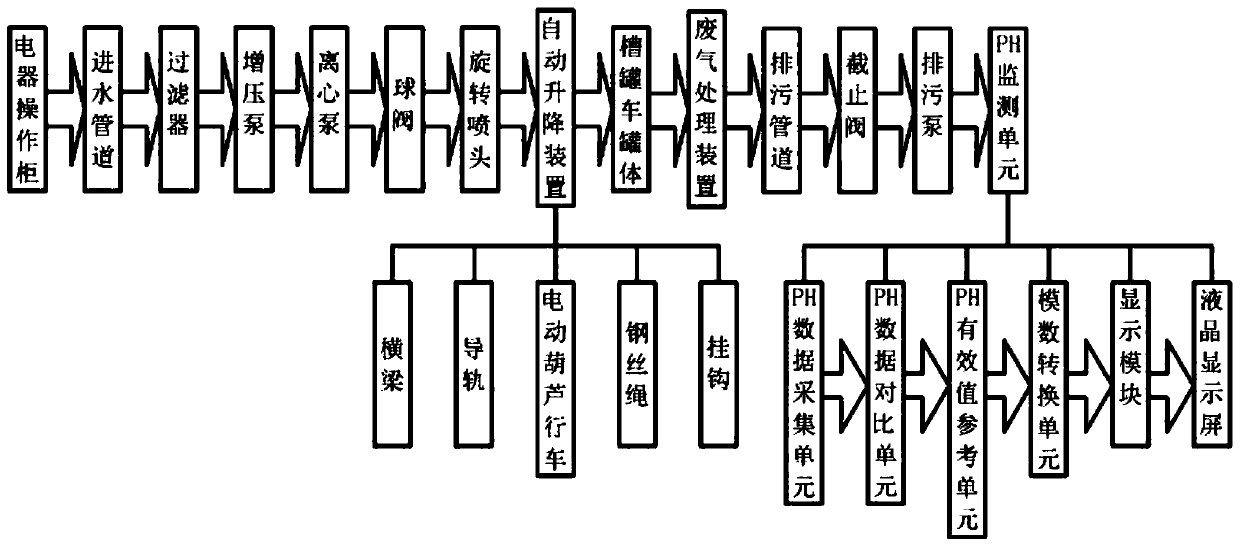

An automatic cleaning system for liquid chemical tanker and its cleaning process

ActiveCN106076999BReduced personal safetyGuarantee personal safetyHollow article cleaningTank truckChemical tank

