Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Prevent deformation and instability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

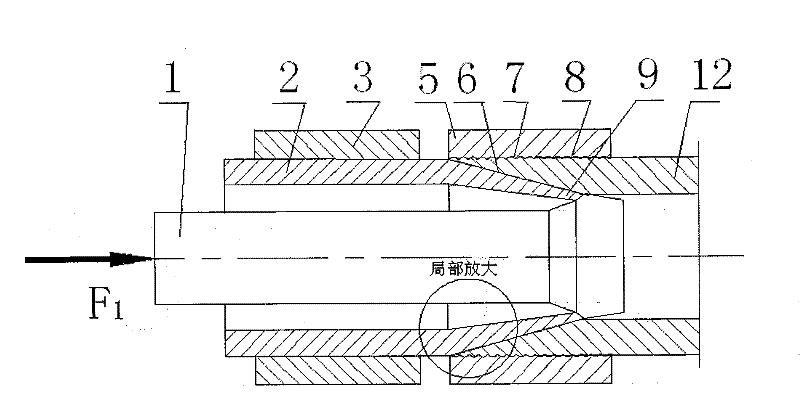

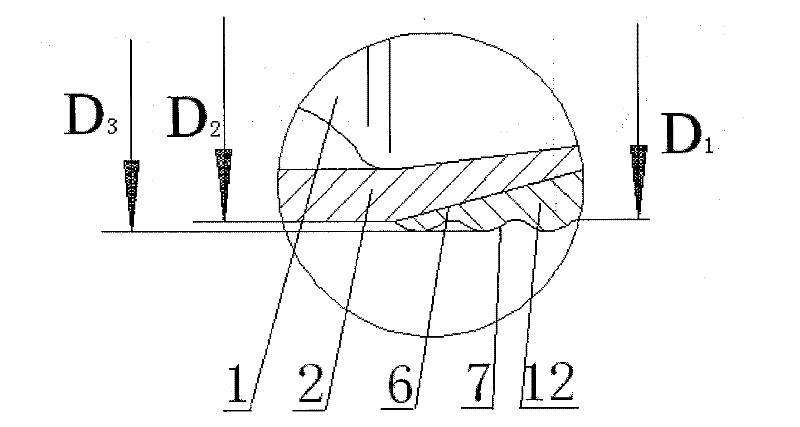

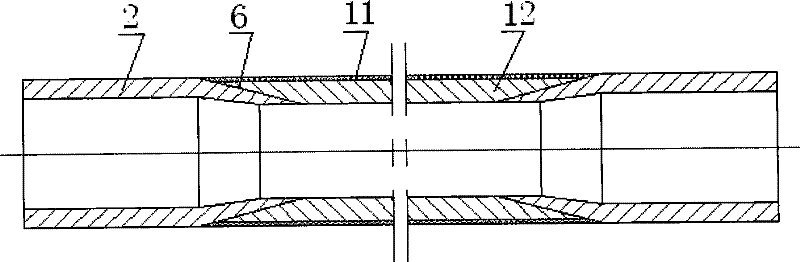

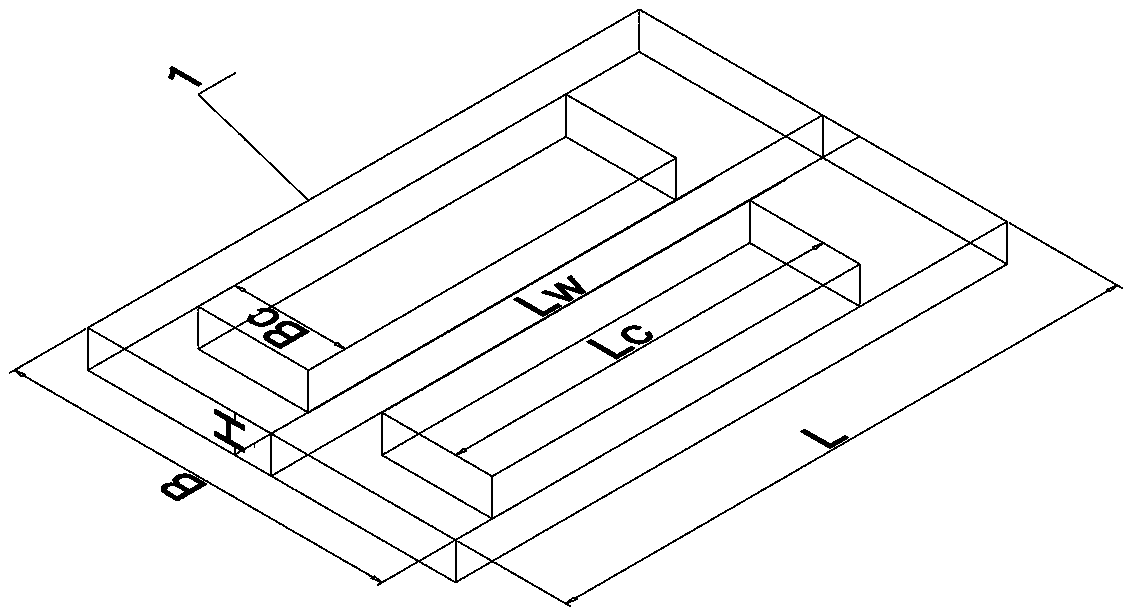

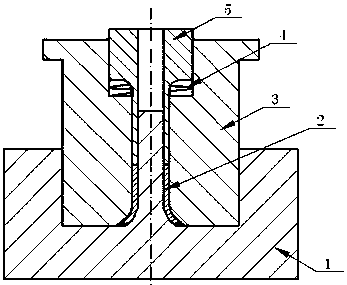

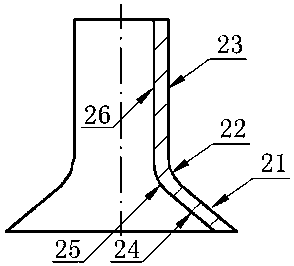

Plug-in type copper aluminum pipe welded joint and method of producing the same

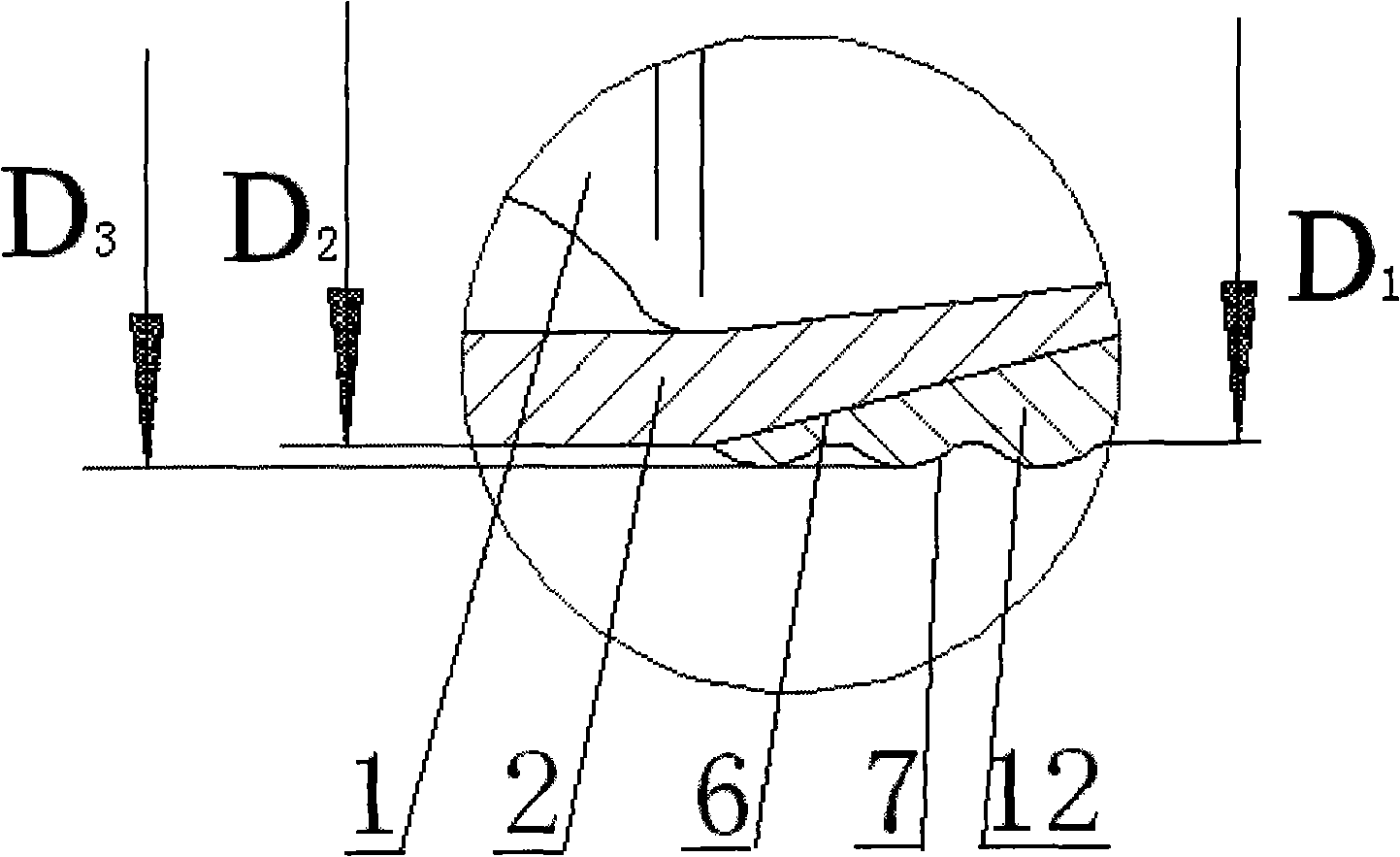

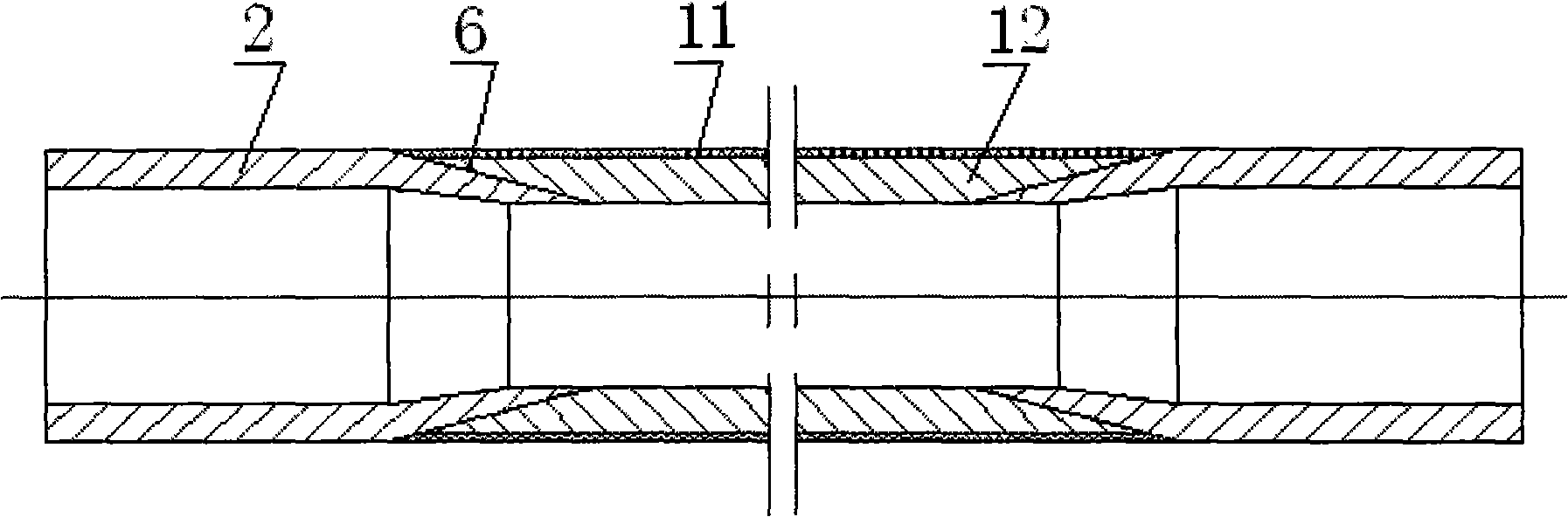

InactiveCN101319741ASame outer diameterNot easy to fall offElectrode featuresNon-disconnectible pipe-jointsMaterials scienceCopper tubing

