Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47results about How to "Precise control of movement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

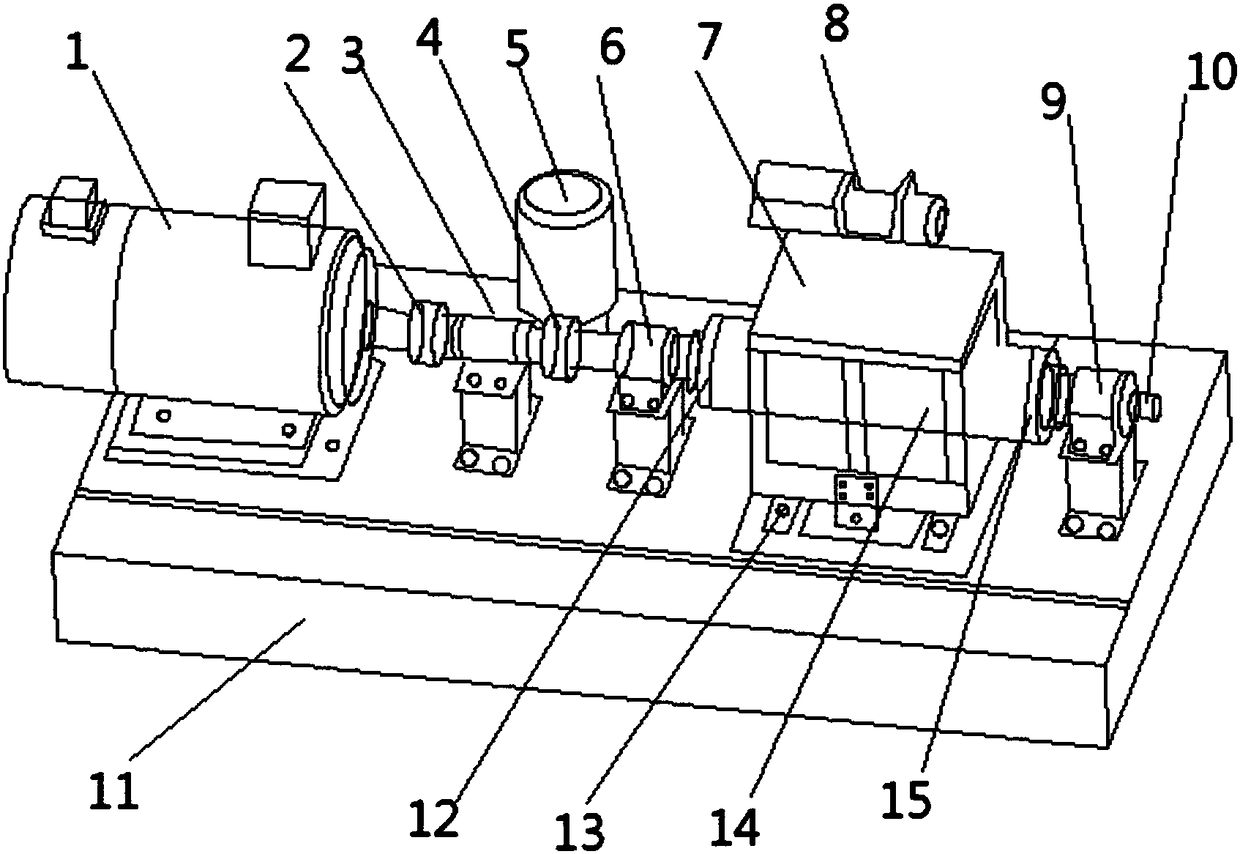

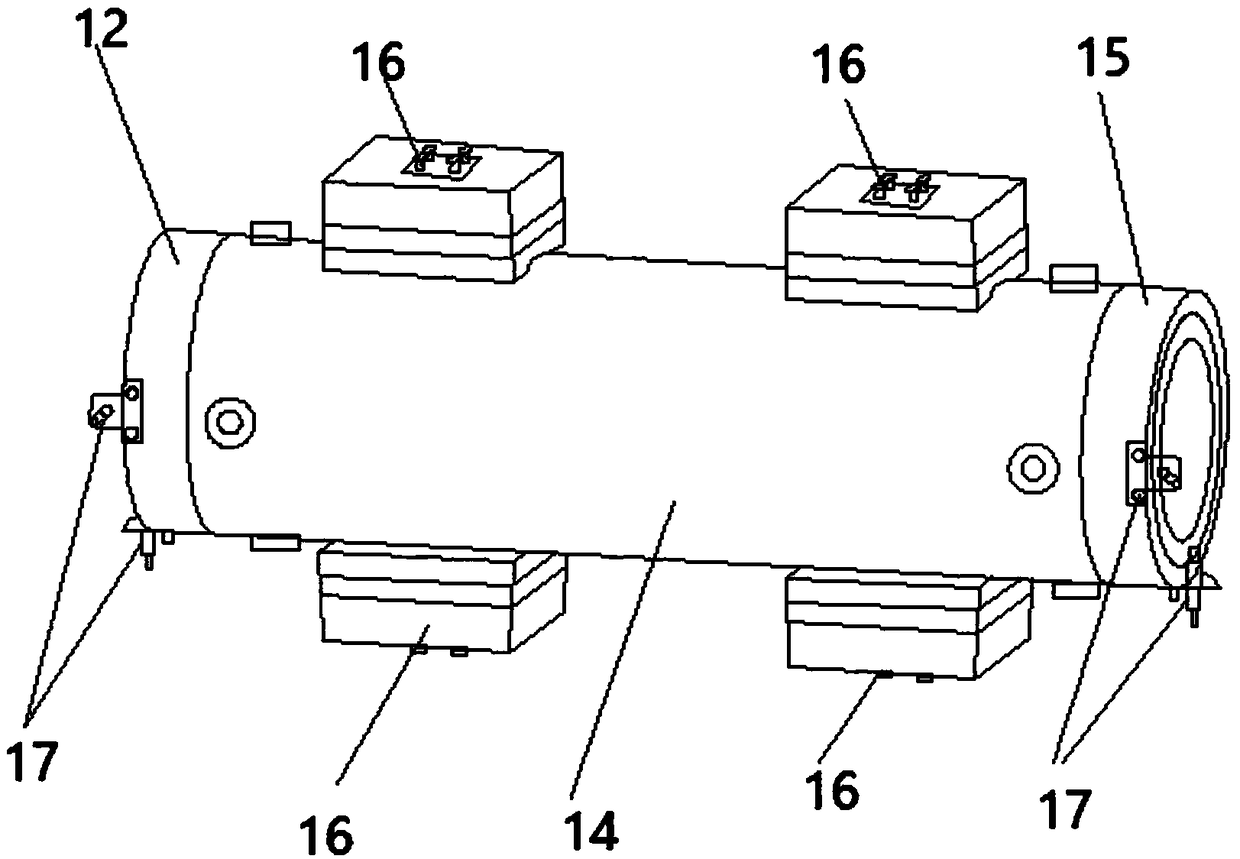

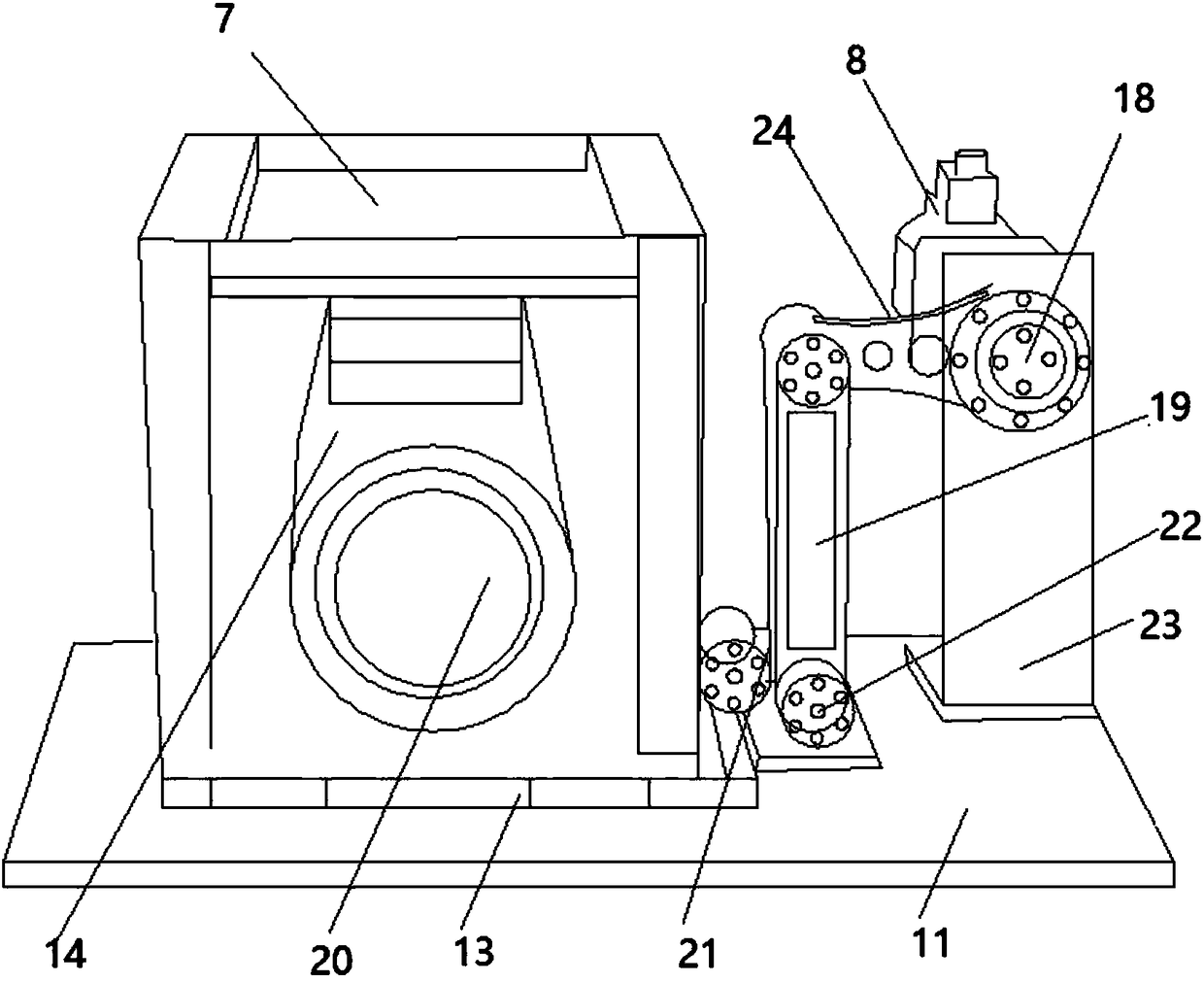

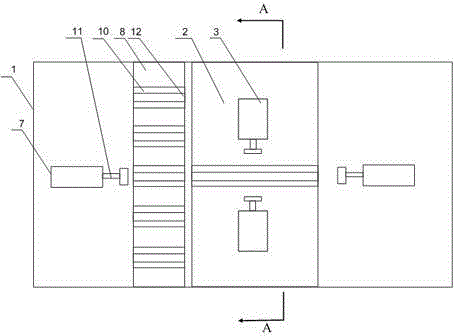

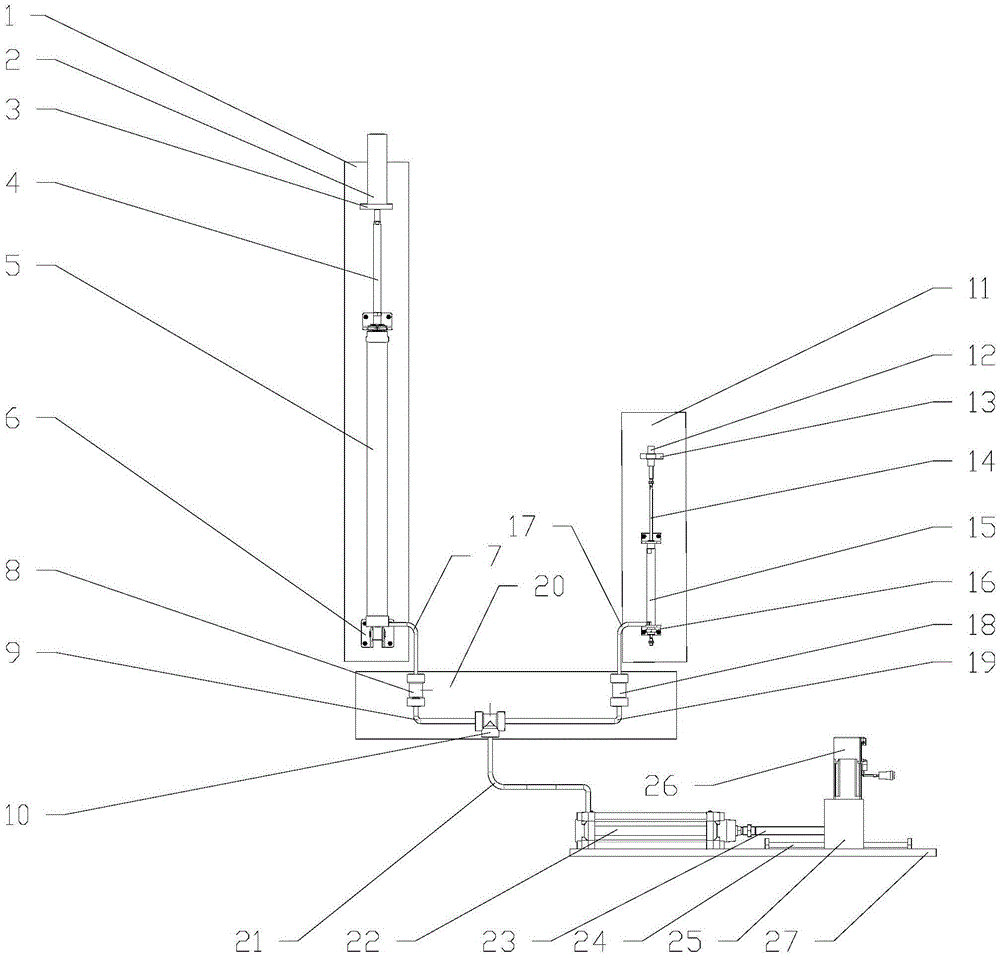

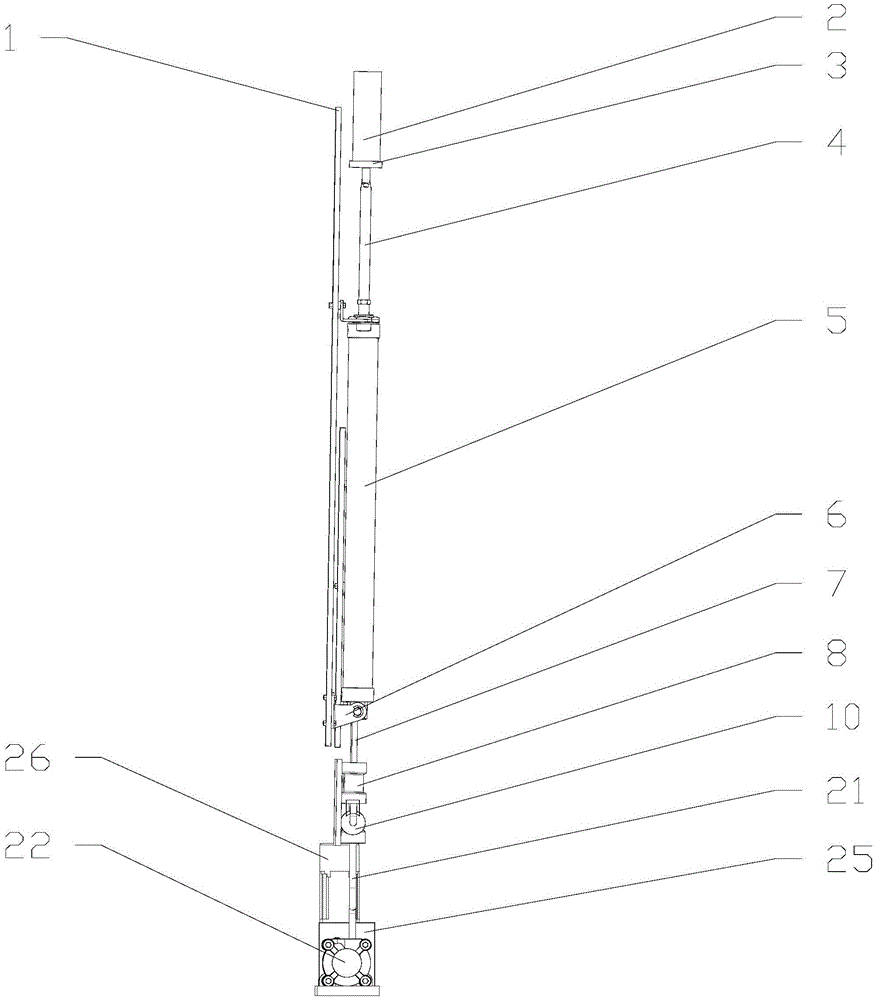

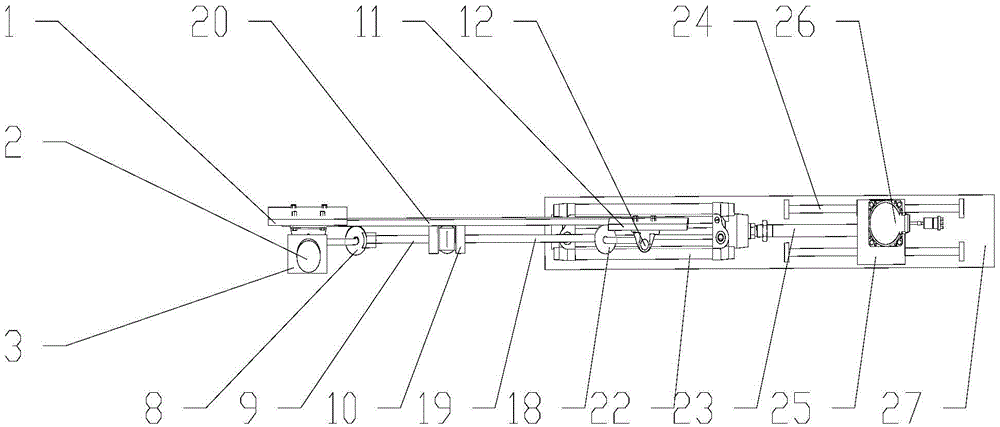

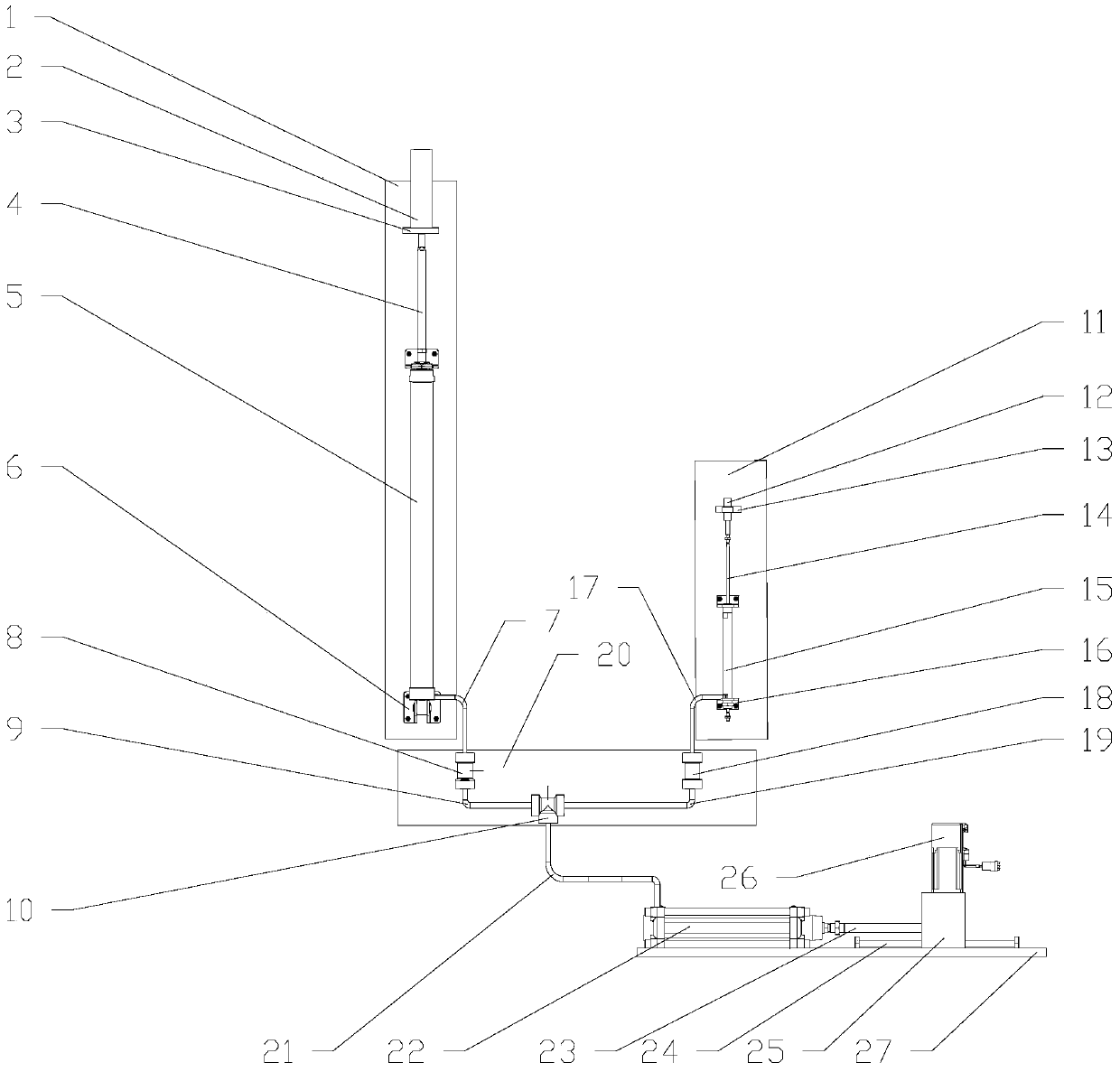

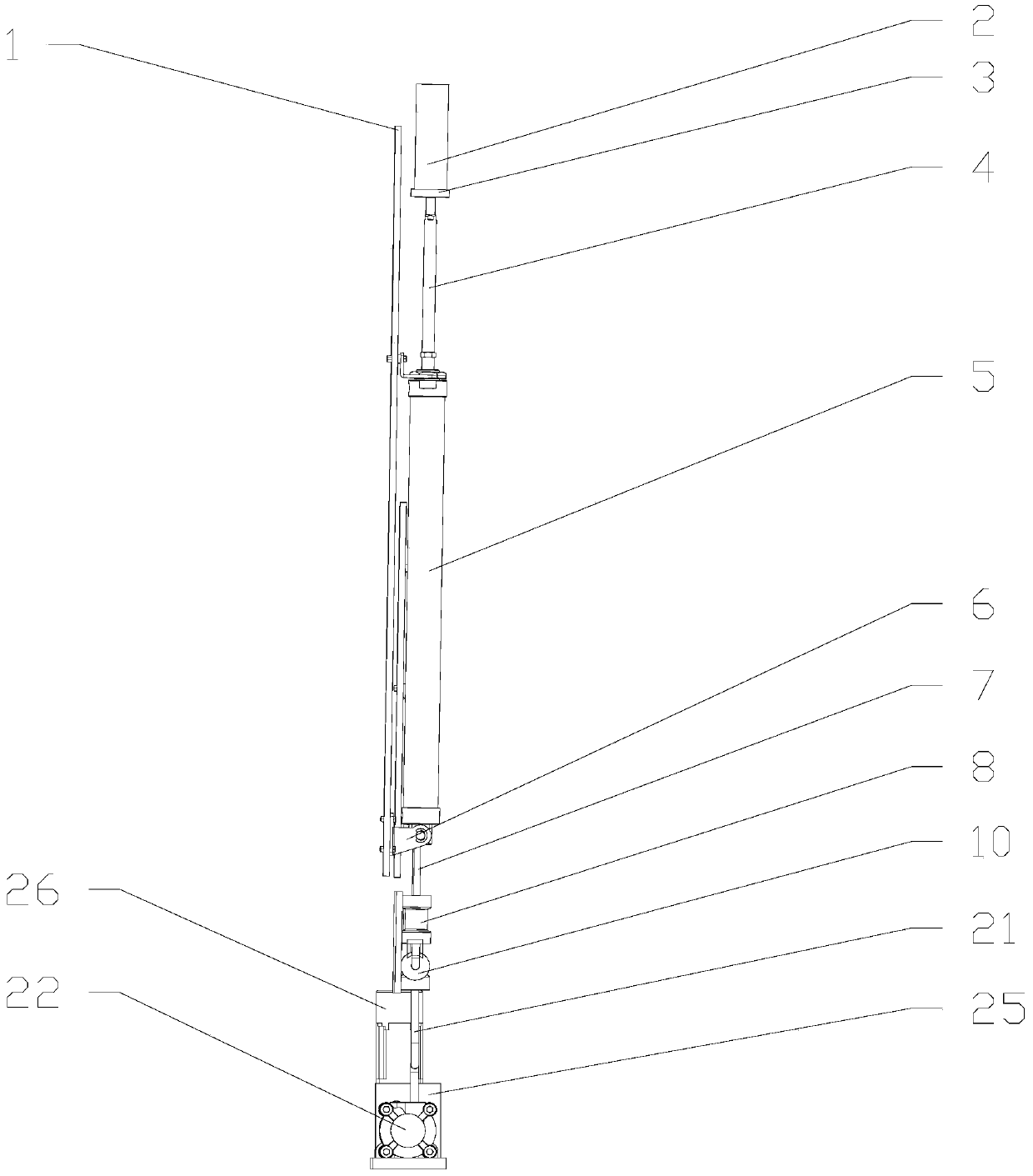

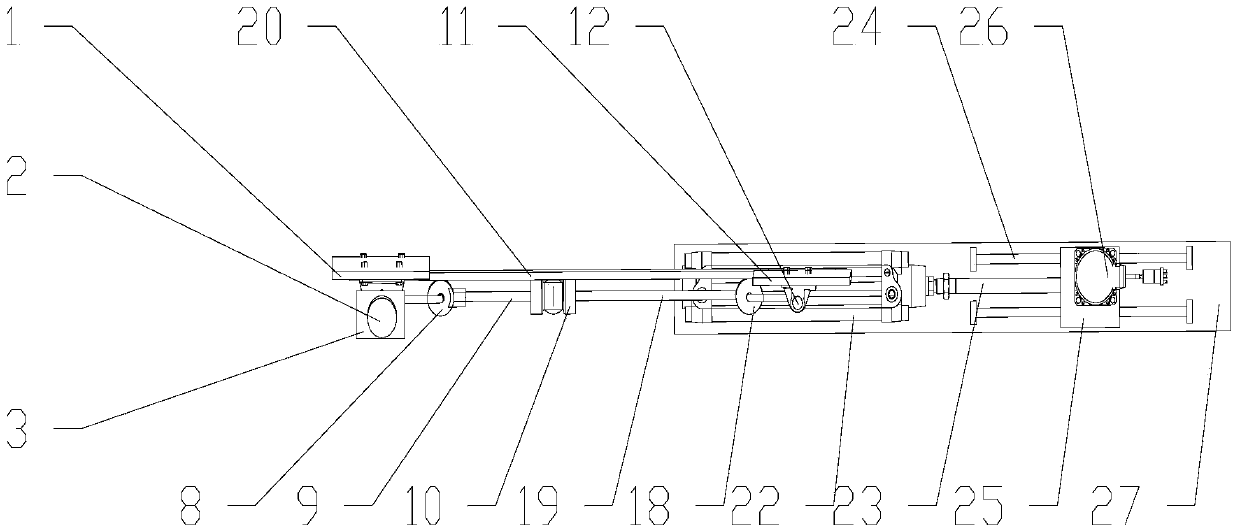

Water lubrication rubber bearing performance test stand and test method thereof

PendingCN108106847ATest operating characteristicsImplement dynamic loadingMachine gearing/transmission testingMachine bearings testingInterference resistanceDrive shaft

The invention discloses a water lubrication rubber bearing performance test stand and a test method thereof. The test stand consists of five portions. A driving portion comprises a variable-frequencymotor, a coupler, a driving shaft, a front supporting bearing and a rear supporting bearing which are successively connected with one another; a water lubrication rubber bearing portion comprises a water lubrication rubber bearing and an outer bearing sleeve, and the bearing sleeve is connected with an outer supporting framework by virtue of a three-shaft force sensor; a loading portion comprisesa supporting framework arranged on a guide rail, as well as a rocker bar mechanism and a shock excitation motor with an eccentric wheel which are connected with the supporting framework in sequence; acontrol test portion comprises a control cabinet, a sensor, a current collection ring, a data acquisition system and the like; and an auxiliary portion comprises a circulating water system, a sealingapparatus, a supporting seat and the like. The driving shaft rotates in the water lubrication rubber bearing, and the static or dynamic loading for the water lubrication rubber bearing can be realized by virtue of the loading system. The water lubrication rubber bearing performance test stand can be used for testing the performance of the water lubrication rubber bearing and is high in interference resistance.