Owner:湖北省安全生产应急救援中心

Lifting device for aero-engine

Owner:邯郸市永年区海翔机械厂

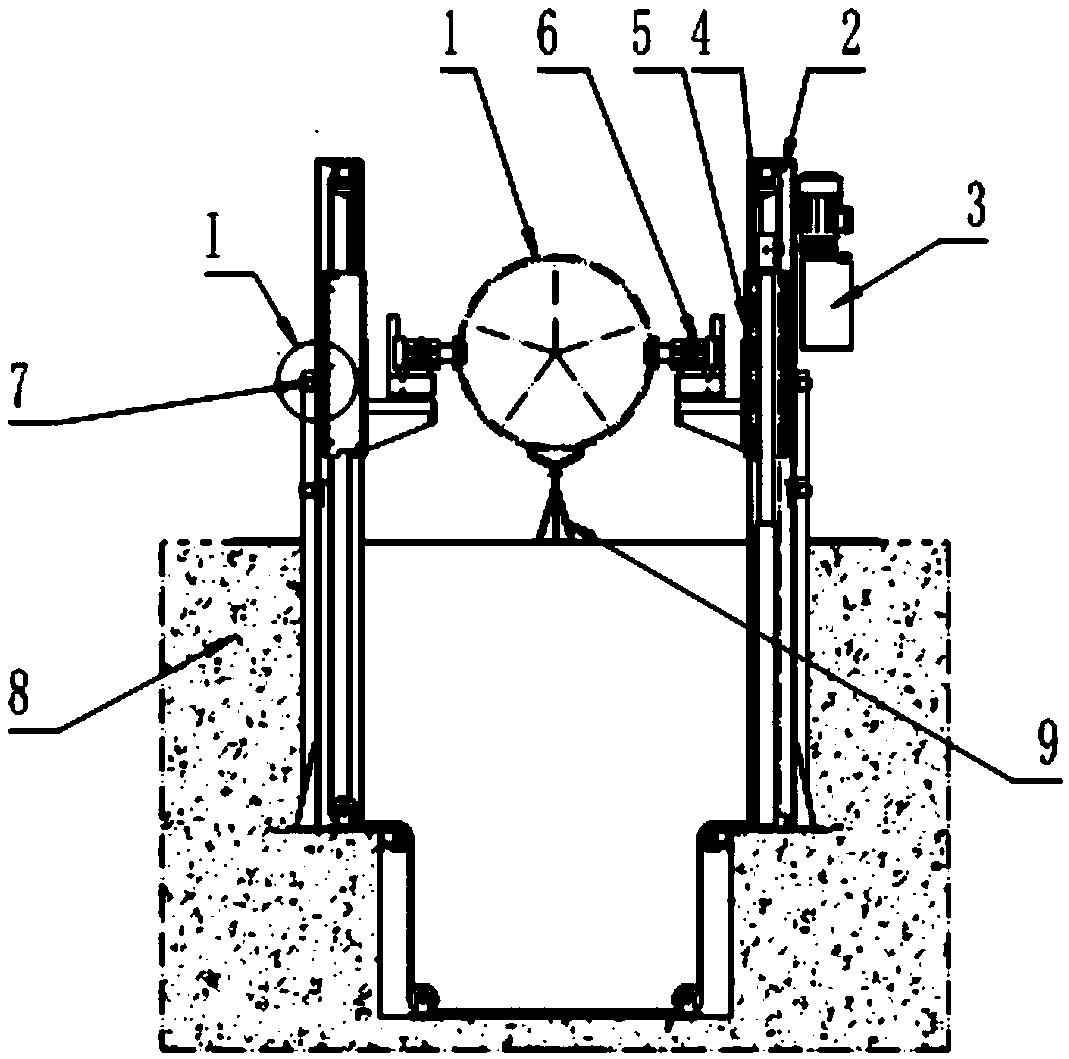

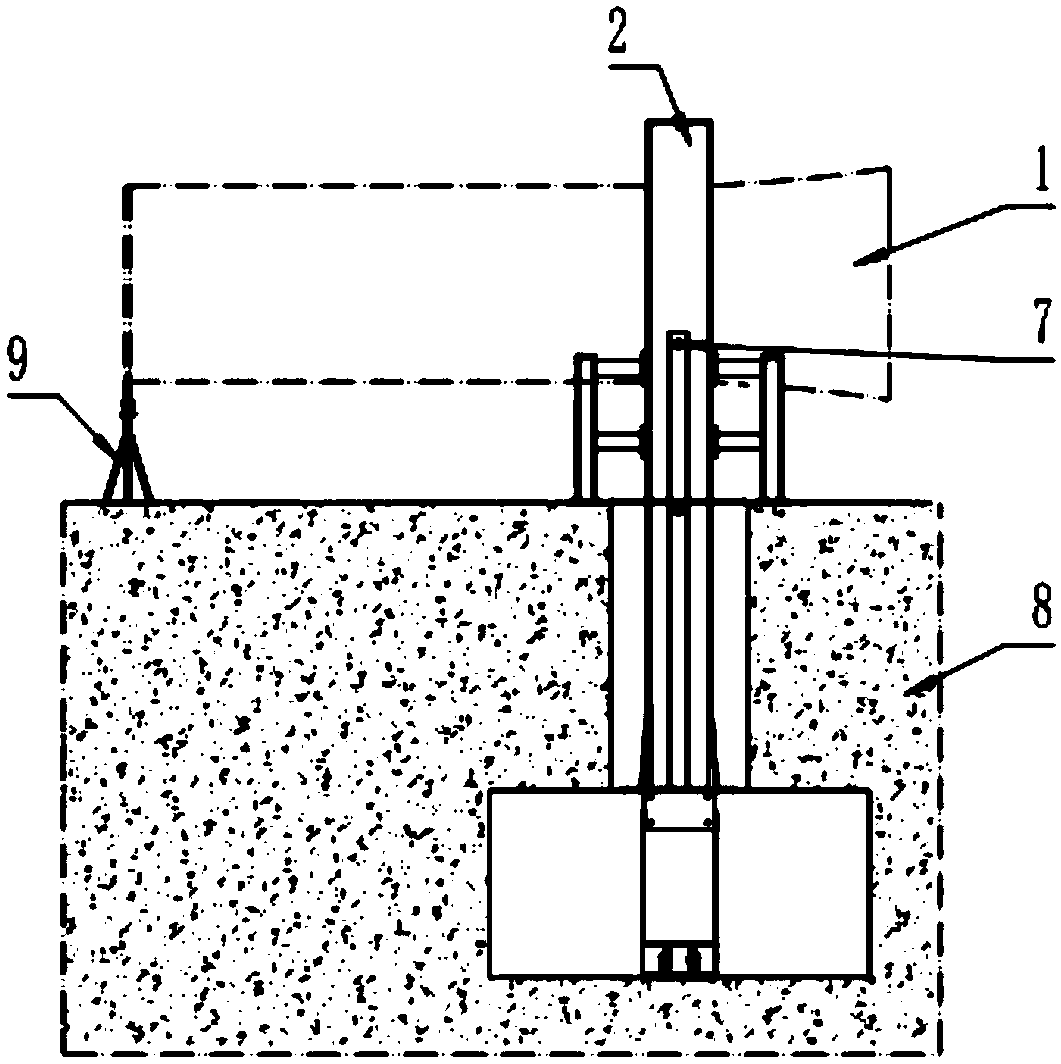

