Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

62results about How to "Reduce radial deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Inlet partial blades for structural integrity and performance

Methods and apparatus for conveying fluids (e.g., liquids, gases, and mixtures thereof) are disclosed. A turbopump in accordance with an exemplary implementation of the present invention comprises an impeller defining at least one flow channel and a shroud defining an opening communicating with the at least one flow channel. In certain advantageous implementations, at least one inlet partial of the impeller extends into the opening defined by the shroud. The at least one inlet partial may advantageously be capable of supporting the opening in the shroud. In some cases, the impeller may include a plurality of these inlet partials.

Owner:THE BOEING CO +1

Inlet partial blades for structural integrity and performance

ActiveUS20050152779A1Reduced scallopingImprove efficiencyPropellersPump componentsImpellerEngineering

Methods and apparatus for conveying fluids (e.g., liquids, gases, and mixtures thereof) are disclosed. A turbopump in accordance with an exemplary implementation of the present invention comprises an impeller defining at least one flow channel and a shroud defining an opening communicating with the at least one flow channel. In certain advantageous implementations, at least one inlet partial of the impeller extends into the opening defined by the shroud. The at least one inlet partial may advantageously be capable of supporting the opening in the shroud. In some cases, the impeller may include a plurality of these inlet partials.

Owner:THE BOEING CO +1

Manufacturing process for high-strength corrosion-resistant aluminum alloy forged piece

ActiveCN108746447AImprove mechanical propertiesImprove corrosion resistanceMetal rollingMaterials preparationRoom temperature

The invention discloses a manufacturing process for a high-strength corrosion-resistant aluminum alloy forged piece. The process comprises the following steps of material preparation, heating, multi-axial forging, mechanical machining, heating, trestle bearizing, heating, ring rolling, mechanical machining, annealing, solid-solution water-quenching, cold pressing deformation, aging and the like. The aging treatment method comprises the steps of first-grade aging, specifically, a ring forged piece subjected to cold pressing is put into a furnace at the room temperature and heated to 90-110 DEGC, heat preservation is performed for 1-3 hours, and air cooling is performed; second-grade aging, specifically, the ring forged piece is put into the furnace when the temperature is reached, heat preservation is performed for 4-8 hours at the temperature of 150-160 DEG C, and air cooling is performed after aging is ended.

Owner:JIANGSU UNIV OF TECH

Casing structure with leaf apex interval control and leaf tip flow control

ActiveCN107435563AReduce the temperatureReduce radial deformationLeakage preventionMachines/enginesCold airCooling effect

The invention discloses a casing structure with leaf apex interval control and leaf tip flow control. A turbine casing and an impact plate form a first cavity, multiple impact holes are limited in the impact plate, a turbine outer ring form a second cavity, multiple turbulent structures, and an air film hole structure and a leak-proof structure are limited on the outer ring; cold air flow enters the first cavity through an air incoming hole, enters the second cavity through an impact hole structure to impact the outer ring, fully cools the turbine outer ring through the turbine structures and flows out from the air film hole structure of the outer ring to form a cooling air film to be finally mixed with main fuel gas; a boss structure on the turbine outer ring is mainly used for blocking formation and development of leaf tip leakage vortex. Heat exchange effect of cooling airflow inside the casing is enhanced, the air film hole structure has good cooling effect on the surface of the turbine casing and a leaf tip position in direct contact with high-temperature fuel gas, the leakage-proof structure effectively lowers leaf tip leakage loss, and turbine efficiency is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Construction method for special underground continuous wall

The invention provides a method for constructing a special underground continuous wall. The underground continuous wall comprises a wall body with indelible embedded barriers, wherein the wall body with the indelible embedded barriers is positioned between barrier-free wall bodies. The construction method comprises the following steps: (a) the normal barrier-free wall bodies on the left and the right sides of the wall body with the embedded barriers are constructed; (b) the operation of groove wall reinforcement is carried out on the grooving area of the wall body with the embedded barriers, and a reinforced structure and the barrier-free wall bodies on both sides form a relatively enclosed area; and (c) special grooving technological construction is carried out in the relatively enclosed wall body area. By adopting the method, the indelible barriers in the wall body of the underground wall can work together with the underground wall, thereby guaranteeing the integrality and the constructional feasibility of the underground continuous wall used as a permanent structure or a space enclosing structure, shortening man-hour, and saving the production cost.

Owner:LONGYUAN CONSTR GROUP

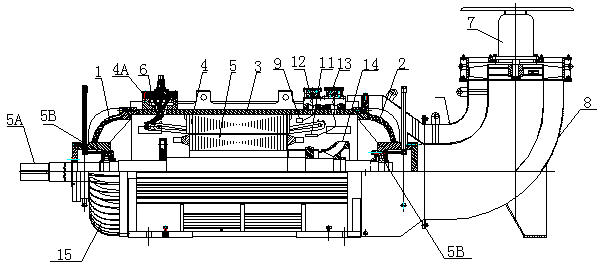

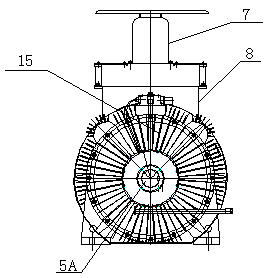

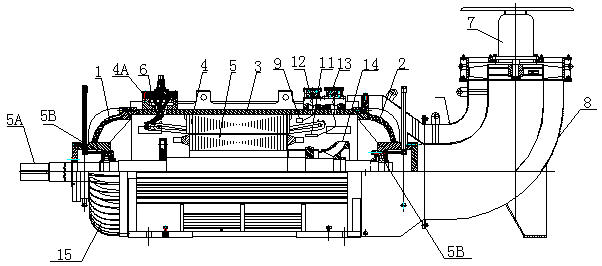

Mining type flameproof submersible motor

InactiveCN101938183AImprove sealingCompact structureStructural associationCooling/ventillation arrangementEngineeringCable line

The invention discloses a mining type flameproof submersible motor, comprising a left end cover and a right end cover; a tube-shaped engine base is hermetically fixedly connected between the left and right end covers, the engine base is internally provided with a stator core, the stator core is internally provided with a rotor, and the output shaft of the rotor stretches out the left end cover; one end of the engine base is hermetically connected with a cable outlet device, the cable of the stator core is led out by the cable outlet device; the upper part of the engine base is provided with a forced cooling fan, the air outlet of the forced cooling fan is provided with a duct, and the outlet of the duct is arranged corresponding to the right end cover. The invention has compact structure, the tube-shaped engine base is hermetically fixedly connected with the left and right end covers, and the tube-shaped engine base is hermetically connected with the cable outlet device, so that the mining type flameproof submersible motor has good sealing property and is applicable to underwater use. The invention has less vibration when in operation and good heat dissipation effect, the existing permeable disaster relief device is not required to be used when the invention is adopted, and cost is greatly saved.

Owner:WOLONG ELECTRIC NANYANG EXPLOSION PROTECTION GRP CO LTD

Inner and outer diameter measuring device for thin-wall bearing ring

InactiveCN111043948AReduce distortionAccurate measurementElectrical/magnetic diameter measurementsMotor driveMeasurement device

The invention discloses an inner and outer diameter measuring device for a thin-wall bearing ring. The device comprises a measuring assembly with two displacement sensors and a calibration assembly for relatively locating the displacement sensors and a thin-wall bearing. A relative measurement method is adopted for measurement; namely, the position of each displacement sensor is calibrated in advance through an inner diameter ring gauge or an outer diameter ring gauge. Then, the thin-wall bearing ring is arranged at the position the same as the position where the ring gauge is calibrated; a motor drives the displacement sensors to rotate, so that the difference between the thin-wall bearing ring and the nominal size can be measured. Therefore, the inner and outer diameters of the thin-wallbearing ring can be accurately measured. Calibration of the relative positions of the thin-wall bearing and the displacement sensors in relative measurement is realized in a simple and effective manner. Human adverse factors are eliminated; deformation of the thin-wall bearing ring in the measuring process is reduced greatly, measuring efficiency and accuracy are improved substantially, the innerdiameter and the outer diameter of a thin-wall bearing are measured; and the device can be conveniently popularized and applied.