Owner:XIAN UNIV OF SCI & TECH

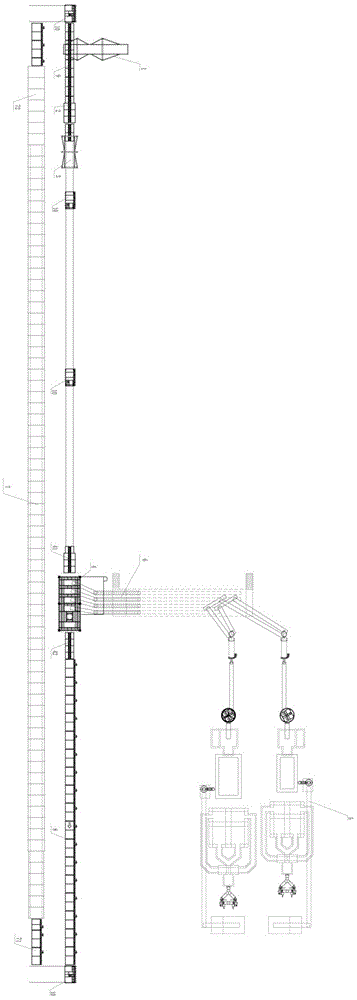

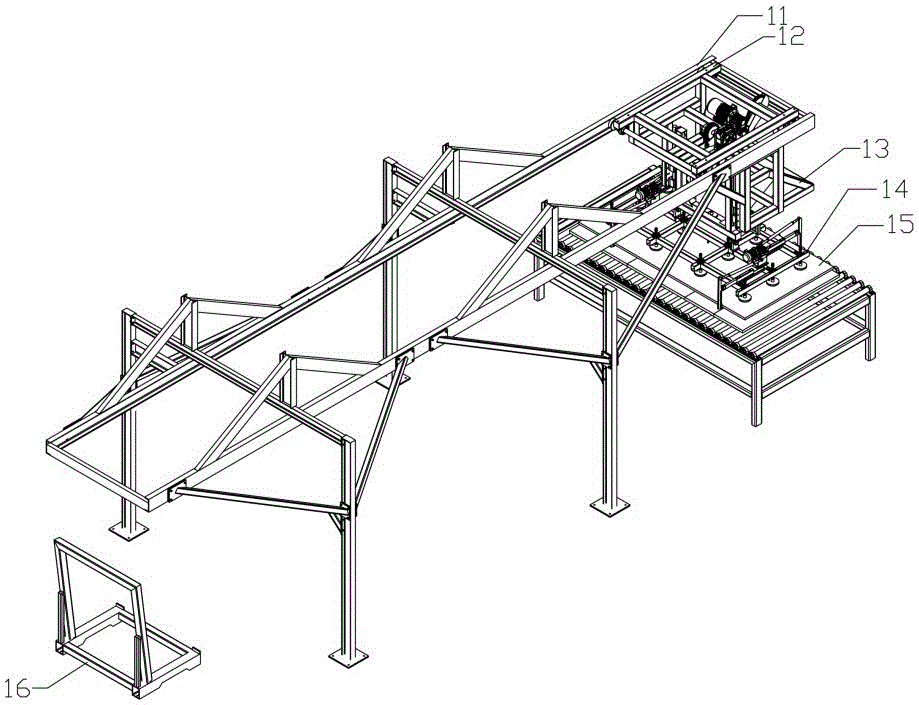

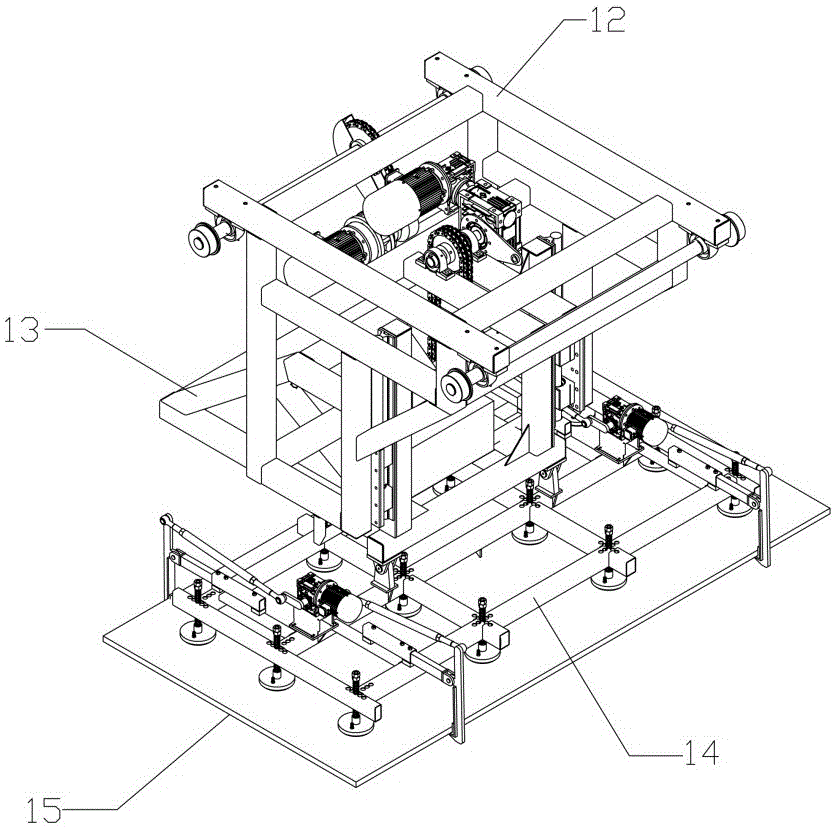

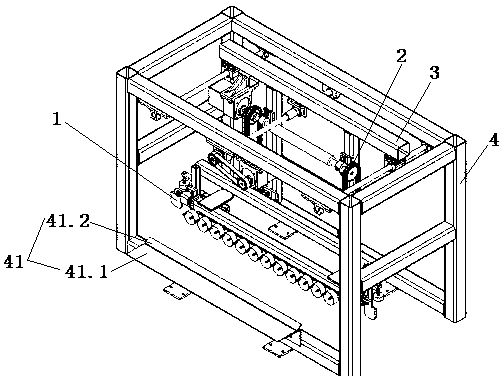

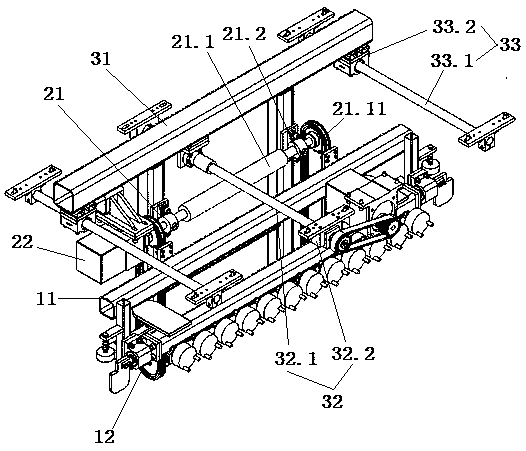

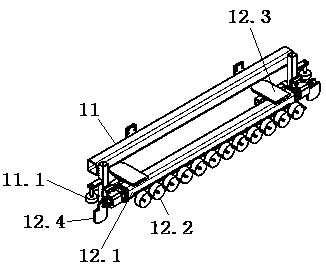

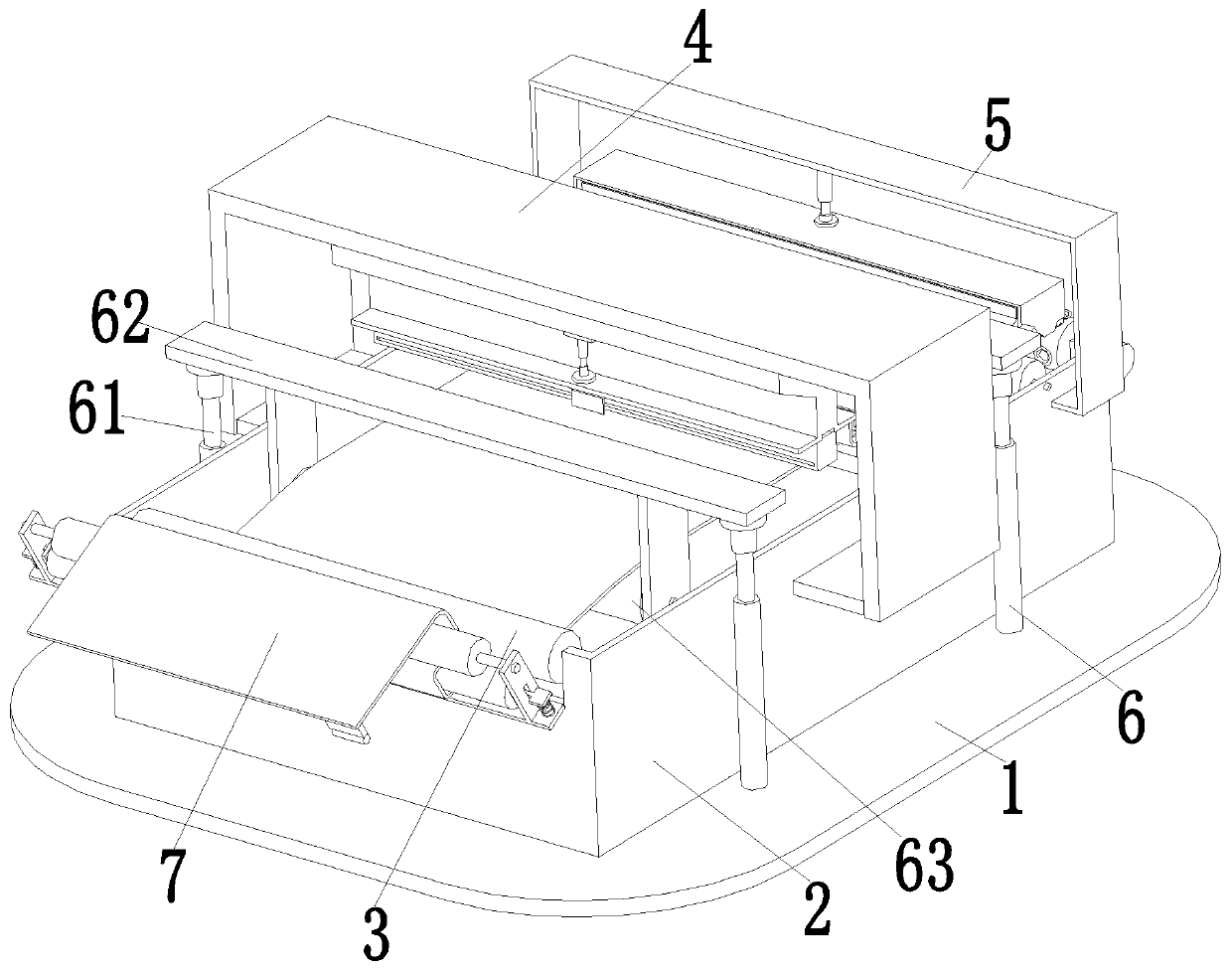

Highly automatic plate-overturning and plate-picking production line for producing large-size decorative plates

The invention discloses a highly automatic plate-overturning and plate-picking production line for producing large-size decorative plates. The highly automatic plate-overturning and plate-picking production line comprises a material mixing machine set, a material distribution mechanism, a kiln, a kiln tail fixed roller table, a kiln furniture, a plate-picking mechanism, a deviation-correcting mechanism and an overturning mechanism, wherein a belt conveyor is disposed between the material mixing unit and the material distribution mechanism; an inlet and an outlet of a material distribution machine position of the material distribution mechanism are respectively equipped with a deviation-correcting roller table and a receiving roller table; the other end of the receiving roller table is connected with a conveying roller table in a matching manner; a kiln inlet and a kiln outlet are respectively equipped with a kiln-incoming roller table and a kiln-outgoing roller table; shuttling roller tables are disposed between the kiln-incoming roller table and the conveying roller table and are used for conveying in a matching manner; the kiln-outgoing roller table is equipped with the shuttling roller tables and the kiln tail fixed roller table which are used for conveying in a matching manner; the kiln tail fixed roller table is sequentially matched with the plate-picking mechanism and the deviation-correcting mechanism for conveying along the movement direction of rollers; and the overturning mechanism and the shuttling roller tables are also disposed between the kiln tail fixed roller table and the deviation-correcting roller table.