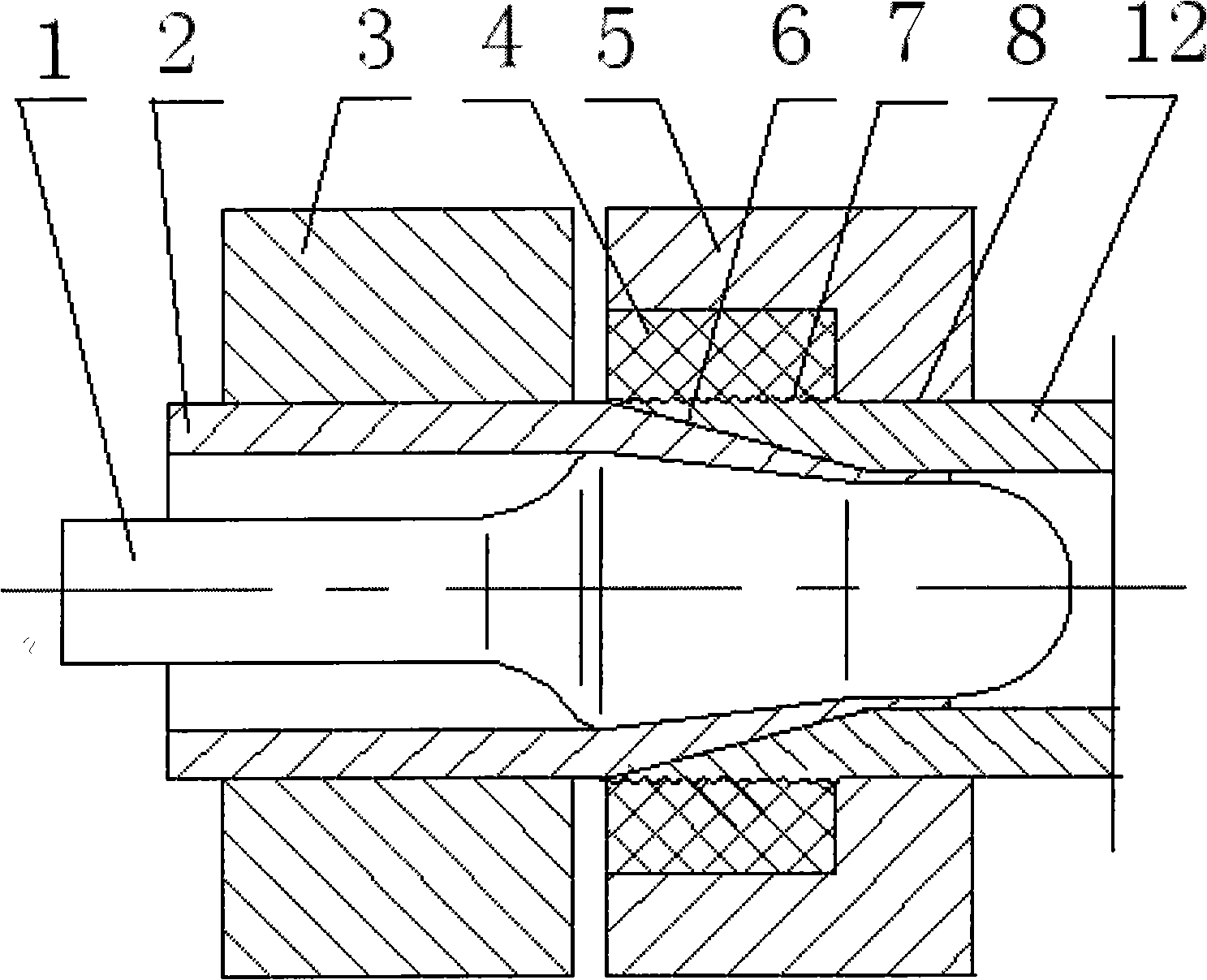

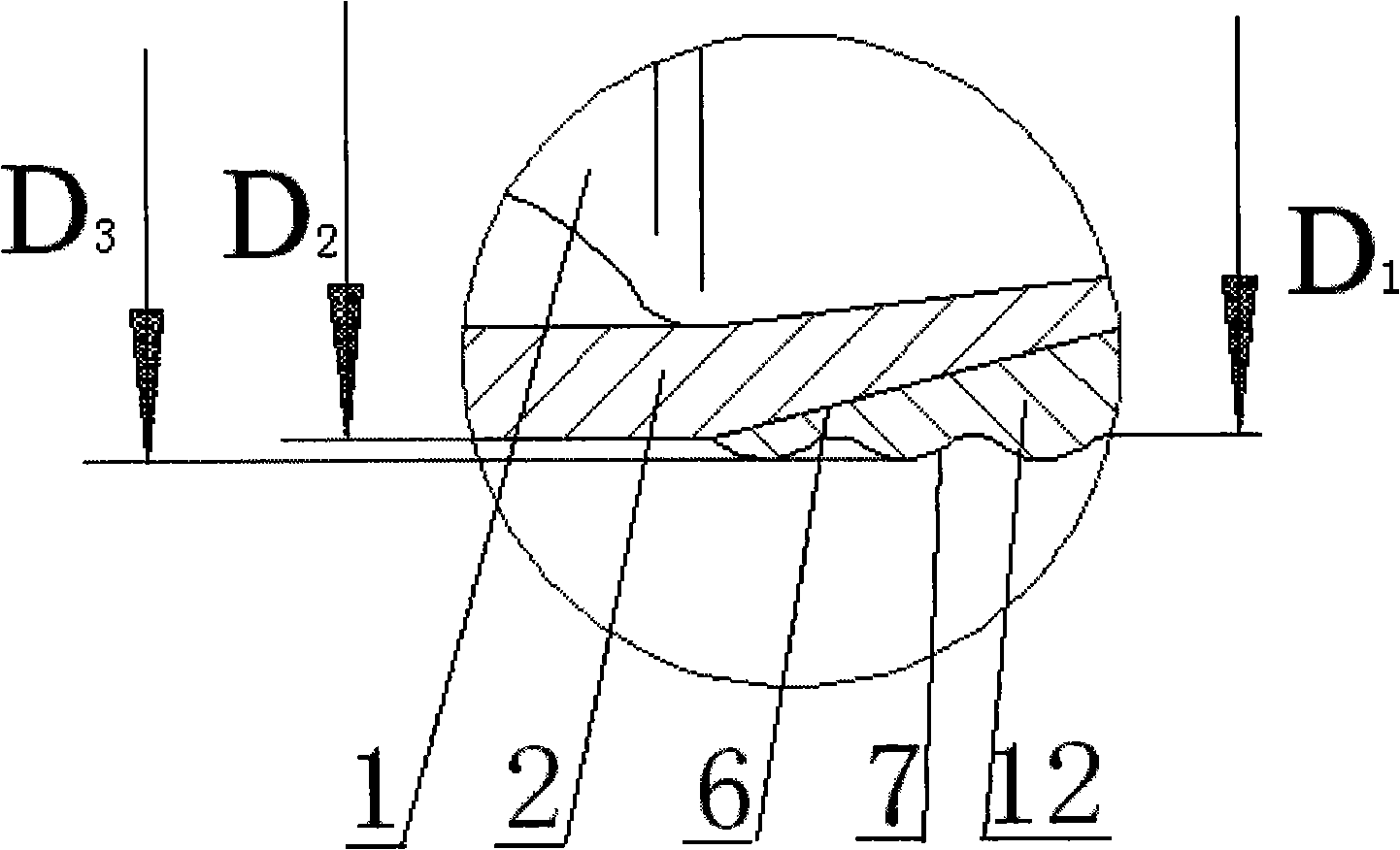

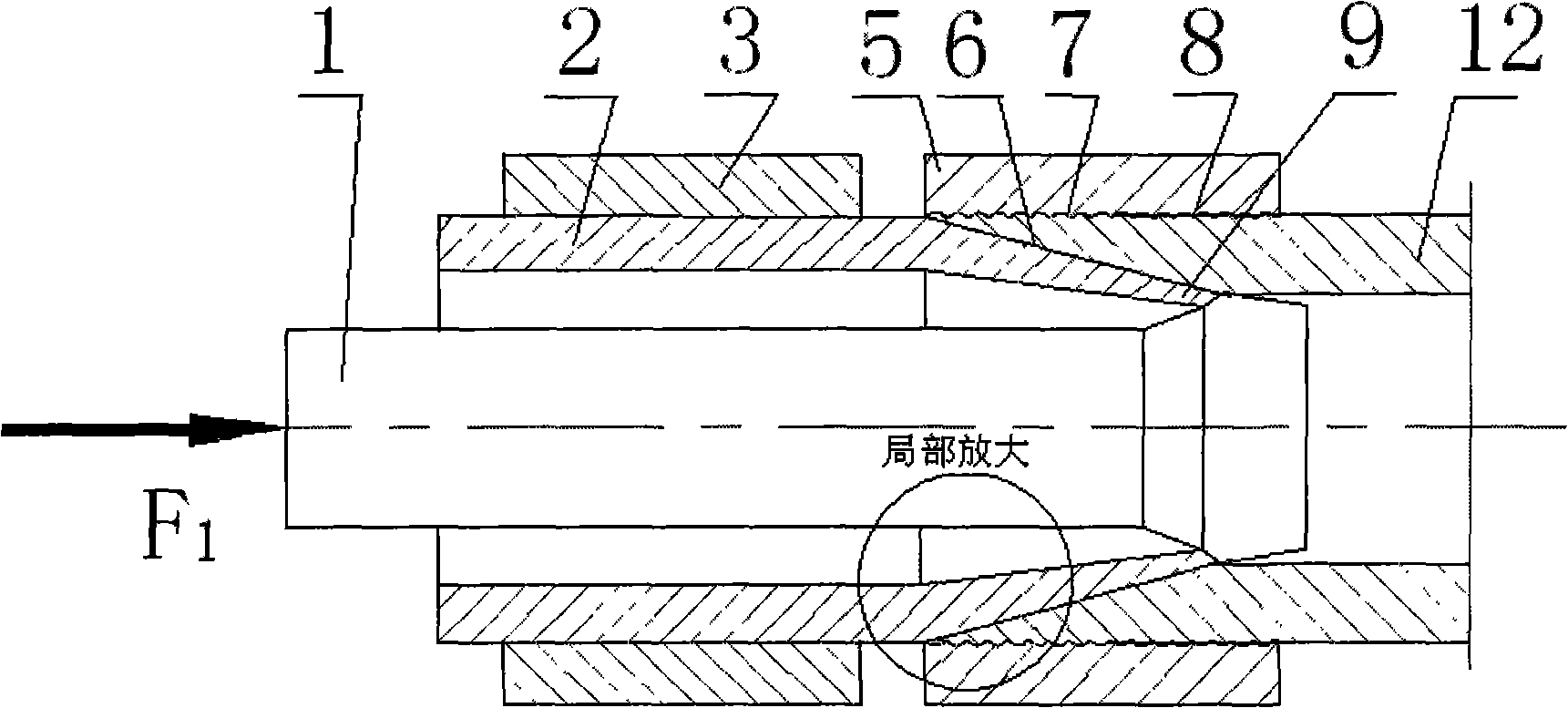

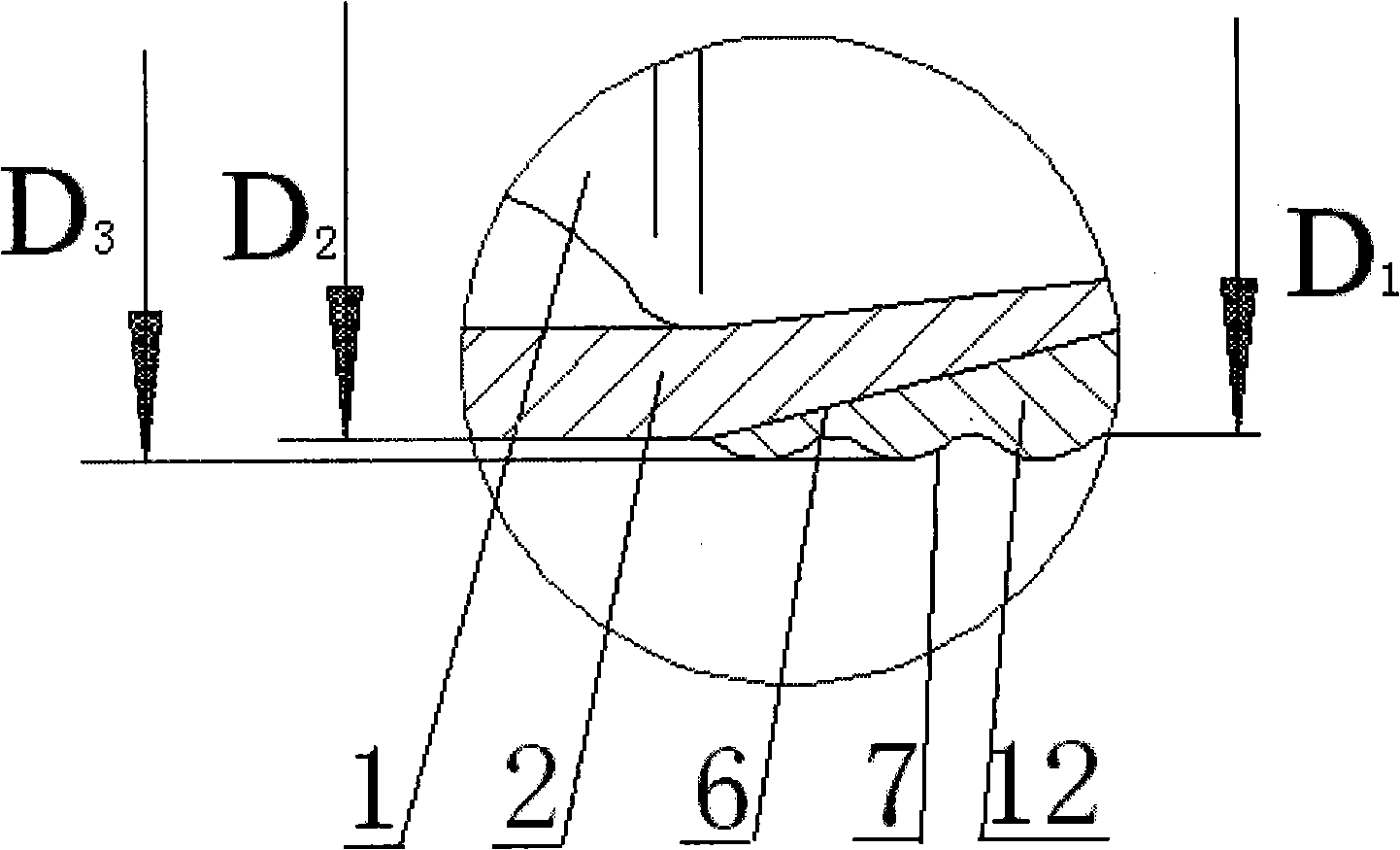

The invention relates to an inserting copper-aluminum pipe welded joint and a method of fabrication thereof. A taper face of weld is arranged at the joint welding position of a copper pipe, and raised grains are arranged on the outer wall of an aluminum pipe. During welding, a mosaic block is arranged at the welding position of the fixed electrode; a groove is arranged in the mosaic block, and raised grains are prepared on the groove; and the nominal diameter of the groove which bears raised grains is identical with the outer diameter of the aluminum pipe. The aluminum fluid melted during welding can be filled in the raised grains of the groove of the mosaic block, so that the deformation of the aluminum pipe is avoided, and the quality and strength of the product are improved. By such welding method, the aluminum pipe can be clamped to avoid breaking off; in addition, the outer diameter of the welding position of the copper-aluminum pipe joint is kept identical with the outer diameter of the aluminum pipe.

Owner:左铁军 +1

Pipe connection used for indoor and outdoor units of air conditioner and its method for making production method

ActiveCN101319742ASame outer diameterNot easy to fall offElectrode featuresNon-disconnectible pipe-jointsEngineeringUltimate tensile strength

The invention relates to a connection tube applied to the indoor machine and outdoor machine of an air conditioner and a manufacture method thereof. A taper face of weld is arranged at the joint welding position of a copper pipe, and raised grains are arranged on the outer wall of an aluminum pipe. During welding, a mosaic block is arranged at the welding position of the fixed electrode; a groove is arranged in the mosaic block, raised grains are prepared on the groove; and the nominal diameter of the groove which bears raised grains is identical with the outer diameter of the aluminum pipe. The aluminum fluid melted during welding can be filled in the raised grains of the groove of the mosaic block, so that the deformation of the aluminum pipe is avoided, and the quality and strength of the product are improved. By such welding method, the aluminum pipe can be clamped to avoid breaking off; in addition, the outer diameter of the welding position of the copper-aluminum pipe joint is kept identical with the outer diameter of the aluminum pipe.

Owner:青岛津海制冷管业有限公司

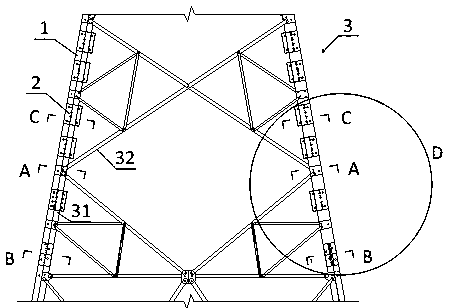

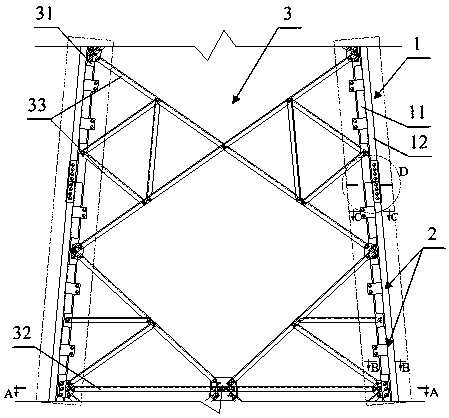

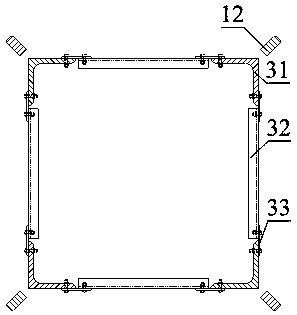

Crossed reinforcing device for power transmission tower

PendingCN108798057APerformance is not affectedPrevent accidents such as collapsesBuilding repairsTowersPunchingEngineering

The invention provides a crossed reinforcing device for a power transmission tower. The crossed reinforcing device comprises reinforcing pieces and a plurality of pairs of external clamping pieces. The reinforcing pieces correspond to angle steel main materials of the power transmission tower, and the reinforcing pieces and the angle steel main materials are arranged oppositely on the outer cornersides of the angle steel main materials to form crossed structures for reinforcing of the power transmission tower. Each pair of external clamping pieces is arranged in two connecting spaces betweenthe outer corner side of the corresponding reinforcing piece and the outer corner side of the corresponding angle steel main material for fixing the reinforcing piece to the angle steel main material.According to the crossed reinforcing device, reinforcing of the reinforcing pieces to the angle steel main materials is ensured, and the influence of original inclined materials / transverse partitionmaterials is skillfully avoided, thus the reinforcing pieces and the angle steel main materials are closely attached, the using performance of the power transmission tower is not affected, construction operation is convenient, the power transmission tower does not need to be punched, welded or detached, damage of punching and welding to the performance of the power transmission tower, especially the strength of the angle steel main materials, is avoided, the accidents such as collapse of the angle steel main materials are prevented, and meanwhile, the difficulty of altitude operation of operators on the power transmission tower is reduced.

Owner:广东省输变电工程有限公司

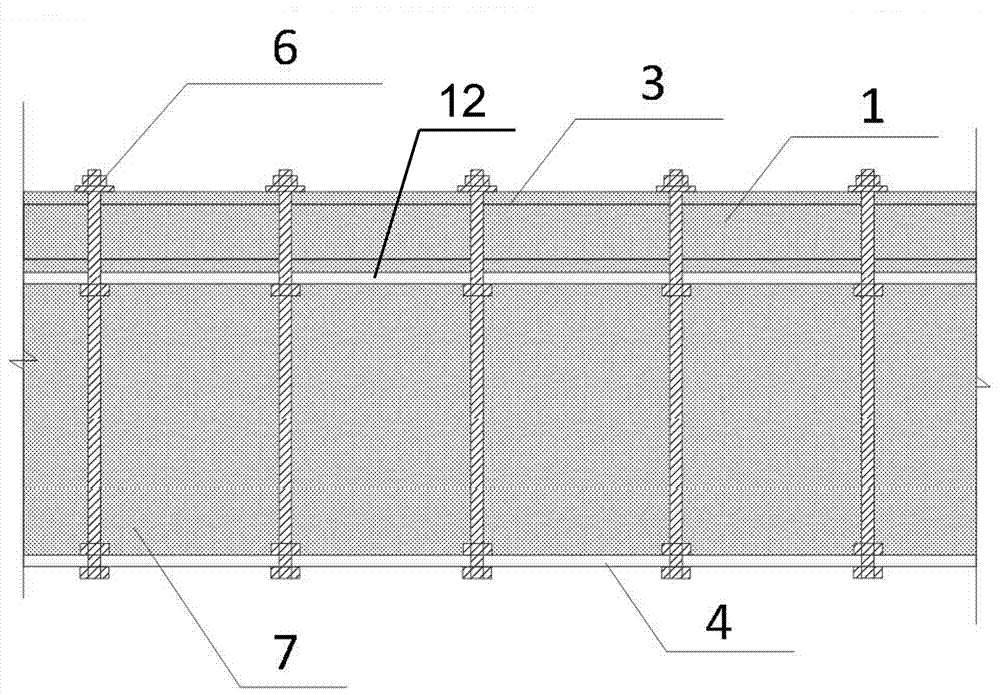

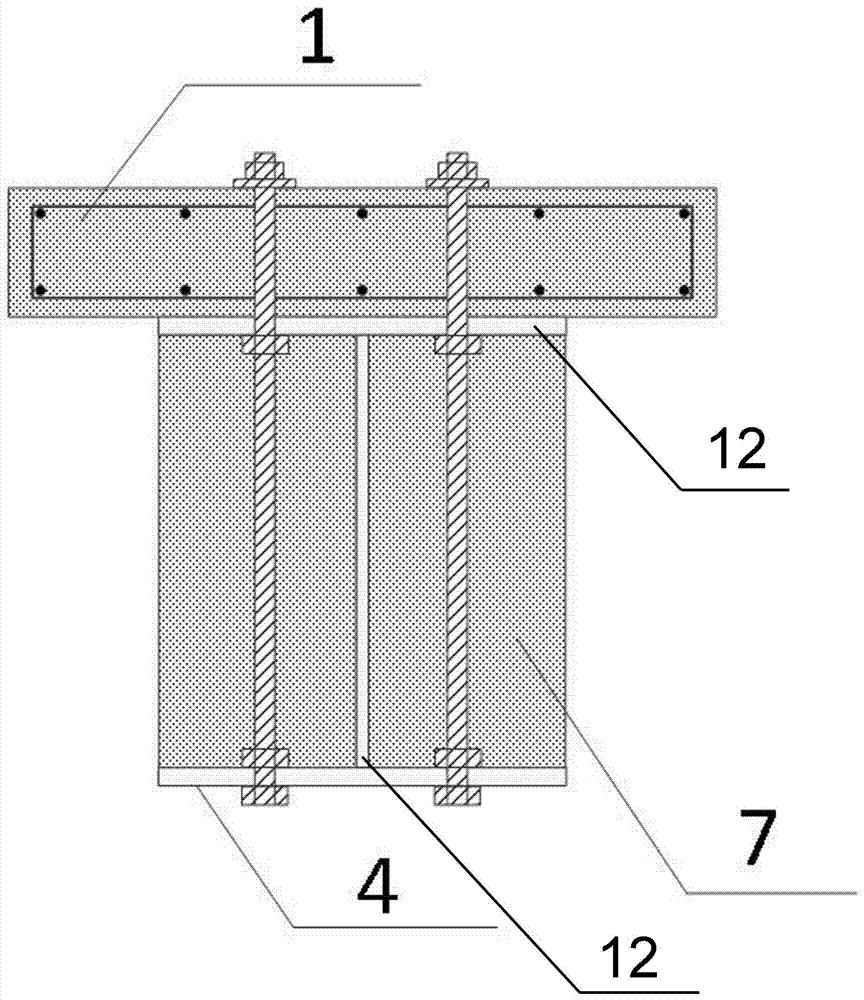

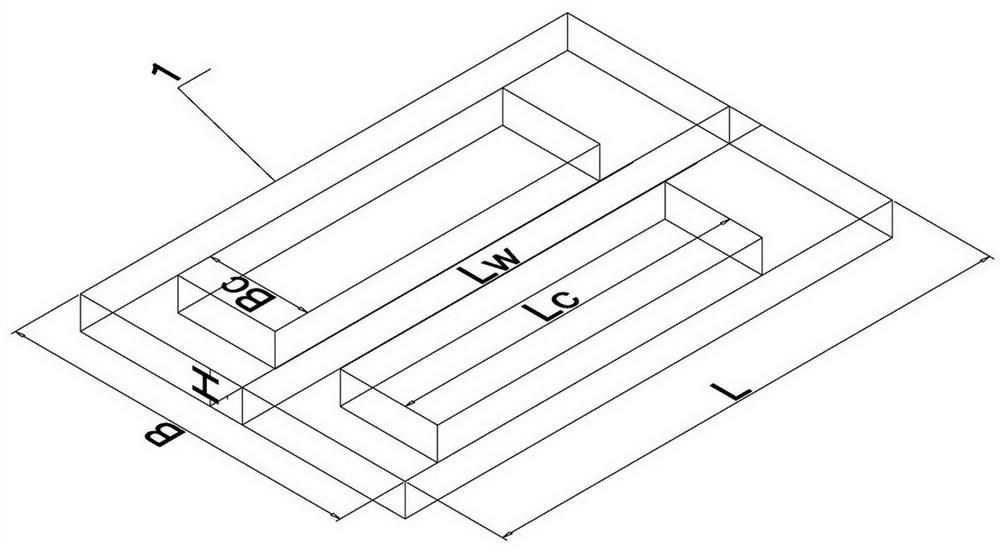

Fireproof and buckling-restrained fabricated composite beam and construction method

ActiveCN107313540AImprove local stabilityImprove bearing capacityFloorsFire proofingRebarTreatment costs

The invention discloses a fireproof and buckling-restrained fabricated composite beam, and belongs to the field of house construction. The fireproof and buckling-restrained fabricated composite beam mainly comprises a prefabricated reinforced concrete slab, a wrapped concrete steel beam, a friction-type high-strength bolt connect set and a rubber sleeve; the prefabricated reinforced concrete slab and the wrapped concrete steel beam are connected into a whole through the friction-type high-strength bolt connect set and the rubber sleeve. According to the fireproof and buckling-restrained fabricated composite beam, through combination of the design philosophy of a recoverable structure, the prefabricated reinforced concrete slab, the wrapped concrete steel beam, the friction-type high-strength bolt connect set and the rubber sleeve are combined mutually, the bearing capacity of steel components is improved, the anti-corrosion and fireproof treatment cost of the steel components is saved, the suitable range of the composite beam is enlarged, fabricated construction of the composite beam is achieved, the time spent on in-situ reinforced assembling, concrete pouring and concrete maintenance is saved, the construction period is shortened to a large extent, the construction efficiency is improved, and the fireproof and buckling-restrained fabricated composite beam has wide application prospects in building structures with steel structures.

