Automatic metal plate grinding machine

A grinding machine, fully automated technology, applied in the direction of grinding frames, metal processing equipment, grinding machine parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

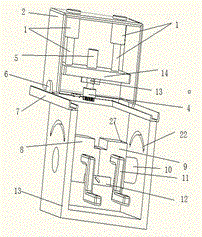

[0015] The specific connection mode and relative movement mode between the various parts of the clamp device. Rocking handle (11) will be welded on the left and right clamp blocks (8) and (9). The switch magnetic seat (12) does not need to be fixed, and is directly sucked on the clamp blocks (8) and (9) by magnetic force. A certain distance can be separated between the clamps (8) and (9), as long as the switch magnetic base (12) can hold the clamp blocks (8) and (9) together. The clamping blocks (8) and (9) are screwed together with the leading screw (10) to realize linear reciprocating motion. Leading screw (10) is placed on base (13) air and gets final product, need not rotate.

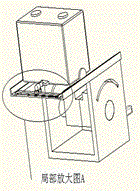

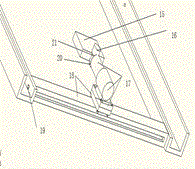

[0016] Grind the connection and relative movement of each part of the box body. Sanding box wheels (6) roll in tracks (7). There is an interference fit between the wheel and the shell of the grinding box, and a clearance fit between the wheel disc and the wheel shaft, which requires a bearing as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com