Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Realize reciprocating linear motion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

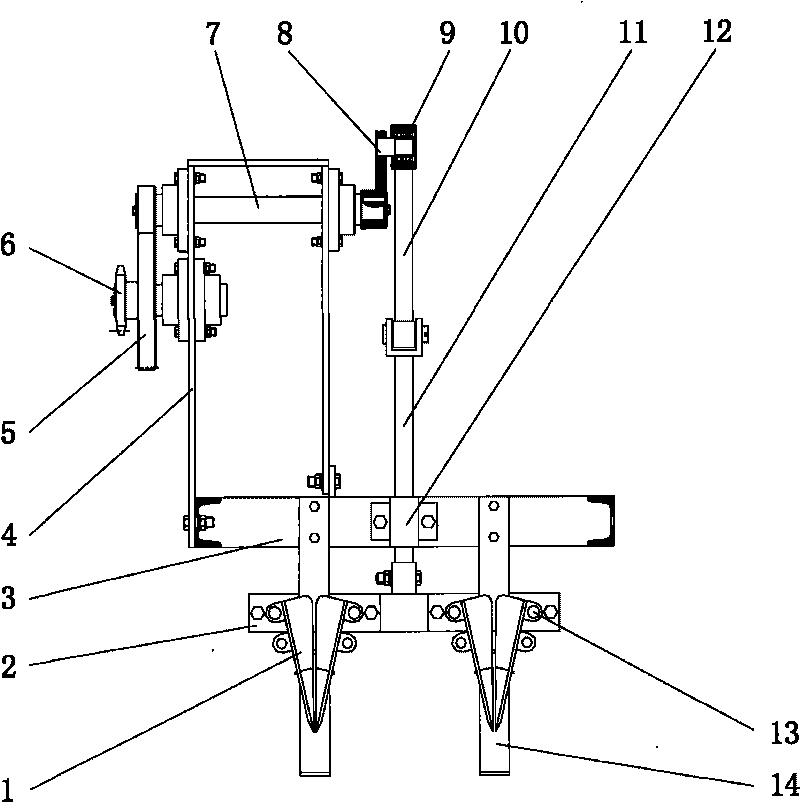

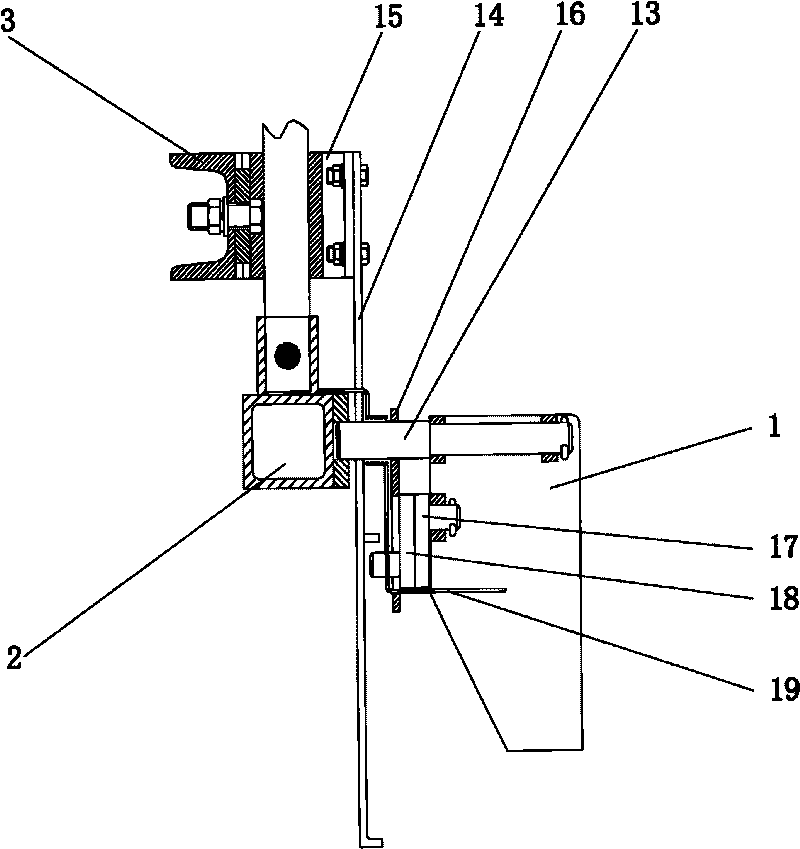

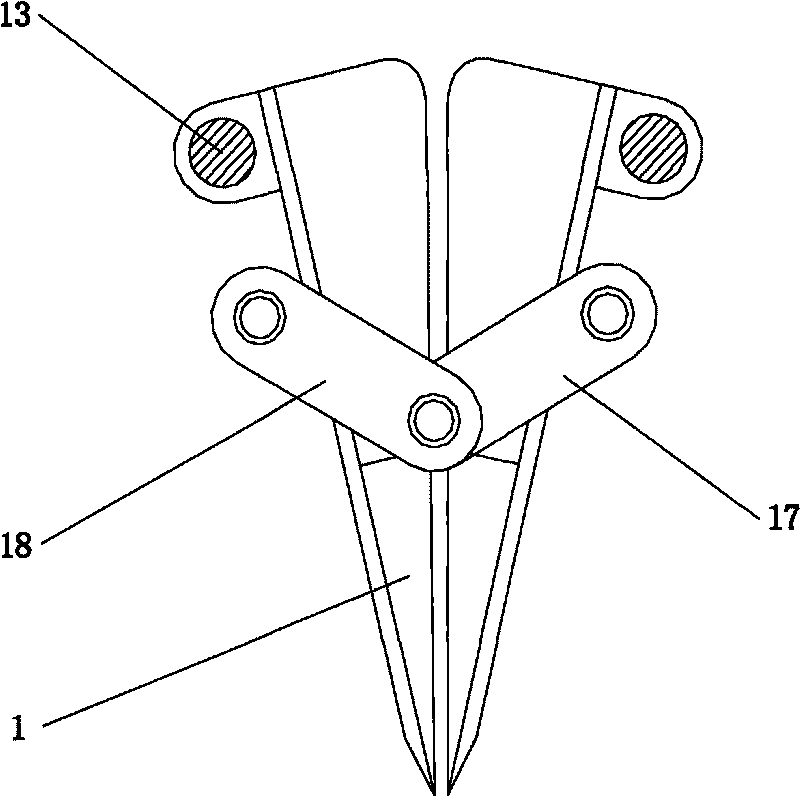

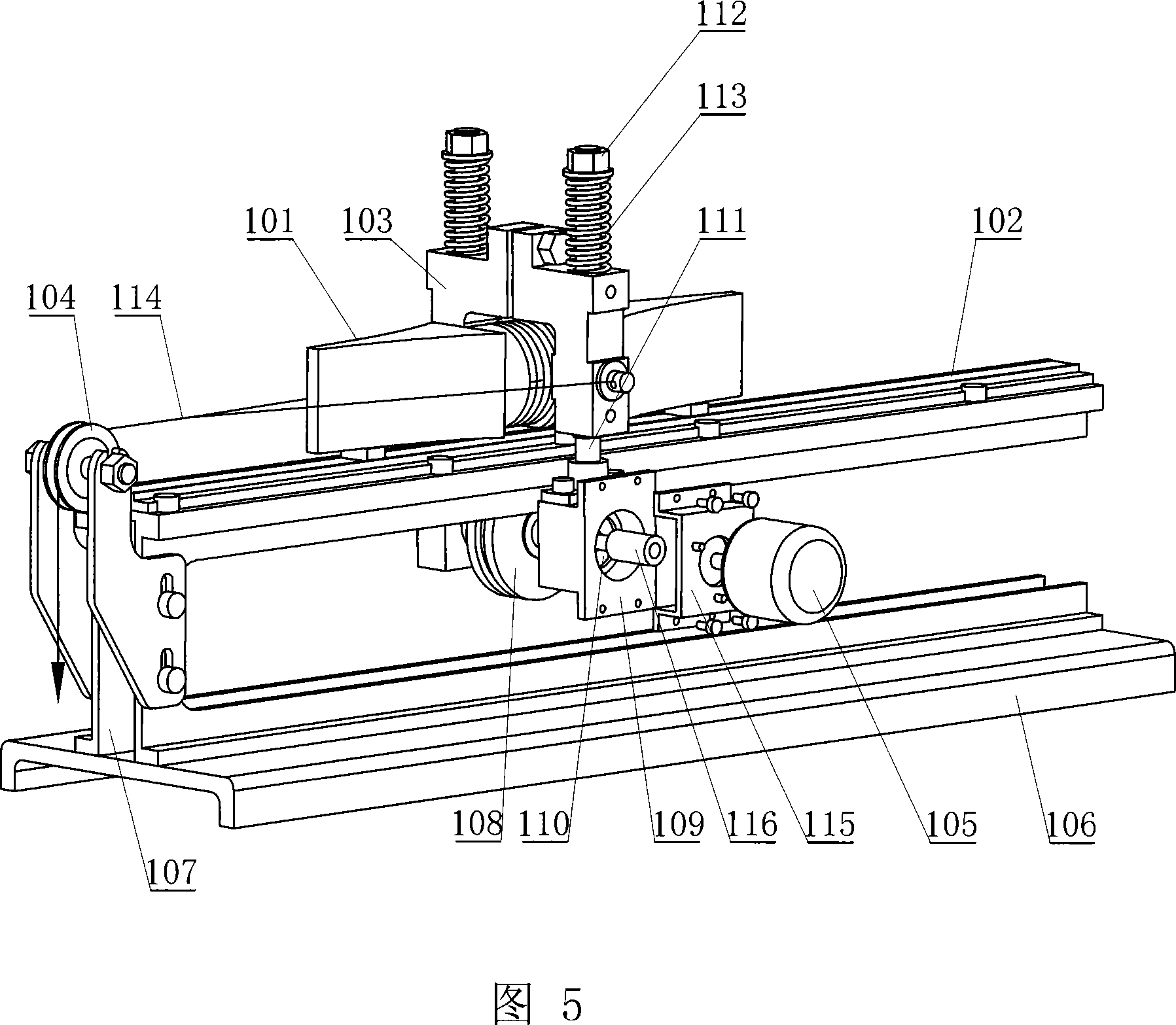

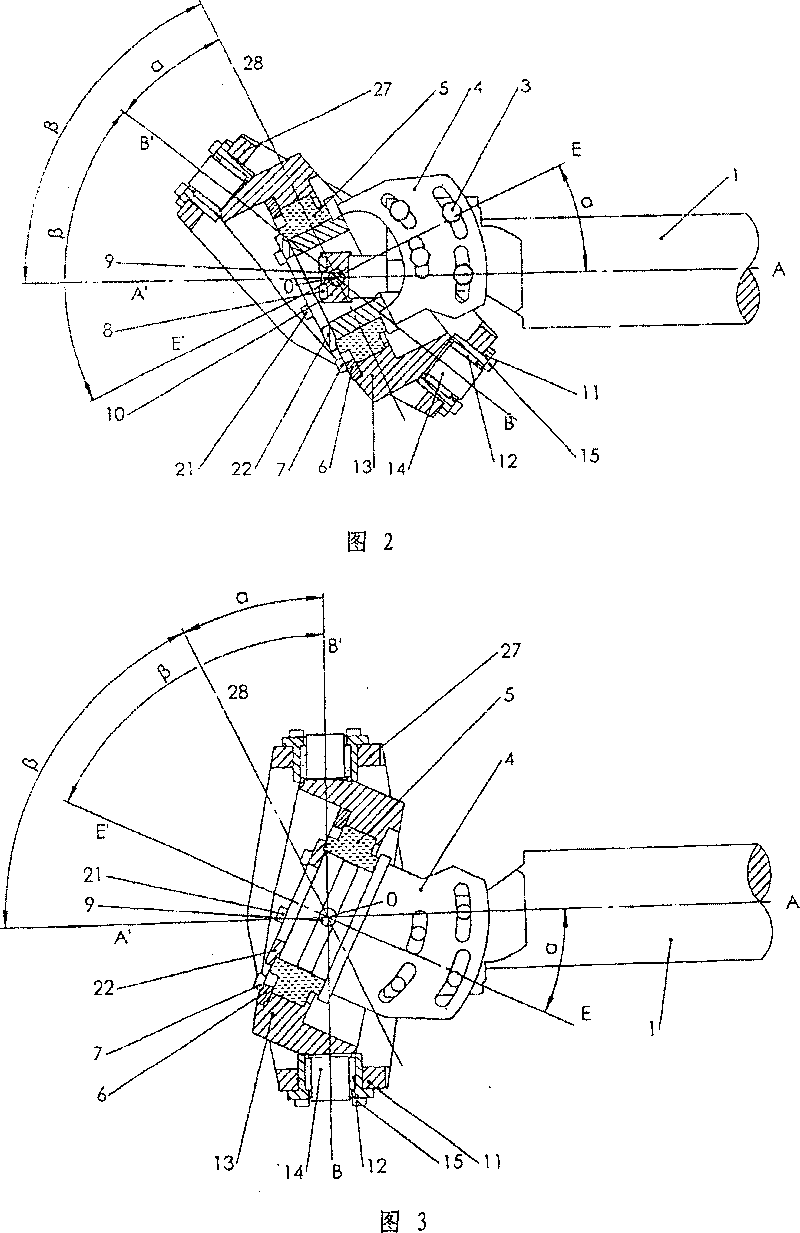

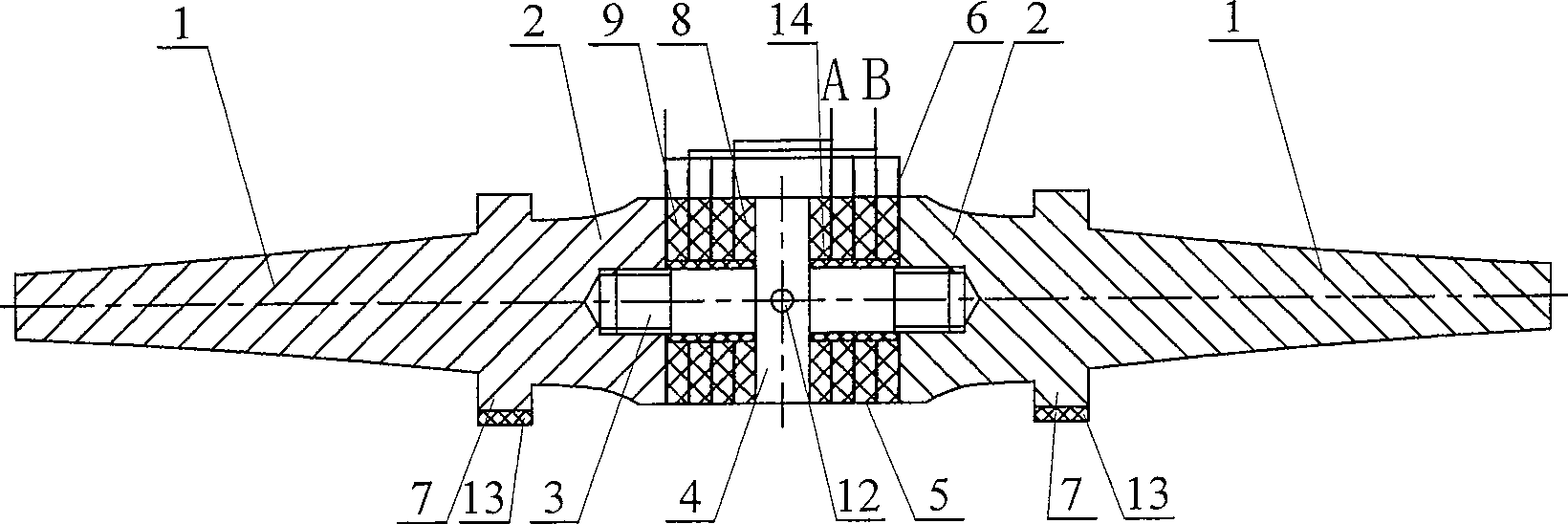

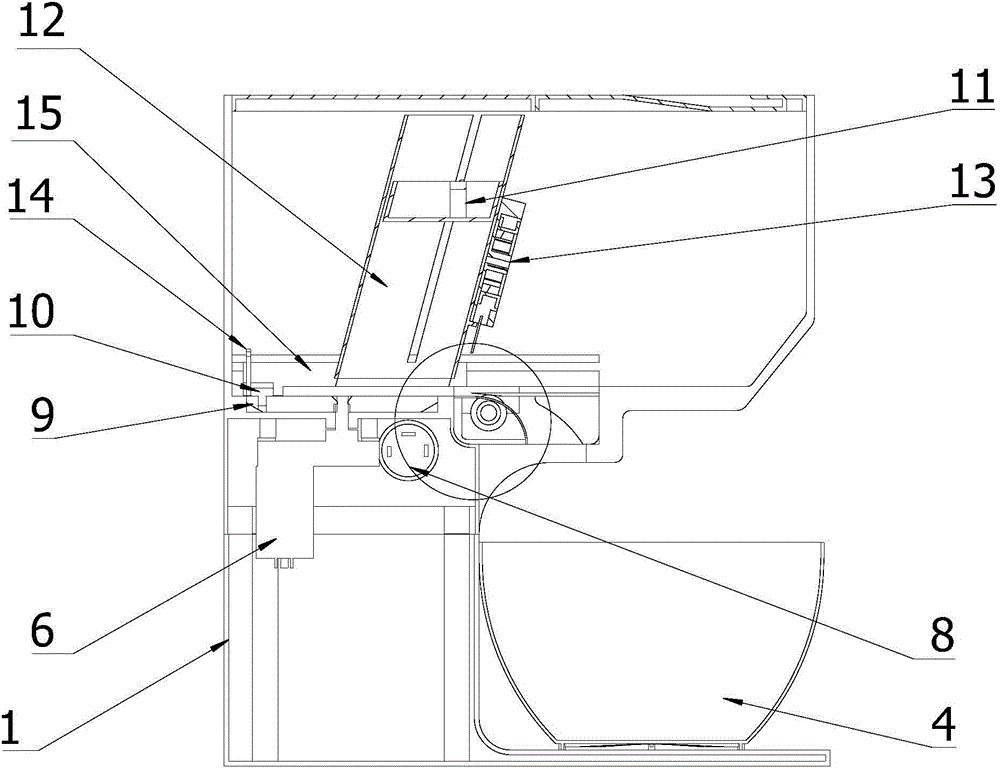

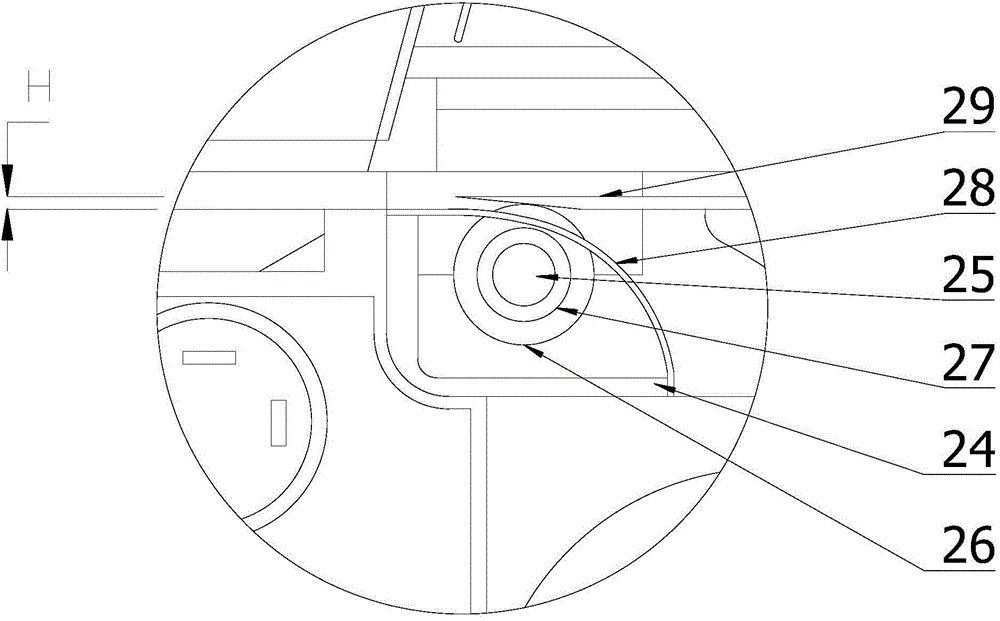

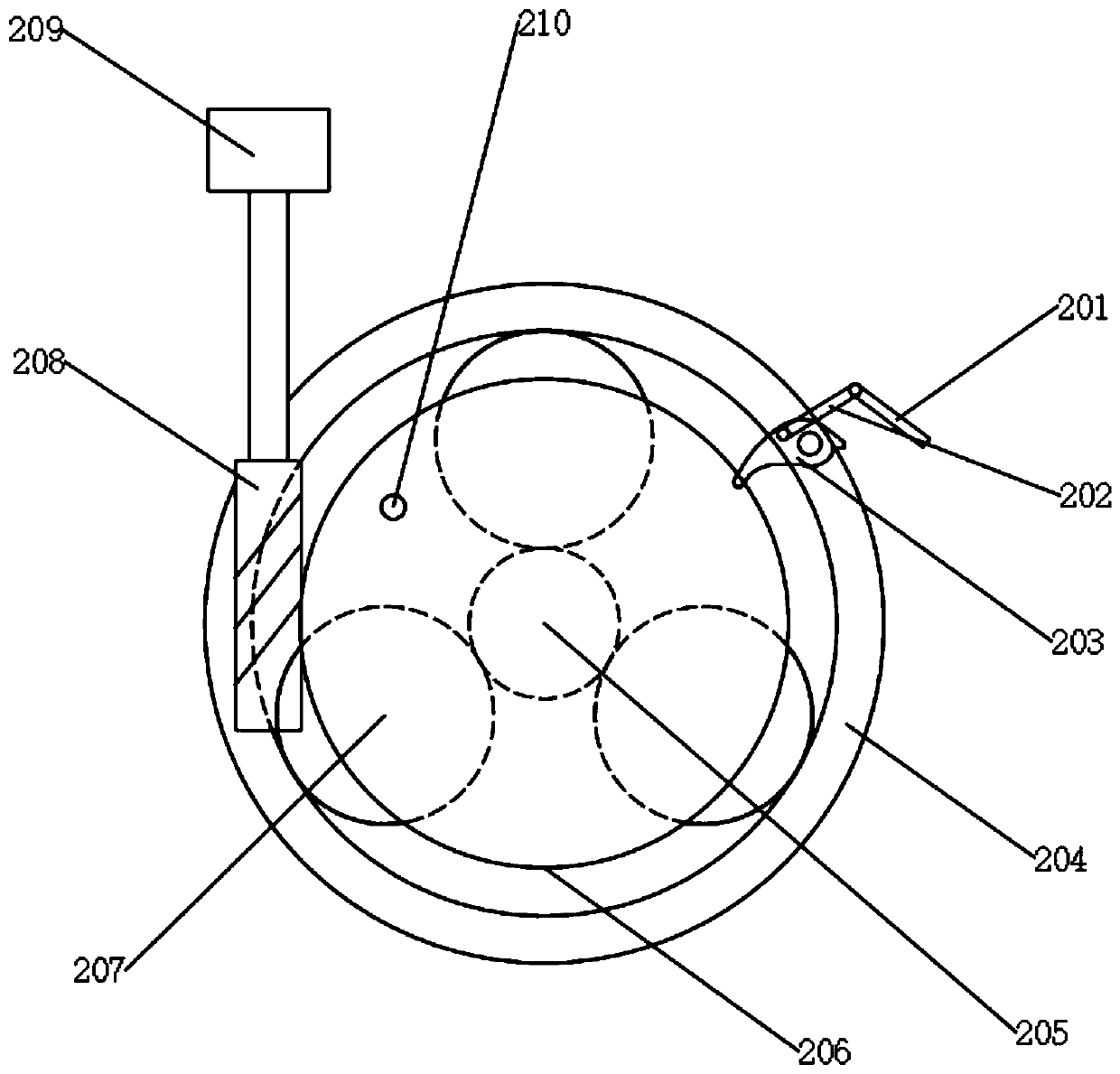

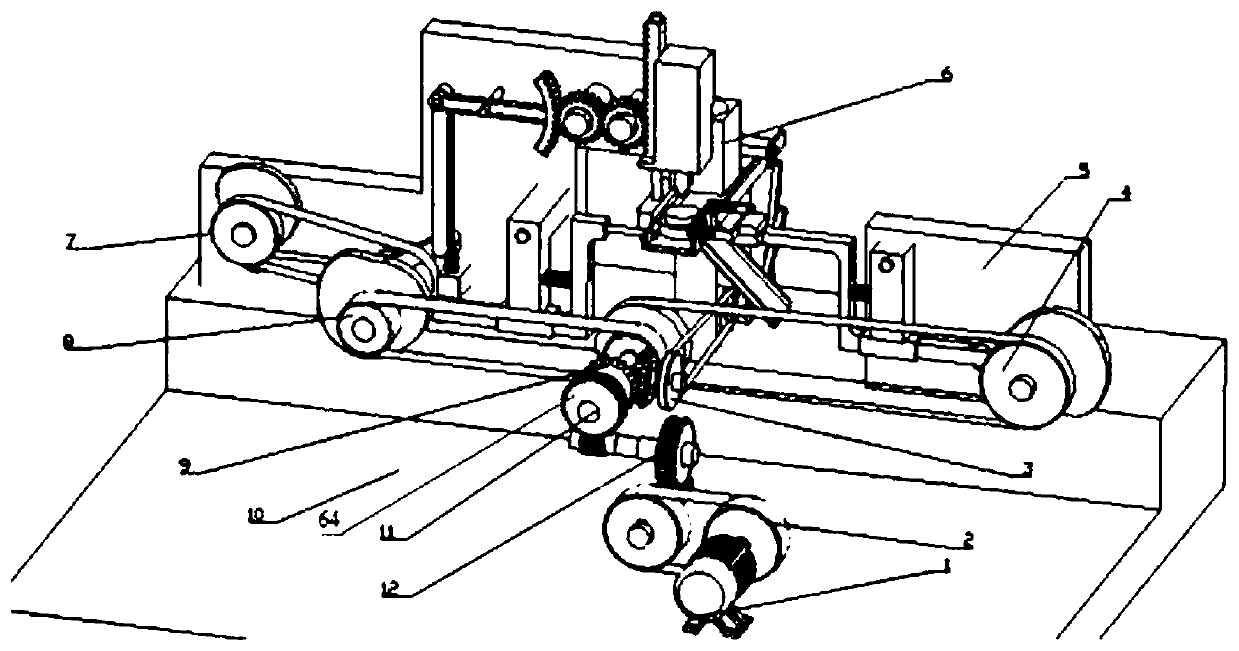

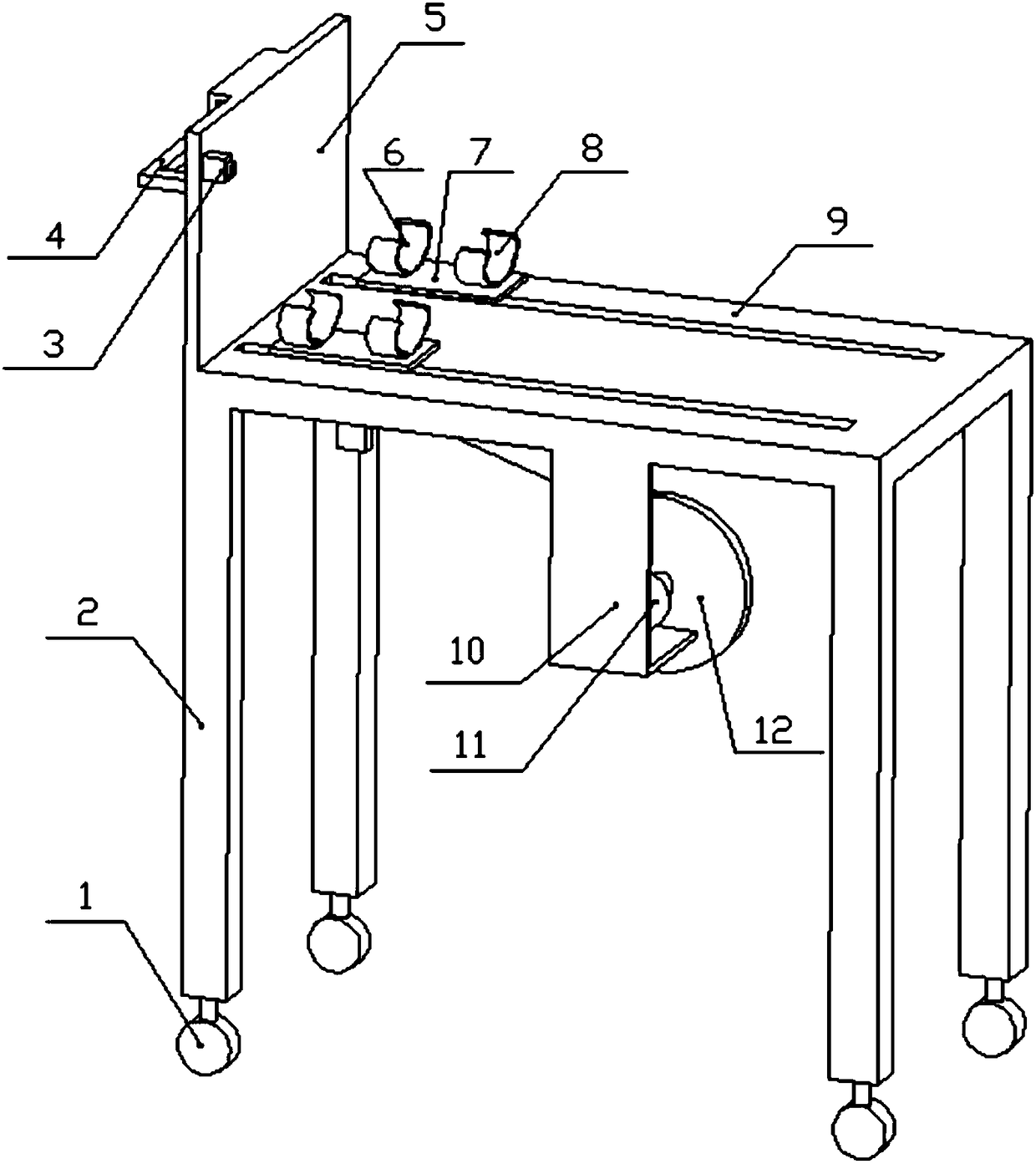

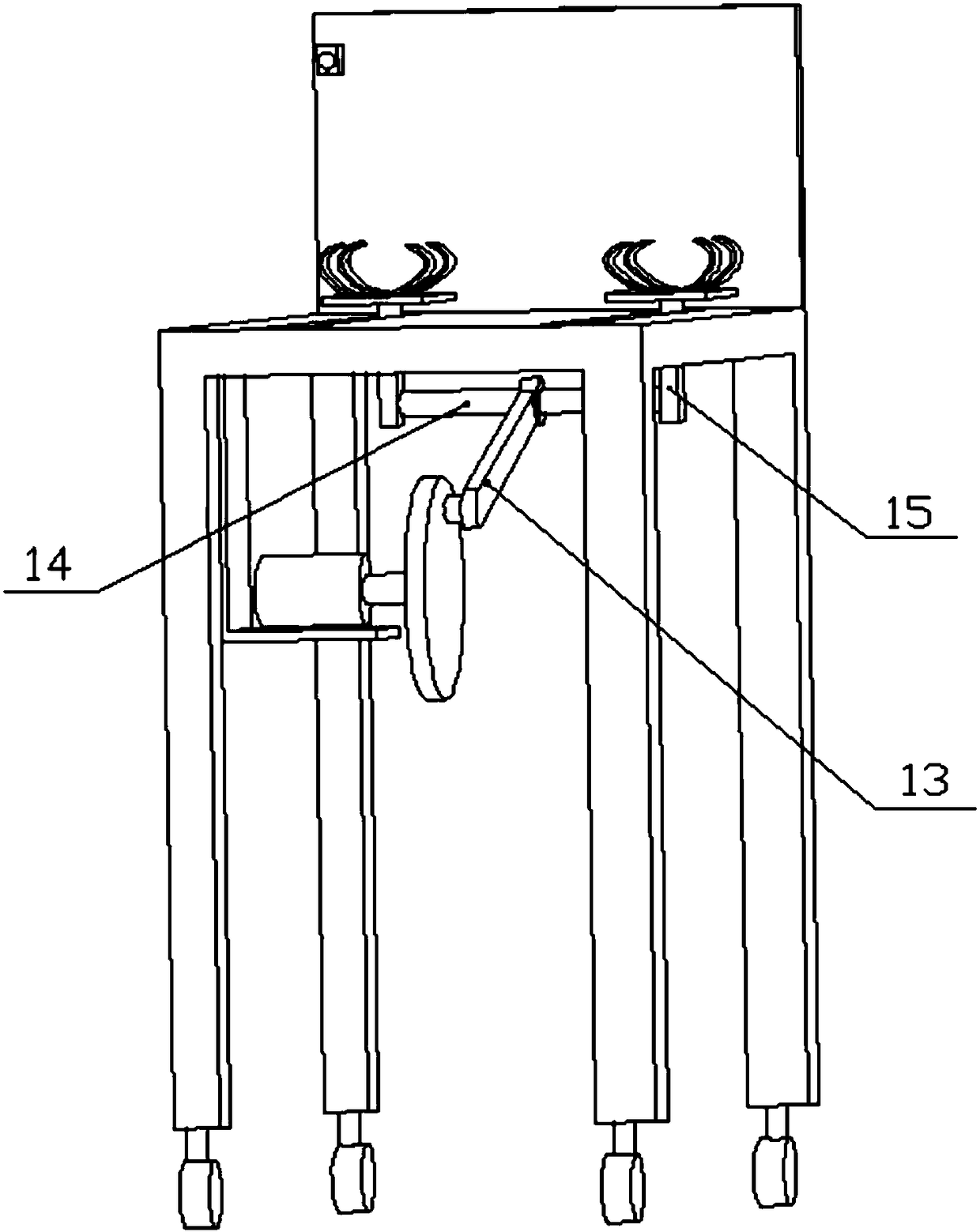

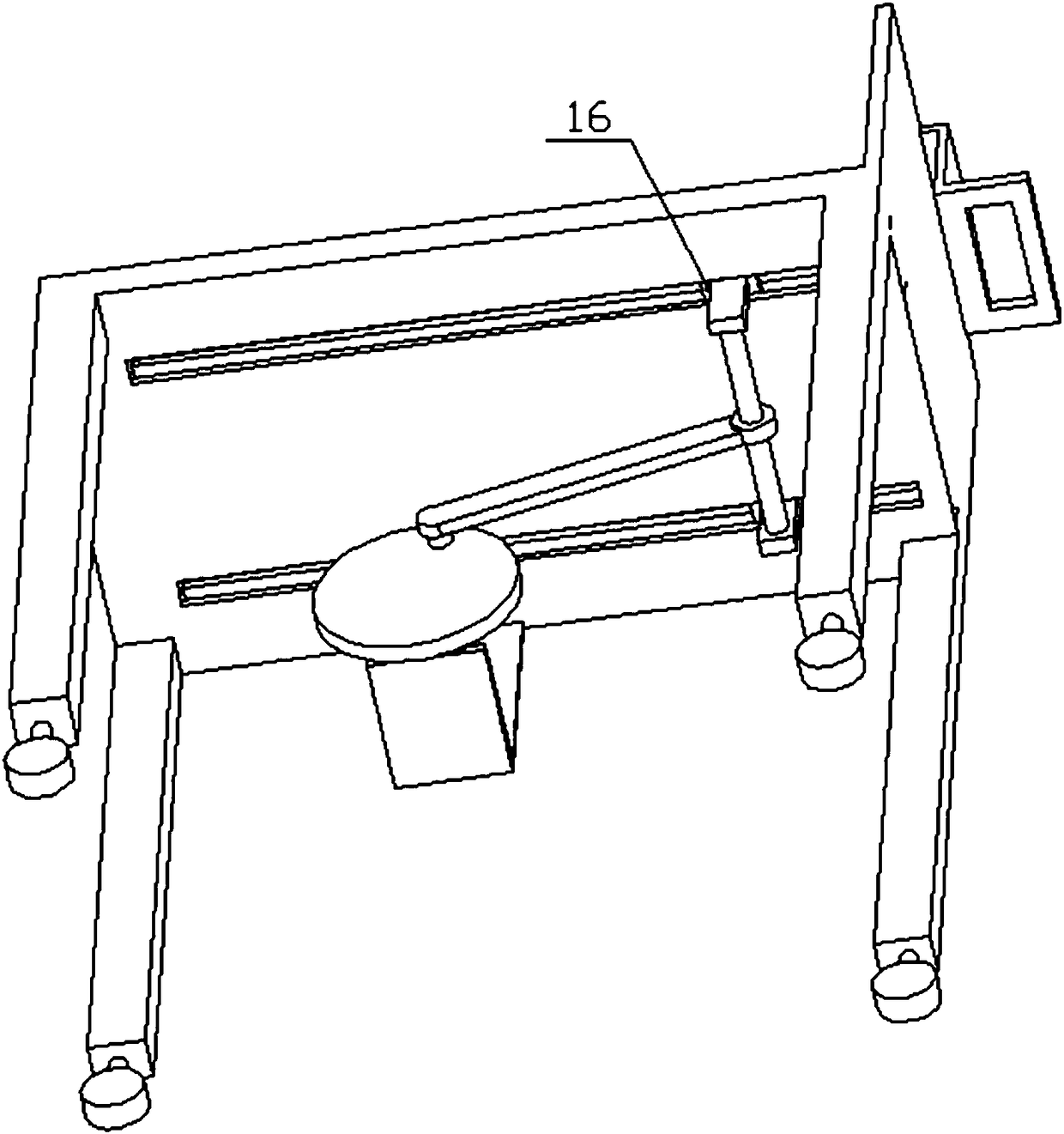

In-line planting device of transplanter

InactiveCN101715670ARealize reciprocating linear motionHigh frequencyTransplantingAgricultural engineeringSeedling

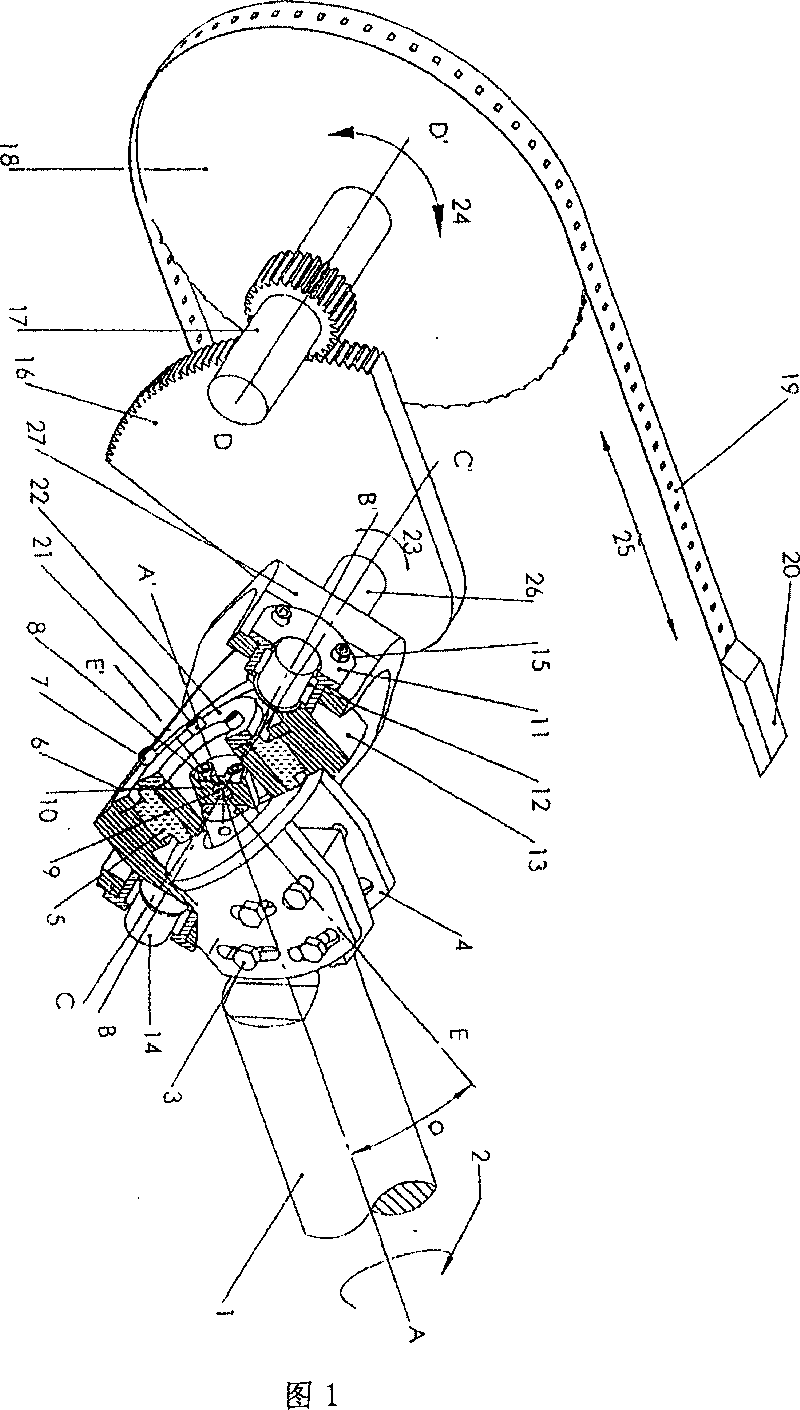

The invention provides an in-line planting device of a transplanter. The in-line planting device is used for perforating cavitation and plant setting operations of transplanting on a film, belongs to the field of agricultural machinery and consists of a driving device, a planting apparatus, a control mechanism and a stand. The reciprocating linear motion of the planting device can be realized by driving a crank link mechanism to act through power. The planting apparatus is in a closed state when moving to a top dead point; pot seedlings are fed into the planting apparatus by a seedling feeding device; the planting device penetrates a mulching film, enters soil and punches holes along the process that the planting apparatus moves to a lower dead point and the planting apparatus is opened under the action of the control mechanism; the pot seedlings are fed into the cavities to finish the seedling planting operation; and then the planting apparatus is closed by a rising control mechanism of the planting apparatus, and thereby next working cycle is turned into. The short planting distance thick planting transplantation can be realized by adjusting the rotating speed of a crank and improving the reciprocating frequency of the planning apparatus. Since the motion curve of the planting apparatus is consistent with that of the pot seedlings in the seedling feeding process, the frequency and the reliability of feeding seedlings can be improved.