Owner:TAIYUAN UNIV OF TECH

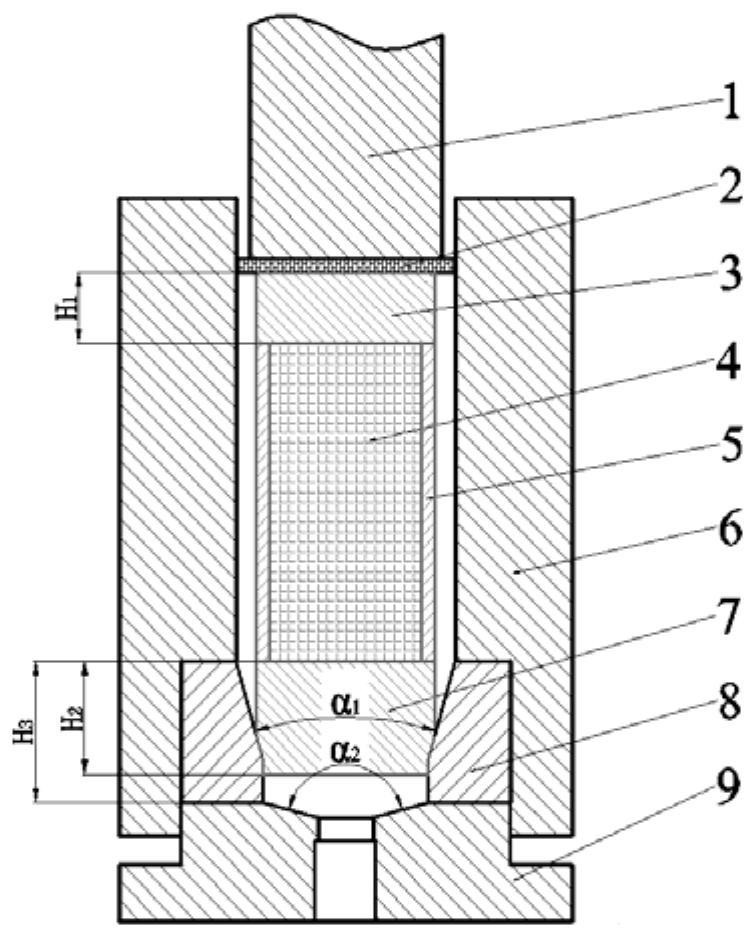

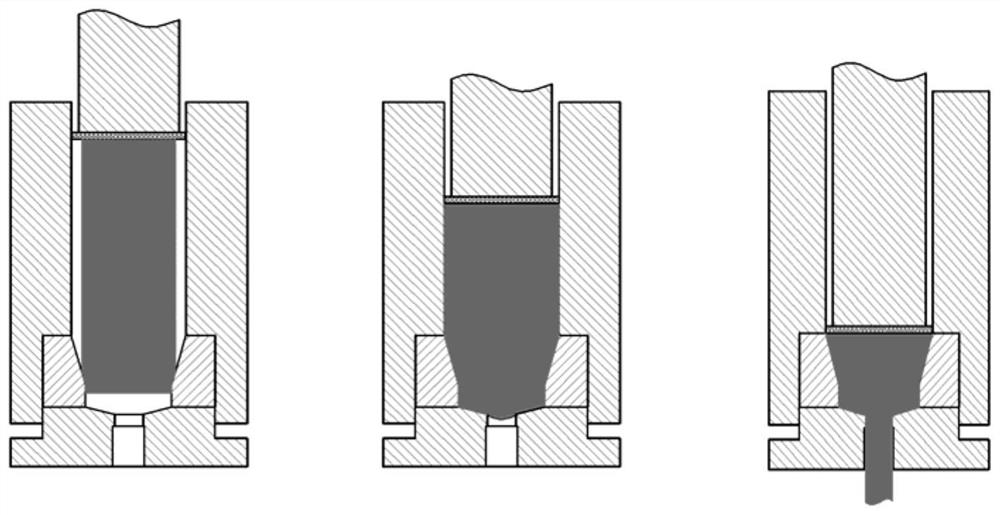

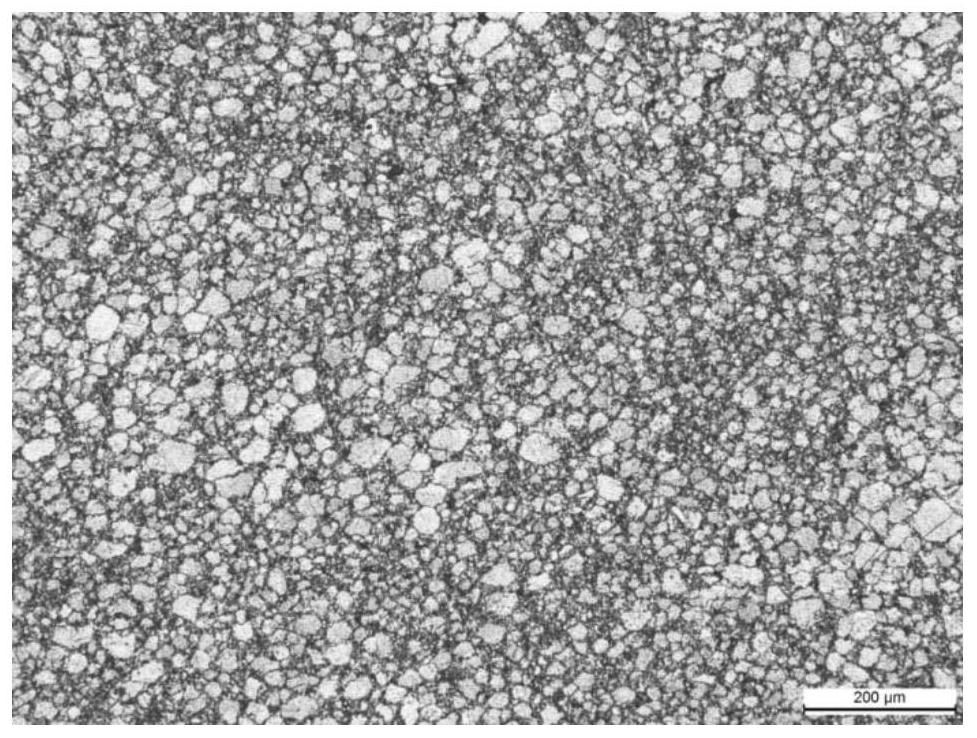

Continuous combined extrusion blooming method for difficult-to-deform superalloy ingot

The invention relates to a continuous combined extrusion blooming method for a difficult-to-deform superalloy ingot. According to the method, the guidance positioning effect of a reducing extrusion female die is utilized to perform reducing extrusion, upsetting deformation and forward extrusion continuous combined extrusion one-off forming in an extrusion cylinder, so that multi-heating-number upsetting blooming in an existing process is omitted. Firstly, part of the cast structure of the difficult-to-deform superalloy ingot is broken through small-deformation reducing extrusion and upsettingdeformation, so that the difficult-to-deform superalloy ingot can generate plastic deformation which is large enough to realize recrystallized grain refinement; meanwhile, the radial constraint effectapplied to the blank by the extrusion cylinder and a cavity of the reducing extrusion female die effectively prevents buckling deformation in the upsetting process of the superalloy ingot with a large height-diameter ratio; and finally, through extrusion deformation with a large extrusion ratio (8:1-12:1), the cast structure with a thick core is fully broken, and a uniform recrystallization behavior is generated on the surface and the core of a bar, so that the uniform fine-grain superalloy bar with the grain size reaching the 7-9 level is obtained.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Method of manufacturing inserted aluminum pipe welded joint

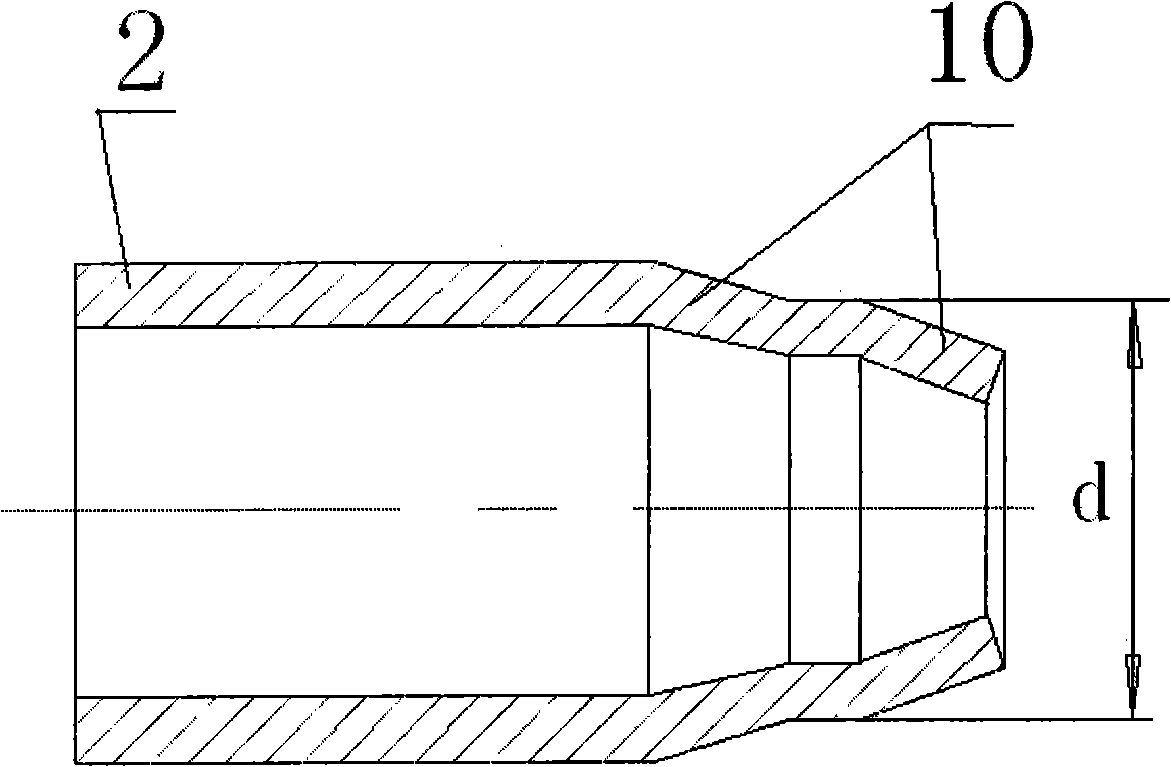

InactiveCN101318255AHigh work pressureImprove roundnessElectrode featuresWelding/cutting media/materialsWorking pressureEngineering

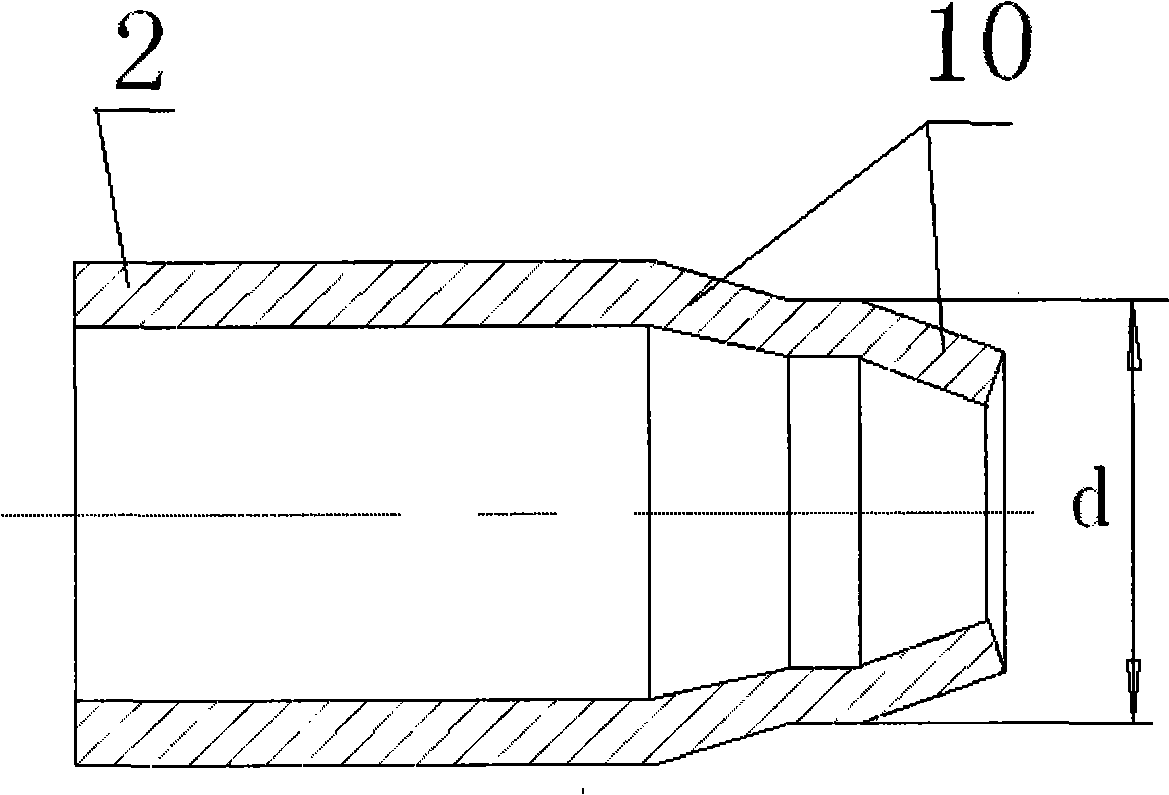

The invention relates to a preparation method of spliced type aluminum pipe welding joints, which is characterized in that a welding part at the pipe end of a hard state aluminum pipe is processed to be a conical welding surface; a welding mandrel is inserted into the hard state aluminum pipe in advance before the welding; the hard state aluminum pipe with the inserted welding mandrel, a soft state aluminum pipe are fixed at a movable electrode and a fixed electrode respectively; the electrodes are moved to drive the hard state aluminum pipe to be inserted into the soft state aluminum pipe movably, meanwhile, the electrodes are electrified until the conical welding surface of the hard state aluminum enters the soft state aluminum pipe completely. The welding mandrel can improve the working pressure of the aluminum pipe joints and the roundness of the soft state aluminum pipe during the propelling process of the welding initial stage; the welding mandrel can restrict the overflowing of spattering matters during the electrifying welding process.

