Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Realize cutting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

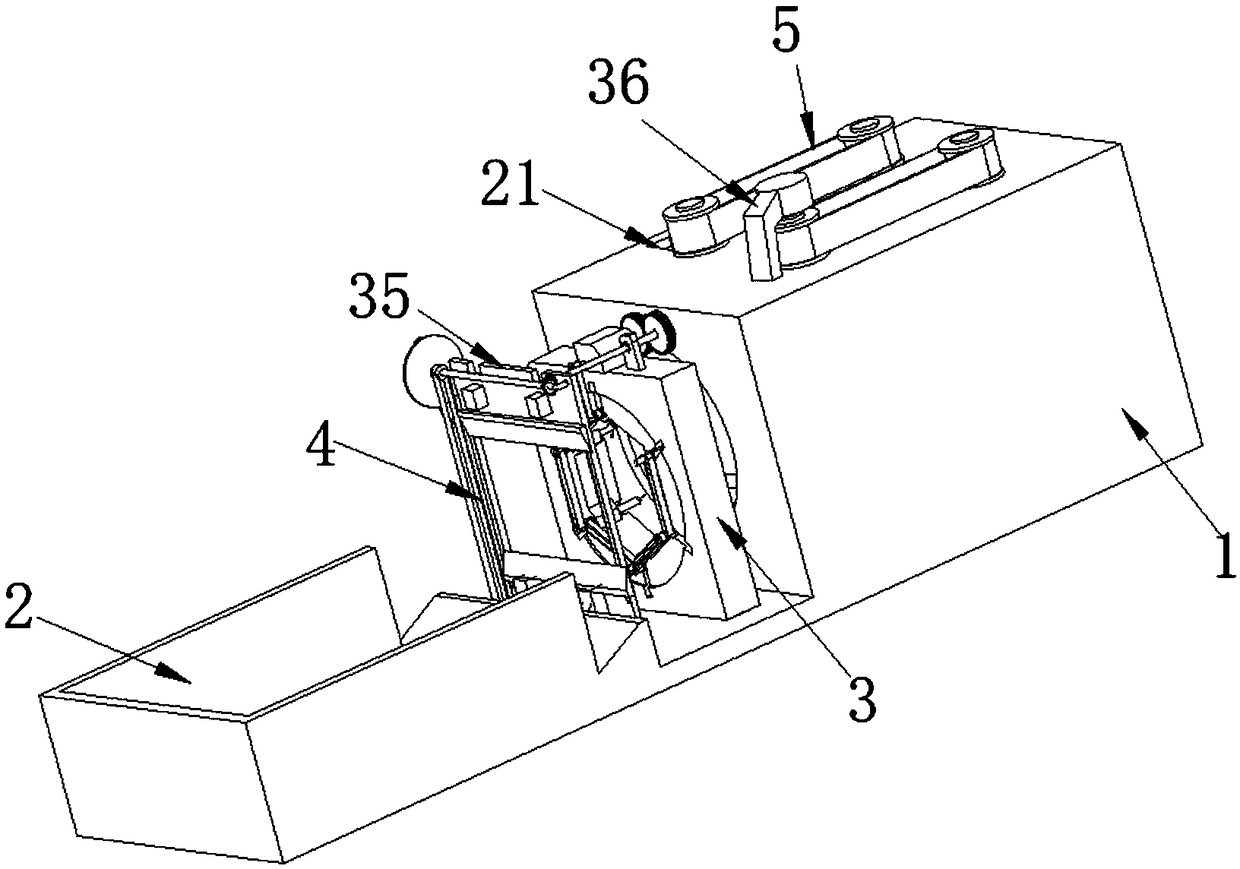

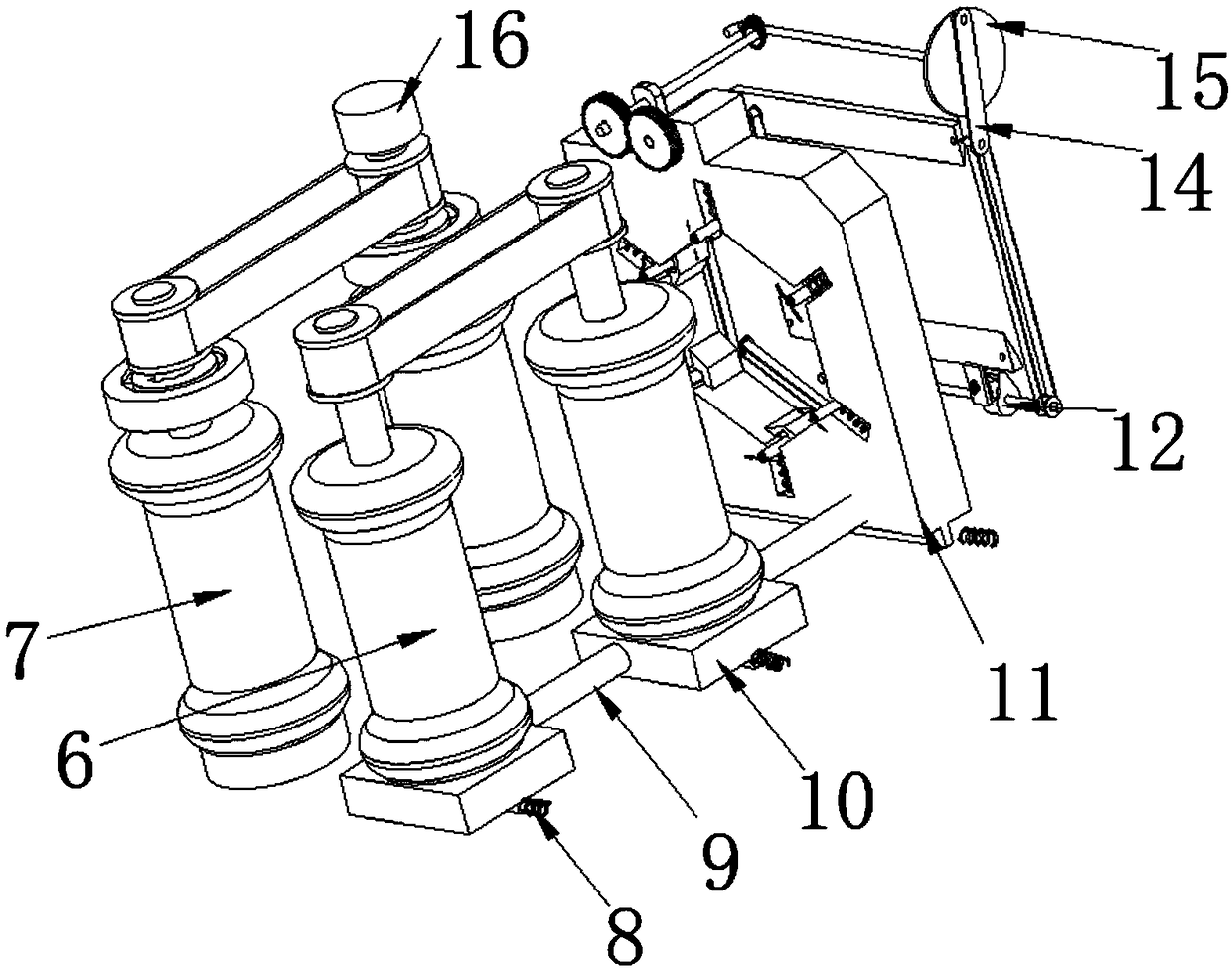

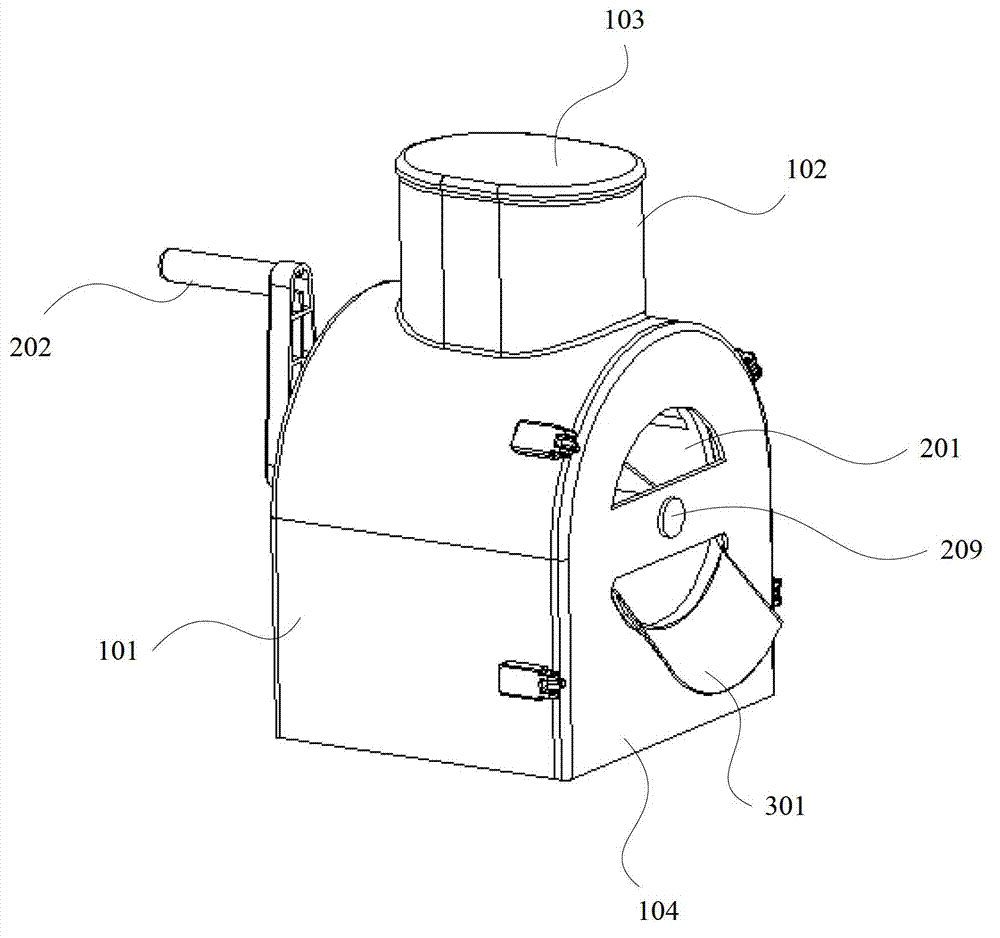

Sugarcane cutting machine

InactiveCN109176633AGood peeling effectShorten the timeVegetable peelingMetal working apparatusEngineeringDrive motor

The invention discloses a sugarcane cutting machine. The sugarcane cutting machine comprises a shell, a finished product box, a peeling mechanism, a cutting off mechanism and a driving mechanism; a driving device is arranged in the shell, the peeling mechanism and the cutting off mechanism are fixed to the top of one side of the shell, the driving mechanism is composed of transmission rolling shafts, fixed rolling shafts, limiting springs, a connecting rod, sliding blocks and a driving motor, the top of the shell is fixedly connected with the driving motor through an L-shaped plate, the transmission rolling shafts, the fixed rolling shafts, the limiting springs and the sliding blocks are symmetrically arranged in the shell, the sliding blocks are in sliding connection with the inner wall of the bottom of the shell, and the two sliding blocks are fixedly connected through the connecting rod. According to the sugarcane cutting machine, through the dual-shaft motor, the peeling mechanismand the cutting-off mechanism are driven at the same time, the two mechanisms can operate at the same time, time is saved, synchronism is increased, through a series of transmission connections, blades can move at the same time, the cutting off effect is better, and work efficiency is improved.

Owner:杭州湘甬机械设备有限公司

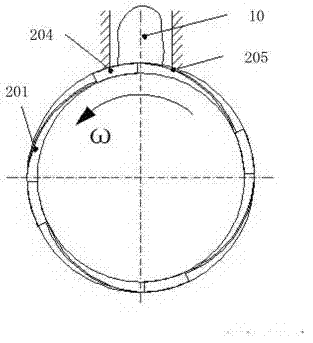

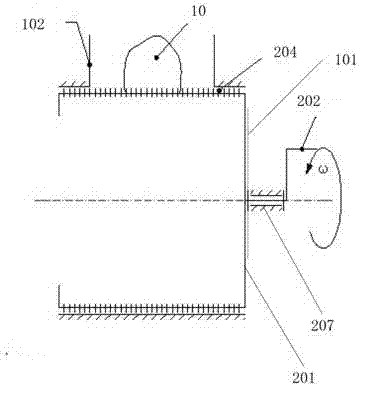

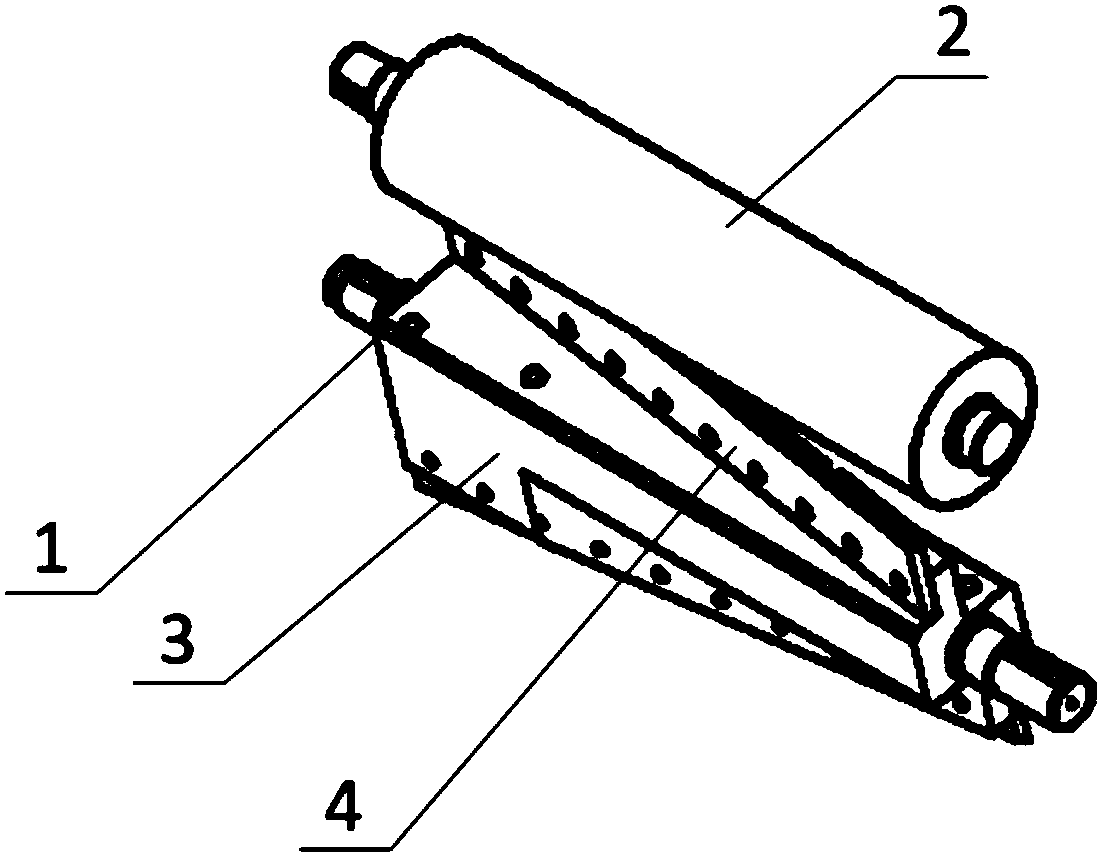

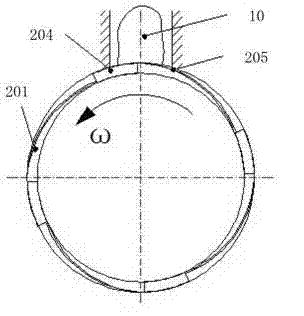

Vegetable cutting device

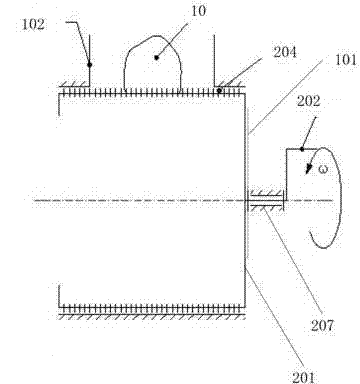

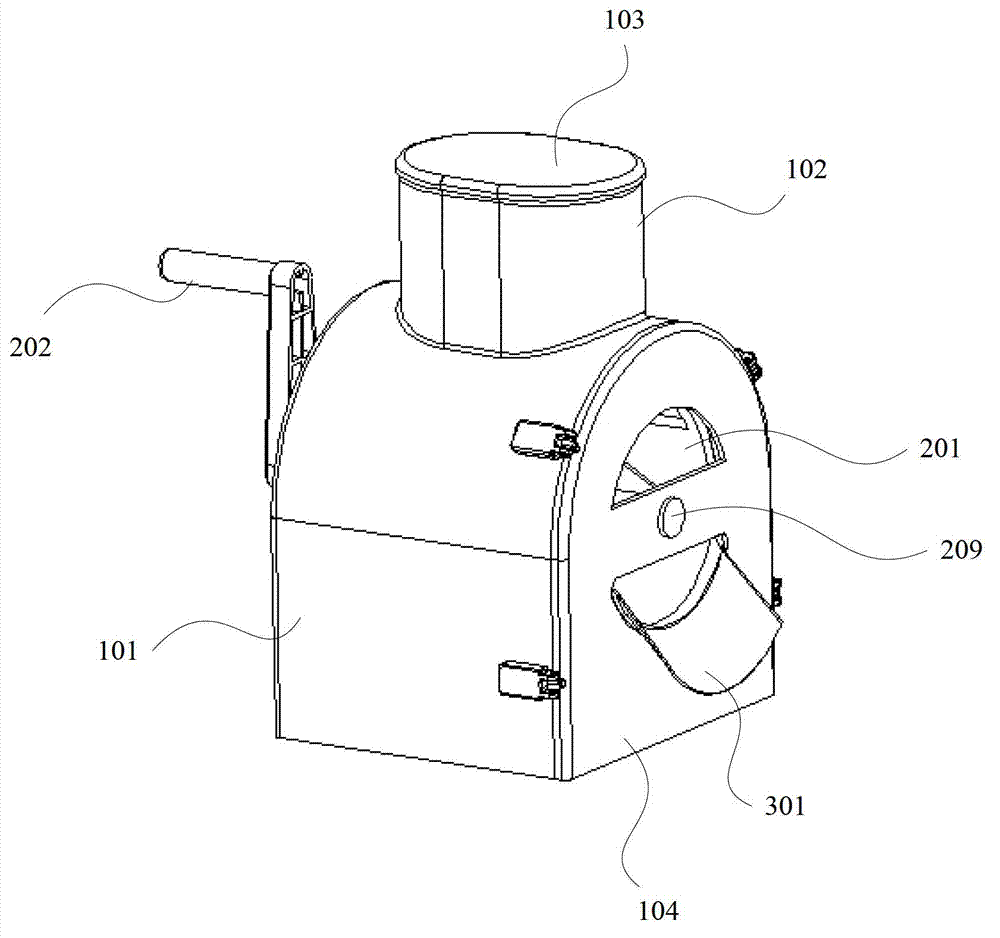

InactiveCN102896655ASimplify operation stepsEasy to replaceMetal working apparatusRotational axisEngineering

The invention relates to a vegetable cutting device which comprises an outer barrel and a cutter barrel. The cutter barrel is arranged inside the outer barrel and can rotate, the outer barrel further comprises a rear plate and a feeding port, wherein the rear plate is used for closing one end of the outer barrel, a rotation shaft support hole is arranged on the rear plate, and the feeding port is arranged at the upper end of a barrel wall of the outer barrel and used for enabling put vegetables to be contacted with the cutter barrel. The cutter barrel further comprises a support plate, a rotation shaft and a plurality of blades, wherein the support plate is used for closing one end of the cutter barrel, a rotation shaft fixing hole is arranged in the center of the support plate, the rotation shaft is arranged along an axis of the cutter barrel, the rotation shaft is fixedly connected with the cutter barrel through the rotation shaft fixing hole, one end of the rotation shaft penetrates through the rotation shaft support hole of the rear plate to extend to the outer portion of the rear plate, a rotation handle is installed on the rotation shaft outside the rear plate, and the blades comprise transverse blades and longitudinal blades which are fixedly installed on the outer barrel wall of the cutter barrel. A problem that vegetables such as potatoes are irregular in shred or slice and vegetable cutting is not safe is solved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Cutter mechanism for packaging bag films