Owner:LUOYANG BEARING RES INST CO LTD

Spark plug and method for producing spark plug

ActiveUS20120153801A1Reduce radial deformationShorten the lengthSpark gapsMachines/enginesSpark plugExtrusion

A spark plug includes a tubular metallic shell extending in the direction of an axis and having a tool engagement portion formed through extrusion. The tool engagement portion has a 12-point shape which is a sectional shape taken orthogonally to the axis and has a plurality of protrusions and recesses provided alternately. As viewed in a section taken orthogonally to the axis, when D (mm) represents the diameter of a circle which passes radially through the outermost positions on the protrusions, and d (mm) represents the diameter of a circle which passes radially through the innermost positions on the recesses, the relational expression 0.45≦(D−d) / 2≦0.75 is satisfied. The spark plug can provide a more reliable restraint on the slippage of a tool at the time of mounting and enables the tool engagement portion to be reliably formed so as to form a desired shape.

Owner:NGK SPARK PLUG CO LTD

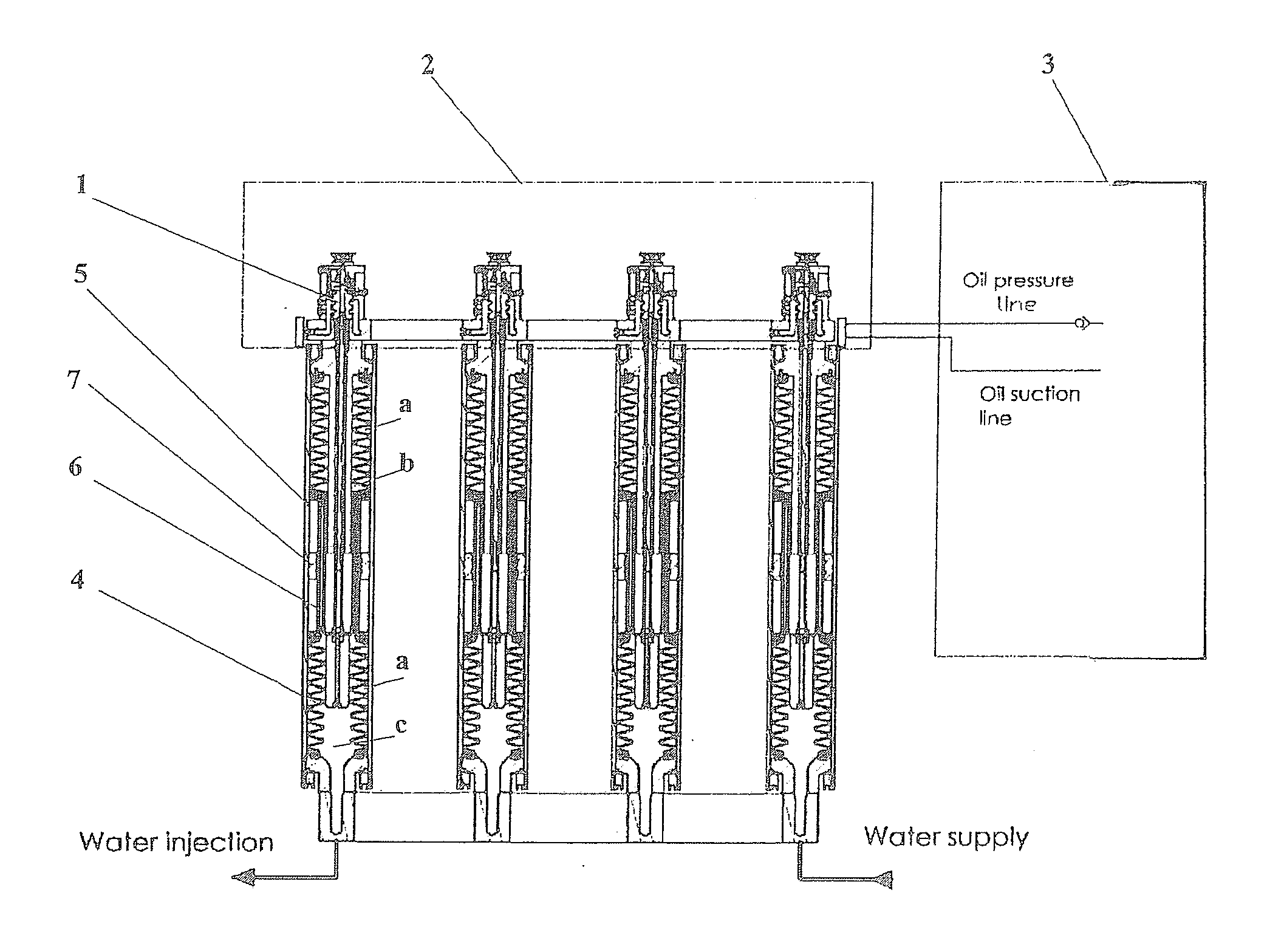

Hydraulically driven machine improvement

ActiveUS8591201B2Improve reliabilityProlong lifeFlexible wall reciprocating enginesFlexible member pumpsHydraulic cylinderDiaphragm pump

A hydraulically driven diaphragm pumping machine comprises a plunger (6) that is slidably mounted in a middle part of the inside of the machine's hydraulic cylinder (5) between first and second bellow-like diaphragms (4,10). Ends of the plunger (6) are connected to the first and second bellows-like diaphragm (10) to define respective first and second outer annular spaces (a) that are independent of one another, and the pressure of fluid in the first annular space (a) is independent of the pressure of fluid in the second annular space (a). The machine may also comprise a hydromechanical switch for commutating a valve (102) to automatically control the supply of hydraulic fluid to the hydraulic cylinder at given moments of the machine's cycle.

