Construction method for preventing instability of shield tunnel under high-sensitivity stratum conditions

A technology with high sensitivity and ground conditions, applied in tunnels, tunnel linings, underground chambers, etc., can solve problems such as tunnel surges, formulate targeted measures, and tunnel damage, so as to improve the ability to withstand external forces and reduce construction investment costs , the effect of improving the overall stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

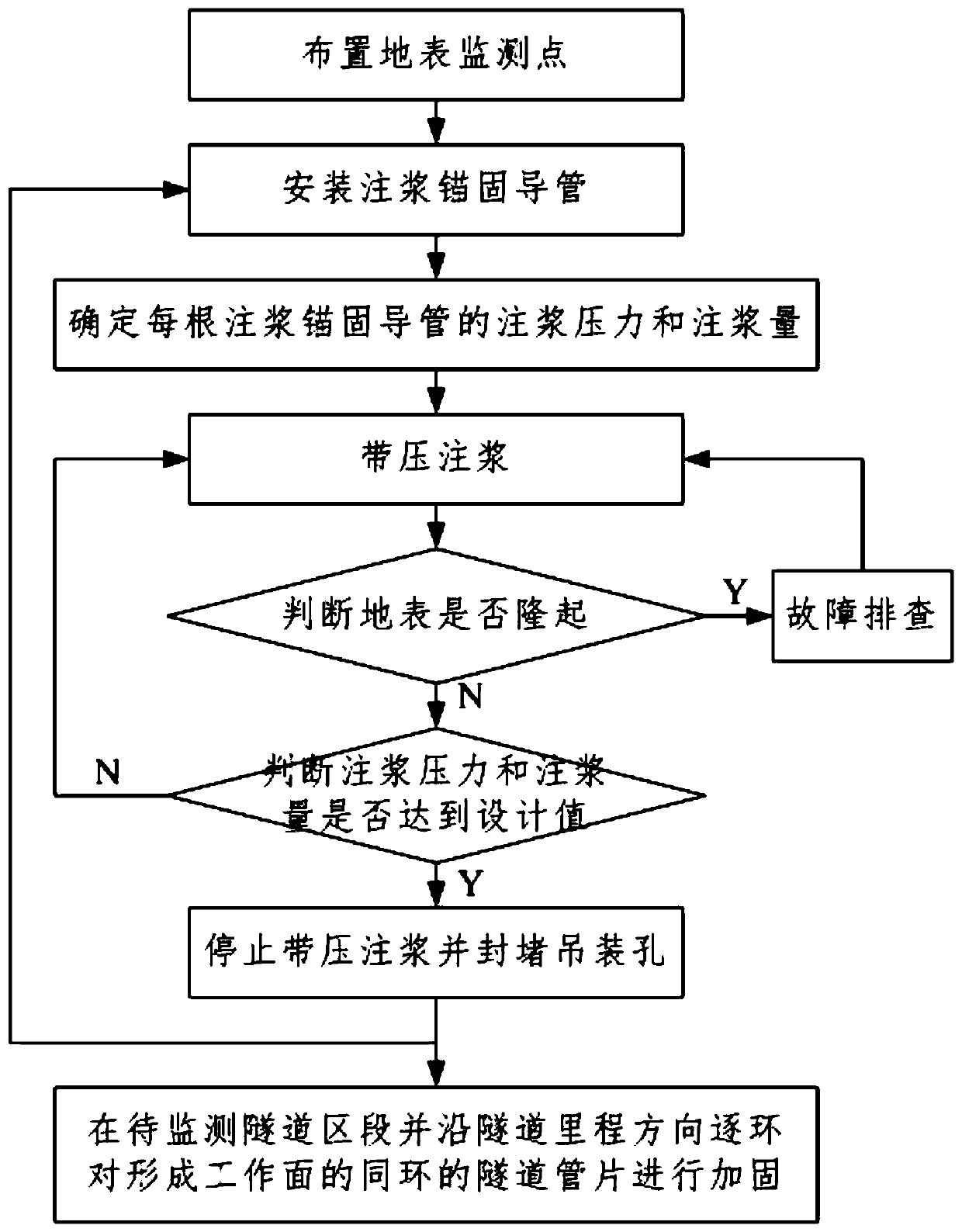

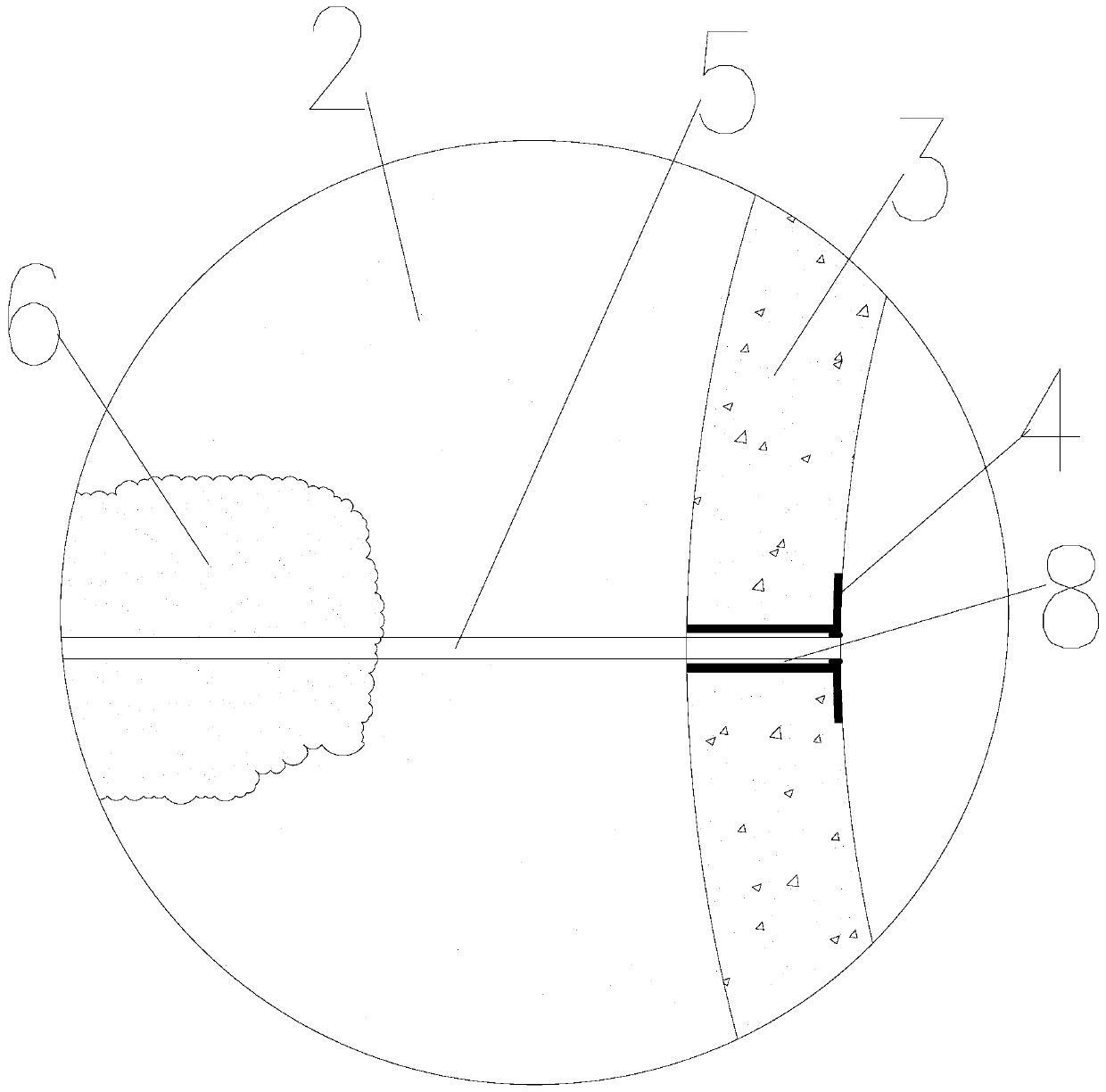

[0044] Such as Figure 1 to Figure 4 As shown, a construction method of the present invention for preventing the instability of a shield tunnel under high-sensitivity ground conditions includes the following steps:

[0045] Step 1. Layout of surface monitoring points: bury multiple position sensors 7 in an array on the ground 1 facing the tunnel section to be monitored. The ground surface area enclosed by the multiple position sensors 7 covers the tunnel section to be monitored and its anchoring area Projected area on the ground;

[0046] The tunnel sections to be monitored are the front N-ring lining segment section of the shield originating tunnel and the rear N-ring lining segment section of the shield receiving end tunnel, where N is a positive integer;

[0047] In this embodiment, the value range of N is 10-20.

[0048] In this embodiment, the position sensor 7 is a linear displacement sensor.

[0049] Step 2: Install grouting anchor pipes: Six grouting anchor pipes 5 are pressed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com