Irregular cutting tool

A technology for cutting knives and special shapes, which is applied in the direction of knives, shearing devices, and manufacturing tools used in shearing machines. It can solve the problems of cumbersome procedures, low processing efficiency, and unfavorable saving of raw materials, etc., and meet the requirements of guaranteed shape and size. , high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

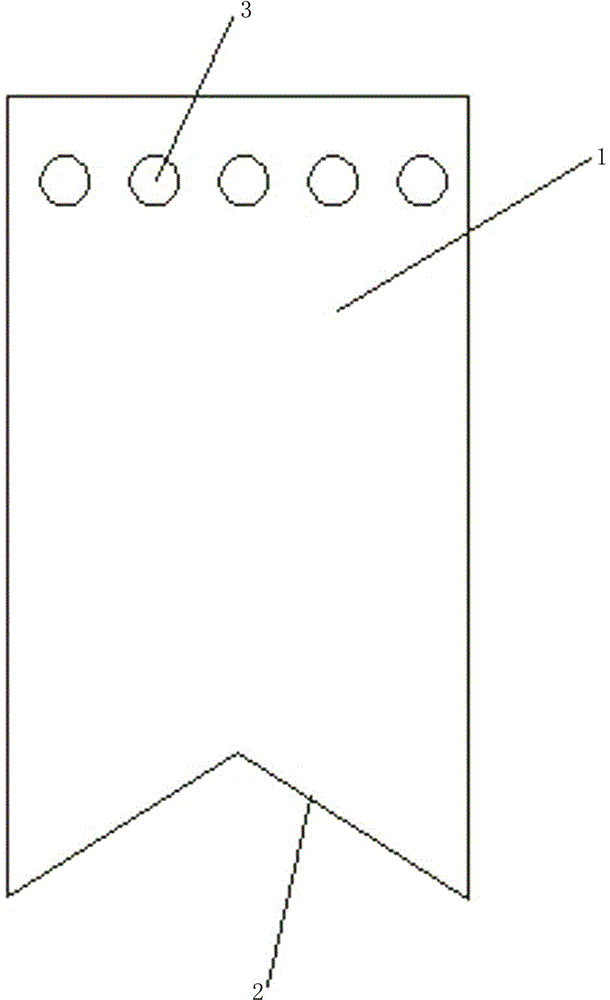

[0014] The design will be further described below in conjunction with the accompanying drawings of the description.

[0015] A special-shaped cutting tool, including a handle 1 and a blade 2, is characterized in that the blade 2 is in a figure-eight shape.

[0016] The shape of the blade 2 is the profile structure of the workpiece to be processed.

[0017] further:

[0018] The above-mentioned special-shaped cutting tool is characterized in that: the angle between the blade 2 and the vertical direction is 60°.

[0019] According to the shape of the structure, the blade 2 can be designed in various angles.

[0020] The special-shaped cutting tool is characterized in that: a tool mounting hole 3 is provided at the end of the handle 1 .

[0021] The above-mentioned special-shaped cutting tool is characterized in that: the number of the tool mounting holes 3 is five.

[0022] The number of tool mounting holes 3 should be reasonably set according to the hardness of the structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com