Owner:佛山市创瓷窑炉有限公司

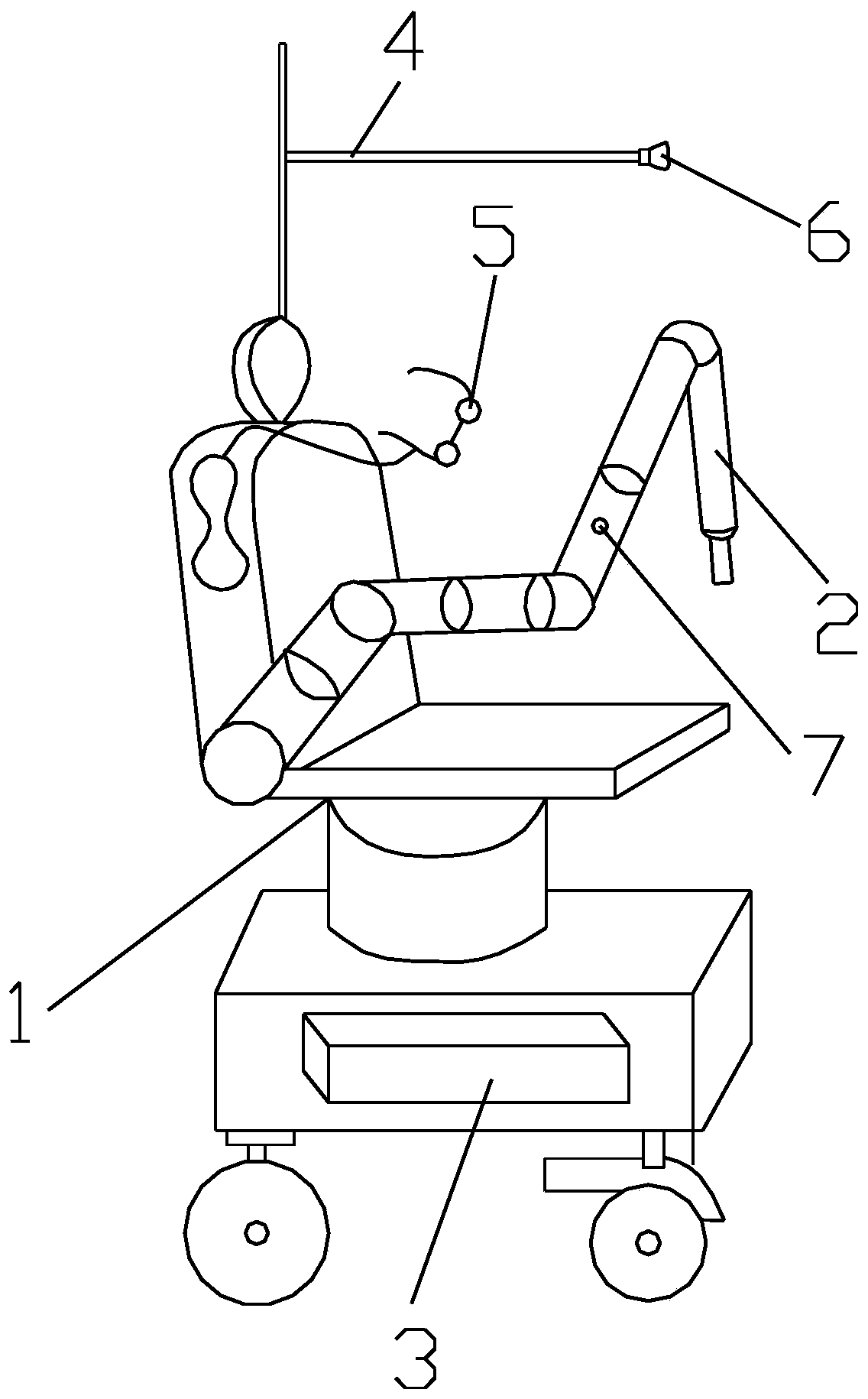

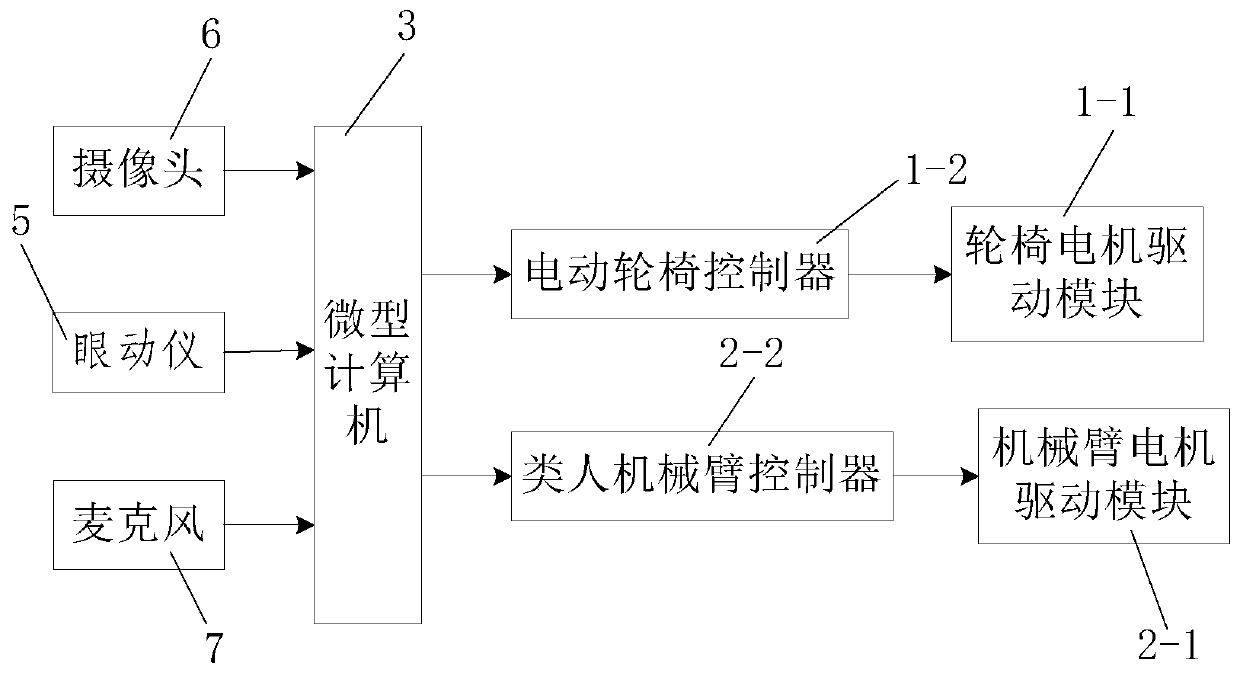

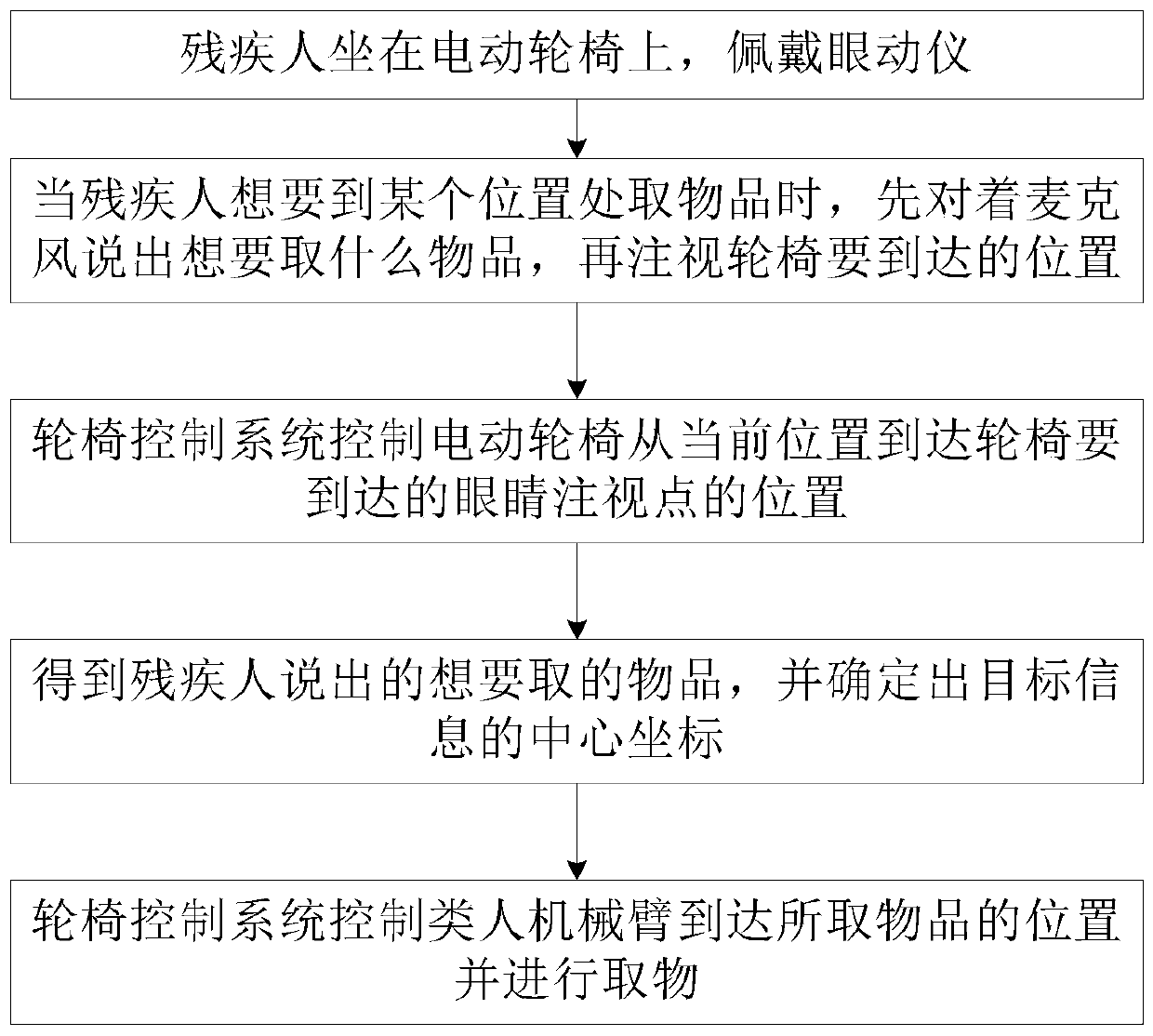

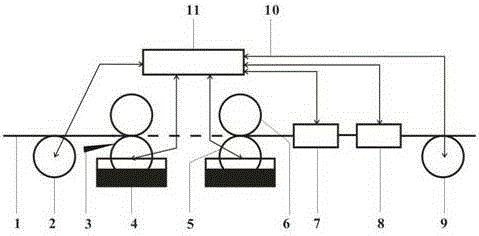

Wheelchair with object-taking function and control method thereof

ActiveCN109875777AHigh acquisition frequencyHigh precisionInput/output for user-computer interactionWheelchairs/patient conveyanceMicrocomputerPower wheelchairs

The invention discloses a wheelchair with an object-taking function and a control method thereof. The wheelchair includes an electric wheelchair, a humanoid robotic arm and a wheelchair control system, and the wheelchair control system includes an eye tracker, a microcomputer, a camera, and a microphone. The method for controlling the object taking includes the steps of: 1. the disabled person sits in the electric wheelchair and wears the eye tracker; 2. the disabled person firstly speaks to the microphone to tell what item he wants to take, and then looks at the position where the wheelchairis to arrive; 3. the wheelchair control system controls the position of an eye gaze point that the electric wheelchair needs to reach from the current position to the wheelchair; 4, the item that thedisabled person wants to take is obtained, and the center coordinate of the target information is determined; and 5. the wheelchair control system controls the humanoid robotic arm to reach the position of the item and take the object. The wheelchair has novel and reasonable design and high control precision, so that the electric wheelchair and the humanoid robotic arm can automatically assist thedisabled person to take things, which greatly facilitates the life of the disabled person and has strong practicability.

Owner:XIAN UNIV OF SCI & TECH

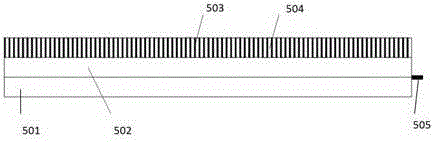

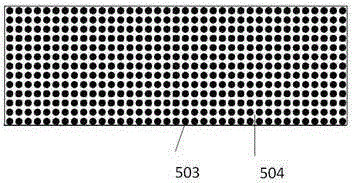

Intelligent electronic intaglio-printing-roll printing system and plate making method

ActiveCN105252883AEliminate plate making processSave plate making materialsRotary intaglio printing pressForme preparationCeramicElectricity

The invention discloses an intelligent electronic intaglio-printing-roll printing system and a plate making method. The system comprises a printing stock, a conveying and winding device, an ink scraping device, an ink tank, an intaglio printing roll, an impression cylinder, a locating and aligning device, a curing device, a winding device, a connection line and an upper computer. According to the intelligent electronic intaglio-printing-roll printing system, according to the graphic information of an original manuscript, piezoelectric ceramics in all ink cells are controlled in real time through the upper computer to be deformed, so that corresponding patterns are formed on the intaglio printing roll, and the plate making step is omitted; the ink cells of the intaglio printing roll can be changed in real time, electronic printing products with different circuit patterns or different breadths are printed, and multi-printing is achieved through one roll; and multiple plate making processes are omitted, plate making materials are saved, and environment-friendly printing is achieved.

