Steel-concrete composite wall with alternately arranged corrugated steel plates and flat steel plates

A technology of corrugated steel plates and alternate arrangement, which is applied in the direction of walls, insulation, building components, etc., can solve the problems of large steel content, difficult connection of insulation and decorative layers, etc., and achieve the effect of saving steel, labor and auxiliary materials, and simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the objectives, technical solutions and advantages of the present invention clearer, the technical solutions of the present invention will be further described below.

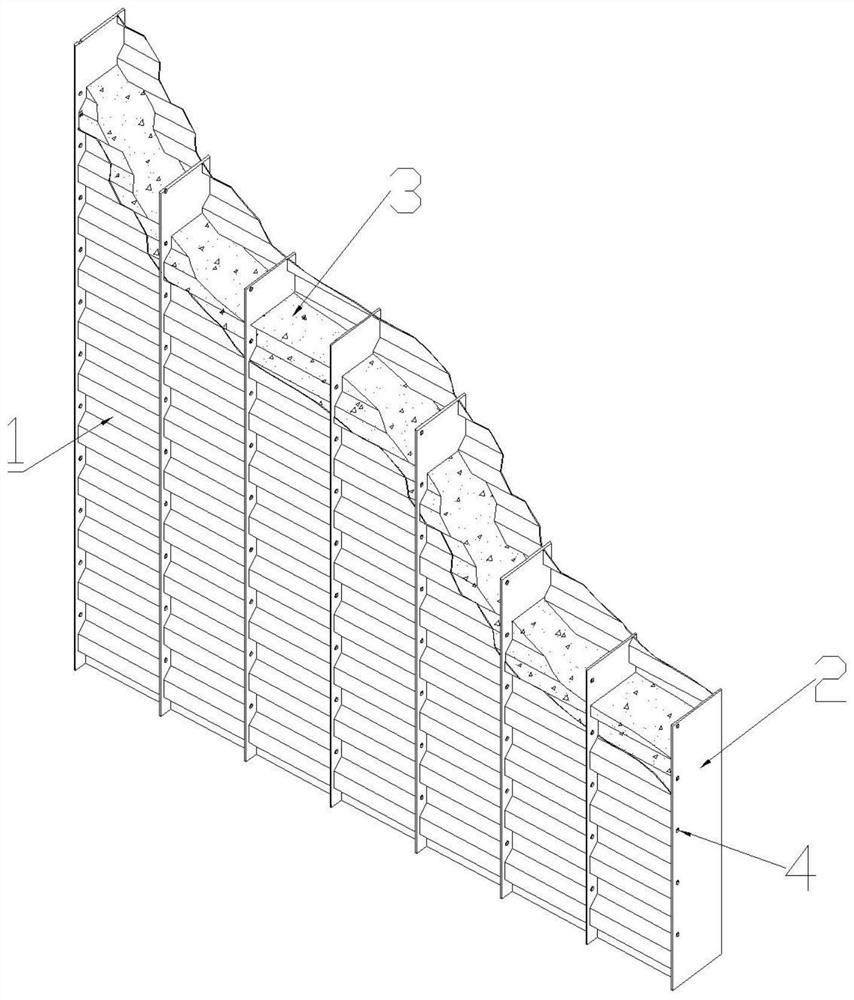

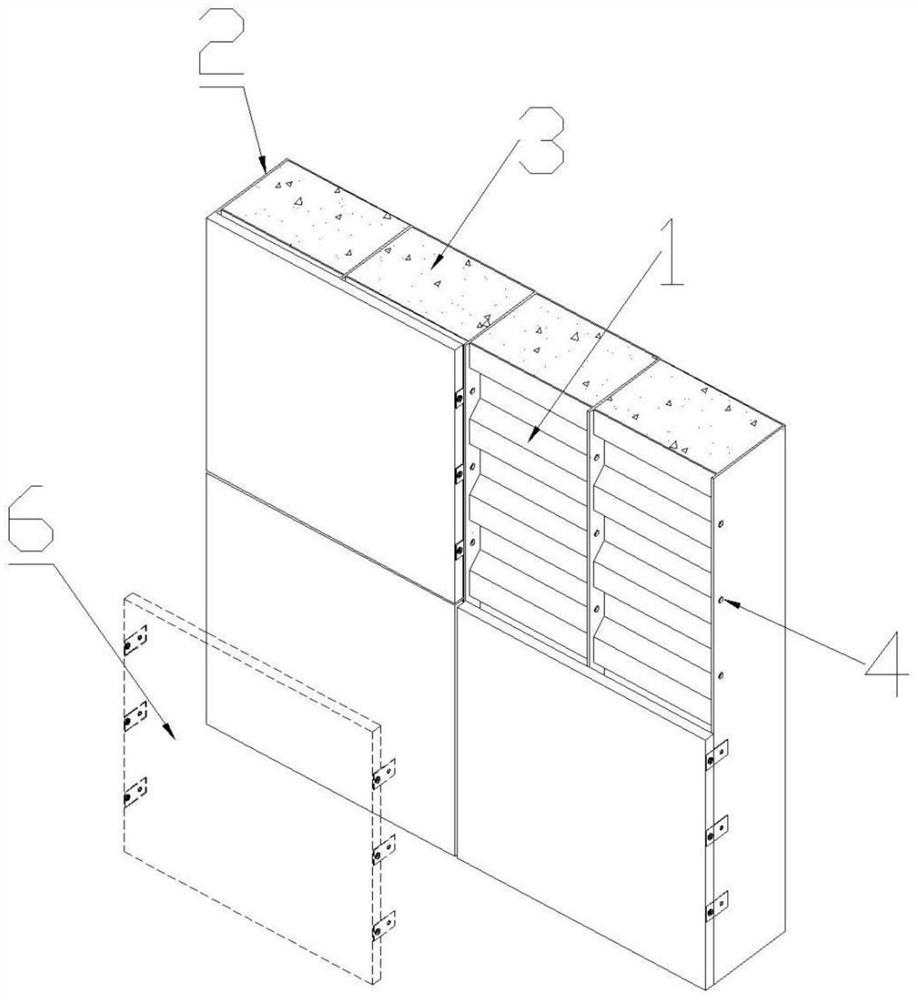

