Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Reduce manual adjustment time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

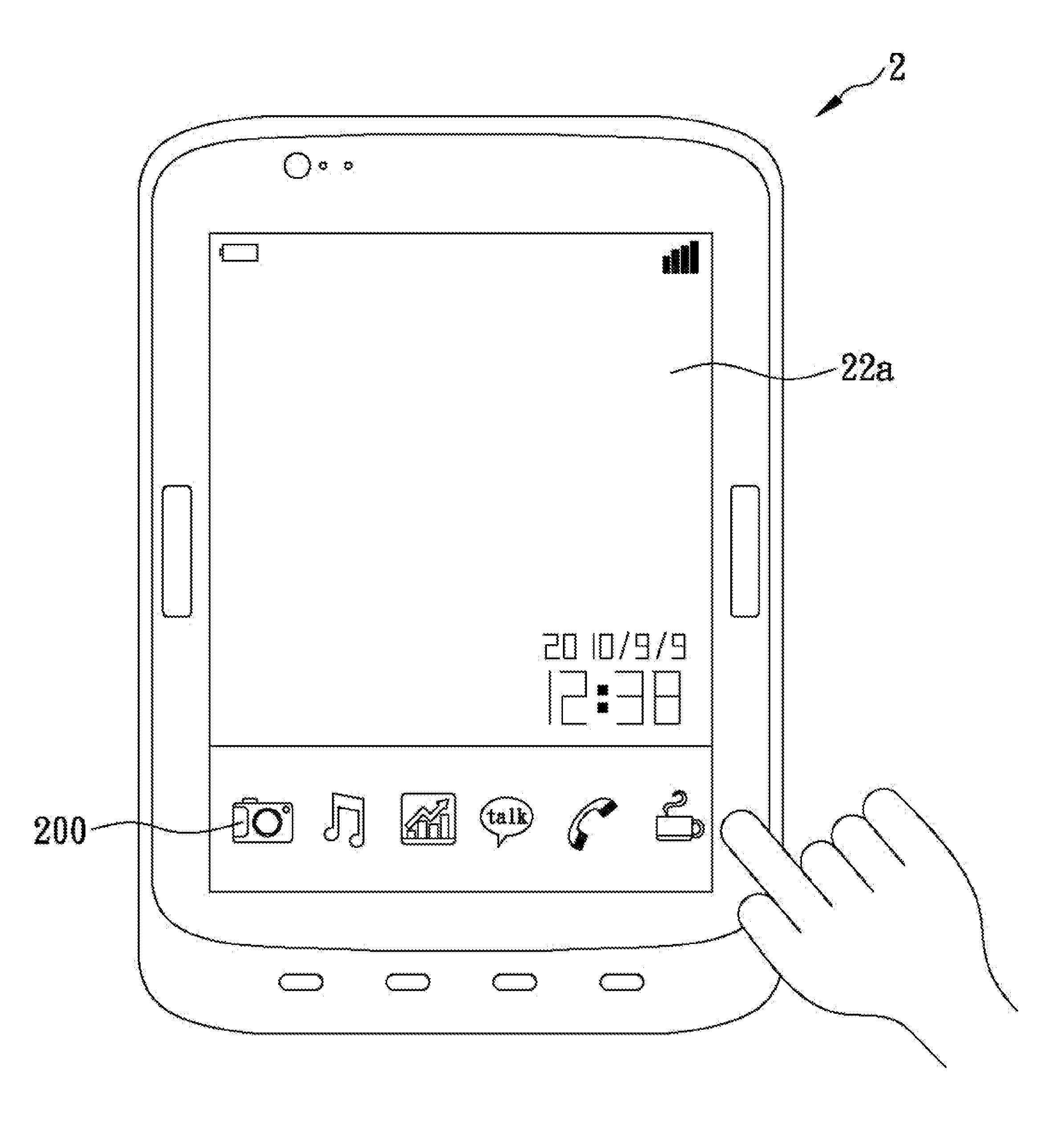

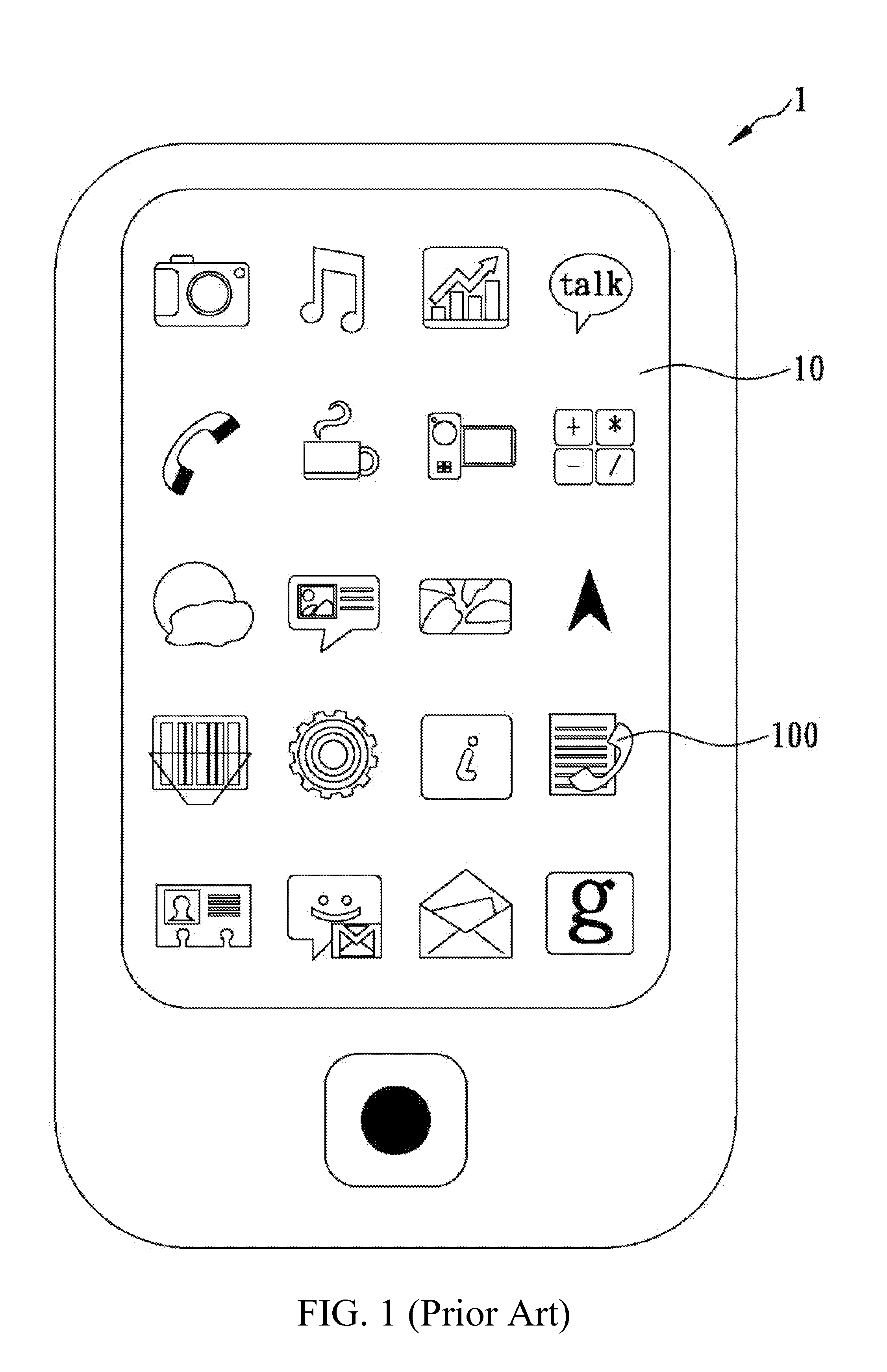

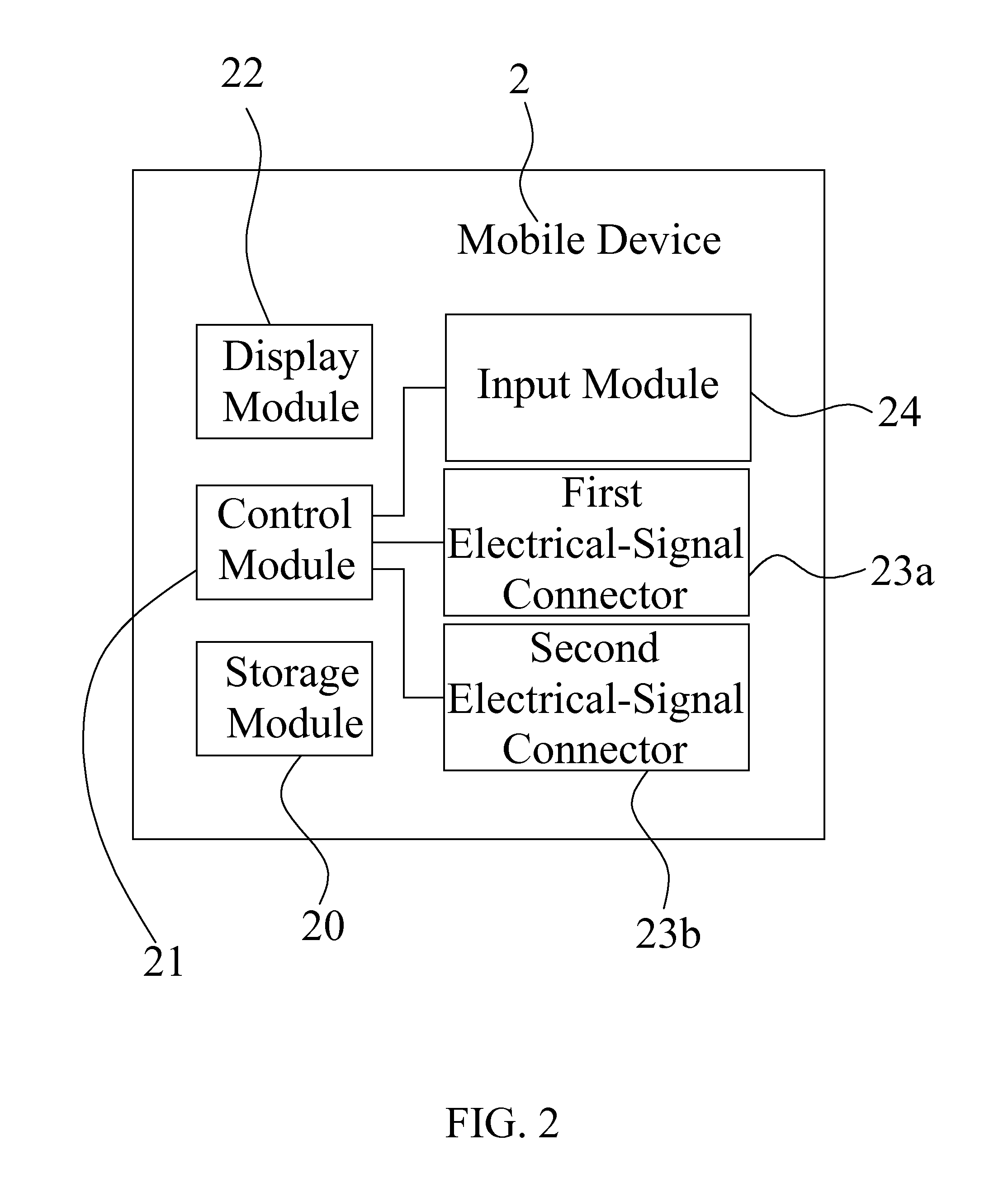

Mobile device capable of automatically switching its operation modes

InactiveUS20120165071A1Save user timeImprove convenienceDigital data processing detailsSubstation equipmentOperation modeElectrical connector

A mobile device capable of automatically switching its operation modes includes a storage module, a control module, a display module and an electrical connector. The storage module is configured to store data of icons controllable to execute an application or function. The control module is configured to direct the data of at least one icon from the storage module to be transmitted to the display module for displaying the icon on a screen. When the control module detects that the electrical connector is electrically coupled to an electronic device, the control module is configured to adjust configuration of the at least one icon, with the adjusted configuration to be automatically displayed on the screen to mark a new operation mode of the mobile device. The configuration of the icon may be adjusted in size, one or more pixels, position, or quantity of the icon.

Owner:YINGHUADA (SHANGHAI) ELECTRONIC CO LTD +1

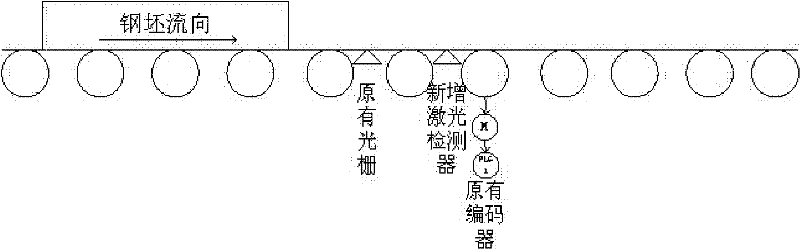

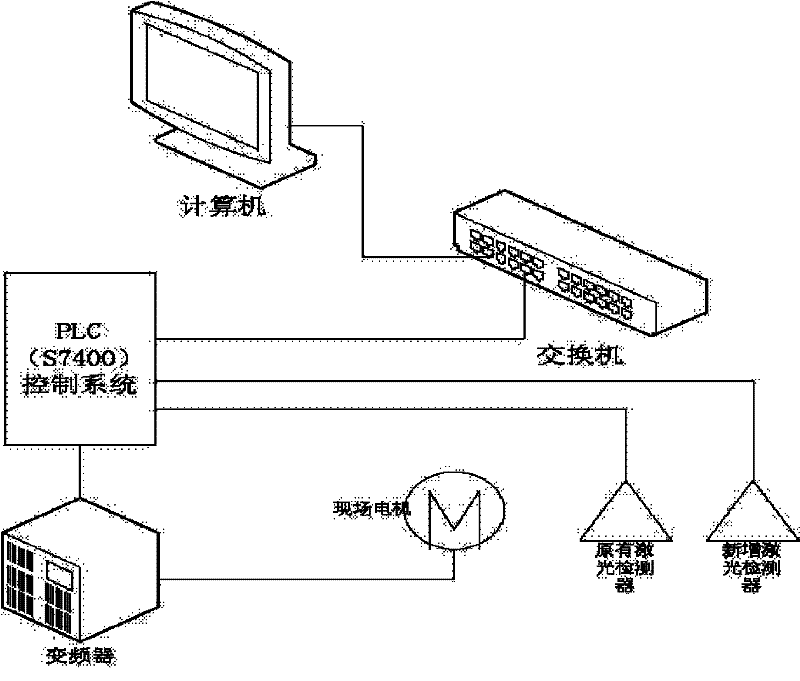

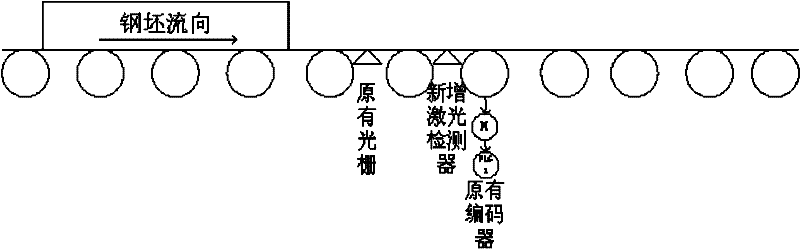

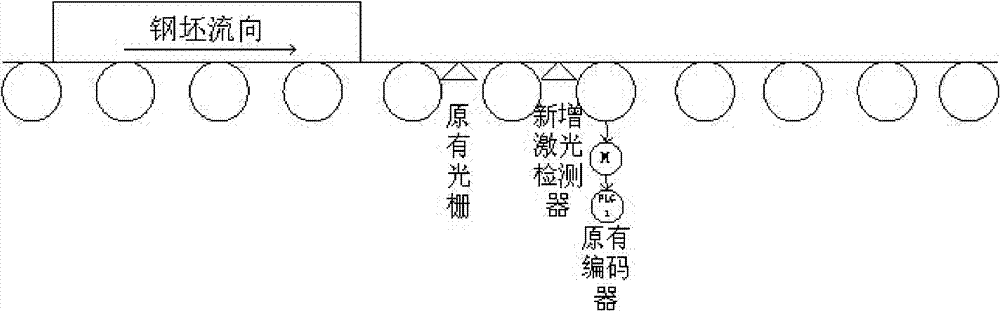

Method for realizing accurate positioning of steel billet delivered into a heating furnace

ActiveCN102230067AHigh precisionImprove stabilityFurnace typesUsing optical meansHeating furnaceMaterials science

The invention relates to the technical field of heating furnace automatic controlling, and discloses a method for realizing accurate positioning of a steel billet delivered into a heating furnace. According to the invention, logic of automatic controlling is skillfully combined with the function of a furnace roller table converter. Without external braking equipment, slipping phenomena occurred after positioning of steel billets with lengths smaller than 2700mm are avoided. With the method, accurate positioning of any sized steel billet can be realized, and slipping does not occur after positioning.