Owner:左铁军 +1

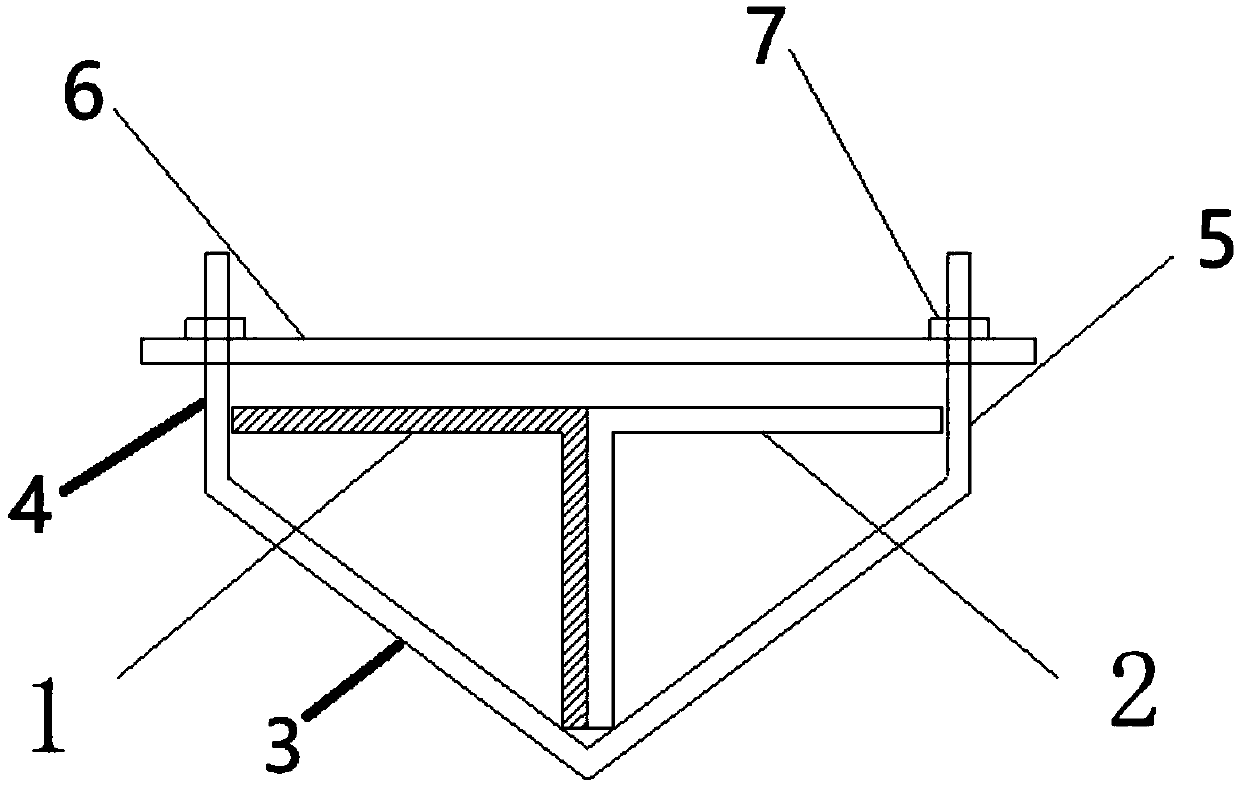

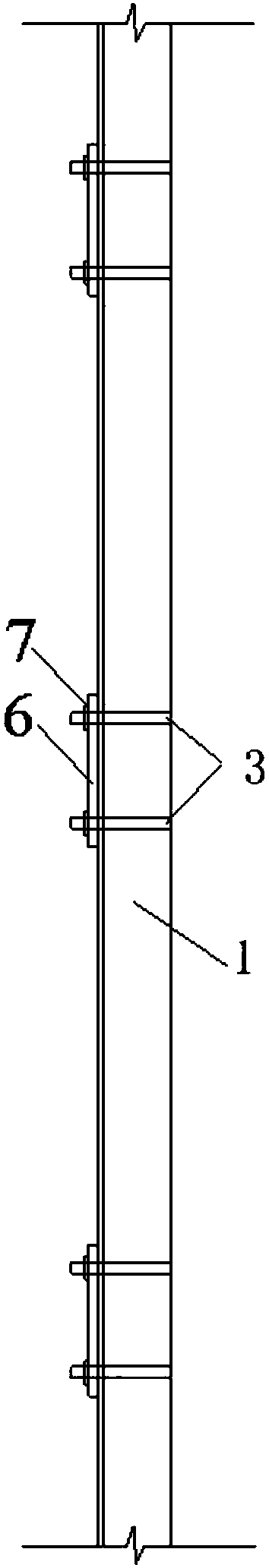

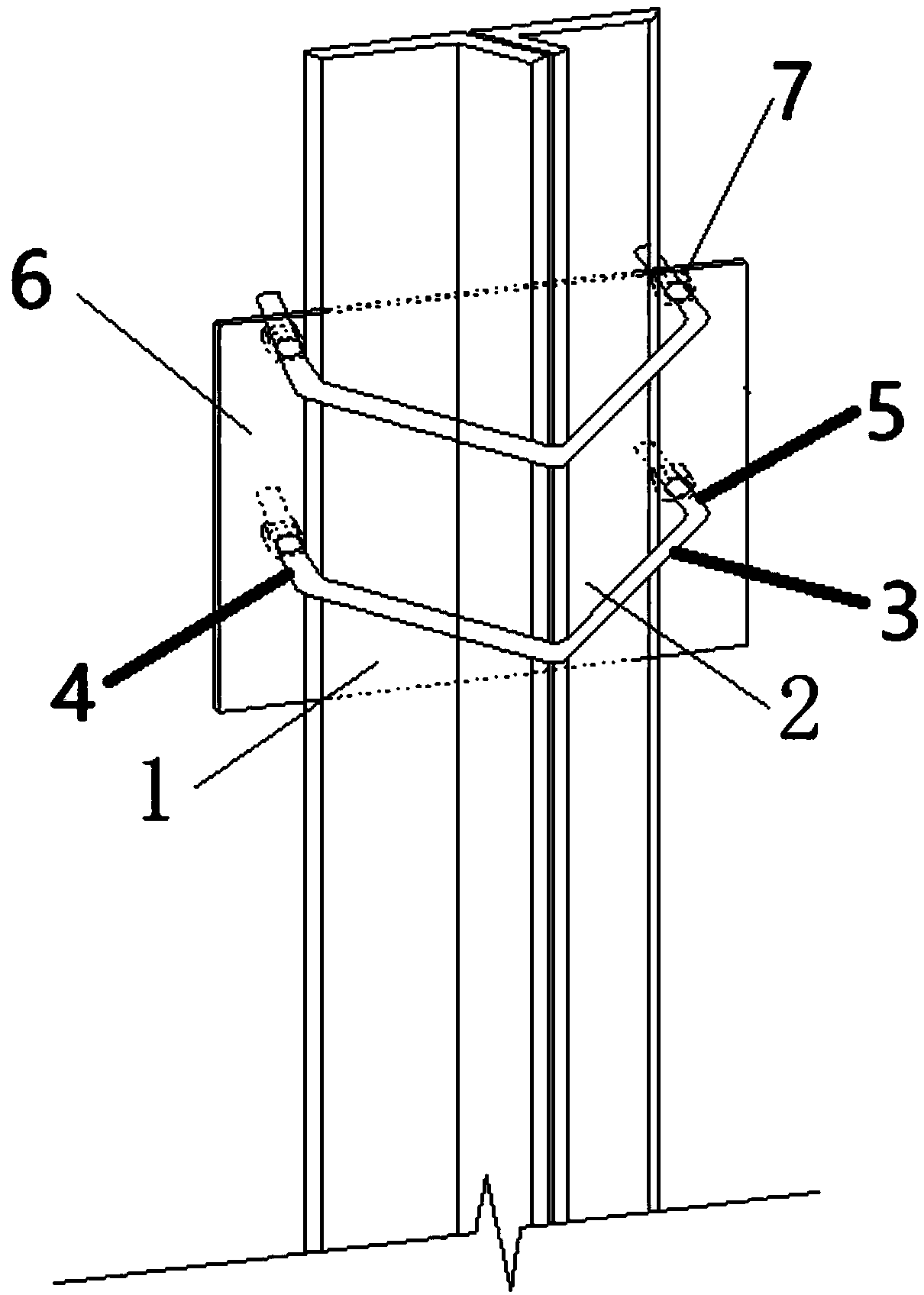

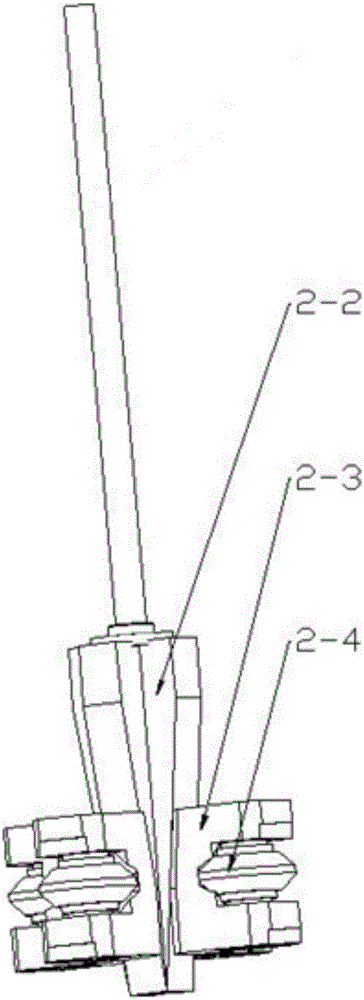

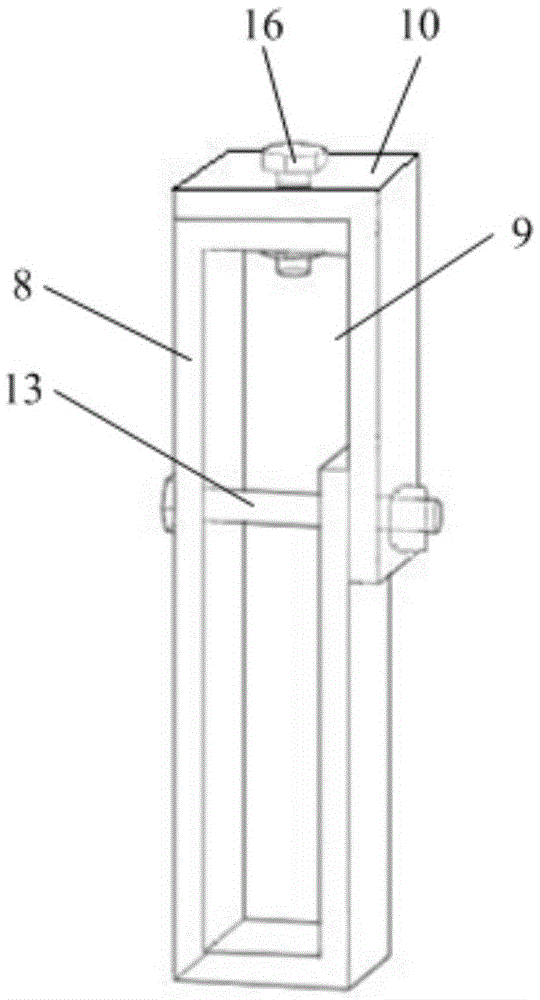

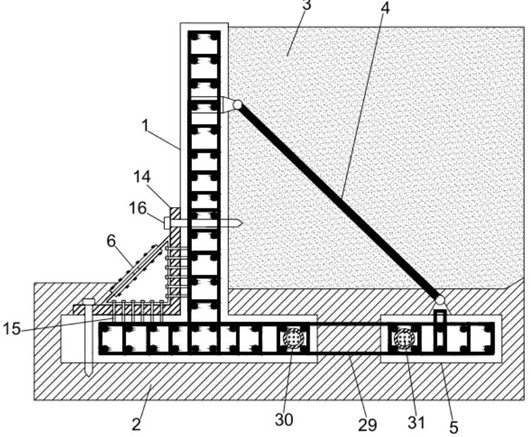

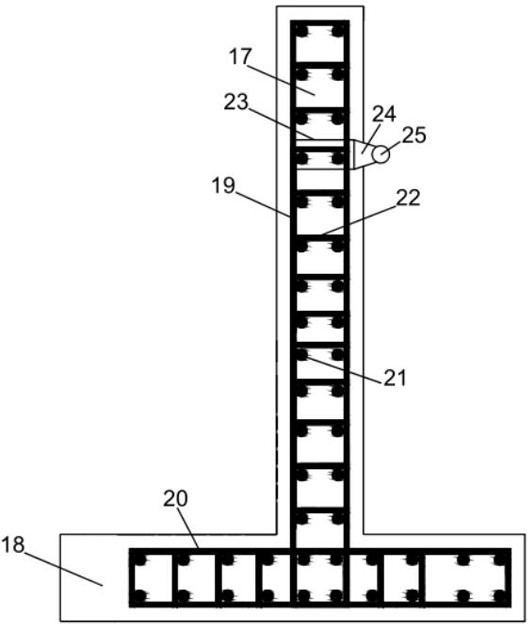

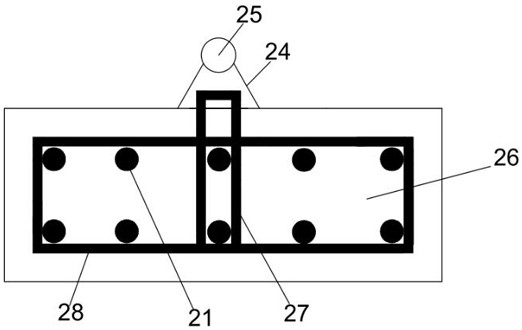

Reinforcing device for power transmission tower angle steel diagonal material

PendingCN107687266APrevent deformation and instabilityBuilding repairsTowersTransmission towerEngineering

The invention belongs to the related technical field of power transmission towers in constructional engineering and particularly relates to a reinforcing device for a power transmission tower angle steel diagonal material. The reinforcing device for the power transmission tower angle steel diagonal material comprises a reinforcing fixture and an auxiliary material, and the auxiliary material madeof angle steel and the power transmission tower angle steel diagonal material are arranged side by side in the left-right direction to form a T-shaped structure. The reinforcing fixture is tightly clamped to the outer contour of the T-shaped structure. In the reinforcing device for the power transmission tower angle steel diagonal material, the power transmission tower angle steel diagonal material and the auxiliary material are arranged side by side in the left-right direction to form the T-shaped structure, and the reinforcing fixture is tightly clamped to the outer contour of the T-shaped structure so that when the power transmission tower angle steel diagonal material is pressed to have the bending and instable tendency, the auxiliary material can jointly bear force with the power transmission tower angle steel diagonal material through the fastening effect of the reinforcing fixture, thus instability and deformation of the power transmission tower angle steel diagonal material areavoided, and the bearing capacity of the power transmission tower angle steel diagonal material is improved.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

Power transmission tower reinforcing device

The invention provides a power transmission tower reinforcing device. The power transmission tower reinforcing device comprises a reinforcing part and a clamping part, wherein the reinforcing part corresponds to a main material of a power transmission tower, is arranged at the outer angle side of the main material, and is used for reinforcing the power transmission tower, and the clamping part encloses a clamping space for clamping the reinforcing part and the main material. By means of the power transmission tower reinforcing device, through the clamping part, the reinforcing part and the main material are clamped, so that the reinforcing part is fixed to the main material, reinforcing of the main material by the reinforcing part is guaranteed, the using performance of the power transmission tower is not influenced, the power transmission tower can be reinforced under the condition of electrified running, the construction operation is convenient, the power transmission tower does notneed to be punched, welded or detached, the damage of punching and welding to the performance of the power transmission tower, particularly the strength of the main material is avoided, accidents likecollapse of the main material are prevented, and meanwhile, the difficulty for operating personnel to work high above the ground on the power transmission tower is lowered.

Owner:广东省输变电工程有限公司

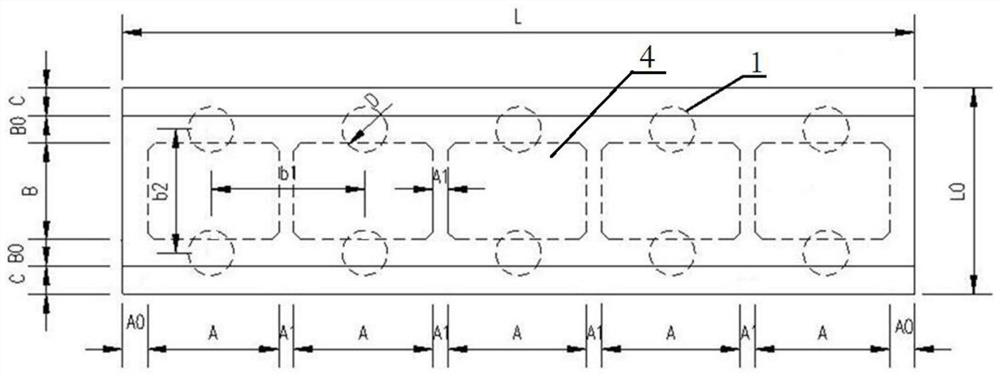

Method for preventing buckling deformation and slippage of honeycomb core curing

ActiveCN110561780AImprove lateral pressure bearing capacityPrevent deformation and instabilityHoneycombMaterials science

The invention discloses a method for preventing buckling deformation and slippage of honeycomb core curing. The 30 cm-50 cm allowance is reserved on the periphery of each component in a honeycomb workpiece, a potting material is used for conducting potting on the 30 cm-50 cm allowance areas of the edges of the honeycomb core, curing is conducted, a honeycomb core plate is combined with an upper gasket and a lower gasket, the edges are aligned and are fixed through adhesive tape, positioning holes are drilled in the allowance areas, 30 mm away from the edges, of the center positions of the edges of the gaskets and the honeycomb core, and positioning pins matched with the workpiece in thickness are manufactured; and adhesive films and upper and lower panel prepreg are laid and pasted to thetwo sides of the honeycomb core where the positioning holes are drilled, during laying and pasting of the adhesive films and the prepreg, avoiding treatment is conducted on the positions of the honeycomb positioning holes, adhesive films are laid and attached to the bonding faces of the upper gasket and the lower gasket, then the upper gasket and the lower gasket are combined with the honeycomb core on which upper panel and lower panel laying and pasting are completed, the positioning holes are aligned, the positioning pins are inserted into the positioning holes in all the edges of the workpiece, and the positions of all the components are locked; and finally, the combined workpiece is subjected to curing treatment, and the 30 cm-50 cm allowance on the edges is removed after the workpieceis cured.

Owner:THE RES INST FOR SPECIAL STRUCTURES OF AERONAUTICAL COMPOSITE AVIC

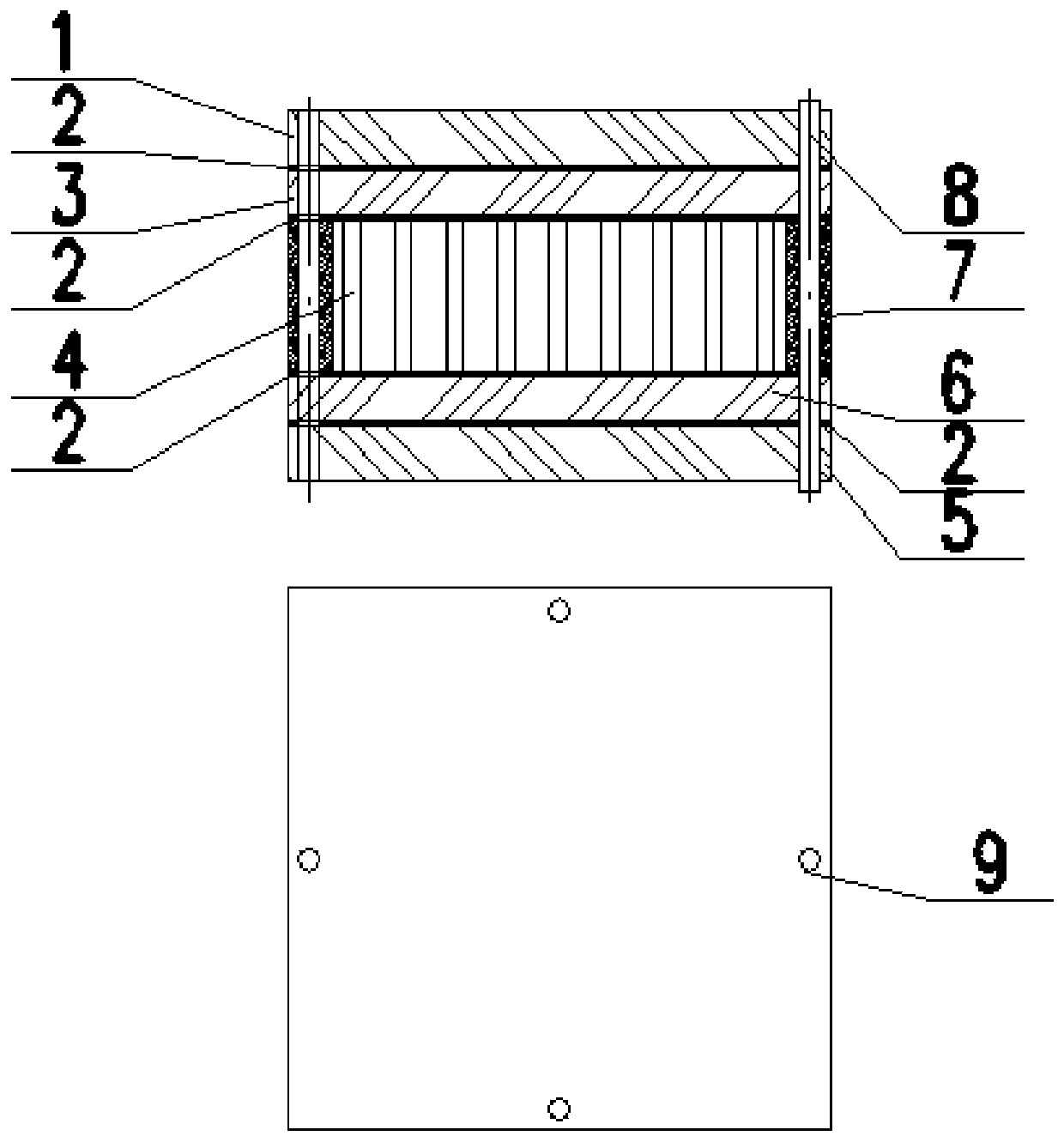

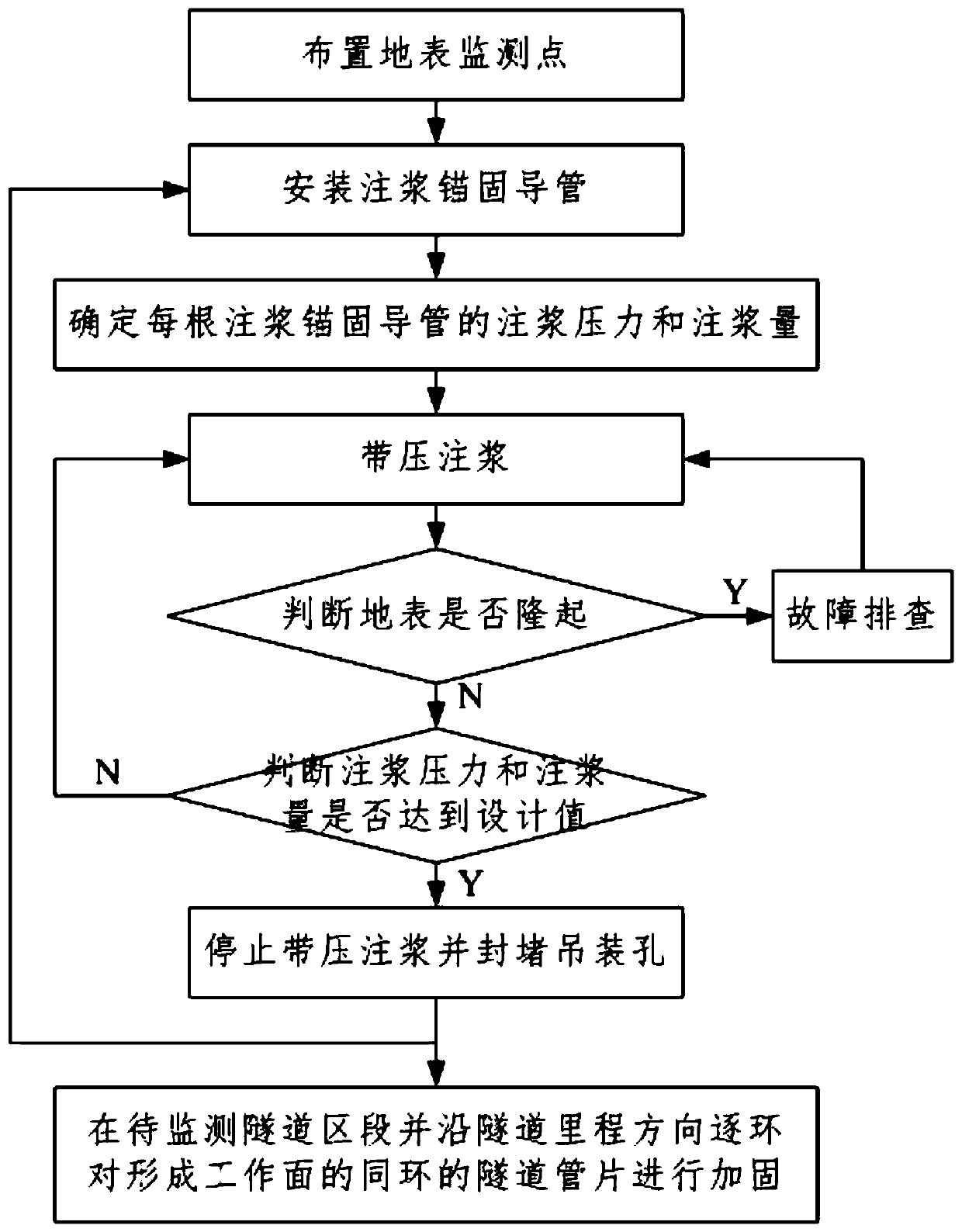

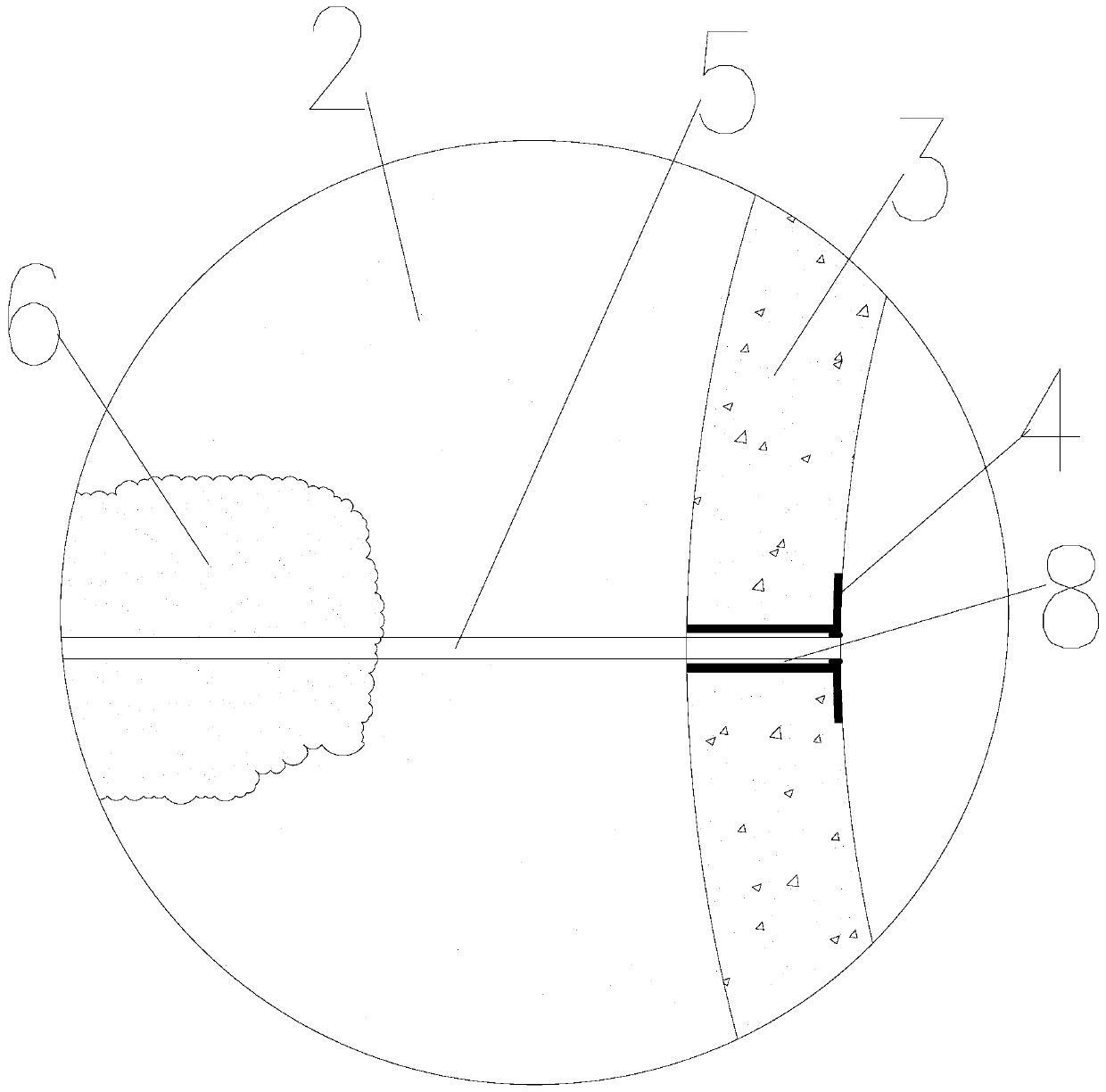

Construction method for preventing instability of shield tunnel under high-sensitivity stratum conditions