Owner:GARNIMAN

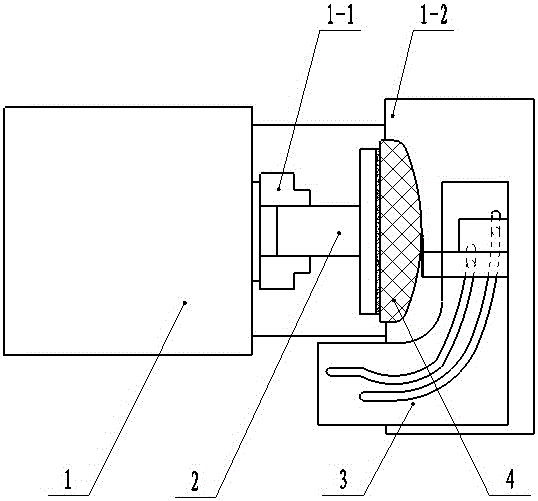

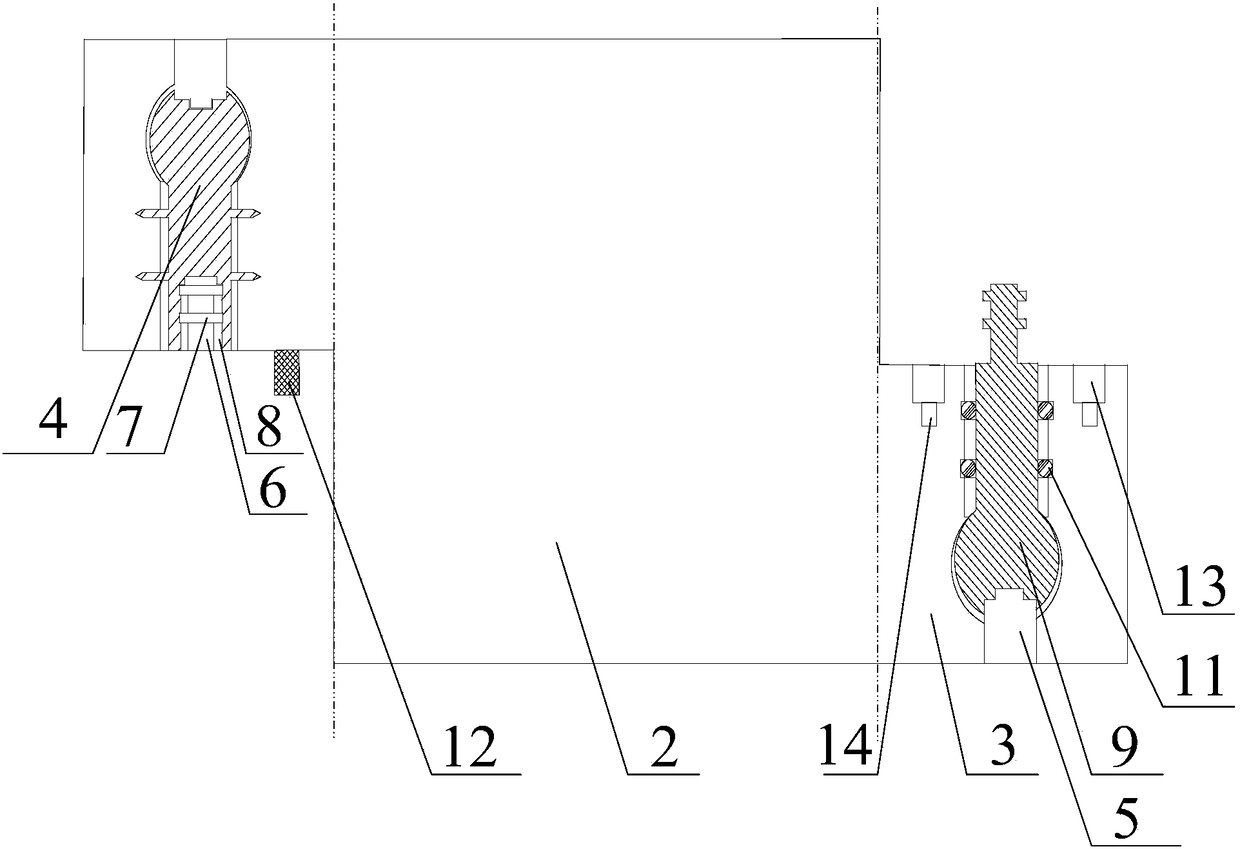

Framework structure of nuclear medicine detector module set

ActiveCN107997779AReduce radial deformationImprove connection stabilityComputerised tomographsTomographyImaging qualityEngineering

The invention discloses a framework structure of a nuclear medicine detector module set and belongs to the technical field of nuclear medicine imaging. The framework structure is used for fixation ofa nuclear medicine detector and an annular support plate and comprises a liquid cooling plate for an installation of a detector, a first fixing plate and a second fixing plate both fixed on two ends of the liquid cold plate and oppositely arranged, a cross beam connecting the first fixing plate and the second fixing plate, wherein the liquid cold plate, the first fixing plate, the second fixing plate and the cross beam are enclosed to form rectangular space accommodating the detector; and opposite surfaces of the first fixing plate and the second fixing plate are fixed on the annular support plate. Powerful support is provided for the detector getting far away from the annular support plate; connection stability of the framework structure and the detector module set can be enhanced; radialoffset of the detector getting far away from the annular support plate can be reduced; installation precision of the detector can be improved; and imaging quality can be increased.

Owner:JIANGSU SINOGRAM MEDICAL TECH CO LTD

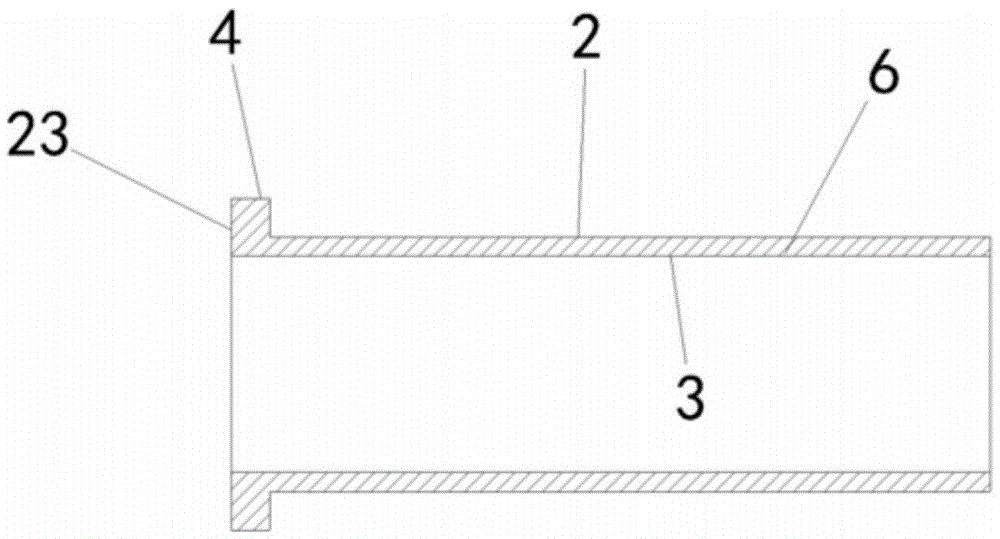

Rim for a bicycle spoked wheel and relative spoked wheel

PendingCN101134423AIncrease stiffnessReduce radial deformationRimsSpoked wheelsMoment of inertiaEngineering

A rim (2) for a bicycle spoked wheel (1) is disclosed, comprising spoke attachment areas (6) and infra-spoke areas (7), wherein the radial section of the rim in a central part (8) of the infra-spoke areas has a greater moment of inertia than the radial section of the rim in lateral parts (9) of the infra-spoke areas (7). It is thus possible to increase the stiffness of the rim (2) to counteract the daisy effect.

Owner:CAMPAGNOLO SRL

Tires with additional cap plies

InactiveCN102294942AShare the stressAvoid excessive concentration of stress pointsPneumatic tyre reinforcementsGround contactEffective solution

In the tire with an additional cap layer according to the present invention, at least one additional cap layer is added between the second belt layer and the third belt layer to improve the resistance to deformation and tearing of the area under load and pressure ability. That is, at least one additional cap layer is respectively lined between the cushion rubber, the two sides of the third belt layer and the tread rubber. On both sides of the tire circumference, the additional cap layer is wound on the sides of the third belt layer and the second belt layer at 360° respectively, so as to optimize the ground contact shape of the tire, improve the safety performance of the use, and effectively solve the problem of the belt Layer delamination, tearing problems.