Owner:XINJIANG AGRI UNIV

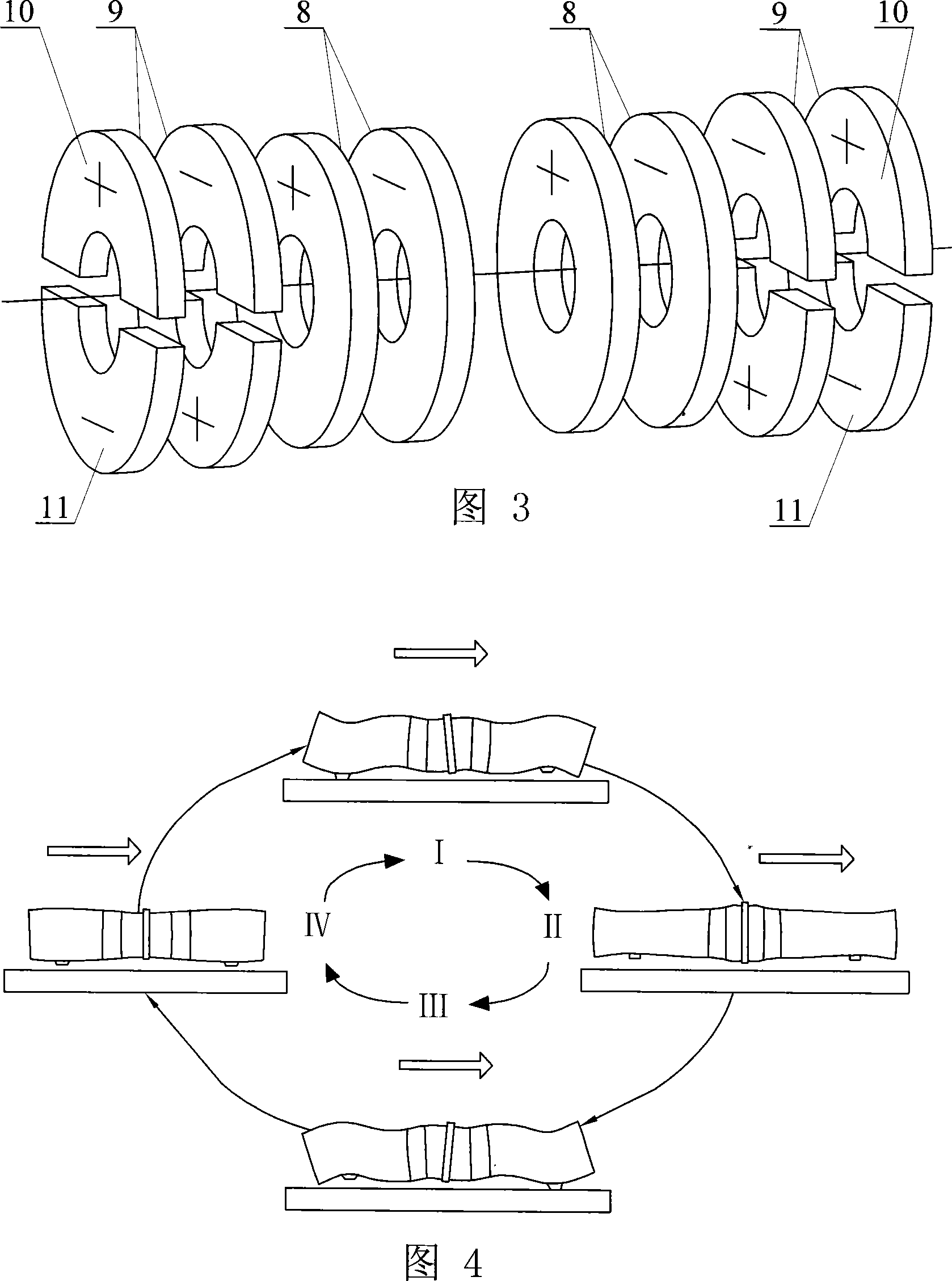

Double-driving foot sandwich converter type longitudinal and bending linear ultrasonic motor

InactiveCN101022257ADegenerate bending frequencyReduce lossPiezoelectric/electrostriction/magnetostriction machinesLongitudinal vibrationFlexural vibration

Owner:HARBIN INST OF TECH

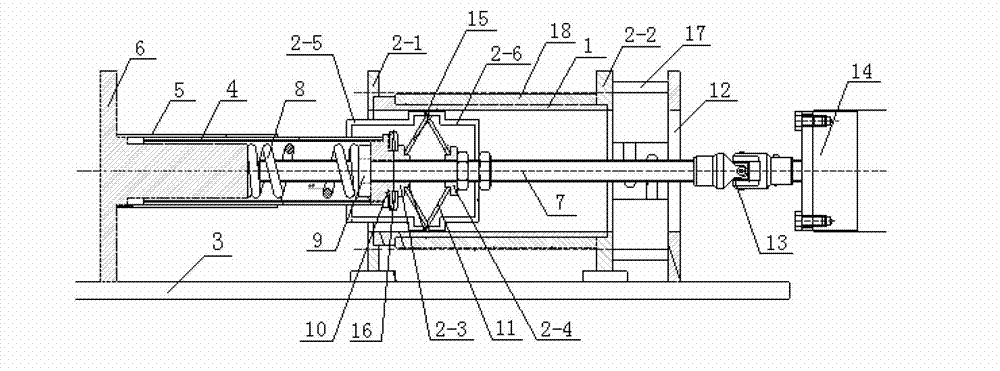

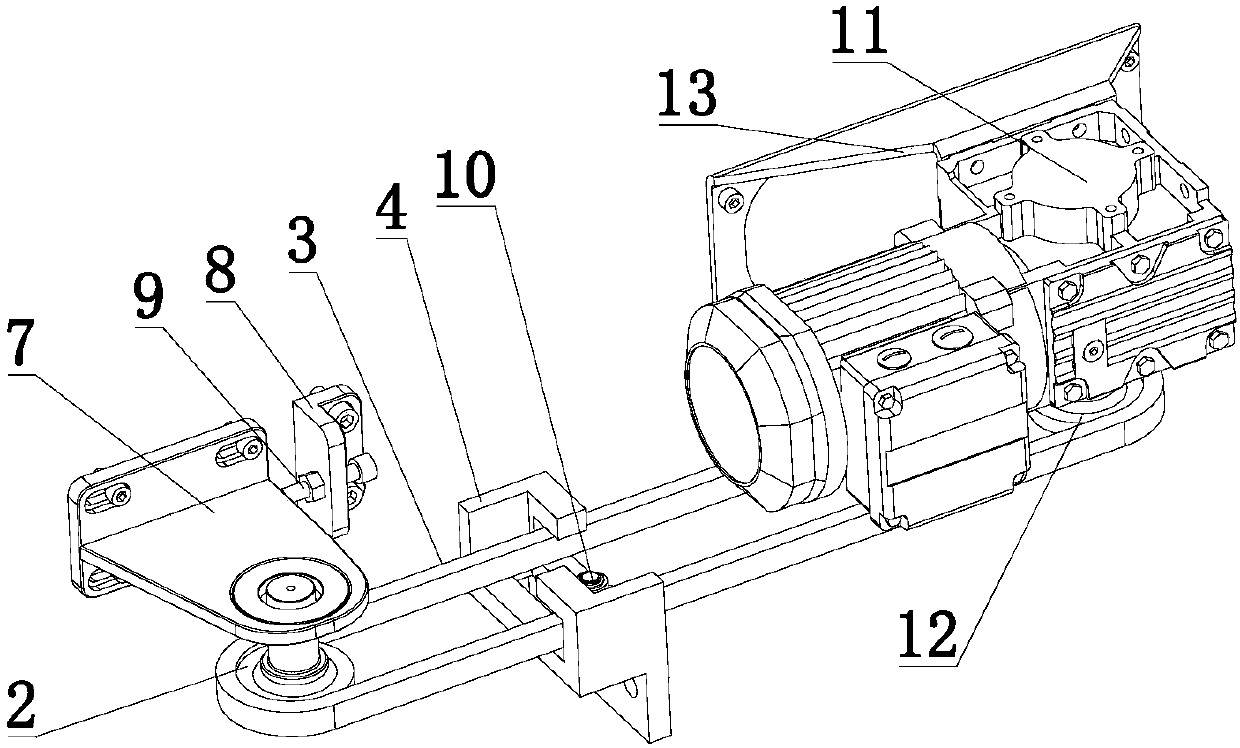

Abrasion tester for cylinder sleeve-piston ring friction pair

InactiveCN103048123ARealize reciprocating linear motionRealize continuously adjustableMachine part testingInvestigating abrasion/wear resistancePiston ringEngineering

The invention discloses an abrasion tester for a cylinder sleeve-piston ring friction pair. The structure of the abrasion tester is as follows: a cylinder sleeve is fixed between first and second positioning frames; an inner sleeve is arranged in an outer sleeve; the outer sleeve is connected with a pressure spring base through a thread; inner ends of a double annular elastic supporting rod are horizontally embedded in grooves of third and fourth positioning frames; a piston ring is arranged in the groove between fifth and sixth positioning frames; an outer diameter of the piston ring is glued to an inner wall of the cylinder sleeve; the inner surface of the piston ring is tightly pressed by the outer ends of the double annular elastic supporting rod; and four stretching force sensors are uniformly mounted between the second positioning frame and a screw carriage at intervals. In the abrasion tester, a piston ring radial loading mechanism is formed by four positioning frames and the double annular elastic supporting rod; a piston ring axial loading mechanism is formed by the pressure spring base and the pressure spring, so that the change condition of explosion pressure endured by the piston ring at practical work is simulated; and the abrasion tester provided by the invention can excellently simulate the practical working condition and has the advantages of short test period, low test cost, and the like.