Owner:HUBEI ZHONGXIN JINGHUA COLOR PRINTING

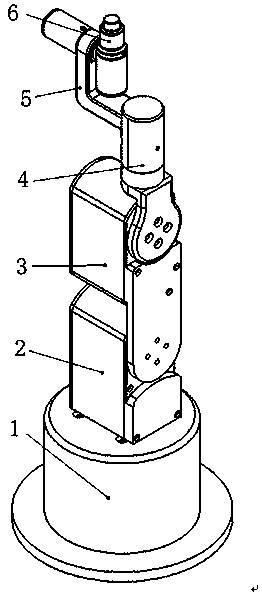

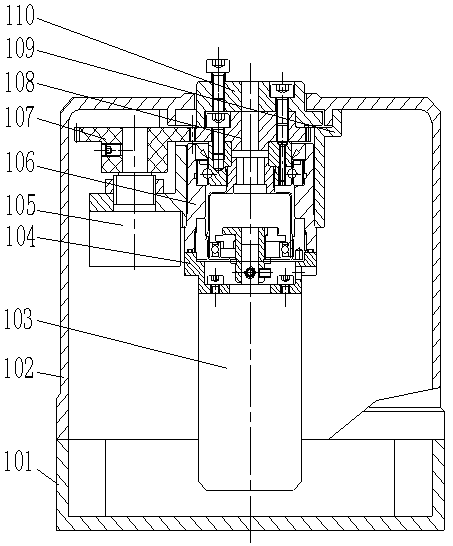

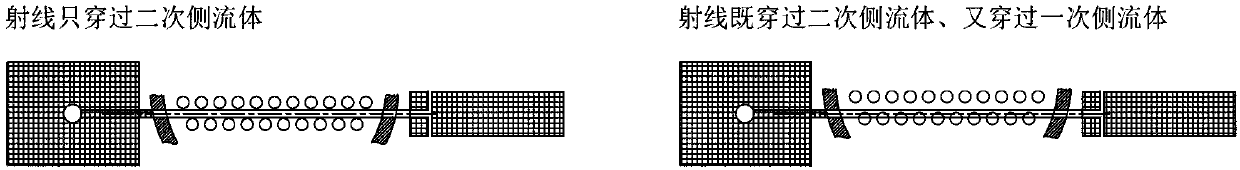

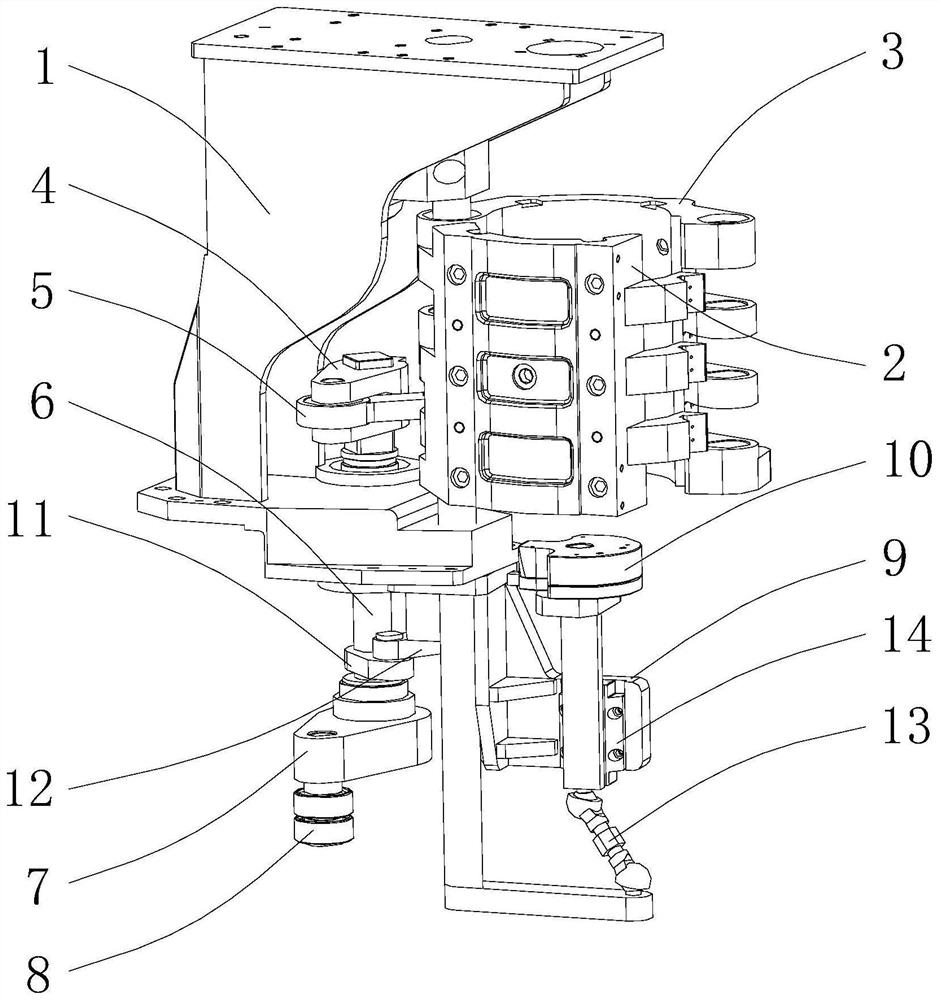

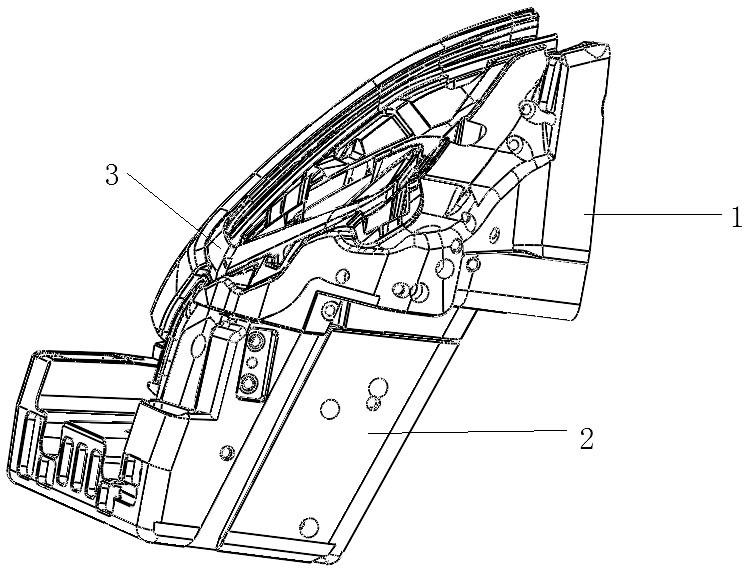

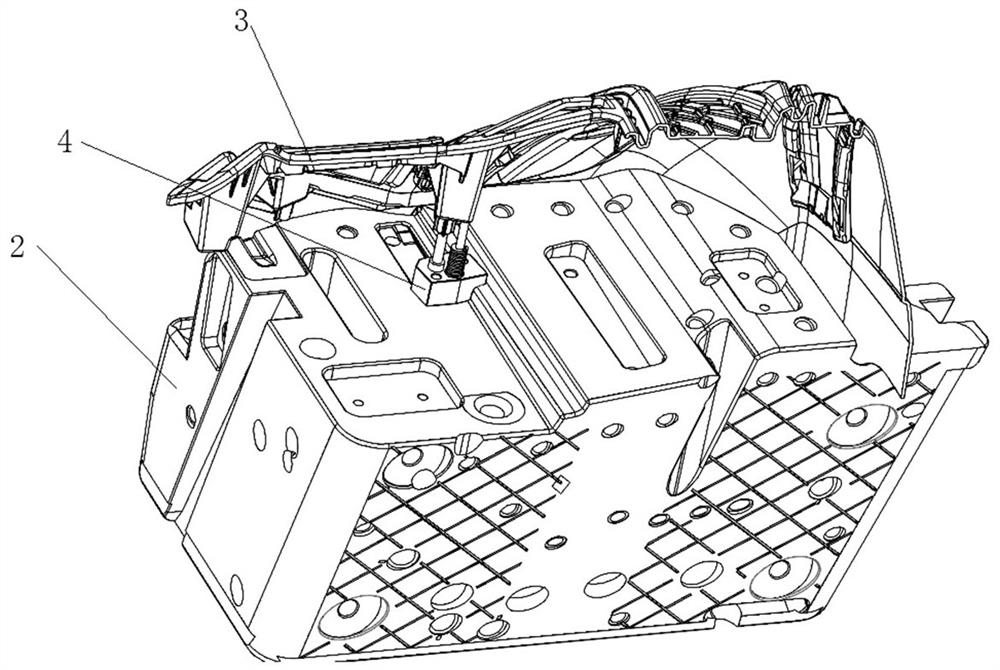

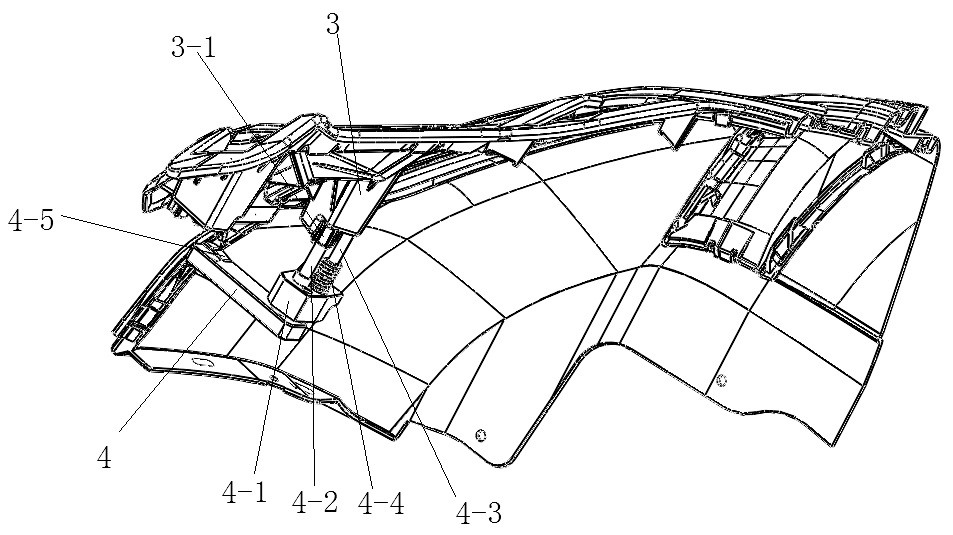

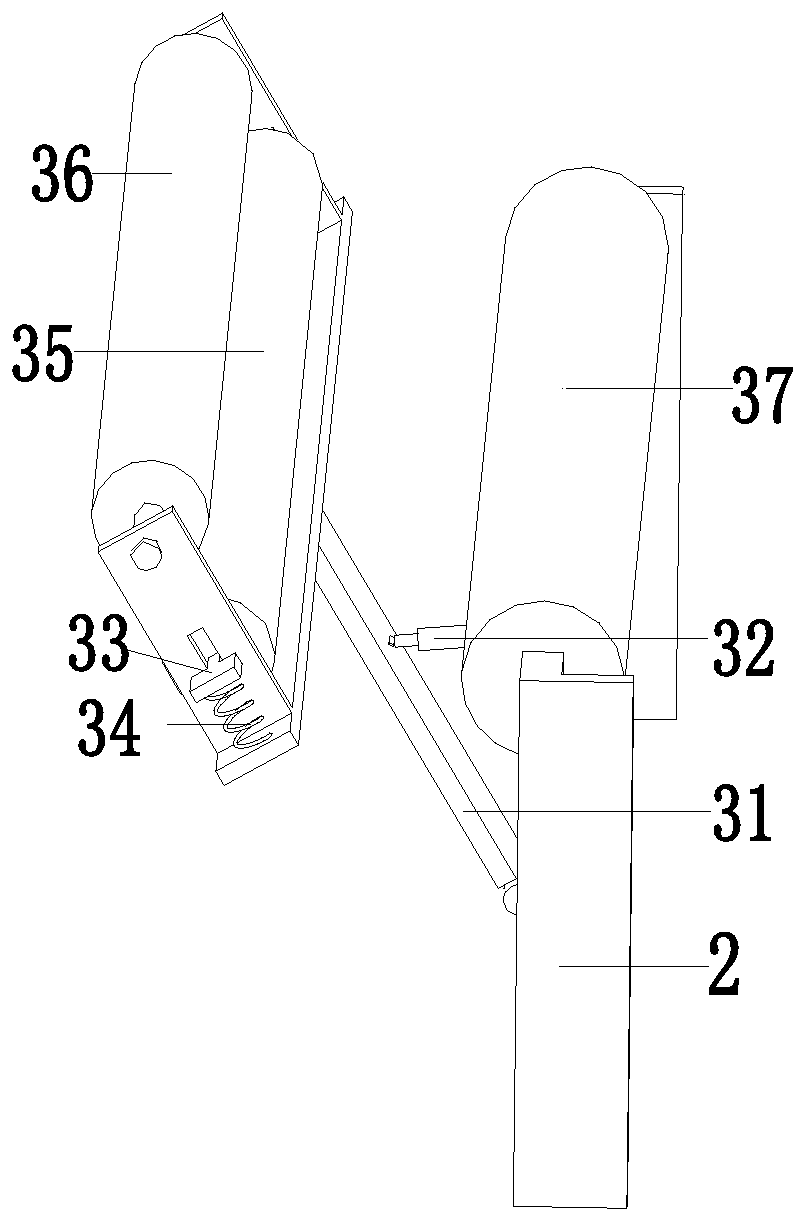

Force-feedback teleoperation main hand

PendingCN108161883APrecise control of movementAvoid linkageProgramme-controlled manipulatorEngineeringTeleoperation

The invention discloses a force-feedback teleoperation main hand. The force-feedback teleoperation main hand comprises a first connecting rod part, a second connecting rod part, a third connecting rodpart, a fourth connecting rod part, a fifth connecting rod part and a knob part which are sequentially connected, all the connecting rod parts are connected through rotating joints, a potentiometer or an encoder is mounted on each rotating joint, wherein motors and decelerators are mounted at the rotating joints among the first connecting rod part, the second connecting rod part and the third connecting rod part; and the motors are connected with the input ends of the decelerators or the motors and input ends of the decelerators are in transmission connection through synchronous belts, and the output ends of the decelerators are connected with the corresponding potentiometers or the encoders. The force-feedback teleoperation main hand can be fixed for being used, and can also be carried by an operator for moving type operation, movement of all the joints can be controlled by fully using flexibility of human hands, and operation is accurate; and the three joints at the tail ends are compactly laid out together, the structure is small and exquisite, and operating space and flexibility of fingers can be fully used.

