Rolling triangular robot

A robot and triangular technology, applied in the field of rolling robots, can solve problems such as the inability to see two-stage or multi-stage transmission electric push rods, small expansion ratio of electric push rods, and high requirements for working environments, achieving simple structure, easy to understand, Effects that are easy to manufacture and engineer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

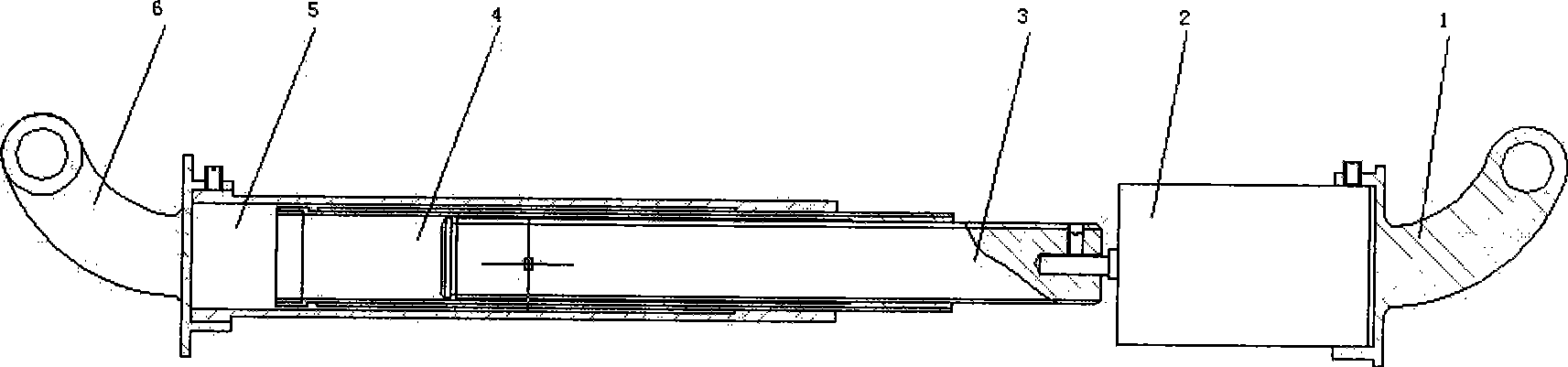

[0029] Rolling one side of a triangle robot, see image 3 , including motor 2, one-section screw 3, two-section screw 4 with one section of internal thread, three-section sleeve 5 with one section of internal thread, sleeve joint 6 and motor joint 1;

[0030] The tail of the motor 2 is fixed on the motor connector 1, and the output shaft of the motor 2 is fixed to the right end of a screw 3 with a tight nail;

[0031] One section of screw rod 3 is threadedly connected with two sections of screw rod 4;

[0032] Two-section screw 4 threads are connected with three-section sleeve 5 threads;

[0033] The three-section sleeve 5 is fixed on the sleeve joint 6;

[0034] Motor joint 1, motor 2, one-section screw rod 3, two-section screw rod 4, three-section sleeve 5 and sleeve joint 6 form one side of a rolling triangle robot;