Owner:SAILUN GRP CO LTD

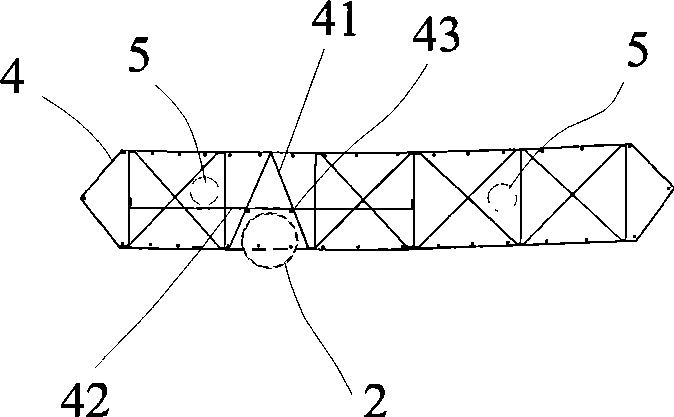

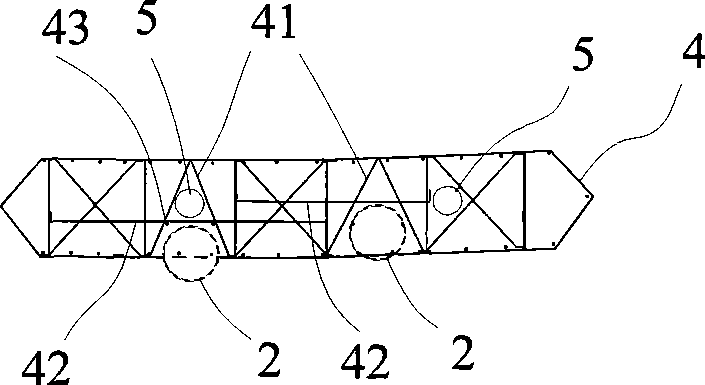

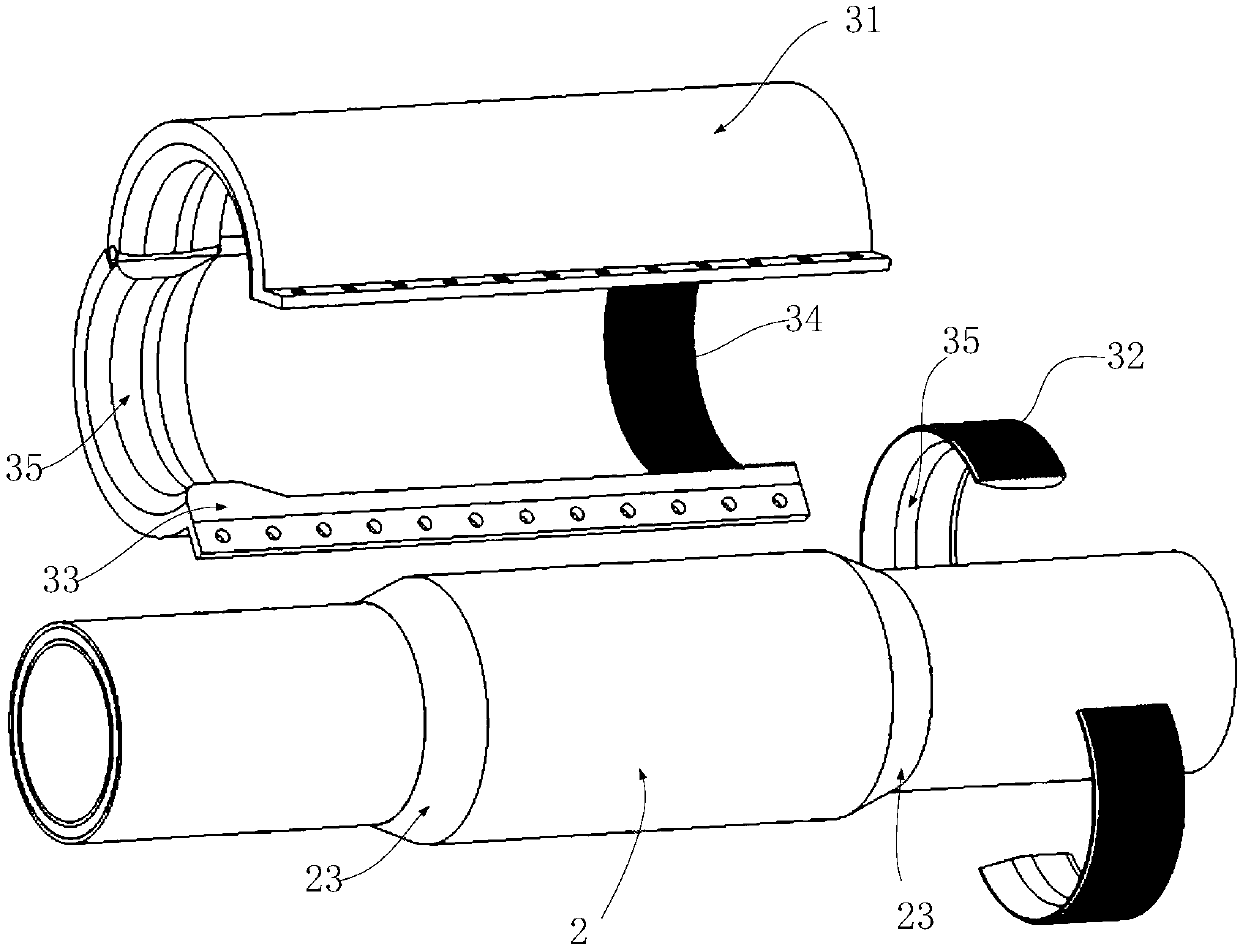

Combined type buckle arrestor for submarine fiber-reinforced composite flexible pipe

ActiveCN107687558AImprove sealingImprove buckling resistancePipe protection against damage/wearStress concentrationInterference fit

The invention discloses a combined type buckle arrestor for a fiber-reinforced composite flexible pipe. The combined type buckle arrestor comprises a metal outer lantern ring and a fiber-reinforced inner lantern ring; the metal outer lantern ring comprises a main lantern ring body, a locking lantern ring body and an elastic seal gasket; the fiber-reinforced inner lantern ring comprises a fiber-reinforced layer and a base body protection layer; the fiber-reinforced inner lantern ring is located on the outer side of the composite pipe and bonded with the composite pipe in a hot-melting mode, thus, the pipe is locally thickened so as to achieving promoting of buckling resistant capacity; and the metal outer lantern ring wraps the fiber-reinforced inner lantern ring in an interference fit modeso that the fiber-reinforced inner lantern ring can be assisted in achieving of buckling arresting, and meanwhile, the composite pipe can be prevented from being bent excessively by means of the gooddeformation resistant performance of the metal outer lantern ring, so that stress concentration of the fiber-reinforced inner lantern ring is reduced. The bonding characteristic of materials of the composite pipe is reasonably utilized to achieve machining of the fiber-reinforced inner lantern ring, and the fiber-reinforced inner lantern ring is assisted by the metal outer lantern ring so as to improve the local structural strength; and the combined type buckle arrestor has the advantages of both a steel pipe welding type buckle arrestor and a steel pipe buckling-pressing type buckle arrestorand has wide popularization value and practical value.