ActiveCN110924978AEasy constructionReduce construction input costsUnderground chambersTunnel liningGeotechnical engineeringStructural engineering

The invention discloses a construction method for preventing instability of a shield tunnel under high-sensitivity stratum conditions. The construction method comprises the steps of 1, arranging surface monitoring points, 2, installing grouting anchoring guide pipes, 3, determining grouting pressure and grouting amount, 4, grouting under pressure, 5, judging whether the surface is uplifted or not,6, judging whether the grouting pressure and the grouting amount reach design value or not, 7, troubleshooting, 8, stopping grouting under pressure and plugging a lifting hole and 9, one by one reinforcing tunnel segments of same rings which form a working surface in a tunnel section to be monitored. The deficiencies of synchronous grouting during shield tunneling under the high-sensitivity stratum conditions are effectively overcome, secondary filling is carried out at the backs of walls, the scope of grouting, filling and reinforcing of the backs of the walls of the tunnel segments is increased, the ability of the segments to withstand external forces is improved, and tunnel settlement deformation is resisted; and meanwhile, the grouting anchoring guide pipes can provide effective support force to lining segments, the overall stability of the shield tunnel is improved, and the risks of deformation and instability of the shield tunnel during construction and operation are effectivelyavoided.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

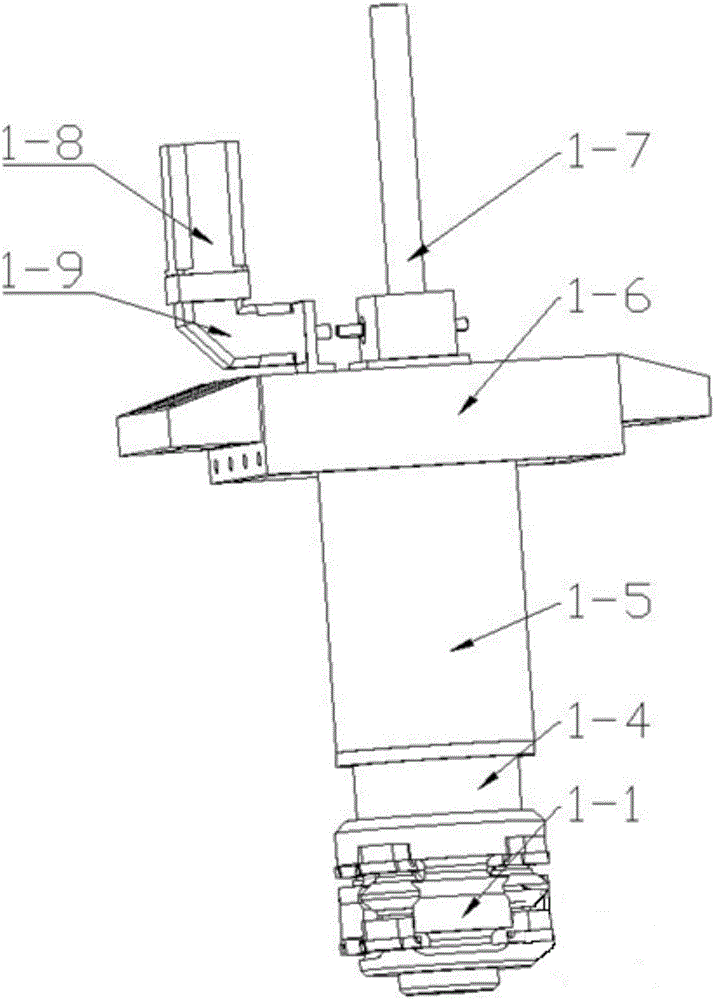

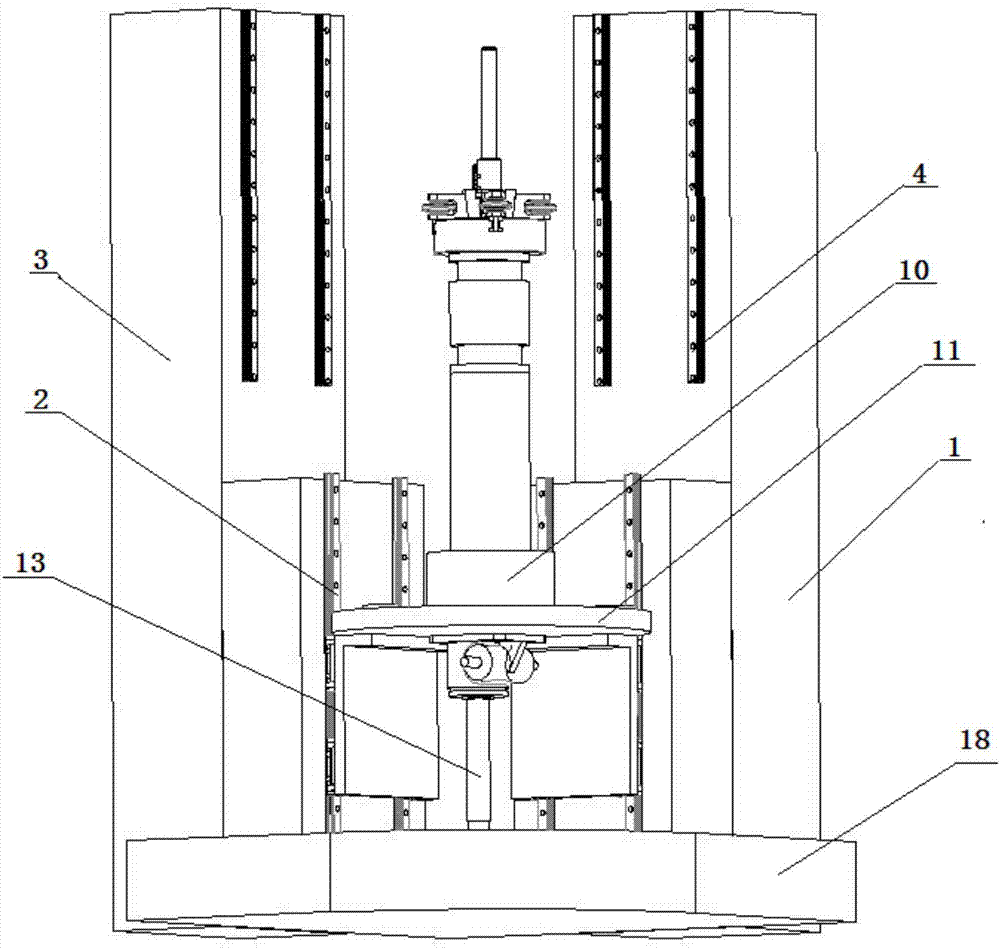

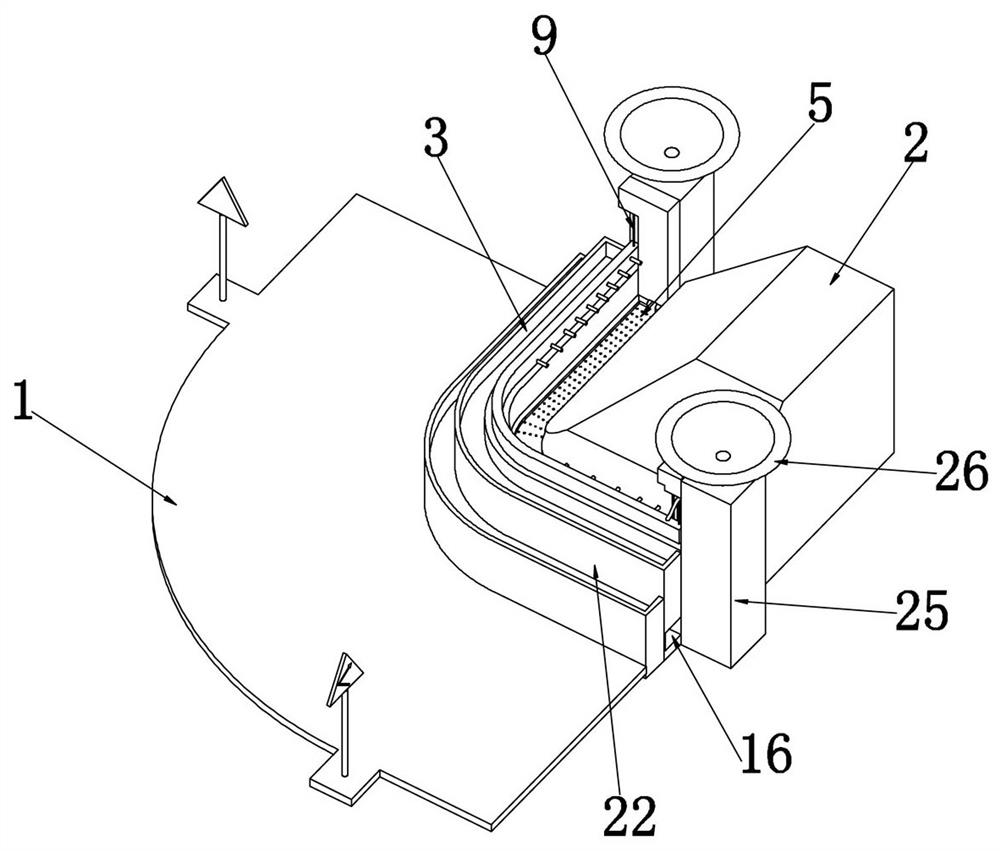

Internal rotation feeding device for large thin-wall cylindrical part pair wheel spinning equipment

ActiveCN106180341AReduce manufacturing costShorten the manufacturing cycleReduction driveEngineering

The invention discloses an internal rotation feeding device for large thin-wall cylindrical part pair wheel spinning equipment, relates to an internal rotation feeding device, and aims to solve the problems of high mold cost, weak generality and long manufacturing period in traditional mold spinning equipment. A conical wedge block coats a feeding lead screw; multiple internal rotation wheel bases are annularly and uniformly mounted on the conical wedge block; one rotating shaft is vertically and rotationally mounted in each internal rotation wheel base; one internal rotation wheel is mounted on each rotating shaft; cross chutes are respectively formed in a rotating base guide sleeve and a wedge block guide sleeve, and are mutually aligned and buckled up and down; a transition sleeve coats the feeding lead screw, and is positioned at the upper end of the wedge block guide sleeve; an upper cross beam is mounted on the transition sleeve; an internal rotation motor is mounted on a speed reducer for transferring power to a speed reducer; and the speed reducer drives the feeding lead screw to rotate. The internal rotation feeding device is suitable for the thin-wall cylindrical part pair wheel spinning equipment.

Owner:HARBIN INST OF TECH

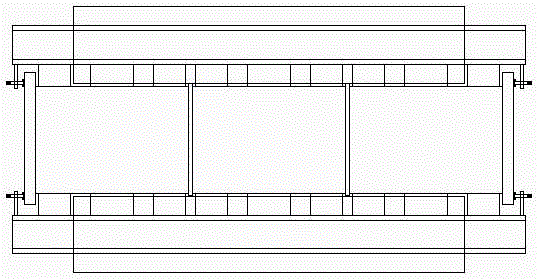

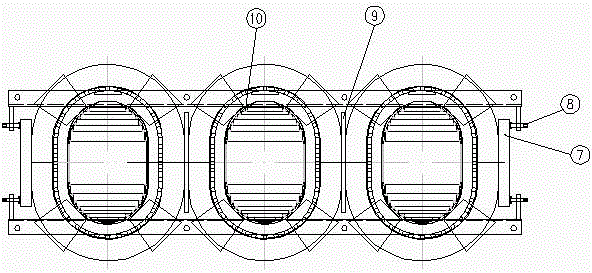

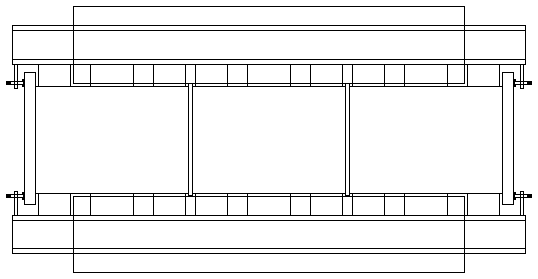

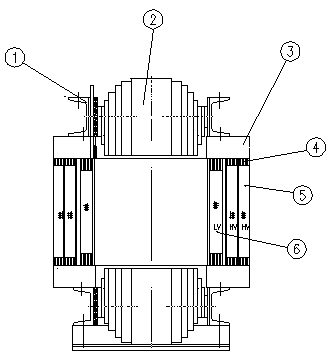

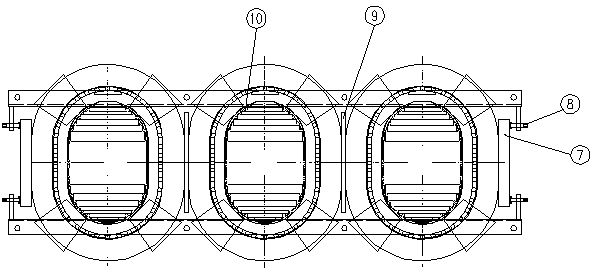

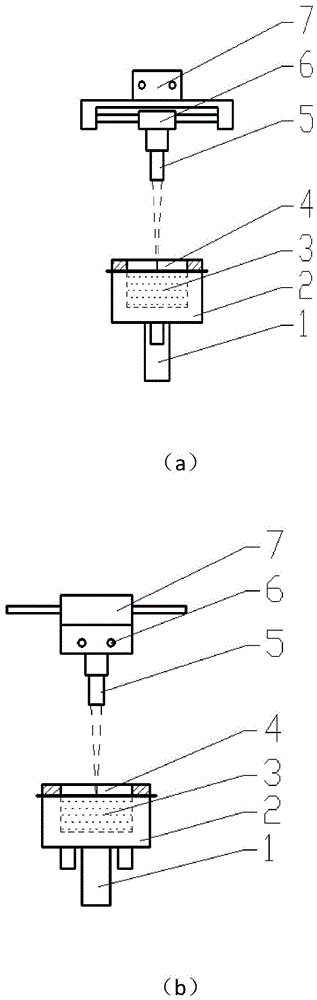

Anti-short circuit transformer and preparation technology thereof

ActiveCN106373756APrevent instability and deformationNo added costTransformers/inductances coils/windings/connectionsCoils manufactureDistribution transformerLow voltage

The invention particularly relates to an anti-short circuit transformer and a preparation technology thereof. The anti-short circuit transformer comprises an A-phase coil, a B-phase coil, a C-phase coil. Each of the A-phase coil, the B-phase coil and the C-phase coil comprises an iron core, a low-voltage coil and a high-voltage coil. Each low-voltage coil and each high-voltage coli are sleeved out of each iron core. An inner insulation paper board, a low-voltage coil lead, interlayer insulation and an end coil of each low-voltage coil form an integrated structure. A lead, the interlayer insulation and the end coil of each high-voltage coil form an integrated structure. Cushion blocks and clamp elements are arranged out of the end coils of the low-voltage coils and the high-voltage coils in sequence. The low-voltage coils, the high-voltage coils and the iron cores are braced through round rods. Clearances among the A-phase coil, the B-phase coil and the C-phase coil are braced through bracing boards. The A-phase coil and the C-phase coil at two ends are equipped with insulation boards. The insulation boards are connected with the lamp elements through thimbles. According to the transformer and the technology, under the condition that raw material costs are not increased, the distribution transformer has an anti-short circuit capability, a winding is effectively prevented from losing stability and deforming when the transformer is in a short circuit, and more profit margins are provided for a producer / manufacturer.

Owner:SHANDONG HUACHI TRANSFORMER

Pipe connection used for indoor and outdoor units of air conditioner and its method for making production method

ActiveCN101319742BSame outer diameterNot easy to fall offElectrode featuresNon-disconnectible pipe-jointsStructural engineeringUltimate tensile strength

The invention relates to a connection tube applied to the indoor machine and outdoor machine of an air conditioner and a manufacture method thereof. A taper face of weld is arranged at the joint welding position of a copper pipe, and raised grains are arranged on the outer wall of an aluminum pipe. During welding, a mosaic block is arranged at the welding position of the fixed electrode; a grooveis arranged in the mosaic block, raised grains are prepared on the groove; and the nominal diameter of the groove which bears raised grains is identical with the outer diameter of the aluminum pipe. The aluminum fluid melted during welding can be filled in the raised grains of the groove of the mosaic block, so that the deformation of the aluminum pipe is avoided, and the quality and strength of the product are improved. By such welding method, the aluminum pipe can be clamped to avoid breaking off; in addition, the outer diameter of the welding position of the copper-aluminum pipe joint is kept identical with the outer diameter of the aluminum pipe.

