Uniform filling device for composite sauce

A filling device and sauce technology, which is applied in the direction of mixers, packaging, mixers, etc. with rotating stirring devices, can solve problems such as inability to fill uniformly, bulge and bulge, and decline in customer satisfaction, so as to avoid granular Uneven material distribution, reducing swelling and swelling, and overcoming the effect of weak fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to better understand the technical solution of the present invention, the present invention will be described in detail below with reference to the accompanying drawings, and the description of this section is merely exemplary and interpretative, and no limitation should be made to the scope of the invention. .

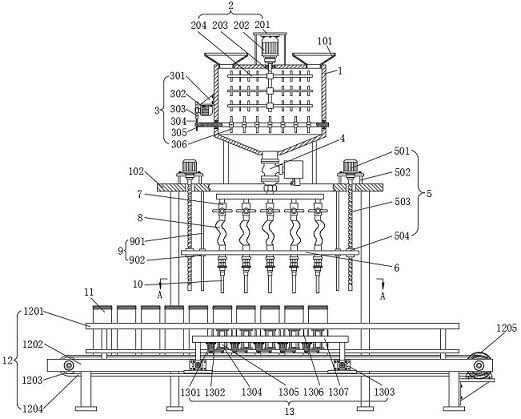

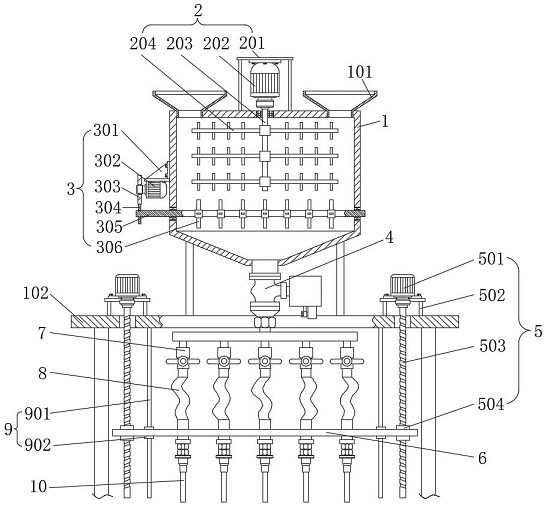

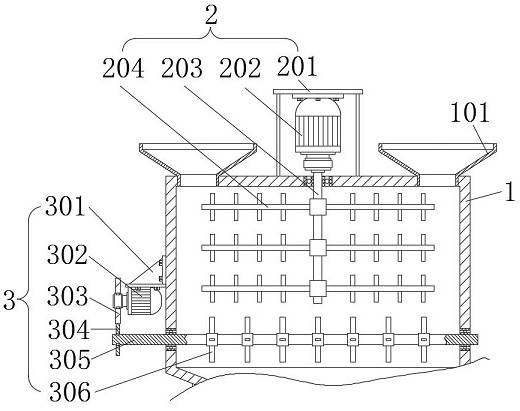

[0026] Such as Figure 1 - Figure 7 As shown, the specific structure of the present invention is: a composite sauce homogeneous filling apparatus, including the chain body 1, the top of the chassis 1 is configured to provide the feed funnel 101, and the first stirring for stirring sauce is provided in the chassis body 1. The portion 2 and the second stirring portion 3, the lower end portion of the chassis 1, the electromagnetic control valve 4 is provided, the electromagnetic control valve 4 outlet end portion is provided with a split joint 7, the lower end portion of the split joint 7 is provided, the delivery tube 8, the lower end portion and the lifting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com