A Forming Method of Thin-Wall Twisted Tube with Large Cross-section Ratio and Triangular Section

A triangular and large cross-section technology is applied in the field of forming thin-walled twisted pipes with larger cross-section than triangular cross-section. It can solve the problems of insufficient fillet forming, large difference in cross-section expansion, and large cross-section change rate to achieve high forming efficiency. Improved forming yield and higher price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further explained below in conjunction with specific embodiments and accompanying drawings.

[0037] The present invention comprises the following steps:

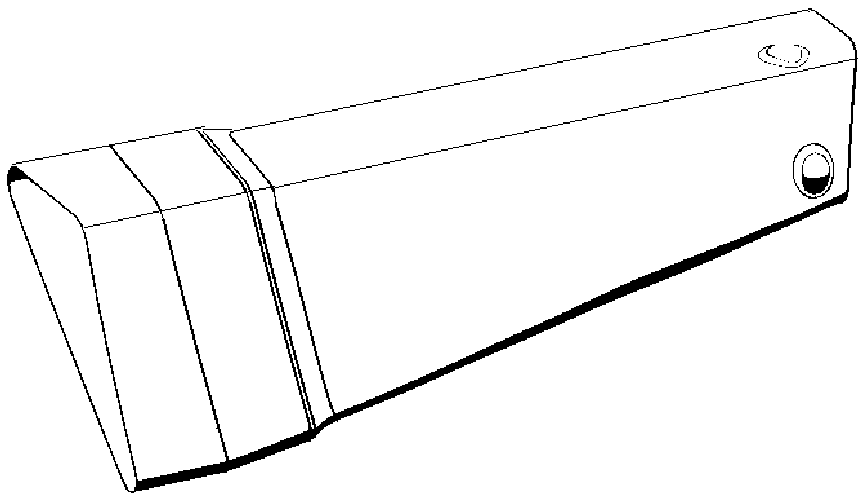

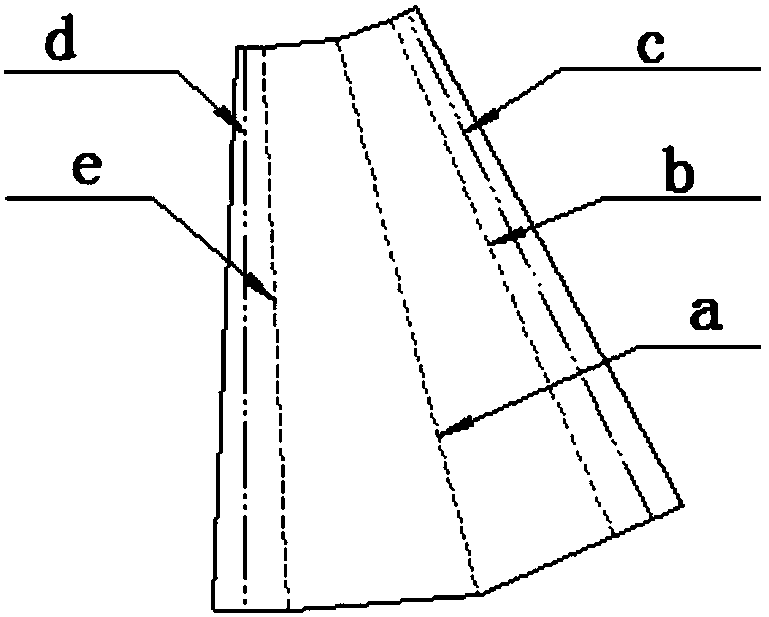

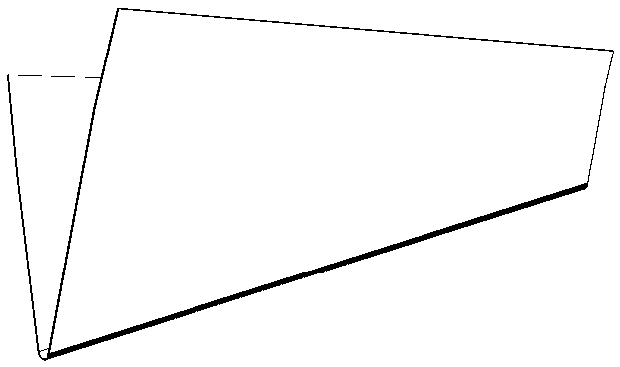

[0038] 1) After bending the sheet metal, cut the weld seam along the longitudinal line, and weld it longitudinally to obtain a triangular pyramid tube. The side is the middle bending line a of the sheet metal, and the trapezoid at both ends of the sheet material is respectively provided with a left bending line e and a right bending line b, and the bending line is respectively provided with a left weld cutting line d and a right welding seam cutting line c , the welding seam cutting line increases the cutting margin of the cutting weld outward respectively; the fillet radius of the cross section of the triangular pyramid tube is less than or equal to the fillet radius of the corresponding cross section of the finished part, and the weld seam of the triangular pyramid tube is divided in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com