Owner:BEIJING SHOUGANG AUTOMATION INFORMATION TECH

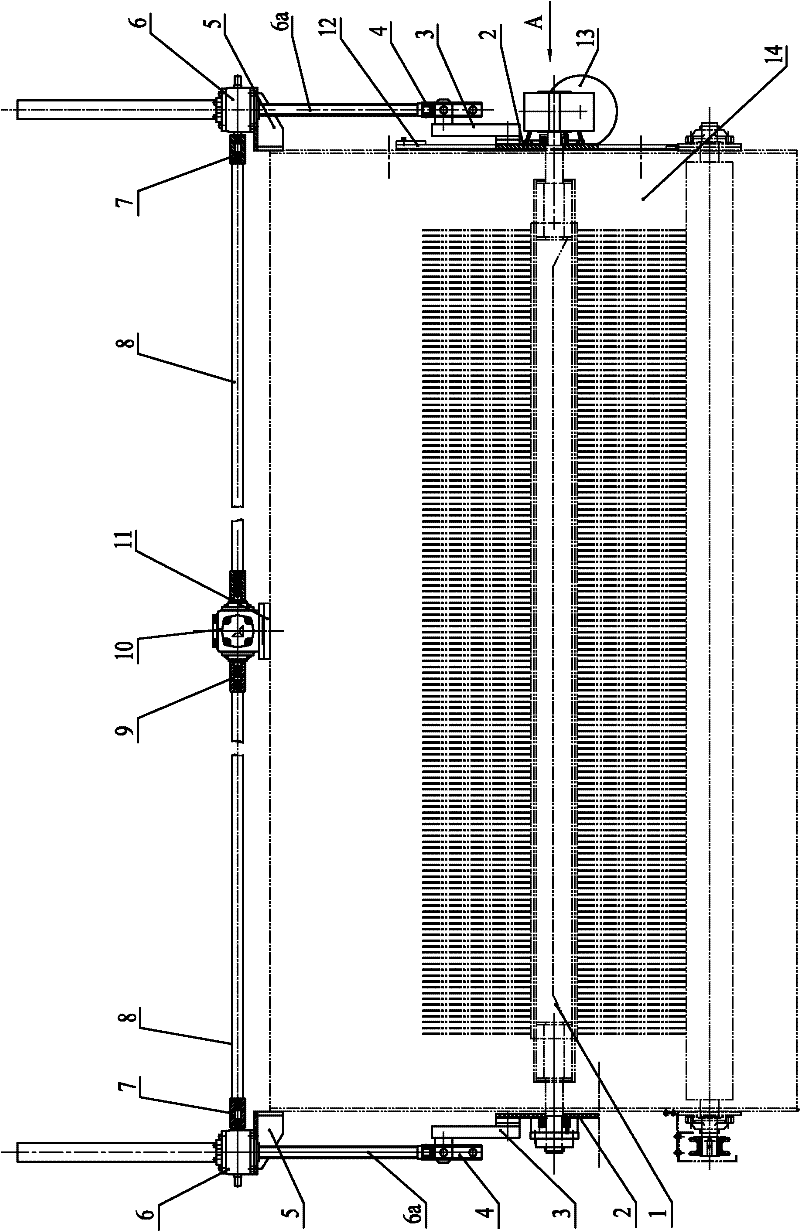

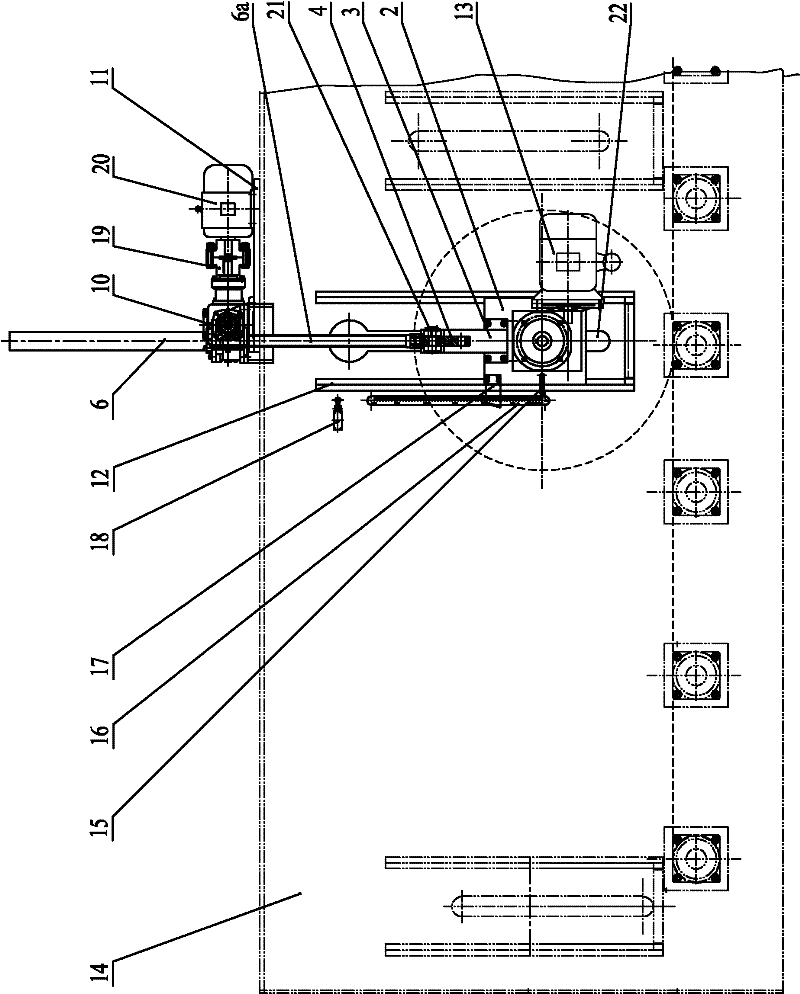

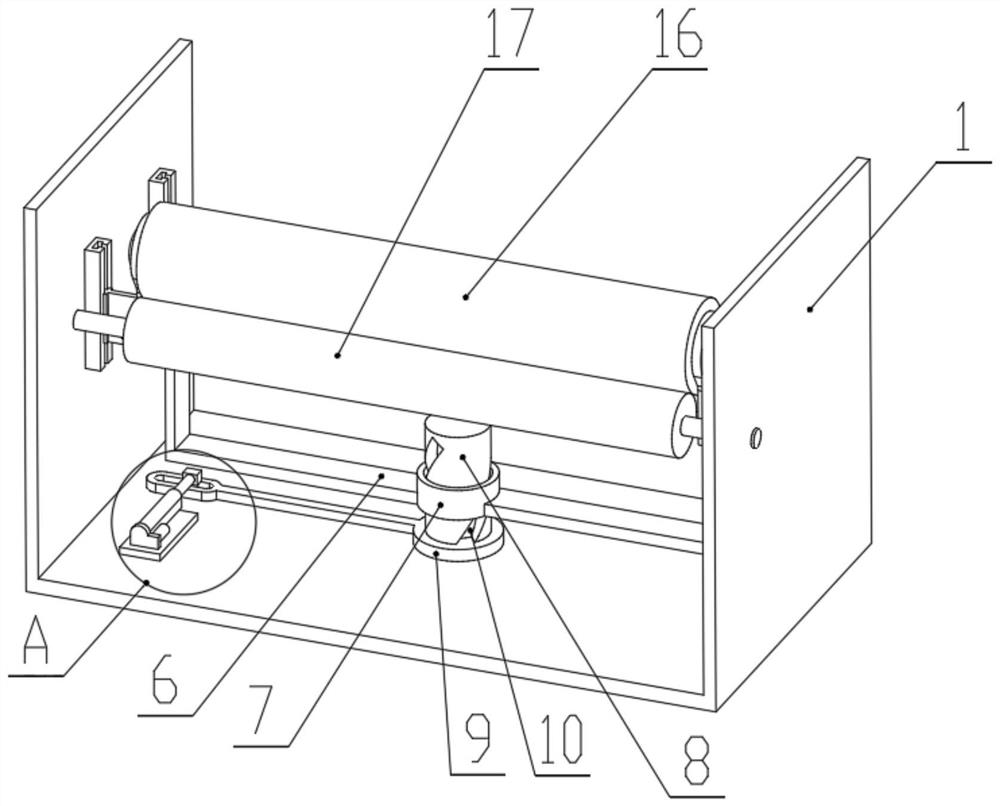

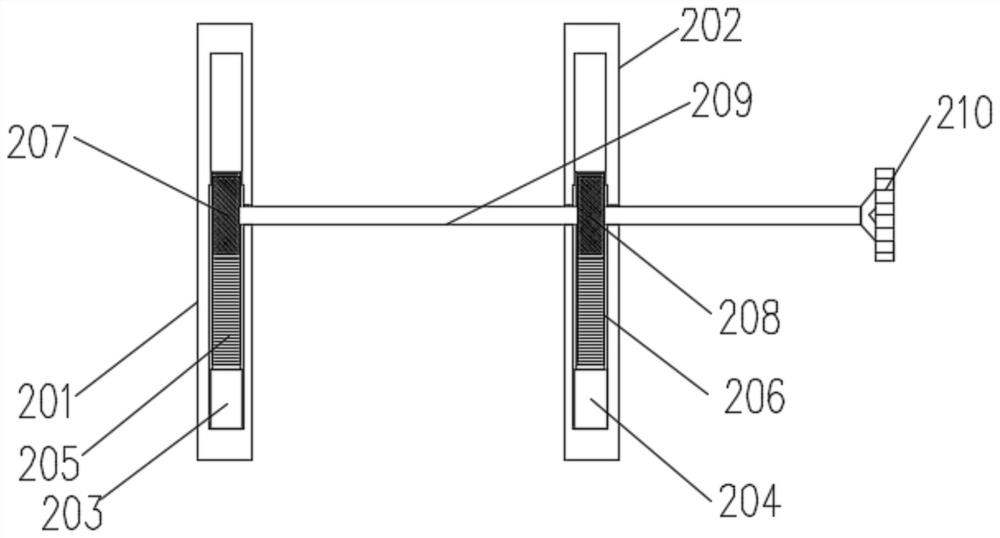

Electric lifting roll brush device

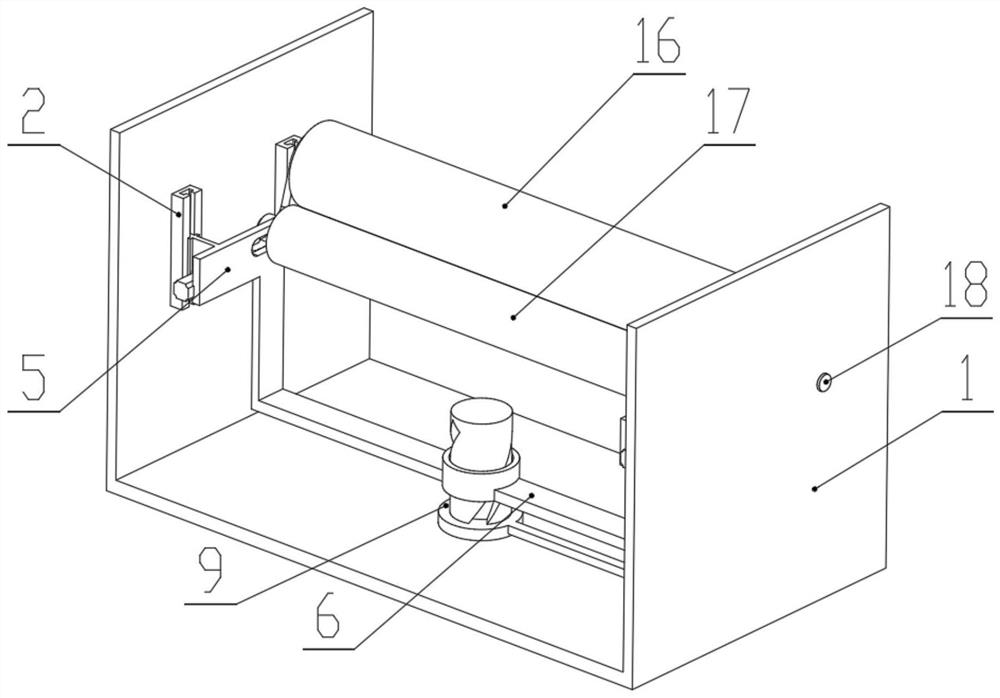

The invention relates to an electric lifting roll brush device which comprises a roll brush arranged in a cleaning chamber. The device is characterized by also comprising a roll brush motor speed reducer, lifting mechanisms and a lifting drive component, wherein the left side wall and right side wall of the cleaning chamber are provided with vertical long mounting holes; two ends of the roll brush are respectively mounted on a sliding plate through a bearing after passing through the long mounting holes; the roll brush motor speed reducer is installed on a sliding plate at one side, and the output shaft of the roll brush motor speed reducer is connected with one end of the roll brush; the left side and right side of the cleaning chamber are respectively provided with one lifting mechanism; two sidling plates at two sides of the cleaning chamber are respectively connected to the lifting mechanisms at the same sides with the sliding plates; the two lifting mechanisms are respectively connected with the lifting drive component; the lifting drive components drive the lifting mechanisms to rotate; and the lifting mechanisms drive the two sliding plates at the two sides of the cleaning chamber and the roll brush to lift. The device provided by the invention has the advantages of inventive, compact and reasonable structure, high working efficiency and high regulating accuracy, the device is convenient to operate and maintain, and two ends of the roll brush are lifted synchronously and stably.

Owner:无锡洲翔成套焊接设备有限公司

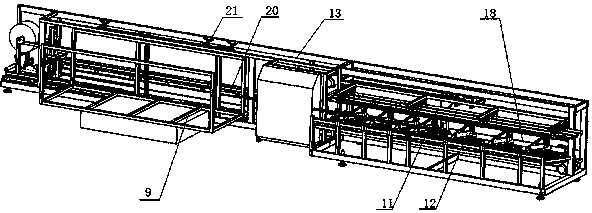

Automatic Bundling Pipe Bagging Machine

ActiveCN105292584BFully automatedSmall footprintWrapper twisting/gatheringBinding material applicationHorizontal axisEngineering

