A method and system for improving the accuracy of capacitance value

A capacitance value and precision technology, applied in the field of semiconductor production machine parameter control, can solve problems such as low machine adjustment efficiency, save manual adjustment time, improve accuracy, and achieve the effect of automatic adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to explain the technical content, constructive features, the purpose and effects of the technical solution, and the specific embodiments are described below, and the accompanying drawings will be described in detail.

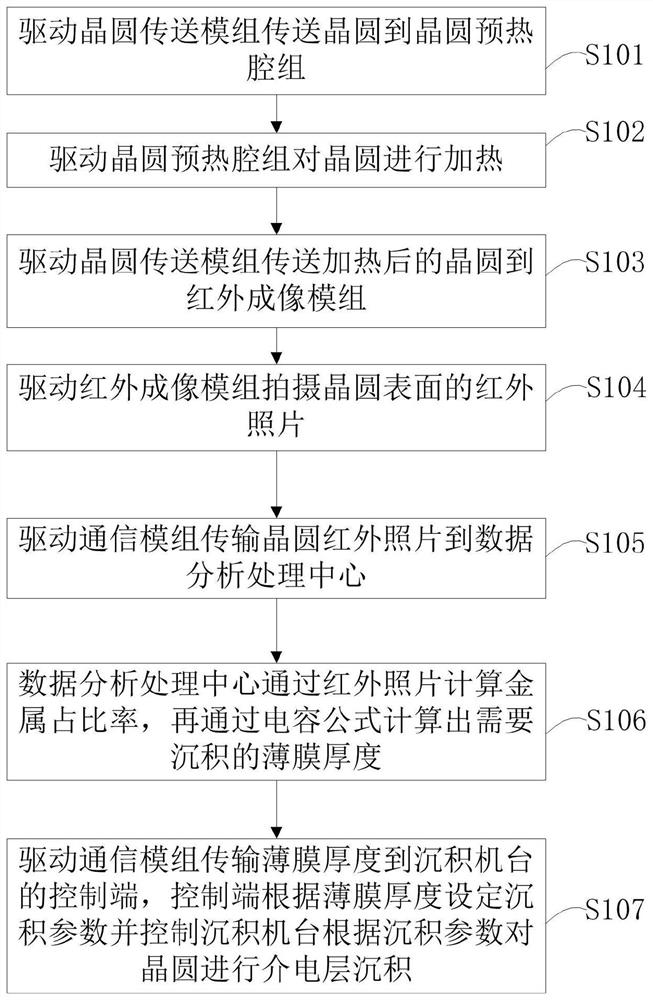

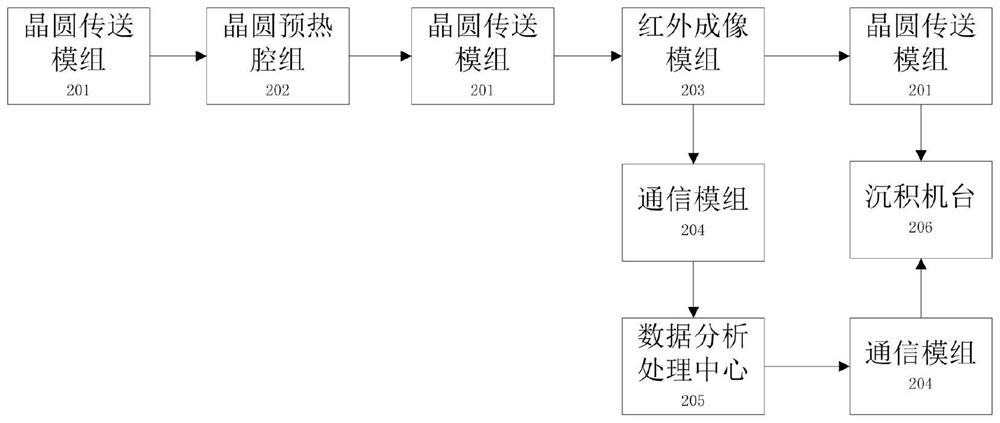

[0046] See Figure 1 to 2 This embodiment provides a method of improving capacitive capacitance value, which can be applied figure 2 System on the system. The main body of the method can be an independent total controller on the system, and the total controller acts as a forwarding and timing of the timing. Alternatively, each step can also be performed by each module. The method includes step S101 driving wafer transmission module transfer wafer to wafer preheating chamber; step S102 drives the wafer preheating chamber to heat the wafer; heating can be the bottom surface of the wafer Then, the heat is conducted through the wafer bottom surface to the wafer top. Step S103 drives the wafer transfer module to transfer the heated wafer to the infrared im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com