Owner:TIANJIN UNIV

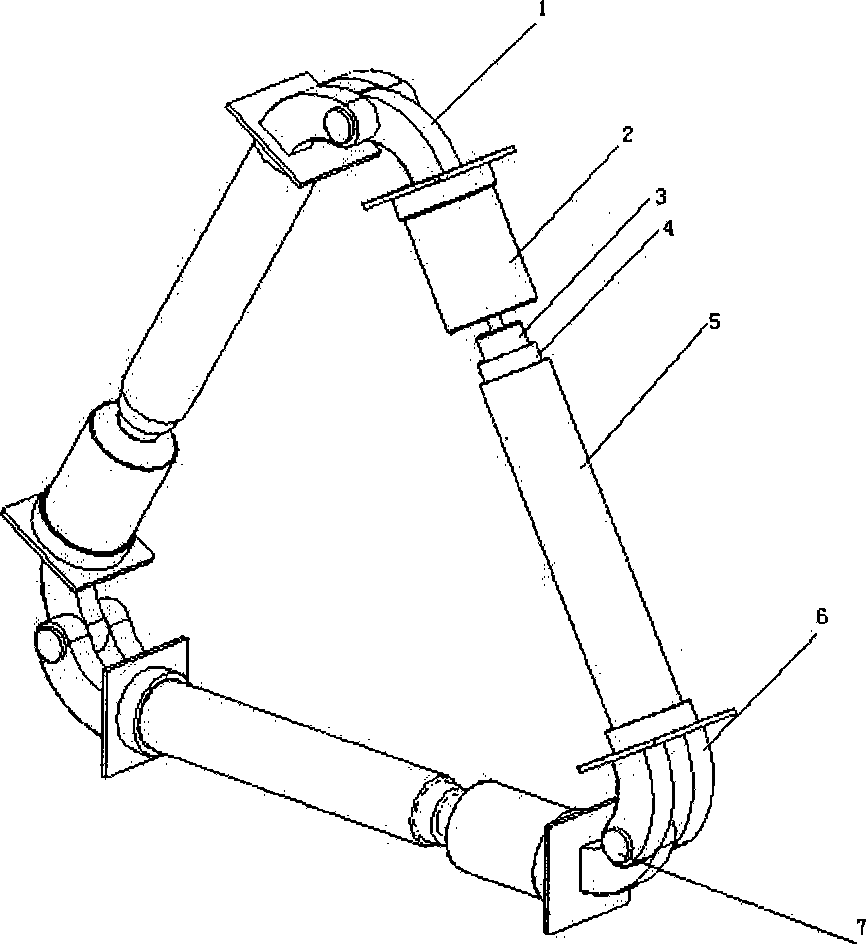

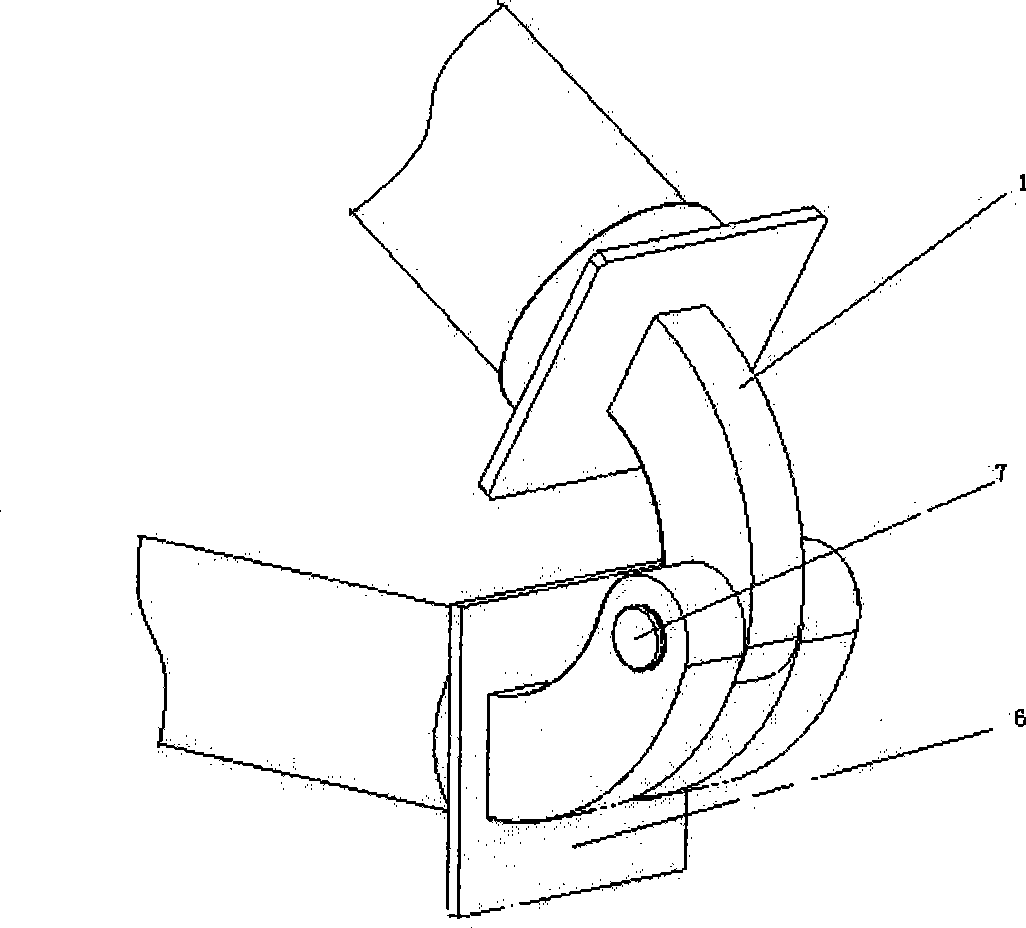

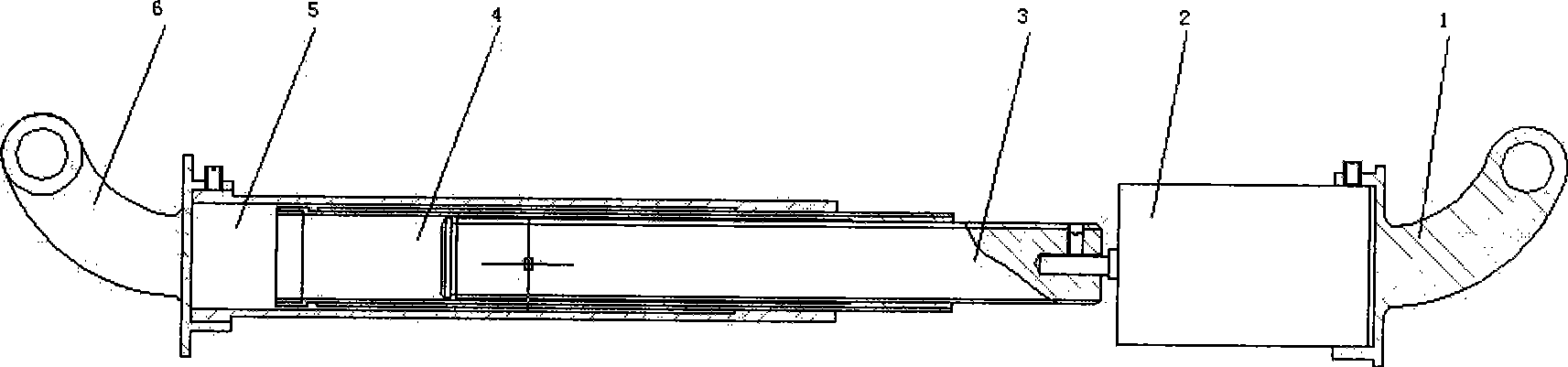

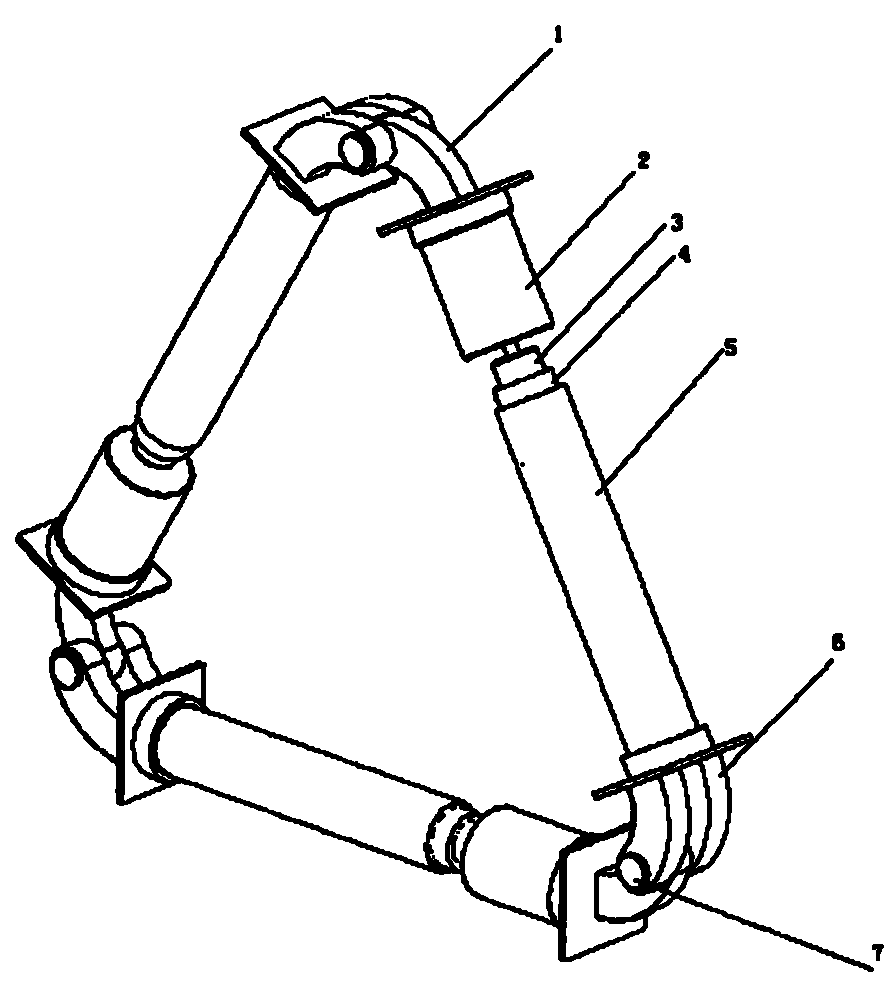

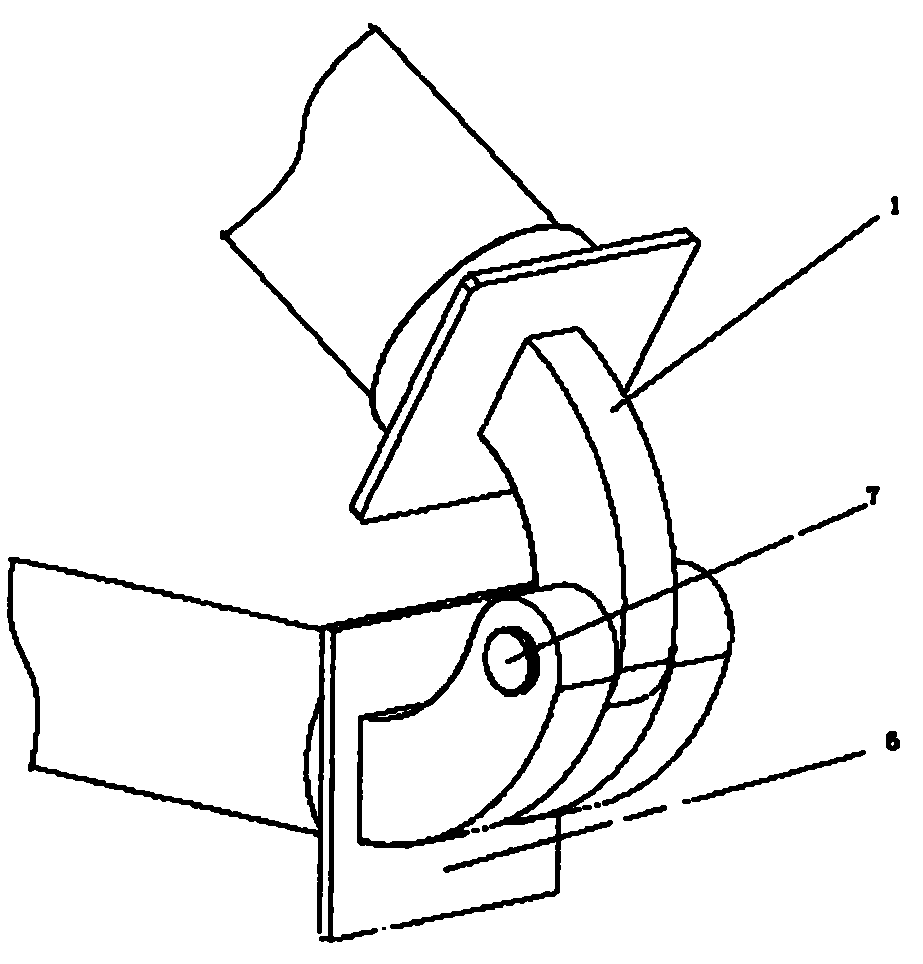

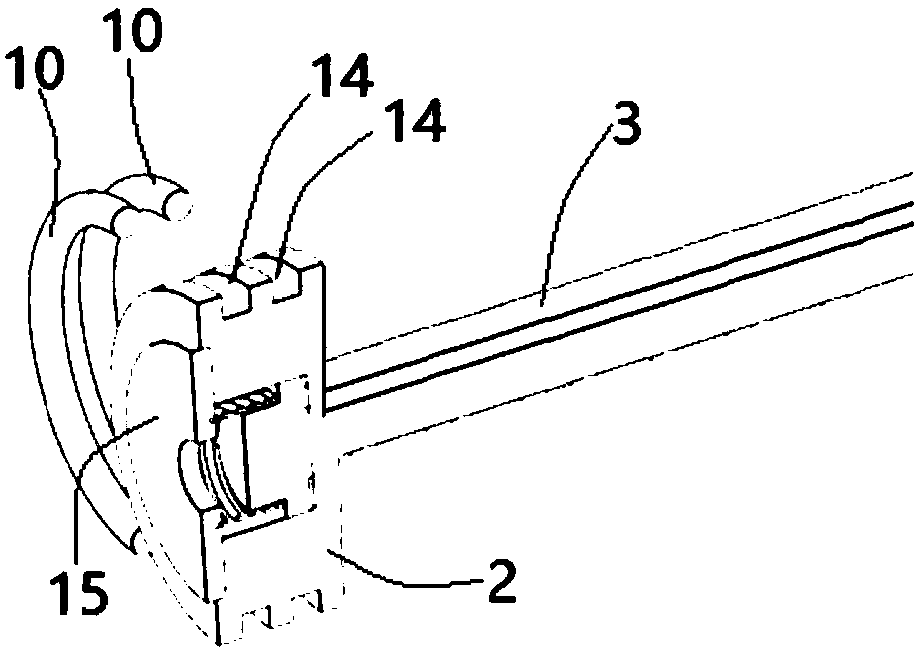

Rolling triangular robot

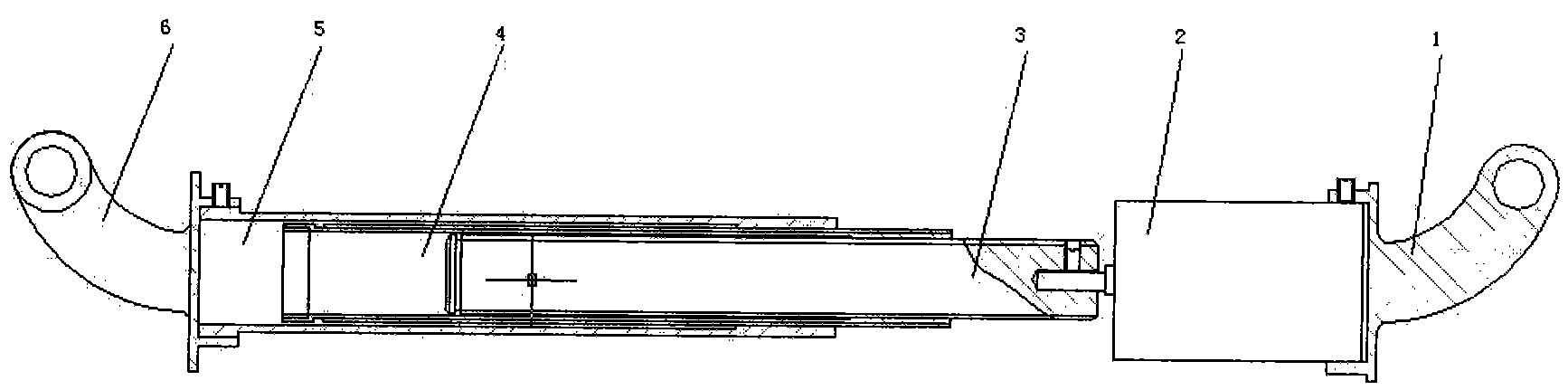

The invention discloses a rolling triangular robot, and relates to a rolling robot. One side of the robot comprises an electric motor (2), a section of a screw rod (3), two sections of screw rods (4), three sections of sleeves (5), a sleeve joint (6) and an electric motor joint (1), wherein the tail part of the electric motor is fixed on the electric motor joint; an output shaft of the electric motor is fixed with the right end of one section of the screw rod through a fastening nail; a section of the screw rod is in threaded connection with two sections of the screw rods; two sections of the screw rods are connected with three sections of the screw rods through the threads; three sections of the screw rods are fixed on the sleeve joint; and the electric motor joint, the electric motor, the one section of the screw rod, the two sections of the screw rods, the three sections of the screw rods and the sleeve joint form one side of the rolling triangular robot. The structures and the sizes of three sides of the rolling triangular robot are the same, and the electric motor joints of each side are connected with the sleeve joint and a cylinder pin of another side in turn through a cylinder pair so as to form the rolling triangular robot. The rolling triangular robot has the advantages of simple structure and easy realization, and provides acknowledge help for middle and primary students on geometric solids and moving robots.

Owner:BEIJING JIAOTONG UNIV

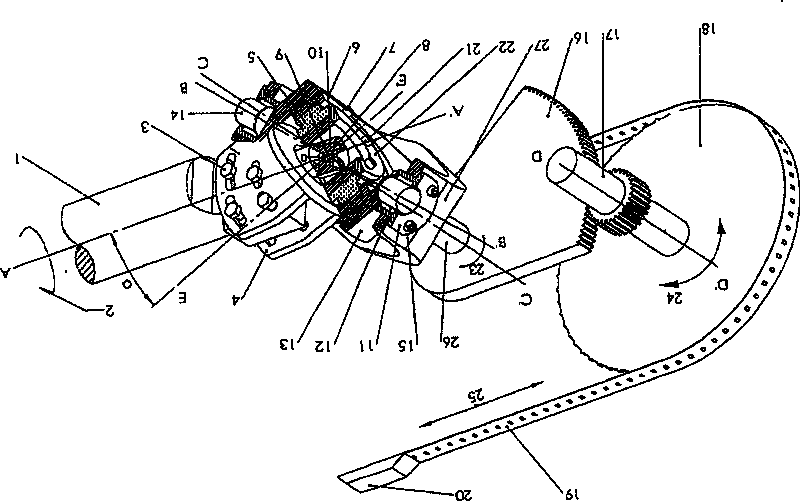

Driving mechanism of rapier belt for rapier loom

A drive mechanism for belt of the rapier loom is made up of backbone, the moving shifter and the wheel. The moving shifter includes distorted head, the central flange, oblique ring, pendular ring andthe wobble gear, is connected to the backbone and the wheel. The distorted head is connected to one end of the backbone and the central flange, which is connected to the backbone head. The oblique ring is connected to the distorted head, the gudgeon installed in which is connected to the pendular ring, the wobble control shaft installed in which is installed the wobble gear which is mated the axle. The mechanism is to change the uniform rotary movement into the swing motion to make the rapier head alternating motion.

Owner:PACIFIC MECHATRONIC GRP

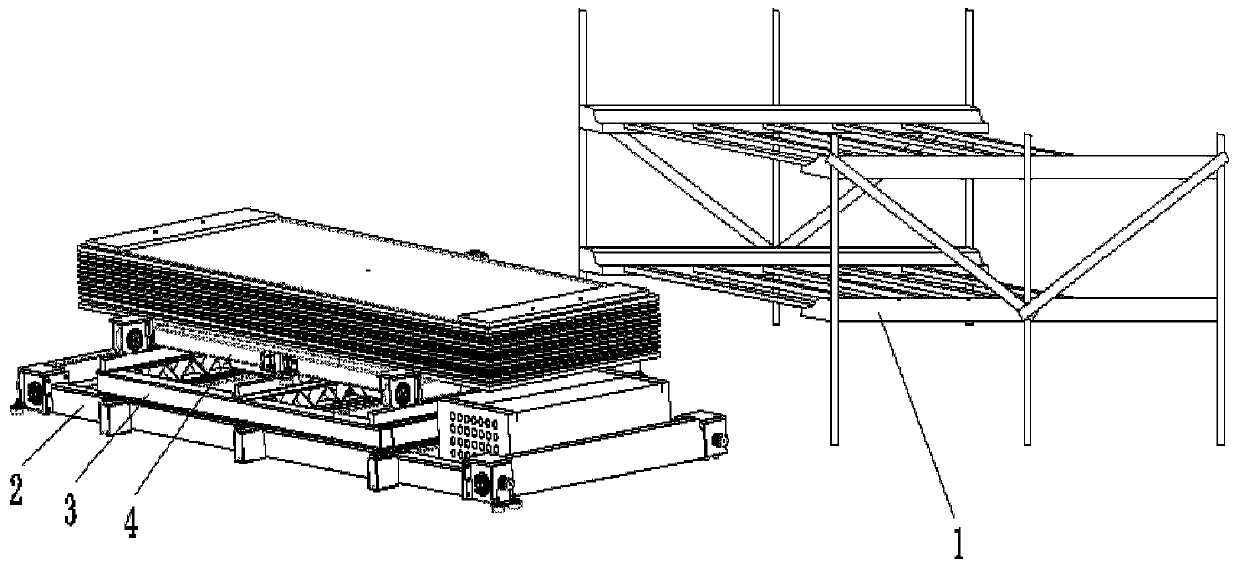

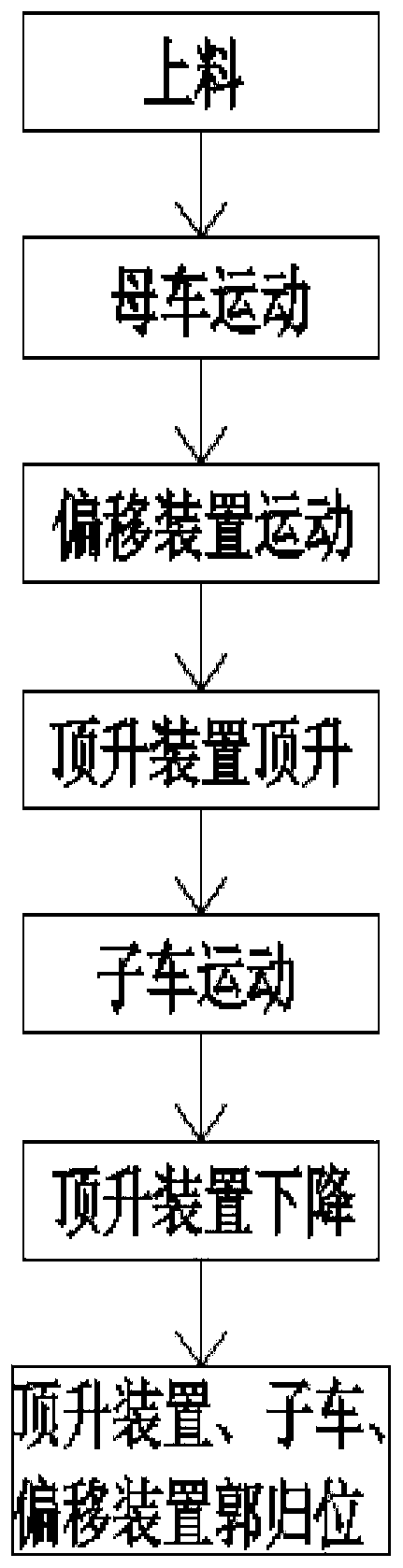

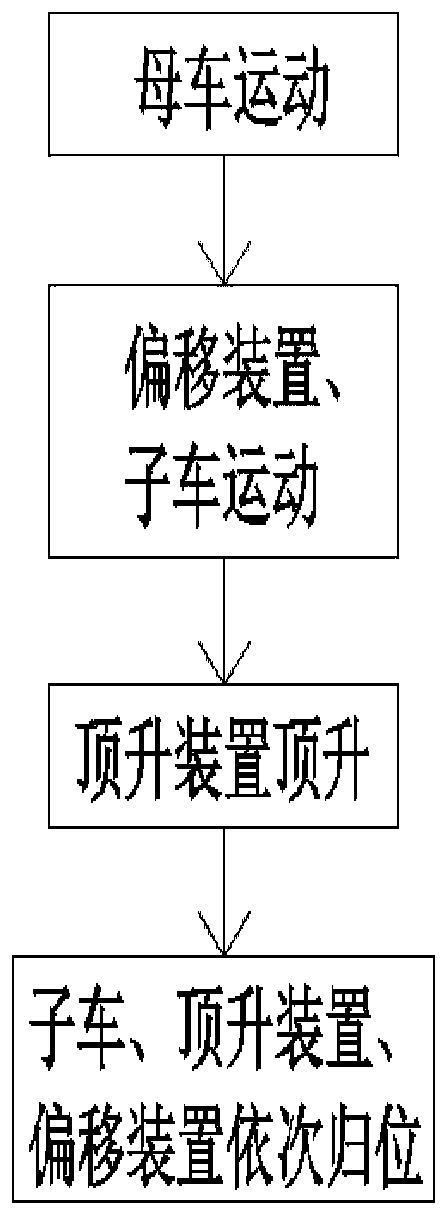

Goods storing and taking method

The invention provides a goods storing method. A child-mother car is adopted and comprises a mother car, a shifting device, a child car and a jacking device sequentially from bottom to top. The goodsstoring method includes the following steps that firstly, goods are placed on the jacking device, and the mother car runs to a designated position; the shifting device is butted to a rail; then, the jacking device is jacked up, and the child car moves along the butted rail; and finally, a hydraulic platform descends, one time of goods storing is completed, and each device returns to seat sequentially. The invention further provides a goods taking method. Firstly, the mother car runs to the designated position; the shifting device is butted to the rail, the child car moves along the butted rail, then, the jacking device jacks goods up, and finally, the child car, the shifting device and the jacking device return to seat sequentially. The shifting mechanism and the child car system can achieve high precision of goods taking and storing. Compared with a conventional goods taking and storing method such as forking, the system structure is small in displacement and operates more stably whena goods taking system takes the goods.

Owner:JIASNGSU GAOKE LOGISTICS TECH CO LTD

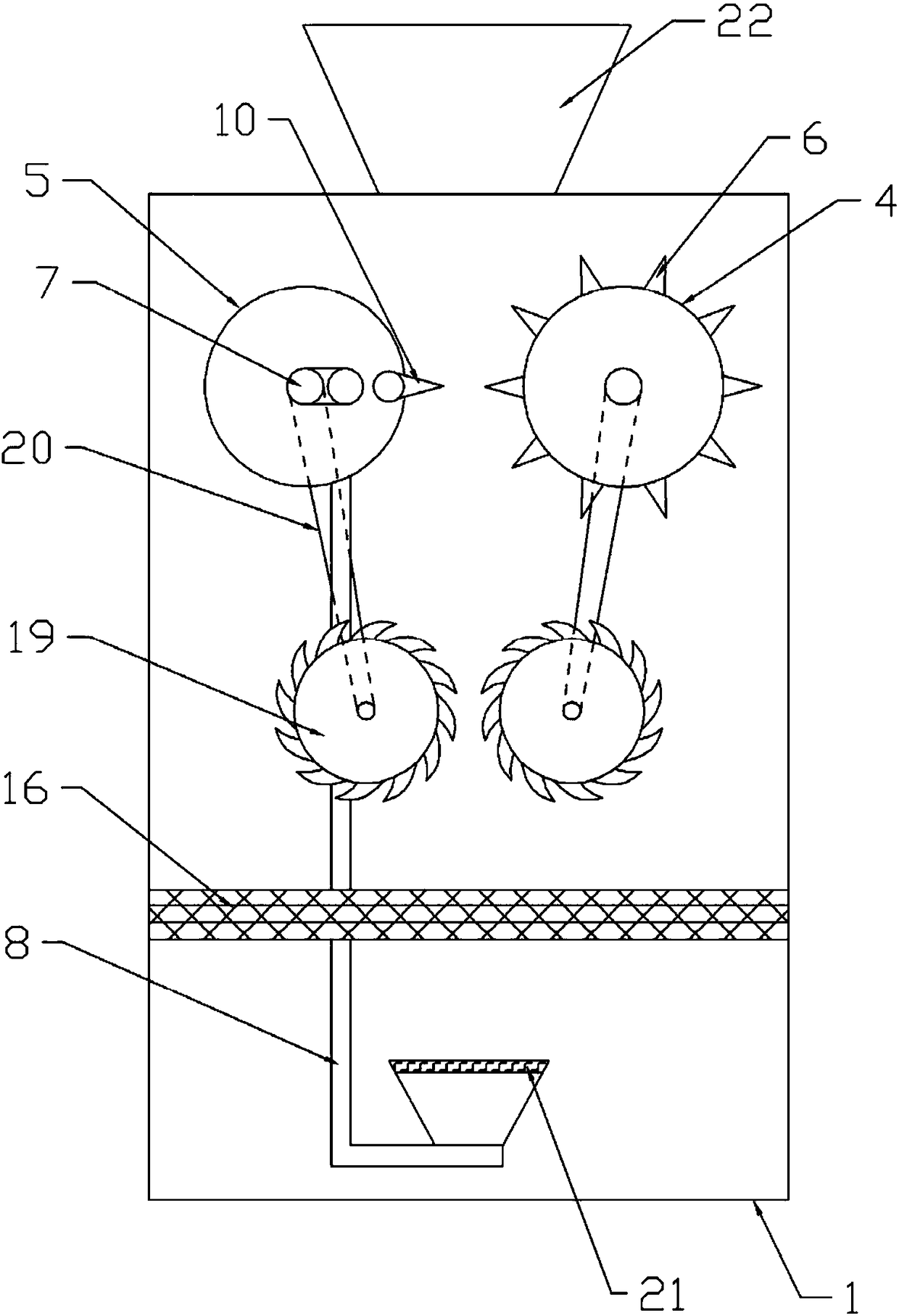

Magnetic separation equipment for waste tire crushing and processing

The invention relates to magnetic separation equipment for waste tire crushing and processing and belongs to the technical field of recycled plastics or other components of plastic-containing wastes.The magnetic sorting equipment comprises a crushing box, a motor and an air blower; a feeding hole is formed in the top of the crushing box, a first pressure roller and a second pressure roller are connected with the inside of the crushing box, the output end of the motor is connected with the first pressure roller and the second pressure roller, a stationary knife is mounted on the peripheral wall of the first pressure roller, a rotating shaft is coaxially connected with the second pressure roller, an air pipe is communicated with the free end of the rotating shaft, and an outlet of the air pipe is formed in the bottom of the crushing box; a cam and a moving knife are rotationally connected with the second pressure roller, a turbine is coaxially connected with the cam and is arranged at the free end of the rotating shaft, a first gear is coaxially connected with the moving knife, a rack is meshed with the first gear, a push block is connected with the rack, and a spring is connected with the push block; a magnetic separation screen is mounted in the crushing box, and a vibrator is connected with the magnetic separation screen. The magnetic separation equipment provided by the invention has the beneficial effects that a waste tire can be effectively crushed by utilizing the shearing forces produced by the stationary knife and the moving knife under high-speed rotation, and further, rubber is separated through the magnetic separation screen.