InactiveCN108016922ARealize cuttingImprove work efficiencyArticle deliveryReciprocating motionEngineering

Owner:CHAORI PROPERTY TIANJIN MINING CO LTD

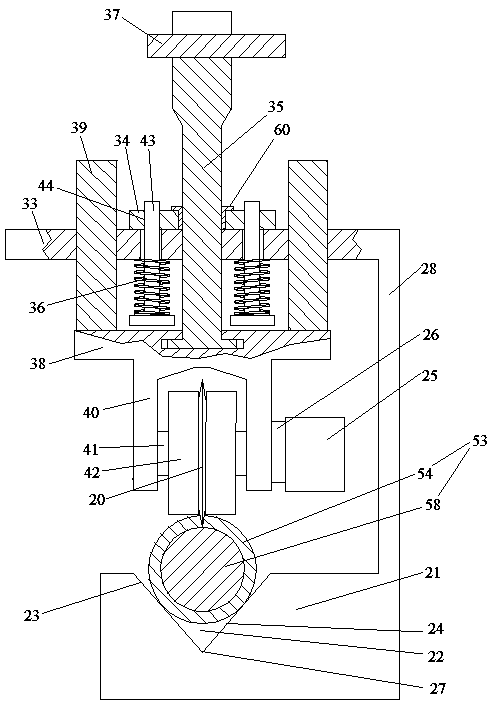

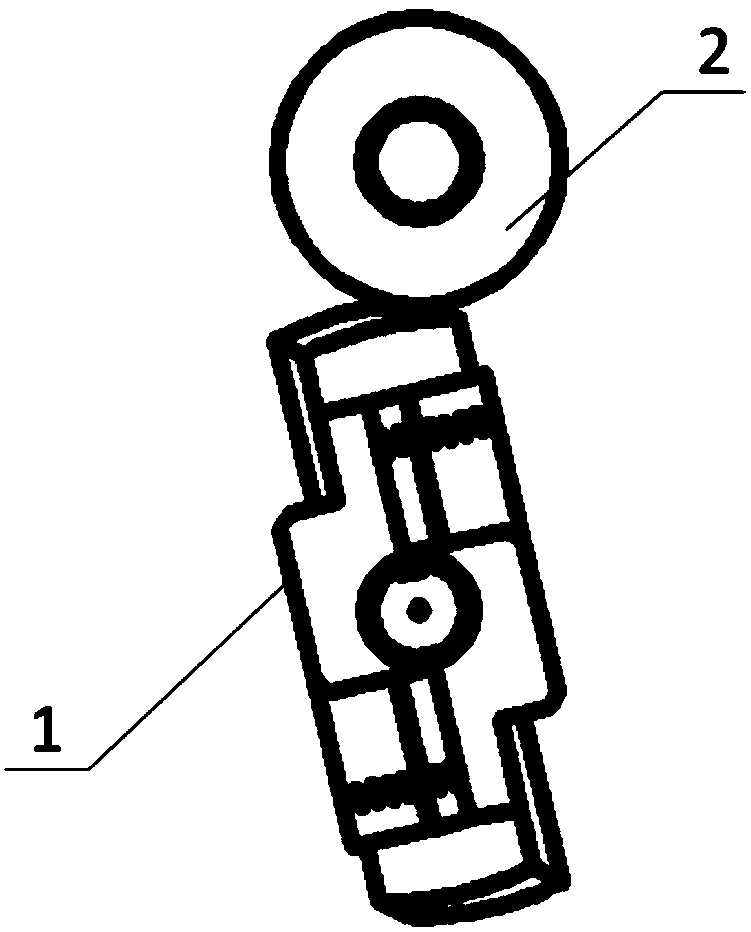

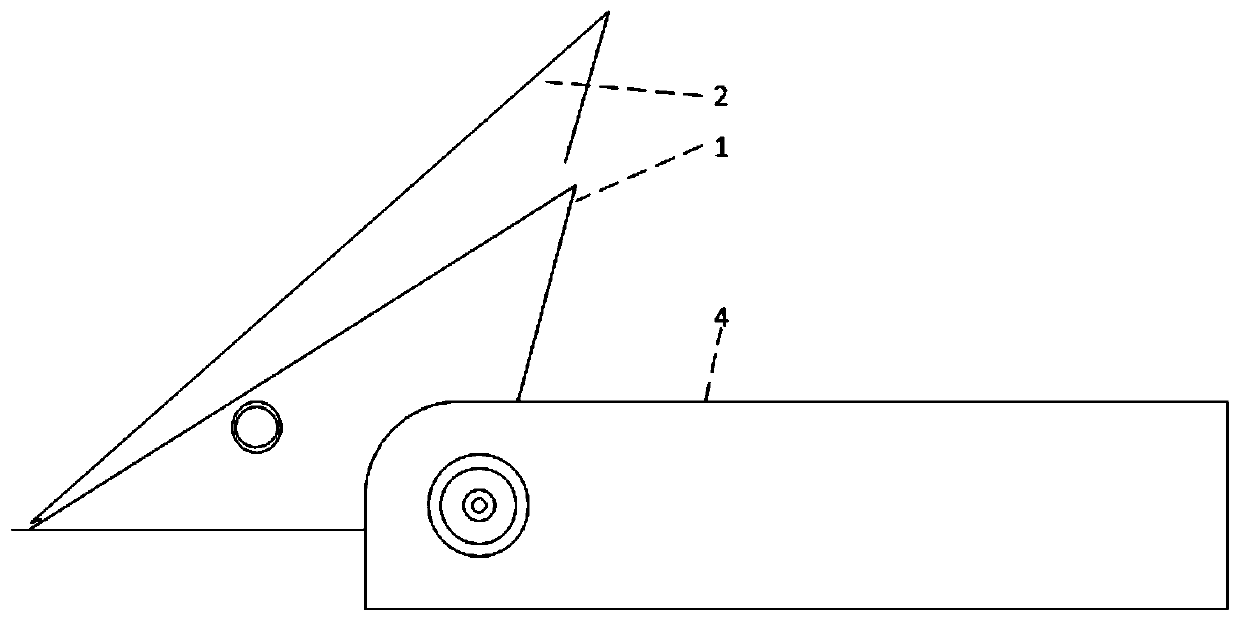

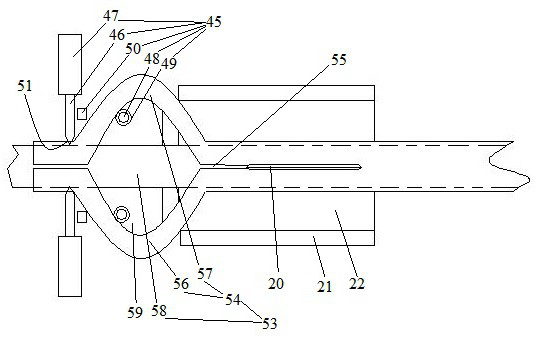

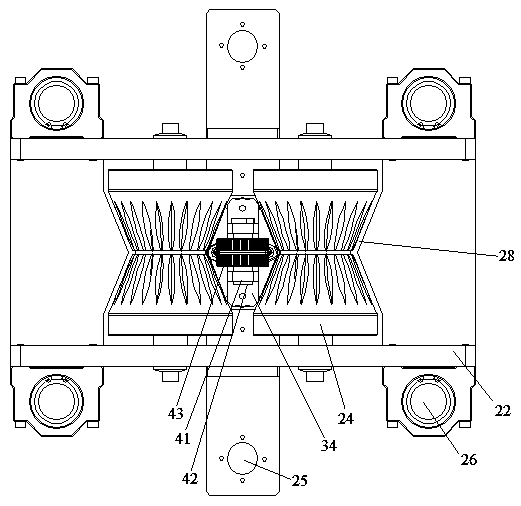

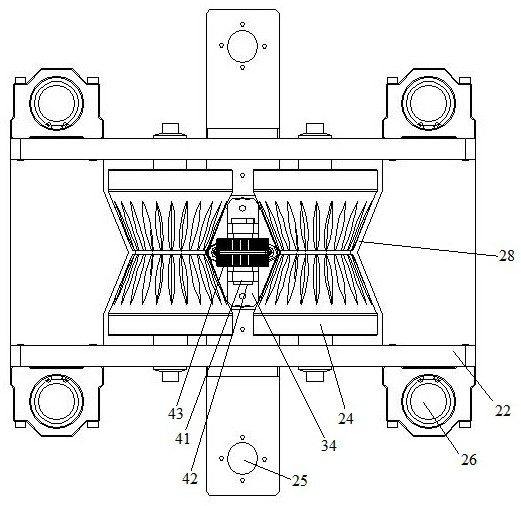

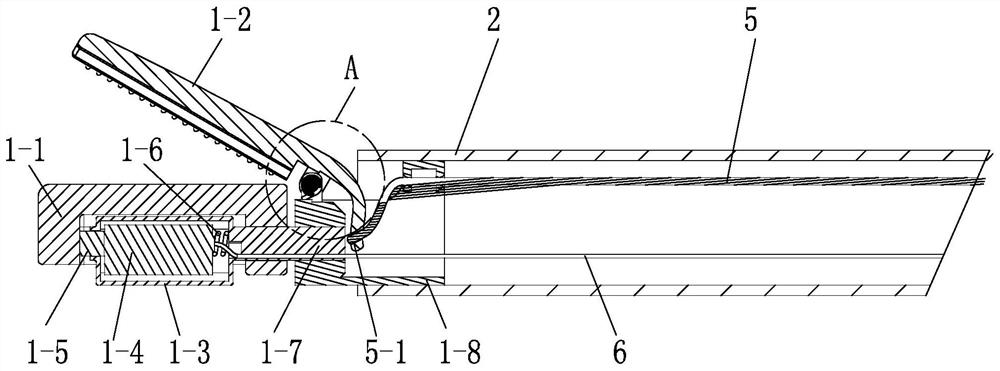

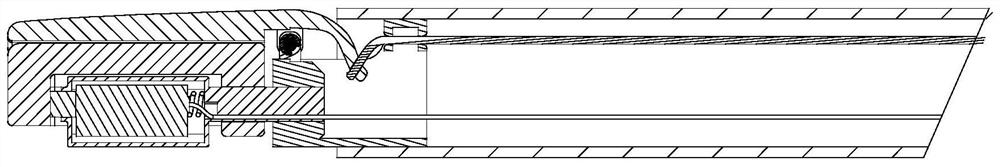

Manpower-driven single-cutter cutting type wire stripping device

ActiveCN111431102ARealize cuttingPeel off effortBasic electric elementsApparatus for removing/armouring cablesEngineeringStructural engineering

The invention relates to a manpower-driven single-cutter cutting type wire stripping device. The device comprises a sectioning knife assembly and a supporting table board provided with a V-shaped centering straight groove., t The inclination angles of the two side walls of the centering groove are equal; the sectioning knife assembly comprises a circular cutting blade, a fixed plate, a movable plate, a blade mounting rod and a blade pressing spring for driving the movable plate to be propped against the fixed plate; one end of the blade mounting rod is connected with the movable plate; the circular cutting blade is connected to the other end of the blade mounting installation rod, the movable plate and the circular cutting blade are distributed on the two sides of the fixed plate, the fixed plate is connected to the supporting table top through a vertical frame, the circular cutting blade is located above the centering straight groove, and the intersecting line of the two planes wherethe two side walls of the centering straight groove are located is located on the plane where the circular cutting blade is locatted. The invention provides aAccording to the manpower-driven single-cutter cutting type wire stripping device which has a good protection effect on a blade, and solves the problem that the manual cutting of a the wire insulation sleeve by using a cutter is strenuouslabor-consuming can be solved.

Owner:ANHUI XINDALU SPECIAL PAINT CO LTD

Elliptical arc-shaped rotary roller cutter of film guide and cutting machine

The invention discloses an elliptical arc-shaped rotary roller cutter of a film guide and cutting machine. The elliptical arc-shaped rotary roller cutter is matched with a rotary roller to complete film cutting, and two mounting surfaces which are symmetrically arranged along a rotating shaft are arranged on the periphery of the cylindrical surface of a rotary cutter holder. Each mounting surfaceis provided with an elliptical arc-shaped rotary roller cutter body with an elliptical arc-shaped cutting edge. The shortest distance a between the axis of the rotating shaft of the rotary cutter holder and the outer circle of the rotary roller serves as the short radius of the elliptical arc-shaped cutting edges, the axis of the rotating shaft of the rotary cutter holder serves as a center line,and a serves as the radius, so that a cylinder is made. The intersection point of the plane where the elliptical arc-shaped cutting edges are located and which is parallel to the mounting surfaces andthe axis of the rotating shaft of the rotary cutter holder serves as the center point of the elliptical arc-shaped cutting edges. The rotary roller cutter has the advantages that in the rotating process of the elliptical arc-shaped rotary roller cutter bodies, the elliptical arc-shaped cutting edges and the rotary roller are kept in a tangent state all the time, and only one tangency point exists; meanwhile, noise during working is reduced, and film cutting is successfully achieved.

Owner:GUANGXI LINGLONG TIRE CO LTD

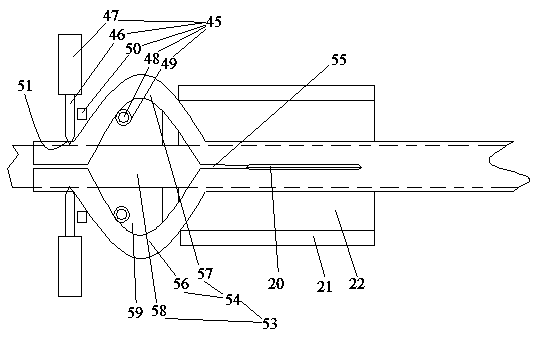

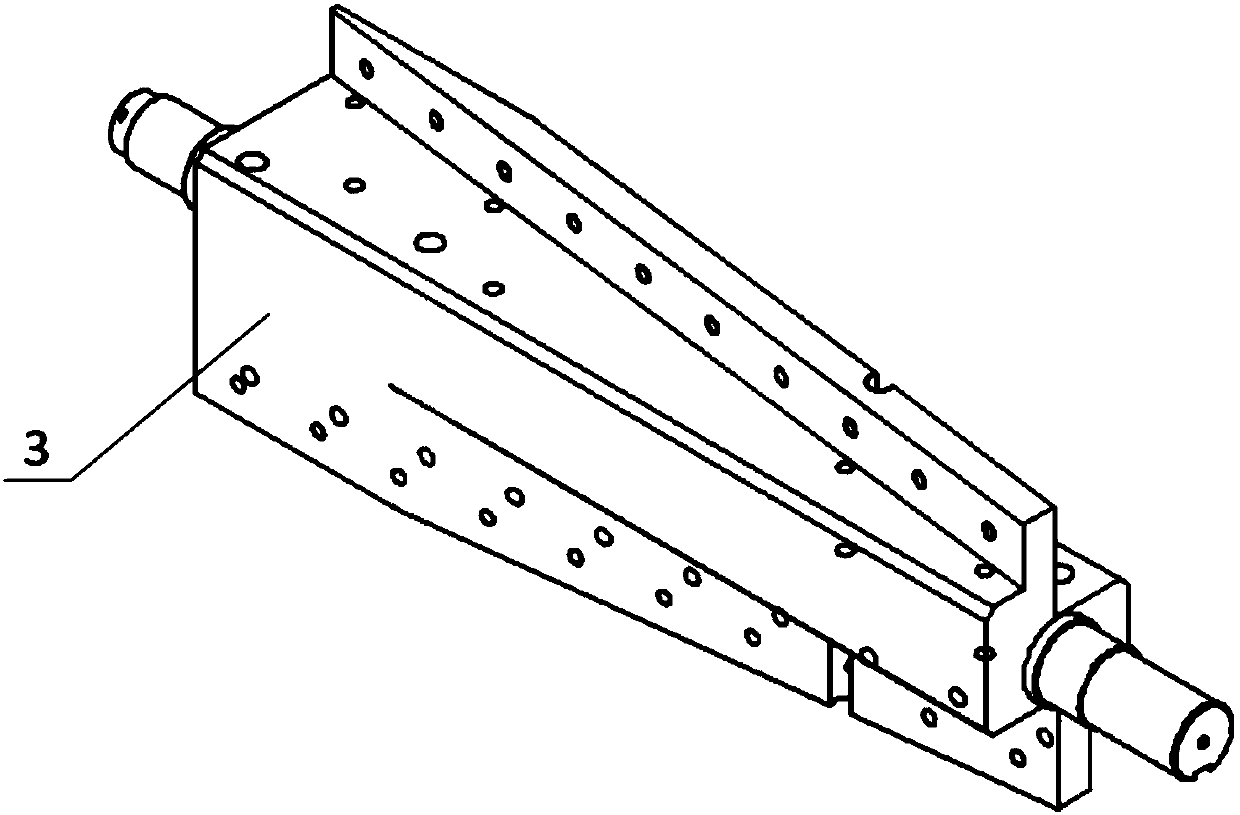

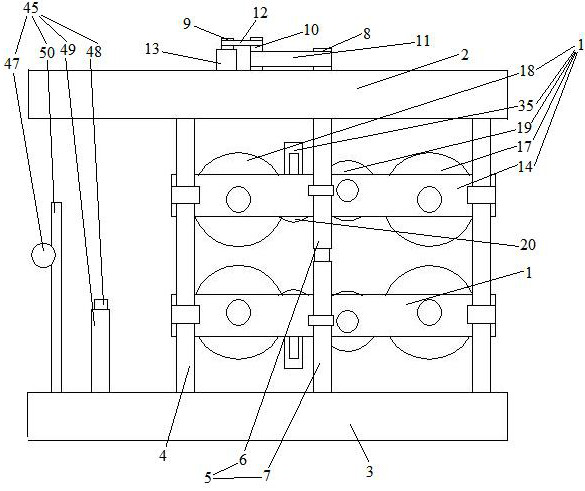

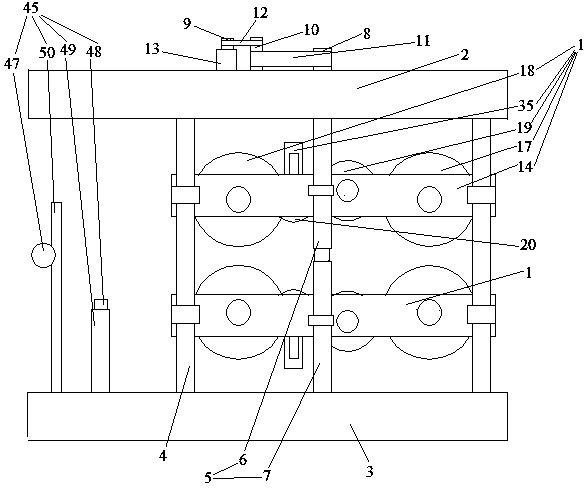

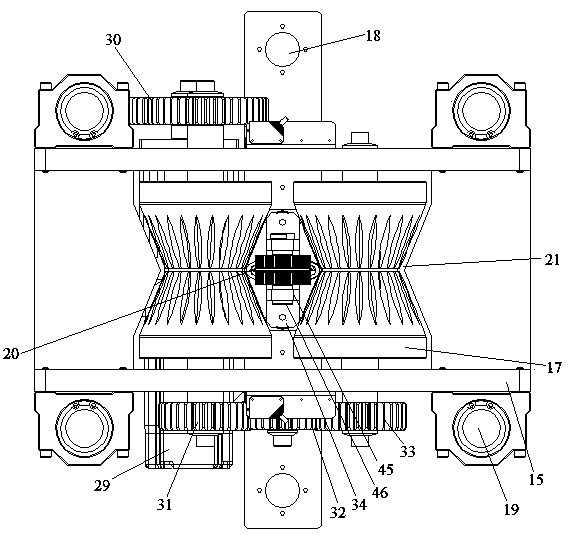

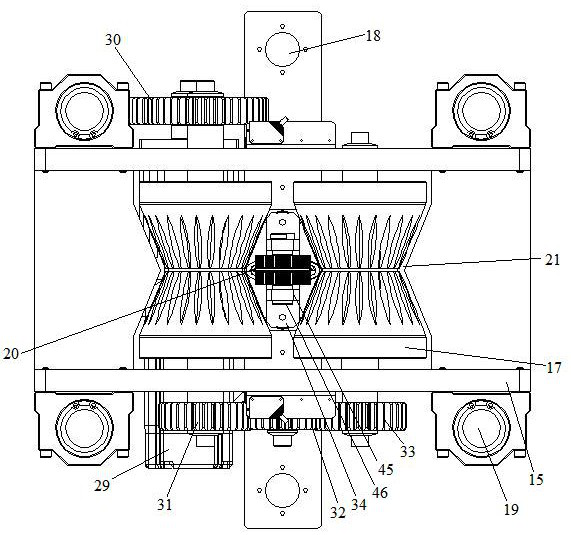

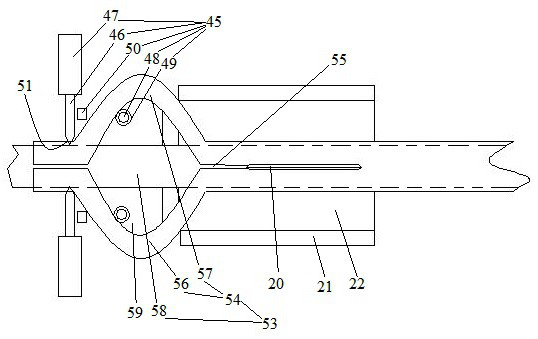

Wire stripping machine

ActiveCN111541192BRealize cuttingReduce radial deformationLine/current collector detailsApparatus for removing/armouring cablesStructural engineeringMachine

The invention relates to a wire stripping machine, which includes two cutting and conveying modules distributed along the up and down directions. Including a circular cutting blade, the positioning wheel on the feed side includes a conical section of the positioning wheel on the feeding side where two small diameter ends are butted together, and the positioning wheel on the feeding side is enclosed between the two positioning wheels on the feeding side Ring groove, the circular cutting blade is aligned with the positioning ring groove of the positioning wheel on the feeding side; the positioning ring grooves of the positioning wheel on the feeding side of the two cutting and conveying modules are aligned, and the feeding wheels of the two cutting and conveying modules are clamped Hold the wire to drive the wire to translate; the circumference of the feed wheel is provided with a number of booster spikes for piercing into the wire insulation sleeve, and the apex angles of the conical sections of the two feed side positioning wheels are equal. The invention has the advantage of being able to cut the wire insulating sleeve, and solves the laborious problem of manually cutting the wire insulating sleeve with a knife.