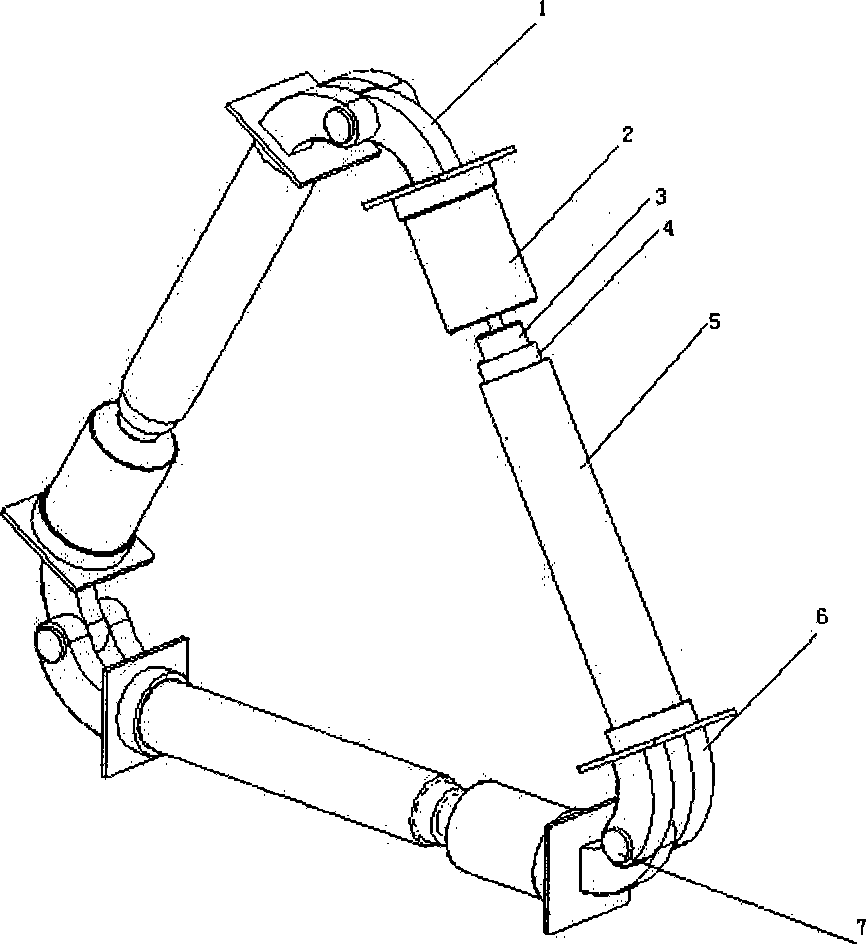

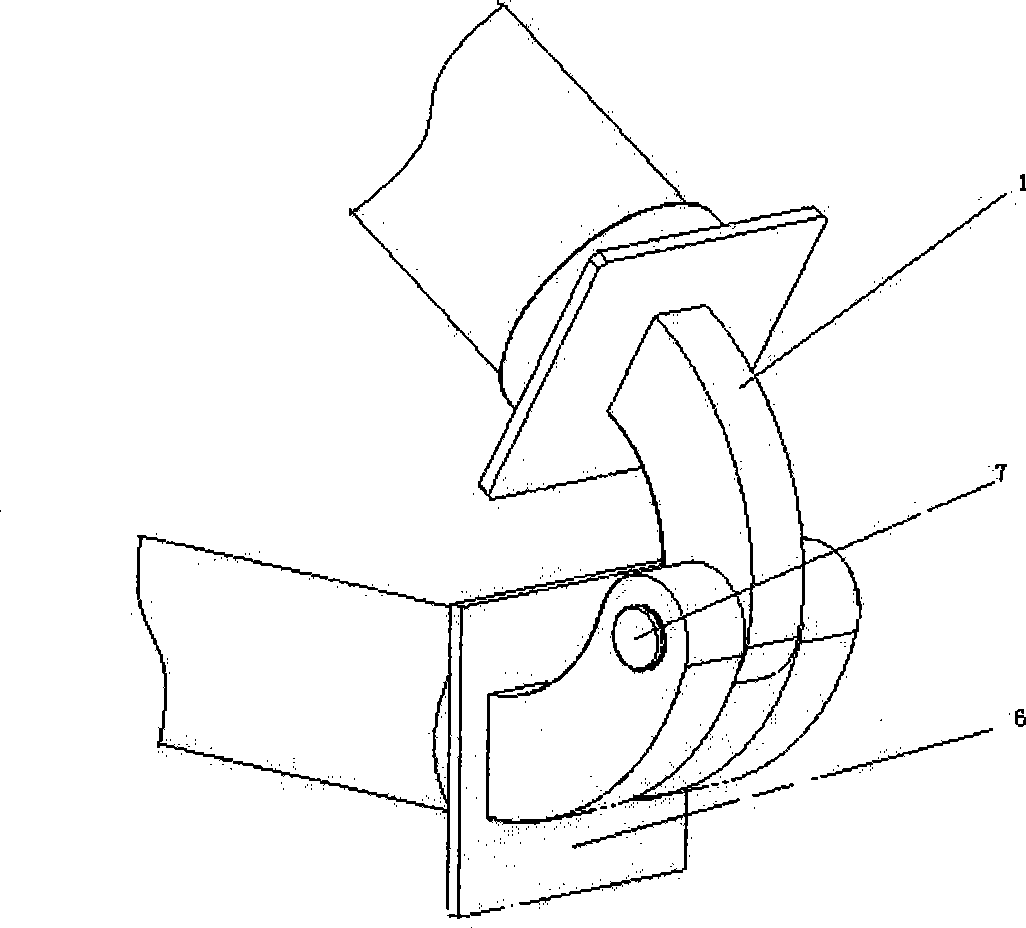

[0035] The three sides of the rolling triangle robot have the same structure and size, and the motor joint 1 of each side is connected with the sleeve join...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com