Owner:青岛津海制冷管业有限公司

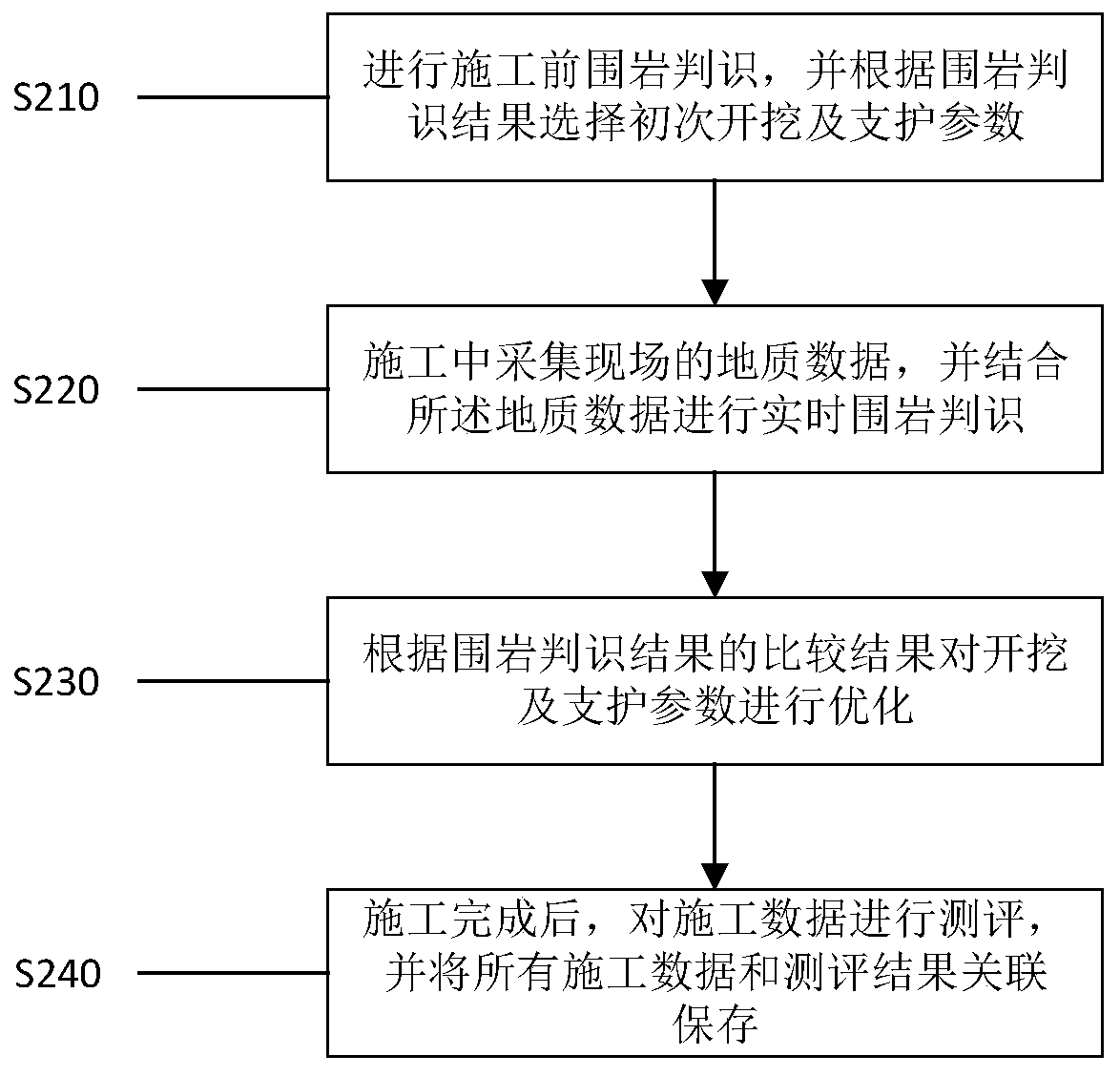

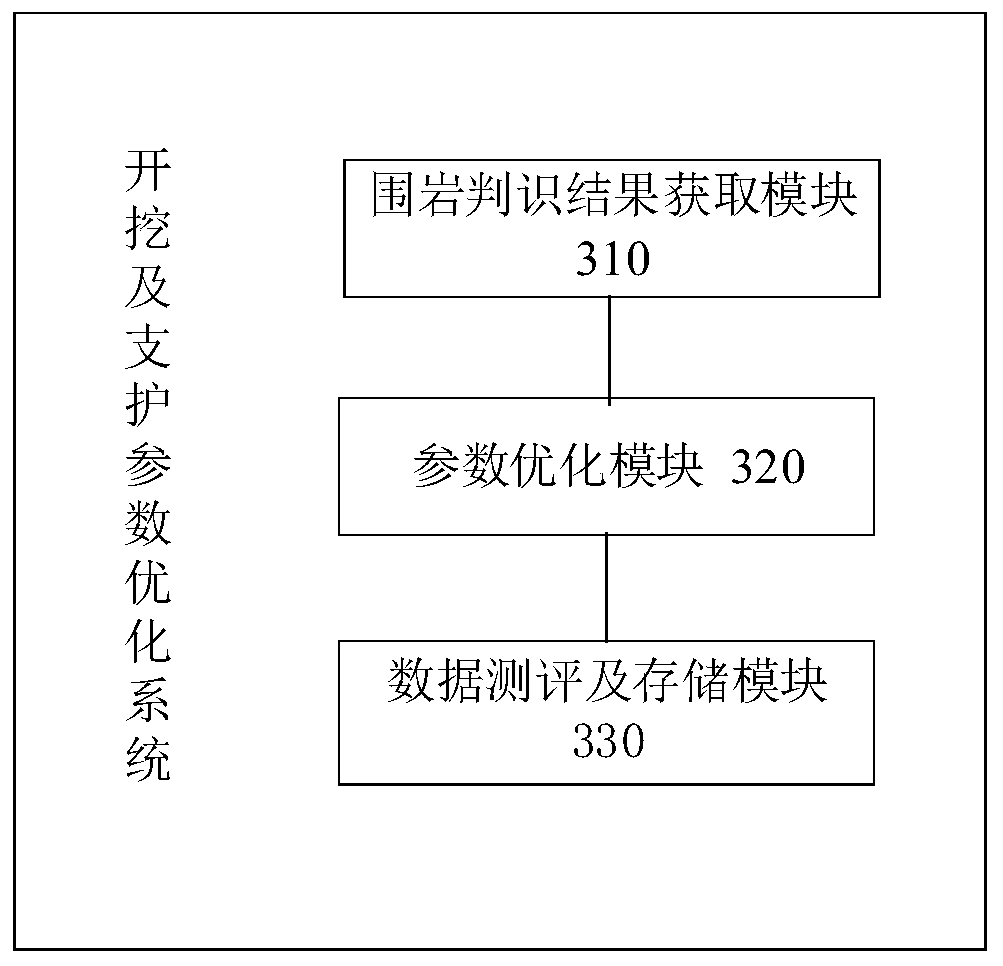

Intelligent selection and optimization method and system for tunnel excavation and support parameters

PendingCN110889532AAvoid manpower and material resources consumptionPrevent deformation and instabilityForecastingResourcesTunnel constructionMaterial resources

The invention discloses an intelligent selection and optimization method and system for tunnel excavation and support parameters. The method comprises the steps that surrounding rock identification before construction is conducted according to geological data before construction, and primary excavation and supporting parameters are determined based on the surrounding rock identification result; then, based on primary excavation and supporting parameter construction, real-time surrounding rock identification is carried out in combination with geological data collected in the construction process; and the current surrounding rock identification result is compared with the previous surrounding rock identification result, and the excavation and support parameters are optimized according to thecomparison result. According to the method and system, excavation and support parameters of tunnel construction can be optimized, unnecessary manpower and material resource consumption in the tunnelconstruction process is avoided, it is guaranteed that the tunnel construction result more accurately meets the design standard, and the situation that deformation and instability occur after a tunnelis built is avoided.

Owner:CHINA RAILWAY CONSTR HEAVY IND

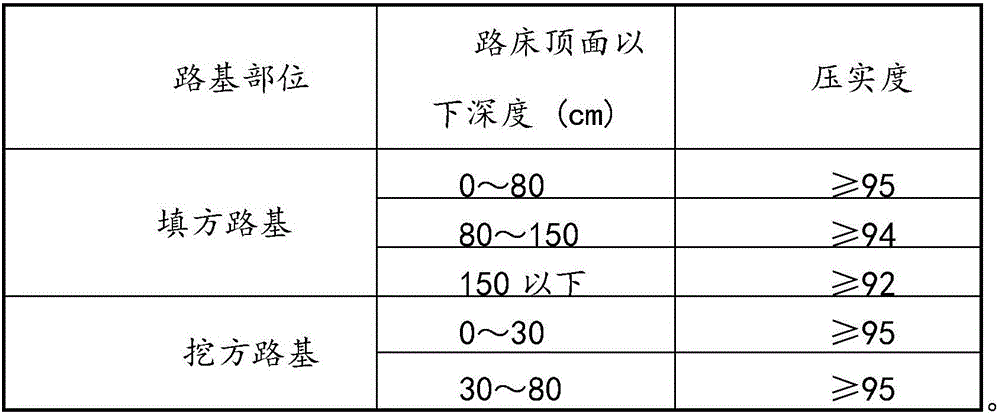

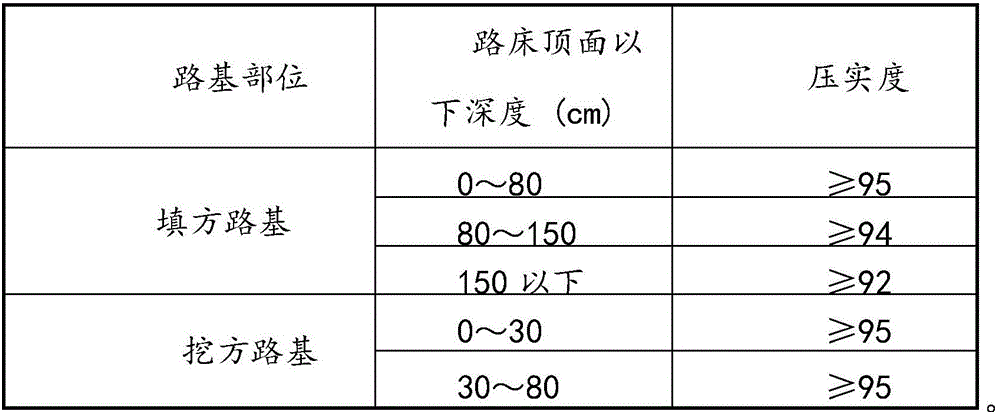

Wind field road construction method

InactiveCN106192645ASmooth drainagePrevent deformation and instabilityPaving gutters/kerbsWind fieldEngineering

The invention discloses a wind field road construction method, comprising road construction, circular culvert construction and retaining wall construction. The road construction further comprises: positioning and paying-off, heaping and paving, subgrade compaction, mud grouting, rolling compaction, surface course paving, wearing course paving and drainage construction. By applying the method, a wind field road site after construction is guaranteed to be good in stability in the whole, the seismic fortification intensity of the site reaches the level 6, and the normal operation of the wind power plant is guaranteed.

Owner:中能建建筑集团有限公司

Welding method loading cold source and displacement-controlled load in welding

ActiveCN108544118AReduce welding stressNo plastic deformationWelding/cutting auxillary devicesAuxillary welding devicesMechanical stretchingInstability

The invention discloses a welding method loading a cold source and displacement-controlled load in welding. The method comprises the following steps of: applying the cold source which has certain power to other positions of a welding part before a welding heat source is applied and in the welding heat source applying process; and if the power of the cold source is insufficient, simultaneously applying displacement-controlled mechanical tensile load in the length direction of a welding seam and in the direction perpendicular to the welding seam. According to the method, the cold source having the certain power acts on other positions of the welding part when the welding heat source is in action; if the total deformation generated by cooling shrinkage in the region is equal to that generatedby free thermal expansion of a heated position, the expansion of the heated position is not hindered, the stress is zero, and plastic deformation is prevented. If the power of the cold source is limited, the total deformation generated by cooling shrinkage is smaller than that generated by the free thermal expansion of the heated position, then the four sides of the welding part can be simultaneously applied with the mechanical tensile load, certain tensile elastic deformation is generated in the overall welding part or in a local part of the welding part so as to compensate or counteract a part of the free thermal expansion deformation of the heated position. In practice, low-stress and plastic-deformation-free welding can be realized, the pressure stress inside the welding part is reduced, and deformation, caused by instability, of a thin plate is prevented.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

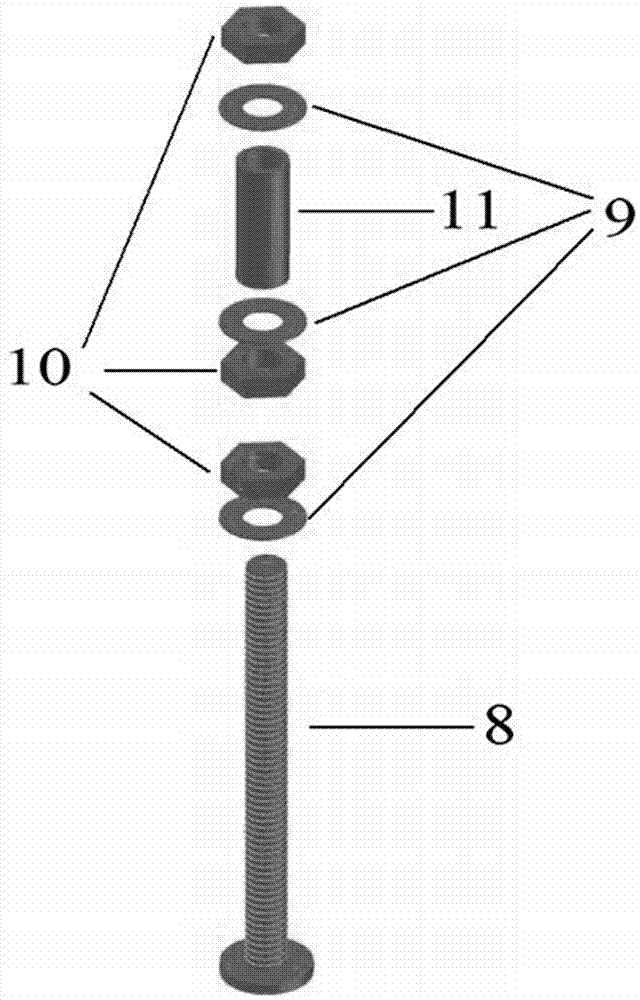

Blind rivet type thin-wall bush with countersunk head and forming method of thin-wall bush

ActiveCN107866477APrevent deformation and instabilityAvoid instabilityShaping toolsInstabilityEngineering

The invention discloses a blind rivet type thin-wall bush with a countersunk head and a forming method of the thin-wall bush. Main points of the technology are that the thin-wall bush includes a bottom seat, a bush, a male mold and a back pressure sleeve. The male mold is arranged on the bottom seat. The bush is arranged between the bottom seat and the male mold. The back pressure sleeve is arranged on the upper side of the male mold. A spring is arranged between the male mold and the back pressure sleeve. The forming method includes the steps of (1), fixing,(2), arrangement of a thin-wall tube stock and a central shaft, (3), arrangement of a spring sleeve and a pushing pipe,(4), arrangement of a pushing sleeve and the male mold, (5), forming of a bush countersunk head, (6), external constraint removing, and (7), forming of a countersunk head bush. The thin-wall bush has the advantages that product forming quality is improved; product dimensional precision is improved; instability anddeformation of the inner diameter and internal round corners of the bush are prevented; instability is avoided; the product quality is effectively improved accordingly; and market prospects are vast.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

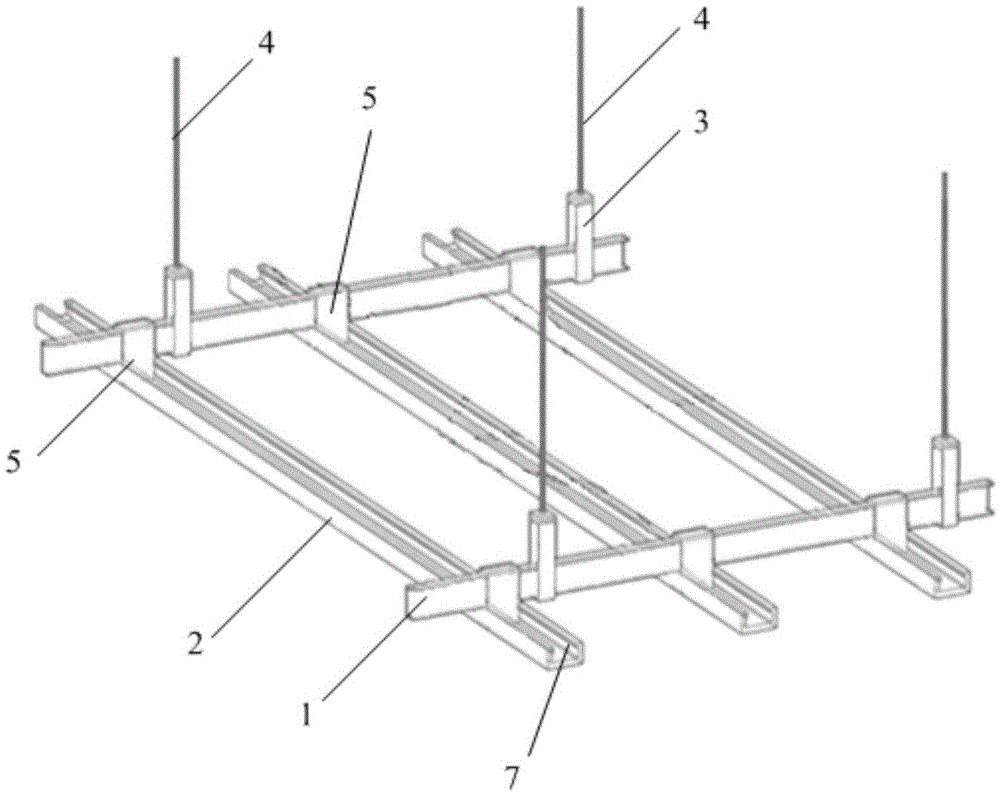

Fastener for light steel keel suspended ceiling

The invention provides a fastener for a light steel keel suspended ceiling. The fastener comprises suspension parts. The suspension parts are arranged on main keels or auxiliary keels which intersect vertically and horizontally to form a suspended ceiling face. The tops of the suspension parts are used for being connected with suspension rods. The suspension parts comprise frames and reinforcing parts arranged on the tops of the frames. The bottoms of the frames are sleeved with the main keels or the auxiliary keels, the reinforcing parts are in the shape formed by rotating L rightwards by 180 degrees, the top faces of the reinforcing parts are connected with the suspension rods and fixed to the top faces of the frames, and the side faces of the reinforcing parts are fixed to the side faces of the frames. The suspension parts are formed by fixing the frames and the reinforcing parts, the effect of connecting the suspension rods with the main keels or the auxiliary keels can be achieved, buckling deformation of openings of the frames can be avoided, the fastener is reliably connected, stress performance is good, rigidity is high, torsional strength is high, the keels are more stable, the failure probability of the suspended ceiling in emergencies such as earthquakes is reduced, the reinforcing parts and the frames are separately arranged and are fixedly connected after being arranged in the keels, and the suspended parts are easy and convenient to install, flexible in detachment and replacement and capable of being reused.

Owner:SHENYANG JIANZHU UNIVERSITY

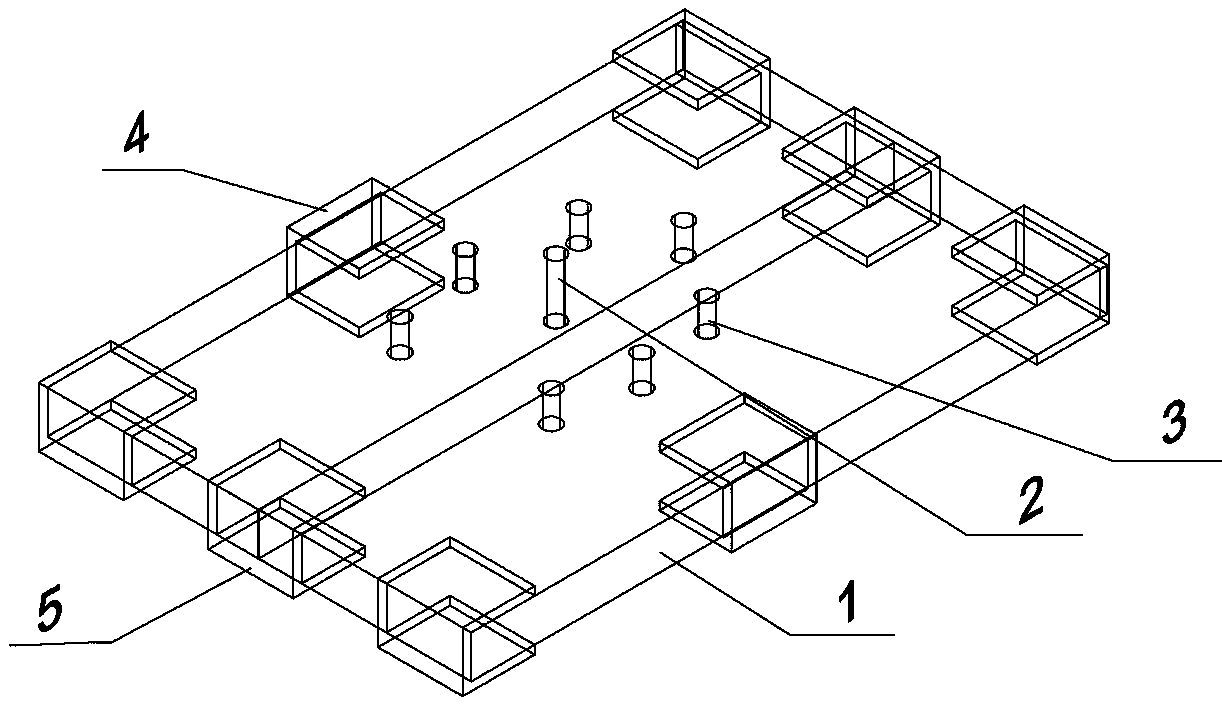

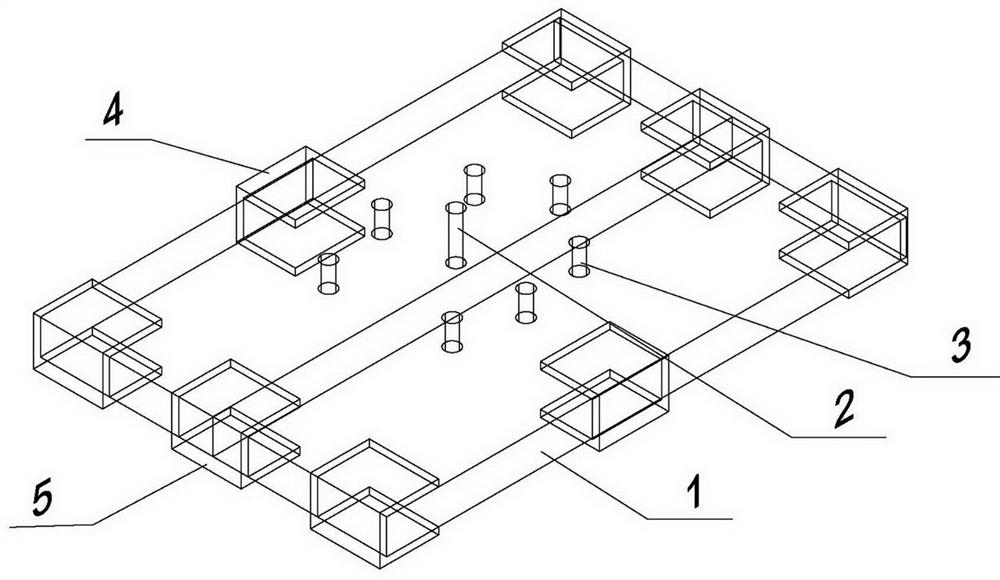

Pile foundation box type retaining wall

PendingCN111622261ALow foundation bearing capacity requirementsReduce the amount of reinforced concreteArtificial islandsUnderwater structuresRebarReinforced concrete

The invention discloses a pile foundation box type retaining wall. The pile foundation box type retaining wall comprises a box body and further comprises foundation piles, a cushion layer and a bearing platform. The box body is fixedly connected to the bearing platform, the bearing platform is fixedly connected to the cushion layer, the cushion layer is fixedly connected to the pile tops of the foundation piles, and the foundation piles are poured into a foundation. The interiors of the box body, the bearing platform, the cushion layer and the foundation piles are connected into a whole through rebars. The functions of retaining soil and reinforcing an unstable slope are integrated, the situation that a gravity retaining wall cannot be arranged due to insufficient bearing force in a soft soil area can be well offset, and the pile foundation box type retaining wall has the beneficial effects that the requirement for the bearing force of the foundation is not high, the use quantity of reinforced concrete is reduced, the engineering manufacturing cost is reduced, the engineering environmental suitability is high, and a retaining effect can be effectively exerted. When the pile foundation box type retaining wall is 12 m or higher and is arranged in soft soil or areas adjacent to water and rock or landslide road sections, the investment can be effectively reduced, and the reliability and the durability are improved.