Owner:重庆九橡化大橡胶科技有限责任公司

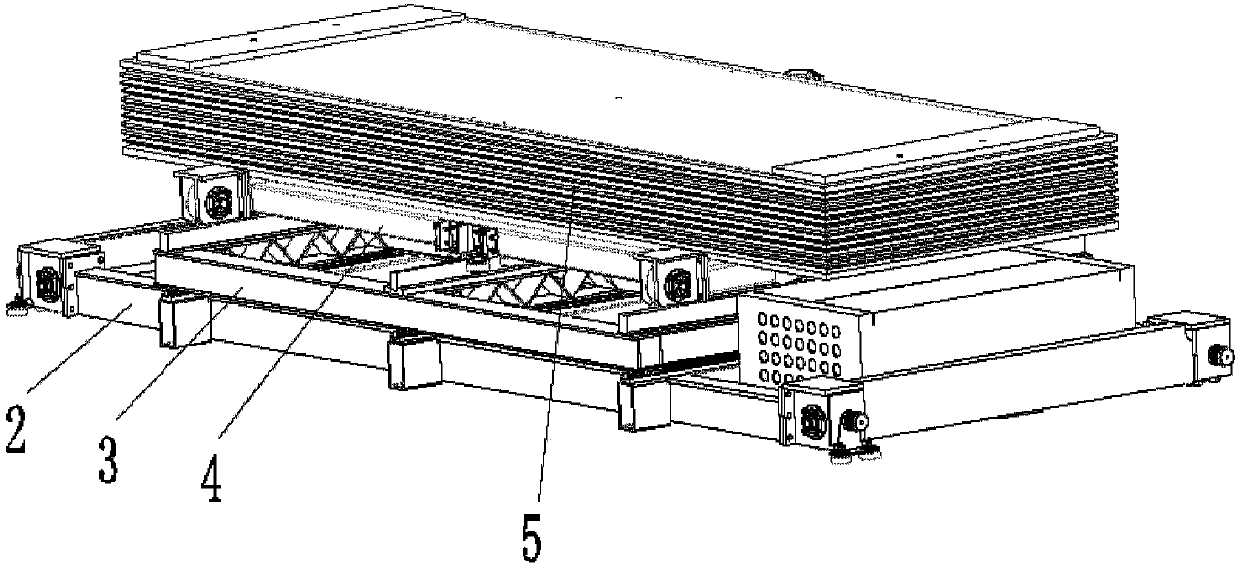

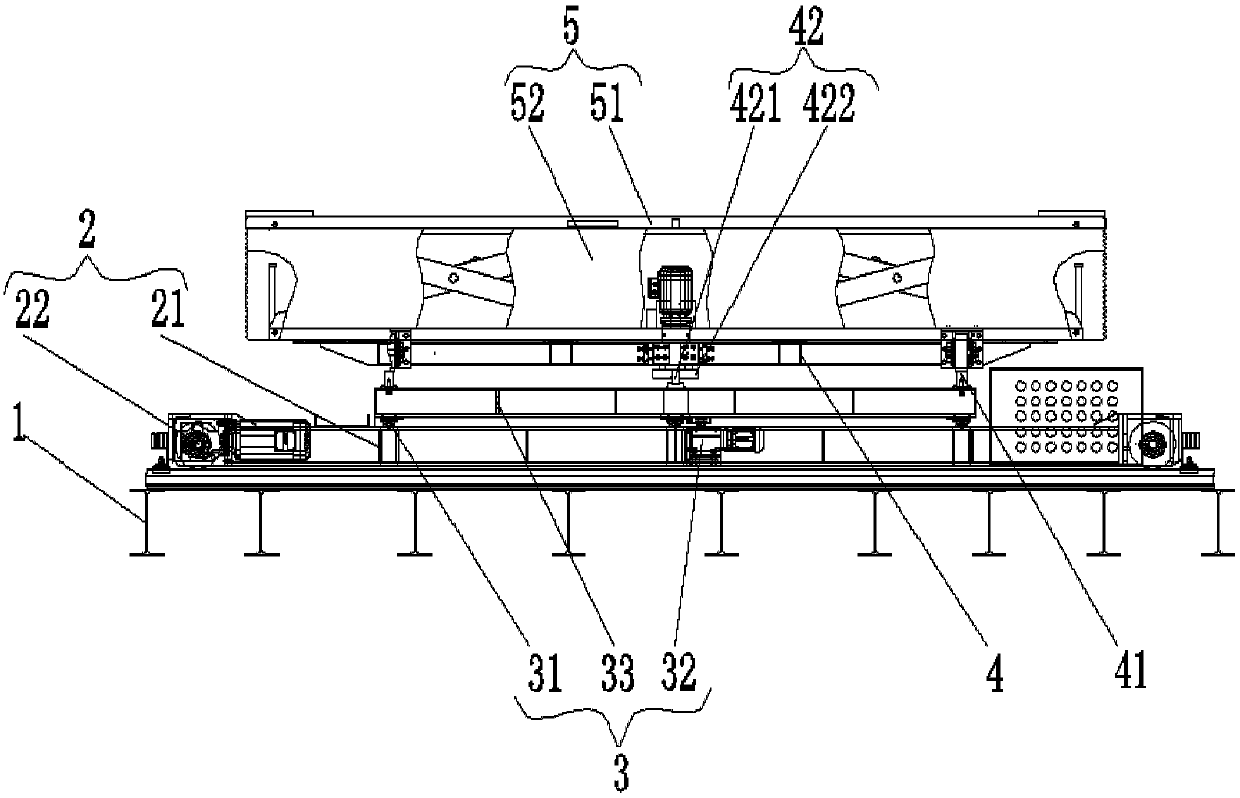

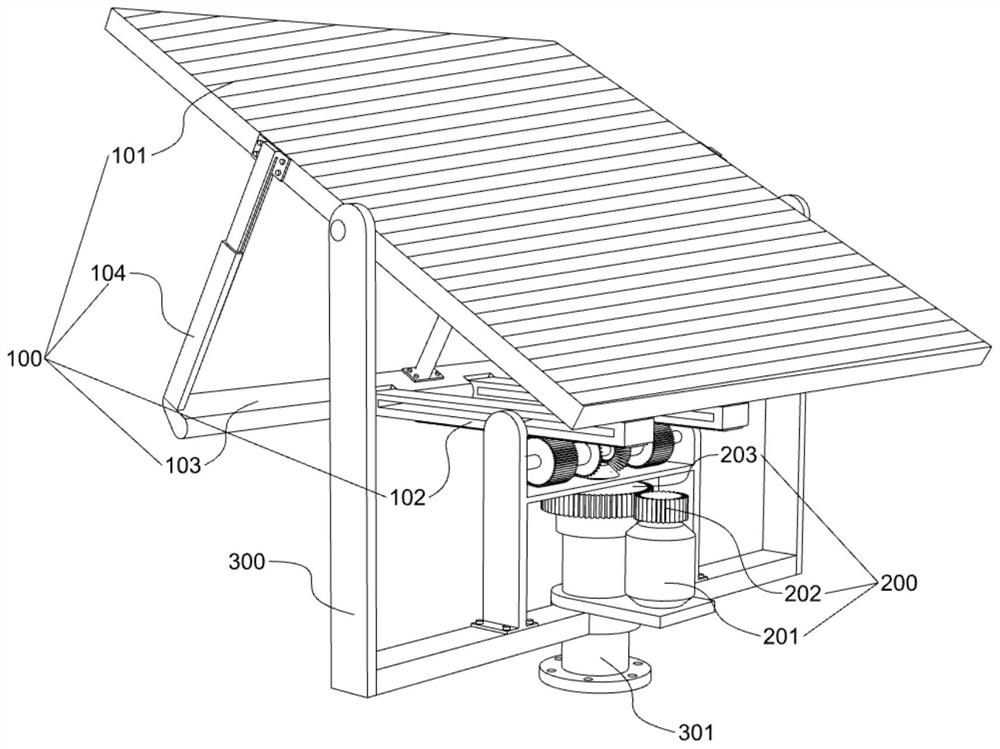

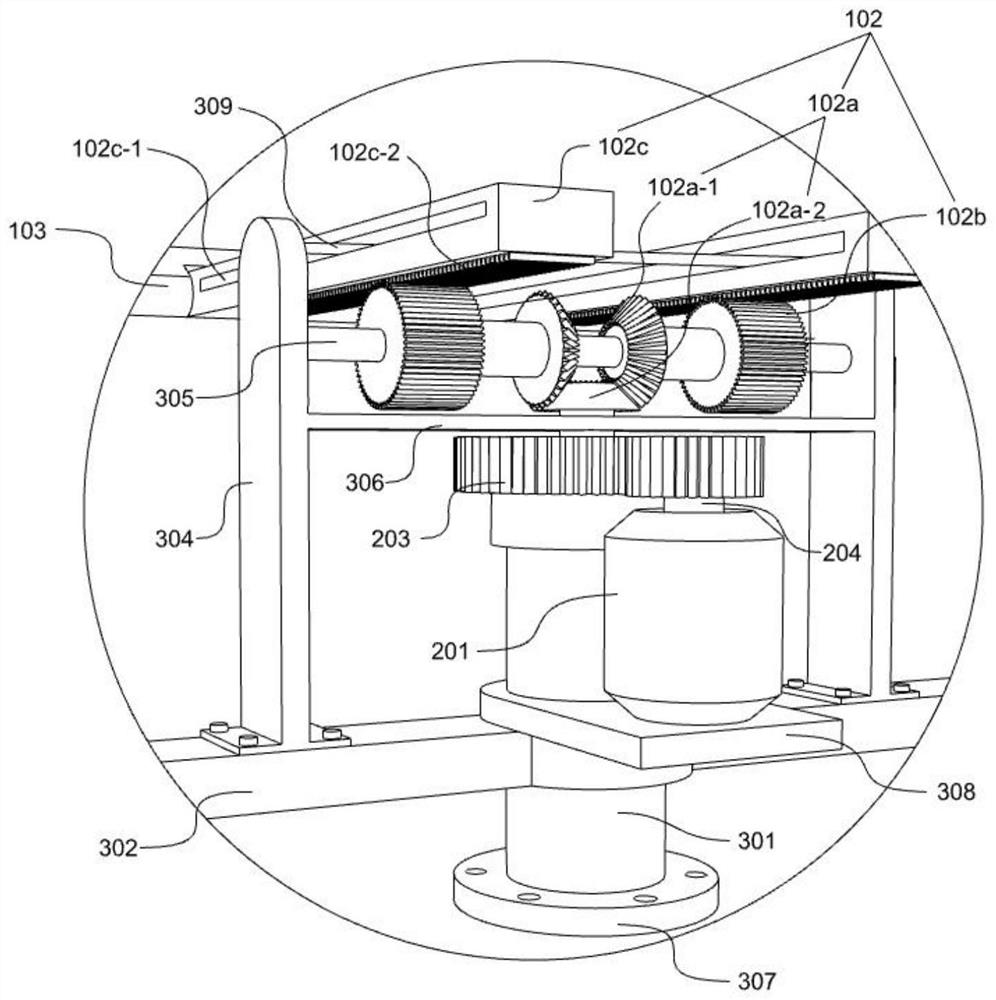

Son-mother vehicle with convenience in accessing extra-large articles

InactiveCN107640536ARealize transportationImprove structural bearing capacityMechanical conveyorsVehicle frameDegrees of freedom

The invention provides a son-mother vehicle with convenience in accessing extra-large articles. The son-mother vehicle comprises a mother vehicle, an offset device, a son vehicle and a jacking device.The mother vehicle has a first degree of freedom of transverse extension and comprises a first driving device and a mother vehicle frame, and the mother vehicle frame can be driven by the first driving device to move along the direction of the first degree of freedom; the offset device is mounted on the mother vehicle frame; the offset device comprises a second driving device and an offset frame,and the offset frame can be driven by the second driving device to move along the direction of a second degree of freedom; the son vehicle is mounted on the offset frame and has a third degree of freedom of longitudinal extension; the jacking device is provided with a jacking platform; the mother vehicle frame and the offset frame mainly comprise box beams. The son-mother vehicle has the advantages that the problem of incapability of accessing extra-long, extra-wide and extra-heavy articles by storage equipment of existing warehousing systems can be pertinently solved by the aid of the son-mother vehicle with the novel structure, and systems are high in access capacity and bearing capacity owing to the box beams.

Owner:JIASNGSU GAOKE LOGISTICS TECH CO LTD

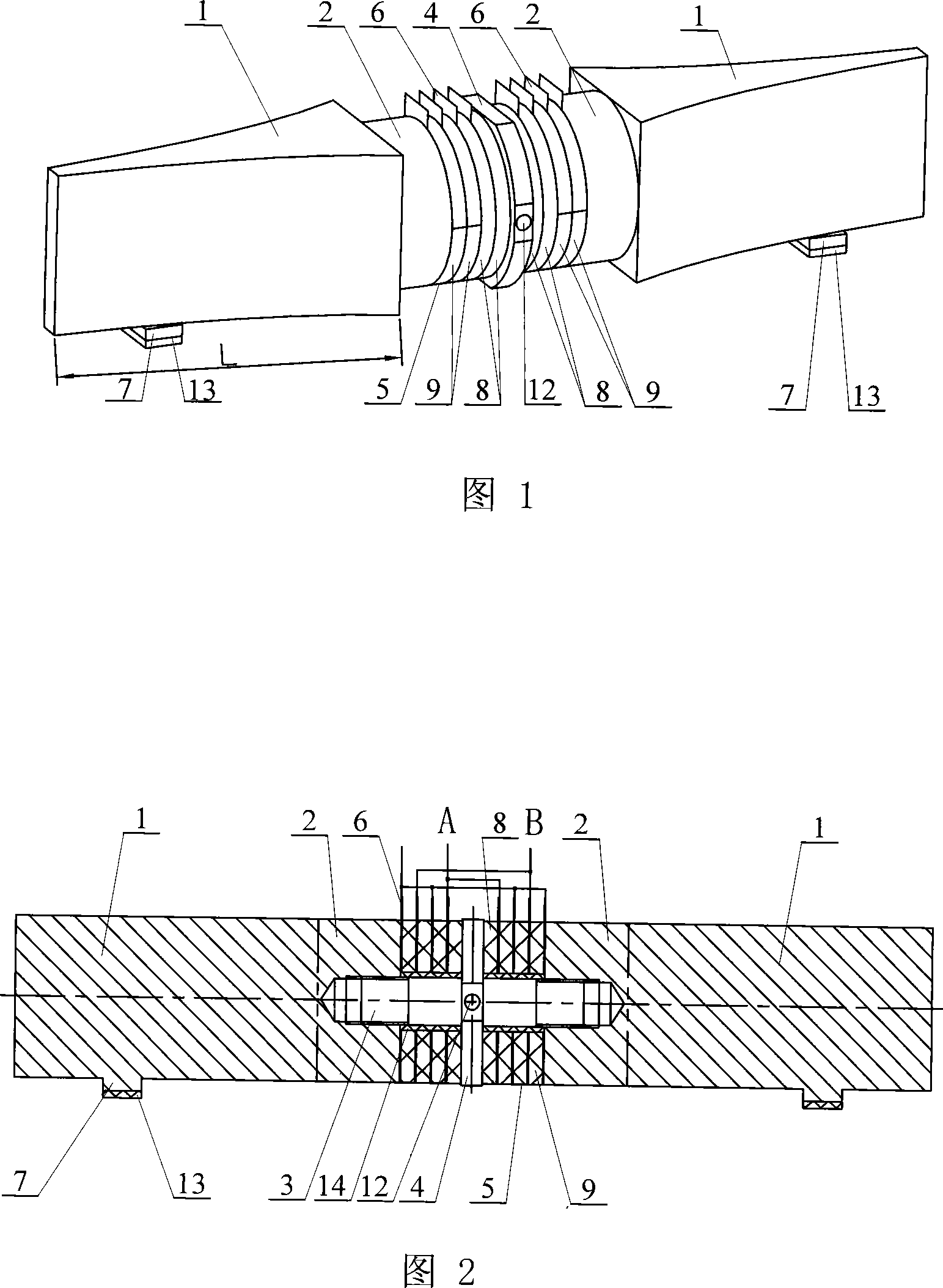

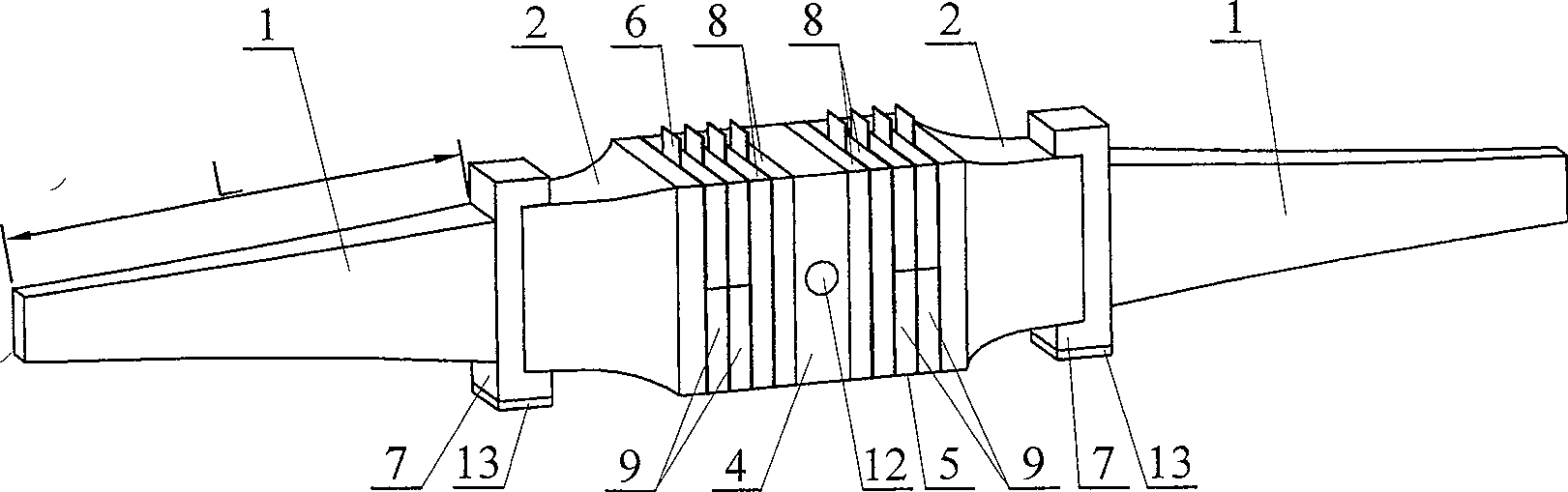

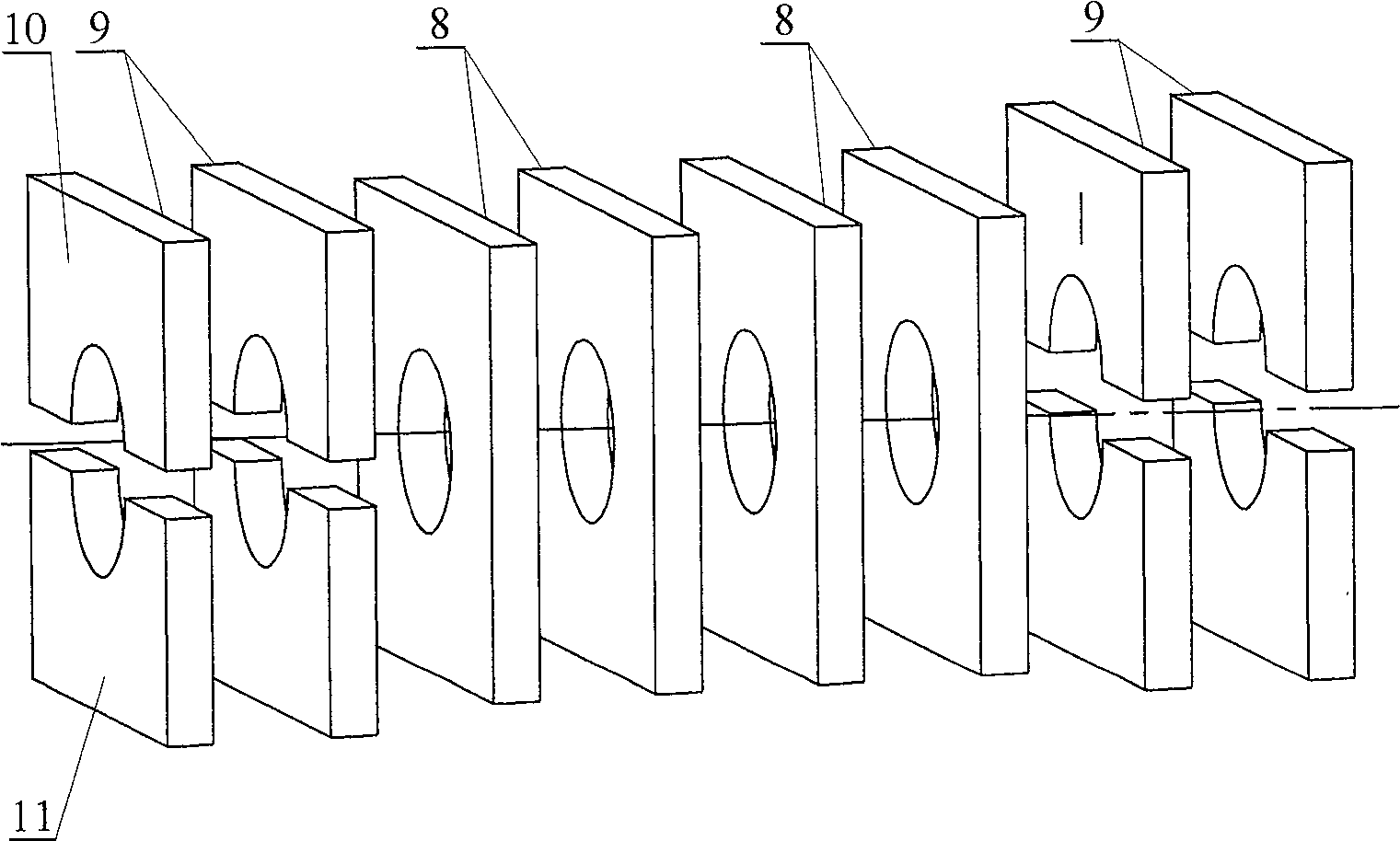

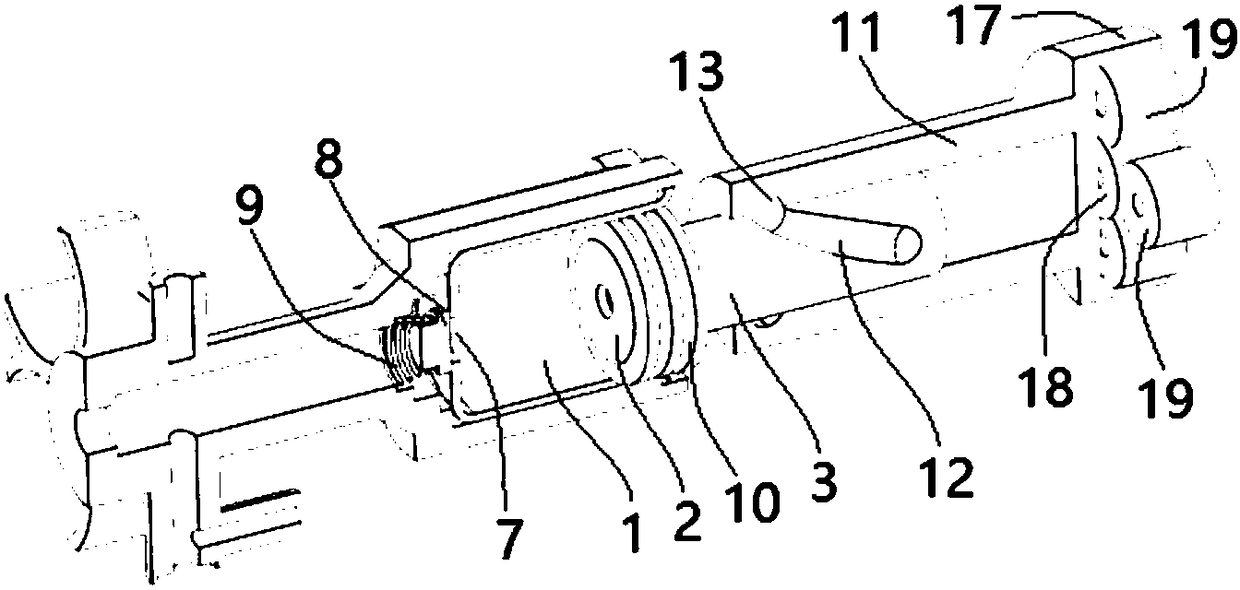

Sandwich transducer type longitudinal and bending linear ultrasound motor with frequency-modulating variable-amplitude rod

InactiveCN100514833CIncrease amplitudeReduce lossPiezoelectric/electrostriction/magnetostriction machinesLow noiseTransducer

The invention relates to a sandwich transducer type longitudinal bending linear ultrasonic motor with a frequency modulation horn, which relates to a linear ultrasonic motor. Aiming at the problems of low motor efficiency, high noise and serious wear in the existing sandwich type longitudinal bending composite linear ultrasonic motor. The stud (3) of the present invention is equipped with a longitudinal bending vibration piezoelectric ceramic sheet and a thin copper sheet (6) and is affixed to the large end of the end cover (2) through the stud (3), and the small end of the end cover (2) The end is fixedly connected to the large end of the FM horn (1) through the driving foot (7), and the driving foot (7) and the bending vibration piezoelectric ceramic sheet (9) are respectively located at the antinode of the bending vibration mode. The piezoelectric ceramic sheet (9) is symmetrically divided into two upper and lower bending vibration piezoelectric ceramic sheets with opposite polarization directions, the polarization direction of the two adjacent bending vibration piezoelectric ceramic sheets, and the two longitudinal vibration piezoelectric ceramic sheets The polarization directions of the ceramic sheets (8) are all opposite, and the length L of the horn (1) is 1 / 2 the longitudinal vibration wavelength. The invention has the advantages of high efficiency, low noise and light wear.