[0030] like figure 1 As shown, the present invention proposes a steel-concrete composite wall in which corrugated steel plates and flat steel plates are alternately arranged, and the composite wall is composed of corrugated steel plates 1, flat steel plates 2 and concrete 3;

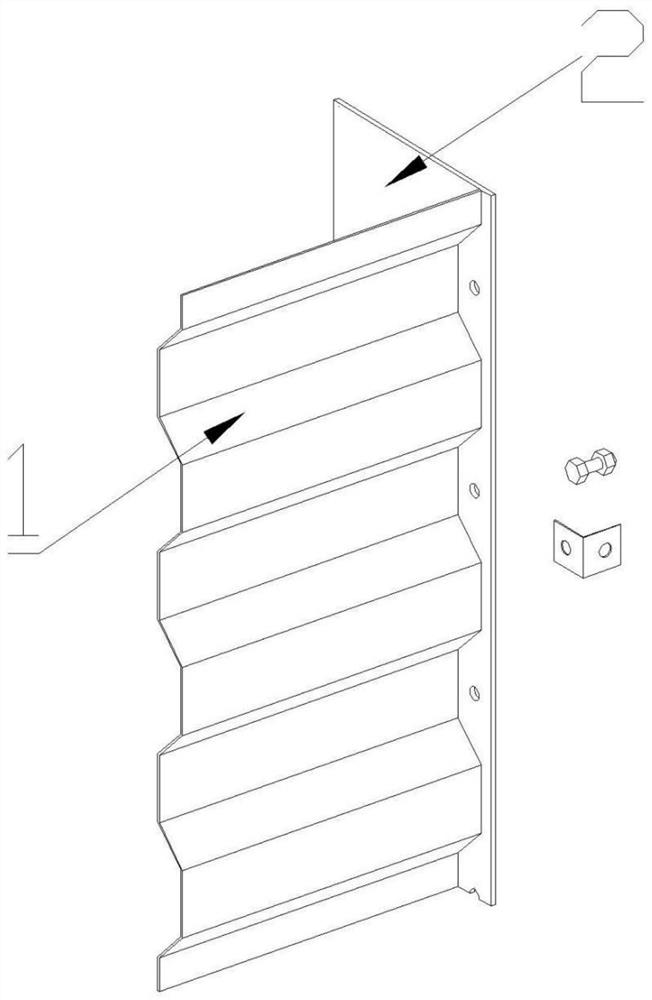

[0031] At least two flat steel plates 2 are arranged in parallel along the wall thickness, two corrugated steel plates 1 are arranged between two adjacent flat steel plates 2, and the corrugated steel plates 1 are arranged horizontally or vertically between the two flat steel plates 2, and the corrugated steel plates 1 The surface is corrugated or wavy. The corrugated steel plate 1 and the flat steel plate 2 are fixed by welding, and the two corrugated steel plates 1 are arranged along both sides of the wall; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com