Hoisting mechanism for installation of cement waste heat boiler and setting method of hoisting mast

The utility model relates to a waste heat boiler and a technology for installation, which is applied to the setting field of a hoisting mechanism for the installation of a cement waste heat boiler and its main component hoisting mast, which can solve the problems of inconvenient use of automobile hoisting, and achieve the effect of saving hoisting costs and reducing construction costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

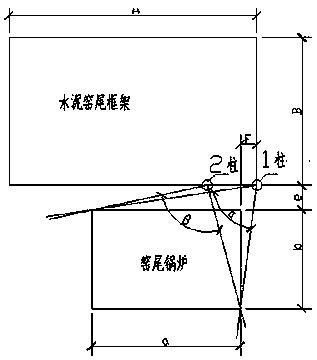

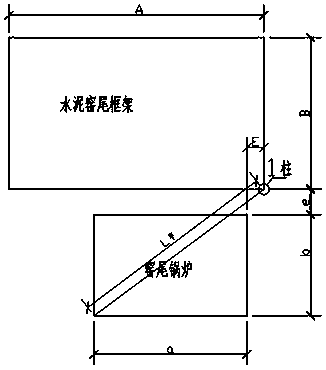

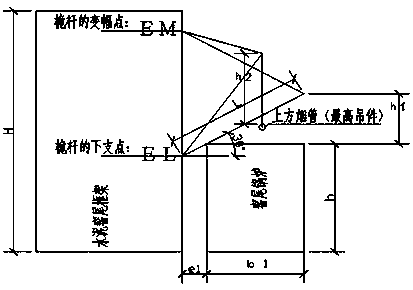

[0022] The hoisting mechanism for cement waste heat boiler installation is set on the cement kiln tail frame and can rotate to cover the kiln tail boiler frame. The cement kiln tail frame is a cubic structure composed of round steel columns and steel beams. The kiln tail boiler frame is set on the cement One side of the frame at the end of the kiln.

Embodiment 2

[0024] On the basis of Example 1, preferably, the setting of the hoisting mast should meet the following conditions: (1) Try to minimize the rotation angle of the mast covering the boiler frame at the end of the kiln; (2) Use the elevation angle Q of the mast 1 30-90°.

Embodiment 3

[0026] On the basis of Example 2, the hoisting mast is set on a round steel column of the tail frame of the cement kiln.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com