Owner:SHANDONG YOUBAOTE INTELLIGENT ROBOTICS CO LTD

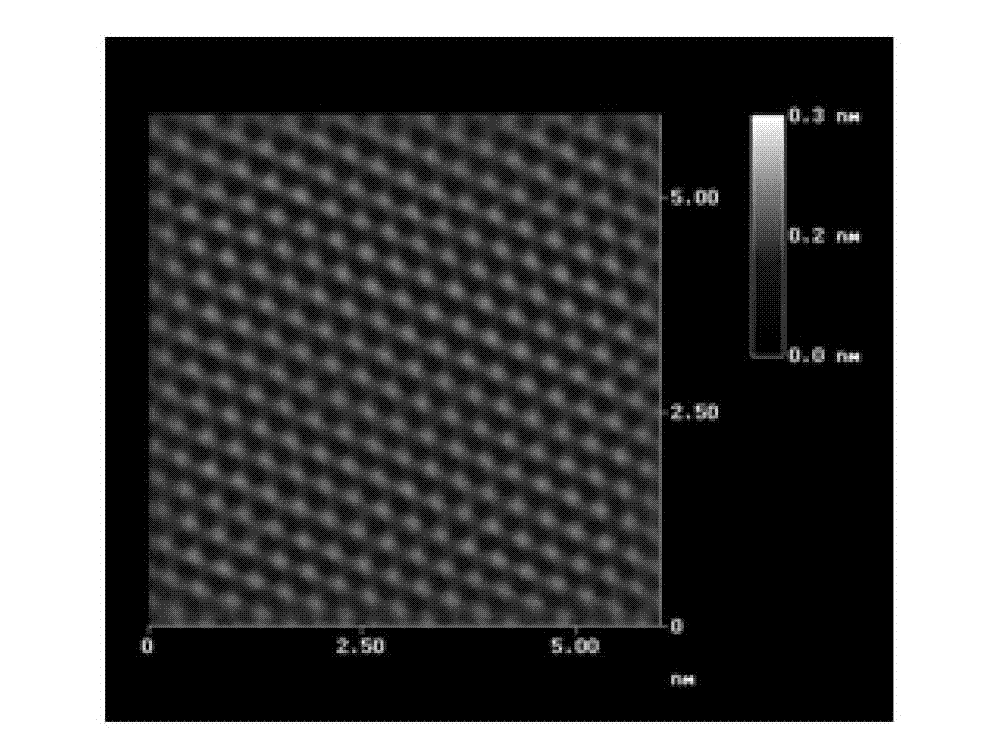

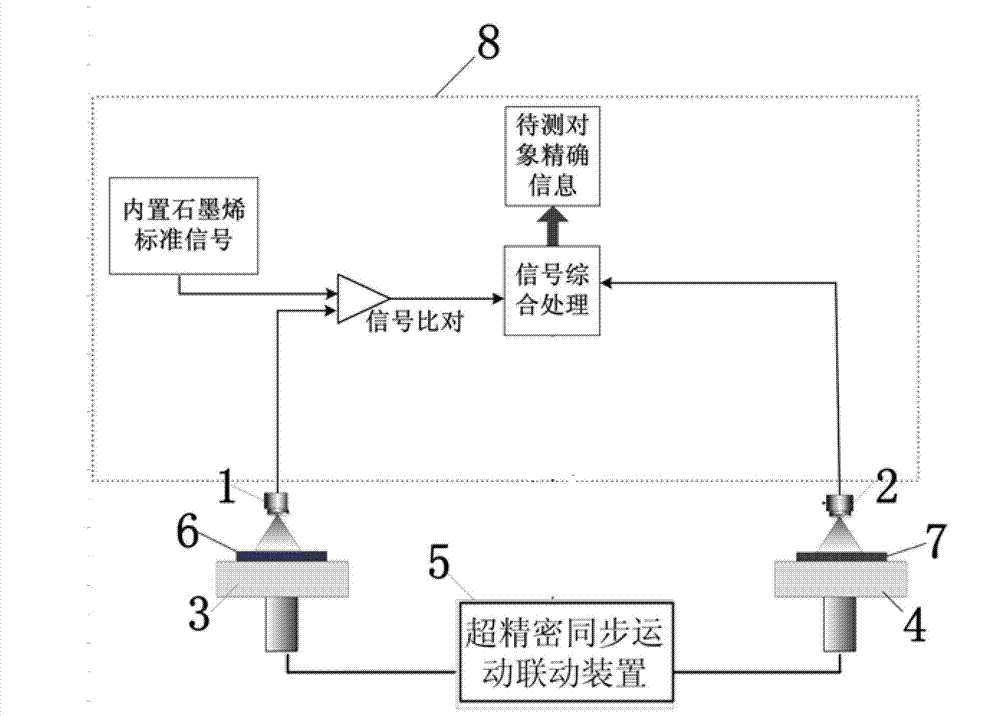

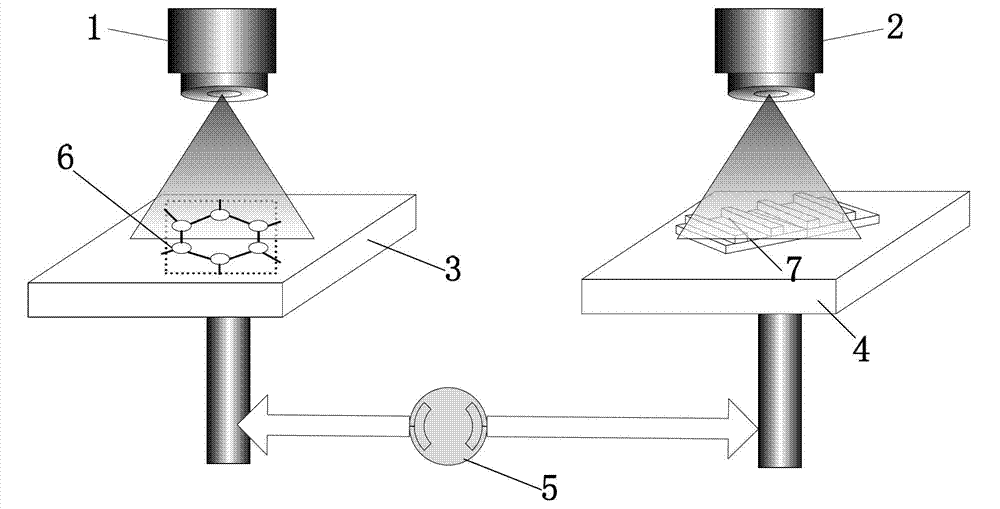

Length measuring and tracing method using graphene bond length as measuring reference

InactiveCN102889866ALong-term stabilityGuaranteed long-term stabilityUsing wave/particle radiation meansReference sampleGraphene

The invention discloses a length measuring and tracing method using a graphene bond length as a measuring reference. The graphene bond length is used as a length measuring and tracing reference, length measuring and tracing are carried out on an object to be detected by the number of detected graphene bond lengths, and sub-nanometer grade precision length measuring and tracing are realized. Ultra-precision synchronous motion control connection is carried out on the object to be detected and a graphene reference sample bearing table, the number of the graphene bond lengths is scanned to represent the motion length of the graphene reference sample bearing table, and the motion of the graphene reference sample bearing table is detected in real time, so that the sub-nanometer grade precision length measuring is carried out on the object to be detected, and sub-nanometer grade precision length measuring and tracing are realized. As graphene lattices are used as the length measuring and tracing reference, the length measuring and tracing method has the characteristics of high stability, high measuring precision capable of reaching a sub-nanometer grade, simpleness, reliability and the like and has wide application prospects in the field of ultra-precision measuring and tracing.