Owner:SUZHOU LEMIFUN ELECTRICAL TECH CO LTD

Wire stripping machine

ActiveCN111541192ARealize cuttingReduce radial deformationLine/current collector detailsApparatus for removing/armouring cablesEngineeringStructural engineering

The invention relates to a wire stripping machine. The machine comprises two sectioning conveying modules distributed in the vertical direction. Each sectioning conveying module comprises a connectingbase, a sectioning knife assembly, a feeding side positioning wheel and a feeding wheel. The sectioning knife assembly comprises a circular cutting blade, the feeding side positioning wheel comprisestwo feeding side positioning wheel part conical sections of which the small-diameter ends are in butt joint together, a feeding side positioning wheel part positioning ring groove is defined betweenthe two feeding side positioning wheel parts, and the circular cutting blade is aligned with the feeding side positioning wheel part positioning ring groove; the positioning ring grooves of the feeding side positioning wheel parts of the two sectioning conveying modules are aligned, and the feeding wheels of the two sectioning conveying modules clamp an electric wire to drive the electric wire totranslate; a plurality of power-assisted spikes used for piercing into a wire insulation sleeve are arranged on the circumferential surface of the feeding wheel, and the vertex angles of the conical sections of the two feeding side positioning wheel parts are equal. The wire stripping machine has the advantage of being capable of sectioning the electric wire insulation sleeve, and the problem thatlabor is wasted when a knife is manually used for slitting the electric wire insulation sleeve is solved.

Owner:SUZHOU LEMIFUN ELECTRICAL TECH CO LTD

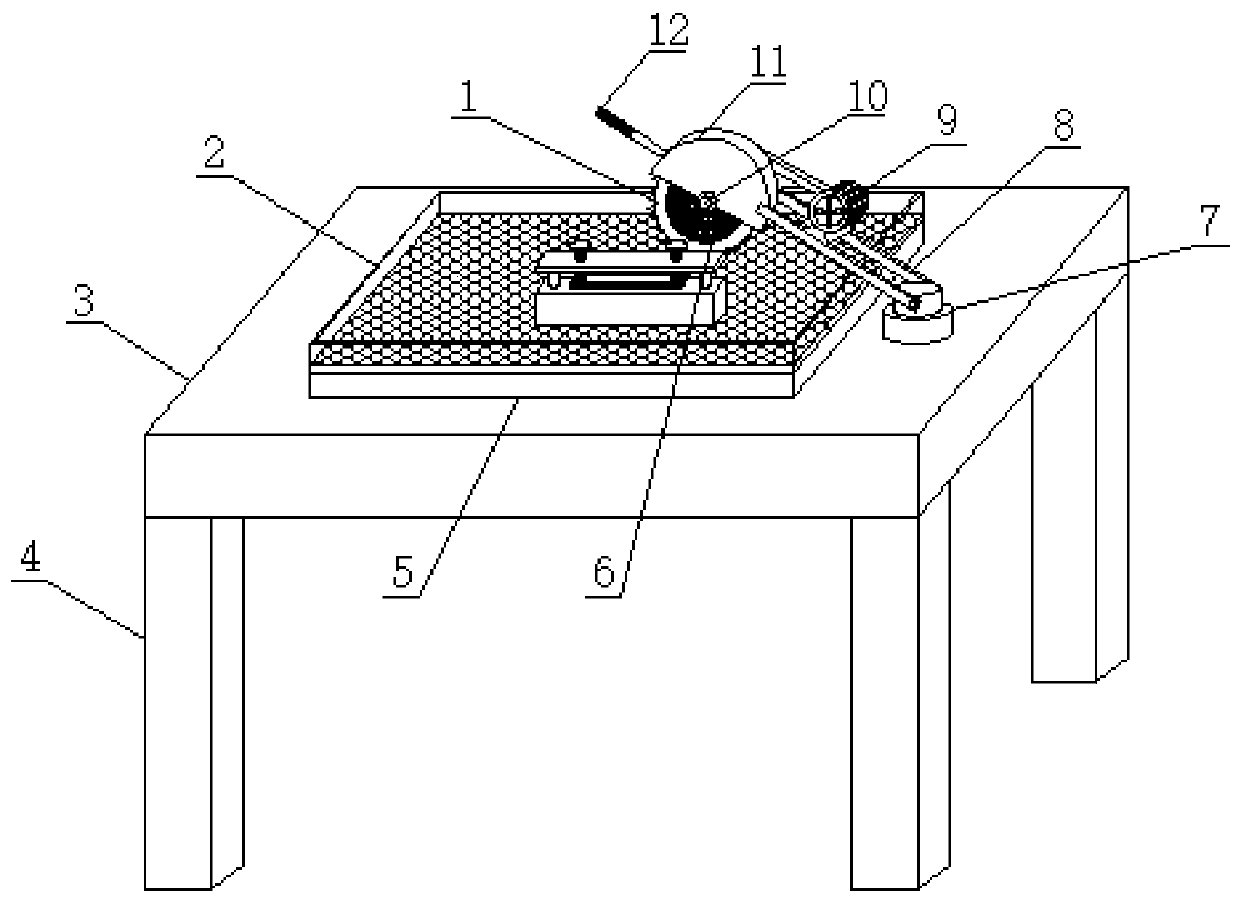

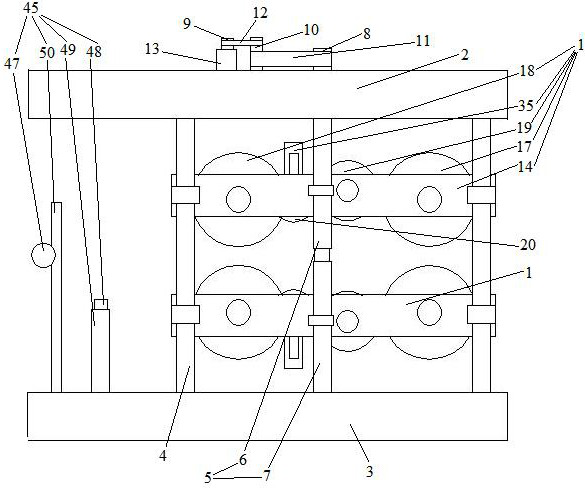

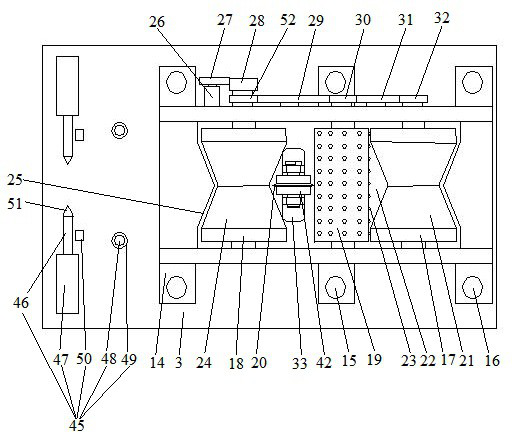

Cutting-polishing integrated machine for PCB machining

InactiveCN111113520ARealize cuttingRealize the integration of polishingGrinding drivesDirt cleaningElectric machineryPolishing

The invention discloses a cutting-polishing integrated machine for PCB machining. The cutting-polishing integrated machine comprises an installation frame and a workbench, the installation frame is installed on the outer wall of the upper end of the workbench, and the upper end of the installation frame is provided with a limiting collection device. The cutting-polishing integrated machine for PCBmachining is mainly composed of a cutting wheel, the limiting collection device, the installation frame, a millstone, a rotary seat, a connection rod, a motor, a fixing table, an extrusion plate, supporting rods, a fixing block, tightening nuts and the other structures; and through combined action of the extrusion plate, the fixing table and the tightening nuts, a PCB needing to be machined can be extruded and fixed, then, through combined action of the cutting wheel and the millstone, the cut PCB is conveniently polished, chippings generated in the cutting and polishing processes can be removed through the collection device, thus, when the PCB is machined, integration of cutting and polishing of the PCB can be achieved, the machining efficiency of the PCB is greatly improved, and the quite good practicability is achieved.

Owner:杭州潮响信息技术有限公司

Wire stripping machine

InactiveCN112600134ARealize cuttingReduce radial deformationLine/current collector detailsApparatus for removing/armouring cablesStructural engineeringKnife blades

The invention relates to a wire stripping machine. The machine comprises two sectioning conveying modules distributed in the vertical direction, each sectioning conveying module comprises a connectingbase, a sectioning knife assembly, feeding side positioning wheels and a feeding wheel, each sectioning knife assembly comprises a circular cutting blade, each feeding side positioning wheel comprises a feeding side positioning wheel part conical section with two small-diameter ends in butt joint together, a feeding side positioning wheel part positioning ring groove is defined between the two feeding side positioning wheels, and the circular cutting blade is aligned with the feeding side positioning wheel part positioning ring groove; the feeding side positioning wheel part positioning ringgroove of the two sectioning conveying modules are aligned, and the feeding wheels of the two sectioning conveying modules clamp the electric wire to drive the electric wire to translate; and a plurality of power-assisted spikes used for piercing into a wire insulation sleeve are arranged on the circumferential surface of the feeding wheel, and the vertex angles of the two feeding side positioningwheel part conical sections are equal. The machine has the advantages that: the wire insulation sleeve can be slit, and the problem that labor is wasted when a knife is manually used for slitting theelectric wire insulation sleeve is solved.

Owner:JIANGSHAN FAFA TECH CO LTD

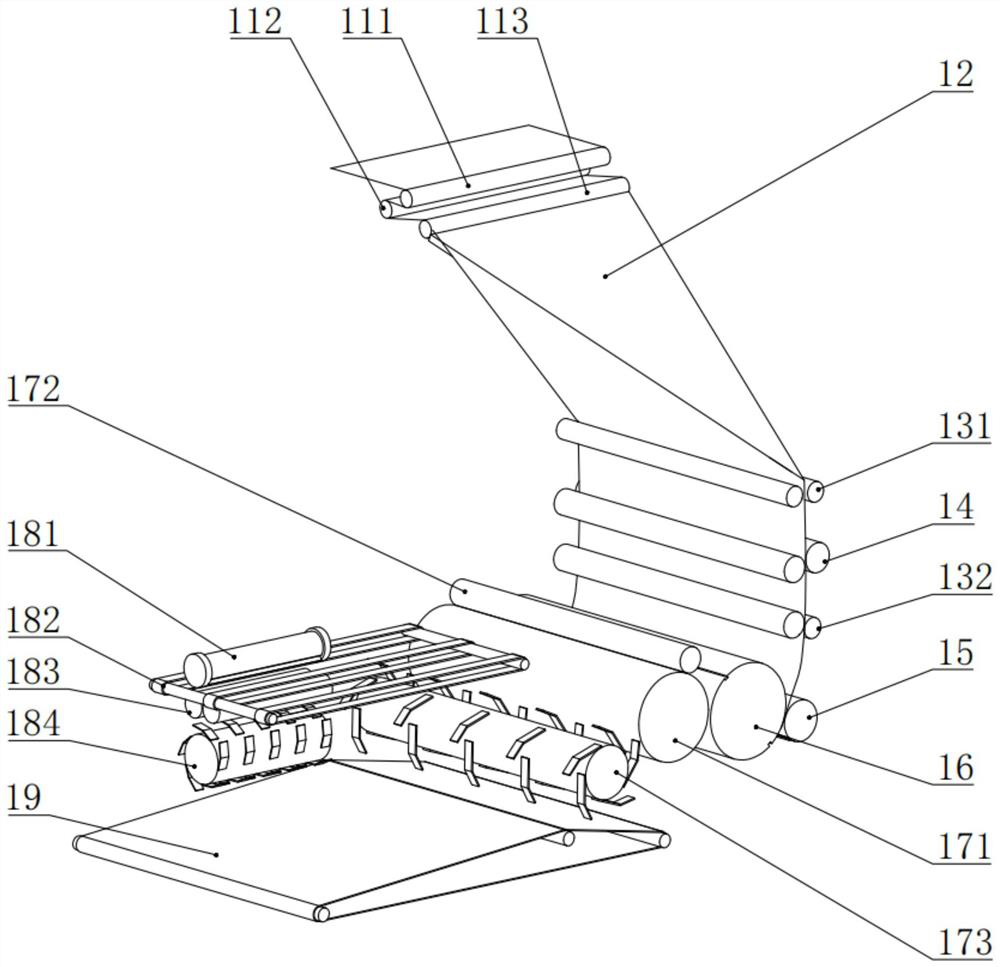

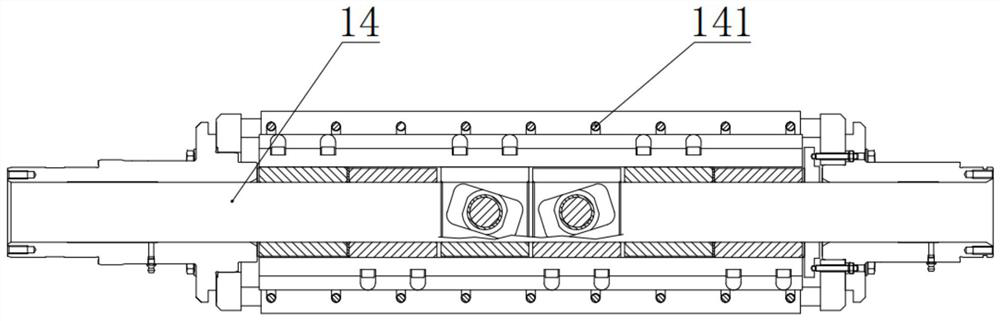

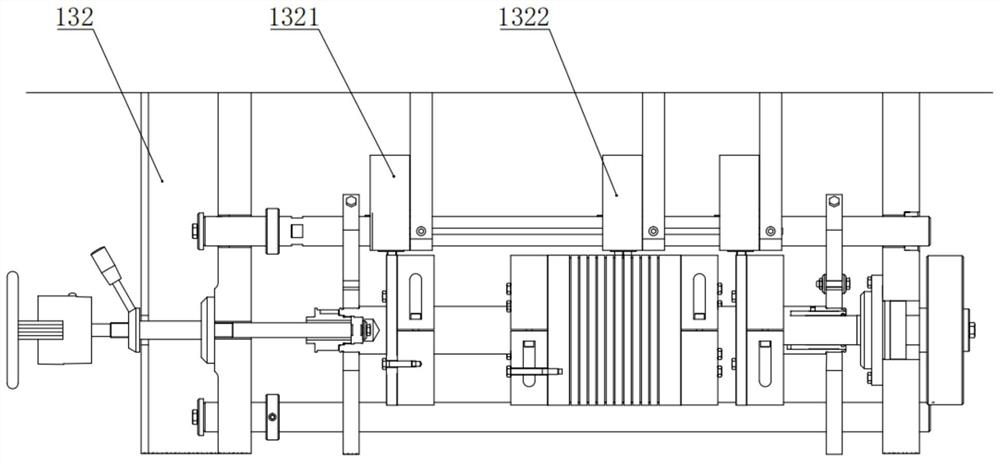

Paraffin section transferring and developing apparatus, sectioning device and method for paraffin sectioning

ActiveCN110749483BEasy to operateAvoid stickingPreparing sample for investigationParaffin waxEngineering

The invention provides a paraffin slice transfer and unfolding instrument. The paraffin slice transfer and unfolding instrument comprises a bracket, a conveying mechanism, a refrigeration mechanism, and an electrostatic mechanism, the conveying mechanism comprises a conveyor belt and a power unit, the conveyor belt is paved on the surface of the bracket, the power unit drives the conveyor belt tomove, a cool air inlet of the refrigeration mechanism is arranged in an inner space of the bracket below the conveyor belt, and the tail end of the electrostatic mechanism is in contact with the conveyor belt and provides static electricity for the electrostatic mechanism or eliminates the static electricity thereof. The invention further provides a slicing device, comprising a fixed seat, and a specimen holder and a blade, which are arranged on the fixed seat, wherein the specimen holder is arranged on the fixed seat in a vertical movable manner, the slicing device further comprises the aboveparaffin slice transfer and unfolding instrument, the paraffin slice transfer and unfolding instrument is arranged on one side of the blade, and the first end of the conveyor belt is close to the knife edge of the blade and receives a paraffin slice cut by the blade. The paraffin slice transfer and unfolding instrument in the scheme can smoothly absorb the paraffin slice; and the slicing device in the scheme can realize the automatic transfer and unfolding of the paraffin slice.