Owner:GUANGDONG LIANSU MACHINERY MFG

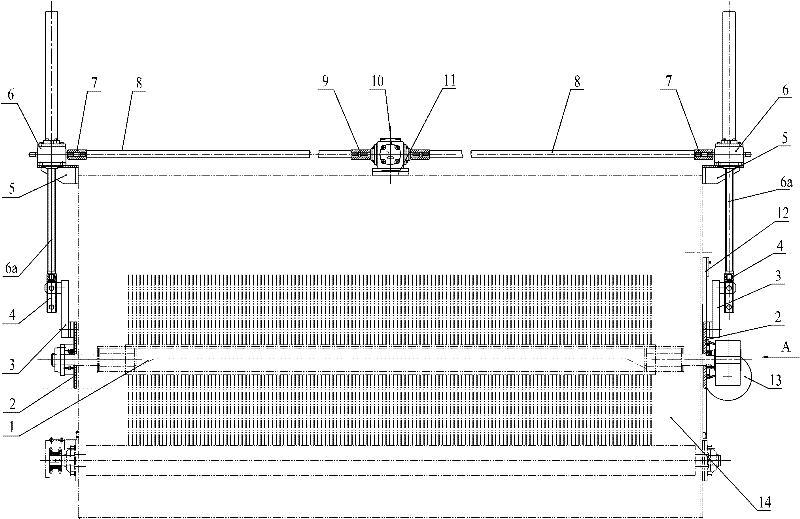

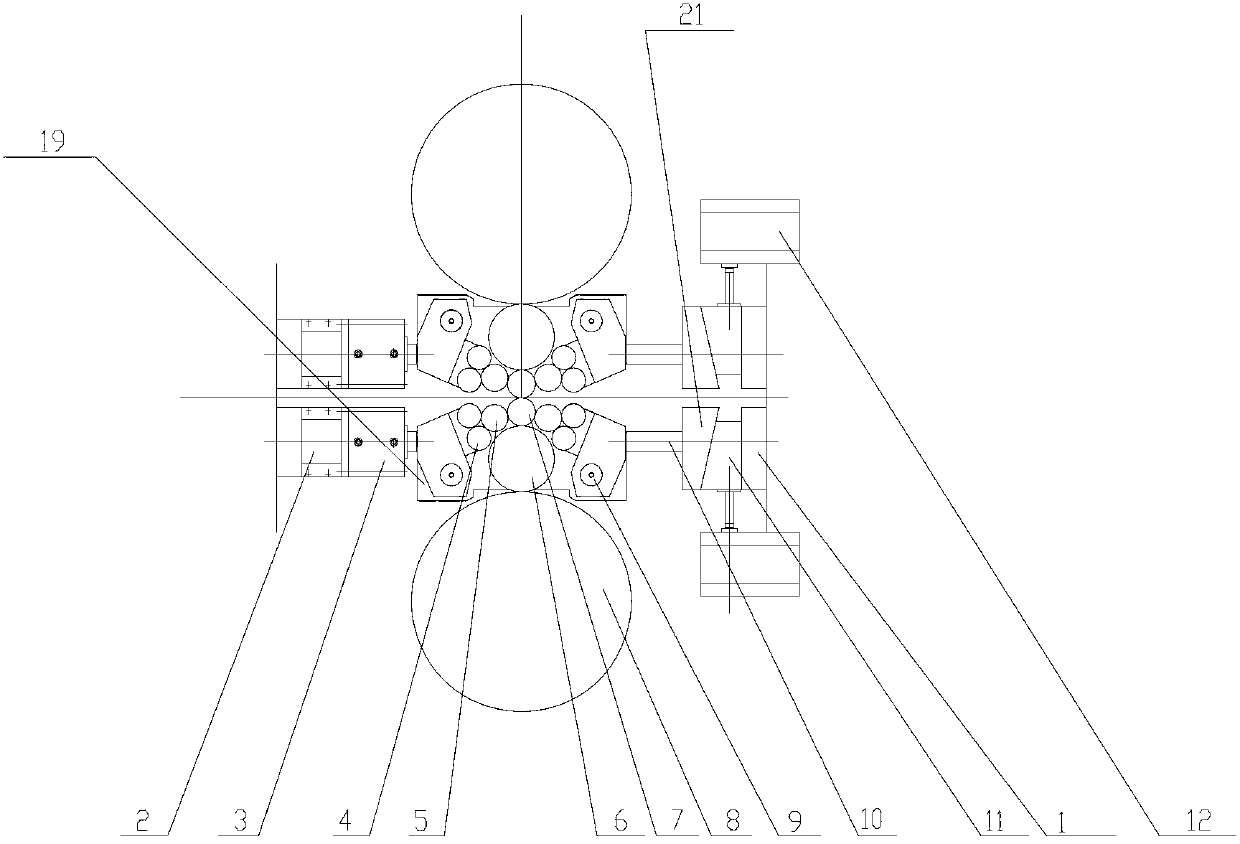

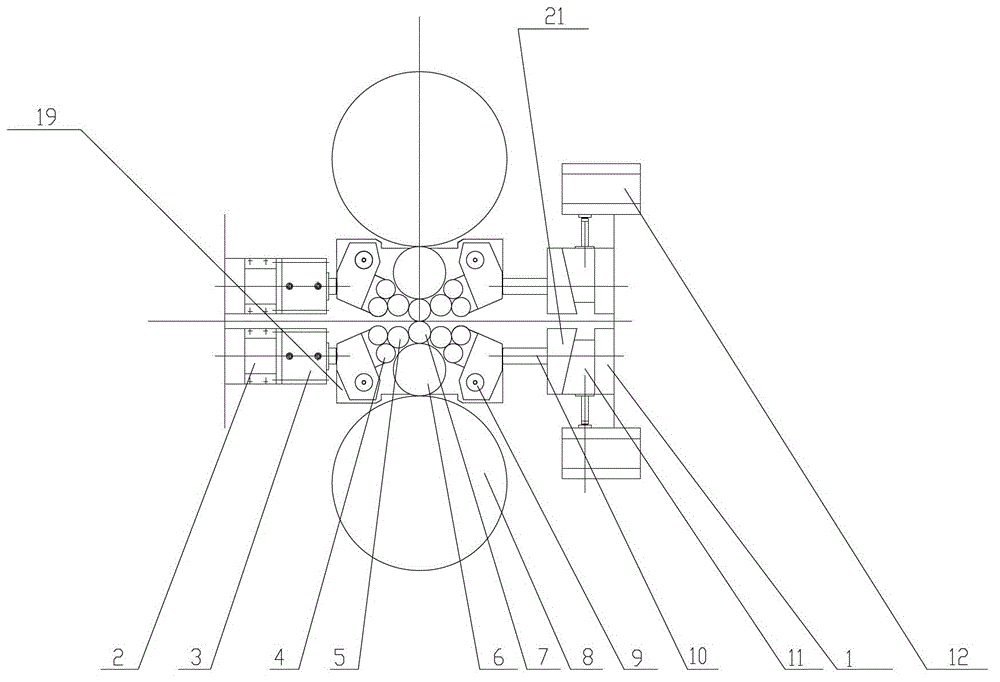

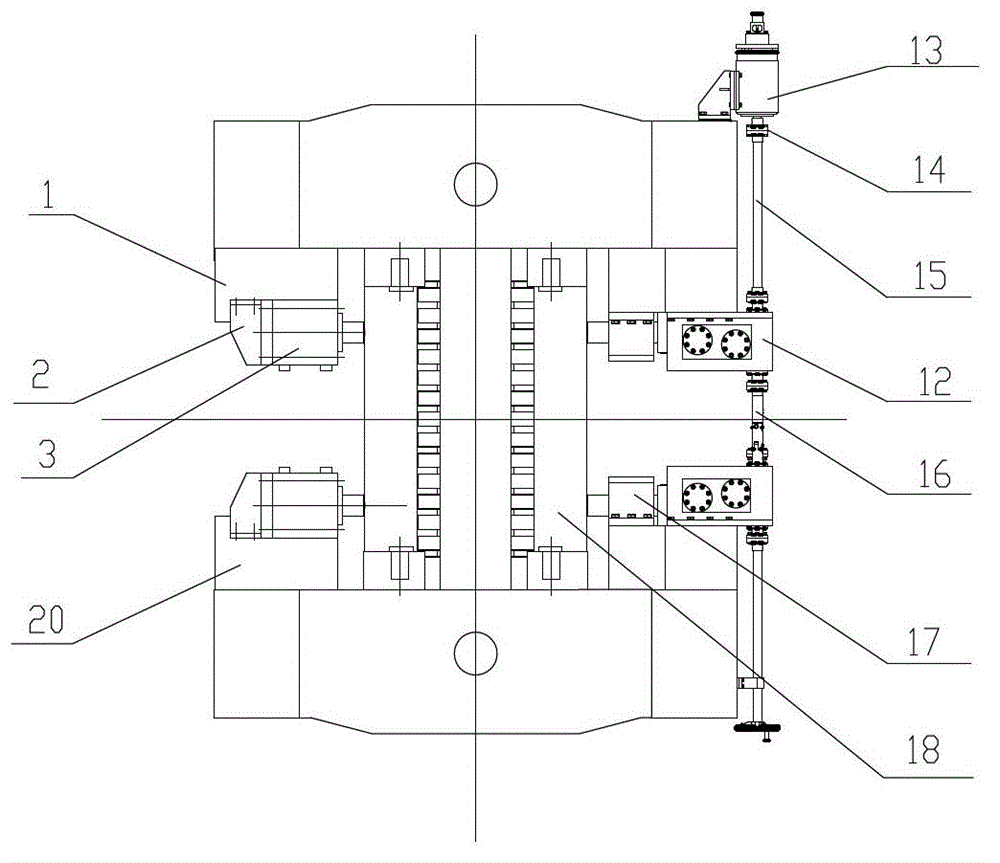

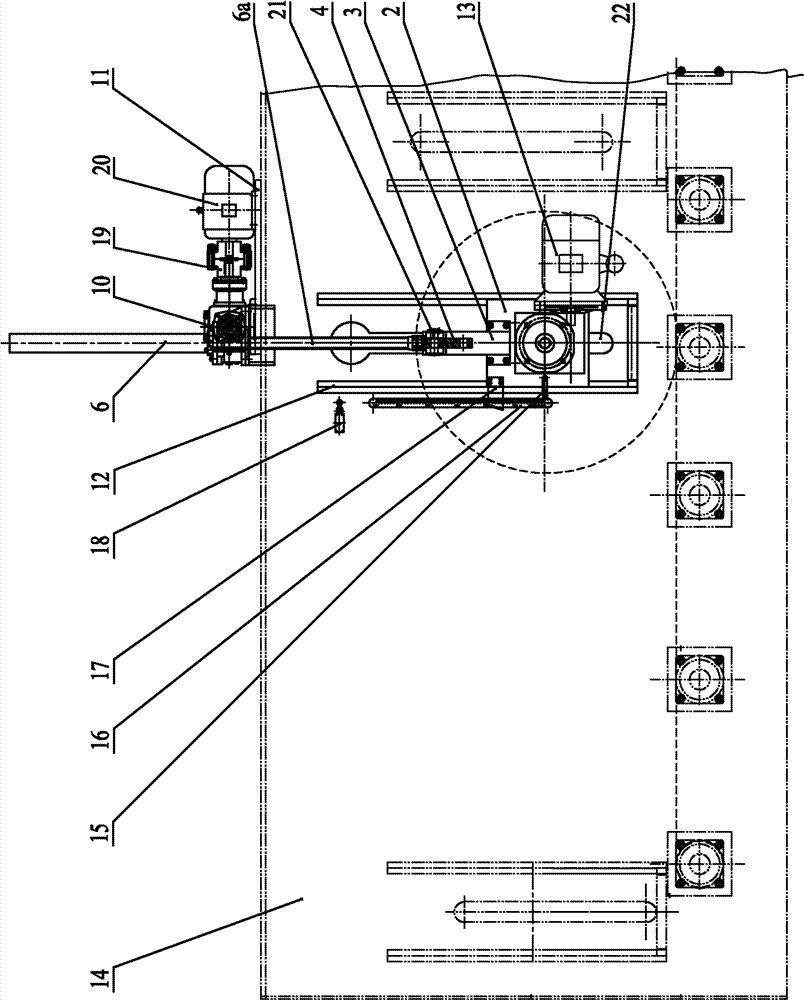

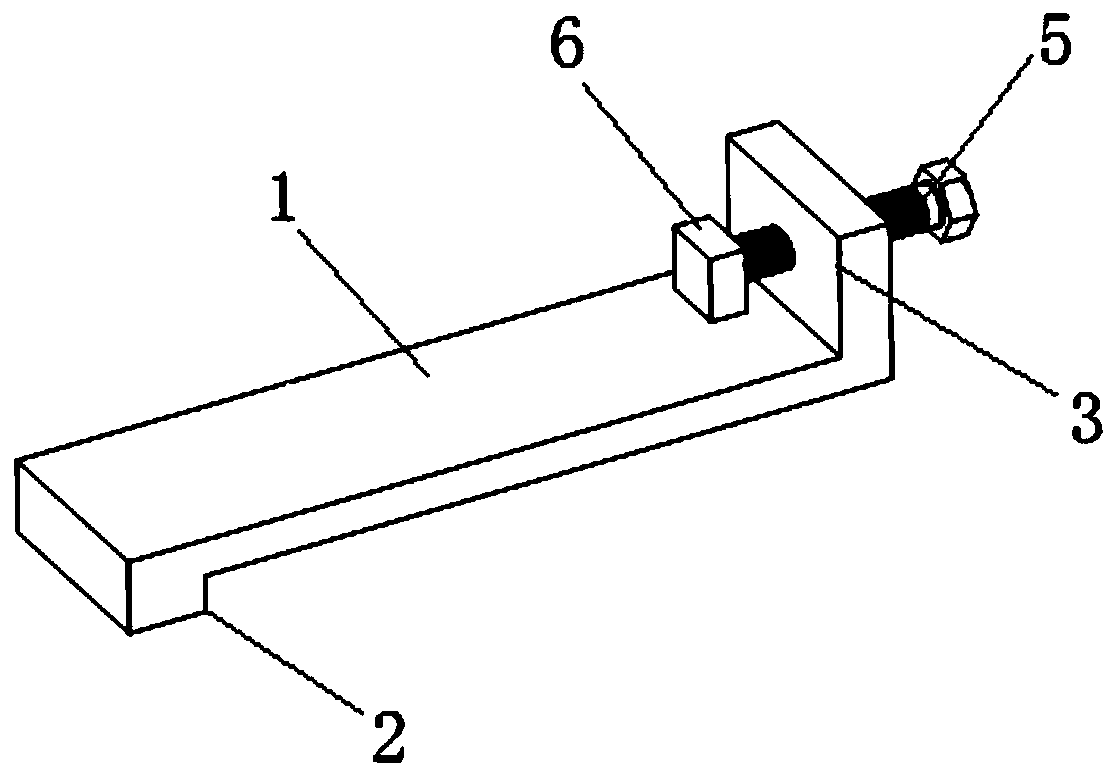

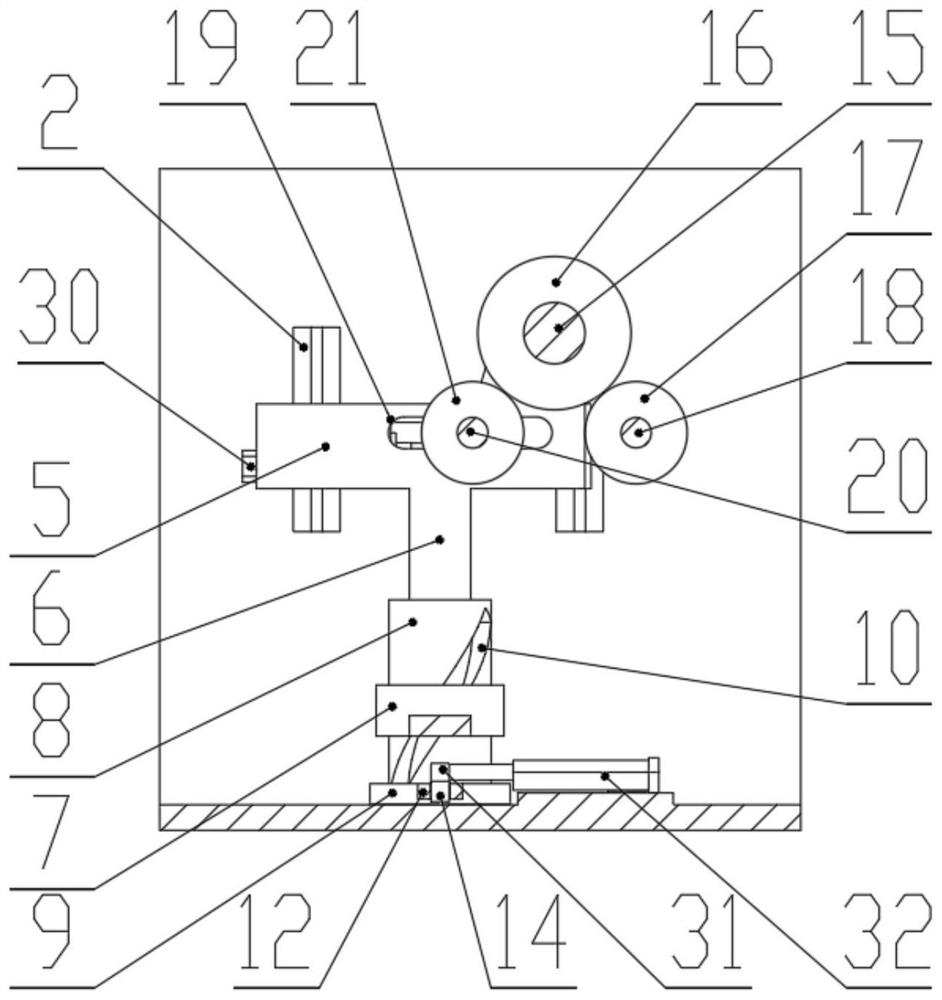

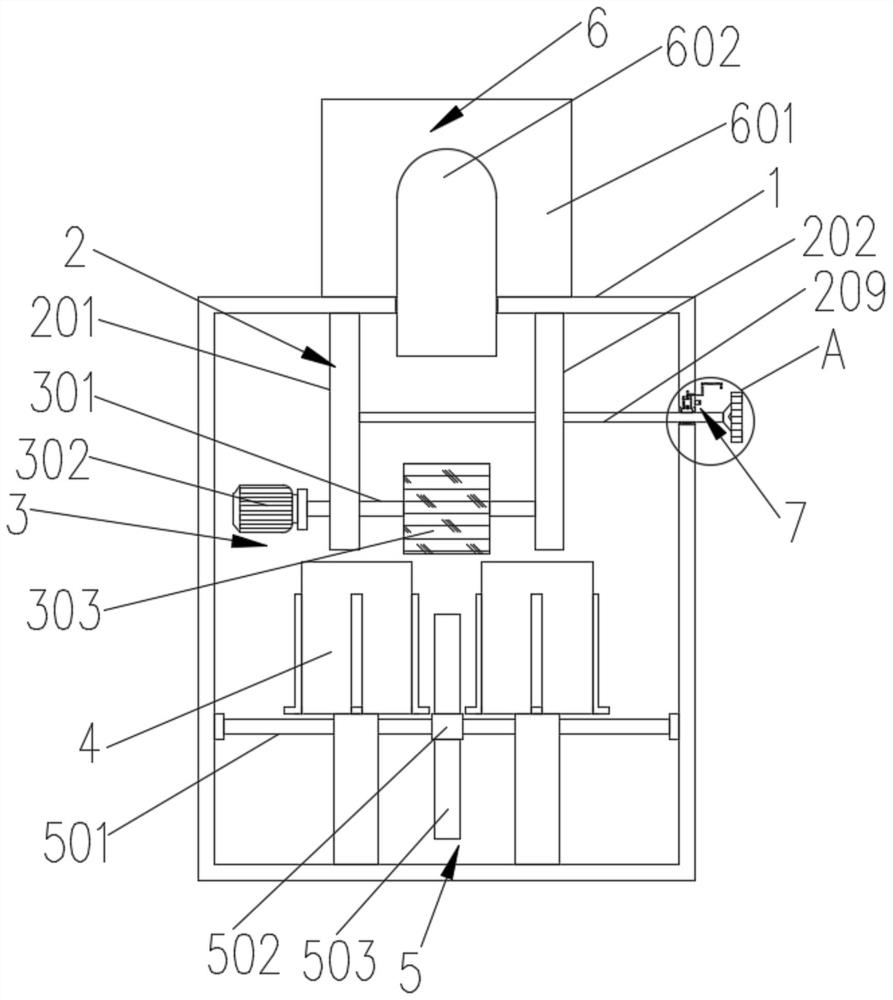

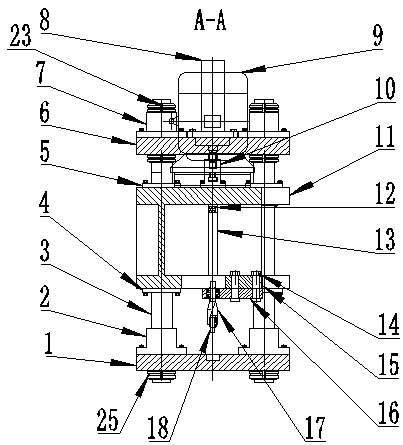

Hydraulic cylinder inclined iron adjustment device of eighteen rolling mill working roll side supports

InactiveCN103341493AReduce processing costsReduce manual adjustment timeMetal rolling stand detailsCounter-pressure devicesHydraulic cylinderWork roll

The invention belongs to the technical field of mechanical equipment, and particularly relates to a hydraulic cylinder inclined iron adjustment device of eighteen rolling mill working roll side supports. The hydraulic cylinder inclined iron adjustment device comprises a first memorial archway, a second memorial archway, eight backing rolls, four side supporting rolls, two middle rolls, two working rolls and two supporting rolls, wherein the working rolls are supported by the supporting rolls through the middle rolls, and the middle rolls are installed on middle roll bearing seats arranged between the two memorial archways. A hydraulic cylinder base is installed on the inner side of the second memorial archway, an ejection hydraulic cylinder is installed on the hydraulic cylinder base, and a push rod of the ejection hydraulic cylinder abuts against the backing beam on one side of the second memorial archway. A worm gear case motor is installed on the transmission side of the first memorial archway, the output end of the worm gear case motor is connected with a connecting rod through a first coupler, and the other end of the connecting rod is connected with a worm gear case through a second coupler. The adjustment device is simple in structure, easy to machine, and convenient and fast to adjust and maintain.

Owner:陶洪瑞

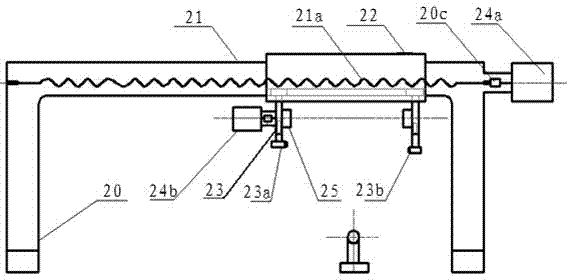

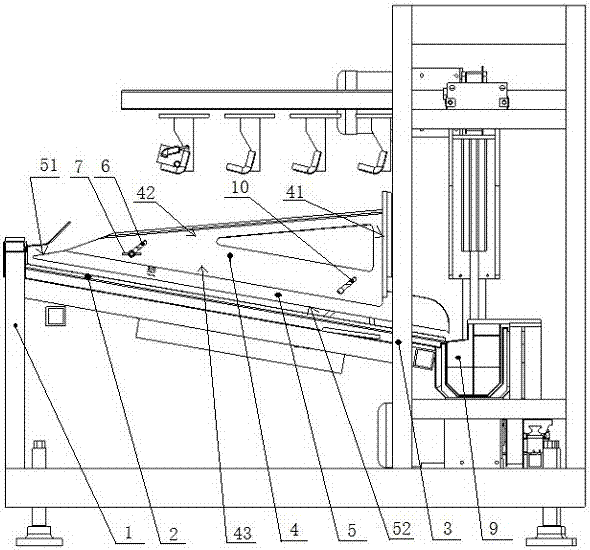

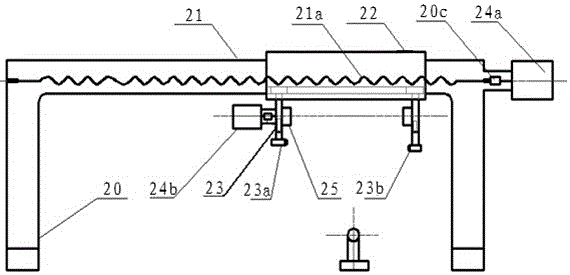

Two-dimensional servo metal plate cutting machine

The invention discloses a two-dimensional servo metal plate cutting machine. The two-dimensional servo metal plate cutting machine comprises a cutting worktable. The left-and-right direction of the cutting worktable is arranged as an X direction and the front-band-back direction of the cutting worktable is arranged as a Y direction. A Y-direction servo module and an X-direction servo module controlled by a servo system are fixed on the side face of the cutting worktable, the X-direction servo module slides front and back on the Y-direction servo module, a cutting mechanism and a lifting reversing mechanism are arranged on the lower part of the X-direction servo module, the lifting reversing mechanism is fixedly connected to the lower part of the X-direction servo module and comprises a lifting air cylinder, a steering air cylinder and a limiting block which is fixed on the side face of the steering air cylinder; the cutting mechanism is fixedly connected to the lower part of the lifting reversing mechanism and comprises a circular cutting blade, a knife rest, a fixed base and a stepping motor. The two-dimensional servo metal plate cutting machine effectively realizes high-efficiency and high-precision cutting of a metal plate, and further can adjust the cutting angel of a tool freely as required, so that the two-dimensional servo metal plate cutting machine is more convenient to operate and wider in application range.