Owner:OCEAN UNIV OF CHINA

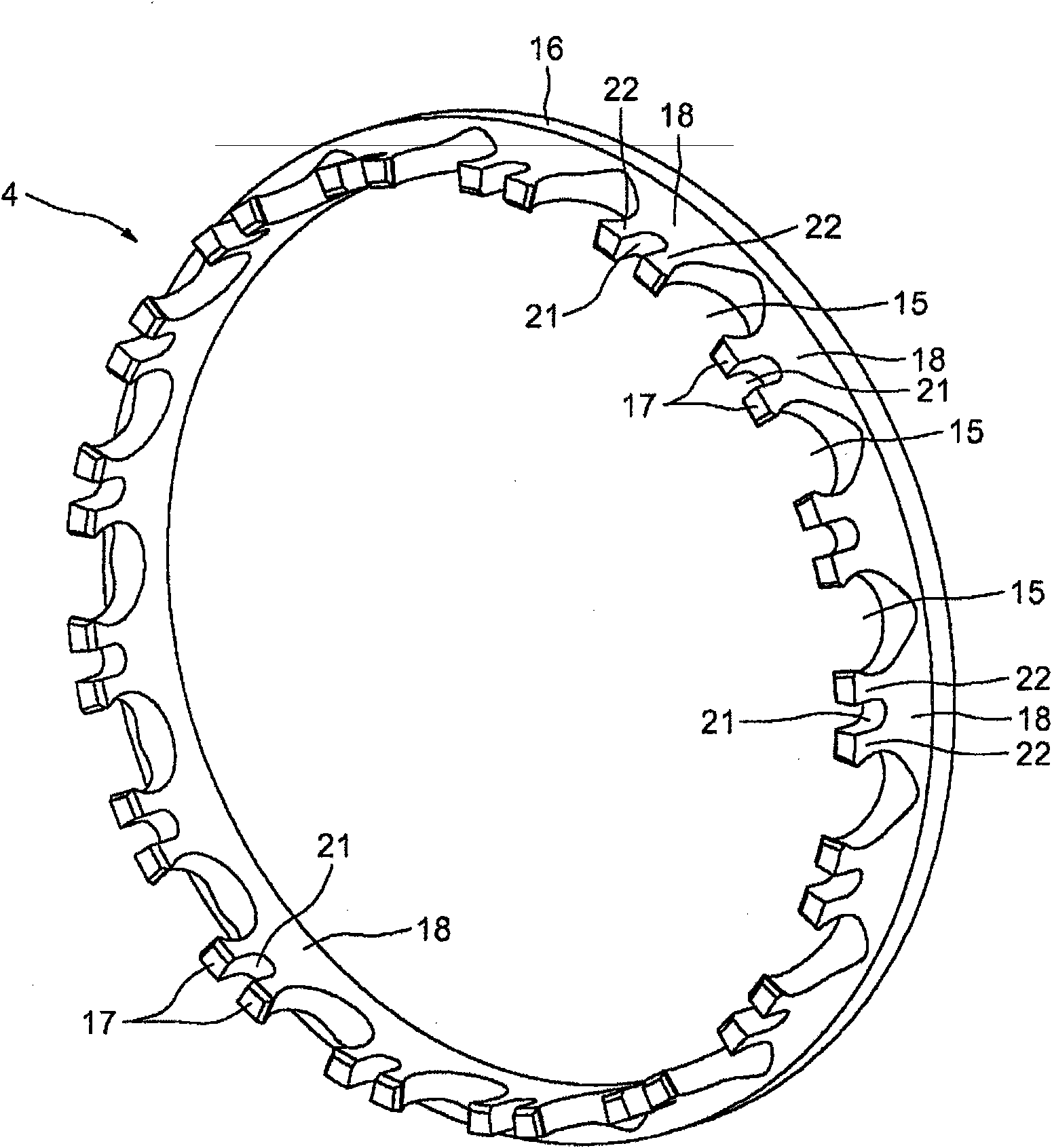

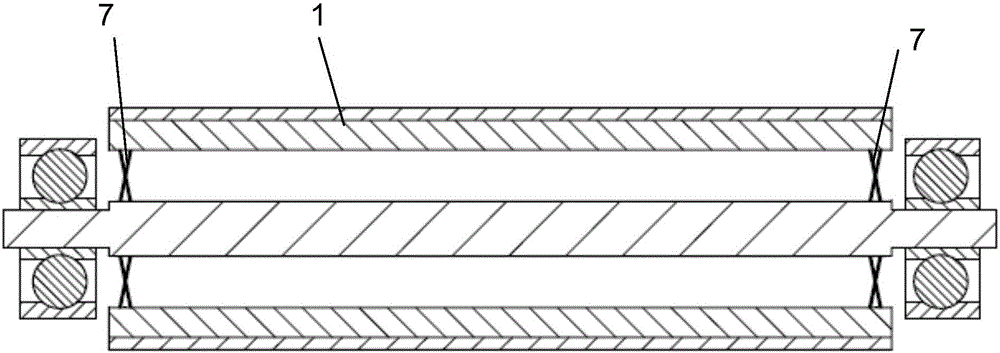

Rolling bearing and cage for such bearing

ActiveCN101821522ALarge radial thicknessReduce radial deformationShaftsBall bearingsRolling-element bearingClassical mechanics

Retaining cage for balls of a rolling bearing, comprising an annular shoulder (16) extended axially by projecting portions (18) definingbetween them sockets (15) for the balls, emerging radially on either side of the cage. The cage was made from a metal and the surface of each socket (15) is designed to cooperate with one of the balls and is defined by an imaginary cylinder with an axis oriented radially and cut by the plane axially delimitingthe cage on the side opposite the shoulder (16) so as to form an axial opening of the socket, the width of this opening being smaller than the diameter of the said imaginary cylinder.

Owner:AB SKF

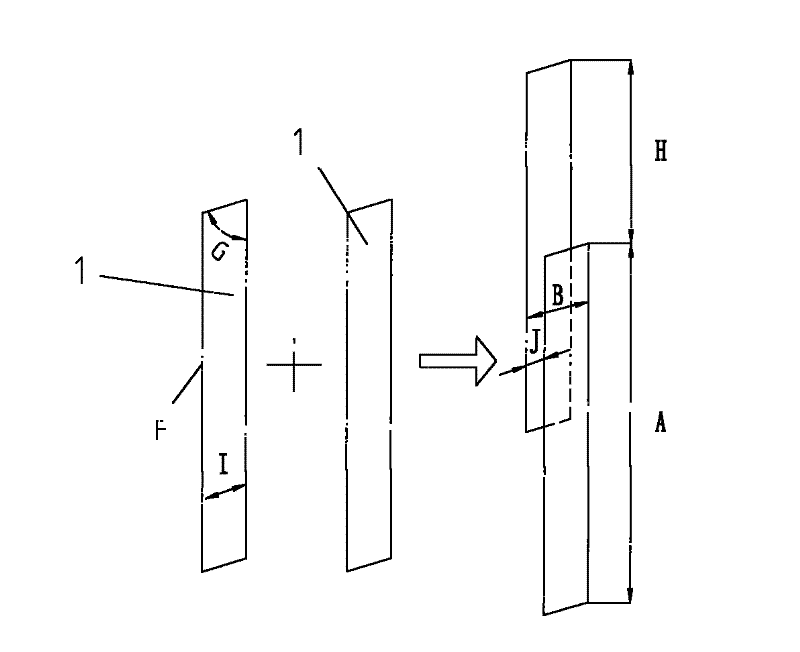

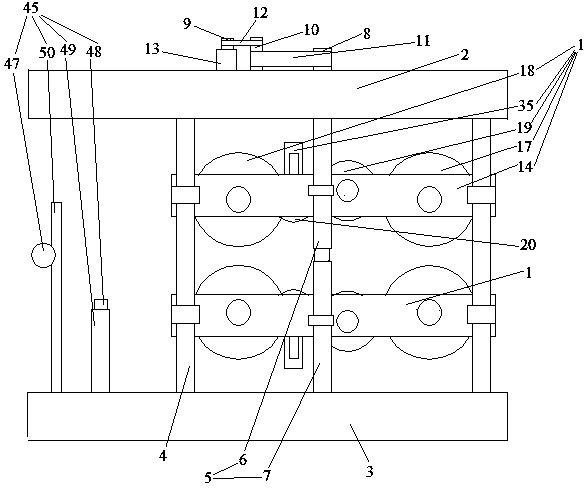

A sponge cutting device

ActiveCN104148671BAvoid dependenceLow costTurning toolsLarge fixed membersStructural engineeringMechanical devices

A sponge cutting device comprises: a lathe, a fixing device, and a guiding device; the lathe includes a lathe spindle and a lathe slide box; the fixing device is fixedly connected to the lathe spindle; the guide is connected to the lathe slide box Fixed connection. The present invention is a sponge cutting device rebuilt by utilizing the rotation of the main shaft of a lathe; it realizes the use of general mechanical devices to solve the problem that the sponge is easily deformed, and also solves the problem that the sponge is deformed due to the extrusion of the cutterhead during the cutting process. The problem of uneven cutting is caused, and it can adapt to the processing of complex rotating surfaces.

Owner:中国人民解放军第五三一一工厂

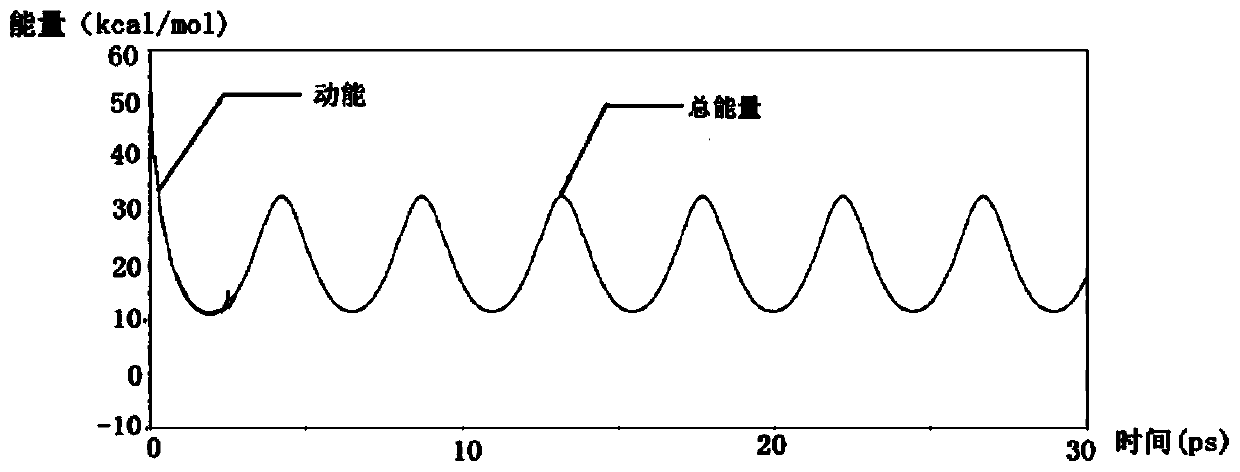

Method for designing low-entropy and safe high-speed milling cutter and high-speed milling cutter