Owner:XIANGYA HOSPITAL CENT SOUTH UNIV

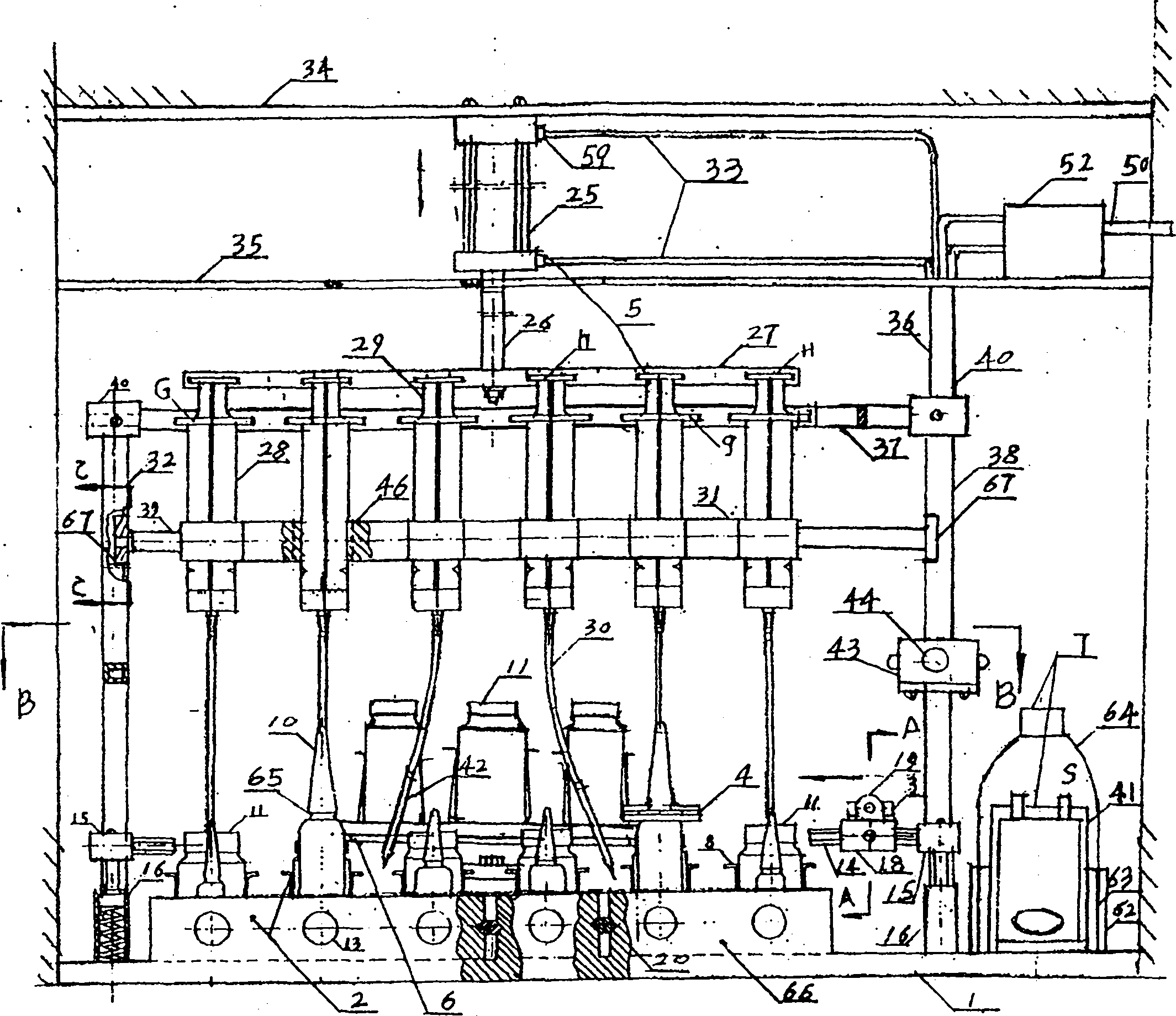

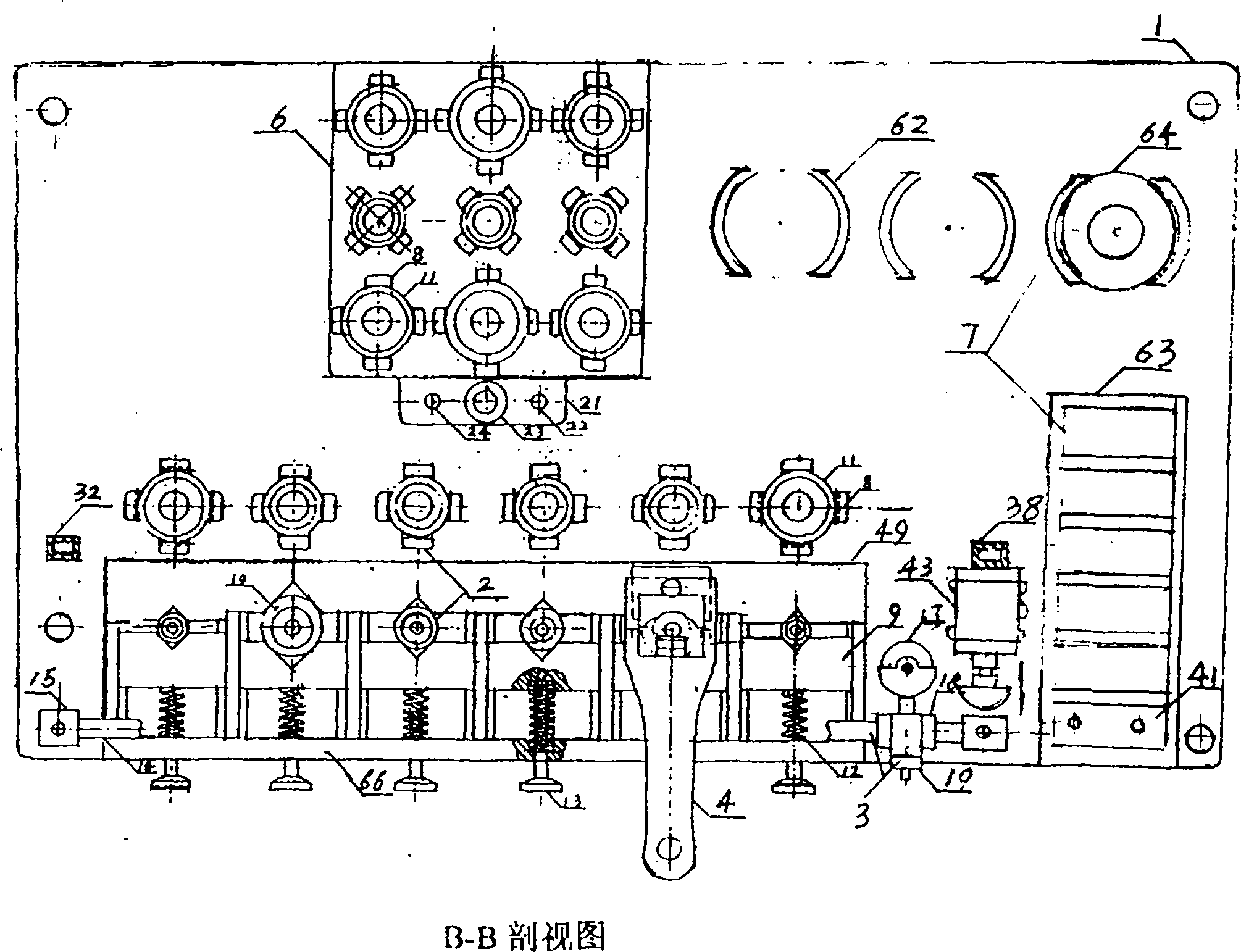

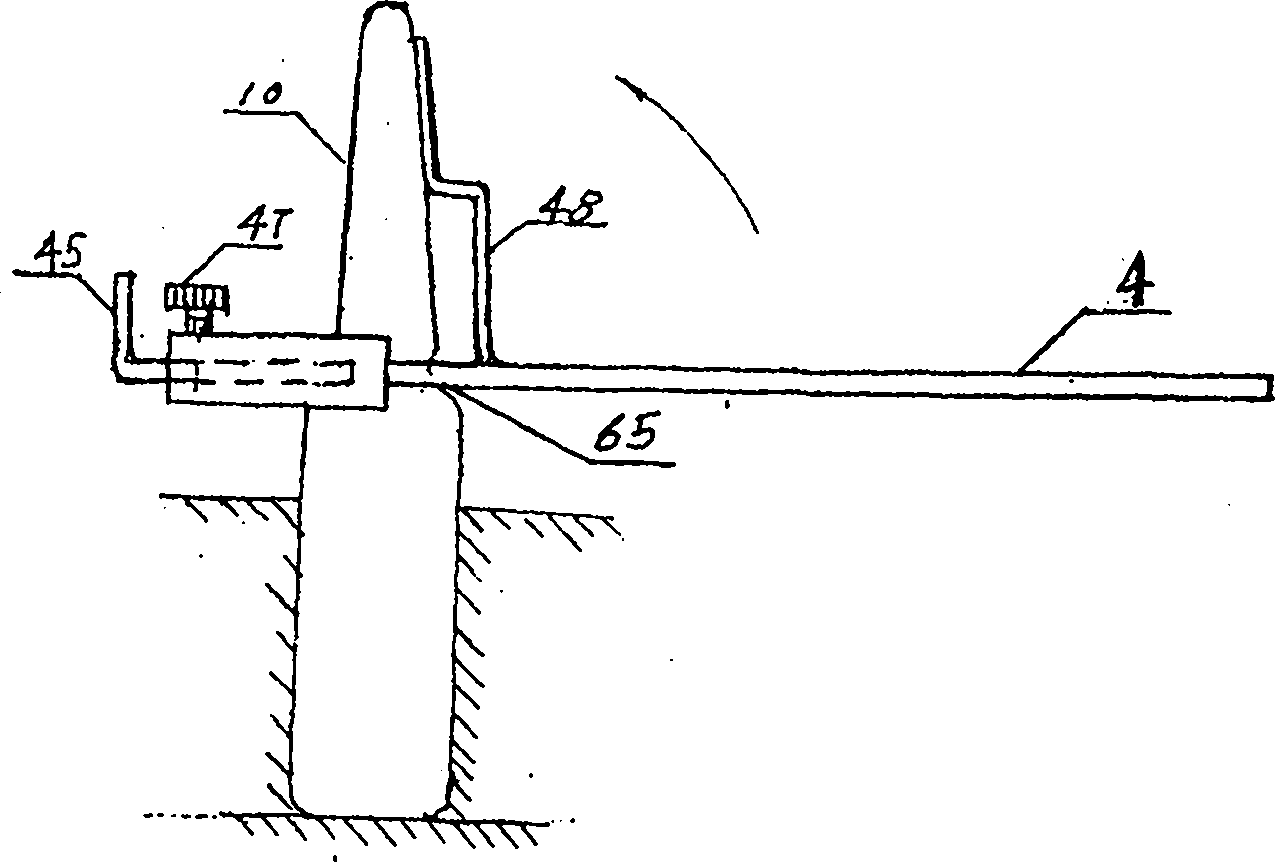

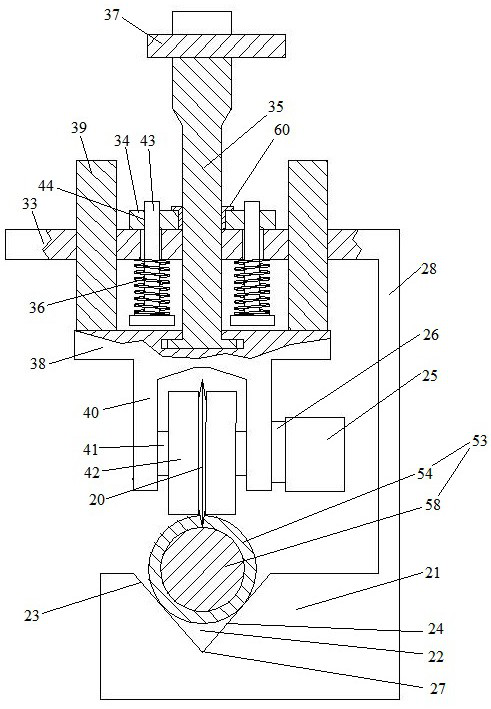

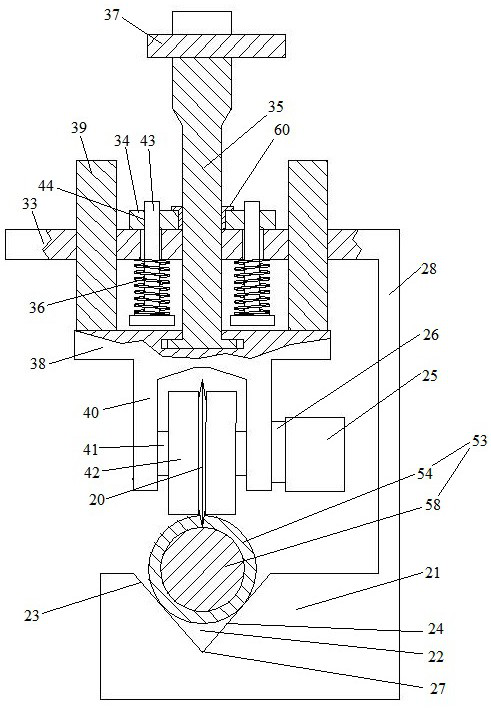

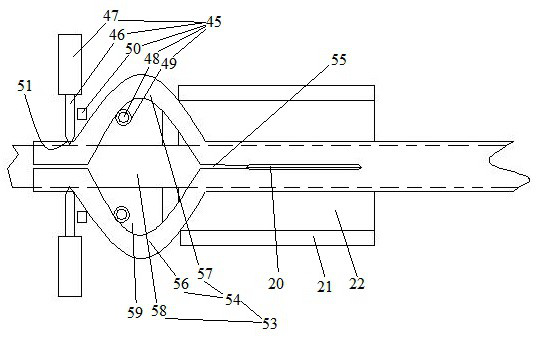

Device for blending medicinal vein medicines

InactiveCN102462870BQuick action structureRealize cuttingInfusion devicesBiochemical engineeringBiosafety cabinet

The invention discloses a device for blending medical vein medicines. The device comprises a baseplate, a clamp, a bottleneck scribing mechanism, a bottle opener, a liquid absorption and injection device, a medicinal oscillator and an administration device. The device aims to overcome the defect of low efficiency of blending medicines mutually in the prior art. According to the device, the baseplate is fixed to a platform in a biological safety cabinet; ampoules and a seal bottle clamp group are arranged on the baseplate; bottlenecks of ampoules of different specifications are scribed by a horizontal expansion piece and a vertical expansion piece; the liquid absorption and injection device and an air cylinder piston rod are fixed with a fixed plate of an injector piston rod by a screw cap; and an injector group is inserted into the fixed plate of the injector piston rod and a groove on a fixed plate of an injection vat. According to the device, manual operation is replaced by a linkage structure to realize the medicine blending processes of the absorption and injection of liquid medicine, dissolution by vibration and administration. The invention has the advantages that the device is convenient to use and economic and is operated by power in the process, and blending efficiency of the medicines is improved greatly. The device is suitable to be applied to vein medicine blending centers of hospitals.

Owner:常骁毅 +2

Manpower-driven single-cutter cutting type wire stripping device

InactiveCN112736788ARealize cuttingPeel off effortBasic electric elementsApparatus for removing/armouring cablesStructural engineeringKnife blades

The invention relates to a manpower-driven single-cutter cutting type wire stripping device which comprises a sectioning cutter assembly and a supporting table board provided with a V-shaped centering straight groove, and the inclination angles of the two side walls of the centering straight groove are equal. The sectioning cutter assembly comprises a circular cutting blade, a fixed plate, a movable plate, a blade installation rod and a blade pressing spring driving the movable plate and the fixed plate to abut against each other, one end of the blade installation rod is connected with the movable plate, the circular cutting blade is connected to the other end of the blade installation rod, and the movable plate and the circular cutting blade are distributed on the two sides of the fixed plate. The fixing plate is connected to the supporting table top through a vertical frame, the circular cutting blade is located above the centering straight groove, and the intersecting line of two planes where the two side walls of the centering straight groove are located is located on the plane where the circular cutting blade is located. The invention provides a manpower-driven single-cutter cutting type wire stripping device which has a good protection effect on a blade, and solves the problem that the manual cutting of a wire insulation sleeve by using a cutter is strenuous.