Owner:HARBIN INST OF TECH

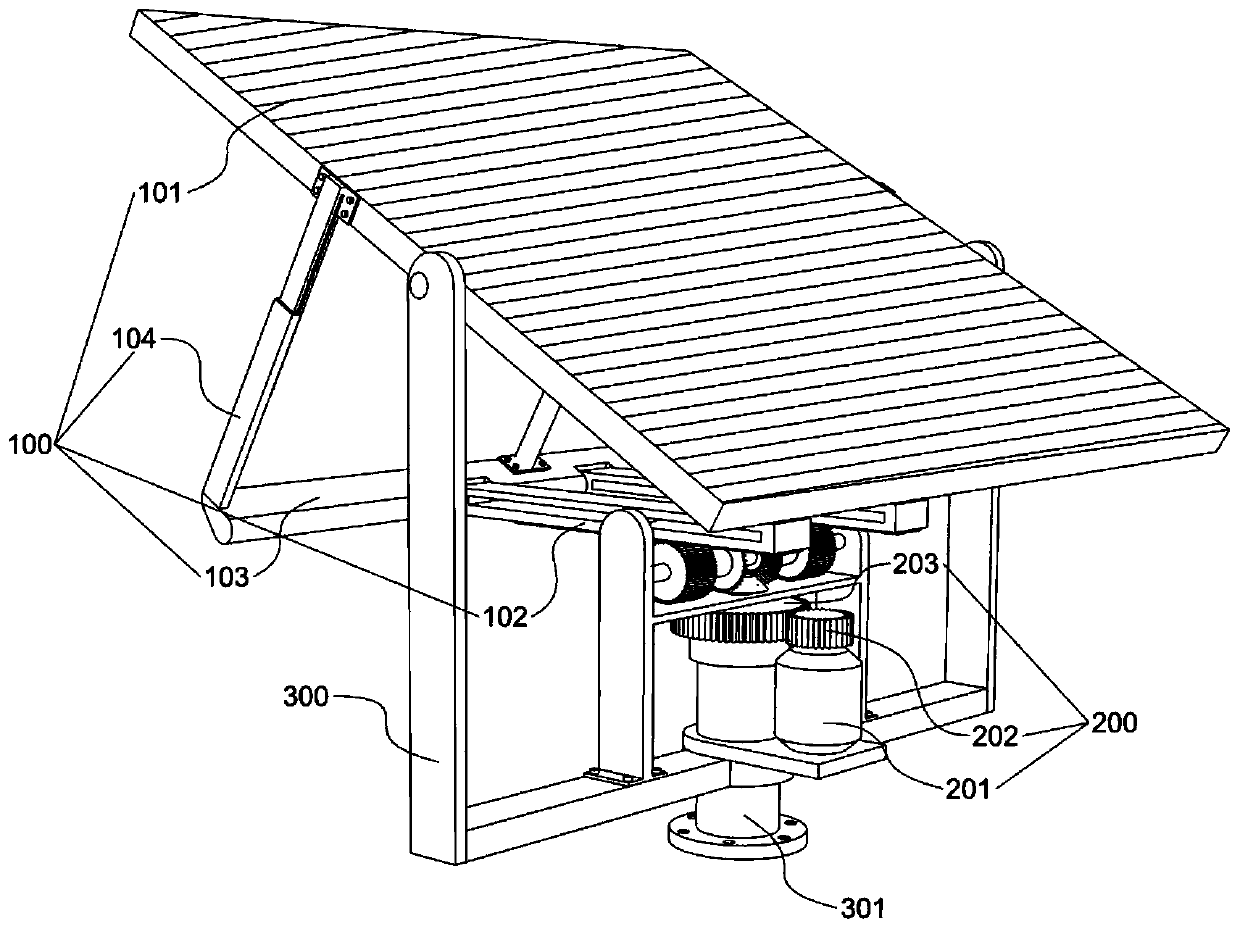

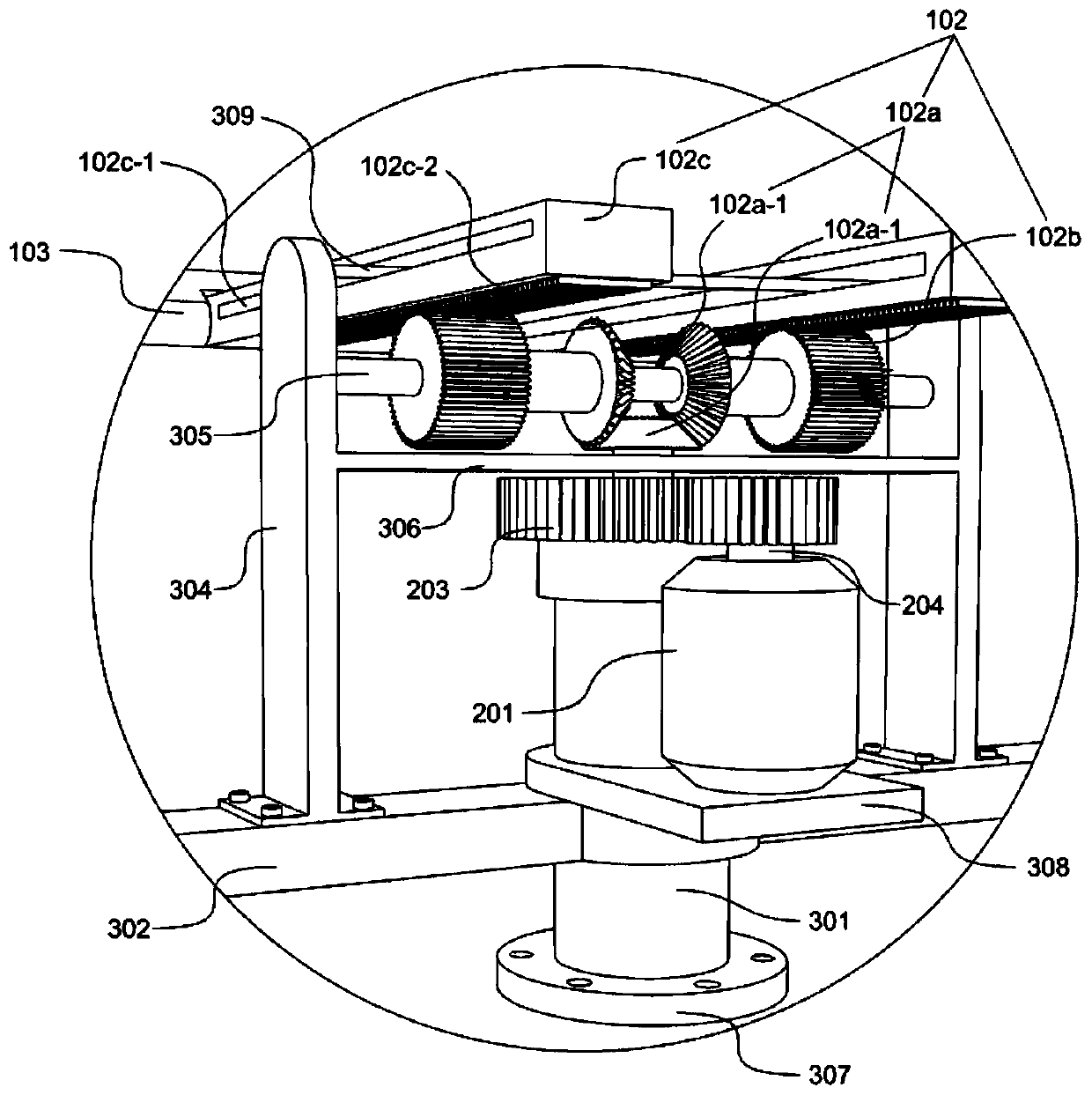

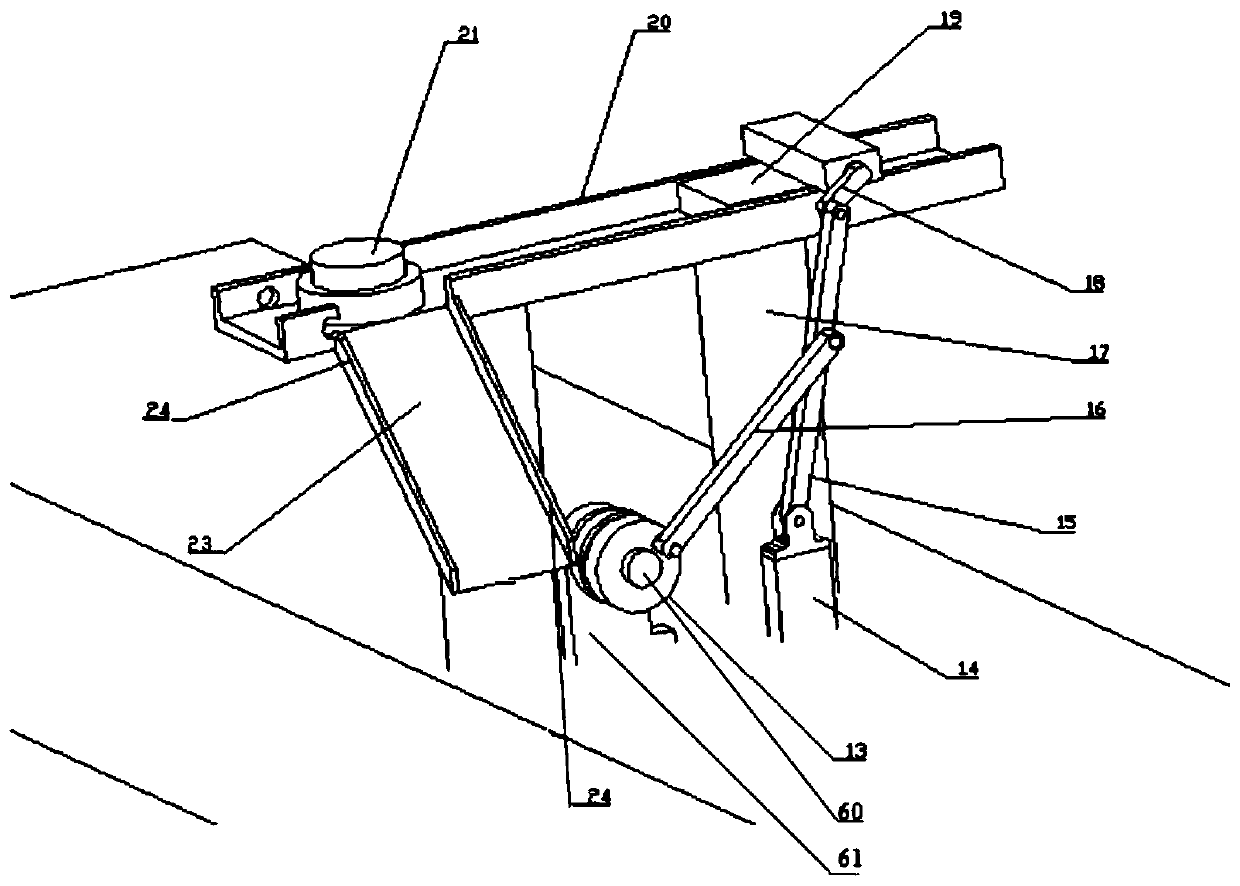

Photovoltaic panel fixing device capable of optimizing sunlight angle

ActiveCN111365868ARealize automatic adjustmentRealize reciprocating linear motionPhotovoltaic supportsSolar heating energyPhysicsSunlight

The invention discloses a photovoltaic panel fixing device capable of optimizing a sunlight angle. The device comprises an inclination adjusting unit, a rotating adjusting unit and a bracket. A photovoltaic panel is fixedly mounted on the inclination adjusting unit, the inclination adjusting unit comprises a transmission assembly matched with the rotating adjusting unit, a transverse rod mounted at one end of the transmission assembly and a telescopic connecting rod connected with the transverse rod and the photovoltaic panel, the rotating adjusting unit is mounted on the bracket while being rotatably connected with a support and drives the bracket to rotate, and comprises a driving mechanism fixedly mounted on the support, a driving wheel driven by the driving mechanism and a second driven wheel engaged with the driving wheel and fixedly mounted on the bracket, the bracket is rotatably connected with the support, and the photovoltaic panel is rotatably mounted on the upper portion ofthe bracket. According to the motion rule of the sun in one day, through joint cooperative work of the inclination adjusting unit and the rotating adjusting unit, the automatic adjusting of the perpendicular incidence angle of the photovoltaic panel towards the sun can be achieved.

Owner:GUIZHOU POWER GRID CO LTD

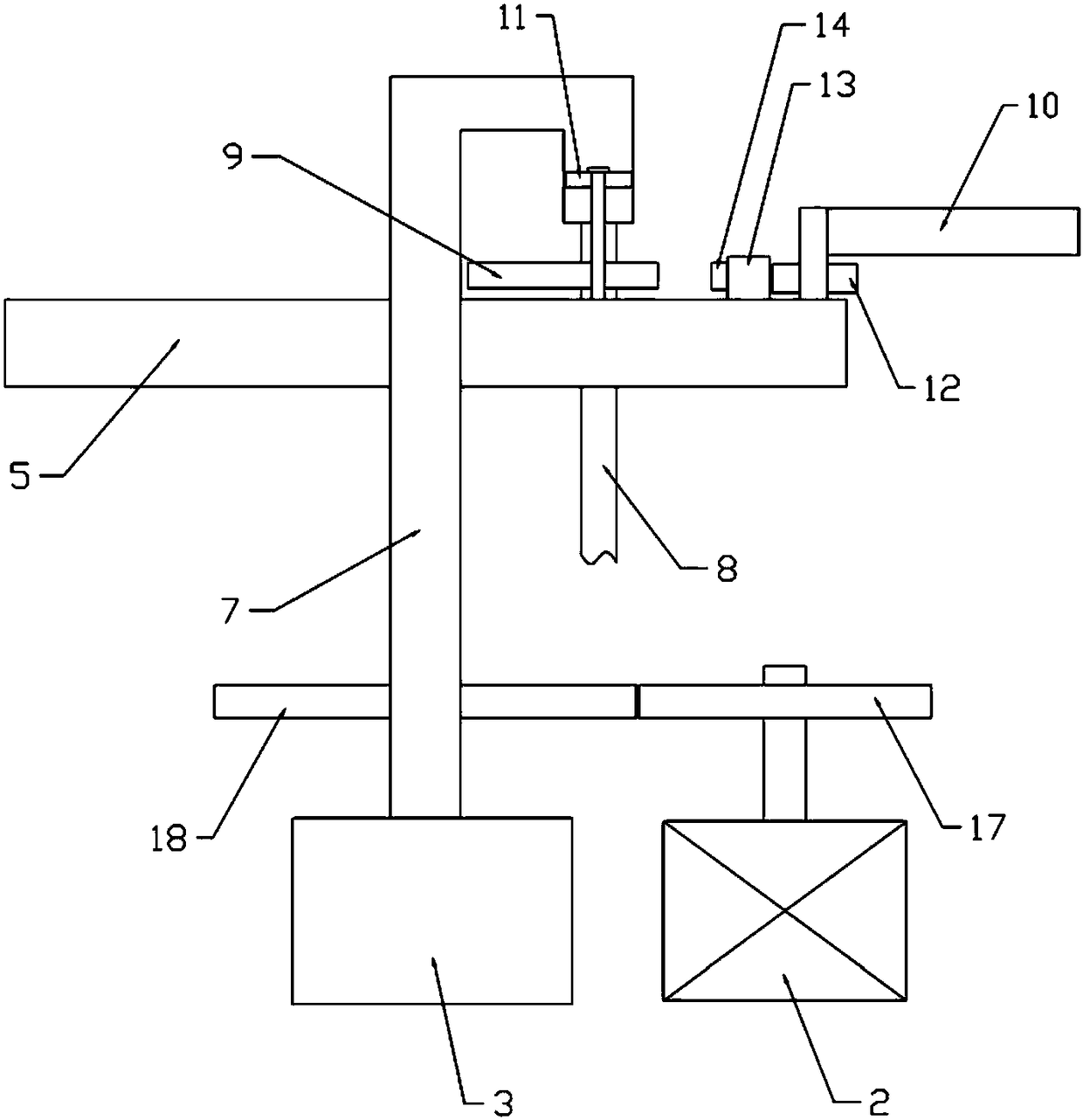

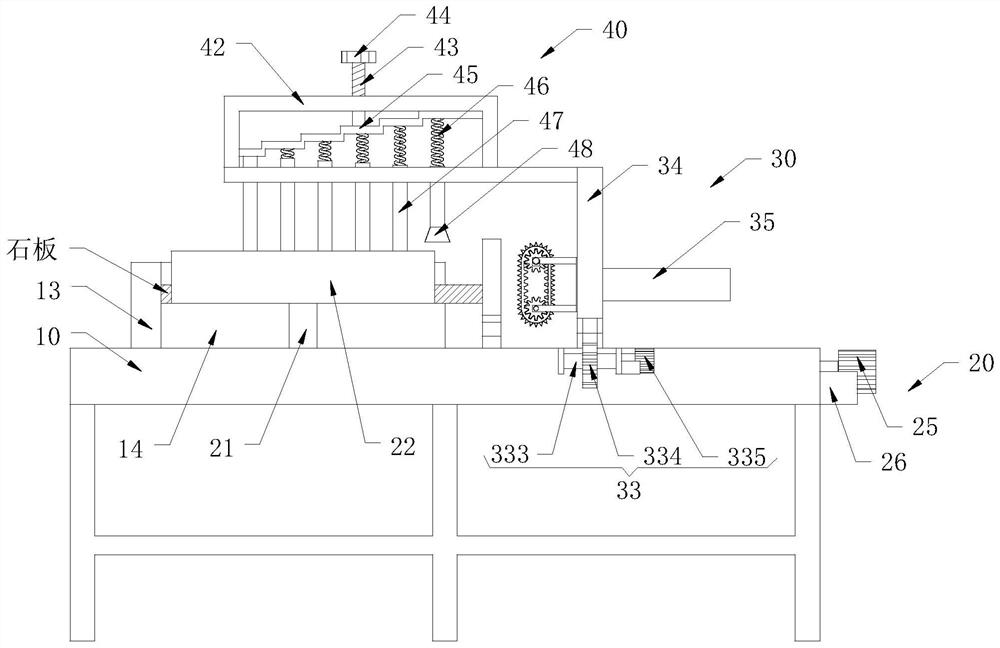

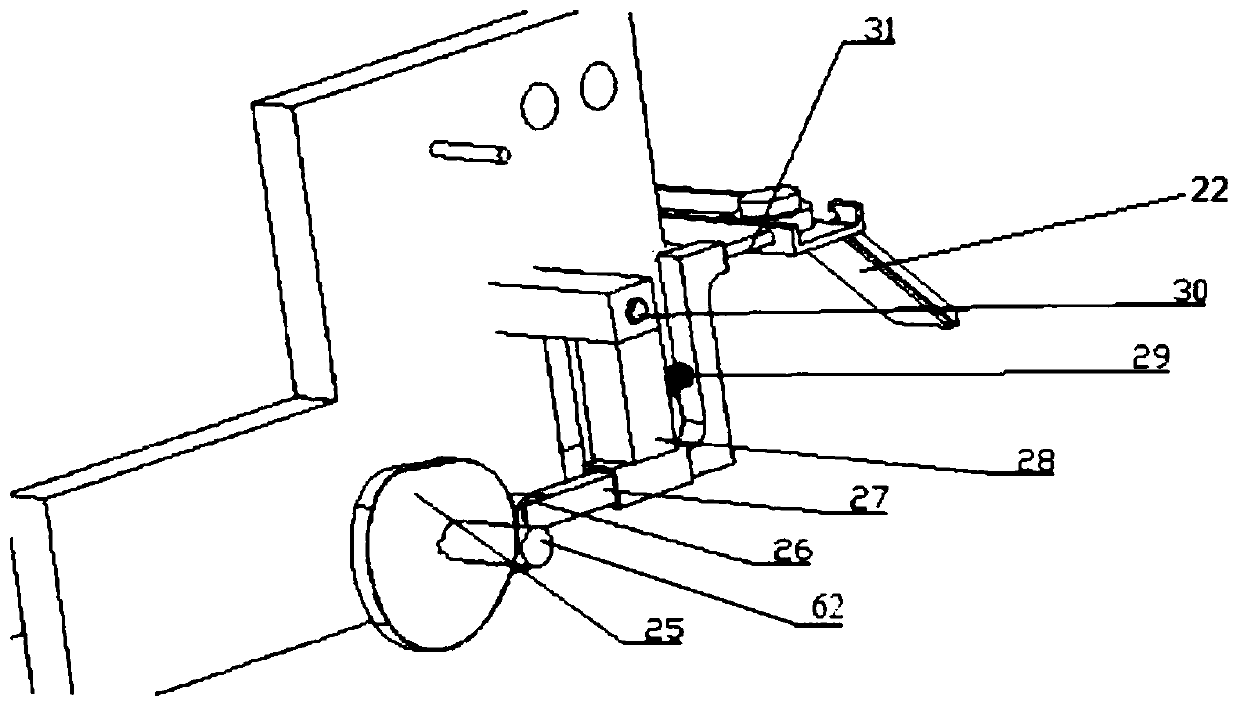

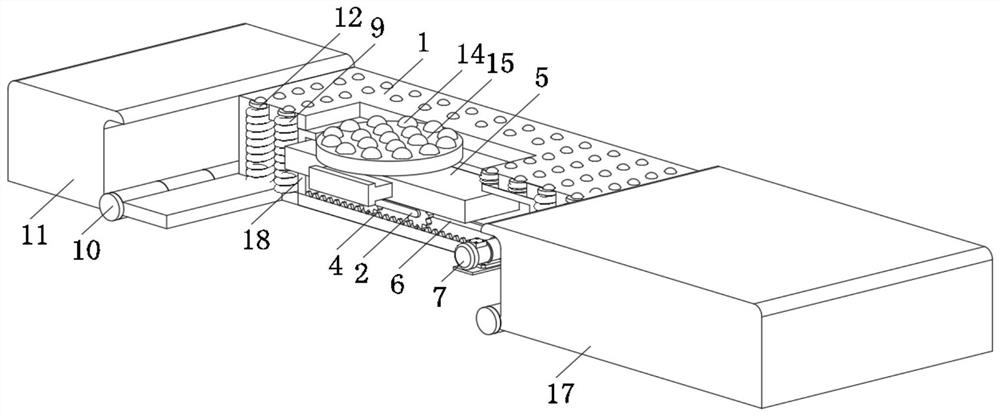

Automatic metal plate grinding machine

InactiveCN106826436AAchieve conversionRealize reciprocating linear motionGrinding carriagesGrinding drivesHydraulic cylinderMotor drive

The invention discloses an automatic metal surface grinding machine. A metal plate to be grinded is fixed by a clamping portion, the particular structure of a protection device portion (22) is as shown in a graph (d), a grinding brush (4) only can vertically move, the plate moves by swinging a rocking handle (11), so that the grinding brush (4) grinds the plate in a matched manner, a left clamp and a right clamp are mutually attracted through a switch magnetic seat (12), the metal plate is fixed, a hydraulic cylinder (17) drives a grinding box (2) moves in a rail (7) through wheels (6), so that the grinding brush (4) moves to the foremost end of the metal plate to be grinded to grind, the grinding brush (4) grinds the tail ends of the plate until unloading after leaving the tail end of the plate, reciprocating grinding is achieved, two hydraulic cylinders (1) drive the grinding brush (4) to close the surface of the metal plate, a motor drives a motor shaft (5), so that the grinding brush rotates, cleanness of the motor is protected by a fan (3), the grinding brush (4) is detachable and includes a coarse brush and a fine brush, so that coarse grinding and fine grinding are facilitated, the grinding machine is full-automatic and replaces manual grinding, and workshop machining environments are improved.

Owner:UNIV OF JINAN

Fully automatic vegetable cutter

InactiveCN104908072AEasy reciprocating motionSave human effortMetal working apparatusReciprocating motionEngineering

The invention discloses a fully automatic vegetable cutter. A feeding mechanism, a feeding drive and transmission mechanism and a cutting mechanism are arranged in a shell of a main machine. The feeding mechanism comprises a material cylinder, a pressing plate, a spring mechanism and a material cylinder sliding block. The spring mechanism comprises a spring shell, a middle ring, a spring and a rope. The two ends of the rope sequentially penetrate through the spring shell and the material cylinder sliding block to be fixed to the pressing plate. The pressing plate is arranged in the material cylinder and slide vertically relative to the material cylinder. The material cylinder is provided with an upper opening and a lower opening and arranged on the material cylinder sliding block. A cam sliding groove is formed in the material cylinder sliding block. The feeding drive and transmission mechanism comprises a first motor, a rotating disc and a cam. An output shaft of the first motor is fixed to the center of the rotating disc. The cam is eccentrically arranged on the rotating disc and matched with the cam sliding groove. The material cylinder sliding block drives the material cylinder to conduct reciprocating rectilinear movement in the shell of the main machine. According to the fully automatic vegetable cutter, the rope is driven through the elasticity of the spring to pull the pressing plate to press food materials all the time, manual food material pressing is omitted, and reciprocating movement of the feeding mechanism is achieved easily.

Owner:马晓东

Rolling triangular robot

The invention discloses a rolling triangular robot, and relates to a rolling robot. One side of the robot comprises an electric motor (2), a section of a screw rod (3), two sections of screw rods (4), three sections of sleeves (5), a sleeve joint (6) and an electric motor joint (1), wherein the tail part of the electric motor is fixed on the electric motor joint; an output shaft of the electric motor is fixed with the right end of one section of the screw rod through a fastening nail; a section of the screw rod is in threaded connection with two sections of the screw rods; two sections of thescrew rods are connected with three sections of the screw rods through the threads; three sections of the screw rods are fixed on the sleeve joint; and the electric motor joint, the electric motor, the one section of the screw rod, the two sections of the screw rods, the three sections of the screw rods and the sleeve joint form one side of the rolling triangular robot. The structures and the sizes of three sides of the rolling triangular robot are the same, and the electric motor joints of each side are connected with the sleeve joint and a cylinder pin of another side in turn through a cylinder pair so as to form the rolling triangular robot. The rolling triangular robot has the advantages of simple structure and easy realization, and provides acknowledge help for middle and primary students on geometric solids and moving robots.

Owner:BEIJING JIAOTONG UNIV

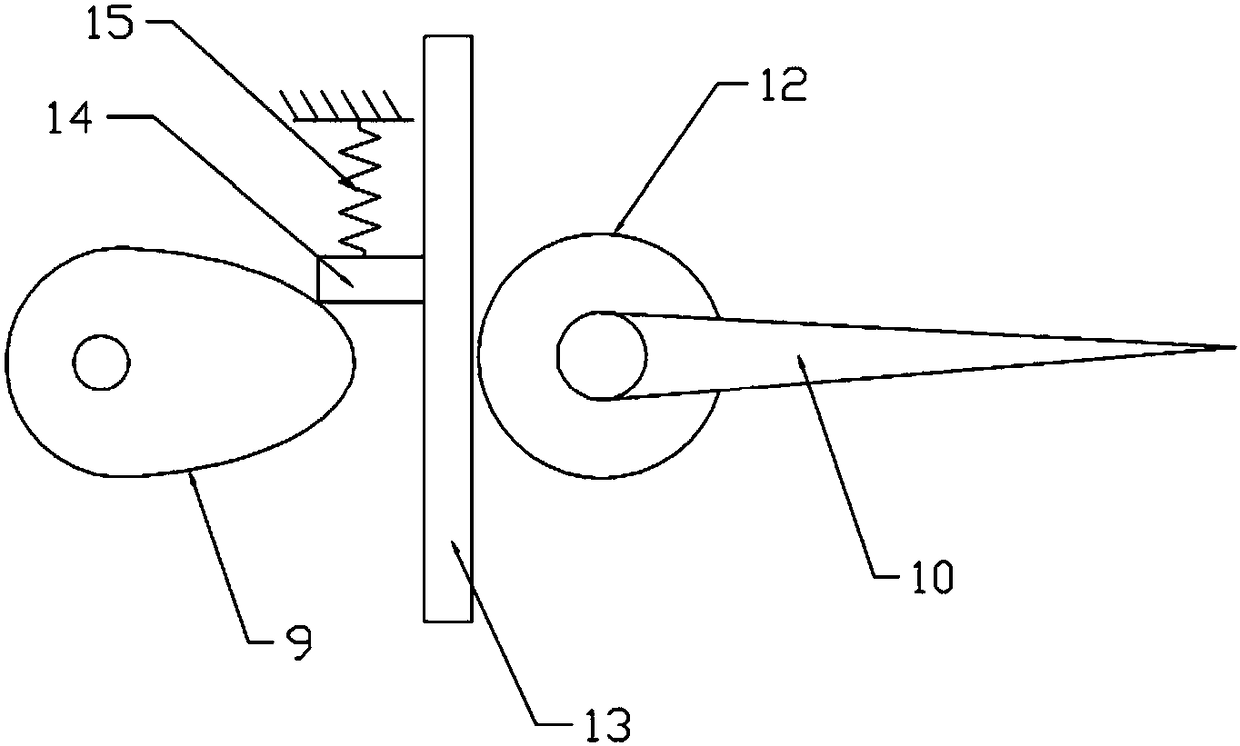

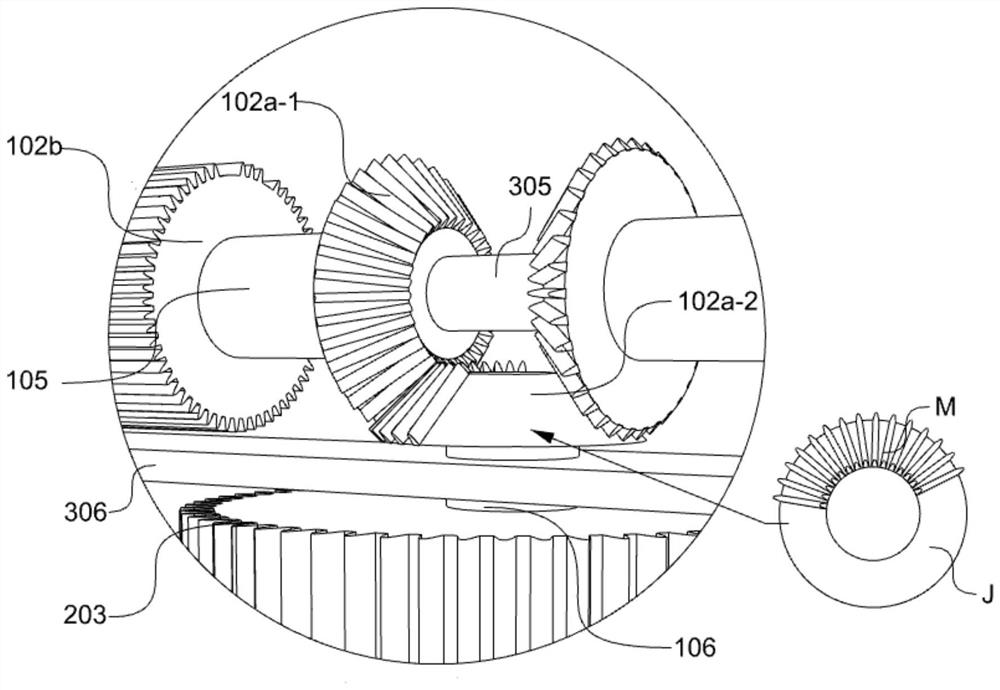

Knife sharpening reciprocating mechanism of shredding machine

PendingCN110293459ARealize reciprocating linear motionExtended service lifeGrinding carriagesGrinding drivesEngineeringMechanical engineering

The invention discloses a knife sharpening reciprocating mechanism of a shredding machine. The knife sharpening reciprocating mechanism of the shredding machine comprises a knife sharpening bottom plate, a knife sharpening device, a driving unit, a reciprocating transmission mechanism, a driving shifting block and a reversing shifting block, wherein the knife sharpening device is movably arrangedon the knife sharpening bottom plate, the reciprocating transmission mechanism is connected with the driving unit, and the driving shifting block is connected with the reciprocating transmission mechanism; the driving unit continuously drives the reciprocating transmission mechanism to do rotary motion, so that the driving shifting block rotates reversely to drive the reversing shifting block to move and finally drive the knife sharpening device to do reciprocating movement. According to the knife sharpening reciprocating mechanism of the shredding machine, the driving unit can be continuouslydriven, and the reciprocating rectilinear motion of the knife sharpening device is achieved without reverse turning, thus prolonging the service life of a motor.

