Steel ball raceway type transmission device and electric air pump

A transmission and raceway technology, applied in the direction of variable displacement pump components, pumps, piston pumps, etc., can solve the problem of non-parallel central axes, and achieve the effects of convenient disassembly and installation, high efficiency and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

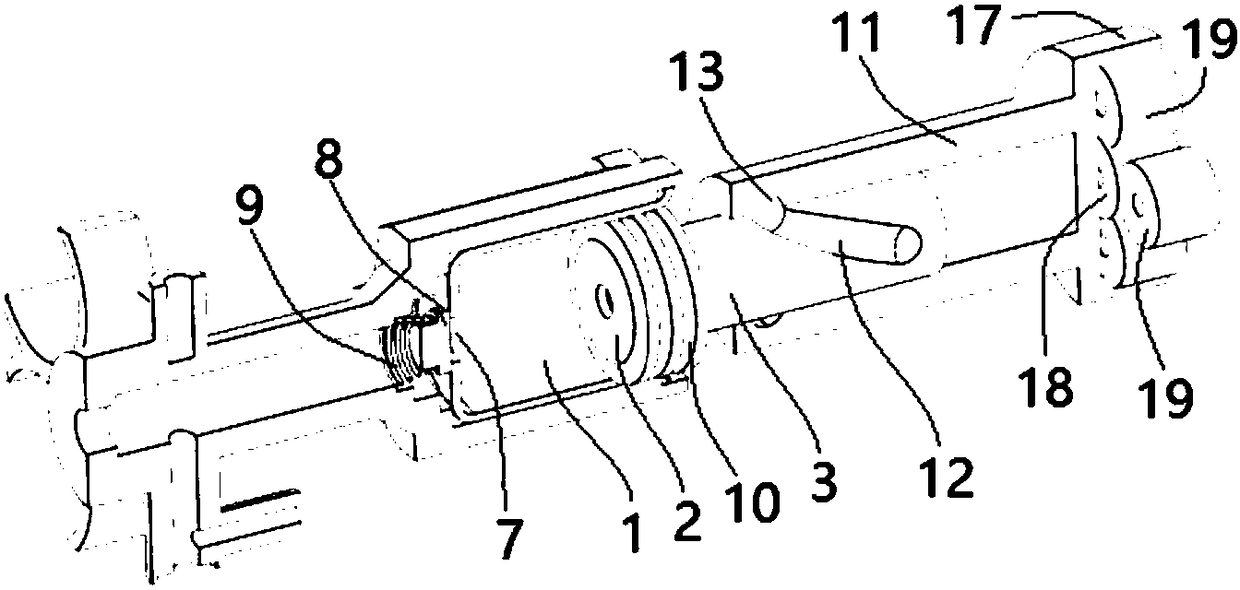

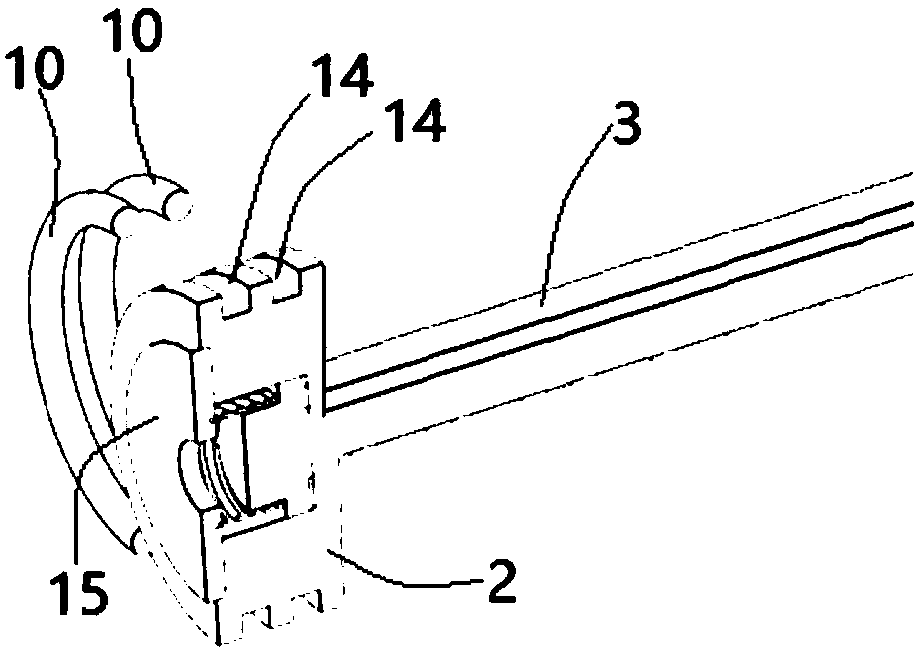

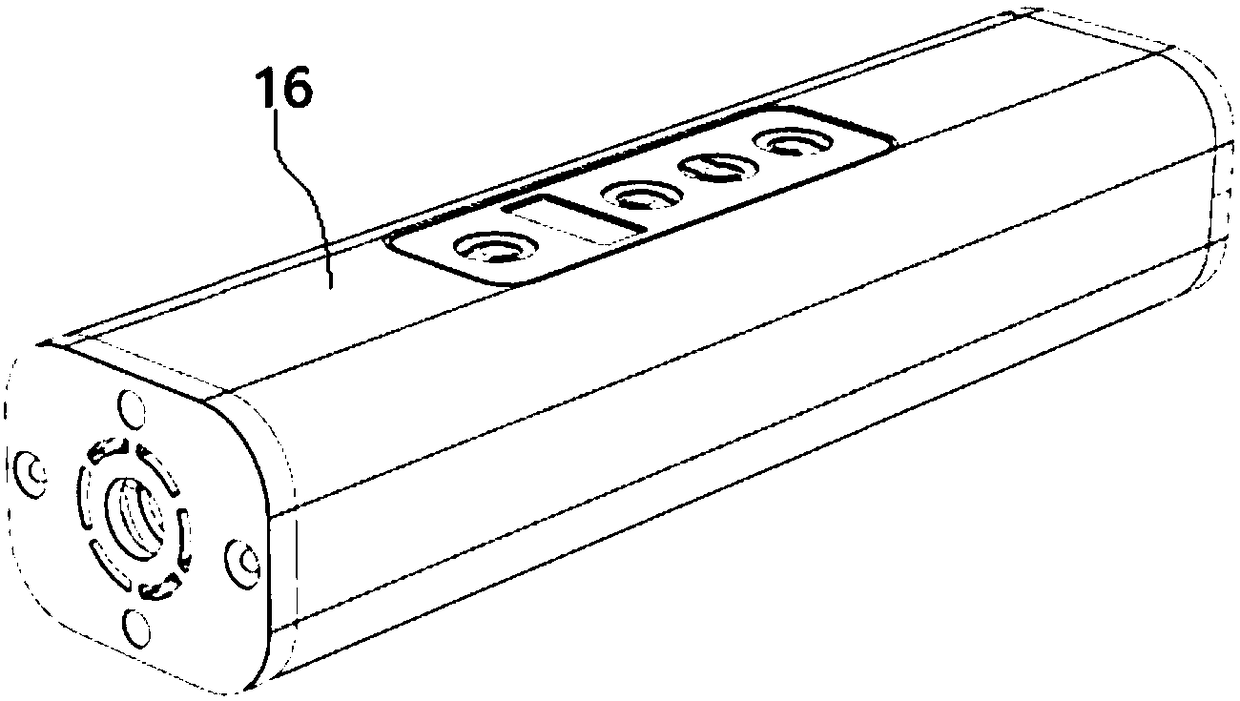

[0042] Such as figure 1 As shown, a steel ball raceway transmission device includes a piston 2, a connecting rod 3, a rotating sleeve 11 and steel balls, one end of the connecting rod 3 and the piston 2 are integrated, and the center of the piston 2 axis and the central axis of the connecting rod 3 are parallel to each other, the connecting rod 3 is located in the rotating sleeve 11, the outer circumference of the connecting rod 3 is provided with a raceway groove 12, and the raceway groove 12 surrounds the outer circumference of the connecting rod 3 in an elliptical shape, and a hemispherical groove 13 is opened on the inner wall of the rotating sleeve 11, and the steel ball is located between the raceway groove 12 and the spherical groove 13 Between, the end of the rotating sleeve 11 away from the connecting rod 3 is connected with the driving motor.

[0043] When the drive motor drives the rotating sleeve 11 to rotate, the spherical steel ball in the hemispherical groove o...

Embodiment 2