Owner:JIANGSHAN FAFA TECH CO LTD

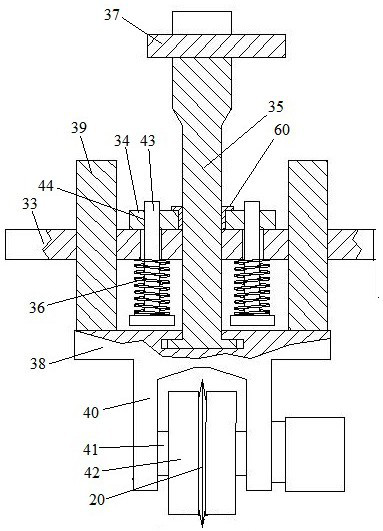

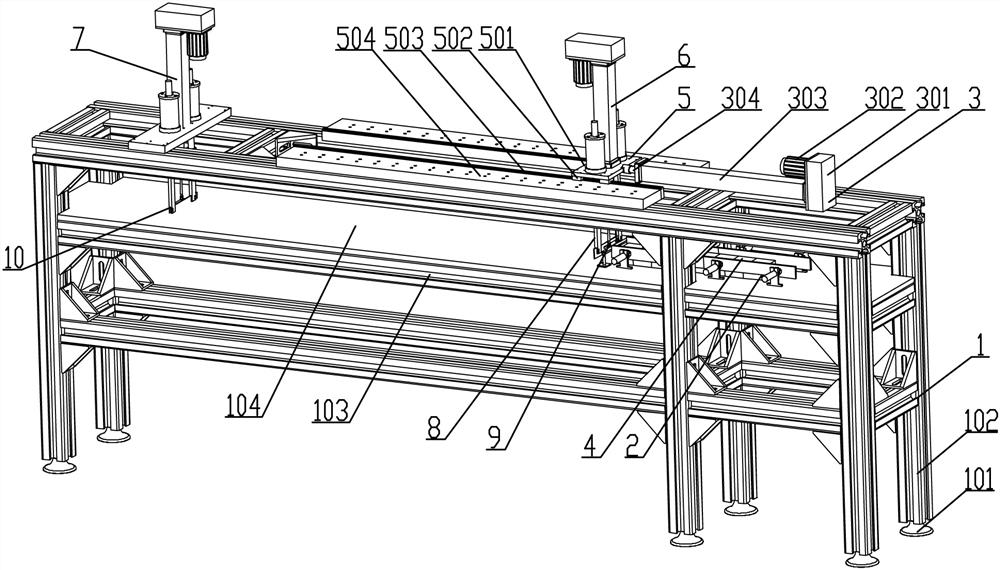

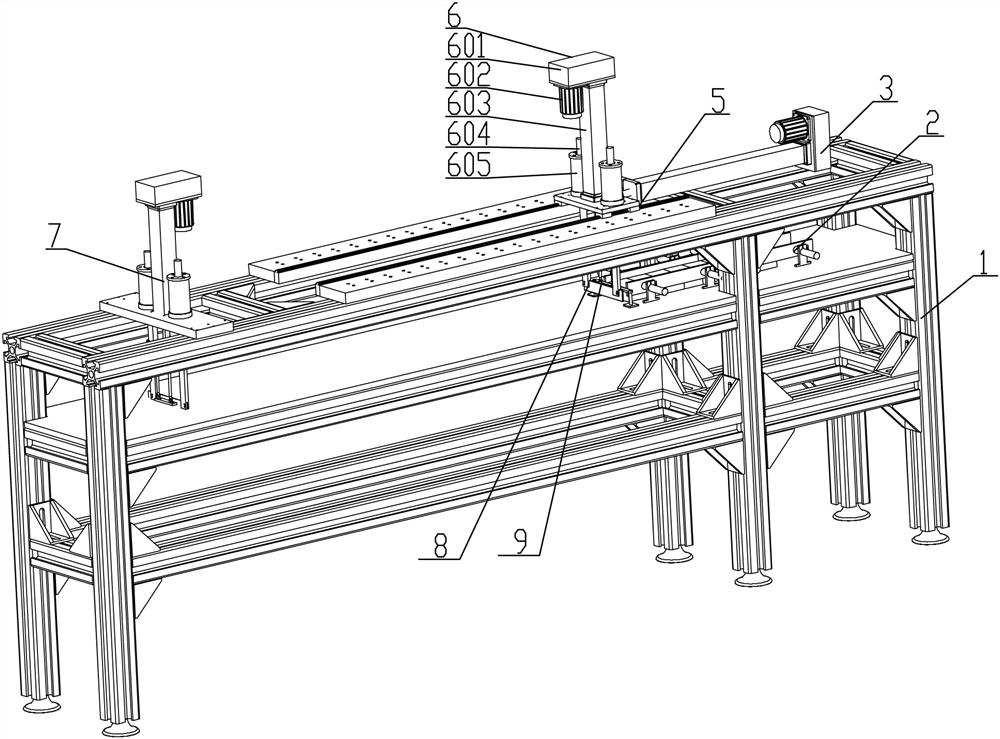

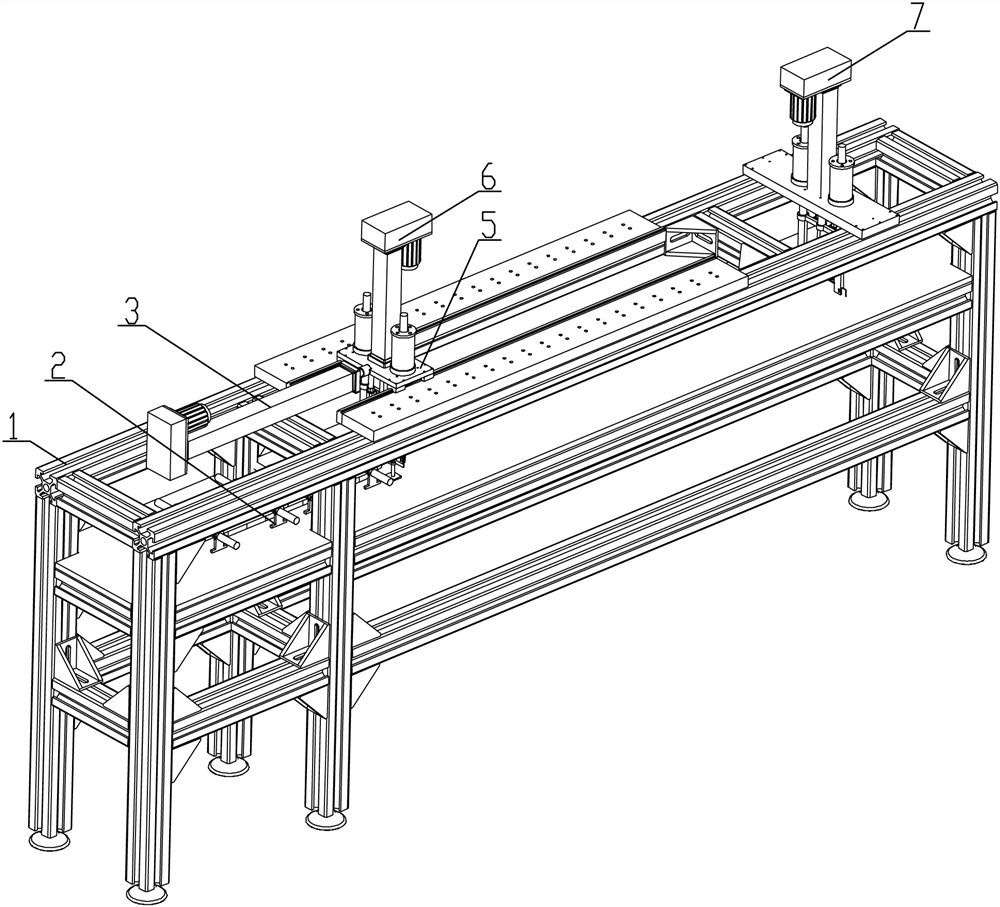

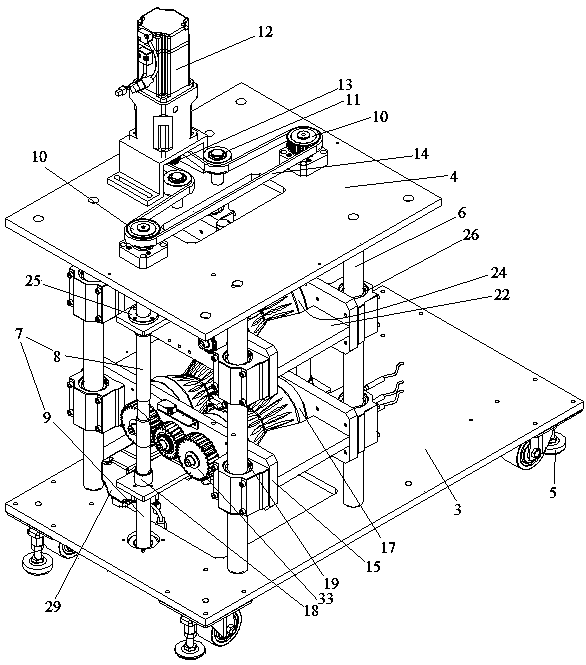

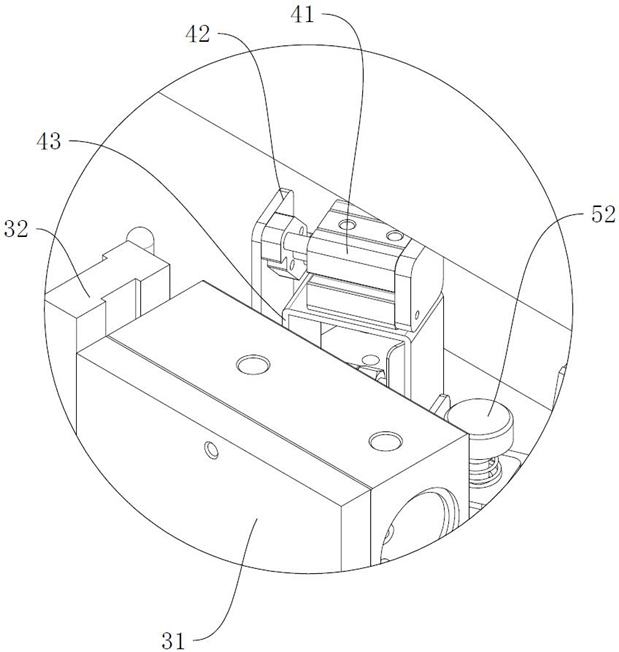

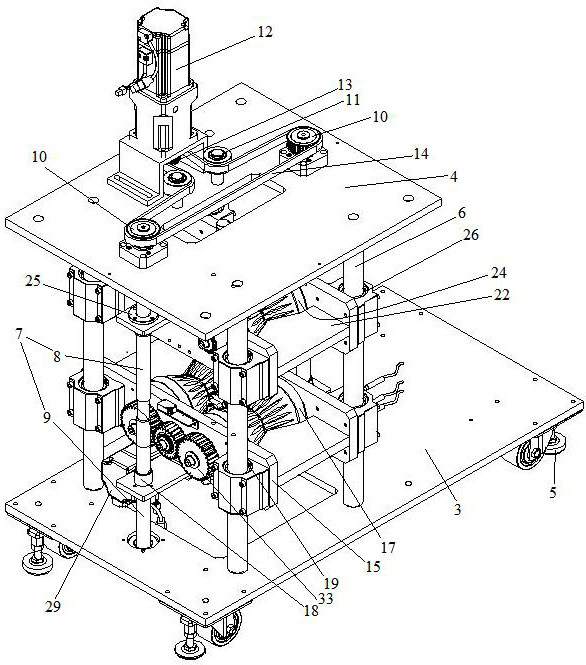

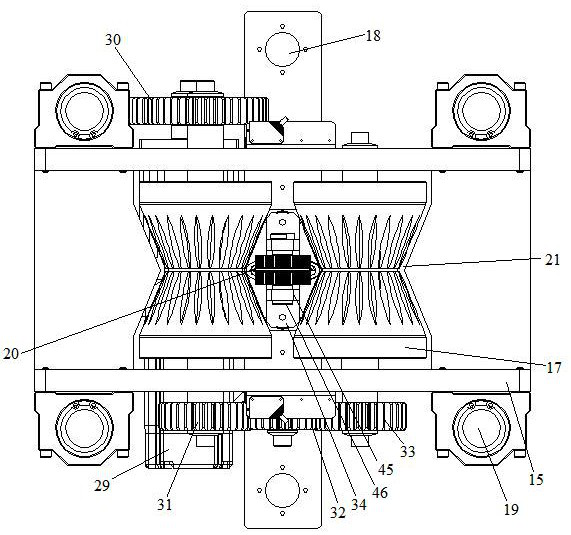

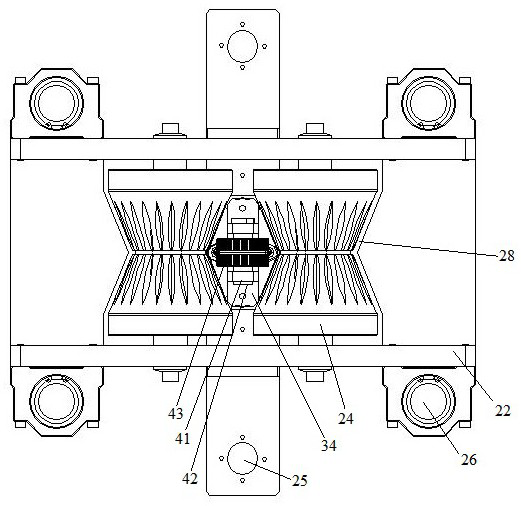

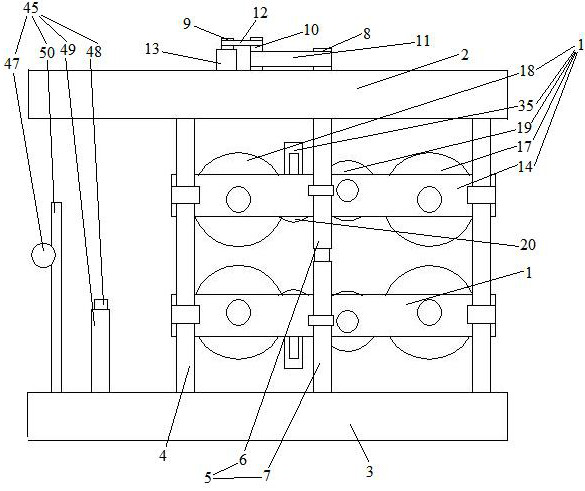

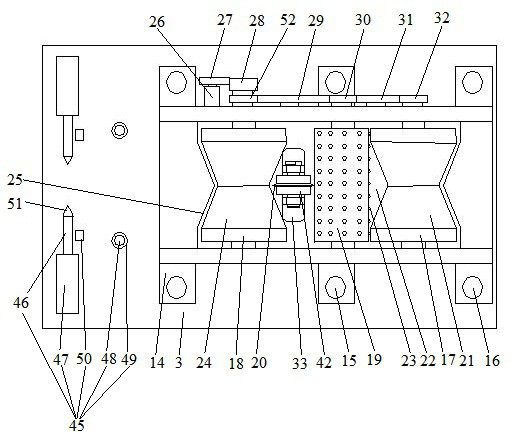

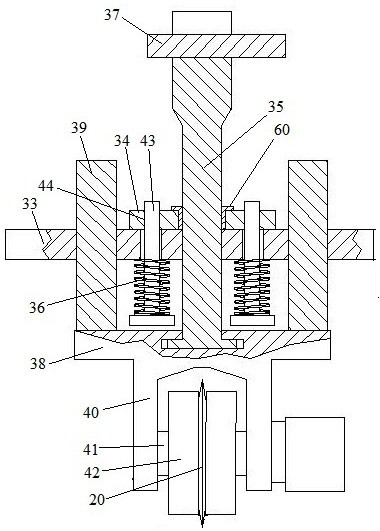

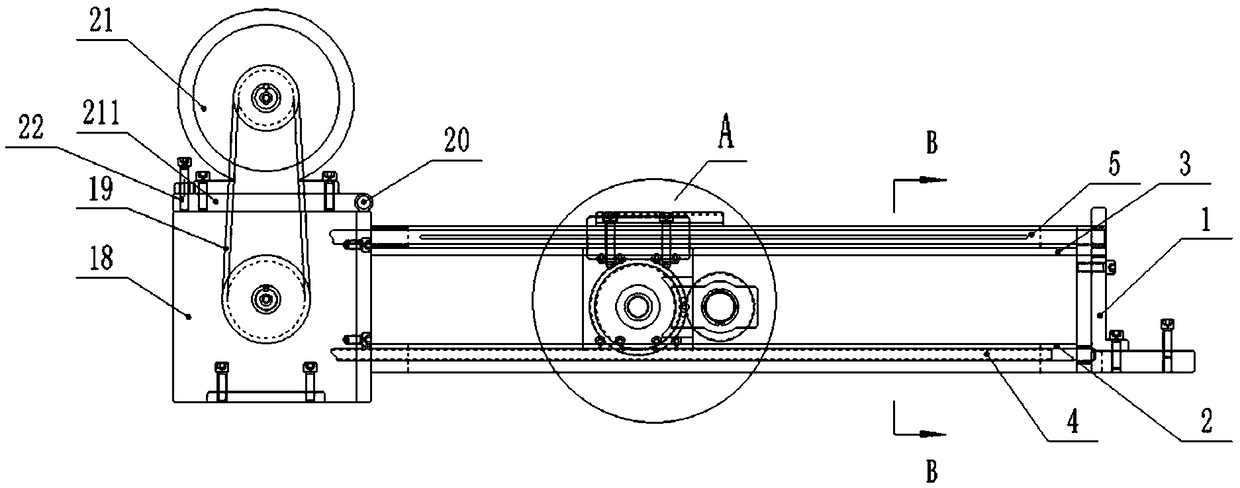

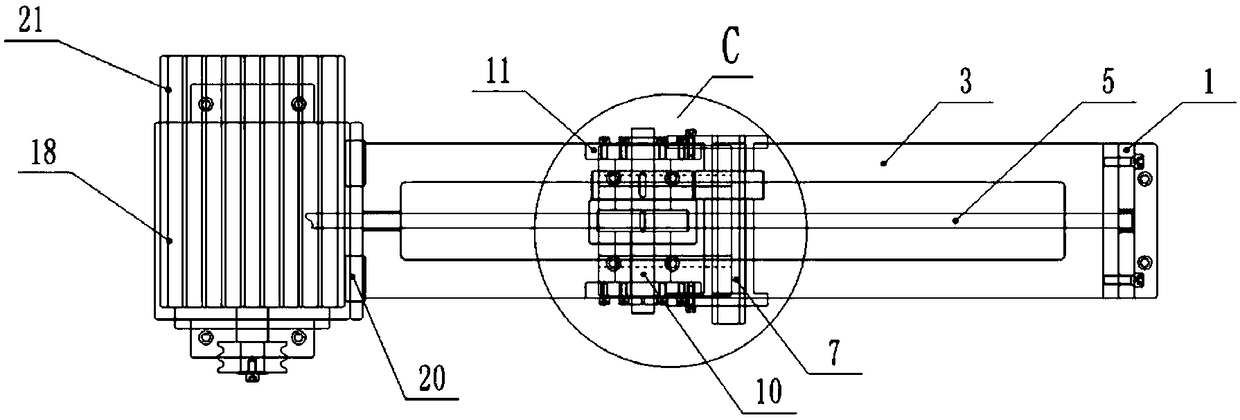

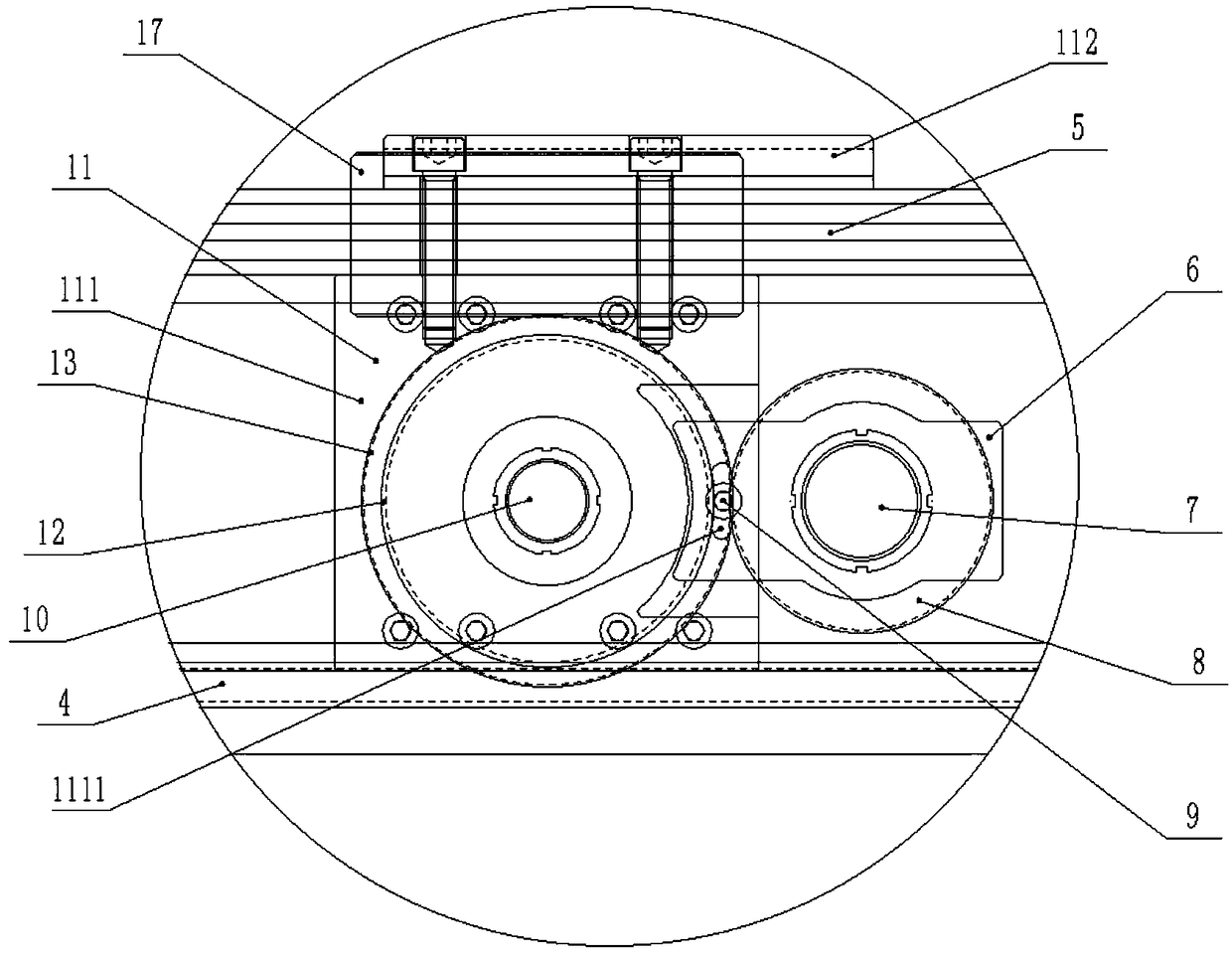

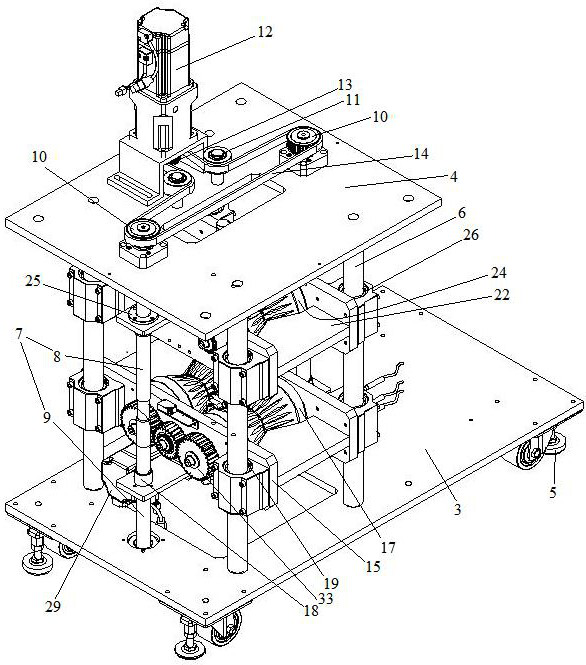

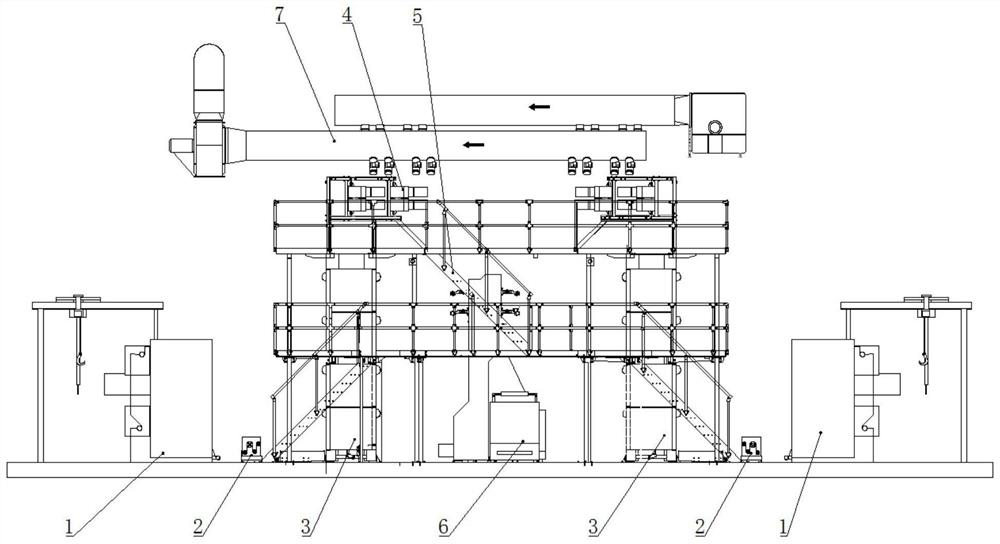

Full-automatic unattended propellant sampling machine and preparation method

ActiveCN112847504AImprove securitySimple frame structureMetal working apparatusTotal factory controlStructural engineeringManufacturing engineering

The invention provides a full-automatic unattended propellant sampling machine and a preparation method. The middle of the top of a rack structure is provided with a sliding rail mechanism, the sliding rail mechanism is fixedly provided with a first cutting-off power mechanism used for slicing propellants, and the bottom end of the first cutting-off power mechanism is fixedly provided with a first cutter assembly; the sliding rail mechanism is connected with a pushing mechanism used for pushing the sliding rail mechanism to move, and the pushing mechanism is fixed to the top of the rack structure; a feeding guide structure used for conveying propellant powder blanks is in butt joint under the first cutter assembly; a second cutting-off power mechanism used for cutting cut medicine strips into dumbbell shapes is mounted on the tail section of the rack structure in a supporting mode; and a second cutter assembly is fixed to the bottom end of the second cutting-off power mechanism. According to the sampling machine, full-automatic equipment is adopted for completing the whole sampling technological process, and parameterized cutting, slicing and slitting of the propellant powder blanks and machining of dumbbell-shaped test pieces are achieved in an unattended mode.

