Mast crane control system for installation of cement waste heat boiler

A waste heat boiler and control system technology, applied in cranes, transportation and packaging, load hanging components, etc., can solve problems such as unusable, high installation position, safety production accidents, etc., to save hoisting costs, save labor, and reduce safety The effect of the accident

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

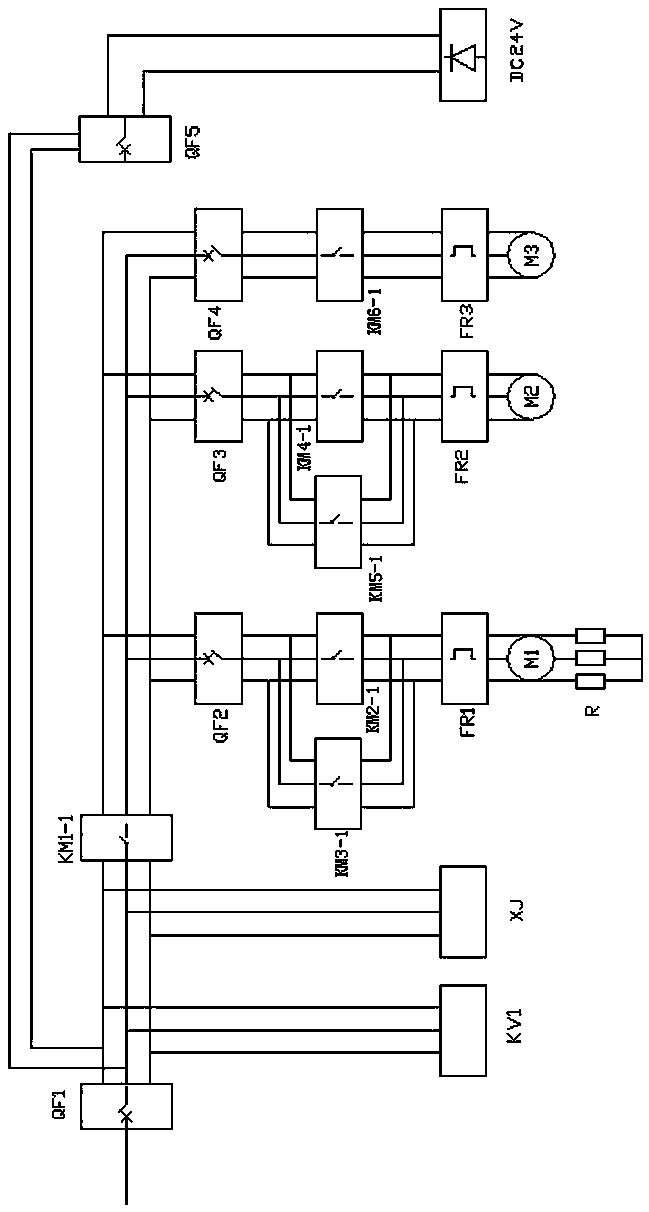

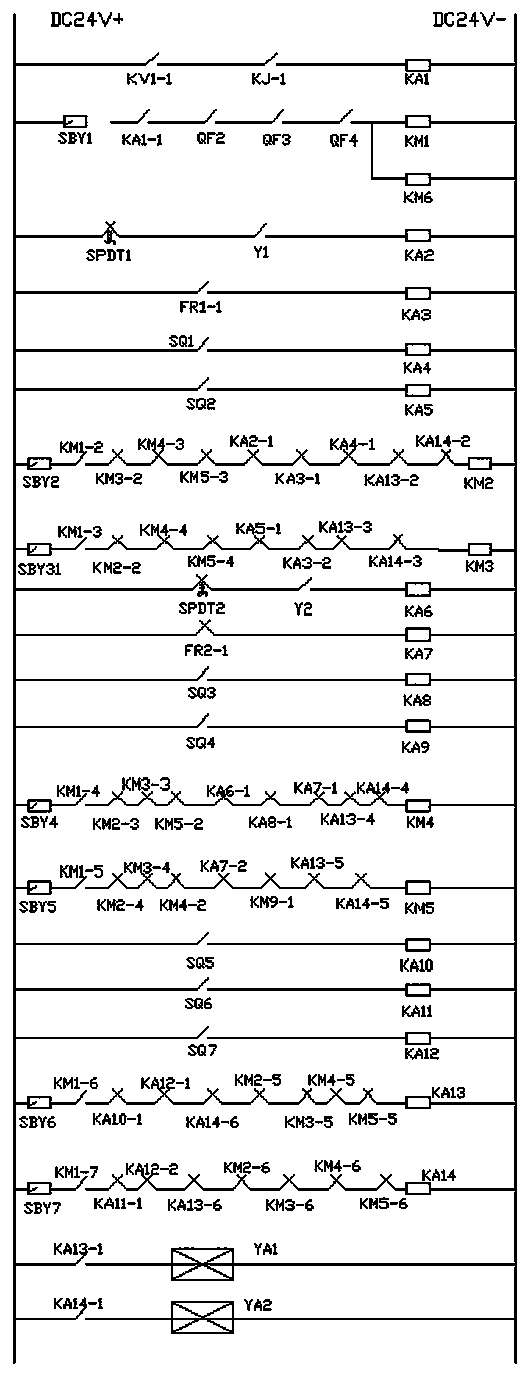

[0018] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation mode combined with the accompanying drawings.

[0019] It can be seen from the drawings that the mast crane control system for cement waste heat boiler installation in this scheme includes the main hook motor M1, the luffing motor M2, the oil pump M3, and the first hydraulic cylinder used to control the left rotation of the mast. The second hydraulic cylinder for the mast to turn right, the oil pump M3 communicates with the first hydraulic cylinder through the first solenoid valve, the oil pump M3 communicates with the second hydraulic cylinder through the second solenoid valve, and its feature is: it also includes a motor M1 for controlling the main hook The second contactor KM2 for forward rotation, the third contactor KM3 for controlling the reverse rotation of the main hook motor M1, the fourth contactor KM4 for controlling the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com