ActiveCN103624308AAchieving Design Across ScalesSolve problems that cannot be described quantitativelyMilling cuttersSpecial data processing applicationsMilling cutterEngineering

The invention relates to a milling cutter designing method and a milling cutter, in particular relates to a method for designing a low-entropy and safe high-speed milling cutter and the high-speed milling cutter, and aims to solve the problems that the entropy cannot be controlled due to disordering of particle swarms of the milling cutter and the safety of the high-speed milling cutter is reduced. According to the characteristic that the disordering of the particle swarms of a high-speed milling cutter assembly is associated with the reducing of the safety, a safety reducing process is described by virtue of an entropy determination method; by virtue of an entropy model, a mesoscopic motion state is judged, and the safety reducing process is determined; by virtue of an entropy control method, a control variable for controlling the safety reducing process is revealed, and the disordering of the particle swarms can be effectively controlled; macroscopic and mesoscopic structure parameters are collaboratively designed by virtue of a low-entropy high-speed milling cutter safety designing method; the safety and stability of the low-entropy milling cutter are verified. The diameter of the milling cutter is 63mm, the number of tool teeth is 4, the tool teeth are unequally distributed, included angles between the teeth are 88 degrees, 89 degrees, 90 degrees and 93 degrees, the tooth root of a tool body is of a chamfer and transition circular arc structure, and a front blade installation angle is 2 degrees. The method is applied to milling cuter designing and high-speed milling.

Owner:HARBIN UNIV OF SCI & TECH

Lathe precision machining method for ultra-thin wall thickness metal pipe parts

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

Variable pitch system of wind power generation set and wind power generation set

ActiveCN111140432ASmall openingReduce wearWind motor controlWind motor combinationsGear wheelWind power generation

The invention discloses a variable pitch system of a wind power generation set and the wind power generation set. The variable pitch system of the wind power generation set comprises a wheel hub, a variable pitch bearing and a variable pitch driver. The variable pitch bearing comprises an outer ferrule and an inner ferrule. The outer ferrule is connected to the wheel hub, and the inner ferrule isconnected to a blade. A variable pitch bearing gear is arranged on the variable pitch bearing. The variable pitch driver is mounted in a selected area and is engaged to a gear of the variable pitch bearing through a gear of the variable pitch driver. The selected area is an area where the radial deformation of the outer ferrule and the inner ferrule is smaller than a preset value. According to thetechnical scheme provided by the invention, the variable pitch driver is mounted in the area where the radial deformation of the outer ferrule and the inner ferrule of the variable pitch bearing is smaller than the preset value. When the variable pitch bearing operates, as the variable pitch driver is mounted in the area where the radial deformation of the outer ferrule and the inner ferrule is relatively small, an opening when the gear of the variable pitch driver is engaged to the gear of the variable pitch bearing can be reduced to the greatest extent, so that wear between the gear of thevariable pitch driver and the gear of the variable pitch bearing can be reduced.

Owner:CSIC CHONGQING HAIZHUANG WINDPOWER EQUIP

Self-generating chilling method for controlling deformation of large complex aluminum copper alloy

The invention and relates to a self-generating chilling method, in particular to a self-generating chilling method for controlling deformation of large complex aluminum copper alloy, and belongs to the field of machinery. Through the self-generating chilling method, the problem that according to an existing large complex aluminum copper alloy component, a casting is deformed during casting forming is solved. The self-generating chilling method has the specific steps that 1, part of a large complex aluminum copper alloy casting is divided into an A area and a B area, and whether self-generating chill blocks are suitable for being used in the A area and the B area is judged; 2, the number of the needed self-generating chill blocks is calculated; 3, the self-generating chill blocks are arranged in the corresponding areas; and 4, cavity positions of the self-generating chill blocks are formed.

Owner:HARBIN INST OF TECH

Hydraulically Driven Machine Improvement

ActiveUS20110020150A1Improve reliabilityProlong lifeFlexible wall reciprocating enginesFlexible member pumpsDiaphragm pumpHydraulic cylinder

A hydraulically driven diaphragm pumping machine comprises a plunger (6) that is slidably mounted in a middle part of the inside of the machine's hydraulic cylinder (5) between first and second bellow-like diaphragms (4,10). Ends of the plunger (6) are connected to the first and second bellows-like diaphragm (10) to define respective first and second outer annular spaces (a) that are independent of one another, and the pressure of fluid in the first annular space (a) is independent of the pressure of fluid in the second annular space (a). The machine may also comprise a hydromechanical switch for commutating a valve (102) to automatically control the supply of hydraulic fluid to the hydraulic cylinder at given moments of the machine's cycle.

Owner:GARNIMAN

Robot modular assemble mechanical arm

ActiveCN108481317ARealize different driving functionsIncrease the lengthProgramme-controlled manipulatorJointsEngineeringMechanical engineering

The invention discloses a robot modular assemble mechanical arm. The robot modular assemble mechanical arm comprises an arm body which includes a plurality of arm sections connected with one another;each arm section comprises a rectangular block, the opposite ends of the rectangular block are each provided with a convex block, a fixed rotation shaft is fixed into one of the convex blocks, one endof the fixed rotation shaft is provided with a driving installation hole communicating with the outside, the other end of the fixed rotation shaft is provided with a fixing hole, the inner wall of the fixing hole is provided with at least one annular groove and a slide groove, one end of the slide groove communicates with the annular grooves, the other end of the slide groove is flush with an opening of the fixing hole, a moving rotation shaft is arranged in the other convex block, one end of the moving rotation shaft protrudes out of the surface of the convex block, and the protruding end ismatched with the fixing hole, can enter the annular grooves along the slide groove and is limited in the annular grooves. The robot modular assemble mechanical arm is formed by assembling the moduledetachable structure, can be freely assembled and lengthened according to the operation environment and is high in flexibility and universality and capable of adapting to various operations.

Owner:浙江中驱电气有限公司

Aluminum electrolytic capacitor

ActiveCN111613449APrevent splashEnsure safetyCapacitor housing/encapsulationCapacitanceHemt circuits

The invention belongs to the technical field of electronics, and particularly relates to an aluminum electrolytic capacitor which comprises a cylindrical aluminum shell. A winding layer comprising a diaphragm and an electrode plate is arranged in the aluminum shell; a pair of pins electrically connected with the winding layer is arranged at the bottom of the aluminum shell; and a top cover is arranged at the bottom of the aluminum shell, and a set of cross-shaped pre-breaking grooves are formed in the top of the top cover. The top of the aluminum shell is sleeved with a telescopic sleeve, thetop of the telescopic sleeve is closed, and the telescopic sleeve can deform and extend in the axial direction of the aluminum shell. Electrolyte is prevented from overflowing through the telescopic sleeve after the top cover bursts, and the circuit safety is ensured; through the telescopic sleeve sleeved at the top of the aluminum shell, the capacitor extends inthe axial direction of the aluminumshell when the capacitor bursts, so that electrolyte splashing is avoided, the safety of other electrical components on the circuit board is ensured, and the maintenance cost is reduced.

Owner:安徽华铭达科技有限公司

Wire stripping machine

ActiveCN111541192BRealize cuttingReduce radial deformationLine/current collector detailsApparatus for removing/armouring cablesStructural engineeringMachine

The invention relates to a wire stripping machine, which includes two cutting and conveying modules distributed along the up and down directions. Including a circular cutting blade, the positioning wheel on the feed side includes a conical section of the positioning wheel on the feeding side where two small diameter ends are butted together, and the positioning wheel on the feeding side is enclosed between the two positioning wheels on the feeding side Ring groove, the circular cutting blade is aligned with the positioning ring groove of the positioning wheel on the feeding side; the positioning ring grooves of the positioning wheel on the feeding side of the two cutting and conveying modules are aligned, and the feeding wheels of the two cutting and conveying modules are clamped Hold the wire to drive the wire to translate; the circumference of the feed wheel is provided with a number of booster spikes for piercing into the wire insulation sleeve, and the apex angles of the conical sections of the two feed side positioning wheels are equal. The invention has the advantage of being able to cut the wire insulating sleeve, and solves the laborious problem of manually cutting the wire insulating sleeve with a knife.