Owner:HUBEI SANJIANG AEROSPACE JIANGHE CHEM TECH

Cable outer sheath cutting method

ActiveCN111262193ARealize cuttingCutting effortApparatus for removing/armouring cablesStructural engineeringKnife blades

The invention relates to a cable outer sheath cutting method, which is characterized in that a cable is enabled to pass between an upper driving cutting assembly and a lower driving cutting assembly,the upper driving cutting assembly comprises two lower driving rollers arranged in parallel and a lower cutting blade located between the two lower driving rollers, and the upper driving cutting assembly comprises two upper driving rollers arranged in parallel and an upper cutting blade located between the two upper driving rollers; when the cable passes through, the upper and lower driving rollers are driven by a driving mechanism to rotate, and the upper driving roller and the lower driving rollers are aligned in a one-to-one correspondence manner to clamp the cable and drive the cable to translate; the upper cutting blade and the lower cutting blade respectively cut above and below the cable protective sleeve along the extension direction of the cable to form cutting gaps, so that the cable protection sleeve is divided into two halves; and the two halves of the cable protection sleeve are stripped from a cable core wire. The invention provides a cable outer sheath cutting device, and solves the problem that manual stripping of the cable protective sleeve with a knife is strenuous.

Owner:ZHEJIANG DAYOU IND CO LTD HANGZHOU SCI TECH DEV BRANCH CO

Sideband material cutting structure, edge surrounding machine comprising sideband material cutting structure, and sideband edge surrounding method

ActiveCN112501797AImpact deliveryAvoid the phenomenon of threadingWorkpiece carriersMattress sewingEngineeringSideband

The invention discloses a sideband material cutting structure, an edge surrounding machine comprising the sideband material cutting structure, and a sideband edge surrounding method. The sideband material cutting structure comprises a rack, a sideband feeding mechanism, a heating device, and a fixing mechanism; the sideband feeding mechanism is arranged on the rack, and the sideband feeding mechanism is used for placing a sideband; the heating device is arranged on the rack and used for heating the sideband, so that the sideband is heated and melted to form a recess for cutting off materials;and the fixing mechanism is arranged on the rack and used for clamping the sideband. The edge surrounding machine comprises the sideband material cutting structure. The provided structure, the edge surrounding machine and the method can conveniently cut off the sideband.

Owner:佛山市众联机械科技有限公司

Cable outer sheath cutting device

ActiveCN111326993BRealize cuttingReduce effortApparatus for removing/armouring cablesStructural engineeringKnife blades

The invention relates to a device for cutting the outer sheath of a cable, comprising a driving mechanism, an upper driving cutting assembly and a lower driving cutting assembly, the upper driving cutting assembly includes a lower mounting frame, a lower cutting blade assembly connected to the lower mounting frame and a lower cutting blade assembly connected in rotation Two lower driving rollers arranged in parallel on the mounting frame, the lower cutting blade assembly is located between the two lower driving rollers, the lower cutting blade assembly includes the lower cutting blade; the upper driving cutting assembly includes an upper mounting frame, connected on the upper mounting frame The upper cutting blade assembly and the two upper driving rollers arranged in parallel on the upper mounting bracket are rotatably connected, the upper cutting blade assembly is located between the two upper driving rollers, the upper cutting blade assembly includes the upper cutting blade; the driving mechanism is used to drive the upper driving The roller and the lower drive roller rotate. The invention provides a device for cutting the outer sheath of a cable, which solves the laborious problem of manually stripping the sheath of the cable with a knife.

Owner:ZHEJIANG DAYOU IND CO LTD HANGZHOU SCI TECH DEV BRANCH CO

Automatic feeding type wire insulation cover removal method

ActiveCN111540546BRealize cuttingReduce radial deformationBasic electric elementsApparatus for removing/armouring cablesEngineeringStructural engineering

The invention relates to an automatic feeding type wire insulation sleeve removal method. A drive mechanism and two cutting and conveying modules distributed along the up and down directions are arranged on the frame. The cutting and conveying modules include a cutting knife assembly and a feeding side positioning Wheel and feeding wheel, the cutting knife assembly includes a circular cutting blade, and the positioning wheel on the feeding side is provided with a positioning ring groove on the positioning wheel on the feeding side; so that the wires are fed into the two feeding rings through the positioning ring groove on the positioning wheel on the feeding side. Between the wheels, the positioning wheel on the feeding side and the feeding wheel clamp the wire to drive the wire to translate; when the wire passes through the circular cutting blade, a cutting gap extending along the wire extension direction is cut out on the wire insulation sleeve, and the wire insulation sleeve is cut along the cutting edge. The gap is broken apart to separate the wire insulation sleeve from the wire conductive core. The invention has the advantage of being able to cut the wire insulating sleeve, and solves the laborious problem of manually cutting the wire insulating sleeve with a knife.

Owner:江山市发发科技有限公司

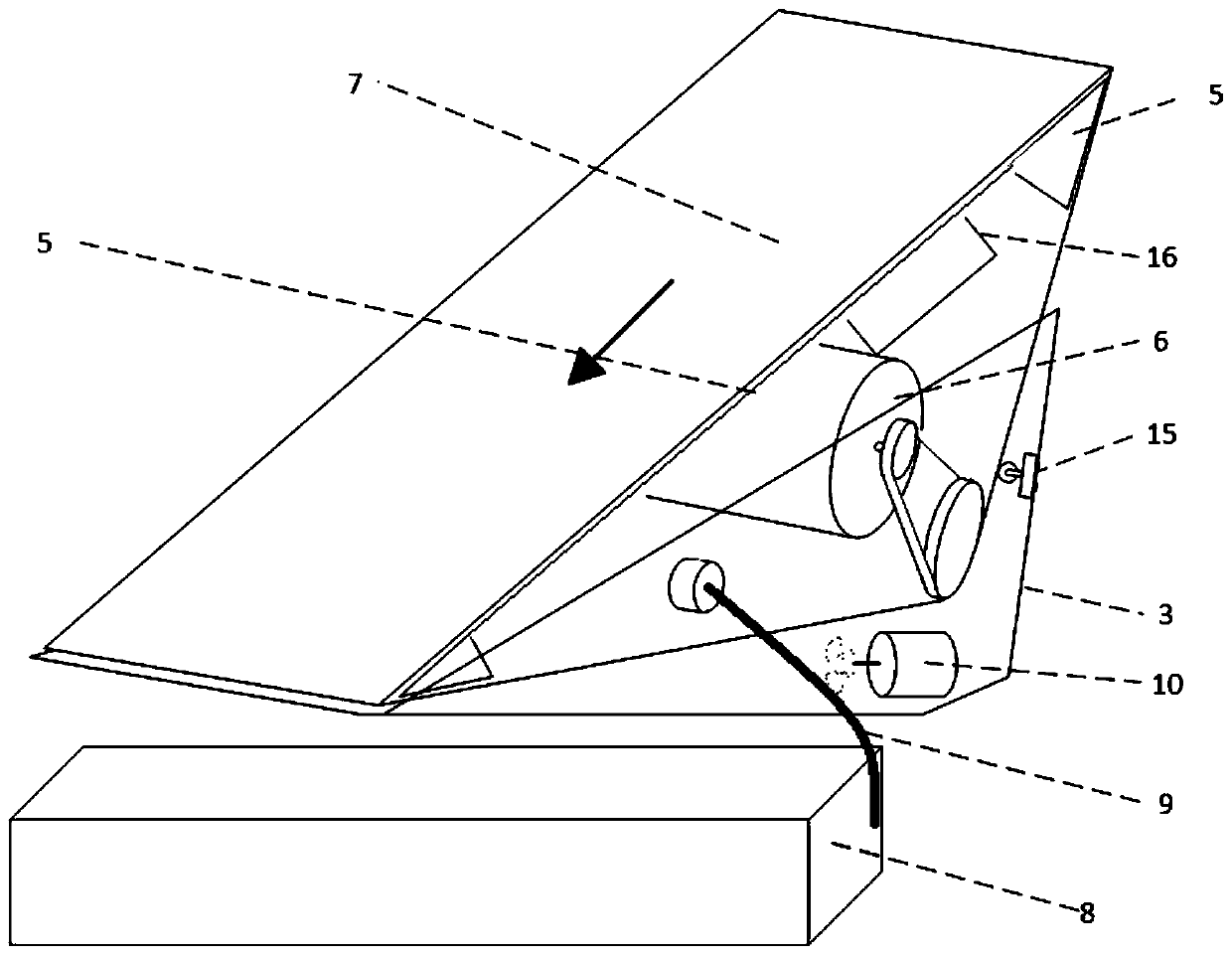

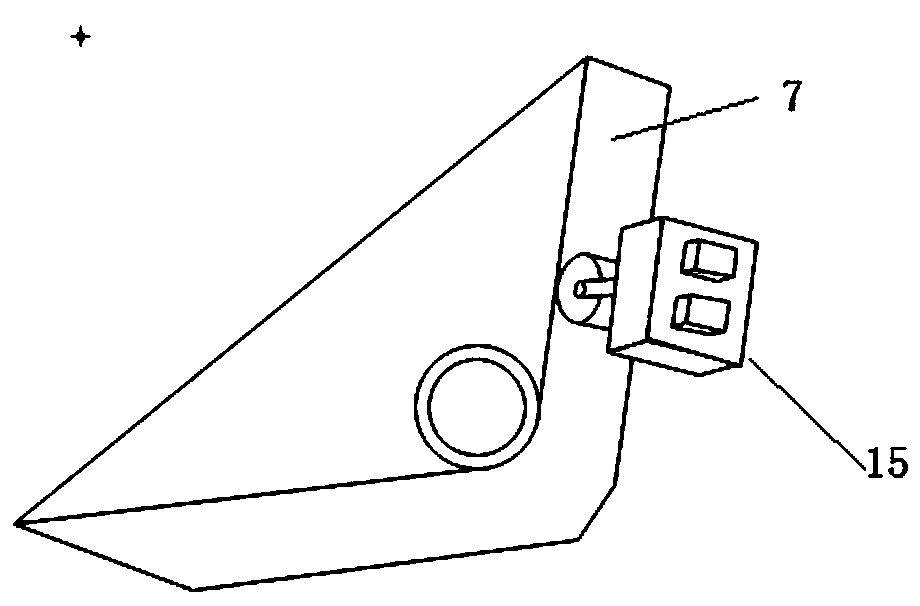

Keyway machining device for rudder hole of rudder

ActiveCN108890323AAchieve rotationRealize cuttingLarge fixed membersMilling equipment detailsMilling cutterEngineering

A keyway machining device for a rudder hole of a rudder comprises an upper rail, a lower rail, a screw and a polish rod. The screw and the polish rod are connected by a reduction gearbox, and a movable frame is fitted between the upper rail and the lower rail to form a relative sliding structure. A spindle and a counter shaft are installed in the movable frame, the spindle and the screw form a worm and gear structure, the polish rod transmits the rotation to the counter shaft through a space train to achieve the rotation of a milling cutter mounted on the shaft end of the counter shaft, and the milling cutter moves with the movable frame and rotates at high speed to complete keyway machining at the same time. The device is compact in structure and reasonable in design. After the device isfixed, a motor outputs the power, the screw drives the movable frame to move to achieve feeding of the milling cutter, and the polish rod transmits the rotation to the counter shaft to achieve the rotation of the milling cutter. By means of the superposition of the movement and the rotation of the milling cutter, a keyway can be machined in the rudder hole.

Owner:浙江东鹏船舶修造有限公司

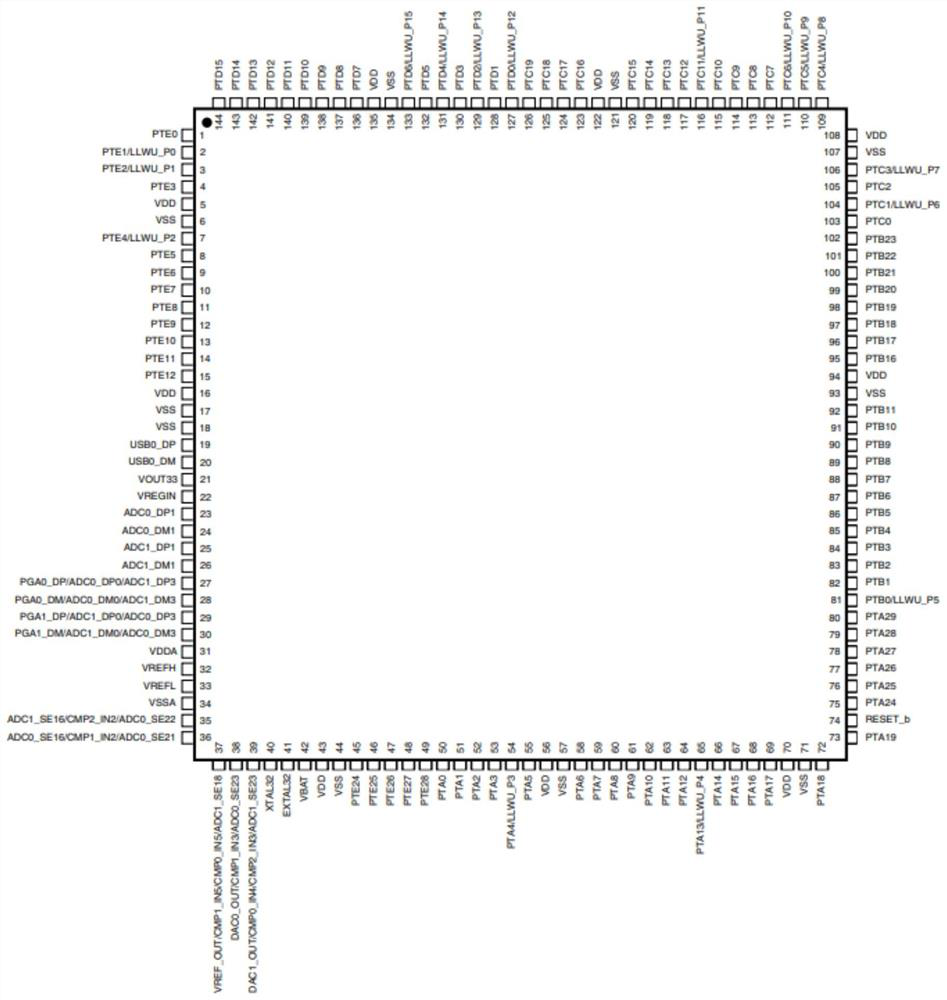

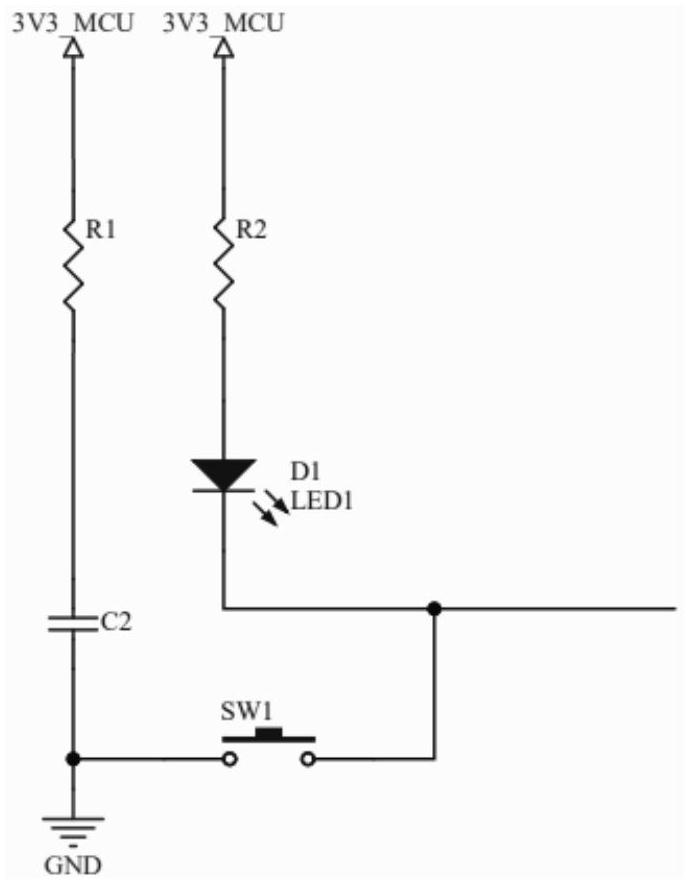

Medical portable ultrasonic scalpel, control system and use method

PendingCN113288344AEliminate capacitive componentsAchieving a state of resonanceSurgeryMicrocontrollerDC - Direct current

The invention discloses a medical portable ultrasonic scalpel and a use method, belongs to the technical field of ultrasonic scalpels, and aims to solve the problems that an existing ultrasonic scalpel is low in integration level, cannot be in a resonance state and cannot feed back frequency in time. The medical portable ultrasonic scalpel is composed of an ultrasonic transducer, an impedance matching module, a microcontroller, a signal generation module, a photoelectric isolation module, a power amplification module, a phase-locked loop circuit, a voltage and current sampling feedback circuit, a direct-current voltage conversion module, a direct-current booster circuit, a man-machine interaction module and a charging module. The whole impedance matching network circuit is in a pure impedance state, current and voltage sampling information is fed back to the processor in combination with the ultrasonic transducer, the scalpel is kept in a resonance state, the ultrasonic scalpel adopts modular design, and therefore the scalpel body, the scalpel head, the transducer and the battery are of a separable structure and can be rapidly assembled and disassembled when needed, and medical staff can conveniently store and carry the device.