Owner:XI AN JIAOTONG UNIV

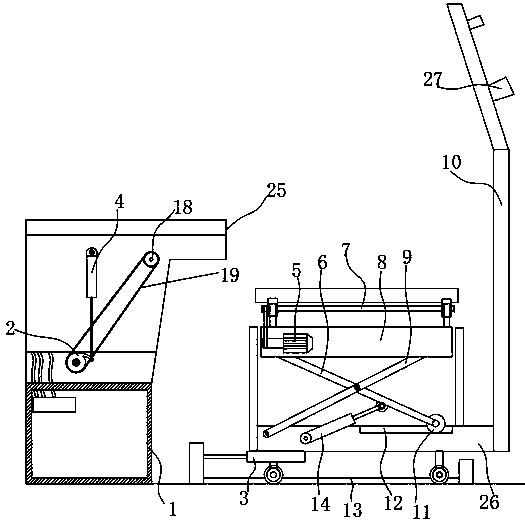

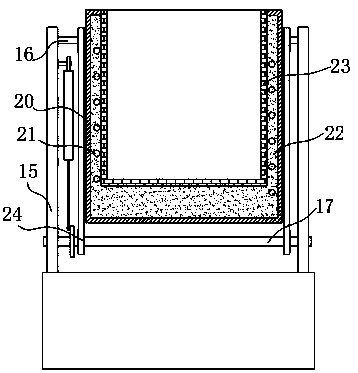

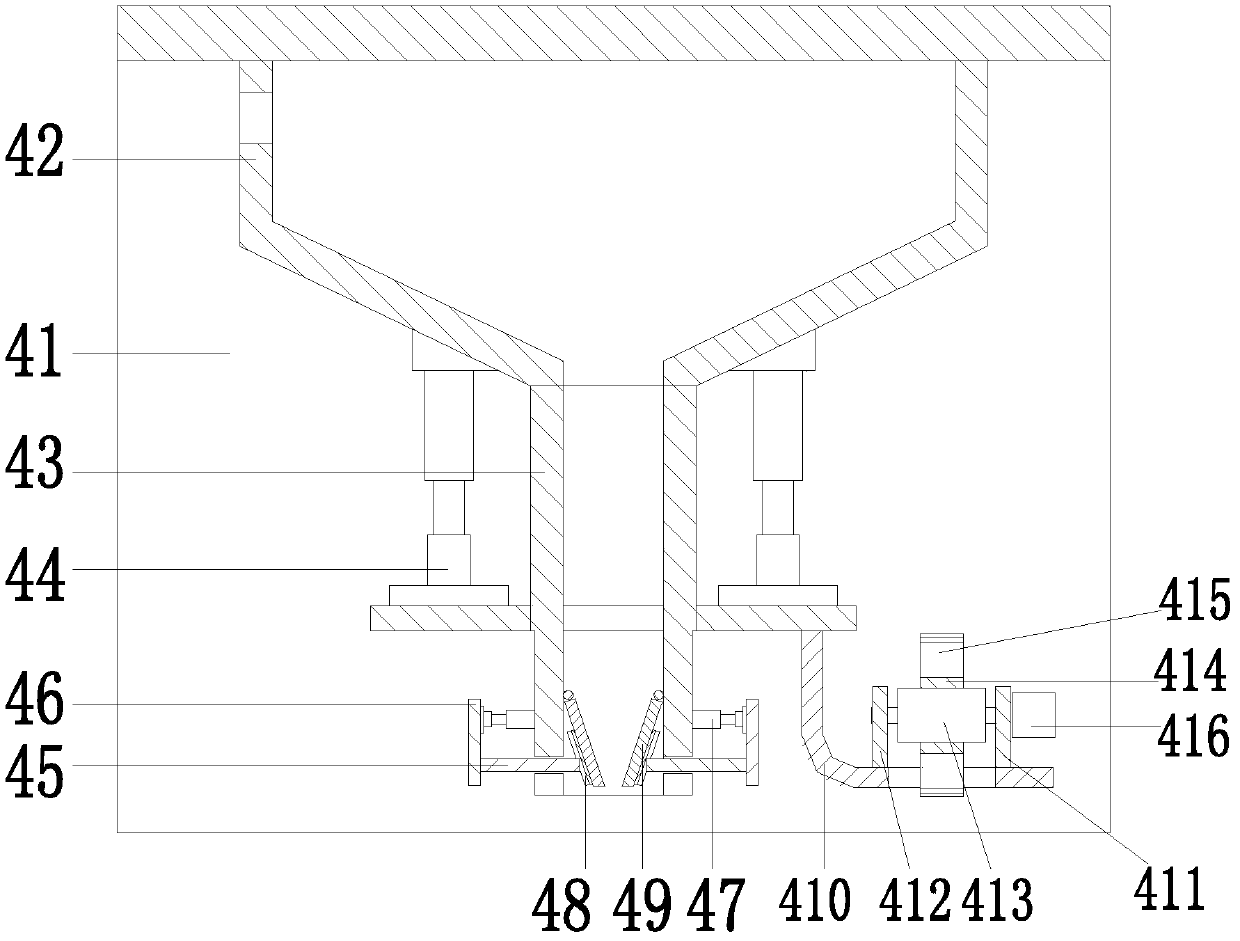

Automatic pouring system

PendingCN107824775AAchieve liftingEasy to liftMelt-holding vesselsMolten metal conveying equipmentsDrive wheelDrive shaft

The invention relates to an automatic pouring system. The system comprises a base, a vertical plate, a fixed shaft, an insulation casing, a crucible, a heating ring, an insulation material, a driven wheel, a transmission shaft, a driving wheel, a cam, a telescoping cylinder, a guide rail and a travelling trolley, wherein a main articulated rod is connected with the rear side of the travelling trolley in a pivoted manner; an auxiliary articulated rod is connected with the middle of the main articulated rod in a pivoted manner; a rolling wheel is arranged at the bottom of the auxiliary articulated rod; an auxiliary guide rail is arranged at the top of the travelling trolley; a supporting seat is provided with a transmission roll; the supporting seat is provided with a conveying motor; the travelling trolley is connected with a lifting cylinder in a pivoted manner; and an expansion rod of the lifting cylinder is connected with the lower middle part of the auxiliary articulated rod in a pivoted manner. The system effectively prevents cooling or oxidation of raw materials by transmitting driving power of the unilateral telescoping cylinder on the transmission shaft, the driving wheel and the driven wheel to the two sides of the insulation casing to enable the crucible to stably turn, and is good in pouring effect. The system is convenient in butt joint of pouring openings through the travelling trolley, realizes the lifting of dies through the telescoping cylinder, the main articulated rod and the auxiliary articulated rod, and is simple in structure.