Owner:云南皓泰公路勘察设计有限公司

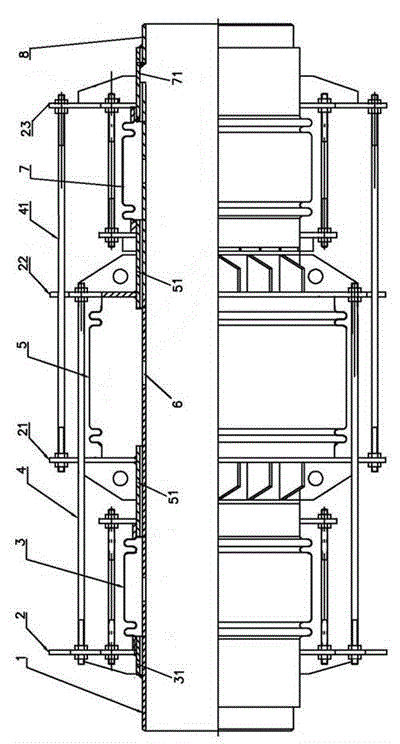

Bellows compensator

PendingCN104832737APrevent deformation and instabilityPipeline expansion-compensationEngineeringFluid pressure

The invention relates to a bellows compensator, which comprises a balance bellows (5), a first bellows (3) and a second bellows (7) are welded onto two ends of the balance bellows (5) through joints; a left end ring (21) and a right end ring (22) are respectively welded onto the joints on the two ends of the balance bellows; a first ear plate (2) is welded onto the left side of the first bellows; a second ear plate (23) is welded onto the right side of the second bellows; a plurality of first pull rods (4) are symmetrically arranged between the first ear plate and the right end ring (22); a plurality of second pull rods (41) are symmetrically arranged between the second ear plate and the left end ring (21); the pipe diameter of the balance bellows is larger than the pipe diameters of the first bellows and the second bellows. Thrust generated by fluid pressure in the balance bellows is larger than thrust in the first bellows and the second bellows, so that the thrust generated by the fluid pressure is balanced; a first joint pipe extends rightwards to the middle part of the right joint, so that the bellows is prevented from being deformed and instable.

Owner:JIANGSU FIVE STAR BELLOWS CO LTD

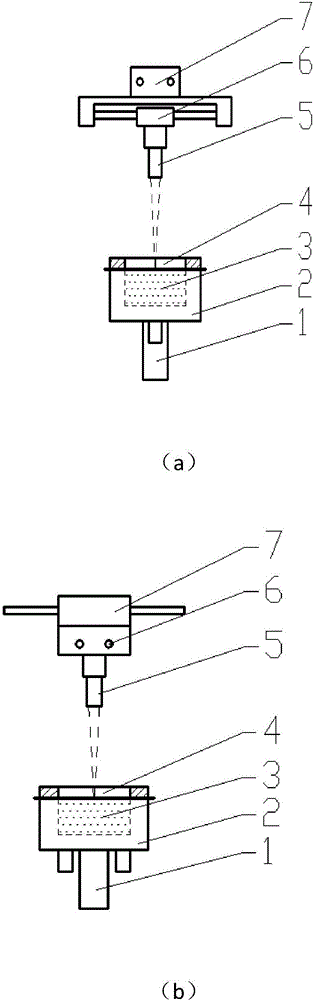

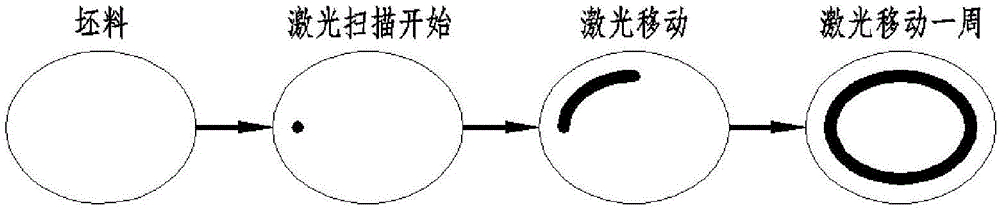

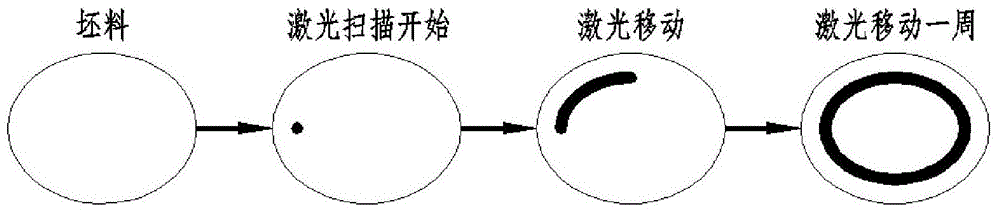

Laser heating induced isostatic pressing loading type die-less forming method of plates

InactiveCN104646479AFacilitates the formation of fine featuresEasy to shapeShaping toolsLiquid mediumOptoelectronics

The invention discloses a laser heating induced isostatic pressing loading type die-less forming method of plates. The method comprises the following steps of: partially heating the plates through laser; applying isostatic pressing on liquid mediums; finishing the die-less forming of the plates by accumulating partial deformations of the plates. According to the laser heating induced isostatic pressing loading type die-less forming method of the plates, the shortcomings that the forming accuracy of a laser thermal stress forming method is not high and intricately shaped parts are difficult to form are overcome, and the machining speed and accuracy are accurately controlled, so that the size accuracy and good surface quality of the formed plates are higher, and the intricately shaped parts can be formed; the forming limit is improved, thus the machining procedures are simplified, the number of the machining procedures is reduced, and the machining efficiency is improved.

Owner:ZHEJIANG SCI-TECH UNIV

Concrete retaining wall structure with energy dissipation and shock absorption functions

PendingCN111980058AImprove integrityImprove stabilityArtificial islandsUnderwater structuresRoad engineeringRebar

The invention provides a concrete retaining wall structure with energy dissipation and shock absorption functions, and belongs to the field of urban underground road engineering and the technical field of public facilities. The structure comprises a concrete weight-adding strengthened pulling plate, a nodal shock absorption and energy dissipation device, a right-angled connecting plate, a tension-compression main energy dissipation steel plate, an auxiliary energy dissipation steel plate, a right-angled strengthened fixing steel plate, a strengthened pulling plate ring-shaped hooping, and a ring-shaped hooping connecting part. A vertical concrete plate is exposed to the outside of an original soil layer, and a vertical ring-shaped hooping is arranged near the edge of the interior of the vertical concrete plate. A horizontal ring-shaped hooping is arranged near the edge of the interior of a horizontal concrete plate. Two rows of longitudinal rebars are uniformly arranged at the inner side of the horizontal ring-shaped hooping. The concrete retaining wall structure with the energy dissipation and shock absorption functions has the beneficial effects that the integrity and stability of the retaining wall is improved, the problems of poor structural strength and high maintenance cost are avoided, the fracture or deformation failure of the retaining wall is avoided, and the structure has the strength and the ability of buffering and shock absorption, which forms a connection system with good shock absorption performance, so as to effectively support subgrade or hillside soil body and prevent soil deformation and instability.

Owner:张延年

A kind of anti-short-circuit transformer and its preparation process

ActiveCN106373756BPrevent deformation and instabilityNo added costTransformers/inductances coils/windings/connectionsCoils manufactureDistribution transformerLow voltage

The invention particularly relates to an anti-short circuit transformer and a preparation technology thereof. The anti-short circuit transformer comprises an A-phase coil, a B-phase coil, a C-phase coil. Each of the A-phase coil, the B-phase coil and the C-phase coil comprises an iron core, a low-voltage coil and a high-voltage coil. Each low-voltage coil and each high-voltage coli are sleeved out of each iron core. An inner insulation paper board, a low-voltage coil lead, interlayer insulation and an end coil of each low-voltage coil form an integrated structure. A lead, the interlayer insulation and the end coil of each high-voltage coil form an integrated structure. Cushion blocks and clamp elements are arranged out of the end coils of the low-voltage coils and the high-voltage coils in sequence. The low-voltage coils, the high-voltage coils and the iron cores are braced through round rods. Clearances among the A-phase coil, the B-phase coil and the C-phase coil are braced through bracing boards. The A-phase coil and the C-phase coil at two ends are equipped with insulation boards. The insulation boards are connected with the lamp elements through thimbles. According to the transformer and the technology, under the condition that raw material costs are not increased, the distribution transformer has an anti-short circuit capability, a winding is effectively prevented from losing stability and deforming when the transformer is in a short circuit, and more profit margins are provided for a producer / manufacturer.

Owner:SHANDONG HUACHI TRANSFORMER

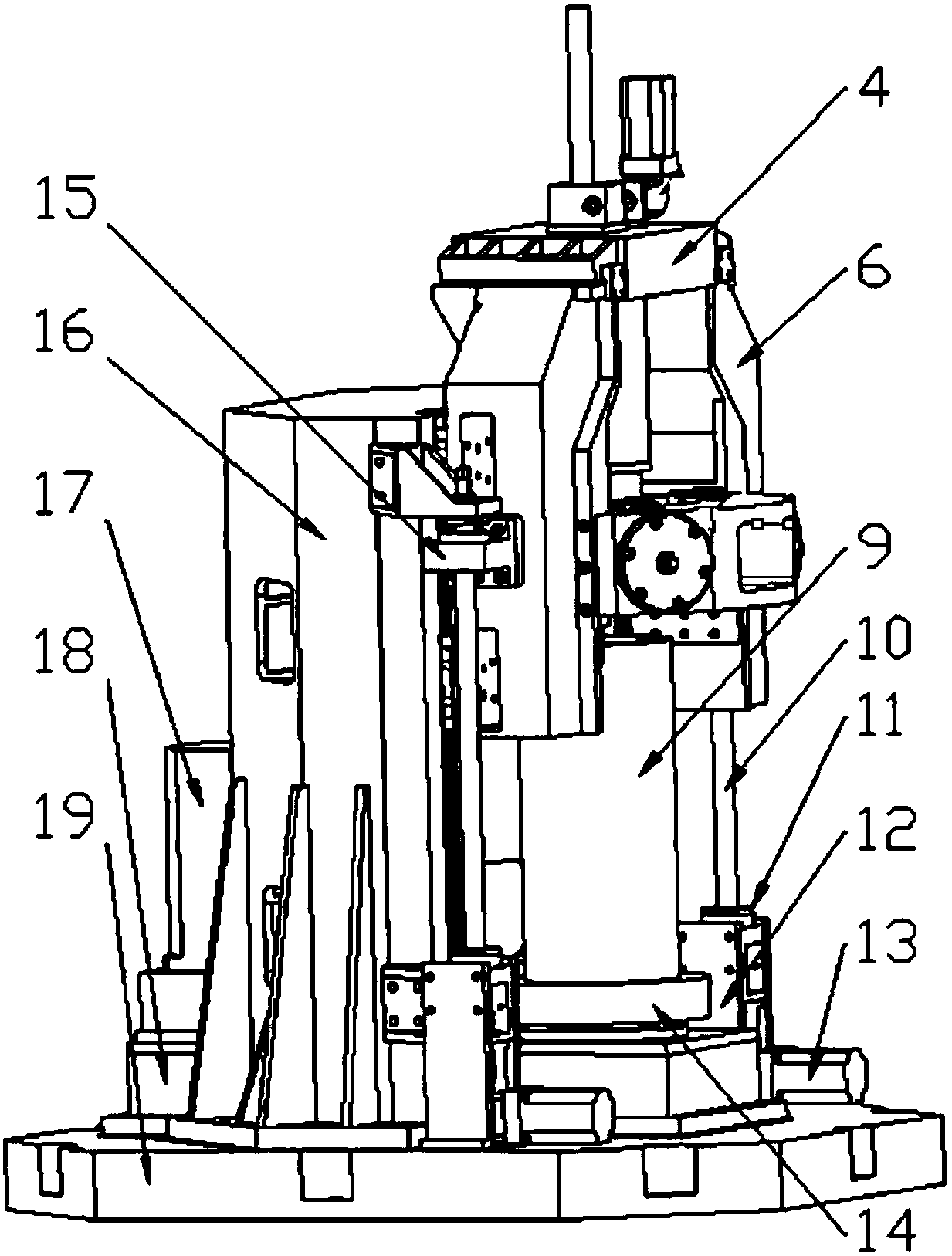

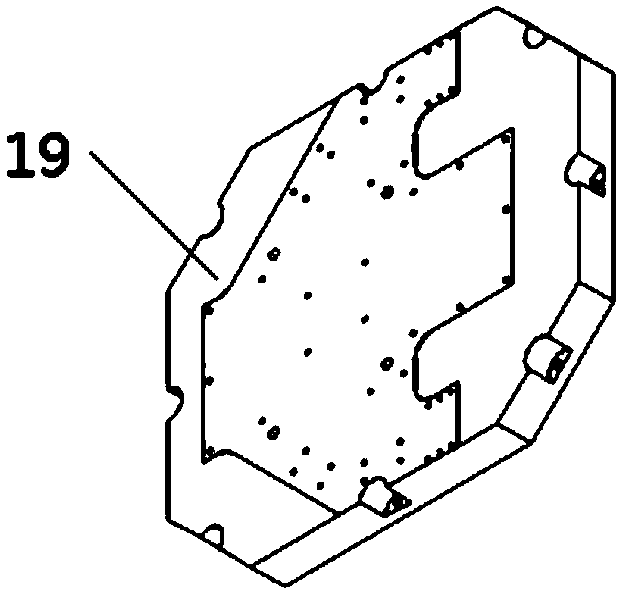

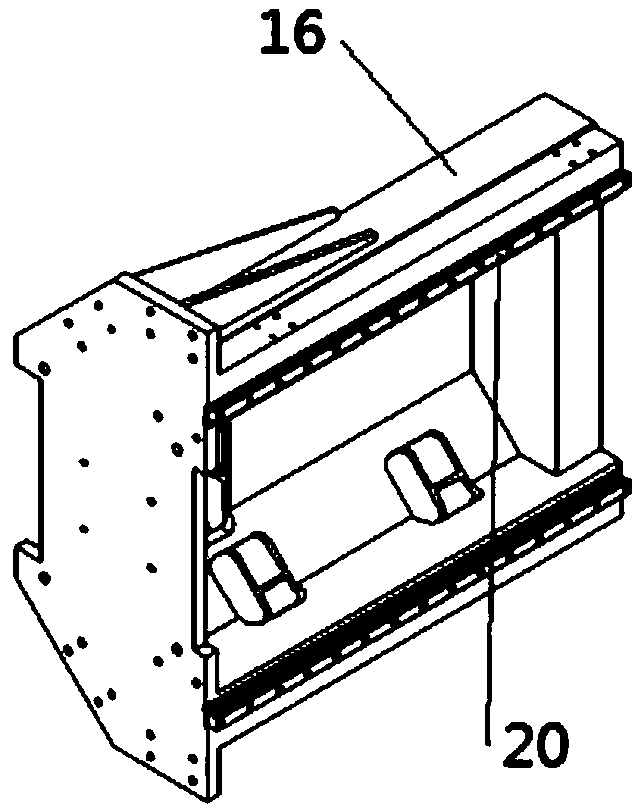

A pair of wheel spinning equipment for forming large thin-walled cylindrical parts

The invention relates to opposite roller spinning equipment, in particular to opposite roller spinning equipment for forming a large thin-walled cylindrical part, and aims to solve the problems that existing die spinning equipment is high in cost, poor in universality and long in manufacturing period as a core die is needed. A chuck substrate fixing base is installed on a rack between an internal rotation guide rail and an external rotation guide rail, a chuck substrate is installed on the chuck substrate fixing base, an external rotation mechanism fixing base is installed on the external rotation guide rail in a sliding mode, and an external rotation disc is installed on the external rotation mechanism fixing base; a bottom plate is installed on an internal rotation guide rail, a lifting motor is installed at the lower end of the bottom plate, one end of a lifting lead screw penetrates through the bottom plate, and the other end of the lifting lead screw is connected with a base; an internal rotation device fixing base is installed on the bottom plate, a worm and gear assembly is installed on the chuck substrate, a three-claw chuck is installed on the worm and gear assembly, multiple pull rods are connected with the external rotation disc, the chuck substrate and the base, an internal rotation device is installed in the internal rotation device fixing base, and the external rotation device is installed in the external rotation disc. The opposite roller spinning equipment is suitable for carrying out opposite roller spinning on the large thin-walled cylindrical part.

Owner:HARBIN INST OF TECH

Welding method with cold source and displacement controlled load along with welding

ActiveCN108544118BReduce welding stressNo plastic deformationWelding/cutting auxillary devicesAuxillary welding devicesThermal dilatationThermodynamics

The invention discloses a welding method for loading a cold source with welding and controlling load with displacement. The method includes: applying a cold source with a certain power to other parts of the weldment before and during the application of the welding heat source; if the power of the cold source is not enough , then a displacement-controlled mechanical tensile load is applied simultaneously in the lengthwise direction of the weld and in the direction perpendicular to the weld. This method is that while the welding heat source acts, a certain power cold source acts on other parts of the weldment. If the total deformation caused by the cooling contraction in this area can be equal to the total deformation of the free thermal expansion of the heating part, then the heating The expansion of the part is not hindered, the stress will be zero, and no plastic deformation will occur. If the power of the cold source is limited, the total deformation caused by the cooling contraction is less than the total deformation of the free thermal expansion of the heating part, and a mechanical tensile load can be applied around the weldment at the same time to generate a certain stretch in the entire weldment or locally Elastic deformation to compensate or counteract the free thermal expansion deformation of a part of the heating part. In practice, welding with low stress and no plastic deformation can be realized, the compressive stress in the weldment can be reduced, and the instability and deformation of the thin plate can be avoided.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

Safety aids for road construction retaining walls

ActiveCN109811788BEffective protection and reinforcementBig spaceArtificial islandsExcavationsArchitectural engineeringRoad construction

The invention relates to a safety assisting device for a road construction retaining wall, and effectively solves the problems that the safety performance of the existing road construction retaining wall is not enough and a staff has difficulties in cleaning the road construction retaining wall. The safety assisting device is characterized by comprising an arc retaining wall arranged between a road and a mountain slope, a groove is arranged between the retaining wall and the mountain slope, the groove is provided with a lifting plate in a sliding and matching way vertically, a second groove isformed in the retaining wall vertically, a reserve baffle is arranged in the second groove in a sliding and matching way vertically, support columns are fixed at the two ends of the retaining wall, pulling ropes are fixed at the upper ends of the two ends of the lifting plate, a fixed pulley is fixed at the upper end of each support column, the upper ends of the two pulling ropes are respectivelyguided by the different fixed pulleys and then connected with the upper ends of the two ends of the reserve baffle, when earthwork slides to the upper end of the lifting plate, the lifting plate gradually sinks but the reserve baffle gradually ascends; the safety assisting device is ingenious in structure and strong in practicality, and the risk of landslip of the mountain slope and the risk of slipping soil to the road are greatly reduced.