Owner:中国人民解放军联勤保障部队第九六二医院 +2

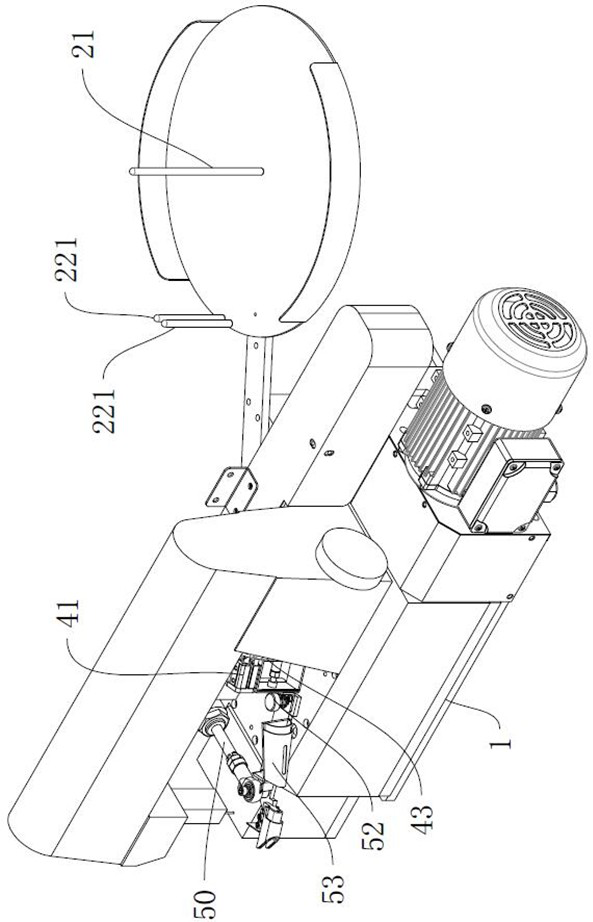

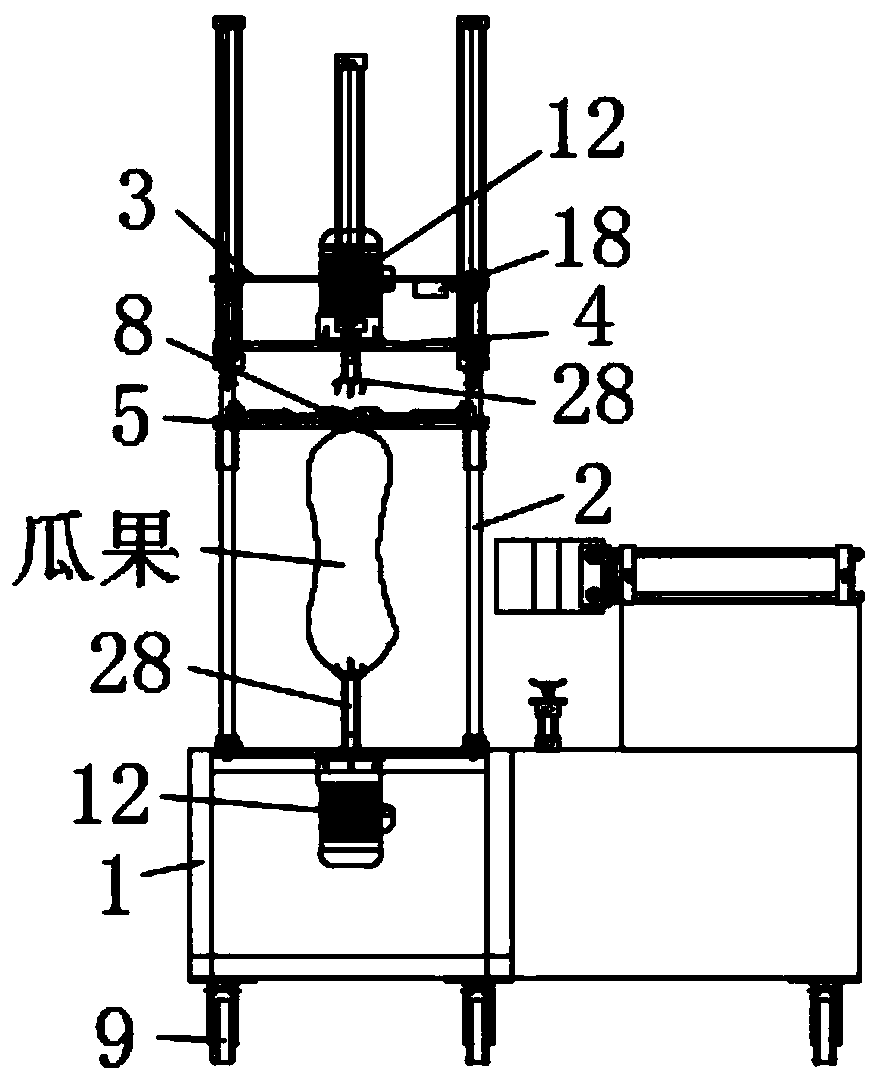

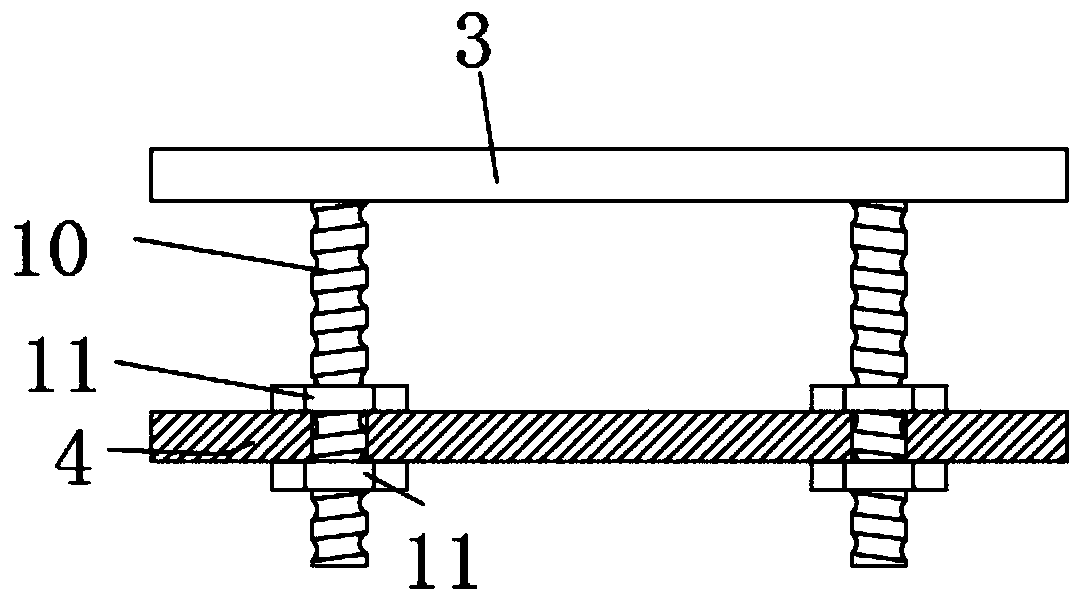

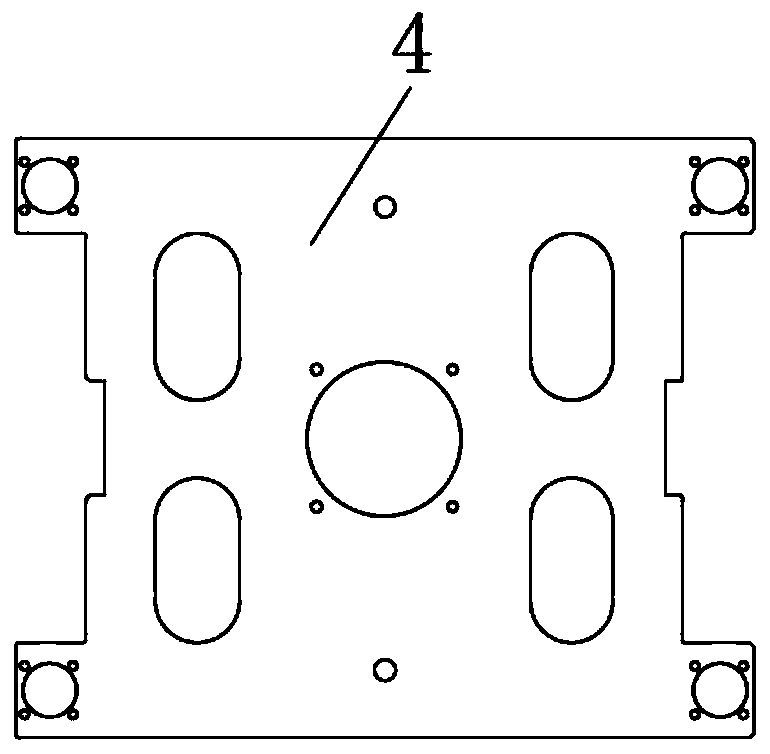

Linear moving type melon and fruit peeler

PendingCN111513535AAchieve rotationAchieve clampingPeelersAgricultural engineeringStructural engineering

The invention discloses a linear moving type melon and fruit peeler which comprises a rack, a connecting rod is vertically and fixedly connected to the top end face of the rack in an upward mode, a transverse plate is fixedly connected to the connecting rod, and the linear moving type melon and fruit peeler further comprises a driving assembly and a peeling assembly. The driving assembly comprisesa moving plate adjustably connected to the lower portion of the transverse plate, and clamping jaws are rotationally connected to the opposite side walls of the moving plate and the rack; the peelingassembly comprises a movable plate which moves up and down along the connecting rod; a driving device for driving the movable plate is fixedly connected to the transverse plate; a through hole for melon and fruit to penetrate through is formed in the movable plate, a movable rod is rotatably connected to the movable plate, the middle of the movable rod is elastically connected with the movable plate, and a peeling knife is fixedly connected to the end, located in the through hole, of the movable rod, so that melon and fruit peels are cut, and convenience is brought to workers.

Owner:颍上县捷科机电设备商贸有限公司

Human-driven single-knife cutting wire stripping device

ActiveCN111431102BRealize cuttingPeel off effortBasic electric elementsApparatus for removing/armouring cablesStructural engineeringKnife blades

The invention relates to a human-driven single-knife cutting type wire stripping device, which includes a cutting knife assembly and a support table with a "V"-shaped centering straight groove, and the inclination angles of the two side walls of the centering groove are equal. , the cutting knife assembly includes a circular cutting blade, a fixed plate, a movable plate, a blade mounting rod and a blade pressing spring that drives the movable plate to abut against the fixed plate, and one end of the blade mounting rod is connected with the movable plate. The shape cutting blade is connected to the other end of the blade installation rod, the movable plate and the circular cutting blade are distributed on both sides of the fixed plate, the fixed plate is connected to the support table through a stand, and the circular cutting blade is located above the centering straight groove , the intersection line of the two planes where the two side walls of the centering straight groove is located is located on the plane where the circular cutting blade is located. The invention provides a human-driven single-knife cutting type wire stripping device with good protection effect on the blade, which solves the laborious problem of manually cutting the wire insulating sleeve with a knife.

Owner:ANHUI XINDALU SPECIAL PAINT CO LTD

A folding machine and uv printing system

ActiveCN111516380BRealize cuttingMeet the process requirementsFolding thin materialsRotary pressesPaper tapeIndustrial engineering

The invention relates to the field of printing equipment, in particular to a folding machine and a UV printing system. The folding machine includes a head registration unit, a triangle plate for first longitudinal folding of a paper tape, and relatively rotating guide rollers, cutting Cutting cylinder, folding needle cylinder and page storage cylinder; UV printing system includes web feeding device, tension control device, printing tower, UV drying device and the above-mentioned folding machine arranged in sequence; said printing tower includes along There are at least two printing units arranged vertically, the UV drying device is arranged on the top of the printing tower, and the UV drying device includes two sets of UV dryers arranged vertically with the paper tape. The present invention adopts a rotary folding machine and a reel paper tape, and sets a complete set of processes of paper feeding, printing, drying, and folding in a set of equipment, and sets a UV drying device on the top of a printing tower to fully clean the paper ink. Dry, and does not require additional cooling and humidification devices.

Owner:青岛桑纳电气有限公司

Cable sheath removal method

ActiveCN111262193BRealize cuttingReduce effortApparatus for removing/armouring cablesEngineeringStructural engineering

Owner:ZHEJIANG DAYOU IND CO LTD HANGZHOU SCI TECH DEV BRANCH CO

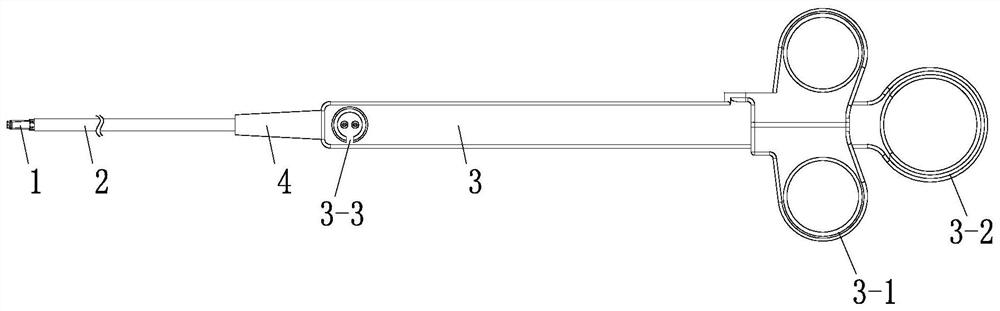

Ultrasonic knife for flexible endoscope

PendingCN112603468ARealize cuttingMeet device size requirementsSurgeryFlexible endoscopeEndoscopic surgery

The invention discloses an ultrasonic knife for a flexible endoscope. The ultrasonic knife comprises a handle part, a protective sleeve and an ultrasonic knife head end; the front end of the handle part is connected with the tail end of the protective sleeve; the front end of the protective sleeve is connected with the ultrasonic knife head end; the ultrasonic knife head end comprises a knife head and a clamp head piece; a transducer is arranged in an inner cavity of the knife head; the knife head is fixedly connected with the transducer through a knife head connecting rod; the transducer is movably arranged in a transducer bridge frame; the transducer bridge frame is fixedly connected with the front end of the protective sleeve through a transducer bridge frame fixing device and a fixing bridge frame; and the transducer can drive the knife head to reciprocate relative to the fixing bridge frame. According to the ultrasonic knife, hard components are all concentrated at the head end of the ultrasonic knife, so that the ultrasonic knife of an ultra-short tip hard part structure is formed, the ultrasonic knife can be applied to a minimally invasive digestive endoscopic surgery guided by the flexible endoscope, and achieves tissue cutting and coagulation.

Owner:刘奇为

Push type wire stripping method

InactiveCN112582946ARealize cuttingPeel off effortBasic electric elementsApparatus for removing/armouring cablesStructural engineeringKnife blades

The invention relates to a push type wire stripping method. The method comprises the steps of manufacturing a supporting table top and a sectioning knife assembly, arranging a centering straight groove on the supporting table top, wherein the sectioning knife assembly comprises a circular cutting blade, a fixed plate, a movable plate, a blade mounting rod and a blade pressing spring,connecting thecircular blade together with the movable plate through the blade mounting rod; inserting an electric wire manually into the centering groove along the extending direction of the centering straight groove and moving, and when the electric wire passes through the circular cutter blade, cutting out an electric wire cutting gap extending along the axial direction of the electric wire from an electricwire insulation sleeve; and then rolling the electric wire 180 degrees in the circumferential direction, passing the electric wire through the centering straight groove again and cutting by the circular cutting blade again to form a cutting gap, wherein the two electric wire cutting gaps cut from the two sides are evenly distributed along the circumferential direction of the guide. The push typewire stripping method has the advantage of being good in blade protection effect, and the problem that labor is wasted when the knife is manually used for cutting the electric wire insulation sleeve,is solved.

Owner:江山市发发科技有限公司

A vegetable cutting device

InactiveCN102896655BEasy to replaceRealize cuttingMetal working apparatusEngineeringMechanical engineering

The invention relates to a vegetable cutting device which comprises an outer barrel and a cutter barrel. The cutter barrel is arranged inside the outer barrel and can rotate, the outer barrel further comprises a rear plate and a feeding port, wherein the rear plate is used for closing one end of the outer barrel, a rotation shaft support hole is arranged on the rear plate, and the feeding port is arranged at the upper end of a barrel wall of the outer barrel and used for enabling put vegetables to be contacted with the cutter barrel. The cutter barrel further comprises a support plate, a rotation shaft and a plurality of blades, wherein the support plate is used for closing one end of the cutter barrel, a rotation shaft fixing hole is arranged in the center of the support plate, the rotation shaft is arranged along an axis of the cutter barrel, the rotation shaft is fixedly connected with the cutter barrel through the rotation shaft fixing hole, one end of the rotation shaft penetrates through the rotation shaft support hole of the rear plate to extend to the outer portion of the rear plate, a rotation handle is installed on the rotation shaft outside the rear plate, and the blades comprise transverse blades and longitudinal blades which are fixedly installed on the outer barrel wall of the cutter barrel. A problem that vegetables such as potatoes are irregular in shred or slice and vegetable cutting is not safe is solved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Reel tower type uv printing system

ActiveCN111516379BShorten the pathImprove printing efficiencyFolding thin materialsRotary pressesPaper tapeIndustrial engineering

Owner:青岛桑纳电气有限公司

Sideband cutting structure and sideband surrounding machine and sideband surrounding method including the same

ActiveCN112501797BImpact deliveryAvoid the phenomenon of threadingWorkpiece carriersMattress sewingEngineeringHot melt

The invention discloses a sideband cutting structure, a sideband wrapping machine including the structure and a sideband wrapping method. The structure includes a frame, a sideband feeding mechanism, a heating device, and a fixing mechanism. The sideband feeding mechanism is arranged on On the frame, the sideband feeding mechanism is used to place the sideband; the heating device is arranged on the frame, and the heating device is used to heat the sideband so that the sideband is heated and melted to form a The sag of broken material; the fixing mechanism is arranged on the frame, and the fixing mechanism is used for clamping the sideband. The fence machine contains the structure. The invention provides a structure for conveniently cutting the edge band, an edge wrapping machine and a method.