Owner:QINHUANGDAO TOBACCO MACHINERY

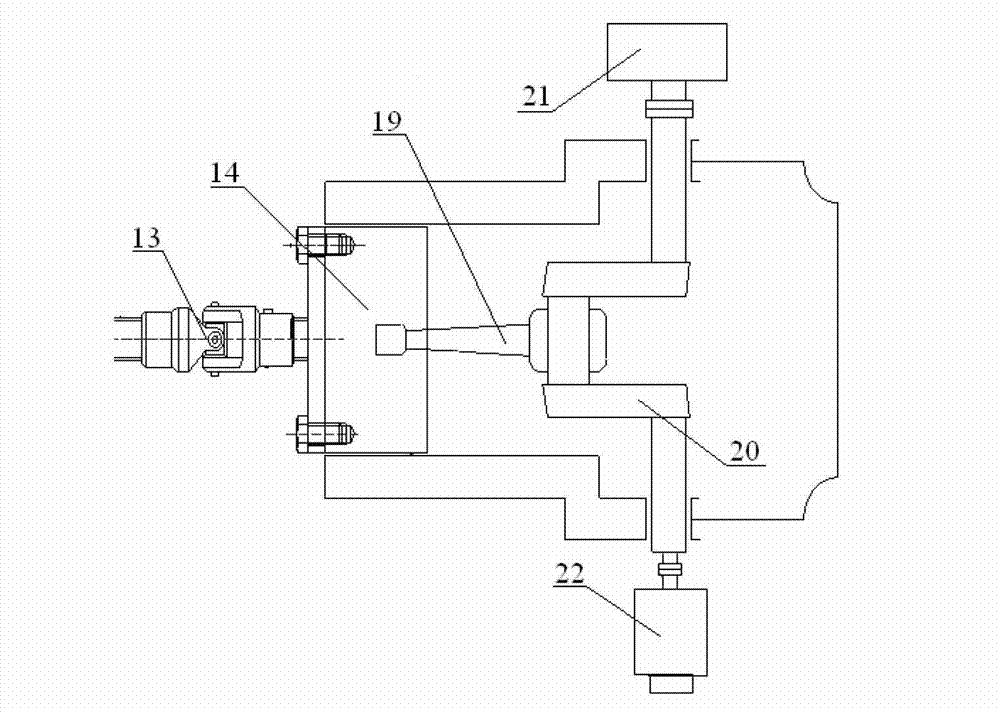

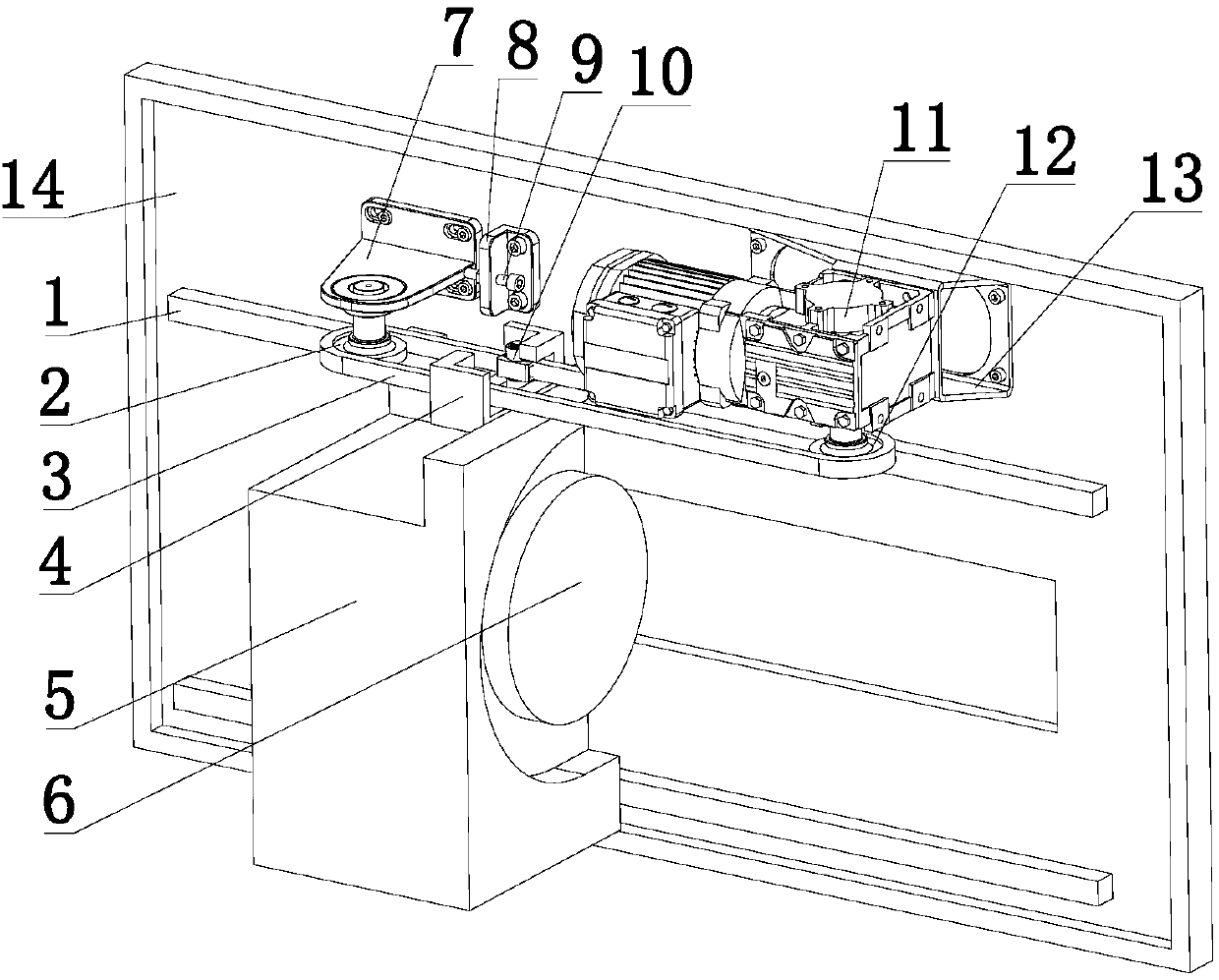

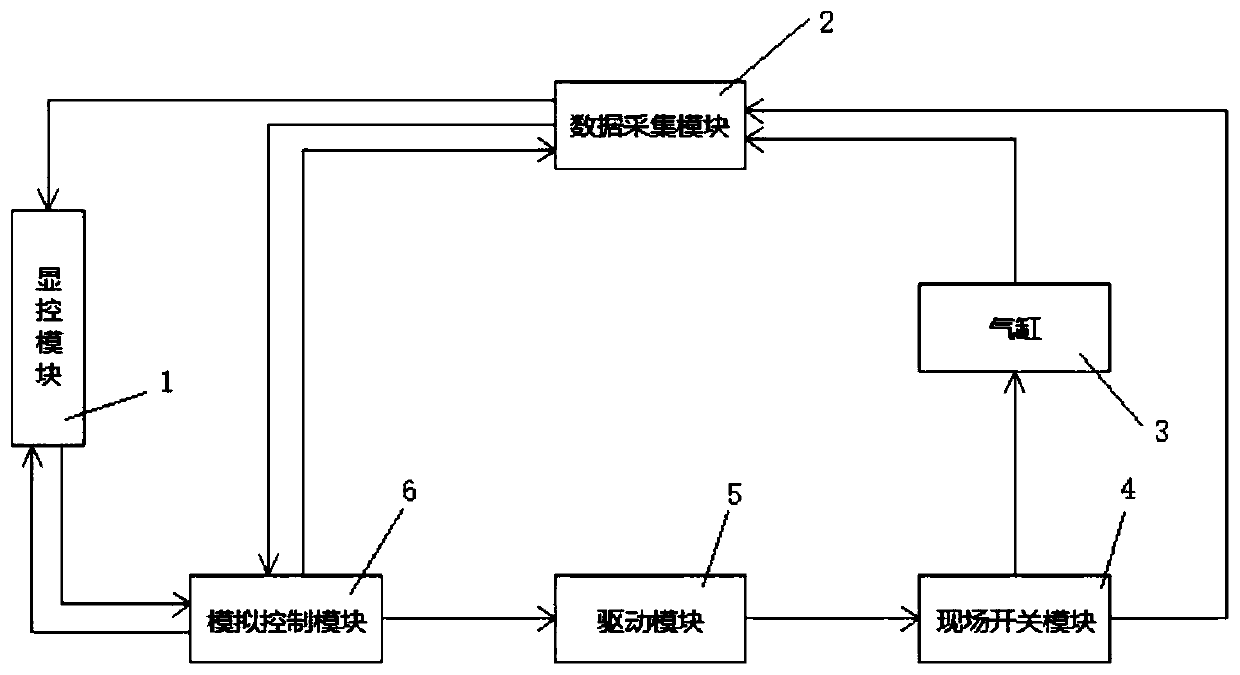

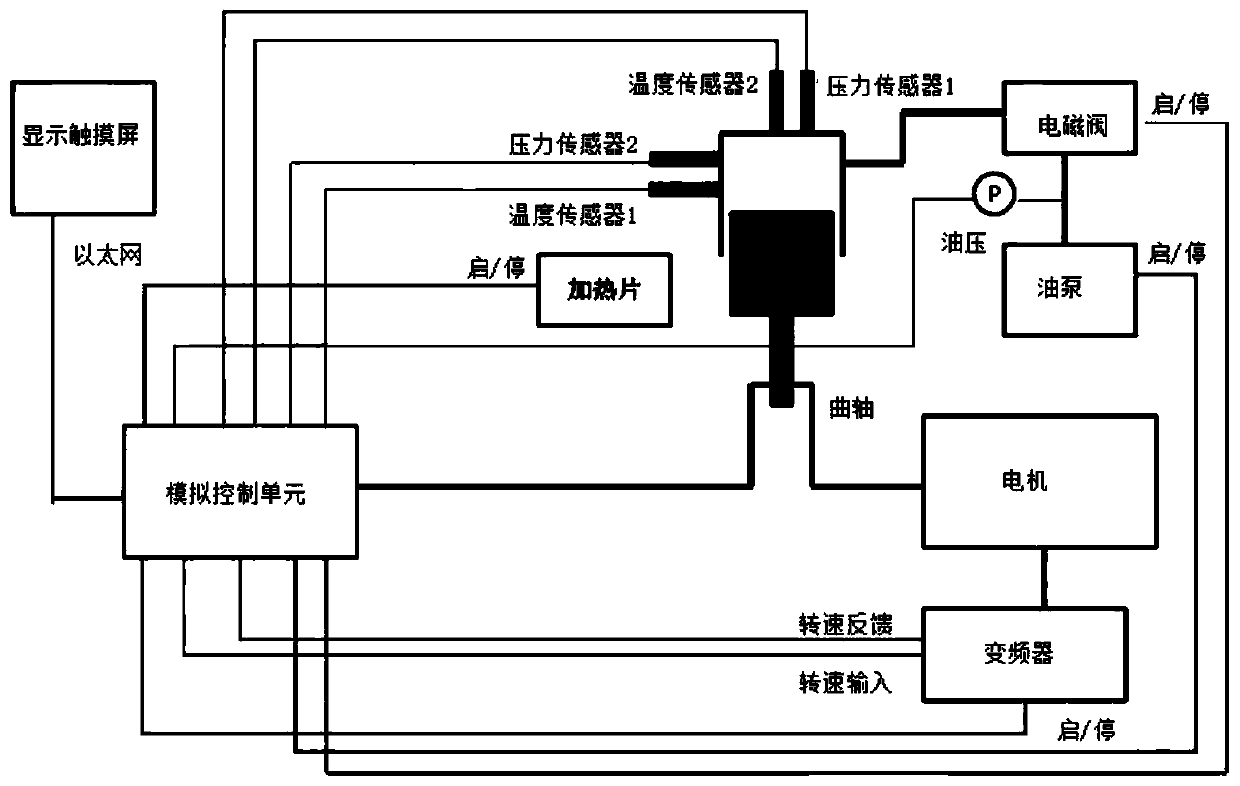

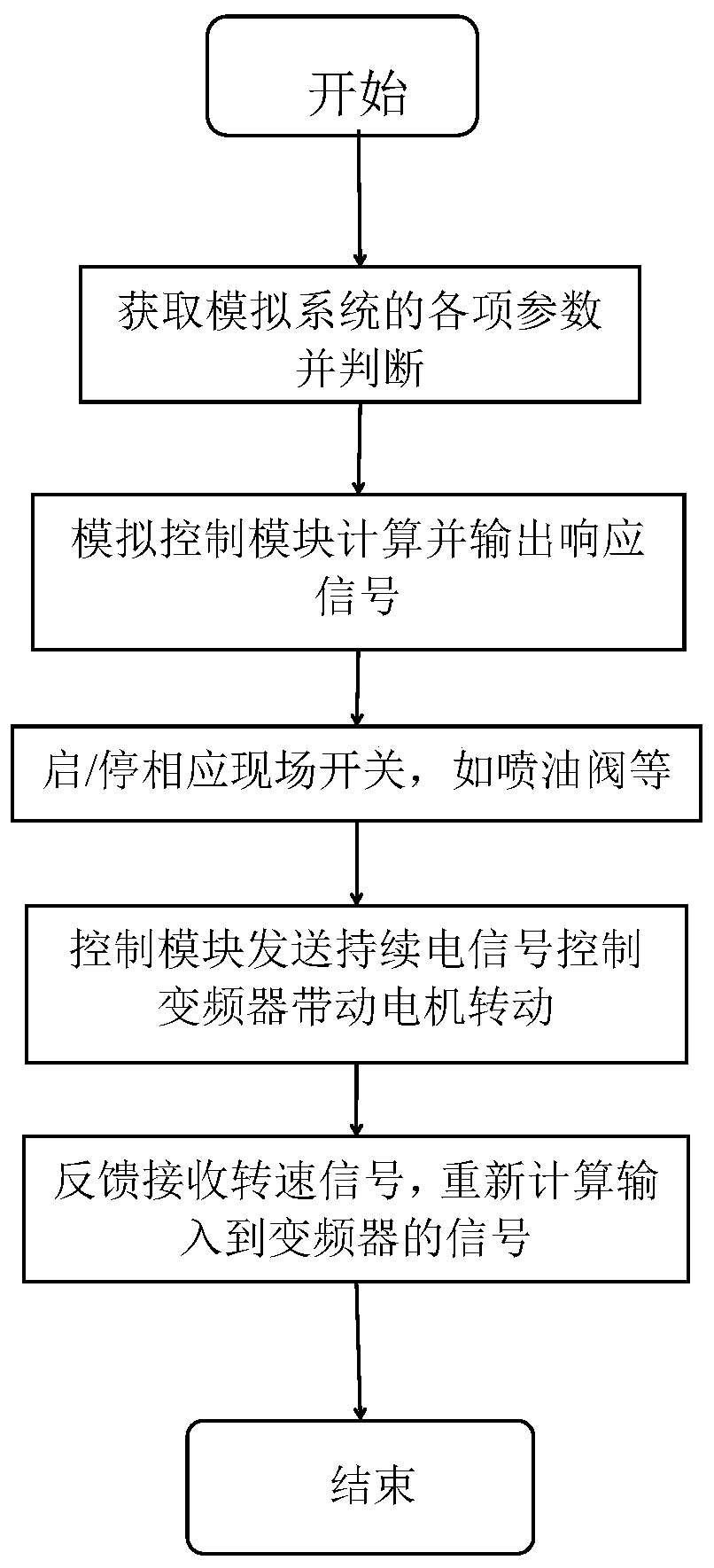

Internal combustion engine cylinder simulation device and control method

InactiveCN109883717AImprove efficiencyControl the direction of operationInternal-combustion engine testingPistonFrequency changer

The invention belongs to the field of internal combustion engines, and in particular relates to an internal combustion engine cylinder simulation device and a control method. The internal combustion engine cylinder simulation device comprises a data acquisition module, a field switch module, a simulation control module, a display control module and the like; the simulation control module is connected with the data acquisition module; the simulation control module is connected with a driving module; the driving module is connected with the field switch module; the data acquisition module is connected with a cylinder; the field switch module is connected with a cylinder module and the data acquisition module; a digital signal, which is a 0-24V voltage signal, is generated according to rotation speed feedback through the simulation control module, so that start and stop functions are realized; the output signal of a frequency converter can be controlled by changing the size and the direction of a current signal, so that the running direction of a motor is controlled; and the purpose of enabling a piston to do a reciprocating linear motion in the cylinder is achieved. According to theinternal combustion engine cylinder simulation device and the control method in the invention, the thickness of an oil film between the cylinder wall and the piston in different working conditions canbe easily analyzed; extremely important application value is provided for further increasing the efficiency of the internal combustion engine; and the application prospect is wide.

Owner:HARBIN ENG UNIV

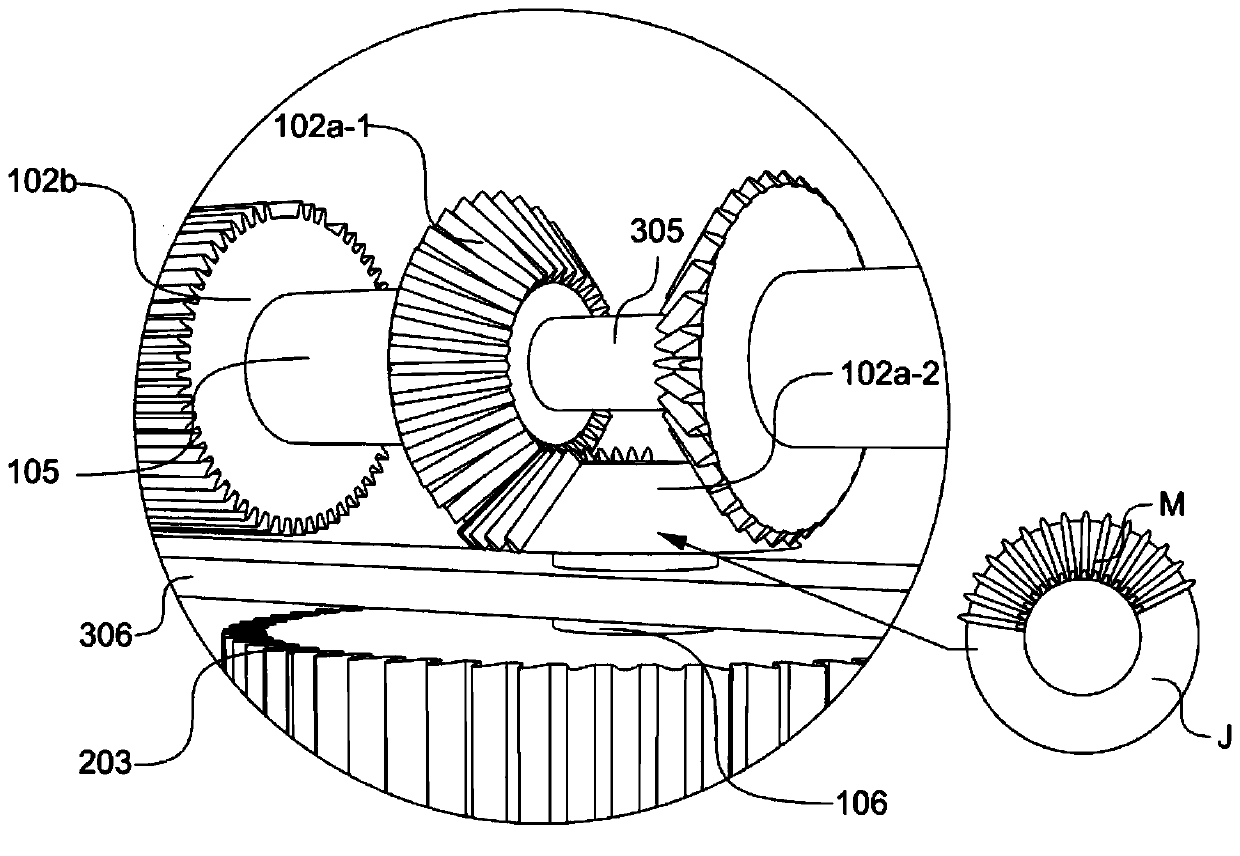

Electromechanical commutator for oil pumping unit

InactiveCN102562974AMovement speed is differentAchieve securityToothed gearingsFluid removalDisc brakeGear system

The invention discloses an electromechanical commutator for an oil pumping unit, which comprises a front-row planet gear system and a rear-row planet gear system, wherein the two planet gear systems share one planet carrier; a rear brake disc is fixed on the planet carrier; the rear brake disc and a normally-closed rear electromagnetic disk brake form a brake device; a front brake disc is fixed on a front-row center wheel; the front brake disc and a normally-closed front electromagnetic disk brake form another brake device; an input shaft is fixedly connected with a front-row inner gear ring and a rear-row center wheel; the front-row center wheel and the planet carrier are idled with the input shaft; a rear-row inner gear ring is fixedly connected with an output shaft; the front-row planet gear is simultaneously meshed with the front-row center wheel and the front-row inner gear ring; and the rear-row planet gear is simultaneously meshed with the rear-row center wheel and the rear-row inner gear ring. According to the electromechanical commutator for the oil pumping unit, a series of problems brought by the fact that a reciprocating rotary oil pumping unit directly commutates by an electromotor can be solved, and therefore, the electromechanical commutator for the oil pumping unit has an important practical value.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

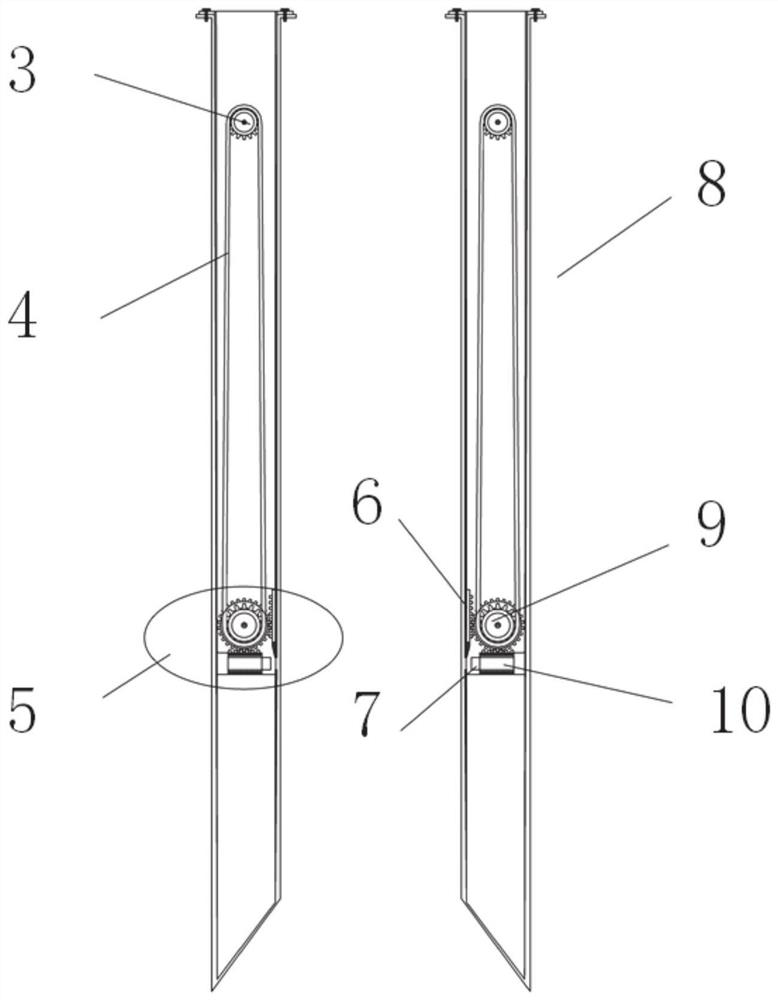

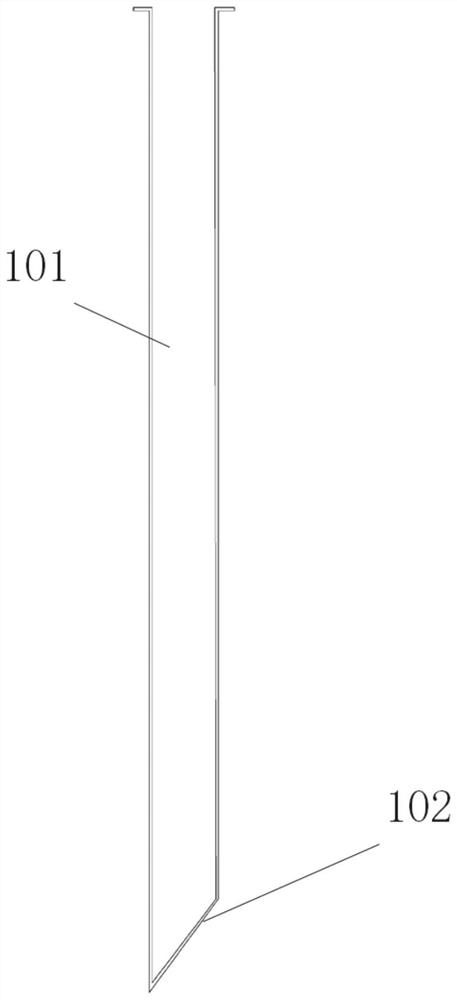

Device and method for detecting compaction degree of on-site filling roadbed based on shear wave velocity

ActiveCN113777169AGuaranteed accuracyGuaranteed reliabilityAnalysing solids using sonic/ultrasonic/infrasonic wavesSoil scienceStructural engineering

The invention discloses a device and a method for detecting the compaction degree of an on-site filling roadbed based on shear wave velocity, and solves the problems that in the prior art, a feeler lever can generate an embedding and extruding effect on a soil body and a bending element is in close contact with roadbed soil to be detected. The device and the method can improve the reliability of a shear wave test result. According to the specific scheme, the device for detecting the compaction degree of an on-site filling roadbed based on shear wave velocity comprises a shear wave excitation mechanism and a shear wave receiving mechanism, and each of the shear wave excitation mechanism and the shear wave receiving mechanism comprises an outer sleeve, a soil sampling inner core pipe and a bending element inner core rod; a first opening is formed in the side wall of the outer sleeve; the soil sampling inner core pipe can be detachably connected with the outer sleeve, so that when the outer sleeve is cut into a soil body, the soil body in the outer sleeve enters the soil sampling inner core pipe, and the soil sampling inner core pipe can move relative to the outer sleeve under the action of external force; and the bending element inner core rod comprises a hollow rod body which can be connected with the outer sleeve, the rod body is provided with a second opening which can be communicated with the first opening, and a movable bending element test piece is arranged in the rod body.

