A folding machine and uv printing system

A printing system and folding machine technology, applied in printing, printing presses, rotary printing presses, etc., can solve the problems of inability to improve printing efficiency, sticky and dirty images of printed products, and inability to meet printing speed, etc., and shorten the paper path. , Wide range of application, easy to install and operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

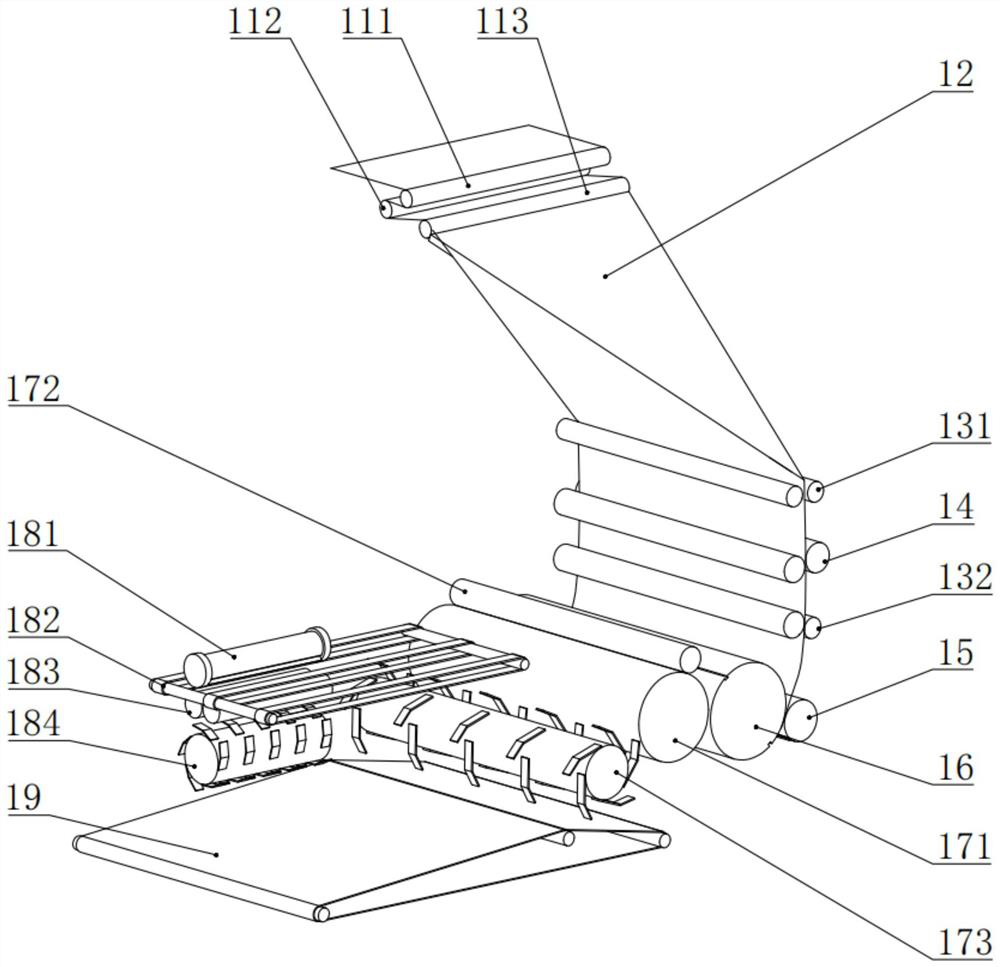

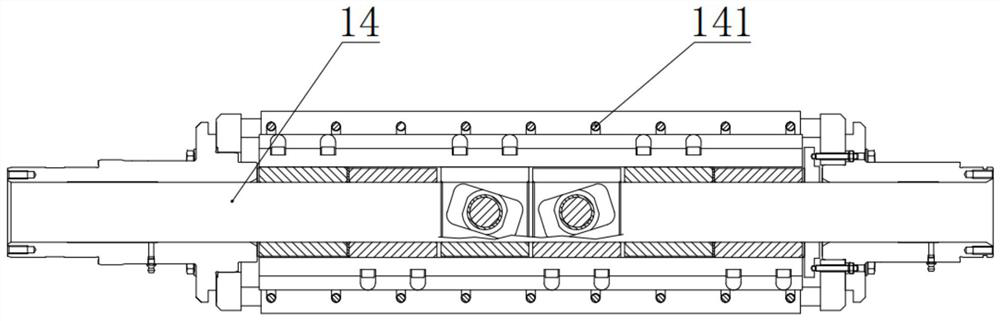

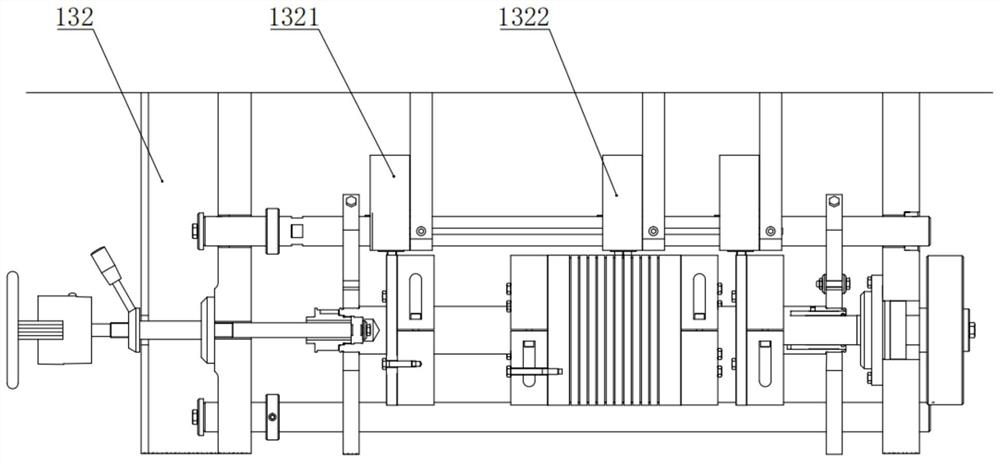

[0036] like Figure 1 to Figure 9As shown, the folding machine 1 includes a head registration unit, a triangular plate 12 for first longitudinal folding of the paper tape, a guide roller, a cutting cylinder 15, a folding needle cylinder 16, and a storage cylinder 171, and the adjacent guide rollers And the rollers rotate in pairs. The head registration unit includes a first fixed guide roller 111, a moving guide roller 112 and a second fixed guide roller 113, and the moving guide roller 112 is used to adjust the cutting position of the paper tape and keep the paper tape in a proper tension state , the second fixed guide roller 113 is arranged parallel to the top of the triangular plate 12, the paper tape passes through the triangular plate 12 to complete the first longitudinal fold, and the guide roller is used to adjust the tension of the paper tape. The guide rollers are arranged perpendicularly to the second fixed guide roller 113 in the horizontal direction, including two...

Embodiment 2

[0042] The difference between this embodiment and embodiment 1 is that, as Figure 13 As shown, there are at least two printing towers 4 in the UV printing system, which are matched with one folding machine 1 through multiple sets of sky head registration units above the folding machine 1, so as to meet the needs of various printed products and reduce the Small footprint and amount of equipment used.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com