Owner:佛山市众联机械科技有限公司

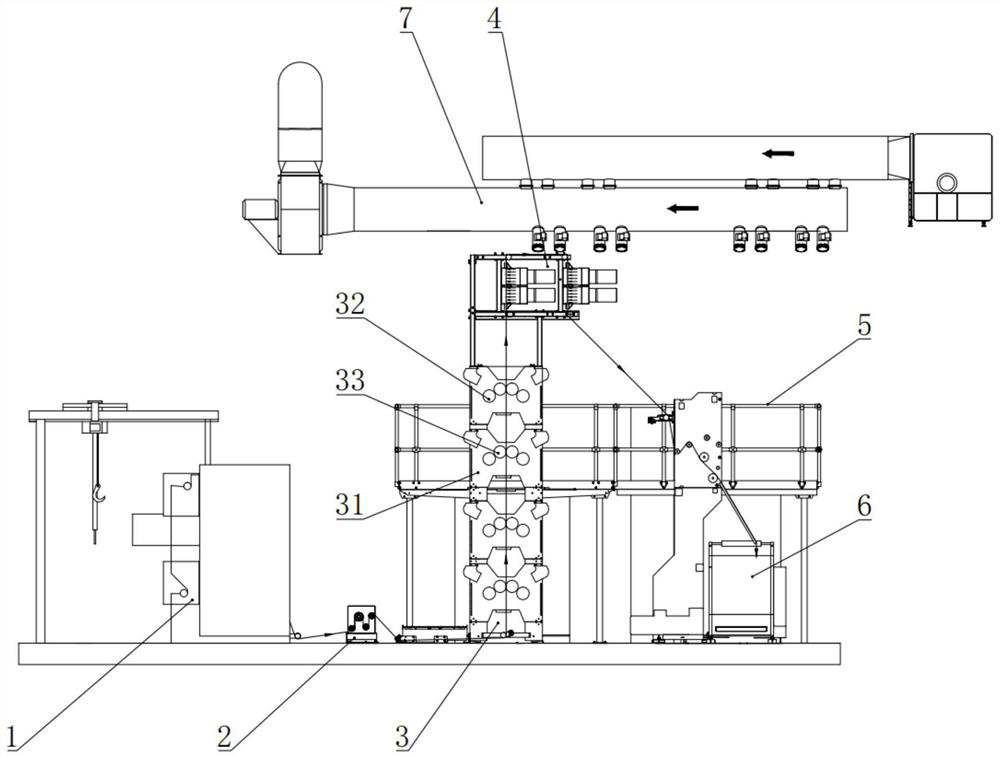

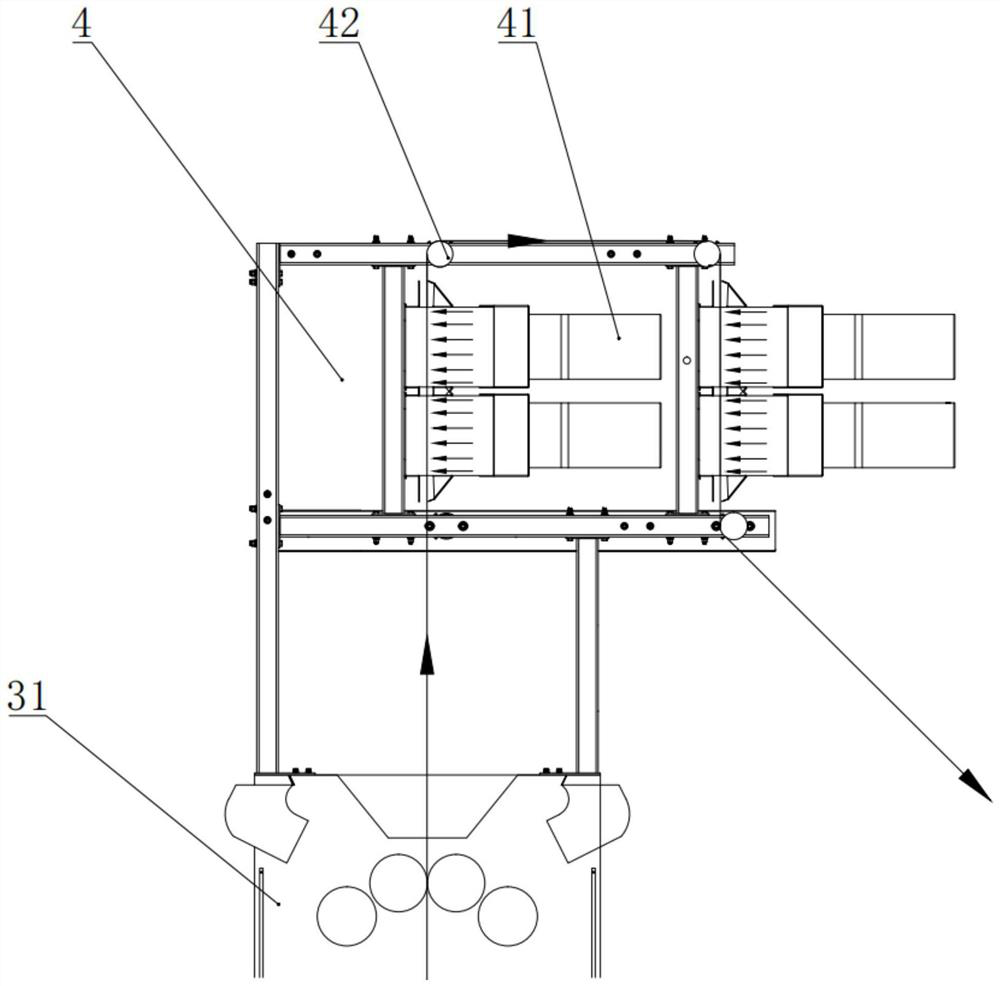

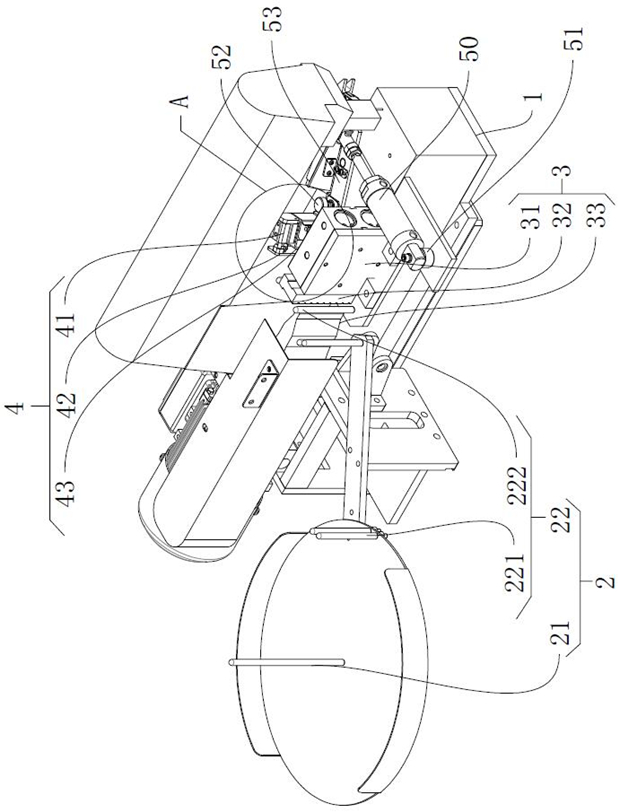

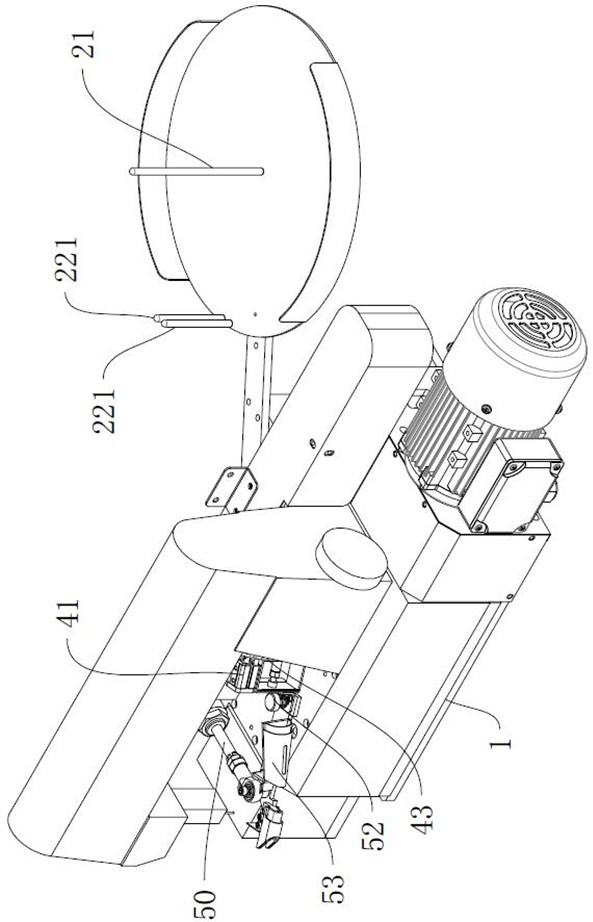

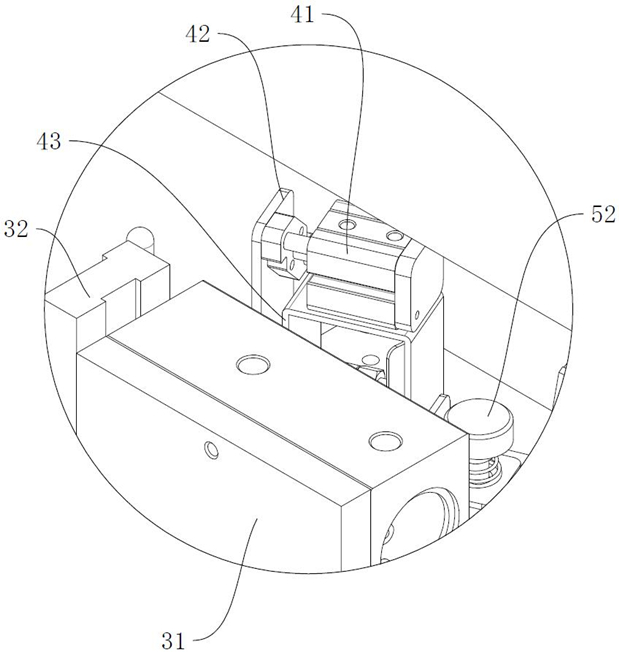

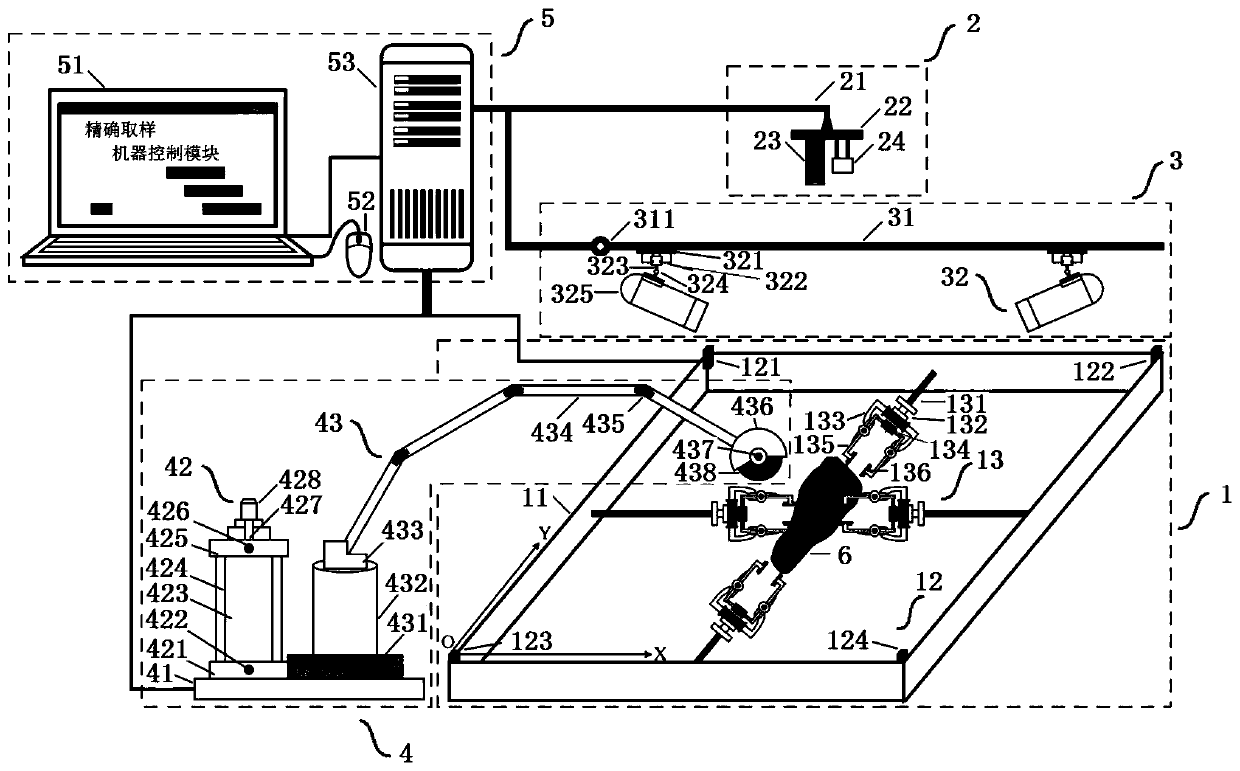

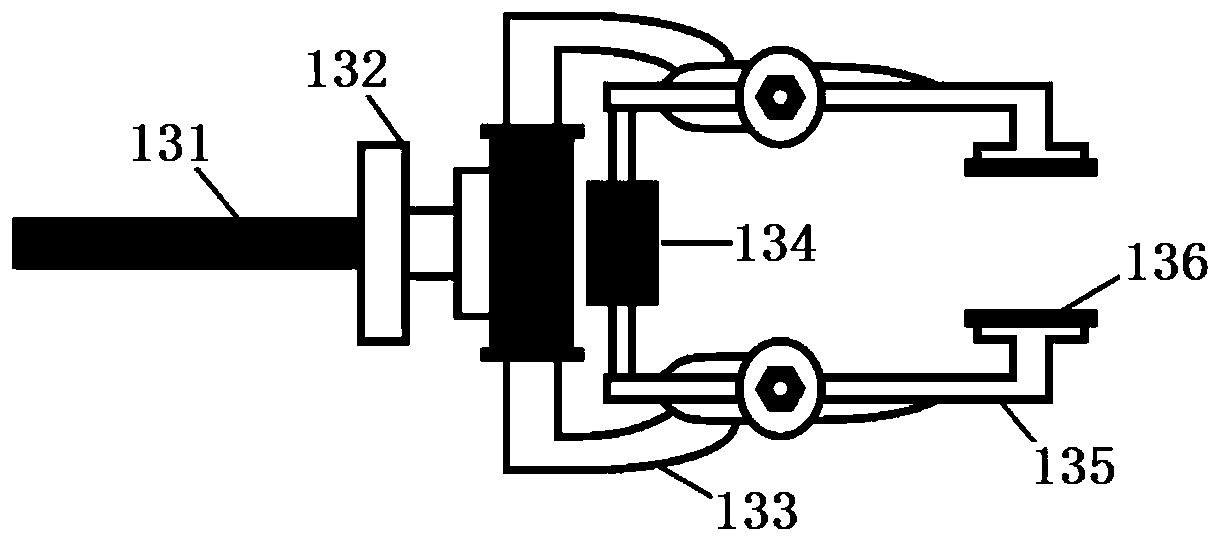

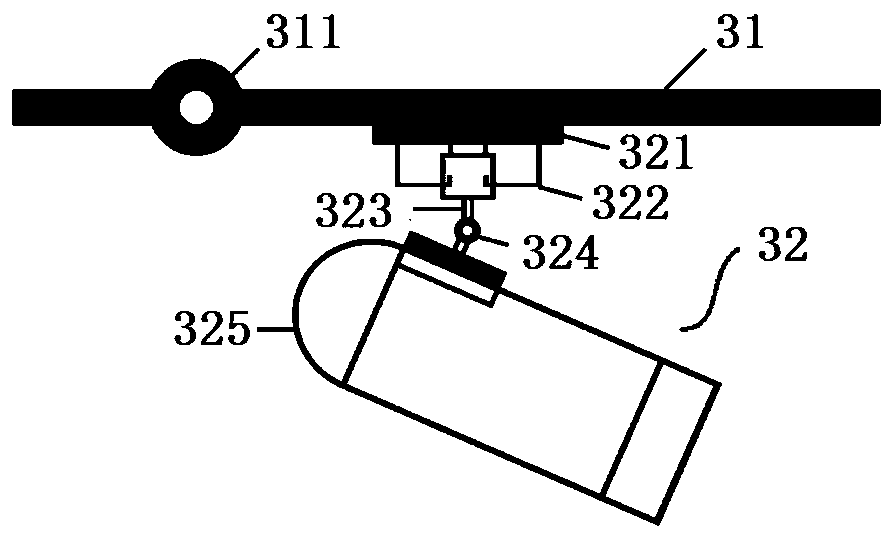

A device and method for accurate classification and sampling of laminar structures in continental tight reservoirs

ActiveCN109765090BImprove cutting accuracyImprove cutting and collection efficiencyPreparing sample for investigationRobot handControl system

The invention relates to a precise classifying and sampling device and device of a continental tight reservoir lamina structure. The device comprises a cutting pedestal system, a laser positioning system, a picture pick-up system, a mechanical arm system and a master control system; the cutting pedestal system is used for clamping a rock sample and providing a cutting sampling space for the rock sample; the laser positioning system is used for sending a laser signal to the cutting pedestal system, establishing a work space plane coordinate system by combining the cutting pedestal system, and positioning the rock sample; the picture pick-up system is used for monitoring a complete image of the working space system and sending the monitored image to the master control system; the master control system sends a sample cutting instruction to the mechanical arm system according to the established working space plane coordinate system, the coordinate value data of the rock sample and the complete image of the working space system; and the mechanical arm is used for cutting and sampling the tight reservoir rock sample. The device disclosed by the invention can be extensively applied to theclassifying and sampling field of the tight reservoir rock.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

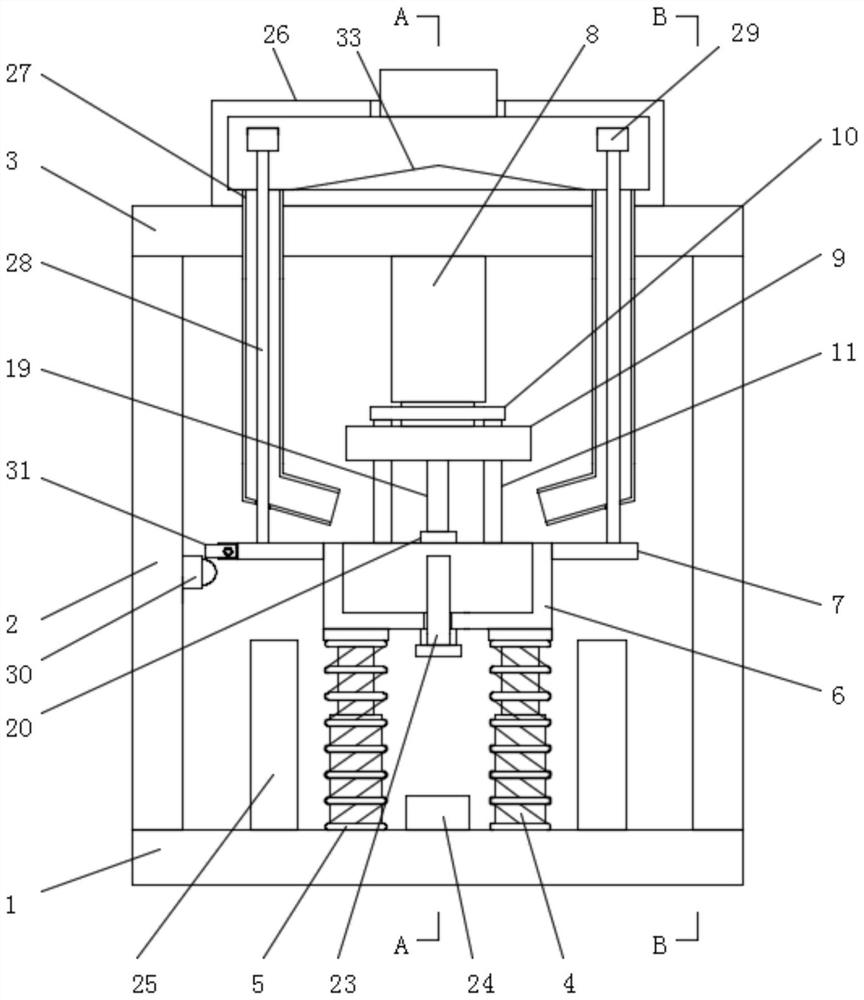

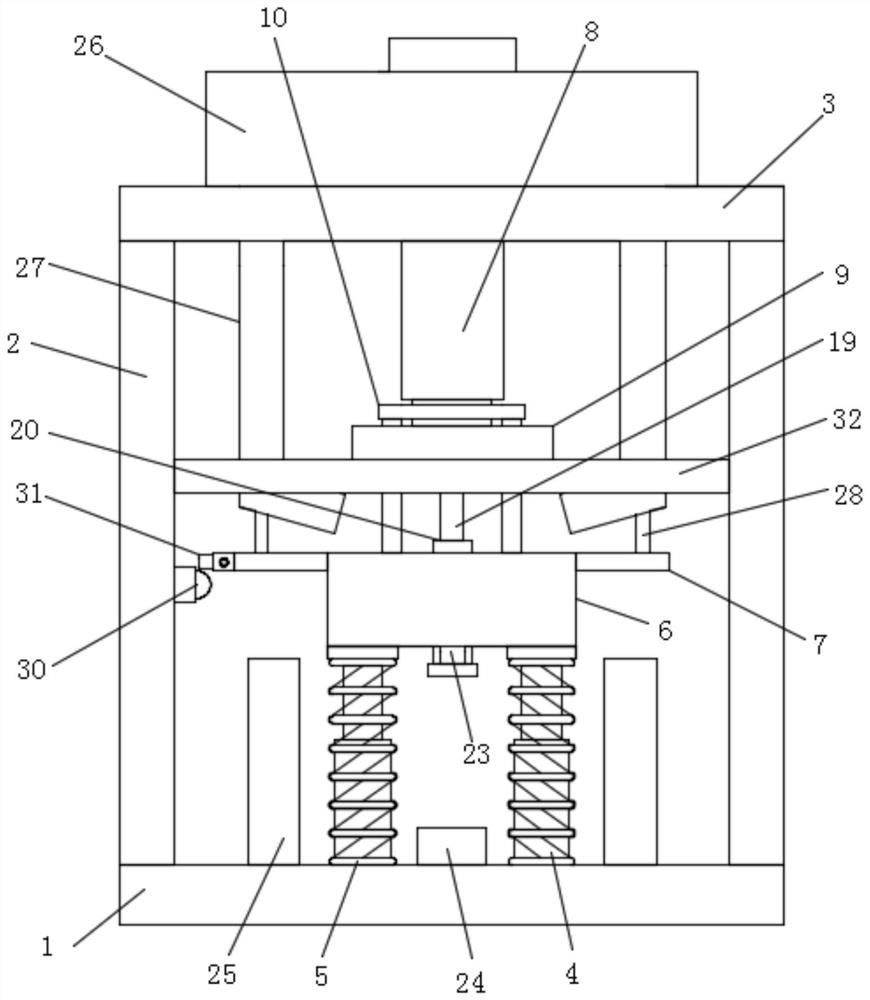

Powder metallurgy blank pressing device with automatic feeding structure

ActiveCN112893835ARealize automatic feeding processRealize cuttingEdge grinding machinesIncreasing energy efficiencyStructural engineeringMechanical engineering

The invention relates to the technical field of blank pressing devices, in particular to a powder metallurgy blank pressing device with an automatic feeding structure. The powder metallurgy blank pressing device comprises a bottom plate, wherein side plates are fixedly mounted on the left side and the right side of the top end of the bottom plate respectively, a top plate is fixedly mounted at the top ends of the two side plates jointly, a pair of telescopic rods are fixedly installed on the left side and the right side of the top end of the bottom plate respectively, the telescopic rods are sleeved with first springs, a mold is fixedly installed at the top ends of the four telescopic rods jointly, and connecting plates are fixedly installed on the upper portions of the left side and the right side of the mold respectively. The powder metallurgy blank pressing device can implement automatic feeding and stop feeding in the mold, manual feeding is not needed, time and labor are saved, a formed part can be automatically ejected out so that the formed part can be conveniently taken out, meanwhile, a switch can be touched to start a grinding mechanism during ejection so that burrs on the surface of the formed part can be ground, the quality of the formed part can be improved after the burrs are removed, and the device is worthy of application and popularization.

Owner:嘉兴市长宏铜业股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com