Owner:郭淑芳

A method for dieless forming of laser heating induced isostatically loaded sheet metal

InactiveCN104646479BFacilitates the formation of fine featuresEasy to shapeShaping toolsLiquid mediumLaser heating

The invention discloses a laser heating induced isostatic pressing loading type die-less forming method of plates. The method comprises the following steps of: partially heating the plates through laser; applying isostatic pressing on liquid mediums; finishing the die-less forming of the plates by accumulating partial deformations of the plates. According to the laser heating induced isostatic pressing loading type die-less forming method of the plates, the shortcomings that the forming accuracy of a laser thermal stress forming method is not high and intricately shaped parts are difficult to form are overcome, and the machining speed and accuracy are accurately controlled, so that the size accuracy and good surface quality of the formed plates are higher, and the intricately shaped parts can be formed; the forming limit is improved, thus the machining procedures are simplified, the number of the machining procedures is reduced, and the machining efficiency is improved.

Owner:ZHEJIANG SCI-TECH UNIV

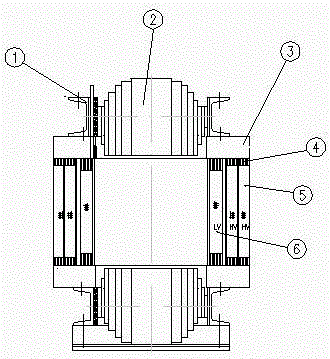

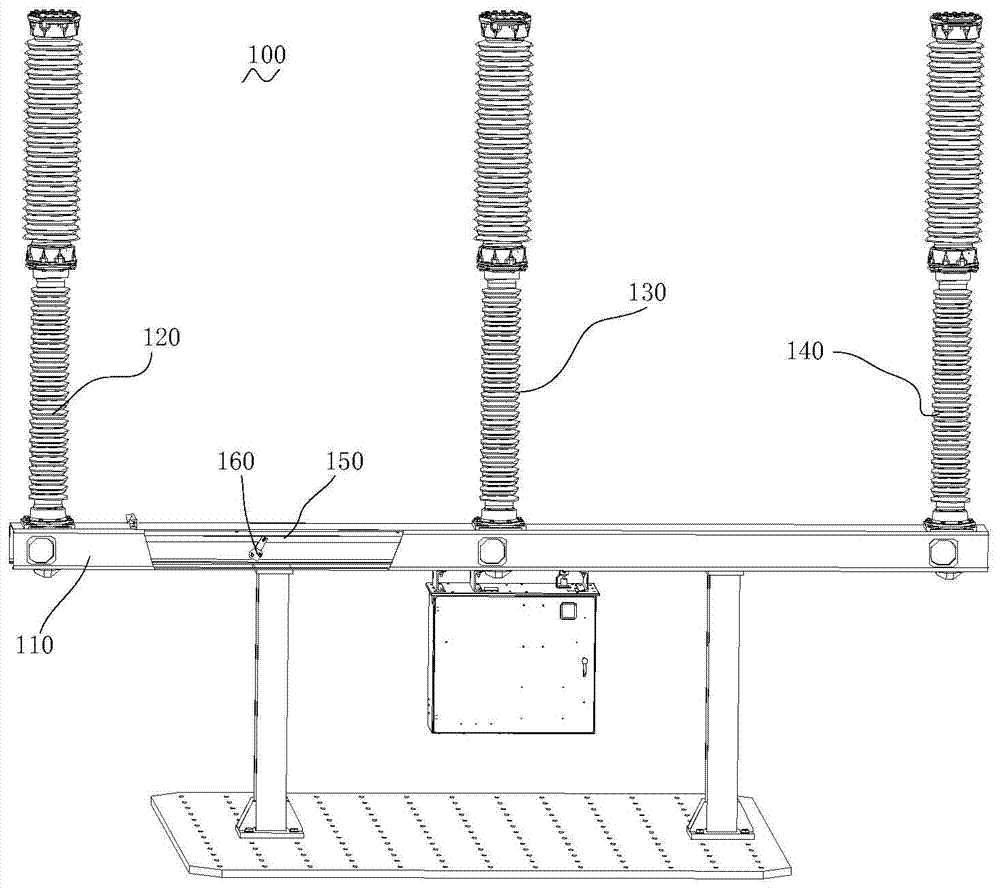

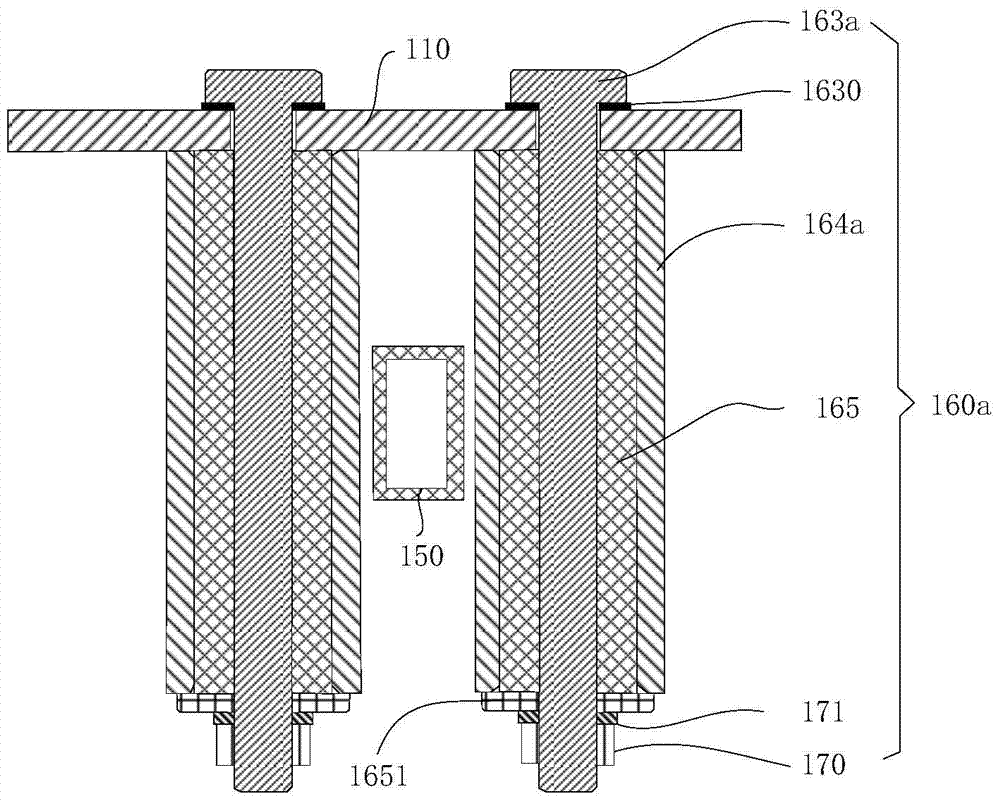

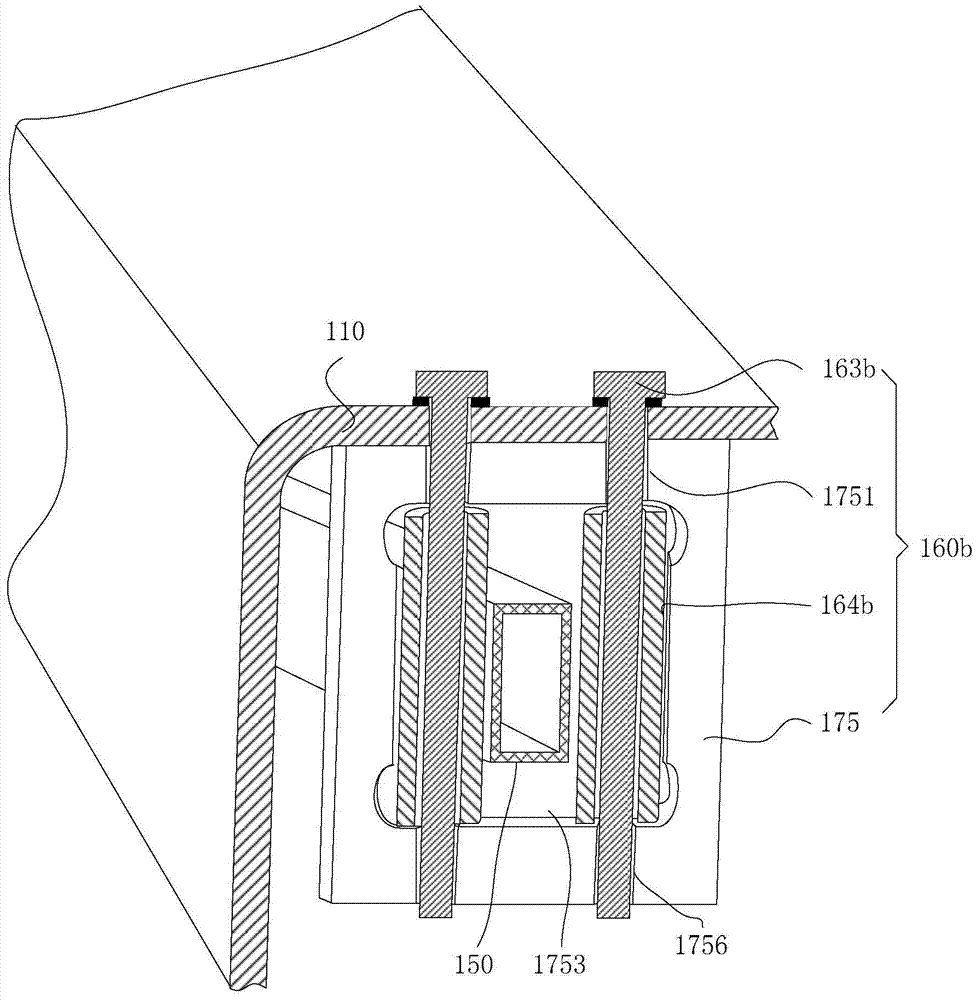

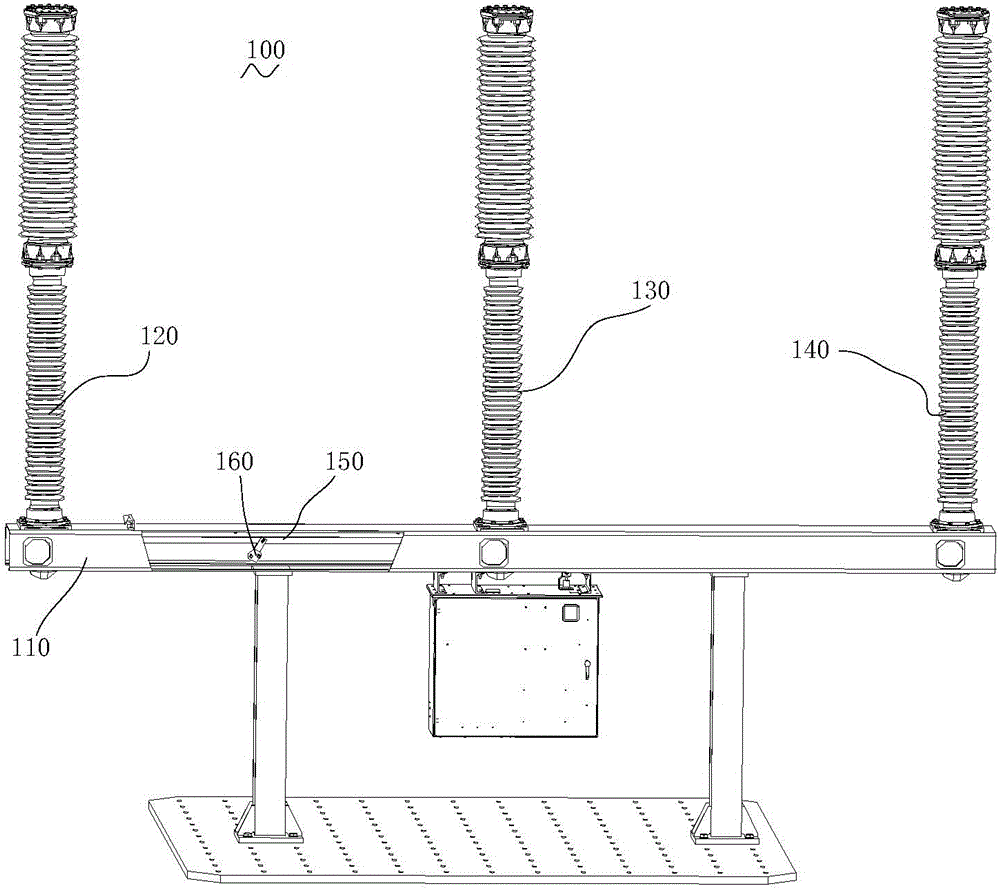

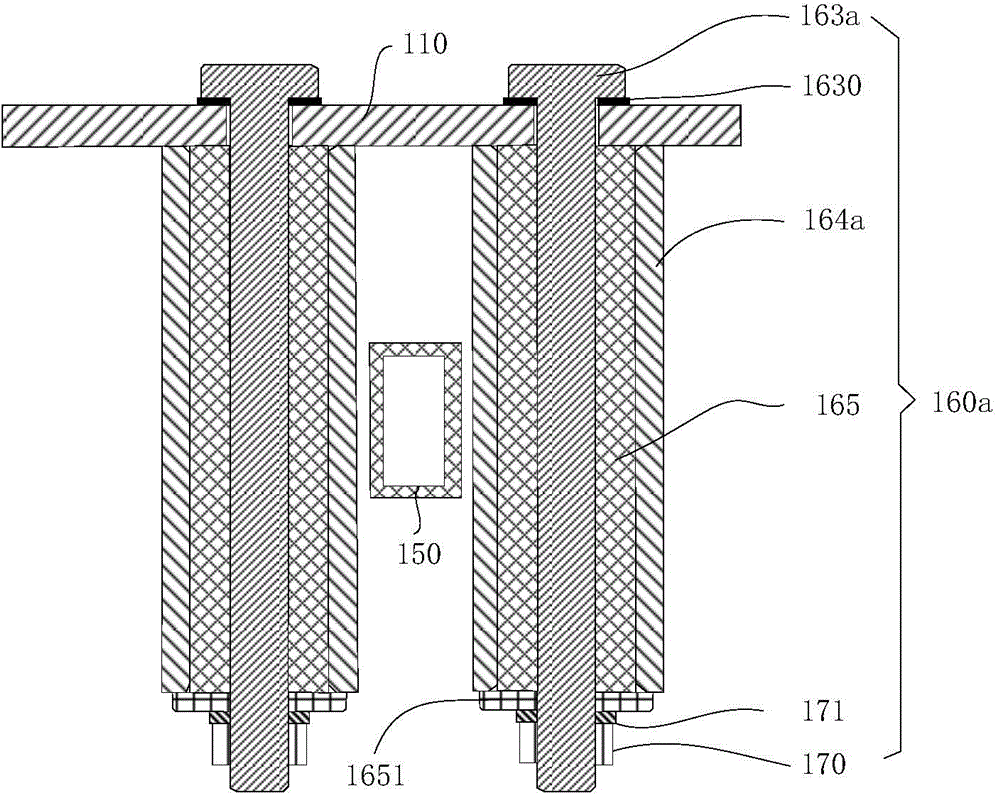

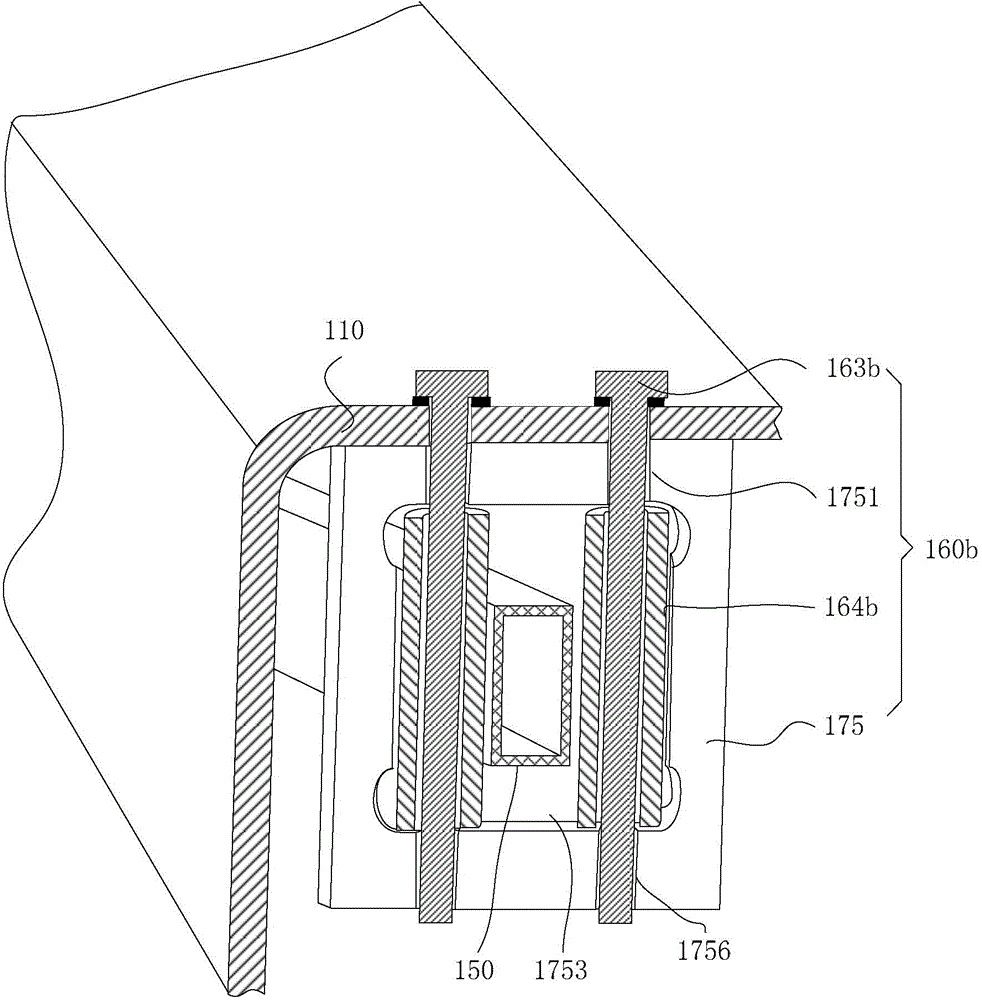

mechanical linkage circuit breaker

ActiveCN104882338BGuaranteed reliabilityGuaranteed stabilityHigh-tension/heavy-dress switchesProtective switch operating/release mechanismsEngineeringCircuit breaker

The present invention relates to a mechanical linkage circuit breaker, comprising a crossbeam and a pull rod, wherein the pull rod is disposed in the crossbeam. The mechanical linkage circuit breaker also comprises a guiding means. The guiding means comprises two load-bearing elements and two guide sleeves, wherein the load-bearing elements are fixed to the crossbeam and located on two sides of the pull rod. The guide sleeves surround the load-bearing elements, respectively, in a rotatable fashion and are spaced apart from the pull rod. Such a mechanical linkage circuit breaker has high reliability and stability.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

A Counter-wheel Spinning Device for Forming Cylindrical Parts with Different Diameters and Wall Thicknesses

ActiveCN106391807BSynchronization of axial movementImproved spinning accuracyTotal thicknessMechanical engineering

The invention discloses an opposite roller spinning device for forming tube-shaped pieces of different diameters and wall thicknesses, and relates to opposite roller spinning devices. The opposite roller spinning device aims to solve the problems that existing mold spinning equipment is high in mold cost, poor in universality and long in manufacturing cycle. According to the opposite roller spinning device for forming the tube-shaped pieces of different diameters and wall thicknesses, a rack is installed on a base, and a gear case is installed on the base; a spindle motor is connected with the input end of the gear case, and an eight-claw chuck is installed at the output end of the gear case; two lifting assemblies are installed at the two sides of the rack correspondingly; two screw nut connecting bases are installed on screw rods of one lifting assembly separately; one side of each screw nut connecting base is connected with a main sliding frame, and the other side of each screw nut connecting base is installed at one side of the rack in a sliding mode; the two main sliding frames are connected through an upper cross beam; and an inner rotation assembly penetrates through the upper cross beam to extend downwards to the position between the two main sliding frames, and an outer rotation assembly is installed between the two main sliding frames. The opposite roller spinning device is used for spinning thin-walled tube-shaped pieces.

Owner:HARBIN INST OF TECH

Mechanical linkage breaker

ActiveCN104882338AGuaranteed reliabilityGuaranteed stabilitySwitchgear arrangementsHigh-tension/heavy-dress switchesEngineeringCircuit breaker

The present invention relates to a mechanical linkage circuit breaker, comprising a crossbeam and a pull rod, wherein the pull rod is disposed in the crossbeam. The mechanical linkage circuit breaker also comprises a guiding means. The guiding means comprises two load-bearing elements and two guide sleeves, wherein the load-bearing elements are fixed to the crossbeam and located on two sides of the pull rod. The guide sleeves surround the load-bearing elements, respectively, in a rotatable fashion and are spaced apart from the pull rod. Such a mechanical linkage circuit breaker has high reliability and stability.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com