Owner:张家港市鑫华易金属材料有限公司

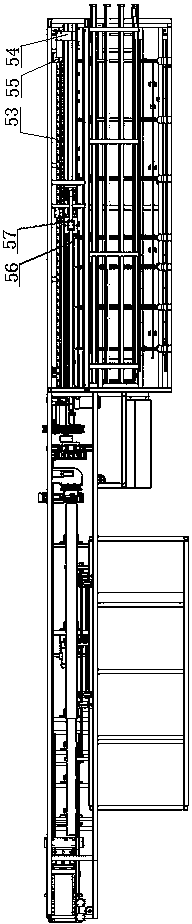

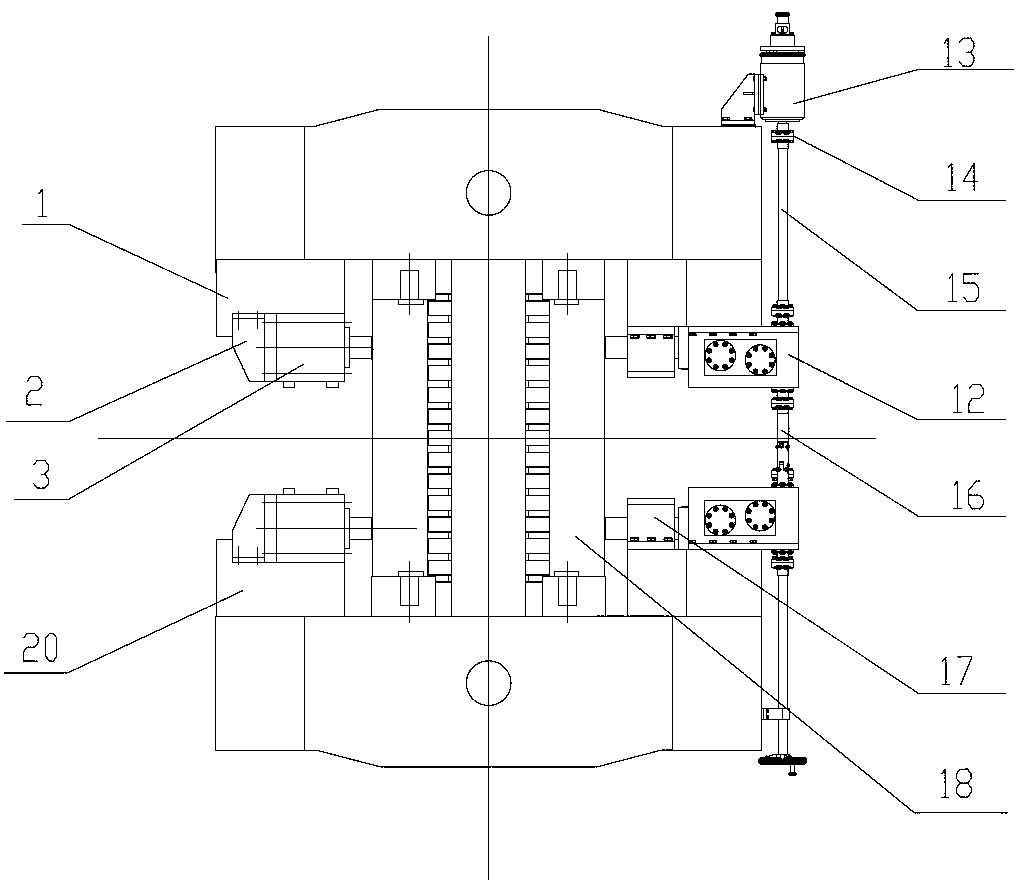

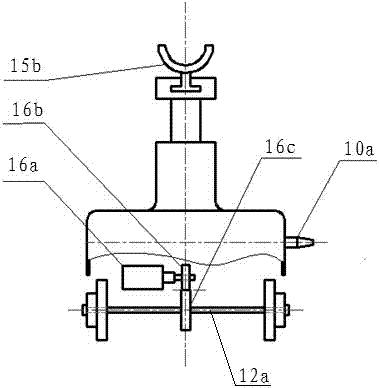

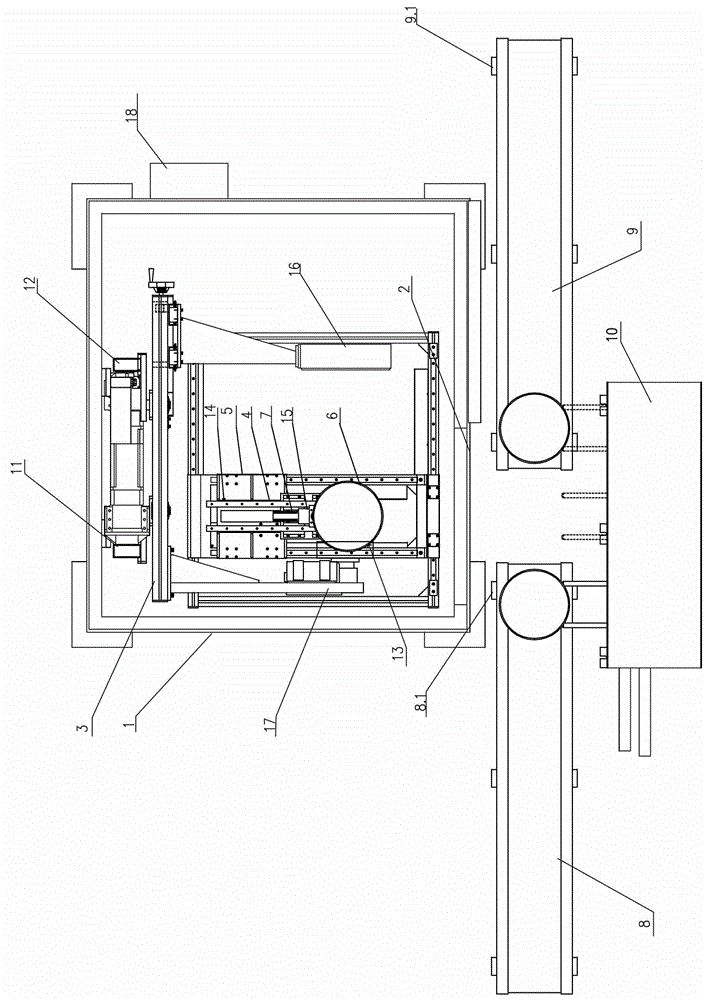

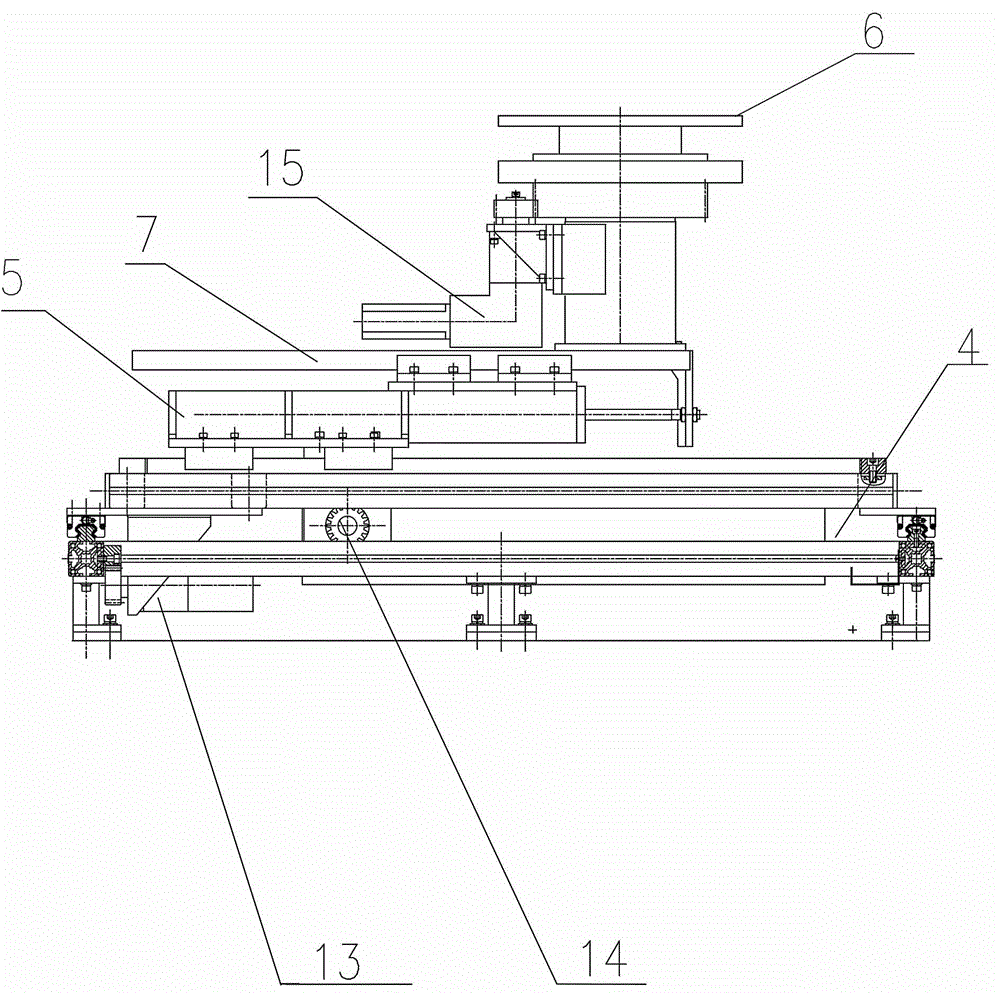

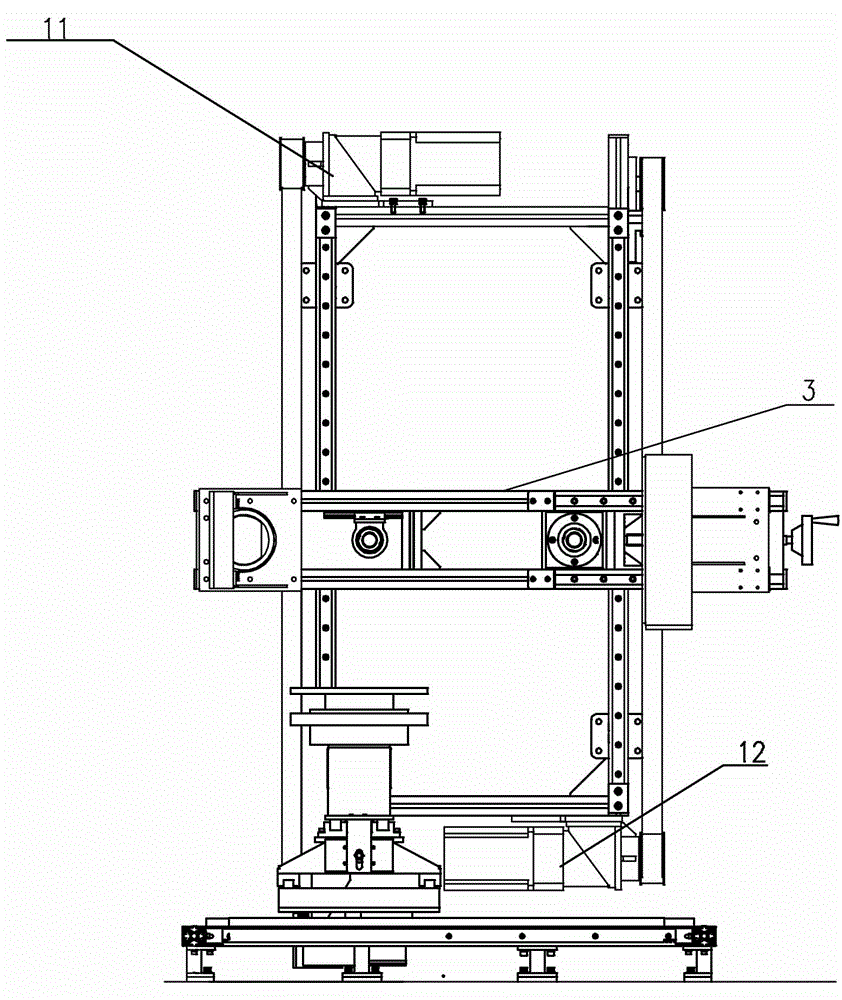

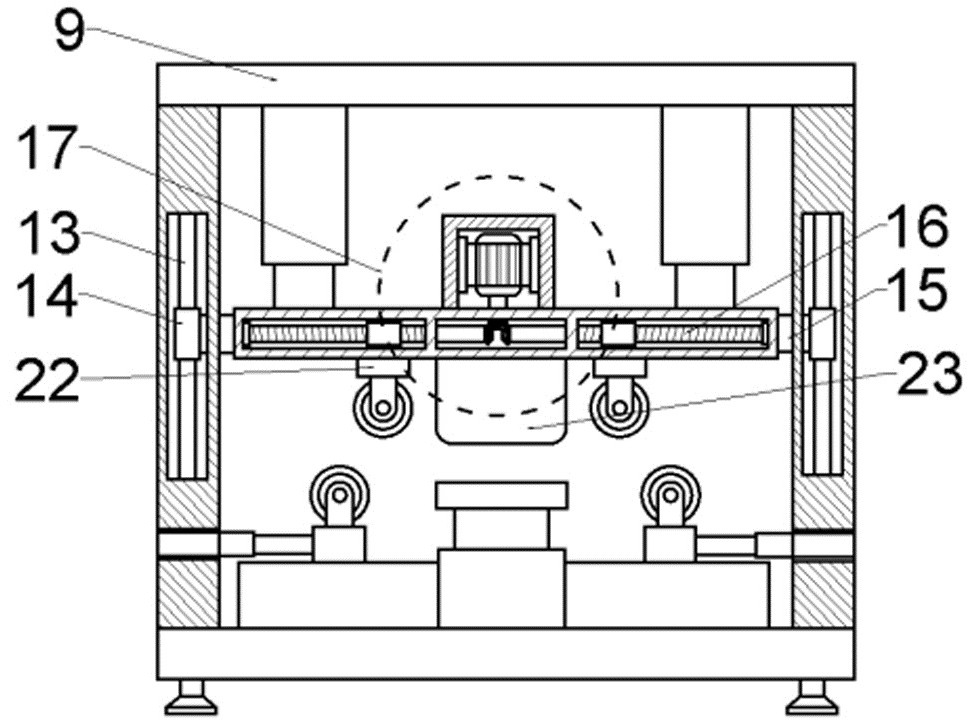

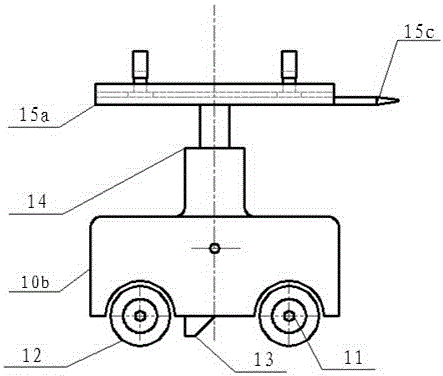

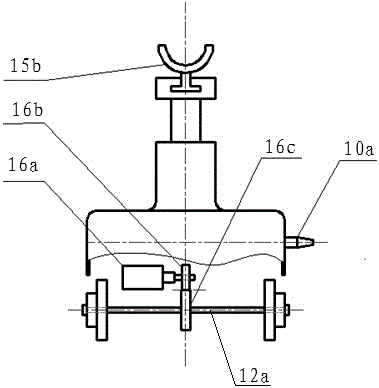

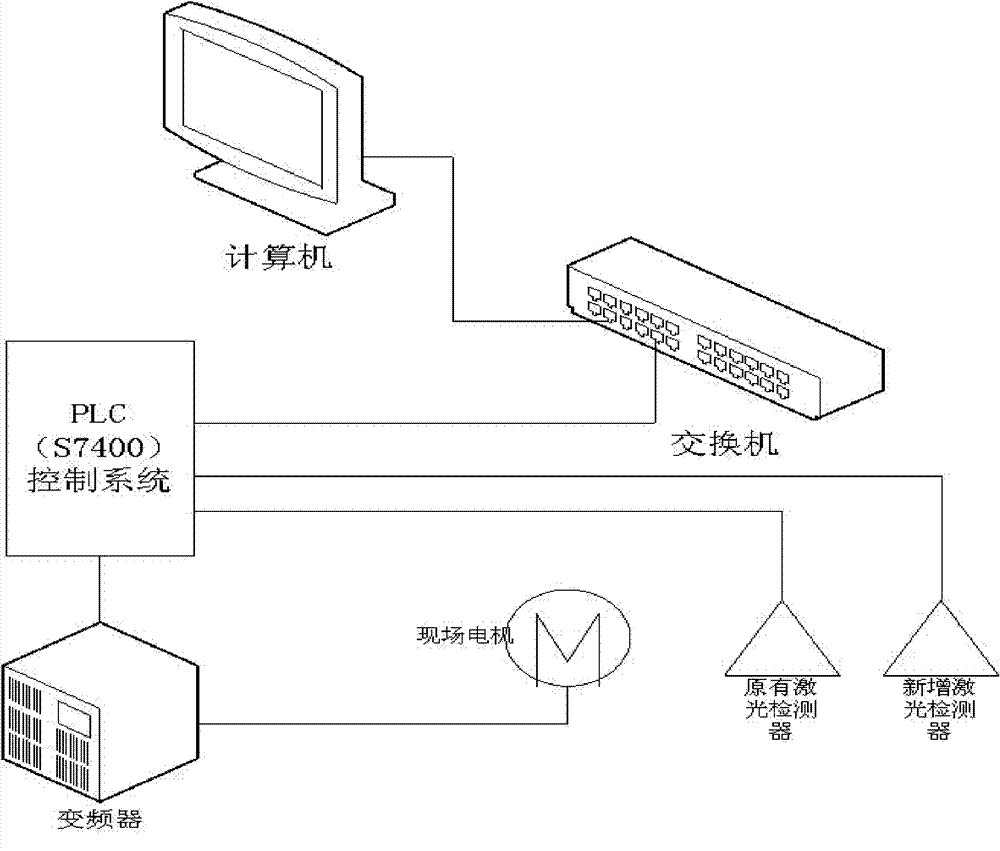

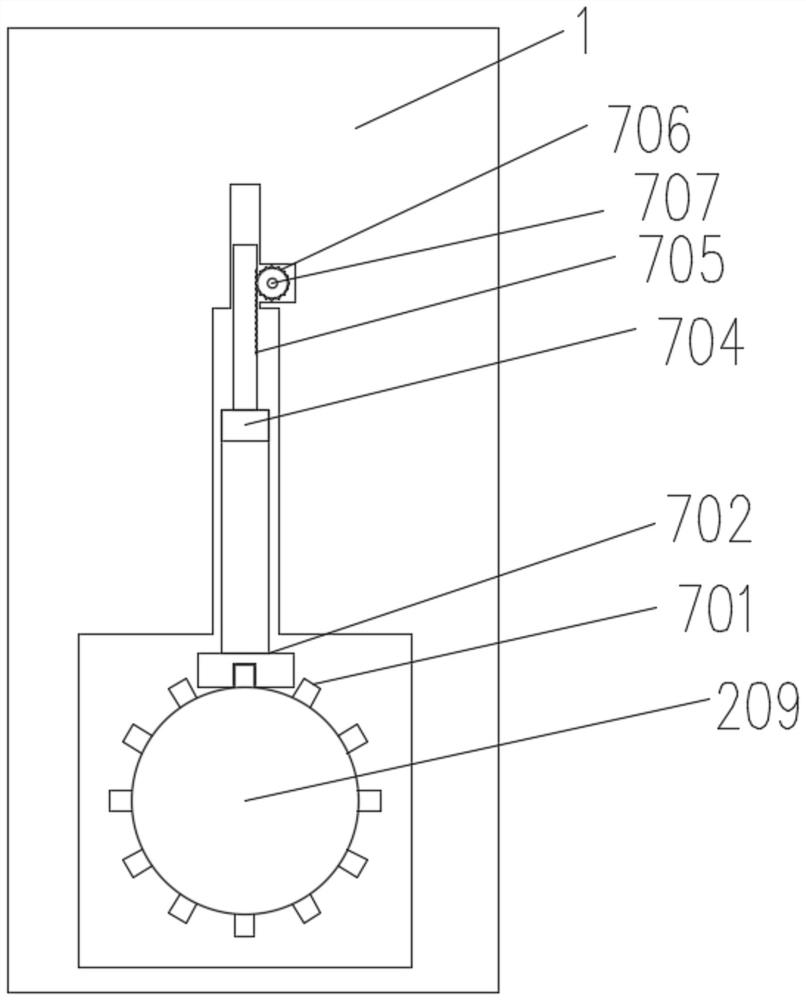

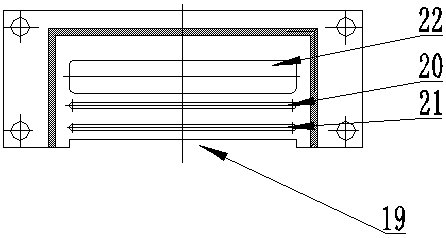

Casting defect ray detection system

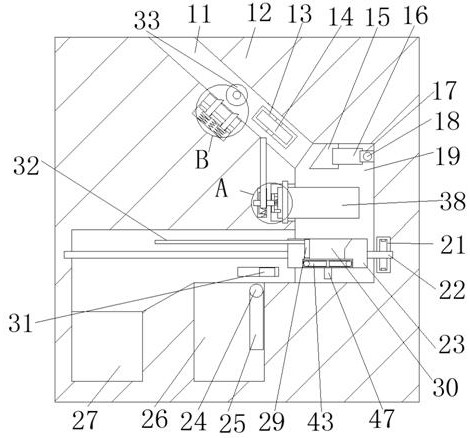

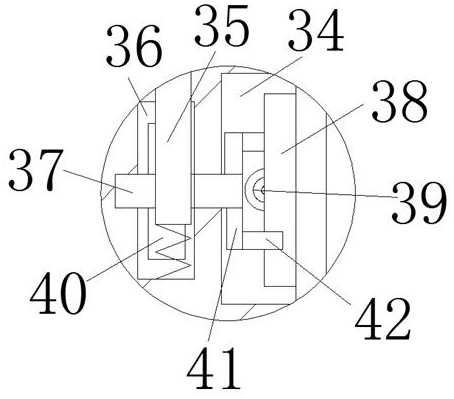

InactiveCN104502383AFast detection timeReduce manual adjustment timeMaterial analysis using wave/particle radiationEngineeringCasting defect

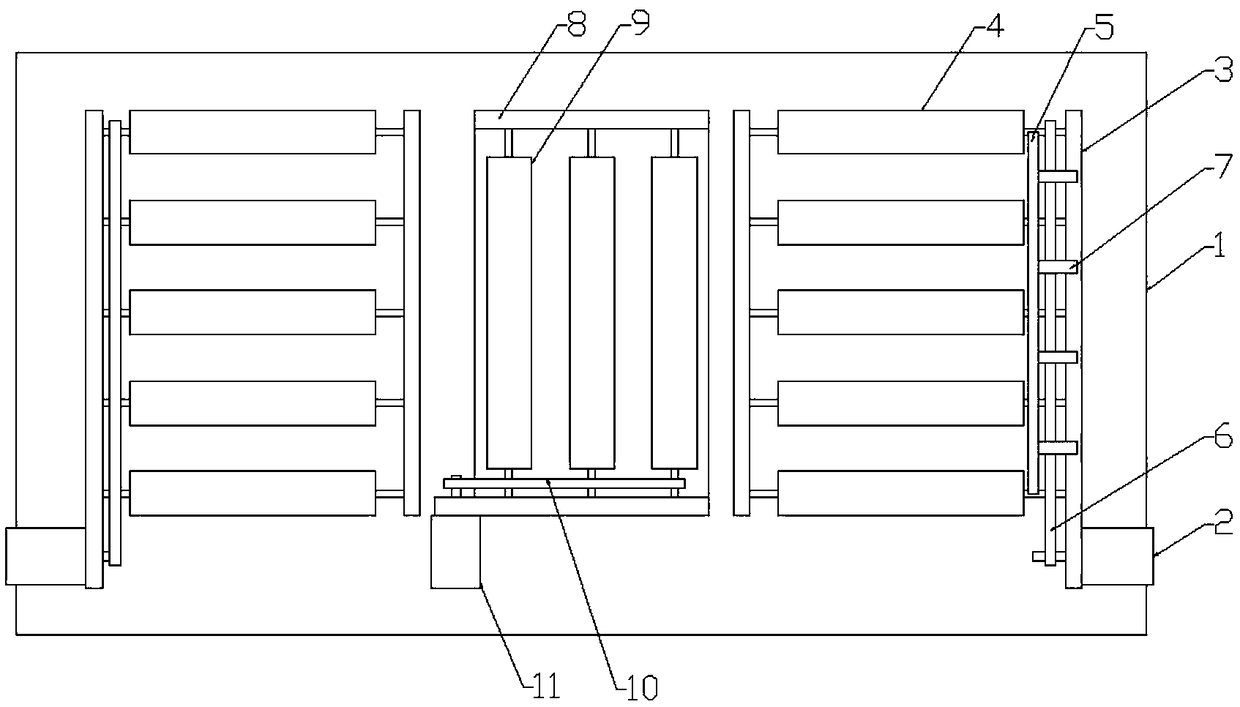

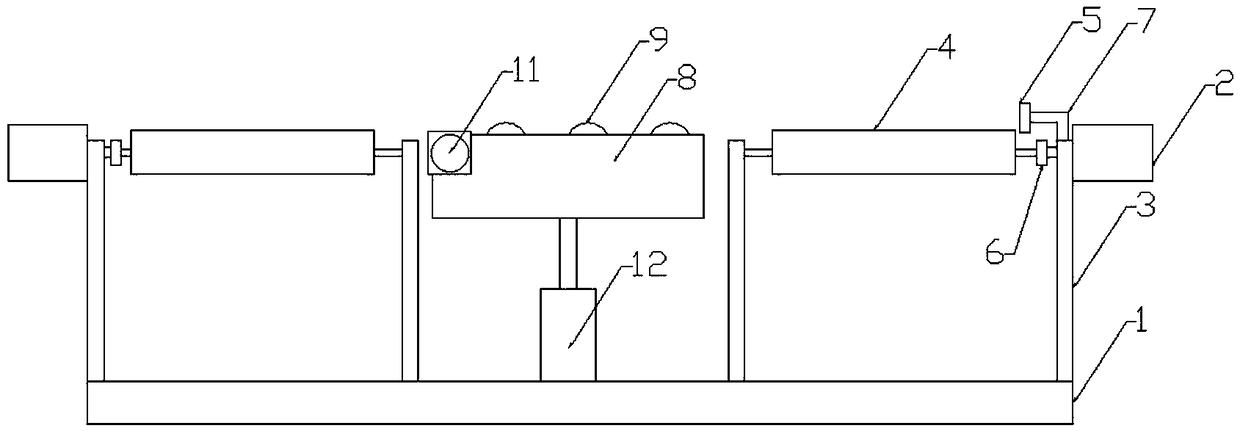

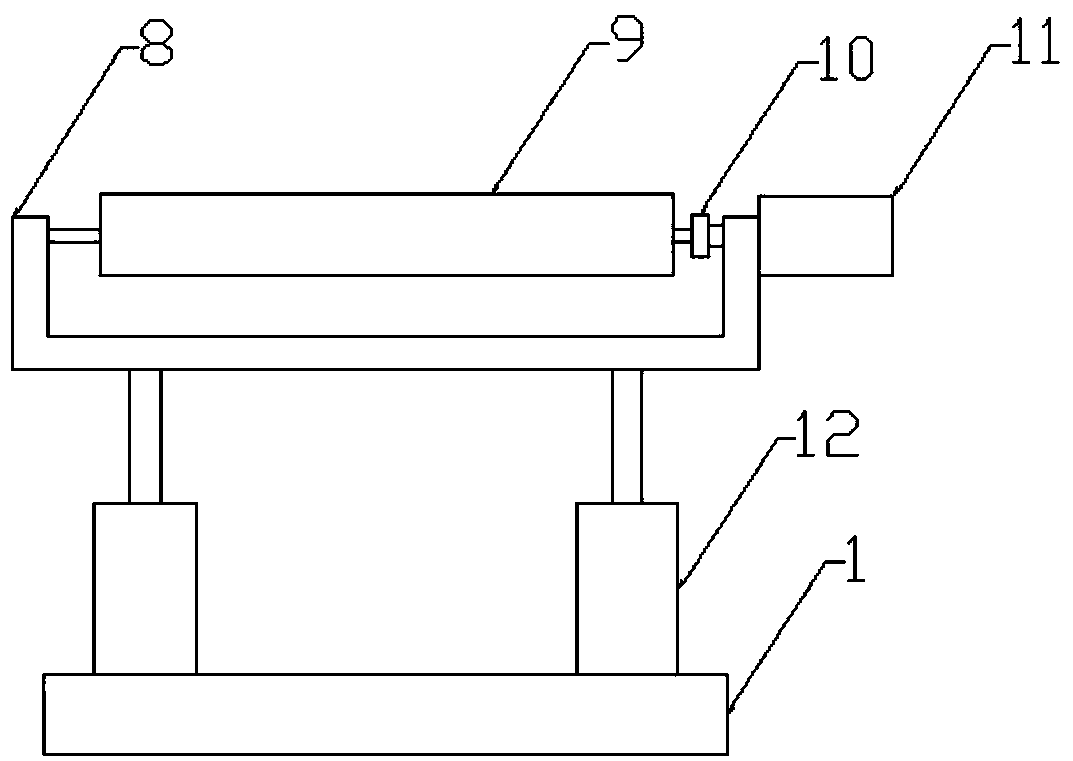

The invention relates to a casting defect ray detection system which comprises a PLC, a casting transport vehicle, a detection chamber, an X-ray generator and a detection device, wherein the casting transport vehicle is used for transporting a casting into the detection chamber, the X-ray generator and the detection device are arranged in the detection chamber, the detection device comprises a detection platform body, a detection guide rail, a detection platform, a casting clamp and a casting drive structure, the casting transported by the casting transport vehicle is mounted on the detection platform by virtue of a casting clamp, the casting drive structure is used for driving the casting to transversely move and rotate, the X-ray generator generates X rays to realize detection of the casting, and the PLC is used for controlling the casting transport vehicle, the detection chamber, the X-ray generator and the detection device. According to the casting defect ray detection system, transportation, transmission and rotation of the casting are all controlled by adopting the PLC with PLC bus control as a center, and axial and radial detection of the casting is realized by virtue of the casting drive structure, so that the manual regulation time is saved, and the integral detection time of the casting is greatly increased.