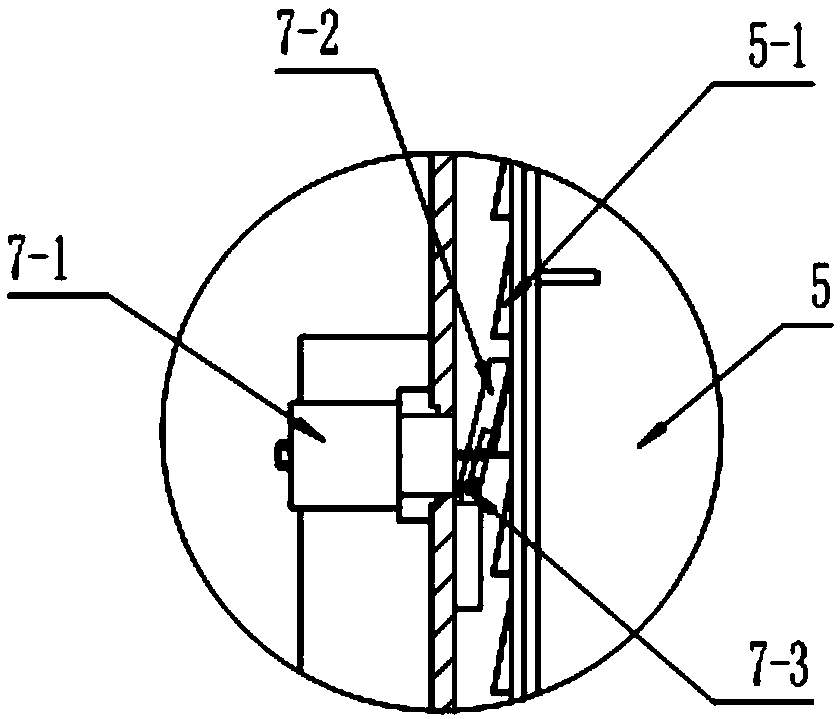

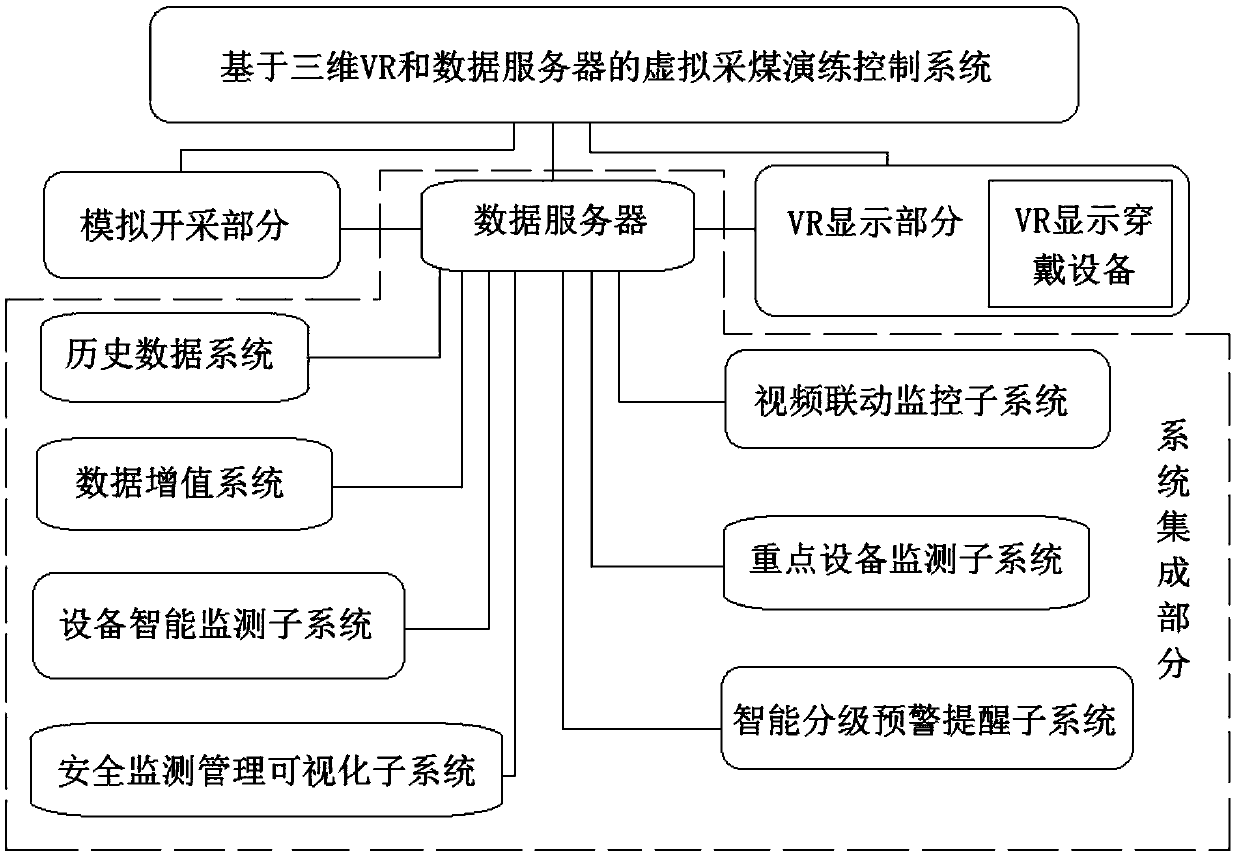

A Virtual Coal Mining Drill Control System Based on 3D VR and Data Server

ActiveCN107272634BImprove securityImprove efficiencyProgramme total factory controlVisual integrationSimulation