Owner:SUZHOU LEMIFUN ELECTRICAL TECH CO LTD

Intermediate supporting structure for rigidity improving and shock absorption

PendingCN107284231AIncrease Rigid Body Mode ValuesReduce vibrationNon-rotating vibration suppressionControl devicesRubber ringLow speed

The invention discloses an intermediate supporting structure for rigidity improving and shock absorption. The structure includes an upper bracket, a lower bracket, a rubber widget and a bearing; the upper bracket and the lower bracket are semicircular and arranged in a buckled mode, the rubber widget is annular, the outer annular surface of the rubber widget is connected in a circular space formed after the upper bracket and the lower bracket are buckled in a clamping mode, the inner annular surface of the rubber widget is provided with a first groove, the bearing is arranged in the first groove, and raised ribs are uniformly arranged between the inner annular surface and the outer annular surface of the rubber widget. According to the intermediate supporting structure for rigidity improving and shock absorption, the situation that vibration of rear axles, a drive system and a vehicle body is intensified due to the vibration of a transmission shaft and the intermediate supporting structure is avoided, fire coupling with a road surface is avoided, on low-speed and high-speed road sections, the vibration noise of the whole vehicle is significantly reduced, and the purpose of reducing the vibration noise is achieved.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

Wire stripping machine

ActiveCN111541192ARealize cuttingReduce radial deformationLine/current collector detailsApparatus for removing/armouring cablesEngineeringStructural engineering

The invention relates to a wire stripping machine. The machine comprises two sectioning conveying modules distributed in the vertical direction. Each sectioning conveying module comprises a connectingbase, a sectioning knife assembly, a feeding side positioning wheel and a feeding wheel. The sectioning knife assembly comprises a circular cutting blade, the feeding side positioning wheel comprisestwo feeding side positioning wheel part conical sections of which the small-diameter ends are in butt joint together, a feeding side positioning wheel part positioning ring groove is defined betweenthe two feeding side positioning wheel parts, and the circular cutting blade is aligned with the feeding side positioning wheel part positioning ring groove; the positioning ring grooves of the feeding side positioning wheel parts of the two sectioning conveying modules are aligned, and the feeding wheels of the two sectioning conveying modules clamp an electric wire to drive the electric wire totranslate; a plurality of power-assisted spikes used for piercing into a wire insulation sleeve are arranged on the circumferential surface of the feeding wheel, and the vertex angles of the conical sections of the two feeding side positioning wheel parts are equal. The wire stripping machine has the advantage of being capable of sectioning the electric wire insulation sleeve, and the problem thatlabor is wasted when a knife is manually used for slitting the electric wire insulation sleeve is solved.

Owner:SUZHOU LEMIFUN ELECTRICAL TECH CO LTD

A kind of anchor for carbon fiber parallel cable and its anchoring method

ActiveCN113802455BImprove the anchoring effectReduce damage rateBridge structural detailsBuilding reinforcementsFiber-reinforced compositeCarbon fiber reinforced composite

An anchor for carbon fiber parallel cables and an anchoring method thereof. The invention belongs to the application field of engineering material CFRP. The invention aims to solve the technical problem that the stress distribution in the anchorage area of the existing CFRP cable anchorage system is not uniform, which leads to the damage of the rod body and the low anchorage efficiency. An anchor for a carbon fiber reinforced composite cable in the present invention includes an anchor cup, a front end splitter plate, a rear end splitter plate, and a sealing bolt. An integral structure composed of a front straight section, a middle straight cone section and a rear triangular groove section, the inner cavity of the front straight section is cylindrical, the inner cavity of the middle straight cone section is truncated conical, and the rear The inner cavity of the end triangular groove section is in the shape of a truncated cone. The anchorage of the present invention adopts the mutual cooperation between the straight cone section and the triangular groove section, which reduces the stress concentration at the front, increases the anchoring effect at the rear of the anchoring area, can improve the anchoring efficiency, and reduces the probability of rod damage, thereby achieving greater bearing capacity .