Owner:SHANDONG UNIV +1

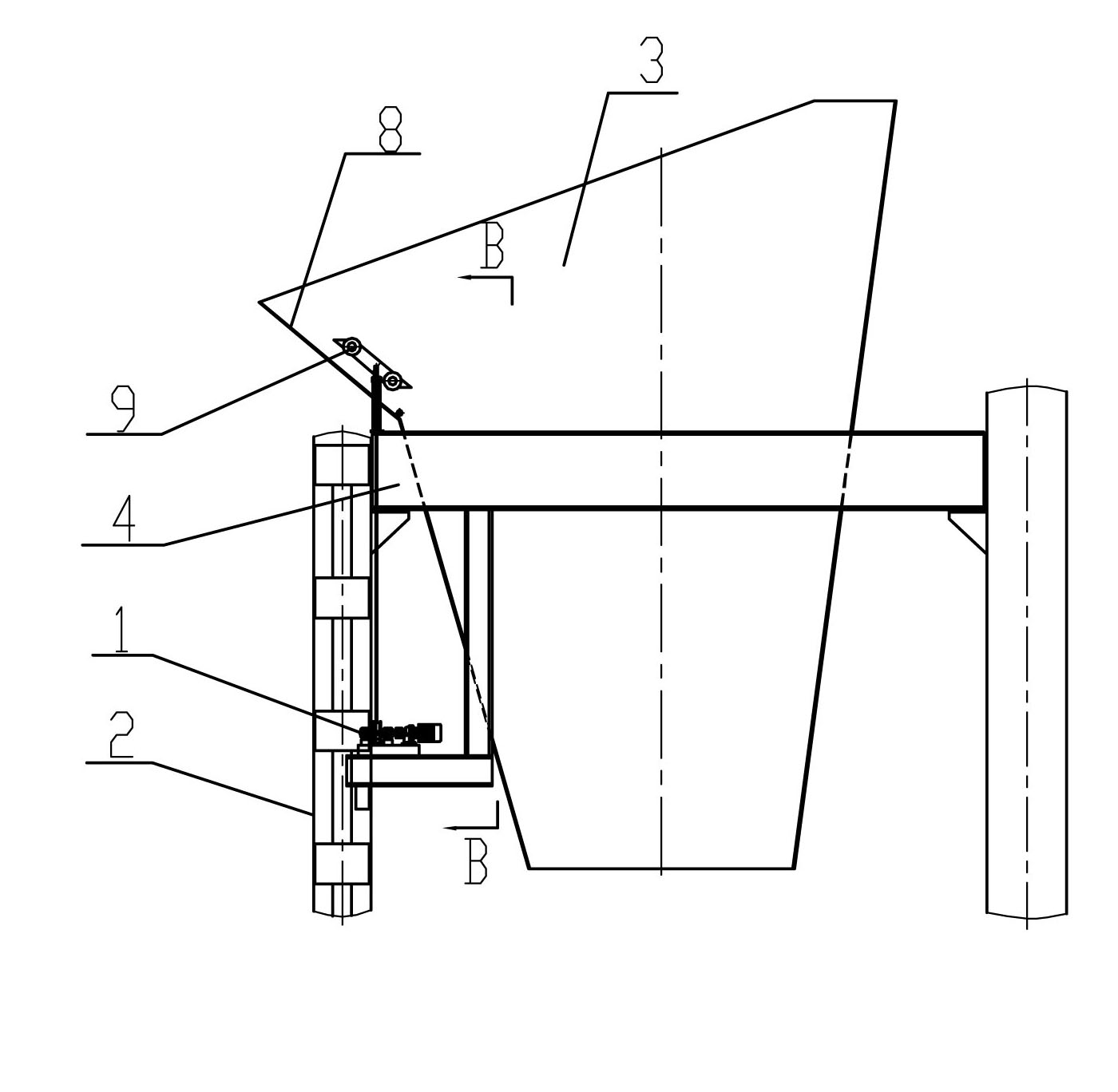

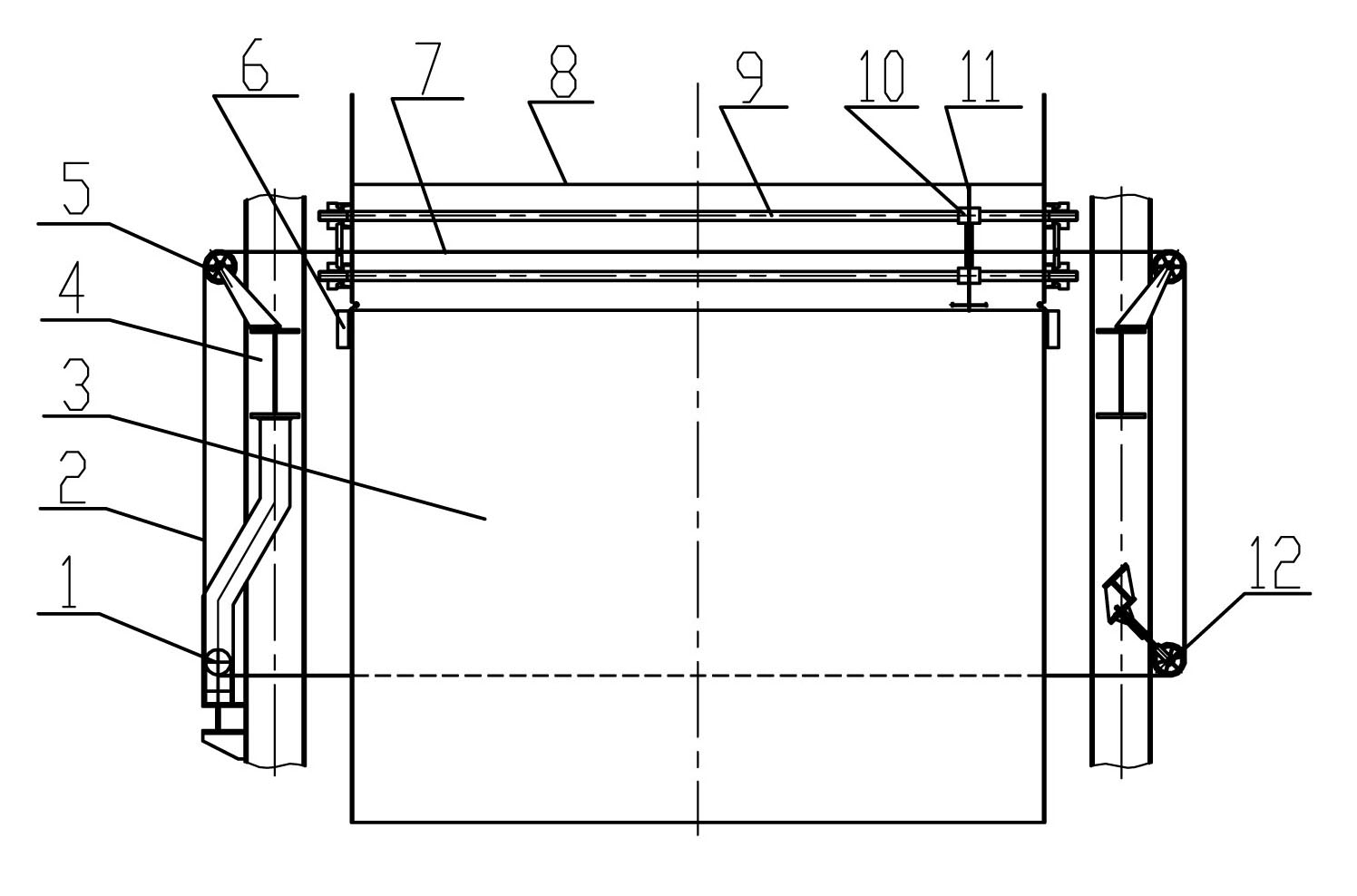

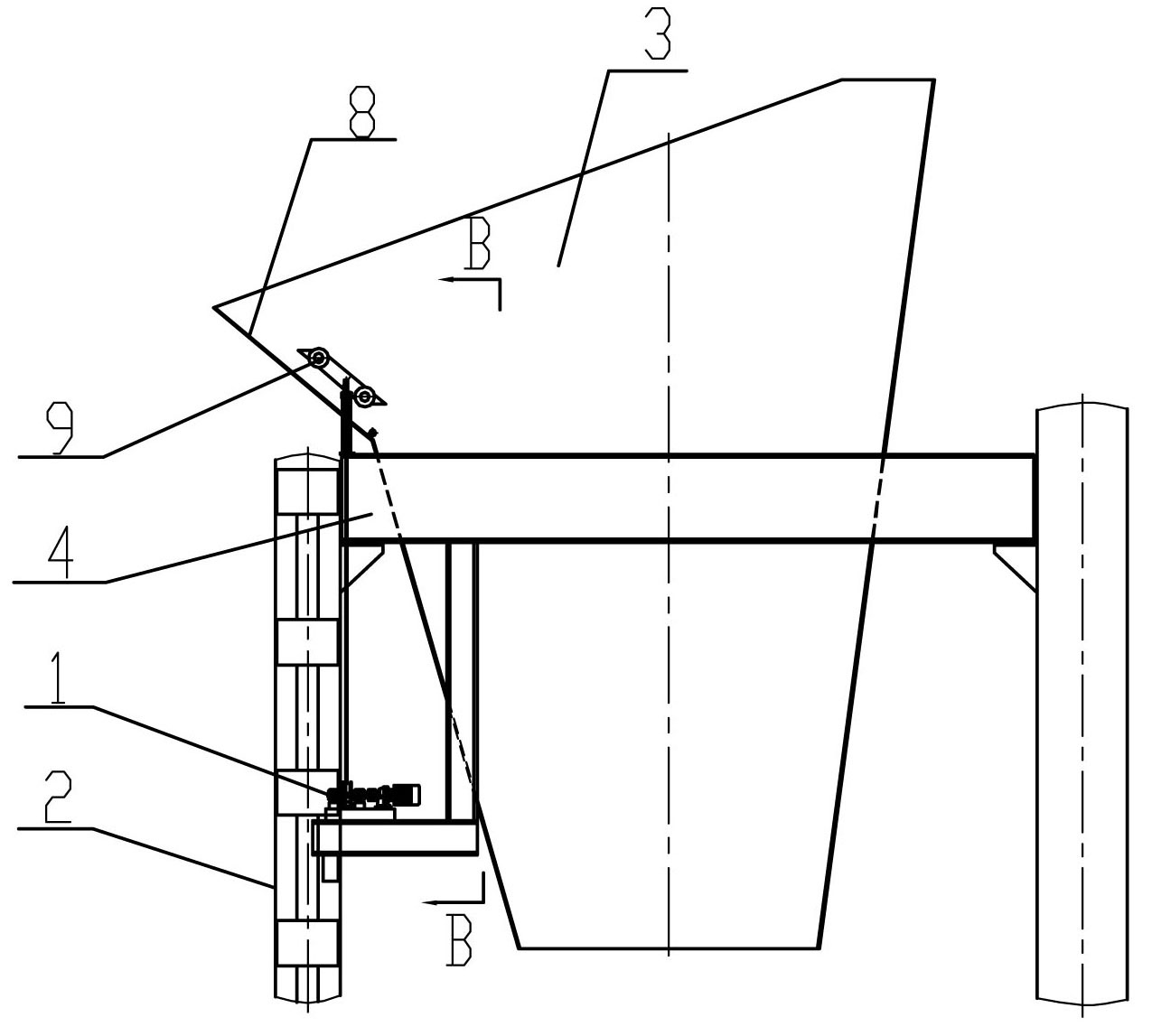

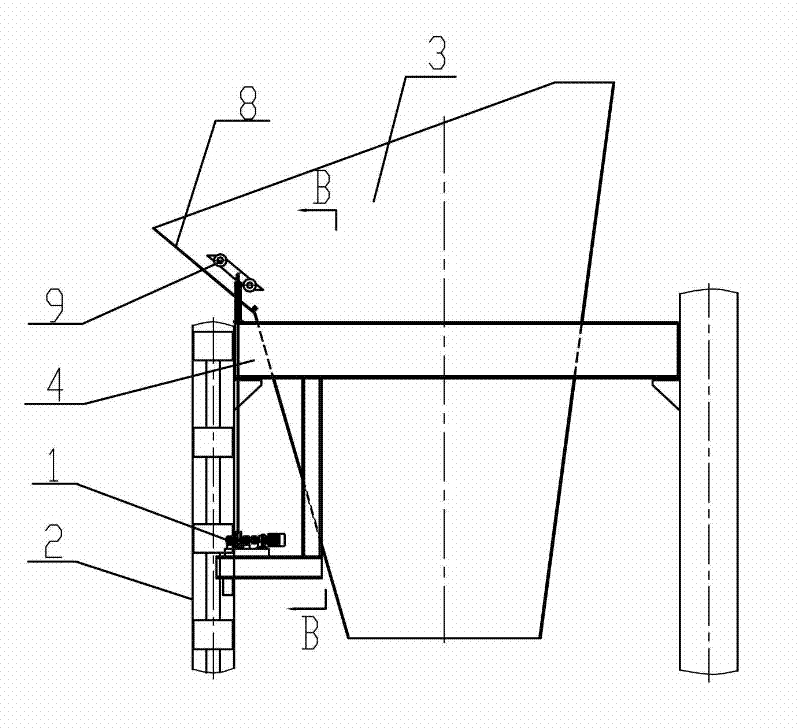

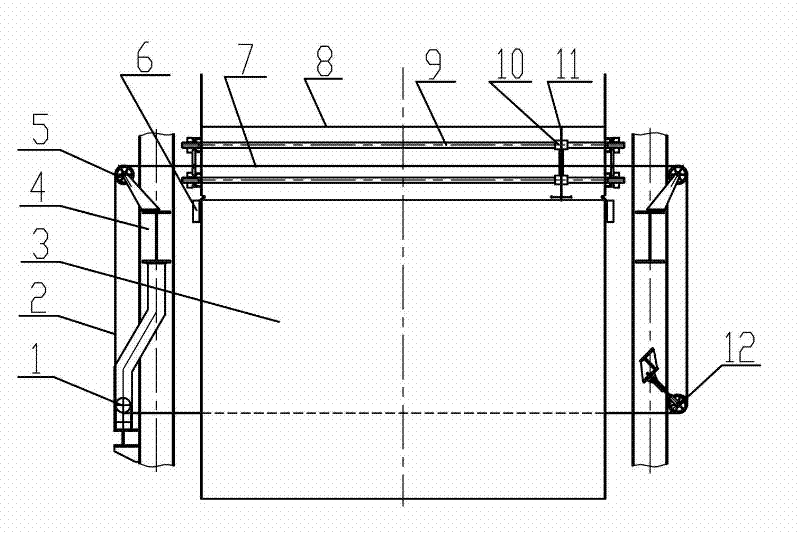

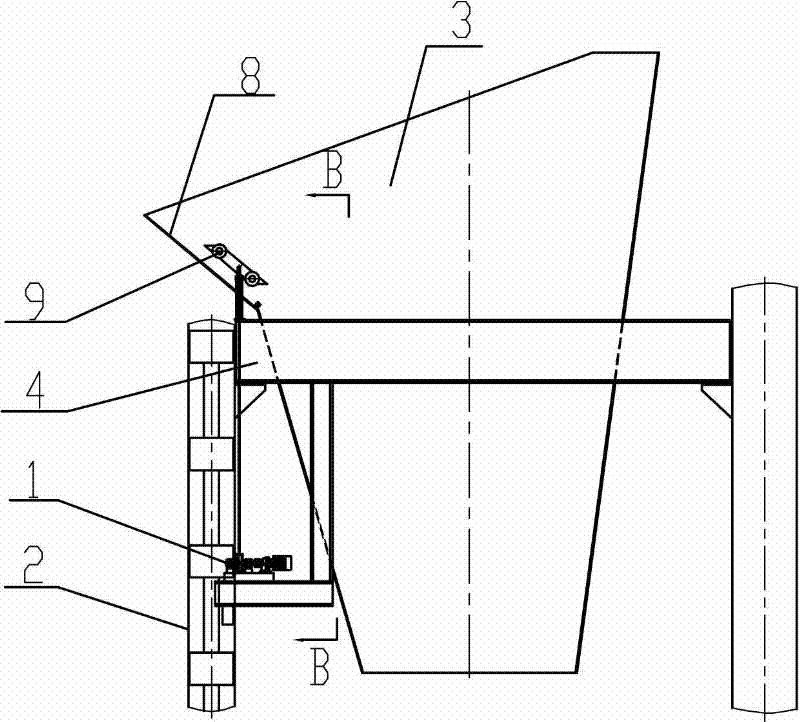

Grate distributing hopper with automatic swiping device

The invention relates to a grate distributing hopper with an automatic swiping device, which comprises a distributing hopper body and is characterized in that the distributing hopper body is provided with an automatic swiping device which comprises a cross beam, a transmission mechanism, a scraper mechanism and approach switches, wherein the cross beam is arranged at two sides of the distributing hopper body and respectively connected with a grate stand, the transmission mechanism is connected with the grate stand, the scraper mechanism is connected with two side plates of the distributing hopper body, and the approach switches are respectively arranged below the scraper mechanism on the two side plates of the distributing hopper body and electrically connected with an electric control device. The transmission mechanism comprises a hoist connected with the grate stand, a tension pulley mechanism connected with the grate stand opposite to the hoist, a fixed pulley arranged on the cross beam and a steel rope respectively connected with the hoist, the fixed pulley and the tension wheel mechanism. The scraper mechanism comprises two guide pipes arranged on the upper parts of the two side plates of the distributing hopper body in parallel, sleeves sleeved on the guide pipes and sliding on the guide pipes, and a scraper connected with the sleeves. The invention realizes automatic swiping of binder and prolongs the service life of the grate distributing hopper.

Owner:NORTHERN ENG & TECH CORP MCC

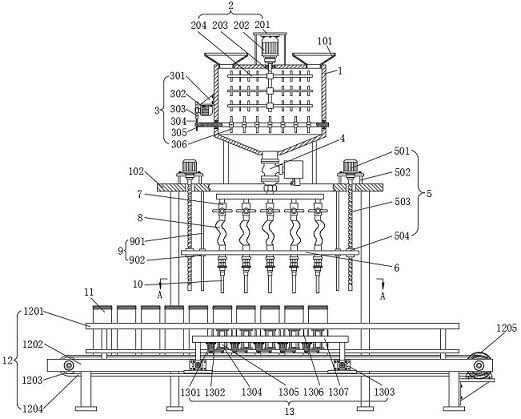

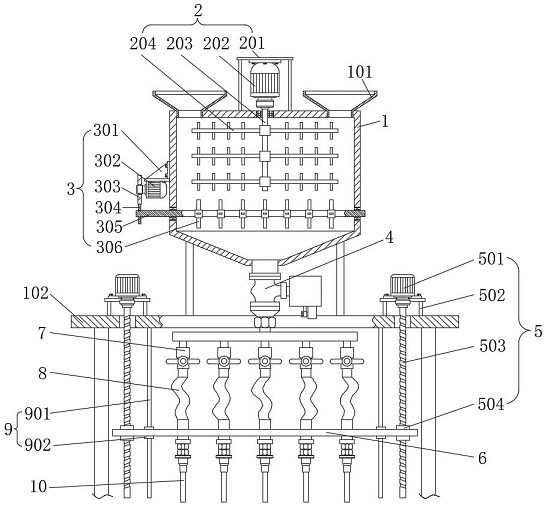

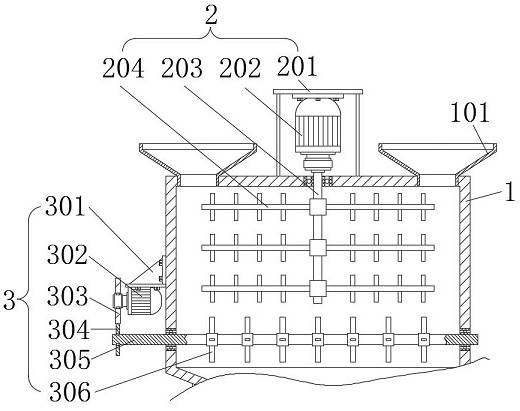

Uniform filling device for composite sauce

PendingCN113135543AUniform weightAvoid offsetRotary stirring mixersLiquid bottlingMechanical engineering

The invention discloses a uniform filling device for a composite sauce, and relates to the technical field of composite sauce filling. The uniform filling device comprises a machine box body, wherein feeding funnels are symmetrically arranged at the top of the machine box body, and a first stirring part and a second stirring part which are used for stirring the sauce are arranged in the machine box body; an electromagnetic control valve is arranged at the lower end of the machine box body, and a diversion connector is arranged at the outlet end of the electromagnetic control valve; a conveying pipe is arranged at the lower end of the diversion connector, and the lower end of the conveying pipe is connected with a filling head arranged on a lifting table; lifting motion parts are symmetrically arranged on the lifting table, and a conveying part used for horizontally conveying sauce containing bottles is arranged below the filling head; and a material uniformizing motion part which enables the sauce containing bottles to rotate in the filling process is arranged at the side part of the conveying part. According to the uniform filling device, batch filling operation can be conducted on the composite sauce, the weight of the filled composite sauce is uniform and consistent, the situation that the filled sauce deviates and accumulates towards one side in the uncertain direction is avoided, and the bulging and swelling phenomena occurring after follow-up sauce packaging are reduced.

Owner:湖南佳元禄食品有限公司

Stone processing and treatment method for indoor decoration material of building

InactiveCN112454679ANot easy to shiftAvoid offsetCovering/liningsWorking accessoriesLinear motionFlagstone

The invention relates to a stone processing and treatment method for an indoor decoration material of a building, and using stone processing and manufacturing equipment. The equipment comprises a workbench and a fixing device arranged at the top of the workbench, wherein a cutting device is arranged at the right side of a bottom plate, and a locating device is arranged at the left side of a firstn-shaped frame. According to the invention, an electric cross-shaped sliding block can move forwards in the width direction of a second cross-shaped groove through cooperation of designed locating baffle, fixing plate and second cross-shaped groove, the electric cross-shaped sliding block drives the locating baffle to move synchronously, and two groups of adjacent trapezoidal plates in the locating baffle are moved to the front end and the rear end of a drawn horizontal straight line; therefore, reciprocating linear motion of the locating baffle can be realized, the corners of a rectangular stone plate to be machined can be conveniently fixed and adjusted at the same time, the cutting machining position is not blocked, time and labor are saved, and the rectangular stone plate to be machined can be cut at any position.

Owner:南京乐飞电科技有限公司

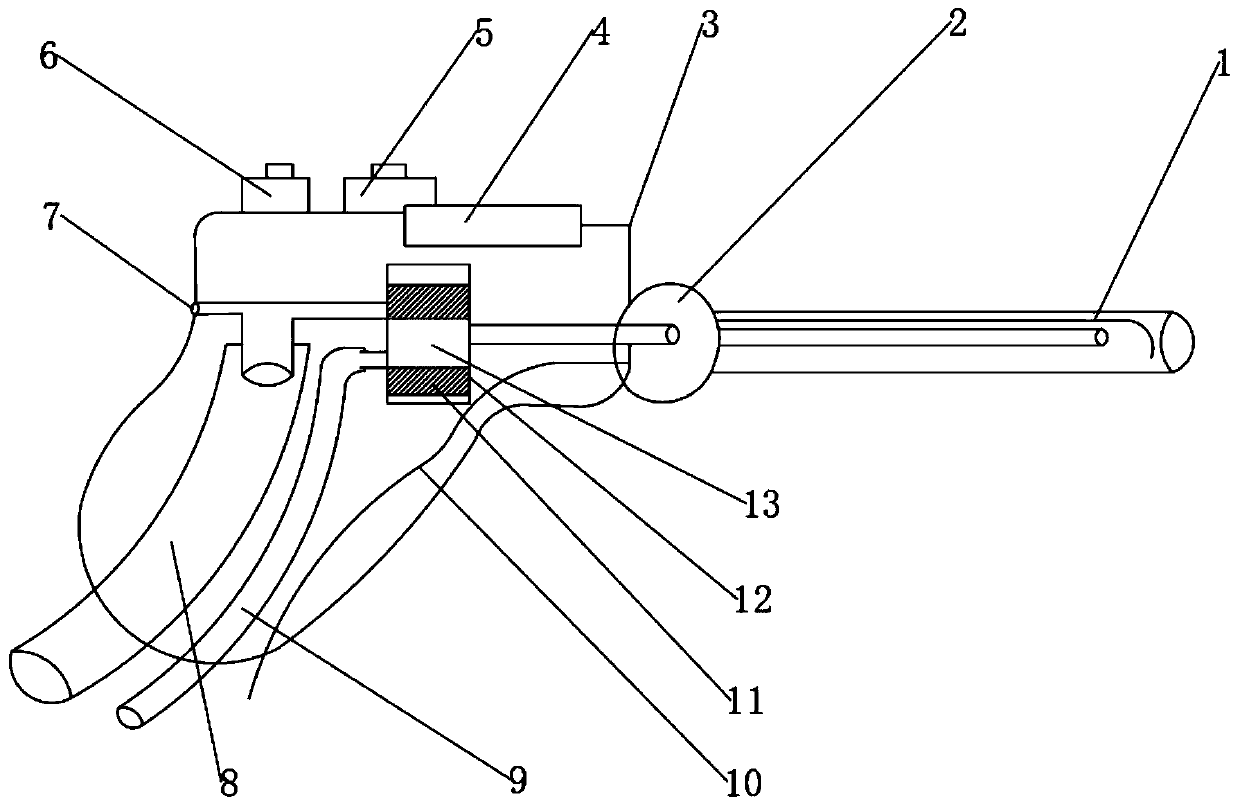

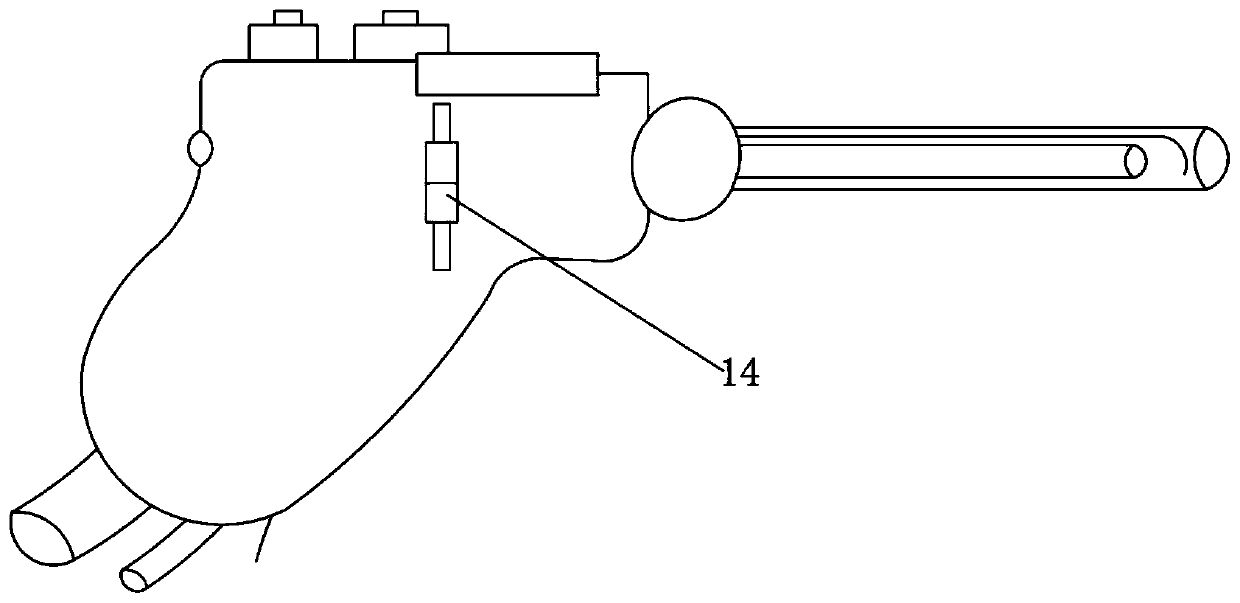

Digital irrigation and ablation equipment

PendingCN110141357ASimple structureEasy to useSurgical instruments for heatingSurgical instruments for aspiration of substancesElectricityEngineering

The invention provides digital irrigation and ablation equipment. The equipment comprises a control part, an irrigation unit, a suction unit, a shell, an ablation device, a conversion unit, an angle adjusting device and a irrigation and sucking joint, wherein the ablation device is arranged in the irrigation and sucking joint, and the irrigation and sucking joint is connected to the angle adjusting device; the angle adjusting device is rotationally connected to the shell; the irrigation unit and the suction unit are respectively connected to the conversion unit, the conversion unit is communicated with the suction unit or the irrigation unit, and the other end of the conversion unit is communicated with the irrigation and sucking joint; and the control part is electrically connected to theirrigation unit and the ablation device. The equipment has the advantages that: the equipment is flexible to operate, is provided with a conversion cavity and a conversion switch, can independently irrigate operation incision or suck the dirt such as blood dirt of the operation incision, and has strong operation adaptability.