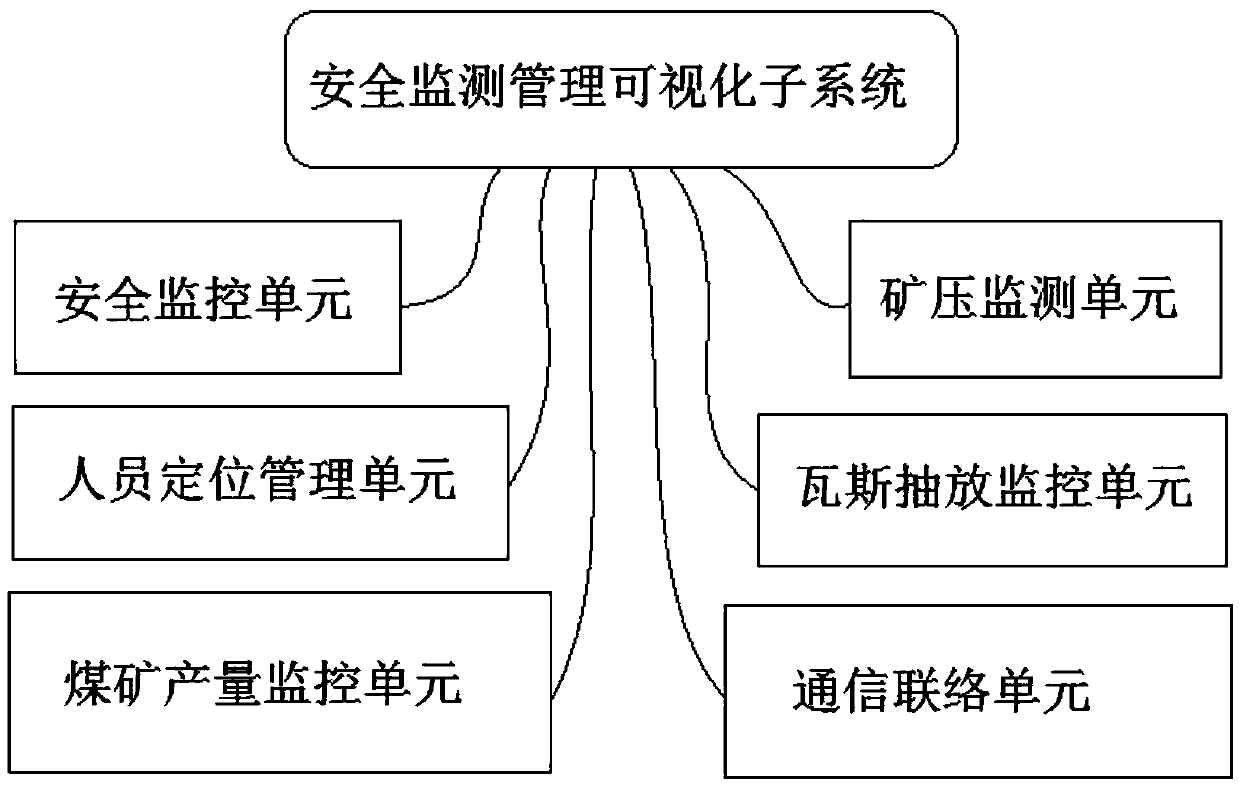

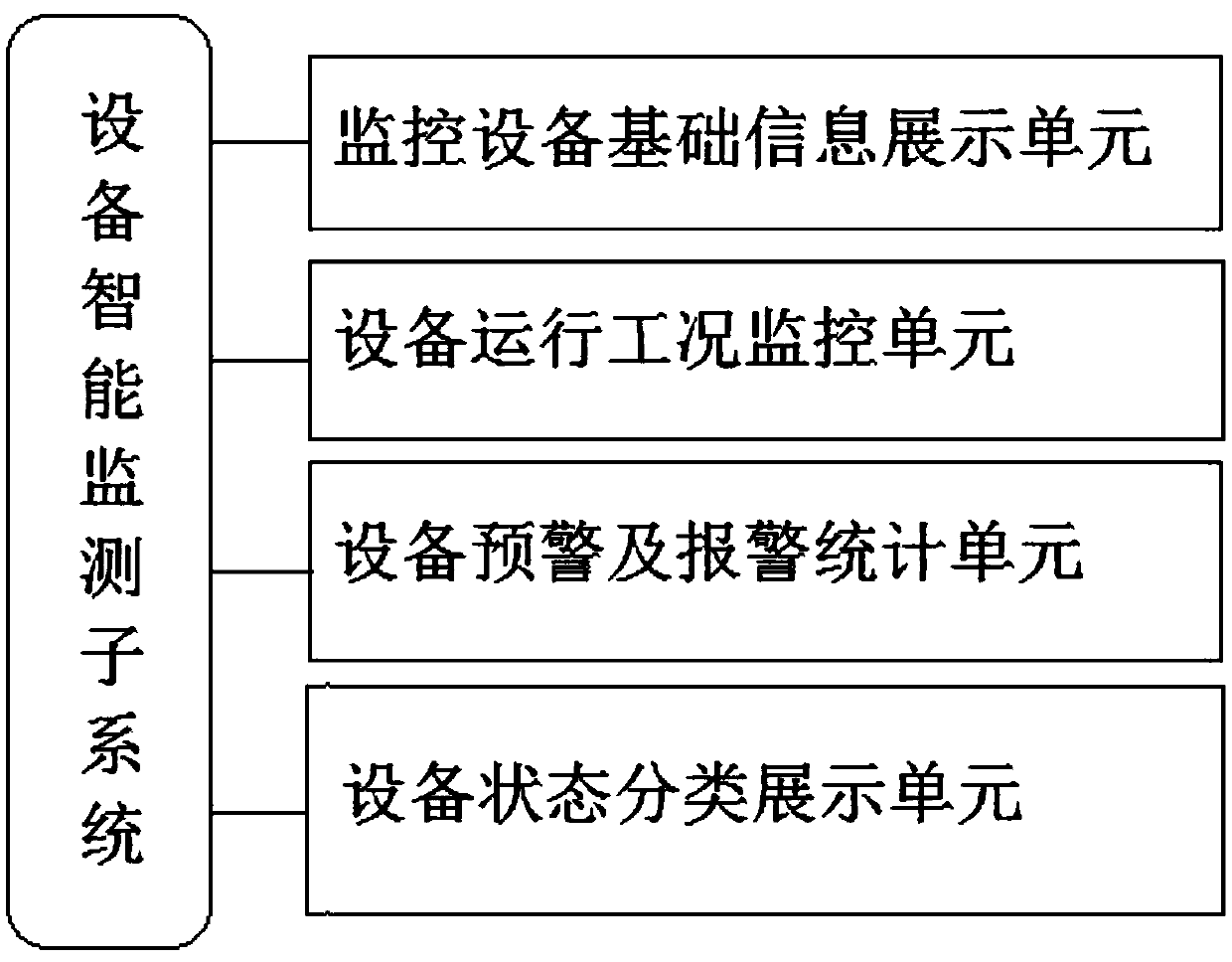

The invention relates to the technical field of coal mining practice control and discloses a three-dimensional VR (virtual reality) and data server based virtual coal mining practice control system. The system comprises a simulation mining portion, a system integration portion and a VR display portion. The simulation mining portion comprises a three-dimensional VR controller and control keys; the system integration portion comprises a data server, a historical data system, an equipment intelligent monitoring subsystem, a safety monitoring management visualization system, a video linkage monitoring subsystem, a critical equipment monitoring subsystem and an intelligent hierarchical early warning subsystem; the VR display portion comprises a VR display wearable device. By a visualization technology and a three-dimensional geographic information system technology, coal mining digital conversion into geometric images is realized, remote control of visual integration is realized, loss caused by equipment damages is reduced, non-stop times can be reduced, technical level of field operators and board operators can be raised, potential safety hazards caused by personnel flow are reduced, and out-of-limit discharge caused by equipment faults can be reduced.

Owner:合肥中盈信息工程有限公司

Mast crane control system for installation of cement waste heat boiler

ActiveCN109052179AEasy to implement modularizationLabor savingLoad-engaging elementsCranesHydraulic cylinderControl system