Owner:CHONGQING UNIV OF TECH

Cable erecting and supporting device for electromechanical installation

InactiveCN111952888ANot easy to damageImprove stabilitySuspension arrangements for electric cablesApparatus for overhead lines/cablesStructural engineeringElectric cables

Owner:吴振亮

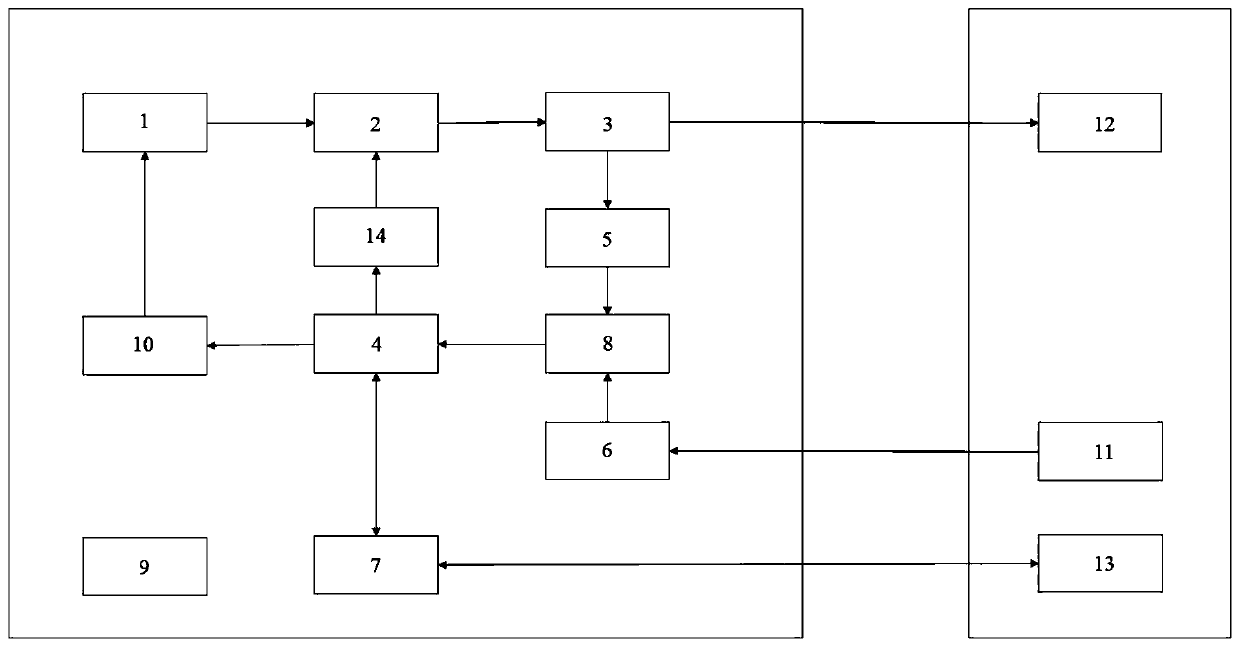

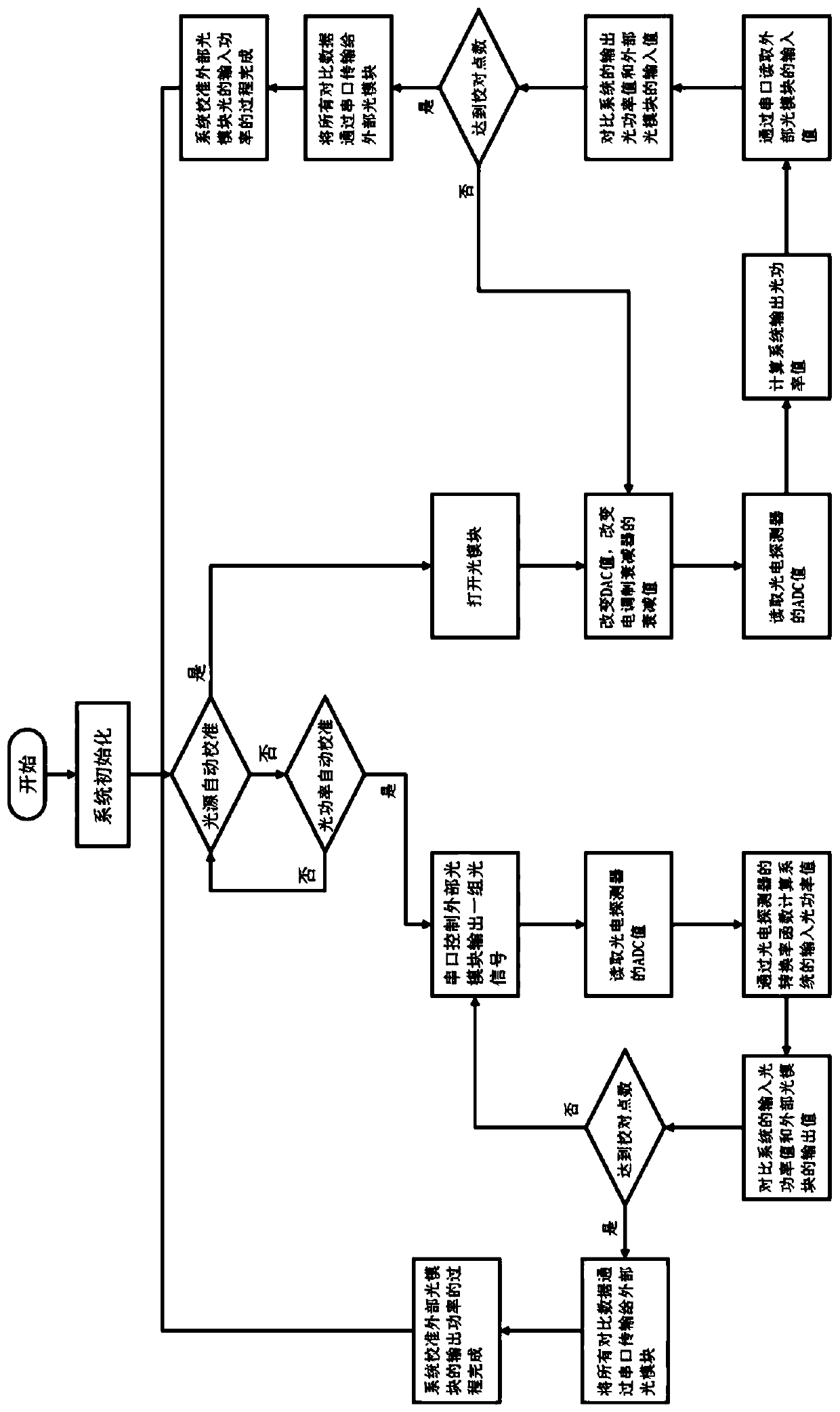

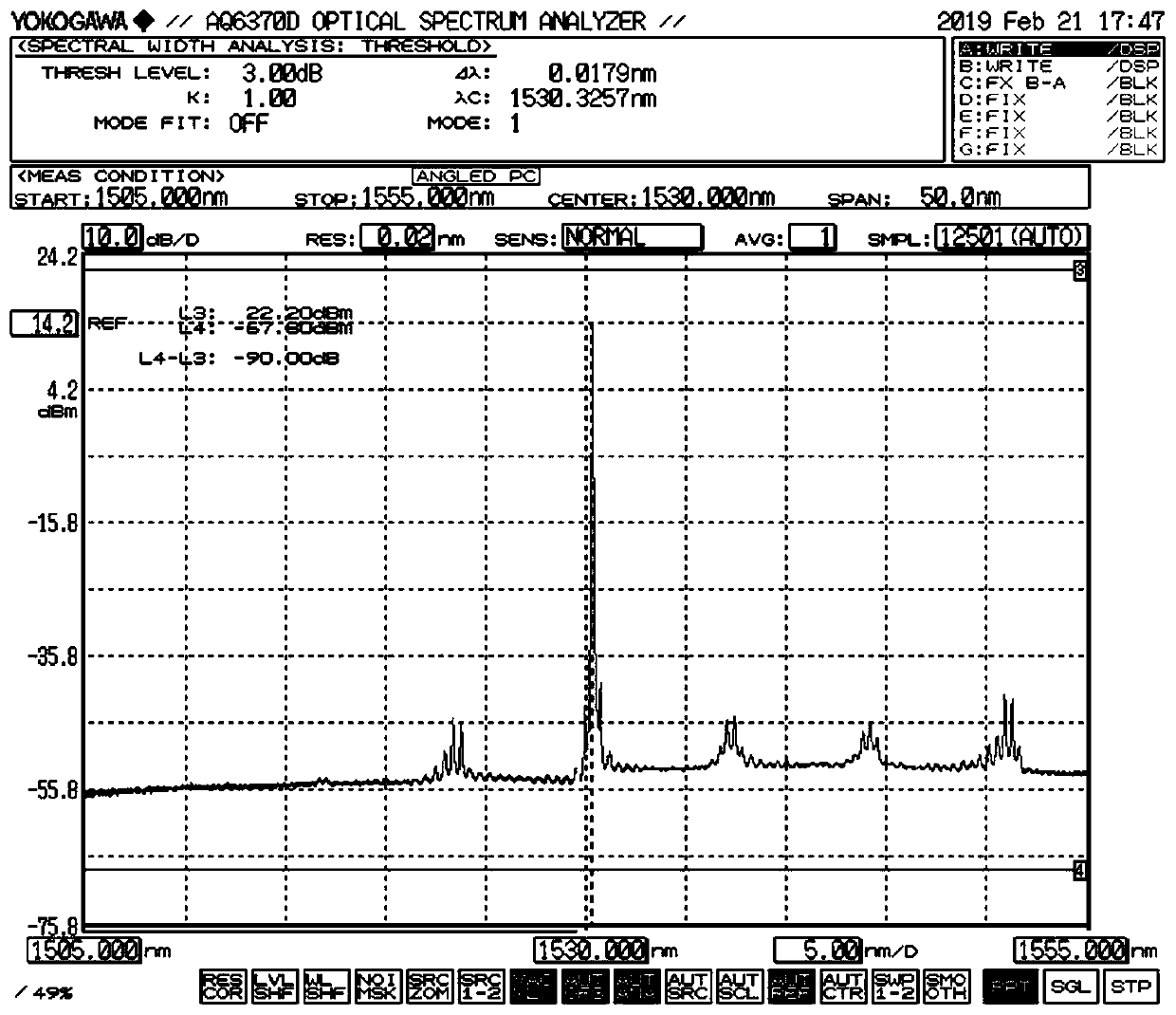

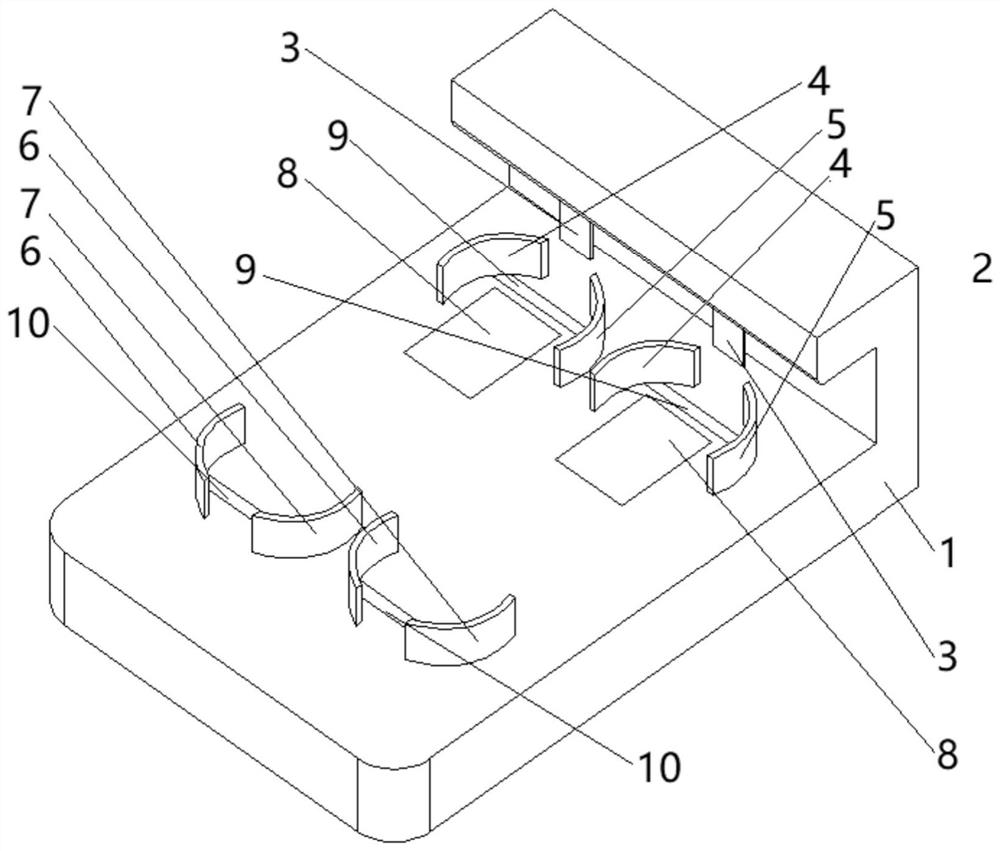

Optical power automatic calibration system and method

InactiveCN111103055AReduce manual adjustment timeReduce space consumptionPhotometry electrical circuitsOptical powerLight source

The invention relates to the technical field of optical communication, in particular to an optical power automatic calibration system and method. The system is characterized in that the system comprises a light source module 1, an electric modulation attenuator 2, a one-input two-output light beam splitter 3, a micro control unit MCU4, an output photoelectric detector 5, an input photoelectric detector 6, a system serial interface 7, an ADC analog-to-digital conversion module 8, a temperature detection control circuit 9, a current driving circuit 10 and an analog voltage control circuit 14. According to the novel optical power automatic calibration system and method provided by the invention, a PID system with built-in control detection is adopted, so that the output optical power is prevented from drifting and distorting. Output and input of optical power are adjusted in a full-automatic mode, and the manual adjusting time is greatly shortened. Functions of a light source, a power meter, an attenuator and the like are integrated into a set of system and are controlled by a micro-control unit, so that the occupied space is small, and the testing method is simple.

