Hydraulically Driven Machine Improvement

a technology of hydraulic drive and machine drive, which is applied in the direction of reciprocating piston engines, flexible wall reciprocating engines, positive displacement liquid engines, etc., can solve the problems of frictional wear of displacement organs and the inability of the drive of the machine to be properly isolated from the pumped material, so as to achieve less complicated and reliable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

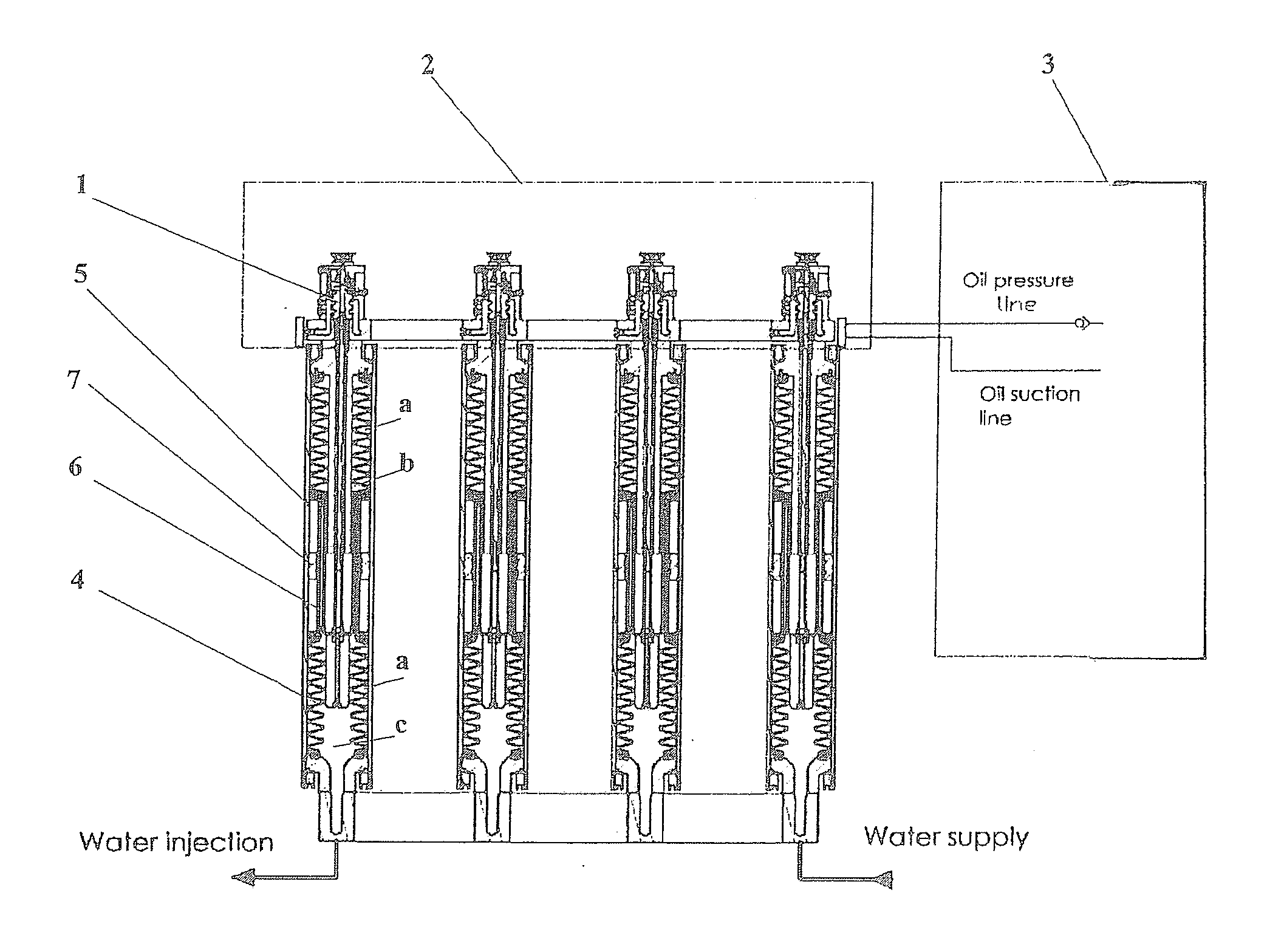

[0023]The principal improvement of the invention relates to a plunger device to provide fluids separation and, as a subsidiary aspect to a hydromechanical switch, it being understood that these two aspects can be incorporated individually or together in a hydraulically driven pumping machine.

Plunger Separating Fluids

[0024]The hydraulically driven pumping machine shown in FIG. 1 comprises one or several cylinders 5, a switching control system 1 and a hydraulic drive unit 3. The machine is normally a multicylinder machine and such basic hydraulic multicylinder machine is described in detail in PCT patent application WO 2005 / 119063.

[0025]To enhance the life of the bellows-like diaphragms, namely to eliminate their radial deformation under pressure differentials arising between internal and external bellows cavities, the basic machine described in WO 2005 / 119063 was improved in the following way.

[0026]The pump's cylinder 5 contains two bellows 4 and 10 (see FIG. 2) mechanically connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com