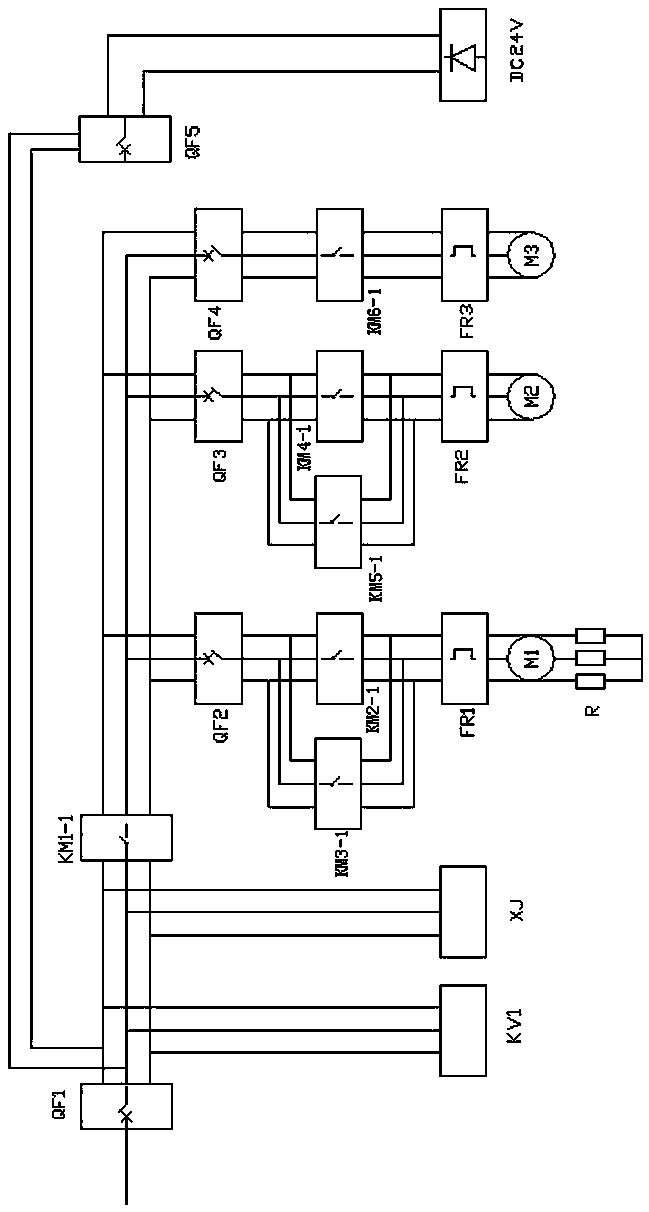

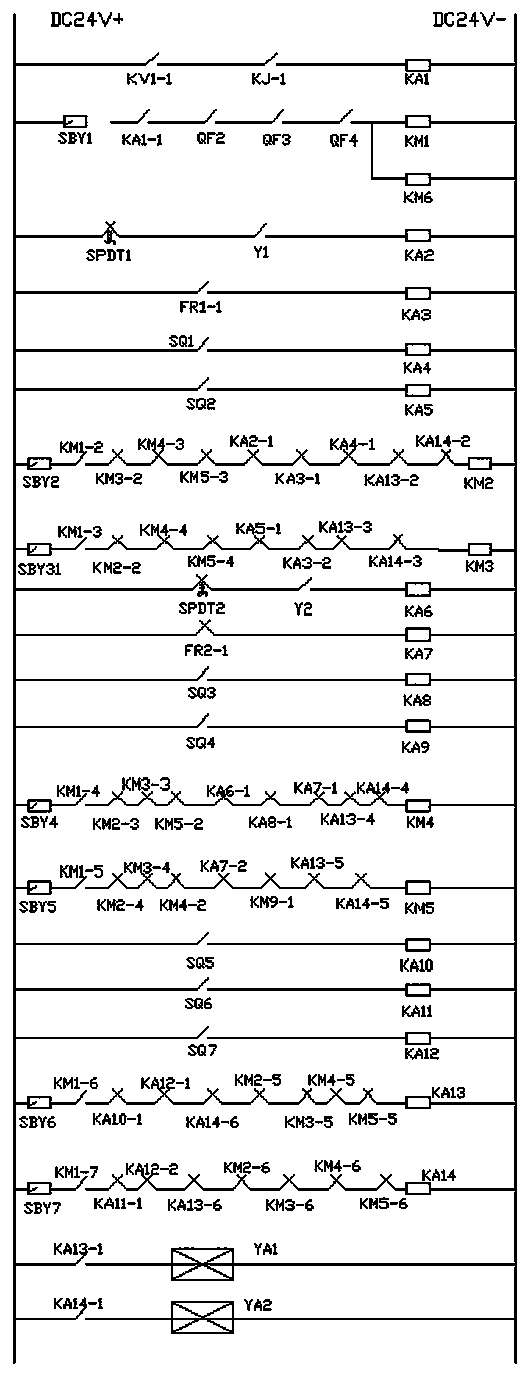

The invention provides a mast crane control system for installation of a cement waste heat boiler. The mast crane control system comprises a main hook motor M1, a variable amplitude motor M2, an oil pump M3, a first hydraulic cylinder used for controlling a mast to rotate leftwards, and a second hydraulic cylinder used for controlling the mast to rotate rightwards, wherein the oil pump M3 communicates with the first hydraulic cylinder through a first electromagnetic valve YA1, and the oil pump M3 communicates with the second hydraulic cylinder through a second electromagnetic valve YA2; and the mast crane control system for installation of the cement waste heat boiler further comprises a second contactor KM2 used for controlling the main hook motor M1 to rotate forwards, a third contactorKM3 used for controlling the main hook motor M1 to rotate reversely, a fourth contactor KM4 used for controlling the variable amplitude motor M2 to rotate forwards, a fifth contactor KM5 is used for controlling the variable amplitude motor M2 to rotate reversely, and a sixth contactor KM6 used for controlling the oil pump M3. The mast crane control system adopts a remote control switch to realizecontrol, so that workers do not need to carry out on-site transportation, safety accidents are avoided, moreover, when the mast is used for hoisting, ascending and descending limiting and variable-amplitude limiting of a main hook are achieved, the rotation limit of a rotary hydraulic cylinder is achieved, and the limits guarantee that the mast can be normally hoisted.

Owner:SHANDONG CONSTR HIGH PRESSURE CONTAINER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com