Owner:上海传输线研究所

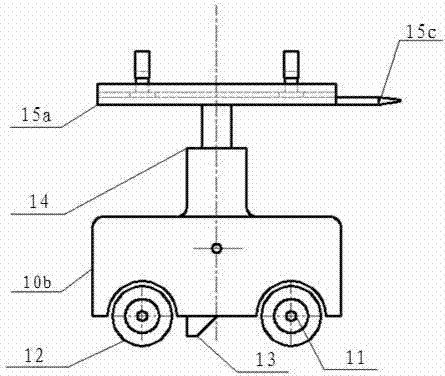

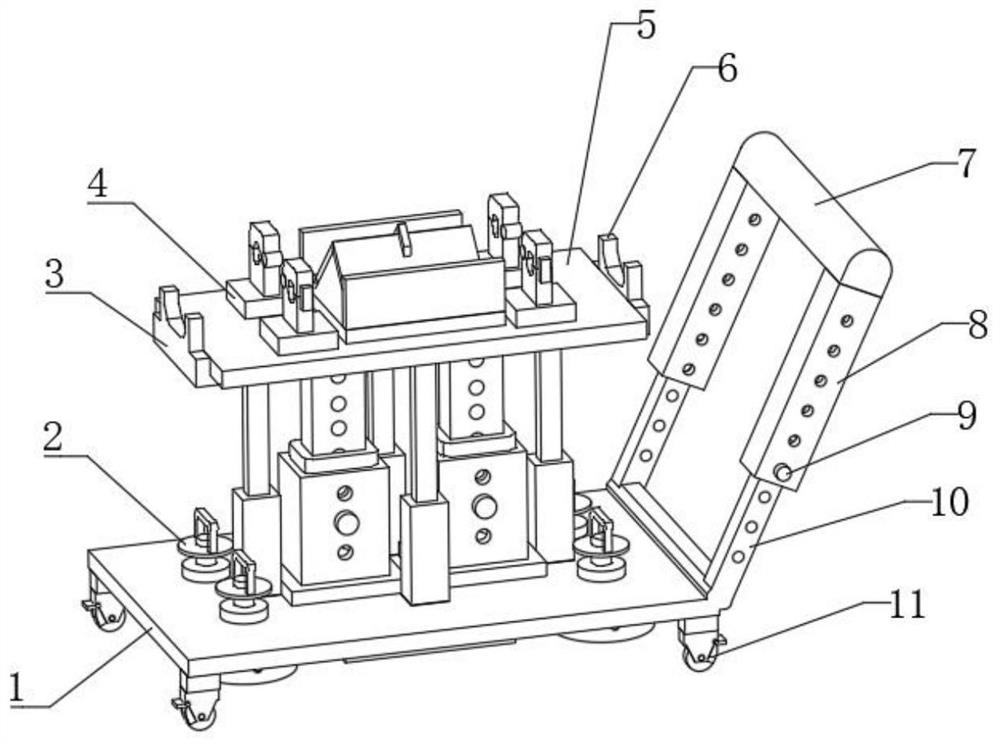

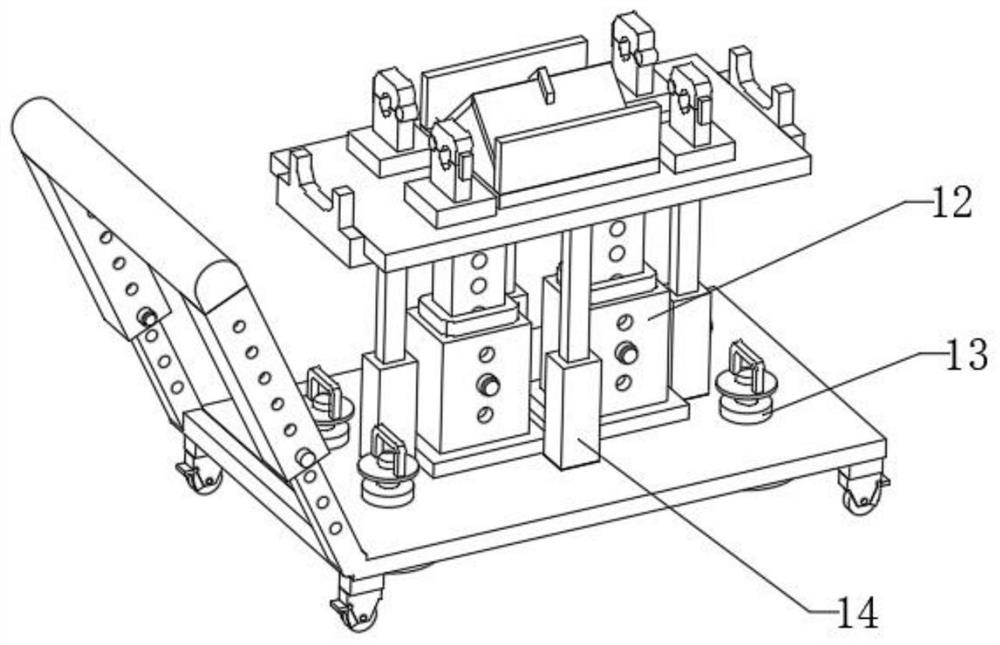

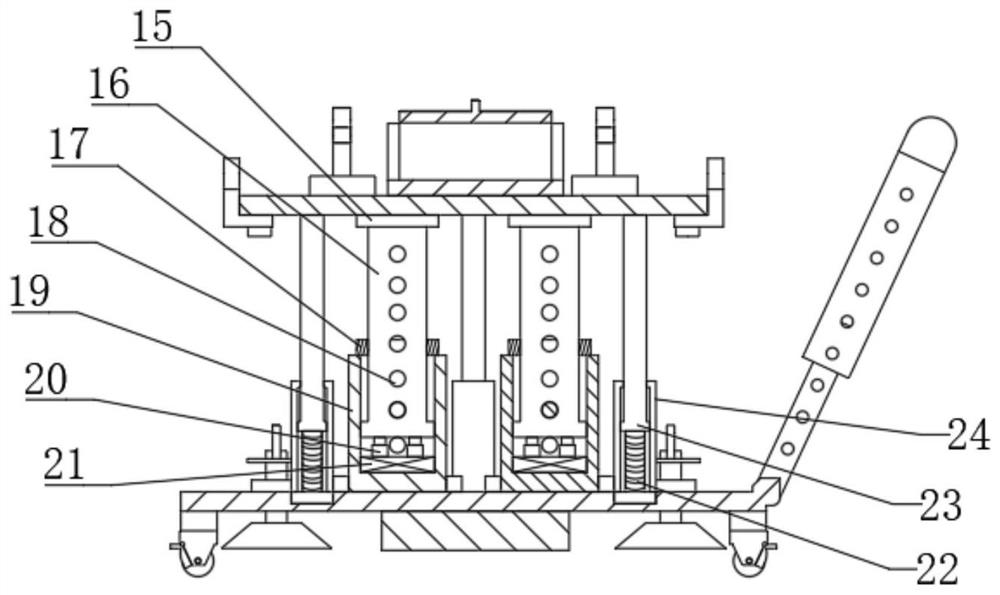

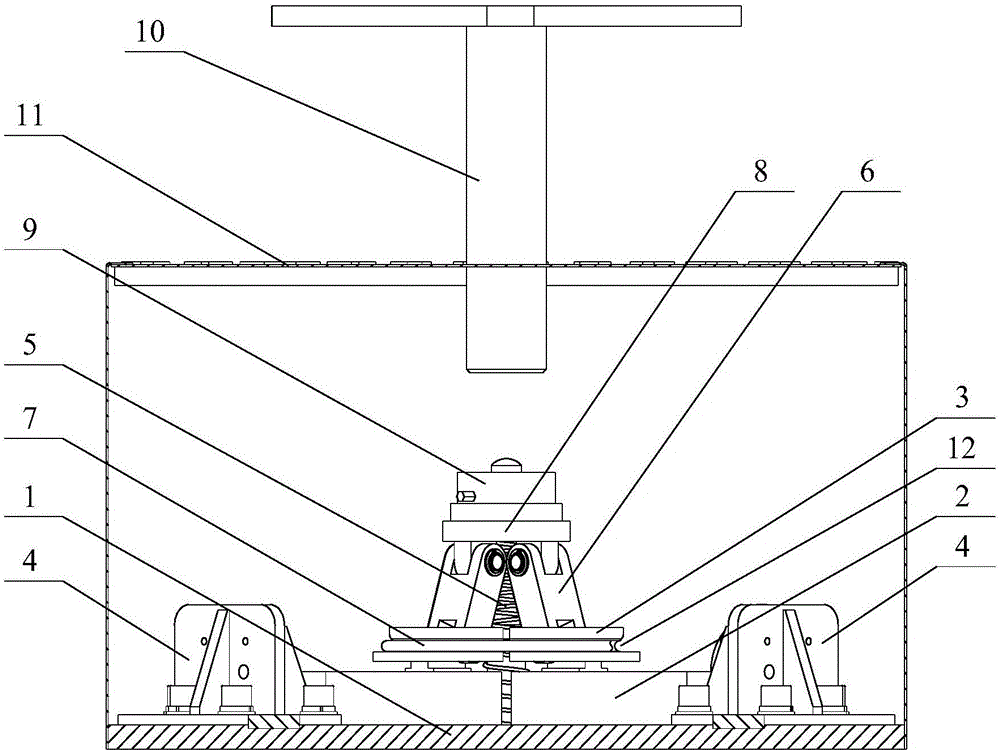

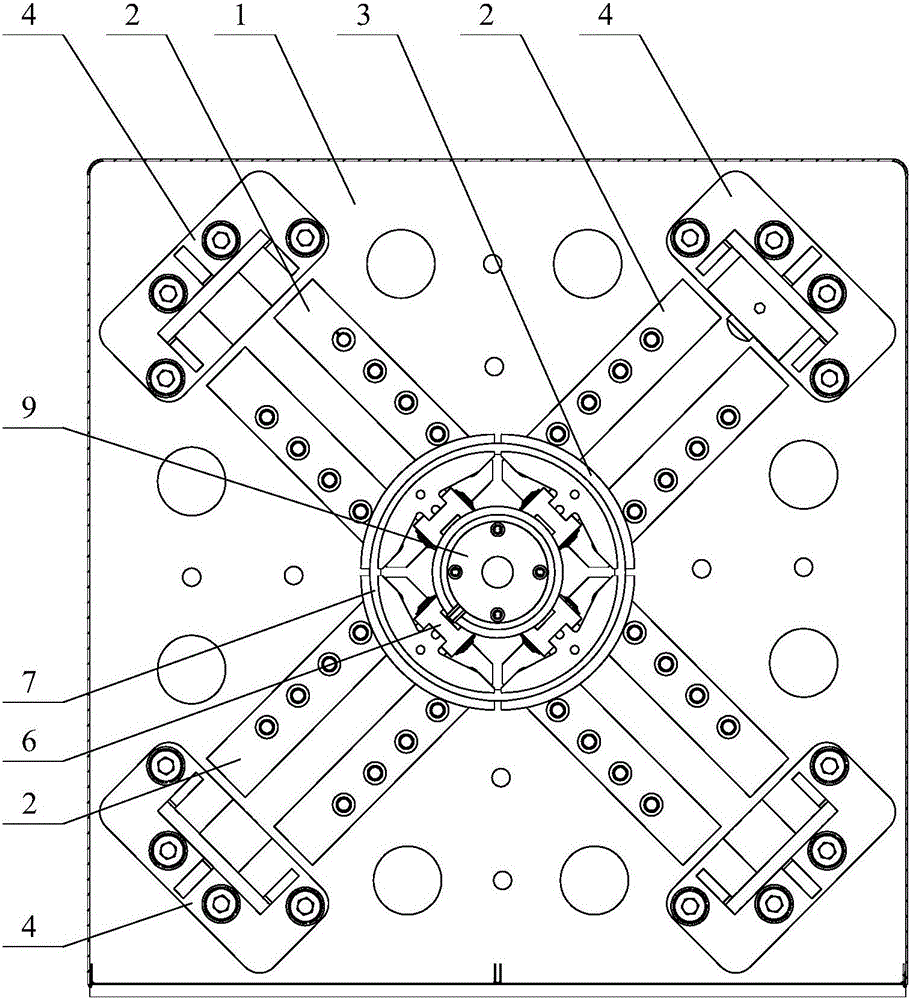

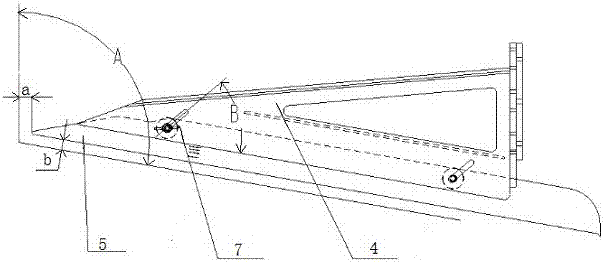

Tension force tester of aviation tire supporting framework

InactiveCN106404544AGuarantee product qualityEliminate errorsMaterial strength using tensile/compressive forcesTire beadAviation

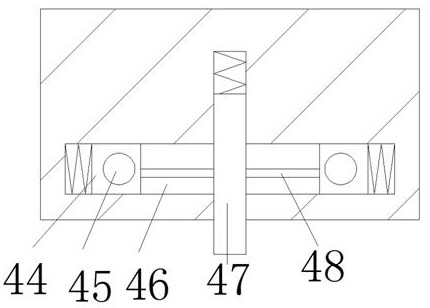

The invention provides a tension force tester of an aviation tire supporting framework, and belongs to the technical field of a tension tester. Four groups of slide ways are fixed on a bottom plate in a cross form, a limiting plate is fixed on the bottom plate at the outer end of every group of slide way, and a tension slide block is placed on every group of slide way; the lower end of the tension supporting arm is hinged with a tension slide block, and the upper end of the tension supporting arm is hinged with a pressing tension disk; a reset spring is placed in the center encircled by four tension supporting arms, the upper end of the reset spring is contacted with the pressing tension disk, and the lower end of the reset spring is contacted with the bottom plate; the pressure sensor is fixed at the upper end of the pressing tension disk, a mandril is arranged at the upper part of the pressure sensor, a groove arranged on an outer curve face of the tension supporting arm is used for placing a tire bead ring. In testing process, four tension supporting arms are evenly stressed towards four sides, the testing result closes to the real value more. The tension force tester can test multiple dimensions of bead rings.

Owner:HARBIN INST OF TECH

Adjusting device for oil cylinder inclined iron for side support of work roll in 18-high rolling mill

InactiveCN103341493BReduce processing costsReduce manual adjustment timeMetal rolling stand detailsCounter-pressure devicesHydraulic cylinderWork roll

The invention belongs to the technical field of mechanical equipment, and particularly relates to a hydraulic cylinder inclined iron adjustment device of eighteen rolling mill working roll side supports. The hydraulic cylinder inclined iron adjustment device comprises a first memorial archway, a second memorial archway, eight backing rolls, four side supporting rolls, two middle rolls, two working rolls and two supporting rolls, wherein the working rolls are supported by the supporting rolls through the middle rolls, and the middle rolls are installed on middle roll bearing seats arranged between the two memorial archways. A hydraulic cylinder base is installed on the inner side of the second memorial archway, an ejection hydraulic cylinder is installed on the hydraulic cylinder base, and a push rod of the ejection hydraulic cylinder abuts against the backing beam on one side of the second memorial archway. A worm gear case motor is installed on the transmission side of the first memorial archway, the output end of the worm gear case motor is connected with a connecting rod through a first coupler, and the other end of the connecting rod is connected with a worm gear case through a second coupler. The adjustment device is simple in structure, easy to machine, and convenient and fast to adjust and maintain.

Owner:陶洪瑞

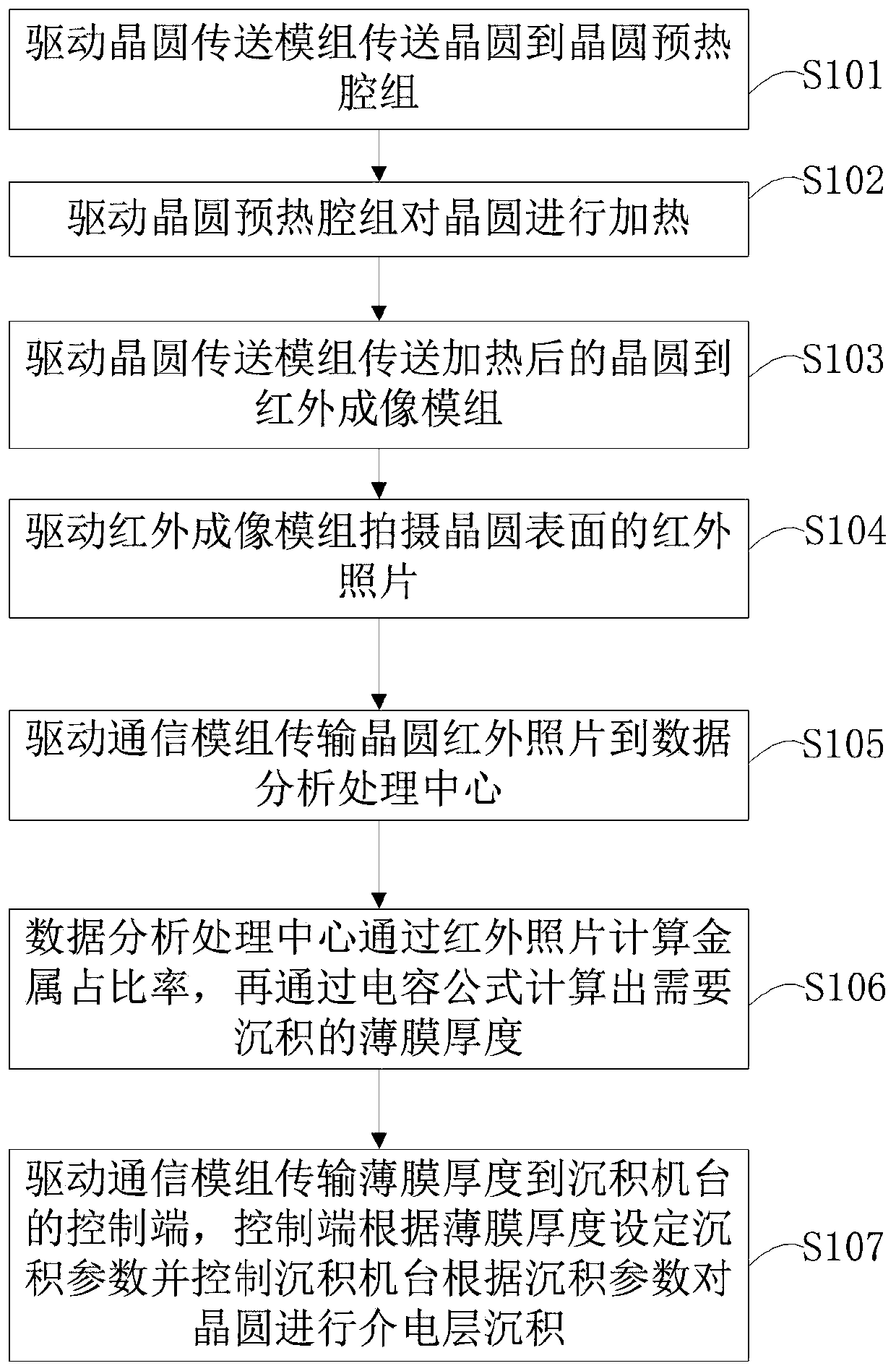

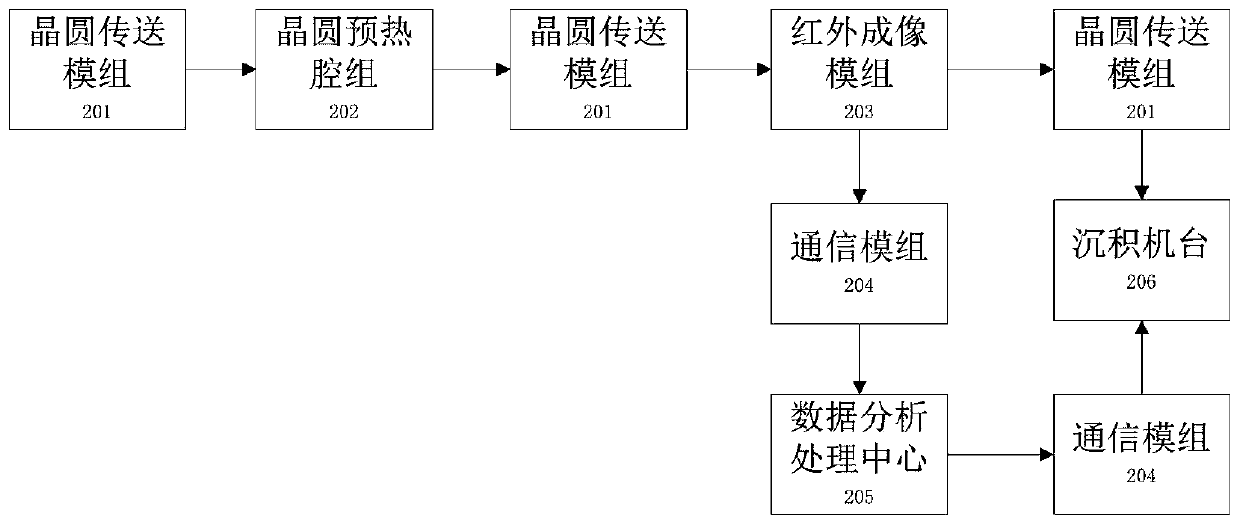

Method and system for improving capacitance value accuracy of capacitor

ActiveCN110082383ARealize automatic adjustmentHigh precisionRadiation pyrometryUsing electrical meansCapacitanceEngineering

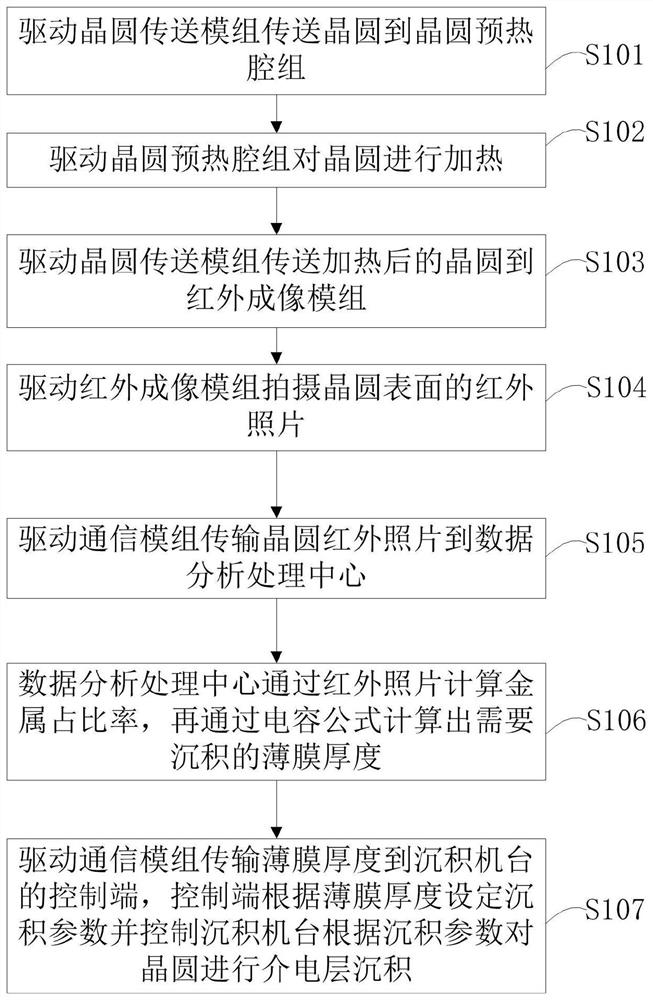

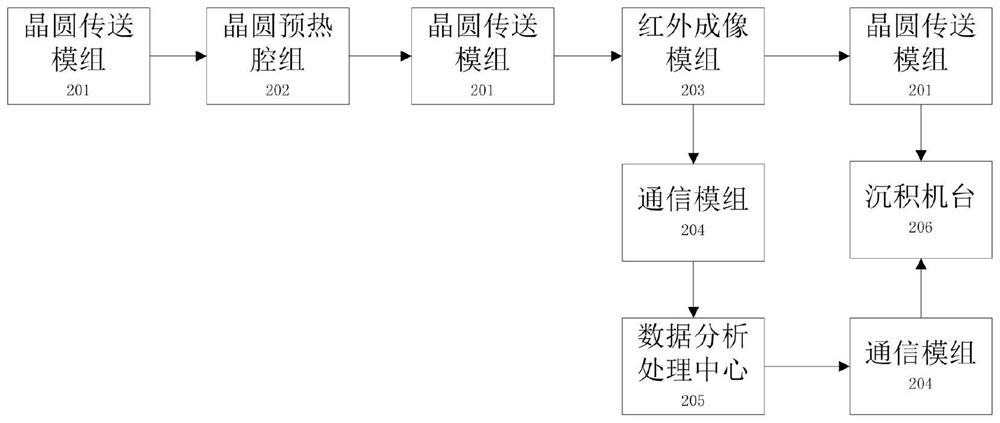

The invention discloses a method and a system for improving the capacitance value accuracy of a capacitor. The method comprises the following steps that: driving a wafer transmission module to transmit a wafer to a wafer preheating cavity group; driving the wafer preheating cavity group to heat the wafer; driving the wafer transmission module to transmit the heated wafer to an infrared imaging module; driving the infrared imaging module to shoot the infrared photo of the surface of the wafer; driving a communication module to transmit a wafer infrared photo to a data analyzing and processing center; and through infrared imaging, calculating the thickness of a film, and automatically applying to dielectric layer deposition. Therefore, the automatic regulation of a deposition parameter can be realized, the capacitance value accuracy of the capacitor is improved, and manual regulation time is saved.

