Multi-axis quick-change drill bit assembly structure and quick-change method for drilling holes in conveyor belts

A technology of assembly structure and drill bit replacement, applied in boring/drilling, drilling/drilling equipment, large fixed members, etc., to achieve the effects of improving processing efficiency, convenient installation and adjustment, and reliable positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

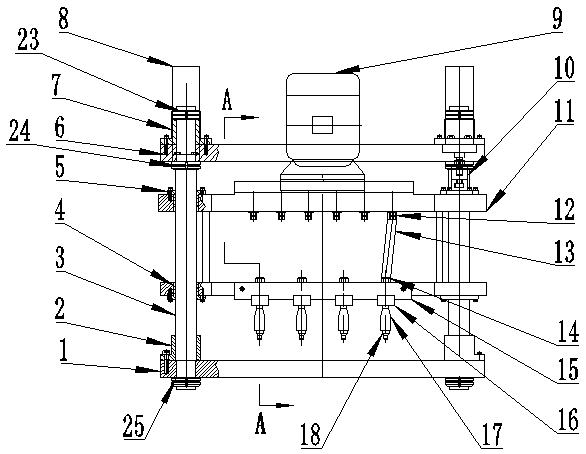

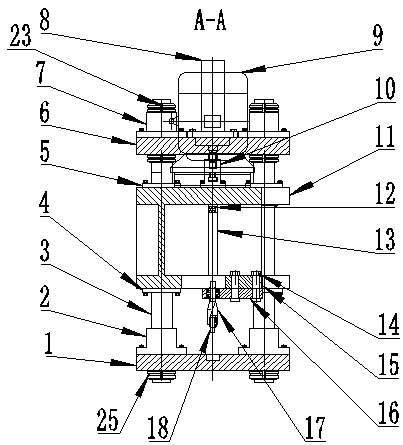

[0018] Such as figure 1 , figure 2 As shown, the present invention includes an upper base plate 6 and a lower base plate 1, the upper base plate 6 and the lower base plate 1 are arranged horizontally and parallel to each other, and vertical guide posts 3 are connected between the upper base plate 6 and the lower base plate 1, and the guide posts 3 have Four, a guide post 3 is arranged at the four corners of the upper base plate 6 and the lower base plate 1 respectively, and the guide post 3, the lower base plate 1 and the upper base plate 6 form a basic frame.

[0019] The lower end of each guide post 3 is fixedly covered with a guide sleeve 2, and the guide sleeve 2 forms a fixed connection with the lower base plate 1, so that the lower end of the guide post 3 and the lower base plate 1 are fixed, and the lower end of the guide post 3 is connected with a round nut 25, and the round nut 25 is located below the lower bottom plate 1, and the lower end of the guide post 3 is li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com