Pile foundation box type retaining wall

A technology for retaining walls and pile foundations, which can be used in infrastructure engineering, water conservancy projects, artificial islands, etc., and can solve problems such as increasing the amount of reinforced concrete, difficulty in fully compacting the backfill of the wall, and large bending moments at the lower part of the vertical wall. Achieve the effect of reducing project cost, reducing the amount of reinforced concrete, and saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

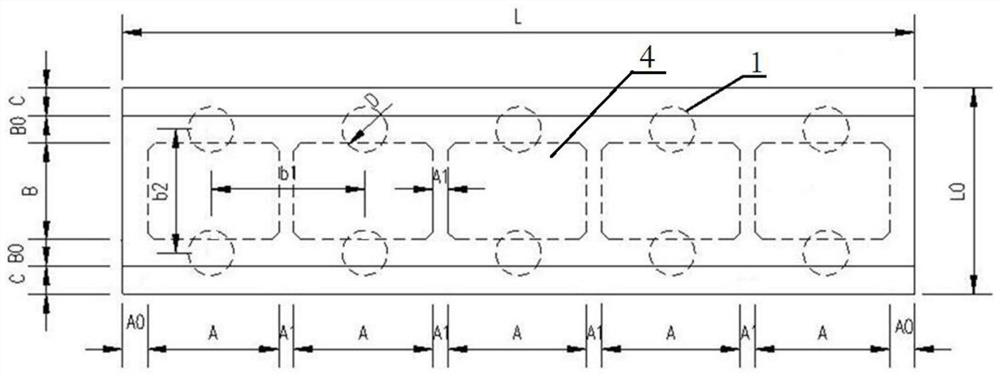

[0032] Such as figure 1 As shown, the present invention provides a pile-based box-type retaining wall, which includes a box 4, a cap 3, a cushion 2, and a foundation pile 1; a box 4, a cap 3, a cushion 2, and a foundation pile 1 The interior of the four components is connected as a whole by steel bars; the box body 4 is consolidated on the cap 3 and is in the form of a cuboid, which is used to bear lateral loads, support roadbed filling or hillside soil, and prevent filling or hillside soil Deformed and unstable subject. The bearing platform 3 is consolidated on the cushion layer 2 and is a component for transmitting and distributing loads.

[0033] Such as figure 2 As mentioned above, the cushion layer 2 is consolidated on the top of the foundation pile 1 to level the horizontal position.

[0034] Such as image 3 As mentioned above, the foundation piles 1 are poured in the foundation, and can be designed as circular bored piles or rectangular artificially dug piles. Th...

Embodiment 2

[0041] The experimental road is the ring bridge project of Luoze River connection line in Yiliang County, Zhaotong City, Yunnan Province. It adopts the fourth-class road standard, the roadbed width is 20m, and the design speed is 20km / h. The project is located at the junction of Luoze River, Fafa River and Xiaomi River. On the west side of the county seat, combined with the surrounding topography, ground objects and geological bodies, the pile foundation box type retaining wall of the present invention is designed and adopted, and good economic and social benefits have been obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com