Owner:山东美珂医疗科技有限公司

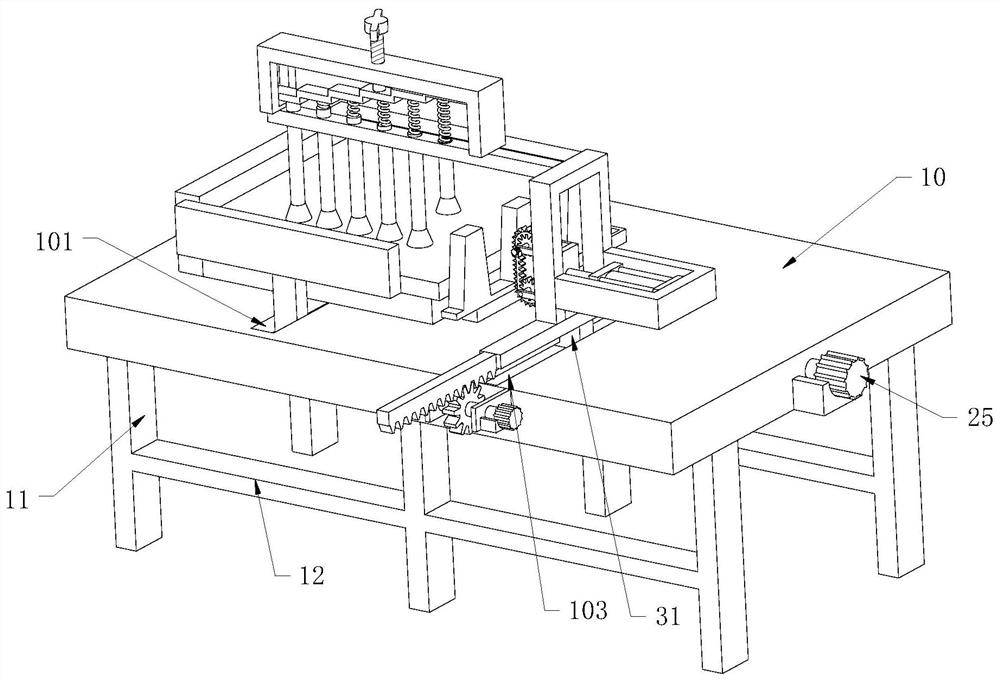

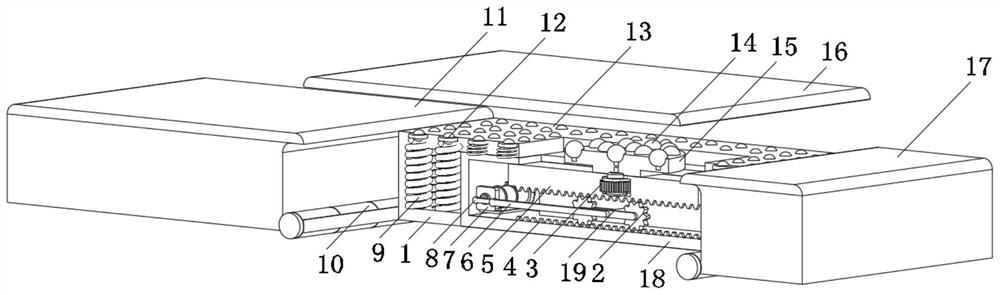

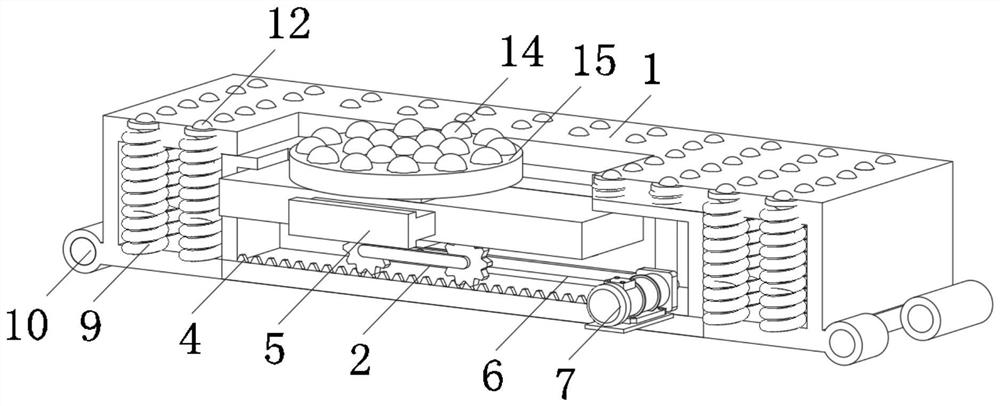

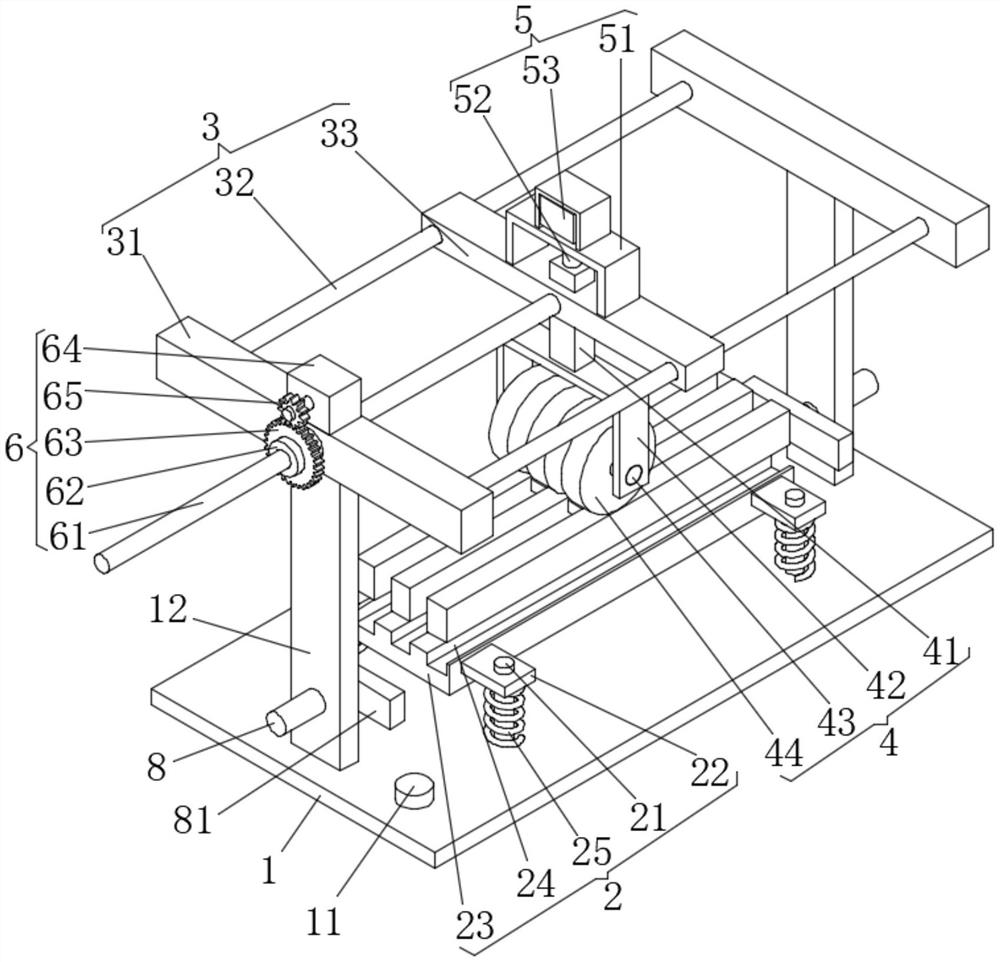

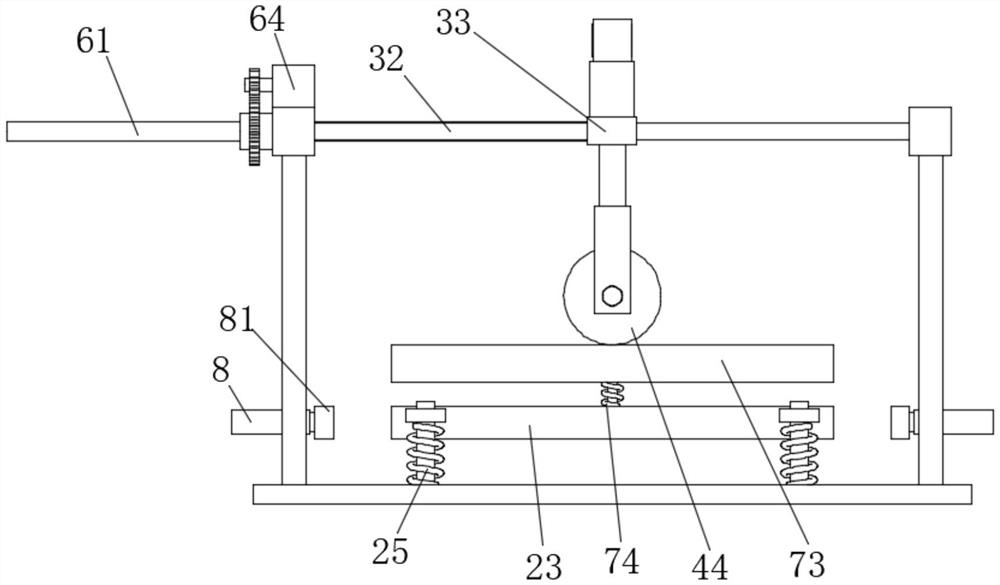

A semi-automatic drilling machine

ActiveCN108284347BRealize reciprocating linear motionGuaranteed production efficiencyFeeding apparatusMetal working apparatusGear driveReciprocating motion

The invention discloses a semi-automatic drilling machine. The semi-automatic drilling machine comprises a base plate, a feeding mechanism, a positioning mechanism, a clamping mechanism, a drilling mechanism, a discharge mechanism and a transmission mechanism; the positioning mechanism is a cam connecting rod mechanism; the feeding mechanism and the positioning mechanism cooperate to realize positioning; the clamping mechanism is a cam connecting rod mechanism; the drilling mechanism drills clamped parts to be machined in a worktable drilling station; the discharge mechanism is a plane seven-rod mechanism; and the transmission mechanism comprises belt transmission and gear transmission. The semi-automatic drilling machine realizes a linear reciprocating motion of a feeding slide block, anintermittent linear reciprocating motion of a positioning rod, an intermittent linear reciprocating motion of a fixture, an intermittent linear reciprocating motion of a cutter and a discharge motionof the seven-rod discharge mechanism after machining, realizes structural simplification when guaranteeing the production efficiency, reduces the production and maintenance costs, saves the manpower and the like.

Owner:HOHAI UNIV CHANGZHOU

A method of depositing and retrieving objects

The invention provides a goods storing method. A child-mother car is adopted and comprises a mother car, a shifting device, a child car and a jacking device sequentially from bottom to top. The goodsstoring method includes the following steps that firstly, goods are placed on the jacking device, and the mother car runs to a designated position; the shifting device is butted to a rail; then, the jacking device is jacked up, and the child car moves along the butted rail; and finally, a hydraulic platform descends, one time of goods storing is completed, and each device returns to seat sequentially. The invention further provides a goods taking method. Firstly, the mother car runs to the designated position; the shifting device is butted to the rail, the child car moves along the butted rail, then, the jacking device jacks goods up, and finally, the child car, the shifting device and the jacking device return to seat sequentially. The shifting mechanism and the child car system can achieve high precision of goods taking and storing. Compared with a conventional goods taking and storing method such as forking, the system structure is small in displacement and operates more stably whena goods taking system takes the goods.

Owner:JIASNGSU GAOKE LOGISTICS TECH CO LTD

A photovoltaic panel fixing device that optimizes the sunlight angle

ActiveCN111365868BRealize automatic adjustmentRealize reciprocating linear motionPhotovoltaic supportsSolar heating energyDrive wheelEngineering

The invention discloses a photovoltaic panel fixing device for optimizing the sunlight angle, which includes an inclination adjustment unit on which a photovoltaic panel is fixedly installed, the inclination adjustment unit includes a transmission assembly matched with the rotation adjustment unit, and is installed at one end of the transmission assembly The cross bar, and the telescopic connecting rod connecting the cross bar and the photovoltaic panel; the rotation adjustment unit, which is rotatably connected with the support, is installed on the support and drives the support to rotate, which includes a drive fixedly installed on the support mechanism, a driving wheel driven by the driving mechanism, and a second driven wheel that meshes with the driving wheel and is fixedly arranged on the bracket; and, the bracket is rotatably connected with the support, and the photovoltaic The plate is rotatably mounted on its upper part. According to the movement law of the sun in a day, the invention realizes the automatic adjustment of the angle of the photovoltaic panel towards the direct sunlight through the cooperation of the tilt adjustment unit and the rotation adjustment unit.

Owner:GUIZHOU POWER GRID CO LTD

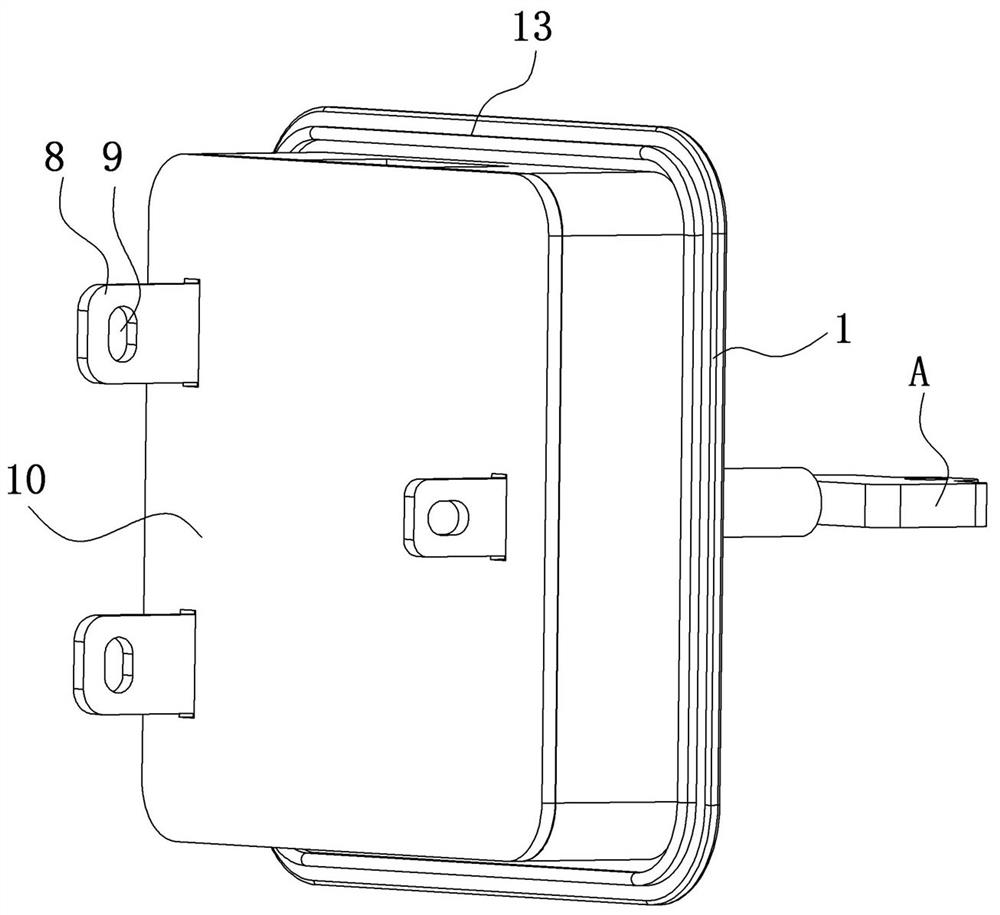

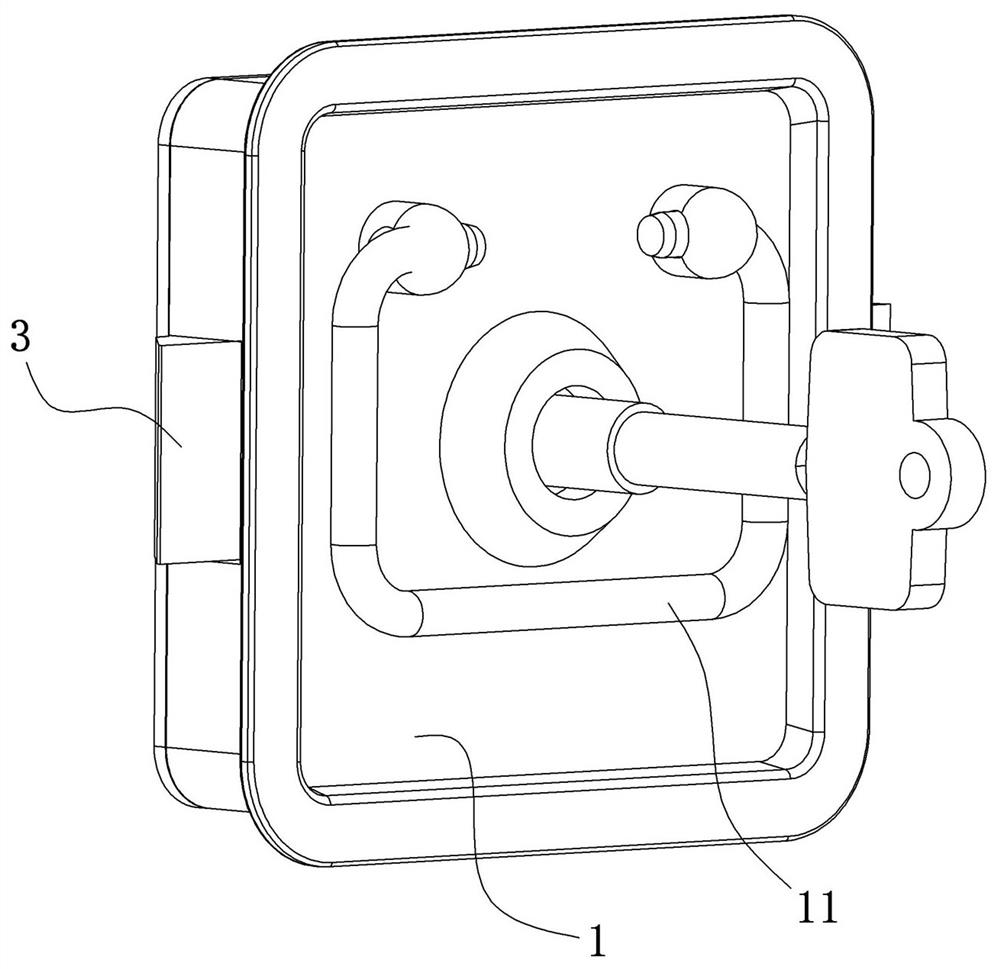

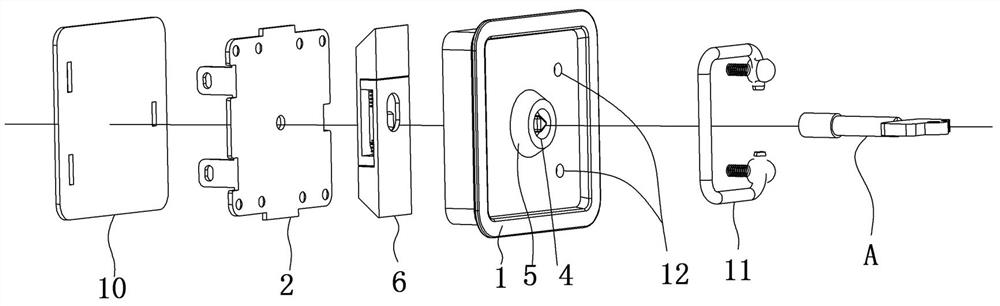

Battery fixing and locking device and locking method

PendingCN113216744AEasy to lockEasy to operateBuilding locksCell component detailsRotational axisBattery cell

Owner:郑州锐晶裕华新能源有限公司

Hospital automatic medicine shaker

InactiveCN108392418AShake the drug evenlyImprove efficiency and qualityPharmaceutical containersMedical packagingFastenerEngineering

A hospital automatic medicine shaker is characterized in that a support platform is mounted above a support frame, a motor control switch is fixedly mounted at the inner side of a retaining plate, a handle is fixedly mounted at the outer side of the retaining plate, a motor support plate is fixedly mounted at the front center of the support platform; a moto drives a crank disc to rotate; a connection rod is mounted on a connection post of the crank disc and is fixedly connected with a movable connection rod; each end of the movable connection rod is fitted with a slider connection plate; the crank disc, the connection rod and a slider form a crank-slider mechanism; a moving plate is connected to the top of the slider; a front clamp fastener and a rear clamp fastener are fixedly mounted onthe moving plate. The hospital automatic medicine shaker has the advantages that the hospital automatic medicine shaker is simple in structure and convenient to operate, allows medicine to be automatically shaken well and is high in efficiency and convenient to use, burden is relieved for workers, arms of medical personnel are protected against fatigue, and the hospital automatic medicine shaker is suitable for hospital clinics and other places.

Owner:梁同国

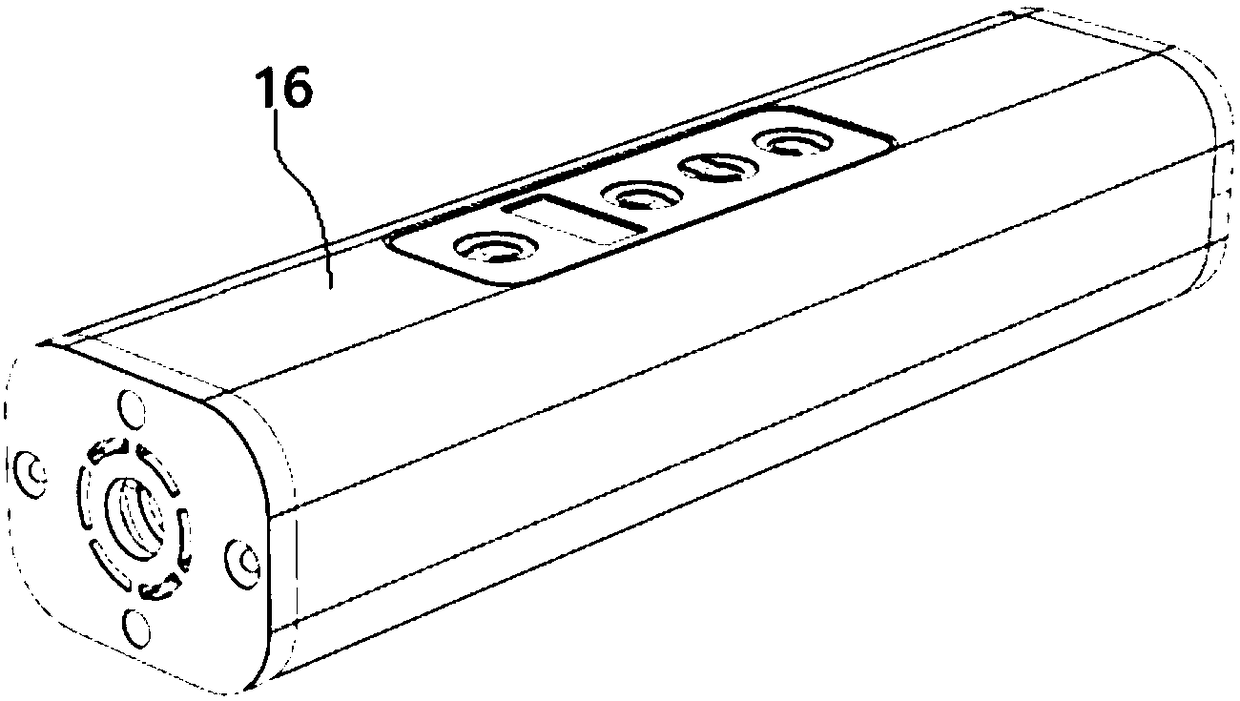

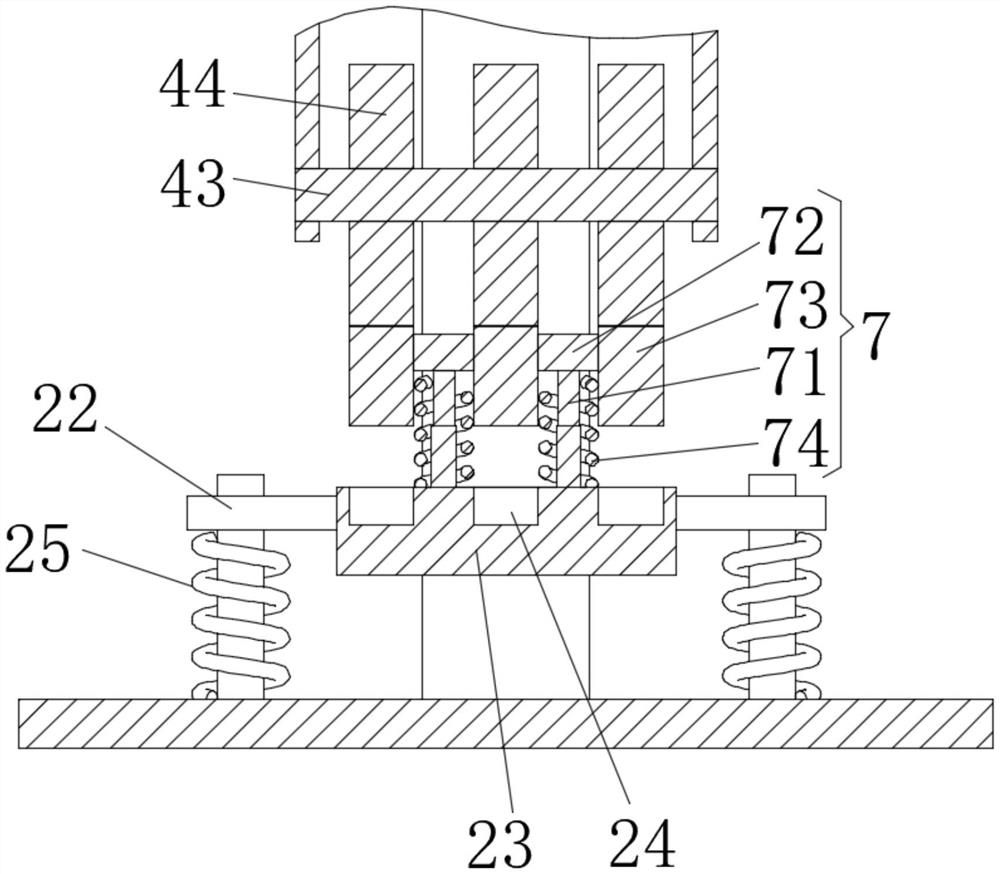

Steel ball raceway type transmission device and electric air pump

PendingCN108386336ARealize reciprocating linear motionFlexible adjustment of transmission ratioPositive displacement pump componentsPiston pumpsReciprocating motionDrive motor

The invention discloses a steel ball raceway type transmission device and an electric air pump, and belongs to the technical field of gas-filling devices. The steel ball raceway type transmission device comprises a piston, a connecting rod, a rotating sleeve and a steel ball, one end of the connecting rod and the piston are of an integrated structure, and the central axis of the piston is parallelto the central axis of the connecting rod. The connecting rod is arranged in the rotating sleeve, a raceway groove is formed in the periphery of the connecting rod, the raceway groove surrounds the periphery of the connecting rod in an oval shape, a hemispherical groove is formed in the inner wall of the rotating sleeve, and the steel ball is located between the raceway groove and the hemispherical groove. A driving motor is connected to the end, away from the connecting rod, of the rotating sleeve, the driving motor drives the connecting rod to drive the piston to perform a reciprocating motion in a cylinder body through the steel ball raceway type transmission device, the direction of the force of the connecting rod applied on the piston is always parallel to the central axis of the piston, and the problem that the central axis of the piston is not parallel to the central axis of the cylinder body during the reciprocating motion is solved. The steel ball raceway type transmission device has the advantages of low energy consumption, high exhaust efficiency and long service life.

Owner:南京塑维网络科技有限公司

Combined intelligent massage mattress

PendingCN114631999AMassage evenlyIncrease the areaElectrotherapyVibration massagePhysical medicine and rehabilitationReciprocating motion

The invention discloses a combined intelligent massage mattress. A power box massage hammer and a waist and back massage cushion massage hammer are arranged in the combined intelligent massage mattress. The sliding strip block massage hammer is arranged at the position, close to the top, in the power box massage hammer in a sliding mode, and the reciprocating driving mechanism is arranged in the power box massage hammer and connected with the sliding strip block massage hammer so as to drive the sliding strip block massage hammer to do reciprocating motion; the massage mechanism is arranged on the sliding strip block massage hammer, and the massage hammer massage mechanism is used for massaging the back of the human body; and the hinge massage hammers are arranged on two sides of the end part of the waist and back massage cushion massage hammer and are fixedly connected with the leg massage cushion massage hammer and the head massage cushion massage hammer, so that the massage mattress can be folded and stored. The massage mattress aims at solving the technical problems that in the prior art, a massage mattress is overall in structure and large in size, carrying is not easy, and the comfort degree and the massage effect cannot be unified, then the comfortable and convenient massage effect is achieved, and use and storage are more convenient.

Owner:XIAMEN IDENO ELECTRONICS TECH CO LTD

Pre-pressing device based on chip packaging

PendingCN114334743AAchieve reductionRegulating pressureSemiconductor/solid-state device manufacturingConveyor partsEngineeringStructural engineering

The invention discloses a pre-pressing device for chip packaging, and relates to the technical field of chip packaging, and the pre-pressing device comprises a base and a carrier assembly. Frame plates are symmetrically arranged on the two sides of the surface of the base, a sliding assembly is arranged at the top ends of the frame plates, a rolling assembly and a lifting assembly are arranged on the sliding assembly, and a moving assembly is arranged on the sliding assembly. The carrier assembly comprises guide rods, side seats, a carrying seat, limiting grooves and springs, the guide rods are evenly arranged on the two sides of the surface of the bottom plate, the side seats movably sleeve the guide rods through sleeve holes in the middles, the two sides of the carrying seat are fixedly connected with the ends of the side seats on the two sides respectively, the limiting grooves are evenly formed in the surface of the carrying seat, and the two ends of each limiting groove are through; according to the pre-pressing device for chip packaging, pre-pressing is more comprehensive and uniform, the pre-pressing pressure can be conveniently adjusted according to needs, and the practicability is high.

Owner:GUANGDONG POLYTECHNIC NORMAL UNIV

Grate distributing hopper with automatic swiping device

InactiveCN101975513BRealize reciprocating linear motionAutomatic cleaning continuousFurnace typesEngineeringElectric control

Owner:NORTHERN ENG & TECH CORP MCC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com