[0047] A steel ball raceway transmission device, its structure is different from that of Embodiment 1, the difference is that: the end of the rotating sleeve 11 away from the piston 2 is equipped with a driven gear coaxial with the connecting rod 3 , that is, the axis of the driven gear and the central axis of the connecting rod 3 are on a straight line, the output shaft of the driving motor is provided with a transmission gear, and the driven gear and the transmission gear are meshed with each other to drive The motor drives the transmission gear to rotate, and then drives the rotating sleeve 11 to rotate. During the rotation of the rotating sleeve 11, the steel ball located in the hemispherical groove 13 rolls in the raceway groove 12, and at the same time drives the connecting rod 3 in the rotating sleeve. The barrel 11 performs telescopic movement along the central axis of the rotating sleeve 11, thereby driving the piston 2 to reciprocate in the cylinder body 1, and the di...

Embodiment 3

[0049] Such as figure 1 As shown, a steel ball raceway transmission device, its structure is compared with the embodiment 1, the difference is that: the end of the rotating sleeve 11 far away from the piston 2 is equipped with a planetary carrier 17, and the planetary carrier 17 The inner wall of the drive motor is provided with teeth, the output shaft of the drive motor is provided with a sun gear 18, and the planet carrier 17 and the sun gear 18 rotate around the same center, the sun gear 18 and the planet carrier 17 A planetary gear 19 is arranged between them, the teeth of the planet carrier 17 mesh with the planetary gear 19, and the sun gear 18 and the planetary gear 19 mesh with each other. The transmission mode of the planetary gear train in this embodiment has It has the advantages of compact structure, small size, large carrying capacity, large transmission power range and transmission ratio range, low operating noise, high efficiency and long life.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com