Owner:福建省福联集成电路有限公司

Auxiliary shoe wearing and taking-off device

Owner:SOUTHWEST PETROLEUM UNIV

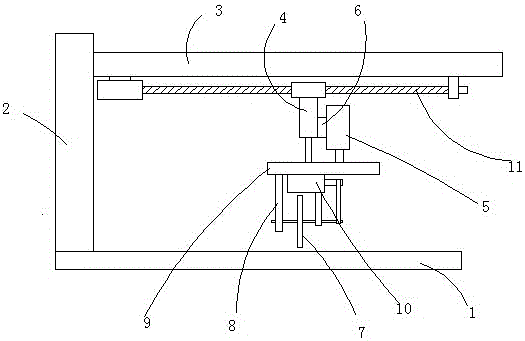

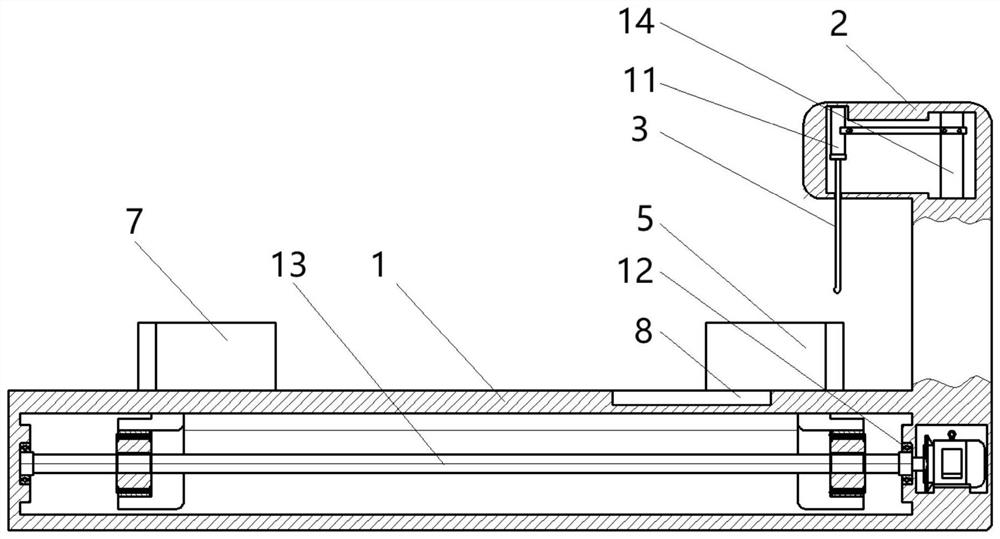

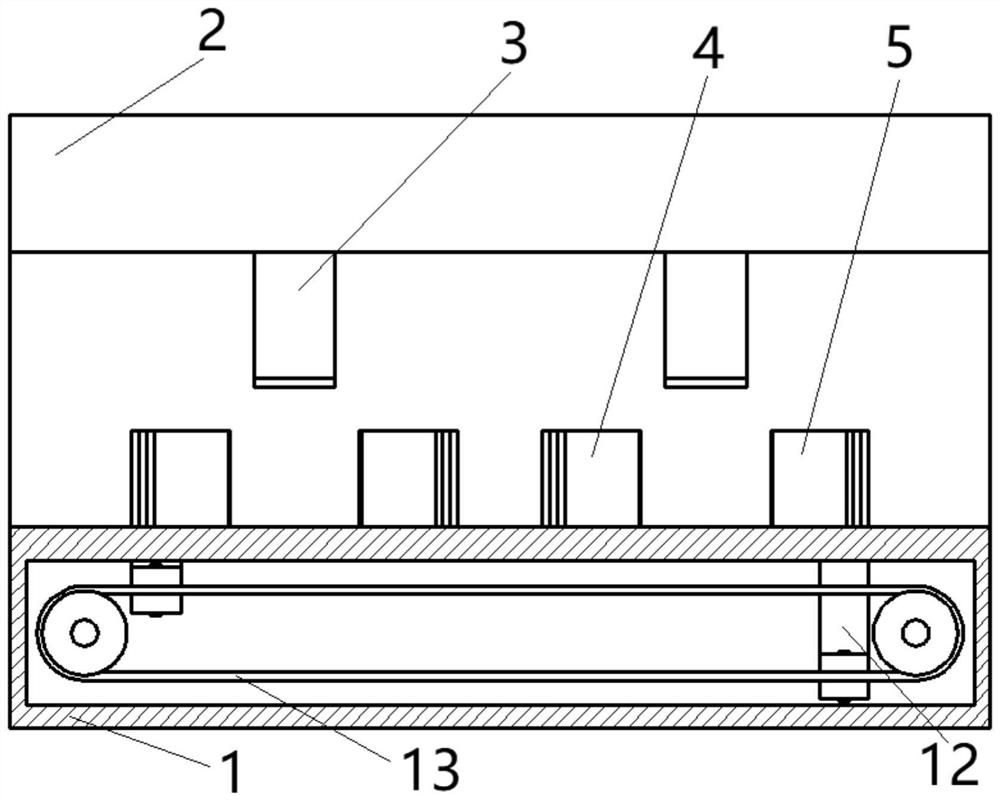

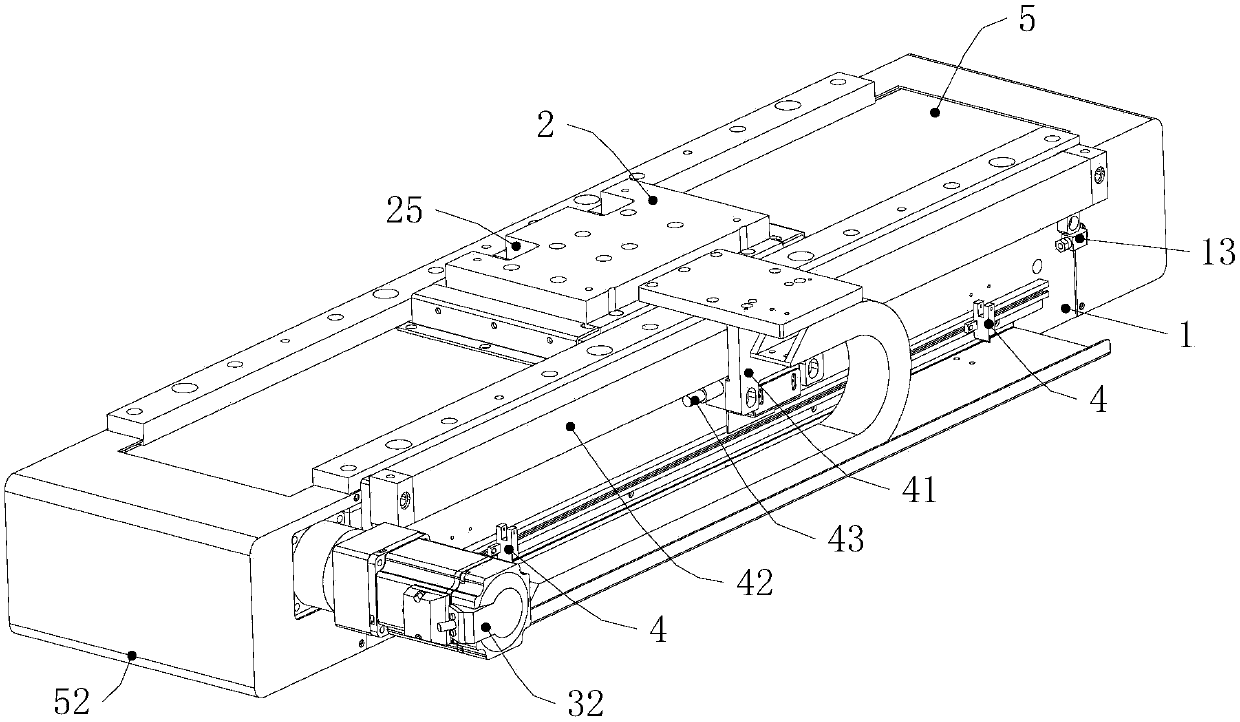

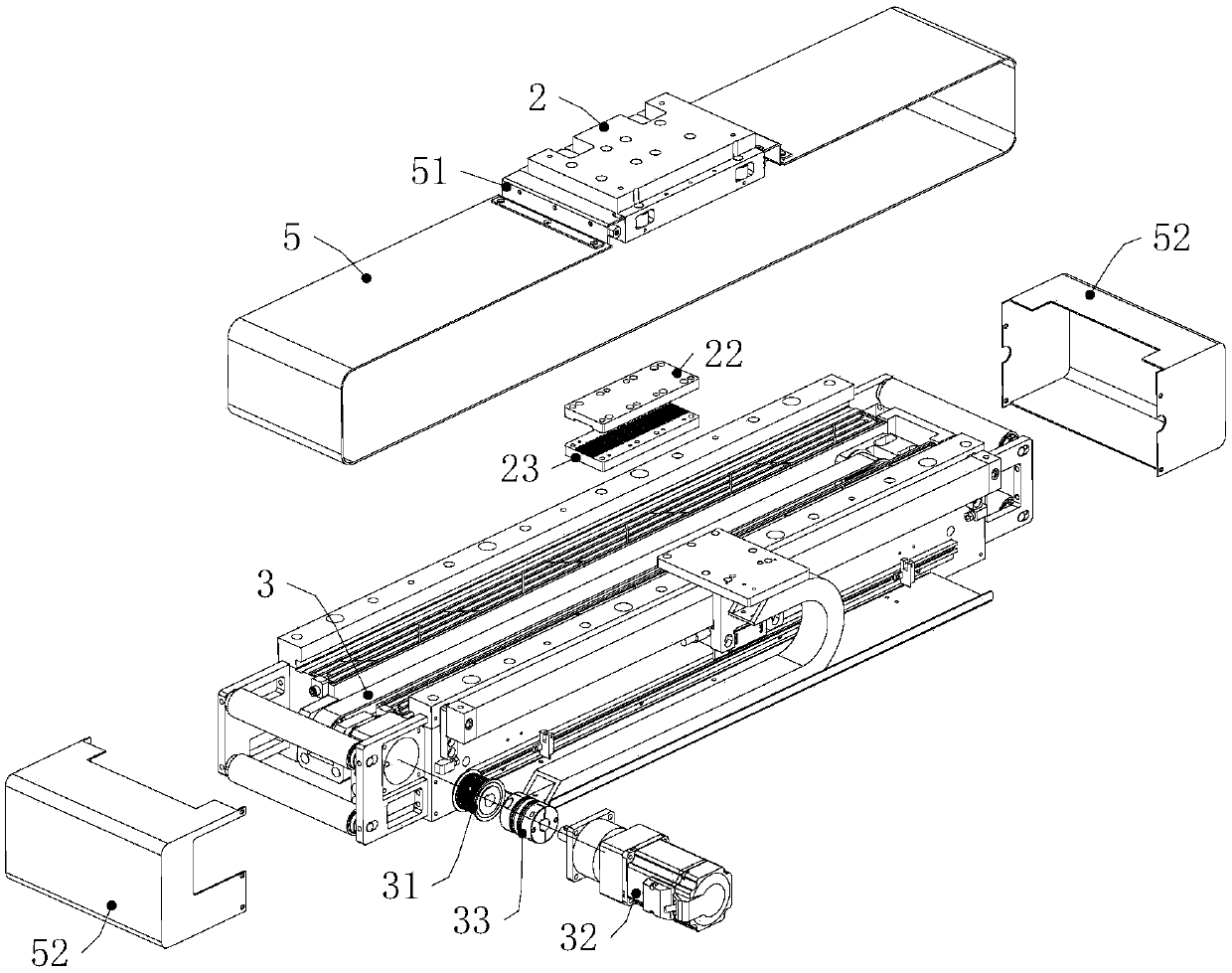

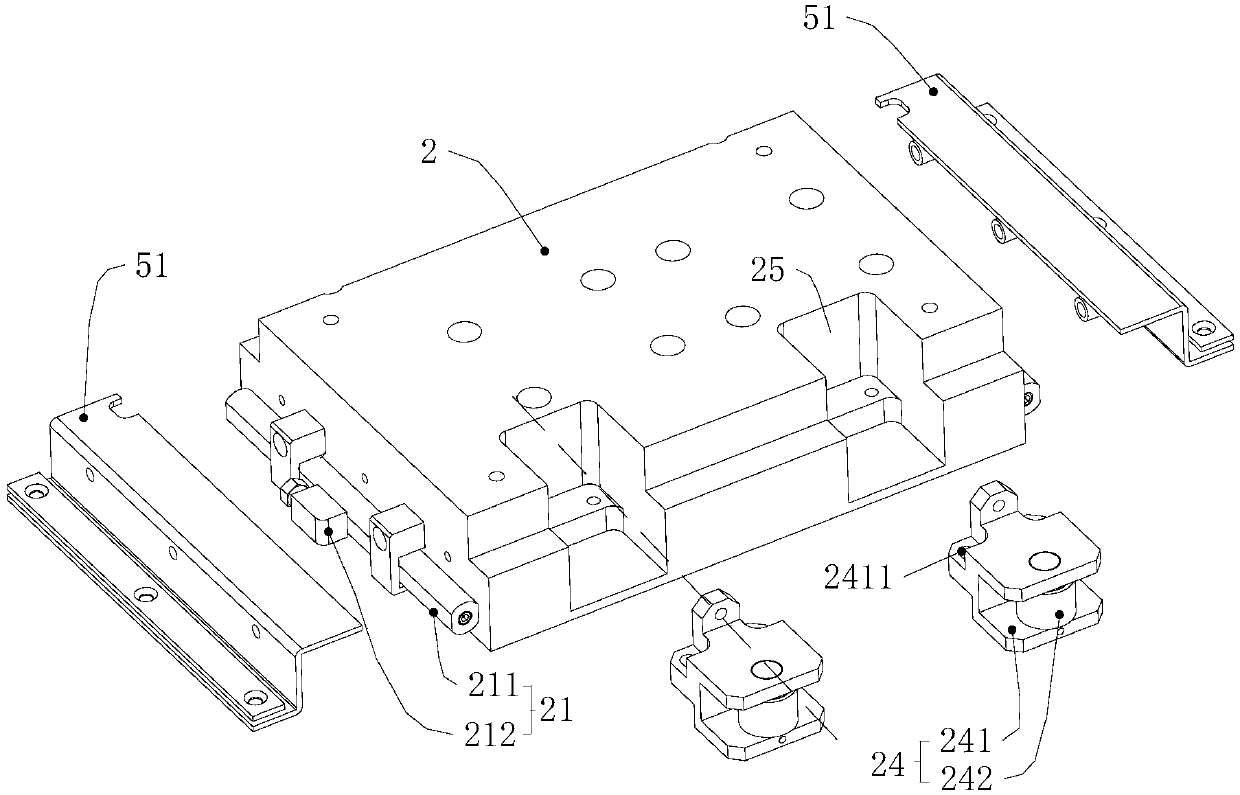

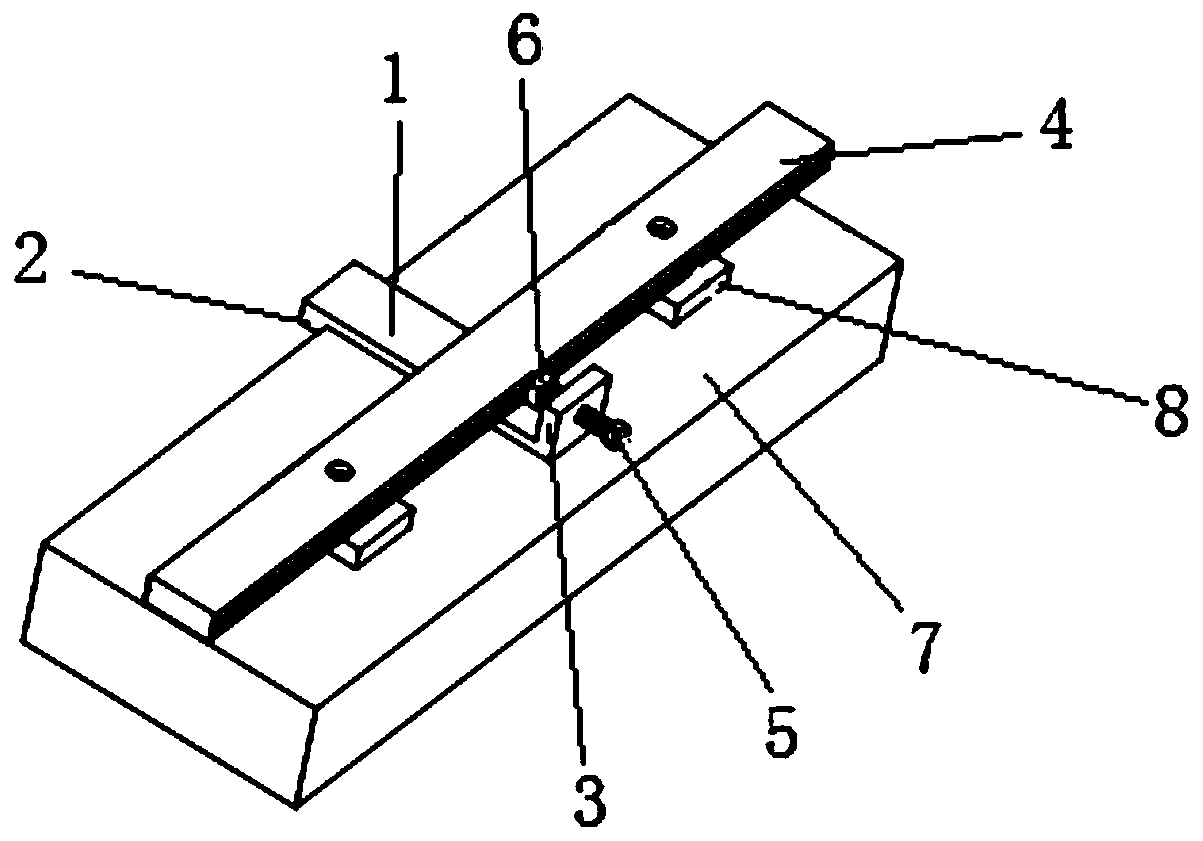

Slide table, coating machine and gluing method

PendingCN110124952AEasy inputEasy outflowPretreated surfacesCoatingsEngineeringMechanical engineering

The invention provides a slide table. The slide table comprises a base and a slide part; the base is provided with a slip part; the slide part is provided with an oil dripping piece; the slip part isprovided with an oil return hole; and lubricating oil dripping from the oil dripping piece flows to the slip part, so that the transverse sliding precision of the slide part on the base is improved. The invention further provides a coating machine; the coating machine comprises a storage tank, a fixture, a mold head, a base plate, a the slide table fixedly connected to the base plate, and a controller; the base plate is provided with a bracket which is assembled with a mold head; the bracket is provided with a lifting mechanism for driving the mold head to ascend or descend; the storage tank is fixedly arranged at the top end of the bracket; and through precise sliding of the slide table, coating liquid is uniform on glued parts, so that the generation of bubbles due to nonuniform coatingof the coating liquid in later procedures is prevented, and the coating quality of the coating liquid is improved. The invention further provides a gluing method; the glued parts are positioned on thefixture, and are calibrated and positioned through a positioning piece; the lifting mechanism is descended, and a gap adjusting mechanism adjusts gaps between the mold head and the glued parts; the slide table moves to a curing device; the coating liquid is coated on the glued parts; and crack outlets are wiped by a wiping mechanism, so that the coating production efficiency and the product quality are improved.

Owner:SHENZHEN MANST TECH CO LTD

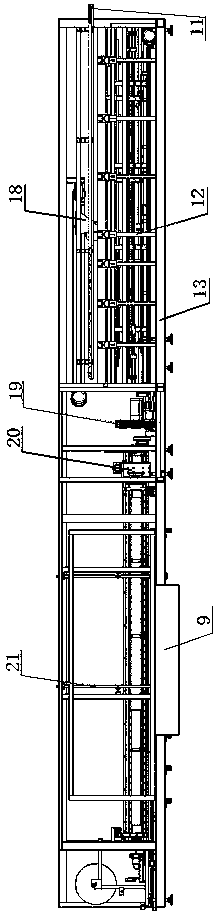

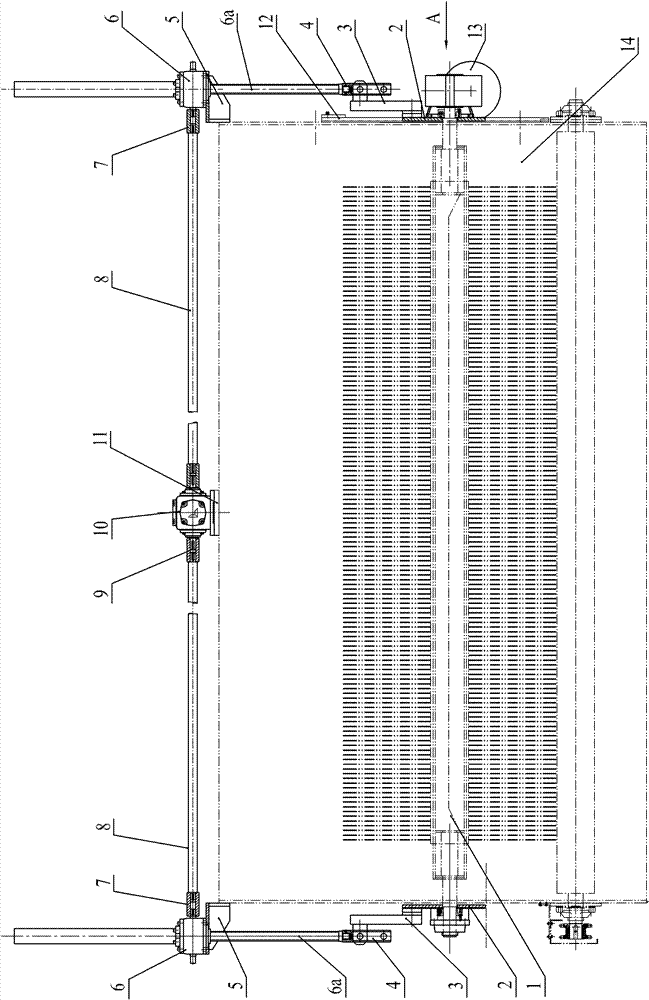

Feeding device for plate splicing welding

InactiveCN108637537AImprove welding efficiencySimple structureWelding/cutting auxillary devicesAuxillary welding devicesTransmission beltEngineering

The invention discloses a feeding device for plate splicing welding. The feeding device comprises a base, wherein first supports are arranged at the two ends of the base; first rollers are arranged between the first supports, first motors are fixed on the side surfaces of the first supports, and the first motors are connected to the first rollers through first transmission belts; an L-shaped frameis arranged at the upper end of one side of one first support, a limiting plate is arranged at the front end of the L-shaped frame, the limiting plate is perpendicular to the first rollers, and a jacking device is arranged in the middle of the base; and a second support capable of ascending and descending vertically is arranged at the upper end of the jacking device, second rollers are arranged on the second support, a second motor is fixed on the side surface of the second support, the second motor is connected to the second rollers through a second transmission belt, and the second rollersare perpendicular to the first rollers. According to the feeding device for the plate spicing welding, the structure is simple, the manufacturing cost is low, the positions of two plates can be accurately adjusted and then the two plates are sent into a jointed plate welding machine, the manual adjusting time is saved, and the welding efficiency of the jointed plate welding is improved.

Owner:WUHU JUNRU THERMAL INSULATION MATERIAL CO LTD

X-ray casting automatic inspection device

ActiveCN103712995BFast detection timeImprove efficiencyMaterial analysis using wave/particle radiationTotal factory controlBus masteringTouchscreen

The invention relates to an automatic X-ray casting detection device. By taking the control of a PLC (programmable logic controller) bus control as a center, the efficiency of a processor is high, the interference resistance is strong, security and reliability in data transmission can be realized, and the automatic X-ray detection can be automatically executed for different castings and different positions. The transmission of the casting is controlled by a PLC bus, the X-ray is automatically adjusted according to the preset condition in the detection of a workpiece on different positions, so that not only can the manual adjustment time be saved, but also the overall detection time of the workpiece can be greatly improved, the limitation caused by the labor skill can be greatly alleviated, no abnormal phenomenon happens in the running process of the device, a system can be stopped through an external emergency temporary button, and the detection can be continued or restarted after the troubleshooting. Each fault point is monitored through a touch screen, the device is started and stopped in a one-key form, the control of the touch screen button is adopted, the service life of the device is prolonged, and the fault points of a mechanical switch can be reduced.

