Blind rivet type thin-wall bush with countersunk head and forming method of thin-wall bush

A countersunk head and bushing technology, which is applied in the field of thin-walled bushings with countersunk head nails and its forming, can solve the problem of being unable to manufacture thin-walled bushings that require high-precision interference installation and connection, which affects the precise control of interference and accumulation Problems such as excess metal can be solved to improve product forming quality, prevent instability and deformation, and improve product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

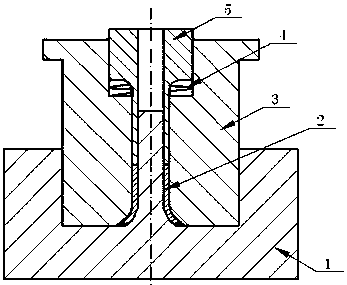

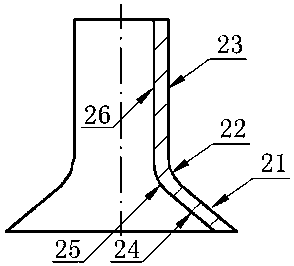

[0035] A thin-walled bushing with a countersunk head, including a base 1, a bushing 2, a male die 3 and a pressure-relief sleeve 5, the male die 3 is arranged on the base 1, and the base 1 and the male die 3 are A bushing 2 is provided, the pressure relief sleeve 5 is arranged on the upper side of the male mold 3, a spring 4 is provided between the male mold 3 and the pressure relief sleeve 5, and the base 1 includes a countersunk profile 12 and a central axis 14. The central axis 14 is set vertically upward at the center of the countersunk profile 12, the top of the central axis 14 is chamfered 15, and the connection between the central axis 14 and the countersunk profile 12 is a circle Angle 13 structure, the bushing 2 includes a bushing pipe outer wall 23 and a bushing pipe inner wall 26, the top and center of the bushing pipe outer wall 26 are provided with a bushing countersunk head outer angle surface 21 and a countersunk head outer rounded corner 22, the top and center ...

Embodiment 2

[0051]A thin-walled bushing with a countersunk head, including a base 1, a bushing 2, a male die 3 and a pressure-relief sleeve 5, the male die 3 is arranged on the base 1, and the base 1 and the male die 3 are A bushing 2 is provided, the pressure relief sleeve 5 is arranged on the upper side of the male mold 3, a spring 4 is provided between the male mold 3 and the pressure relief sleeve 5, and the base 1 includes a countersunk profile 12 and a central axis 14. The central axis 14 is set vertically upward at the center of the countersunk profile 12, the top of the central axis 14 is chamfered 15, and the connection between the central axis 14 and the countersunk profile 12 is a circle Angle 13 structure, the bushing 2 includes a bushing pipe outer wall 23 and a bushing pipe inner wall 26, the top and center of the bushing pipe outer wall 26 are provided with a bushing countersunk head outer angle surface 21 and a countersunk head outer rounded corner 22, the top and center o...

Embodiment 3

[0067] A thin-walled bushing with a countersunk head, including a base 1, a bushing 2, a male die 3 and a pressure-relief sleeve 5, the male die 3 is arranged on the base 1, and the base 1 and the male die 3 are A bushing 2 is provided, the pressure relief sleeve 5 is arranged on the upper side of the male mold 3, a spring 4 is provided between the male mold 3 and the pressure relief sleeve 5, and the base 1 includes a countersunk profile 12 and a central axis 14. The central axis 14 is set vertically upward at the center of the countersunk profile 12, the top of the central axis 14 is chamfered 15, and the connection between the central axis 14 and the countersunk profile 12 is a circle Angle 13 structure, the bushing 2 includes a bushing pipe outer wall 23 and a bushing pipe inner wall 26, the top and center of the bushing pipe outer wall 26 are provided with a bushing countersunk head outer angle surface 21 and a countersunk head outer rounded corner 22, the top and center ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com