Owner:UNIV OF SCI & TECH BEIJING +1

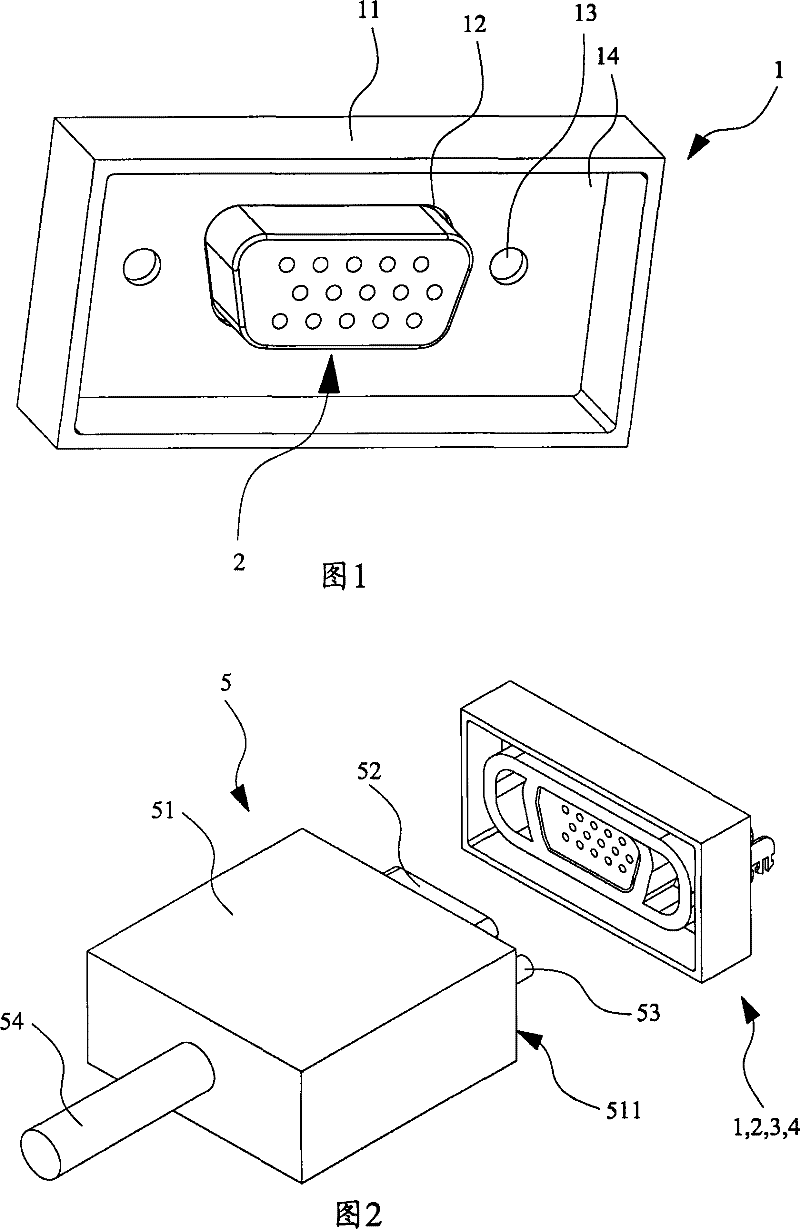

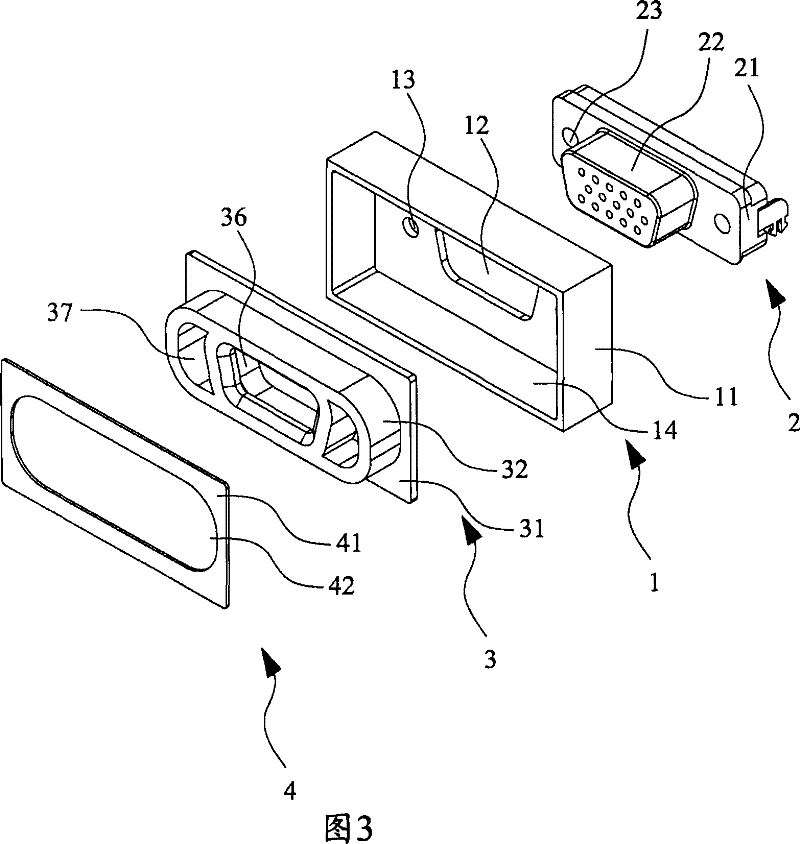

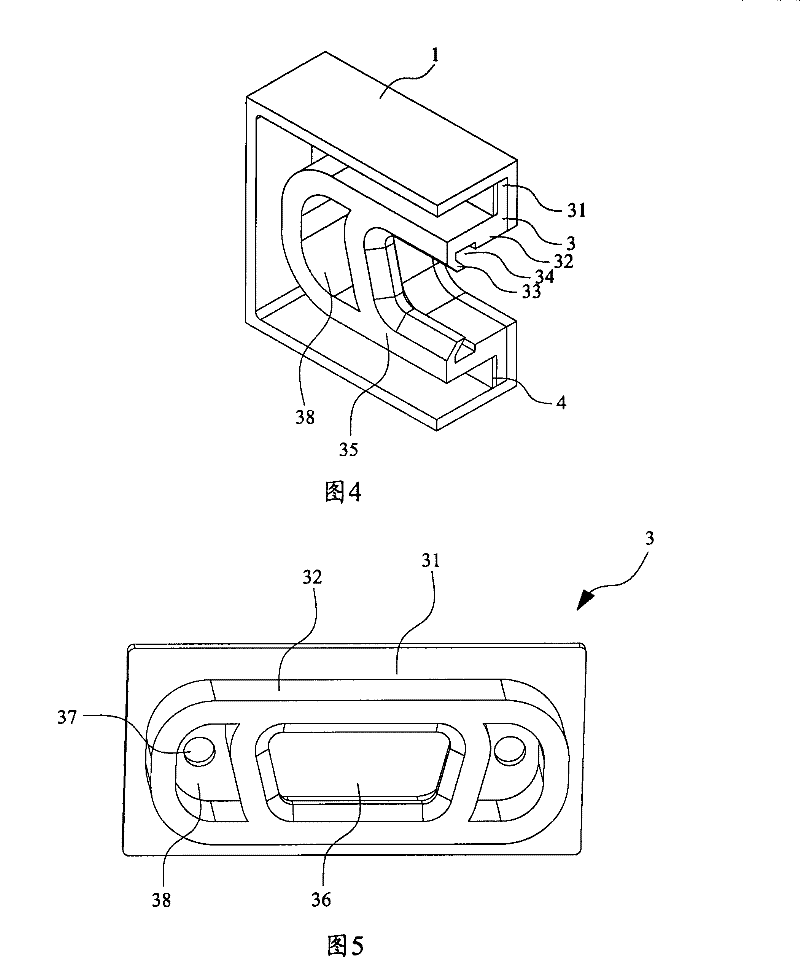

Notebook computer and waterproof sealing structure used for port connection

ActiveCN101498955BAchieving a watertight sealImprove applicabilityDigital data processing detailsMechanical engineering

Owner:LENOVO (BEIJING) LTD

High-temperature composite machine with high temperature compensation function

InactiveCN106042590AImprove cooling effectAvoid deformationLaminationLamination apparatusEngineeringHigh heat

The invention discloses a high-temperature composite machine with a high temperature compensation function. As a cooling mechanism is arranged, a rubber roller can be effectively cooled, and through temperature compensation, the deformation of the surface of the rubber roller is avoided, so that the influence on the thickness of a composite material is reduced, and the product precision requirements are met. In addition, through a supporting mechanism, axial and radial deformation of a heating composite roller can be reduced.

Owner:LINGQI ENVIRONMENTAL PROTECTION EQUIP FACTORY SHANGHAI

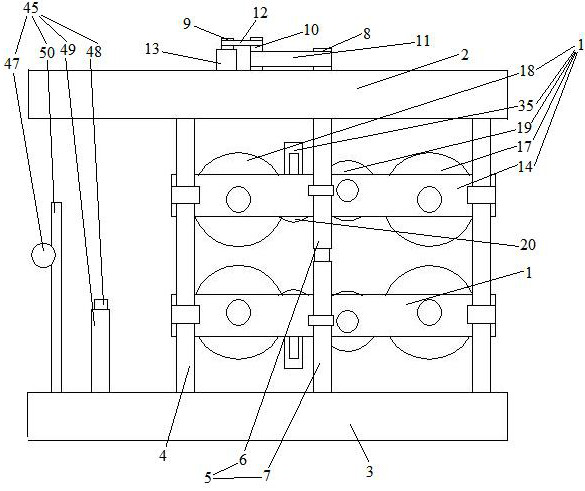

Milling machine fixture

PendingCN112809432AHigh positioning accuracyReduce radial deformationPositioning apparatusMetal-working holdersMachineThin walled

The invention discloses a milling machine fixture. The milling machine fixture comprises a fixing base, a positioning flat key, a rotating hand wheel, a supporting plate, a locking bolt, a bearing bush, a main movable block rotating shaft, a main movable block body, a main movable block push rod, a main movable block positioning element, connecting shafts, auxiliary movable block rotating shafts, auxiliary movable block bodies, auxiliary movable block push rods, auxiliary movable block positioning elements, a pressing disc, a pressing support, a pressing hand wheel, a fixing bolt, a long connecting rod and a short connecting rod. By the adoption of the design, when thin-wall sleeve type parts are positioned, the positioning precision is improved, radial deformation is reduced in the clamping process, the machining precision is improved, the number of the connecting shafts and the number of auxiliary movable blocks can be flexibly selected, and the milling machine fixture can be suitable for the thin-wall sleeve type parts with different length sizes.

Owner:HEBEI INSTITUTE OF ARCHITECTURE AND CIVIL ENGINEERING

Three-blade concave face ball-tooth dill bit applicable to self-drilling type hollow anchoring system

The invention provides three-blade concave face ball-tooth dill bit applicable to a self-drilling type hollow anchoring system and belongs to full-steel drill bits. Three cutting edges which are not mutually connected, a lower groove located in the middle of the drill bit and four ball teeth distributed in the lower groove are installed on the head portion; the directions of the two main cutting edges are the same, the main cutting edges are sunken towards the rotating direction, and the vice cutting edge is sunken towards the direction opposite to the rotating direction; one main cutting edge and the vice cutting edge are mutually symmetrical relative to the bisecting surface of an arc scrap discharging groove between the two cutting edges, a water outlet hole is distributed in the two scrap discharging grooves correspondingly, and water passing holes are formed in the outer wall of the drill bit below the main cutting edge adjacent to a scrap discharging groove without a water outlet hole; and distribution of three outer ring s ball teeth is the same as that of the cutting edges, and the center of the fourth ball tooth is located nearby the center of the lower groove. According to the three-blade concave face ball-tooth dill bit applicable to the self-drilling type hollow anchoring system, through work division of the three cutting edges, overall drilling efficiency is high, and design of the lower groove enables the precision of a finished hole to be promoted; and the water outlet holes and the water passing holes are arranged correspondingly, so that while rocks, soil and the cutting edges are effectively wetted by pressure water, direct reverse impacting of the pressure water and scraps of the rocks and the soil is avoided.

Owner:洛阳恒诺锚固技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com