Owner:DONGDAN AOLONG RADIATIVE INSTR GRP

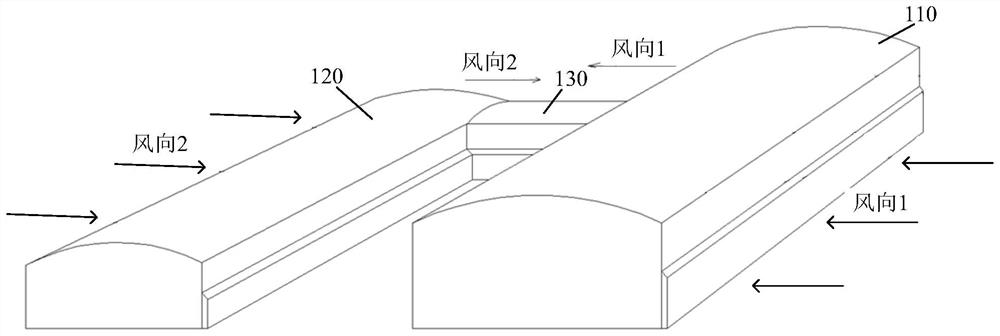

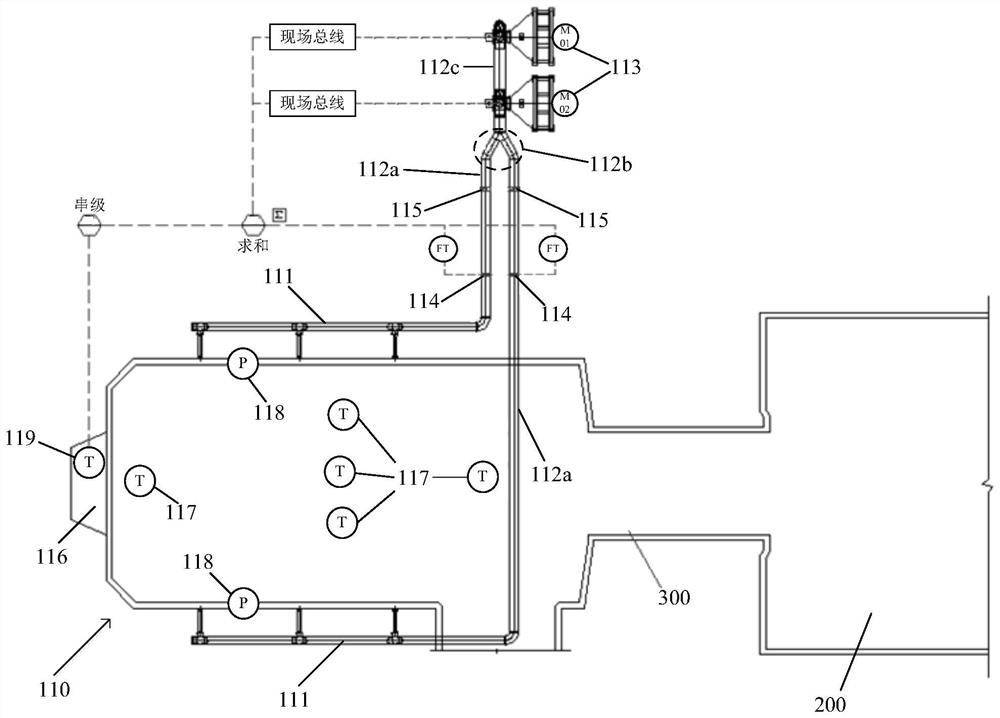

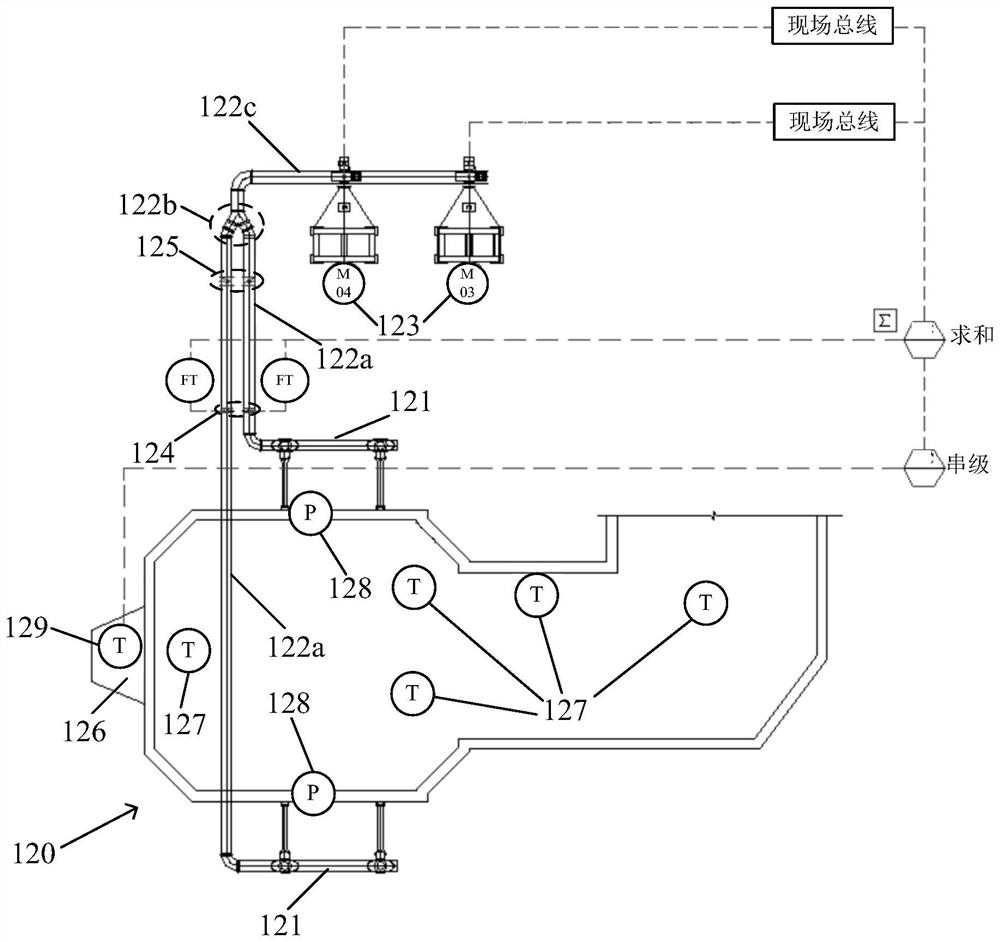

System, method and equipment for controlling dilution air volume of cooling part of one-kiln two-line melting furnace

ActiveCN114292008AAvoid manual adjustmentAvoid the problem of dilution wind interactionGlass furnace apparatusGlass productionAir volumeControl cell

The invention provides a one-kiln two-line melting furnace cooling part dilution air volume control system, method and equipment, and the system comprises a signal collection unit which is used for respectively obtaining the temperature of a flow liquid channel, the dilution air flow and the dilution fan operation frequency corresponding to a main line cooling part and a branch line cooling part; the cascade control unit is used for constructing a cascade control relation among the temperature of a flow liquid channel, the flow of dilution air and the running frequency of a dilution fan corresponding to the main line cooling part and the branch line cooling part respectively; and the decoupling control unit is used for eliminating the influence of cross coupling between the two cooling parts by utilizing a decoupling control algorithm according to the cascade control relation of the main line cooling part and the branch line cooling part, so that the two cooling parts independently control the temperature of the corresponding liquid flow channel by adjusting the dilution air flow. The problem of manual adjustment of a dilution air cooling system of a traditional float glass factory is avoided, and the problem of mutual influence of dilution air of two cooling parts is avoided; the manual adjustment time is saved, and the production efficiency is improved.

Owner:CHINA TRIUMPH INT ENG

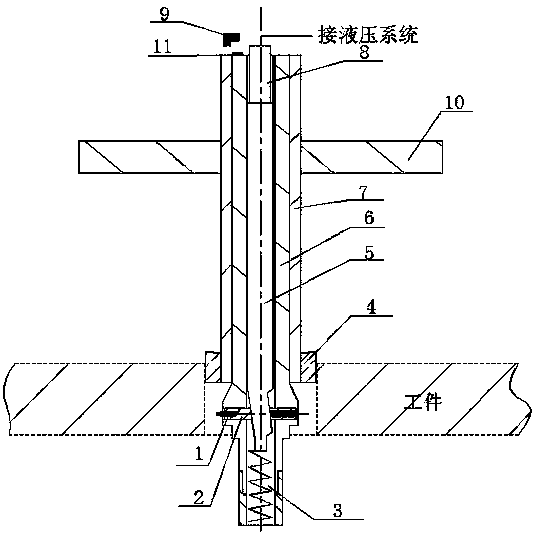

Machining device of thin and long in-hole groove

ActiveCN103028787BIncrease stiffnessImprove machining accuracyMeasurement/indication equipmentsFeeding apparatusFixed frameMachining

The invention provides a machining device of a thin and long in-hole groove, which is characterized by comprising a fixing frame (10), a positioning block (4), an outer sleeve (7), an inner sleeve (6) and an ejection rod (5), wherein the positioning block (4) is inserted into a workpiece hole; one end of the outer sleeve (7) is connected with the fixing frame (10) and the other end of the outer sleeve (7) is connected with the positioning block (4); the inner sleeve (6) is sleeved inside the outer sleeve (7); one end of the inner sleeve (6) stretches out of the outer sleeve (7) and is provided with a groove cutter bar (2); the groove cutter bar (2) is provided with a groove cutter (1); the ejection rod (5) is sleeved into the inner sleeve (6); one end of the ejection rod (5) is inserted into the groove cutter bar (2) and is provided with an inclined plane and the other end of the ejection rod (5) is connected with a pressing head (8); and the inner sleeve (6) is further provided with a resetting spring (3). The machining device of the thin and long in-hole groove has the advantages of good rigidity, high machining precision and high automation degree, can realize self-centering and controllable angle, can save a lot of manual adjusting time, is suitable for batch machining, is good for reducing the machining cost, and improves the economic benefits.

Owner:安徽新诺精工股份有限公司

Automatic strapping machine pressure material support material adjustment mechanism

ActiveCN105270668BEasy clearance adjustmentSimple structureBundling machine detailsTime costMachine press

The invention discloses a pressing and supporting material regulating mechanism of an automatic bundling taping machine. The pressing and supporting material regulating mechanism comprises a support frame, wherein the support frame comprises a first support vertical part, a second support vertical part and a support inclined part which is fixedly connected between the first support vertical part and the second support vertical part, an obtuse angle is formed between the first support vertical part and the support inclined part, so that a pipe can roll down on the support inclined part in an inclined mode, a fixed pipe guide frame which is used for leading the pipe to roll down in the inclined mode is arranged above the support inclined part, a sliding material pressing plate which is arranged in parallel to the support inclined part is embedded into the fixed pipe guide frame, a chute is formed in the fixed pipe guide frame, an included angle formed between the chute and the support inclined part is one half of the obtuse angle formed between the first support vertical part and the support inclined part, and the chute is movably connected and matched with a sliding shaft which passes through the sliding material pressing plate, so that one end of the sliding material pressing plate is embedded into the fixed pipe guide frame. The pressing and supporting material regulating mechanism has the advantages of simple integral structure and rapidity in regulating a gap through which the pipe passes, and the labor and time cost is greatly saved.

Owner:GUANGDONG LIANSU MACHINERY MFG

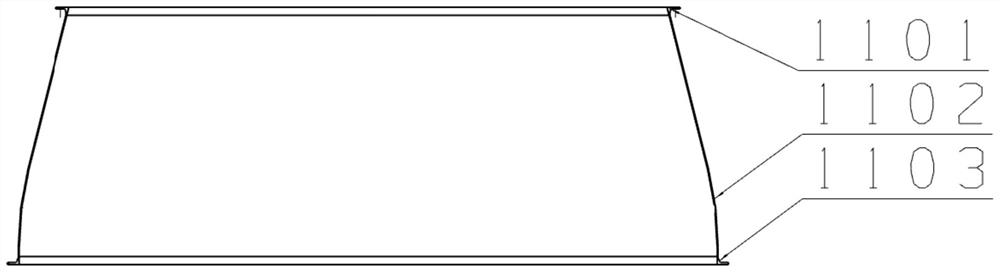

Bending mechanism and operation method for intelligent carbon skateboard production convenient for rapid operation

ActiveCN111151600BAvoid shakingIncrease productionMetal-working feeding devicesPositioning devicesSlide plateManufacturing engineering

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

Electric lifting roll brush device

ActiveCN102229119BSmooth liftIngenious structureAbrasive machine appurtenancesMotor speedBrush device

Owner:无锡洲翔成套焊接设备有限公司

A casting defect ray detection system

InactiveCN104502383BFast detection timeReduce manual adjustment timeMaterial analysis using wave/particle radiationEngineeringCasting defect

Owner:CHONGQING UNIV OF TECH

Guide rail straightness adjusting method and adjusting device

PendingCN110281004AGuaranteed correction accuracyHigh linear precisionMetal working apparatusEngineeringMechanical engineering

Owner:GUANGXI YUCHAI MASCH CO LTD

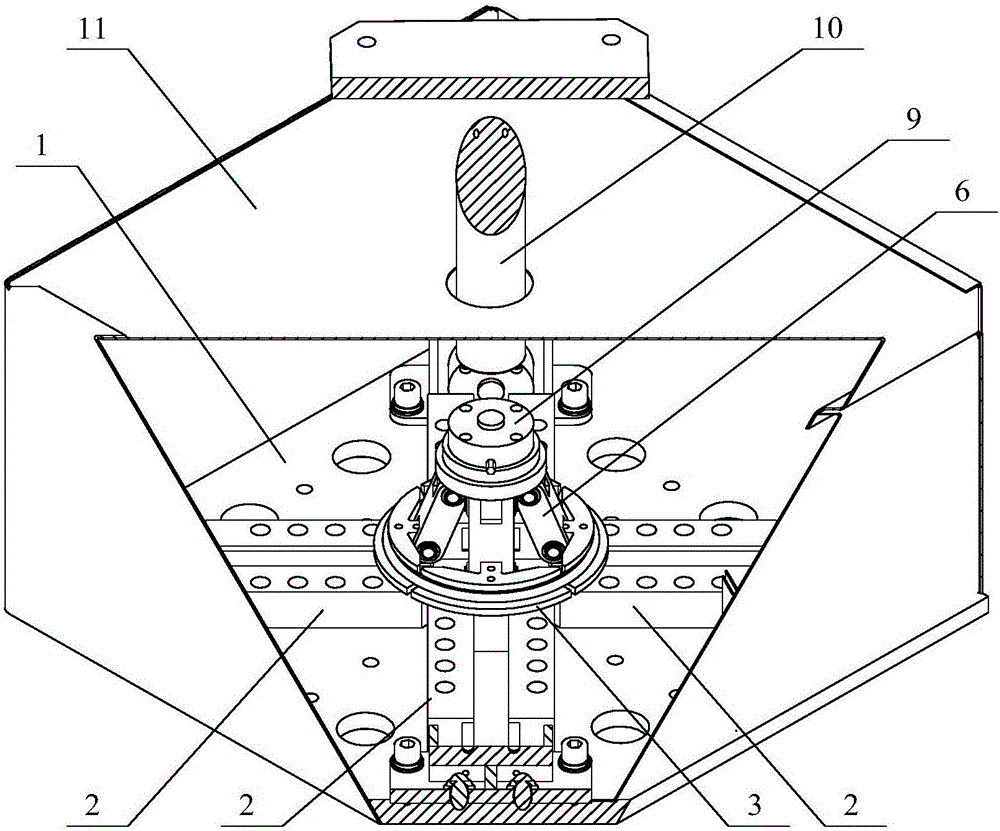

A welding device and method for argon arc welding with double-weld expansion core support

ActiveCN112192007BSolve assembly welding problemsQuick assemblyWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringArc welding

The invention discloses a welding device and method for argon arc welding with a double-weld seam expansion support. A double-layer expansion structure is adopted. The lower expansion mechanism is provided with a long rod nut, and the long rod nut extends out of the upper expansion mechanism for operation. Control the opening and closing of the lower expansion mechanism; the upper expansion mechanism uses a hollow positioning shaft plus a layer opening and closing nut to control the opening and closing of the upper expansion mechanism. This setting can effectively separate the operation of the upper expansion mechanism and the lower expansion. heart agency. The invention solves the problem of assembling the welding assembly, makes the cylindrical part that is easily deformed into an elliptical ring rounded by expansion blocks, ensures fast assembly, greatly reduces the manual adjustment time, ensures fast welding assembly, convenient operation, and good welding quality , overcame the difficulty of welding, so that the cylindrical parts that were easy to deform into elliptical rings are rounded by expansion blocks, ensuring fast assembly, greatly reducing the time for manual adjustment, and suitable for popularization and application.

Owner:AECC AVIATION POWER CO LTD

A lithium battery conduction test device for electronic equipment

The invention discloses a lithium battery conductivity testing device for electronic equipment, which includes a body, a sorting cavity is arranged inside the body, and a feeding trough with an upward opening is connected to the left side wall of the sorting cavity. The bottom wall of the cavity is connected with a collection cavity with an upward opening and a waste cavity. The waste cavity is located on the right side of the collection cavity. The bottom wall of the feeding trough is provided with a chute with an upward opening. There is a slider, the front and rear walls of the chute are slidably installed with a push plate on the lower side of the slider, and an inclined rod is installed on the left and right symmetrical sliding of the push plate and the slider, and the inclined rod is connected by a supporting spring. The bottom wall of the chute, the push plate is connected to the bottom wall of the chute through a tension spring, and the rear side wall of the chute is provided with a swing groove. This device has a simple structure and is easy to operate. The cooperation between them drives the turning disc to rotate, so that the lithium battery can be turned over automatically, which reduces the time for manual adjustment and facilitates follow-up work.

Owner:徐州储盈电子科技有限公司

A method and system for improving the accuracy of capacitance value

ActiveCN110082383BRealize automatic adjustmentHigh precisionRadiation pyrometryUsing electrical meansCapacitanceWafer

Owner:福建省福联集成电路有限公司

A extrusion self-adjusting device for printing machinery

ActiveCN112477383BEasy to operateImprove work efficiencyRotary pressesPrinting press partsPrinting pressMechanical engineering

Owner:江华九恒数码科技有限公司

Method for realizing accurate positioning of steel billet delivered into a heating furnace

ActiveCN102230067BHigh precisionImprove stabilityFurnace typesUsing optical meansHeating furnaceBraking equipment

The invention relates to the technical field of heating furnace automatic controlling, and discloses a method for realizing accurate positioning of a steel billet delivered into a heating furnace. According to the invention, logic of automatic controlling is skillfully combined with the function of a furnace roller table converter. Without external braking equipment, slipping phenomena occurred after positioning of steel billets with lengths smaller than 2700mm are avoided. With the method, accurate positioning of any sized steel billet can be realized, and slipping does not occur after positioning.

Owner:BEIJING SHOUGANG AUTOMATION INFORMATION TECH

Corner polishing machine for wood board processing

InactiveCN112548755AImprove efficiencyGuaranteed uniformityEdge grinding machinesGrinding drivesElectric machineryDust control

The invention discloses a corner polishing machine for wood board processing. The corner polishing machine comprises a case, a lifting mechanism, a polishing mechanism, a conveying device and an adjusting mechanism are arranged in the case, a dust removing mechanism is arranged at the top of the case, a fixing mechanism is arranged on the side face of the case, a board inlet is formed in the frontface of the case, and a wood outlet is formed in the back face of the case. According to the corner polishing machine for wood board processing, a motor works to polish corners of a wood board, manpower is replaced with machinery, efficiency is higher, and product uniformity is guaranteed; and the adjusting mechanism is arranged, so that the polished corners of the wood can be adjusted when the wood is conveyed, a polishing roller can polish other corners of the wood conveniently, the manual adjusting time is shortened, and therefore the working efficiency of the polishing machine is improved, and through cooperative use of the adjusting mechanism and the polishing mechanism, the polishing machine automatically and comprehensively polishes the corners of the wood board, so that automaticprocessing of the wood board is realized, and the loss of human resources is reduced.

Owner:恒凌金属制品(湖州)有限公司

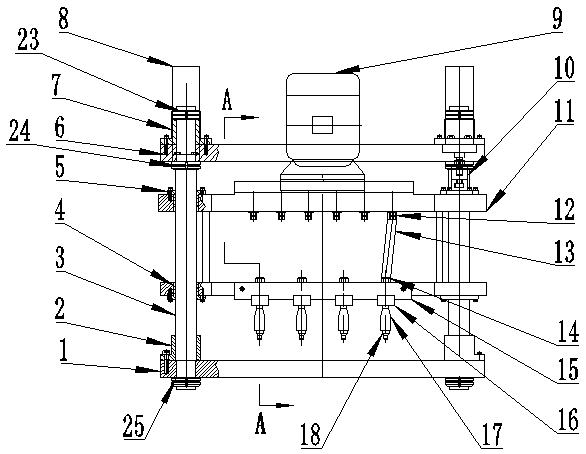

Multi-axis quick-change drill bit assembly structure and quick-change method for drilling holes in conveyor belts

ActiveCN105397140BGuaranteed shape requirementsGuaranteed size requirementsLarge fixed membersBoring/drilling machinesPunchingUniversal joint

Owner:镇江三维输送装备股份有限公司(中外合资)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com