Owner:太仓黑龙智能工业科技有限公司

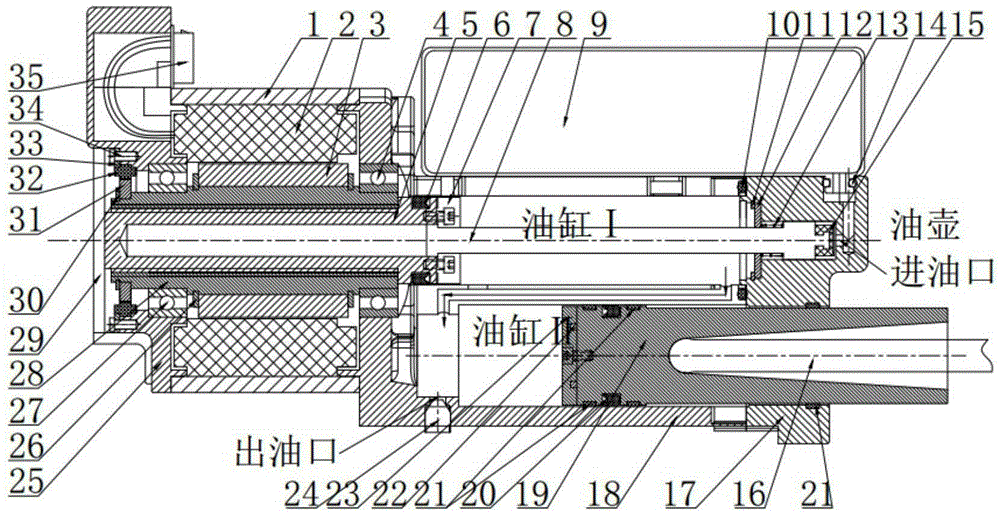

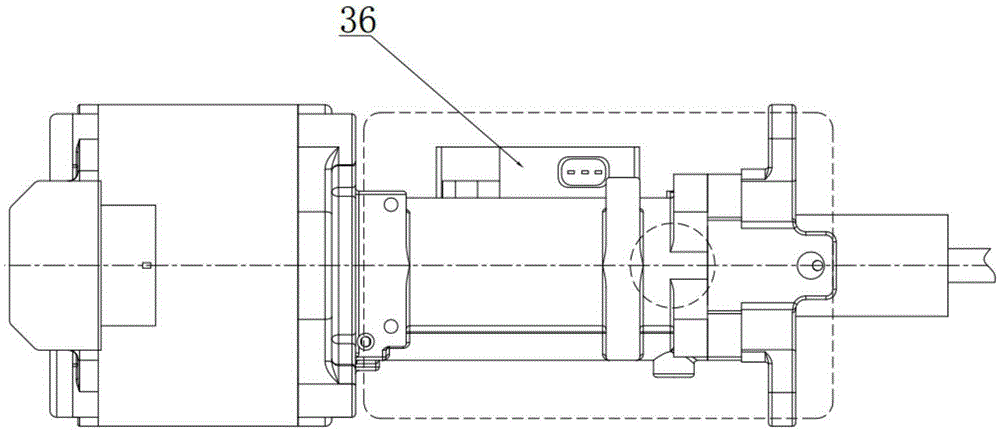

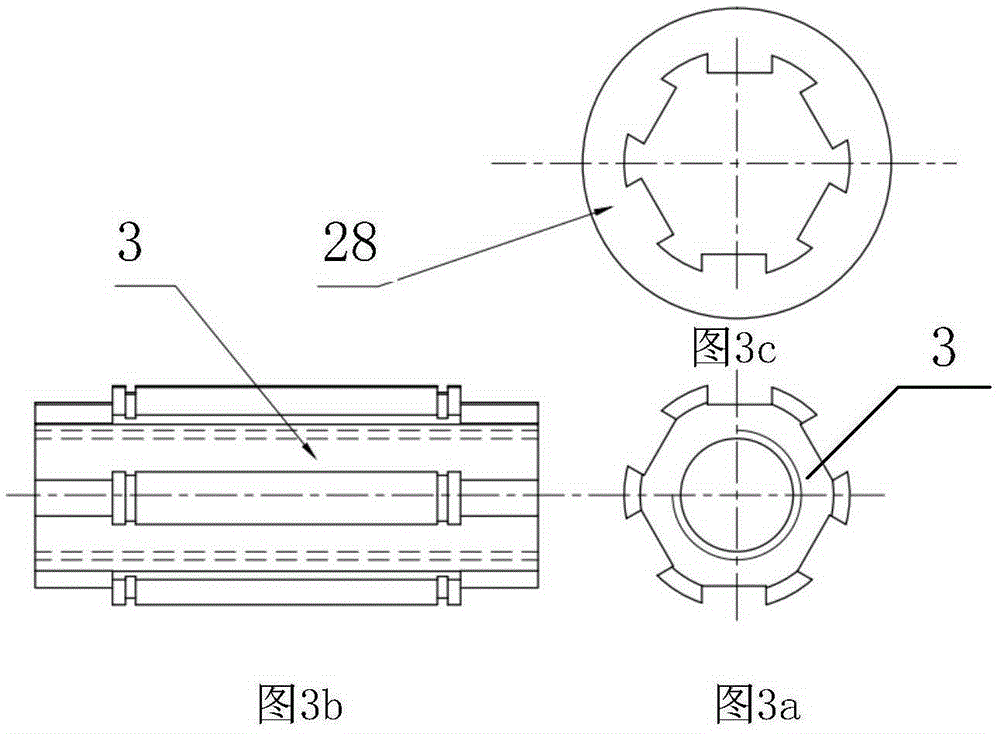

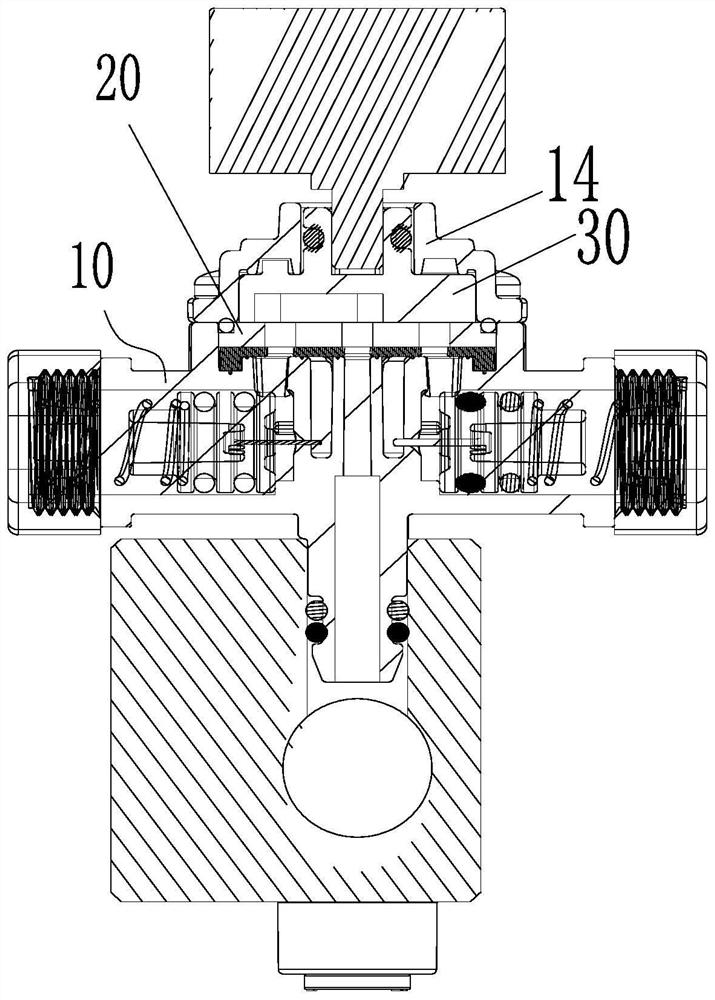

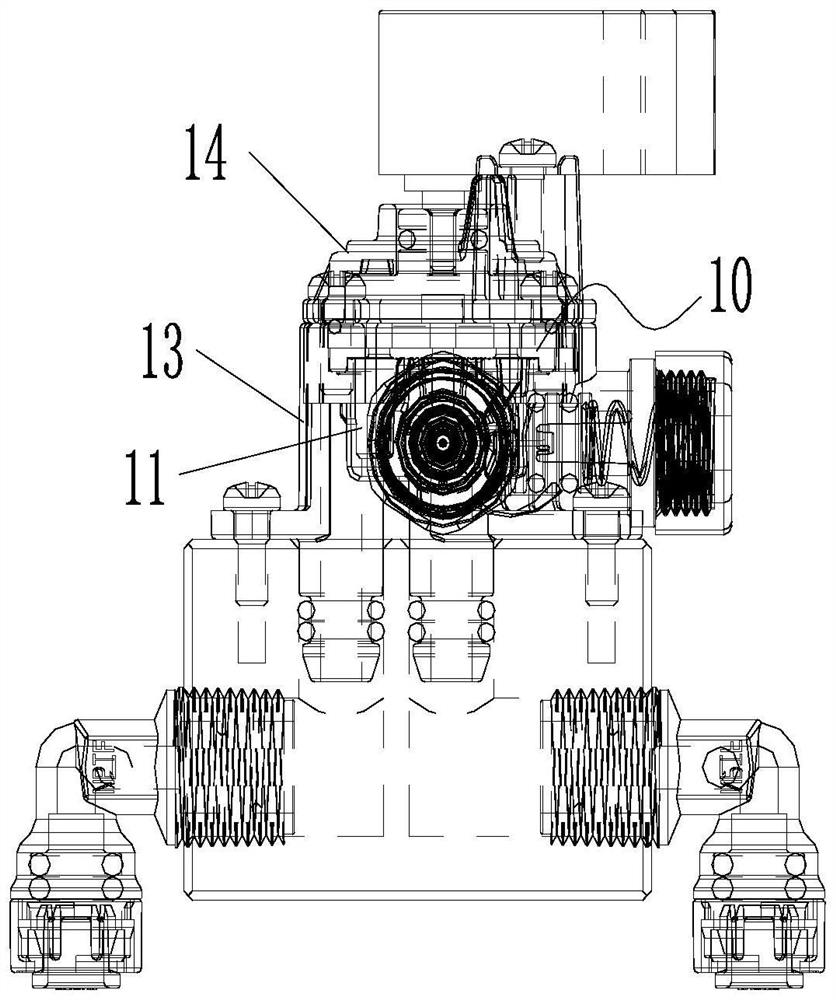

Motor-driven hydraulic clutch and automobile

ActiveCN105402273AClutch realizationPrecise control of rotationNon-mechanical actuated clutchesMotor driveElectric machinery

Owner:武汉理工通宇新源动力有限公司

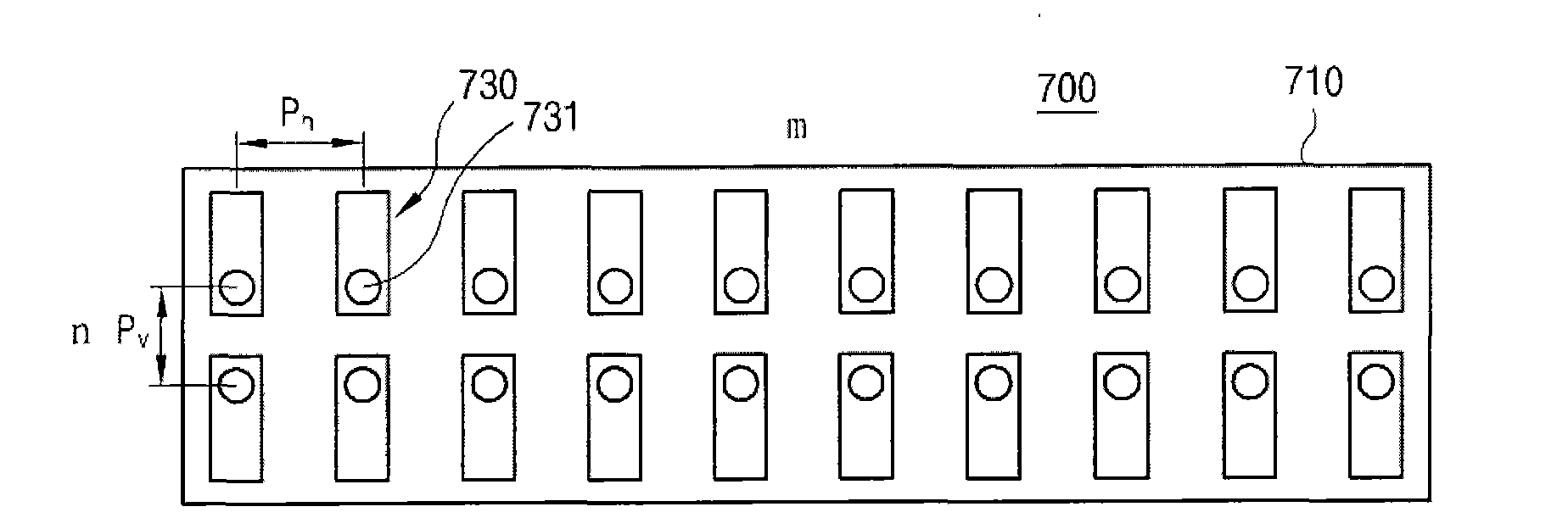

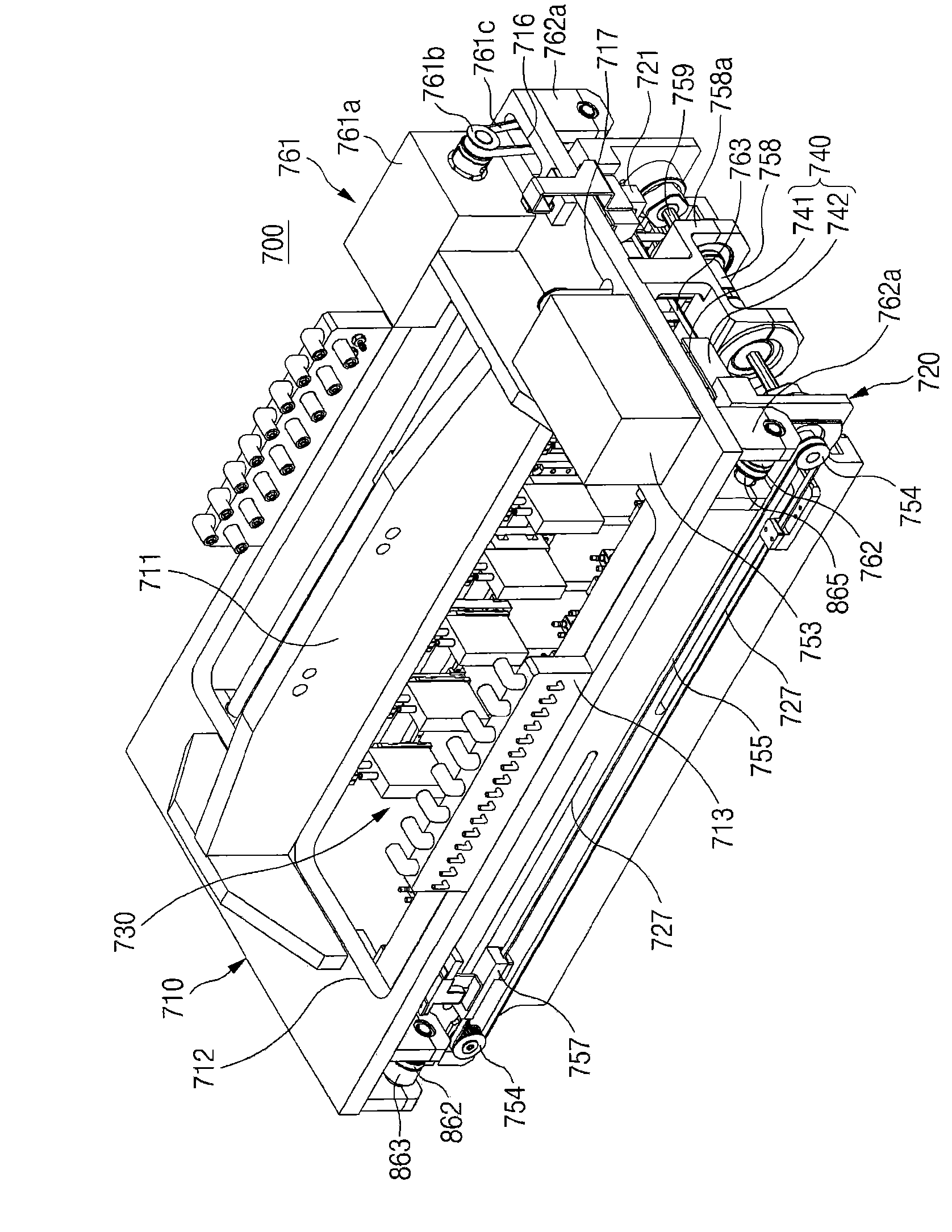

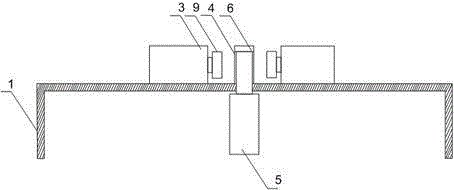

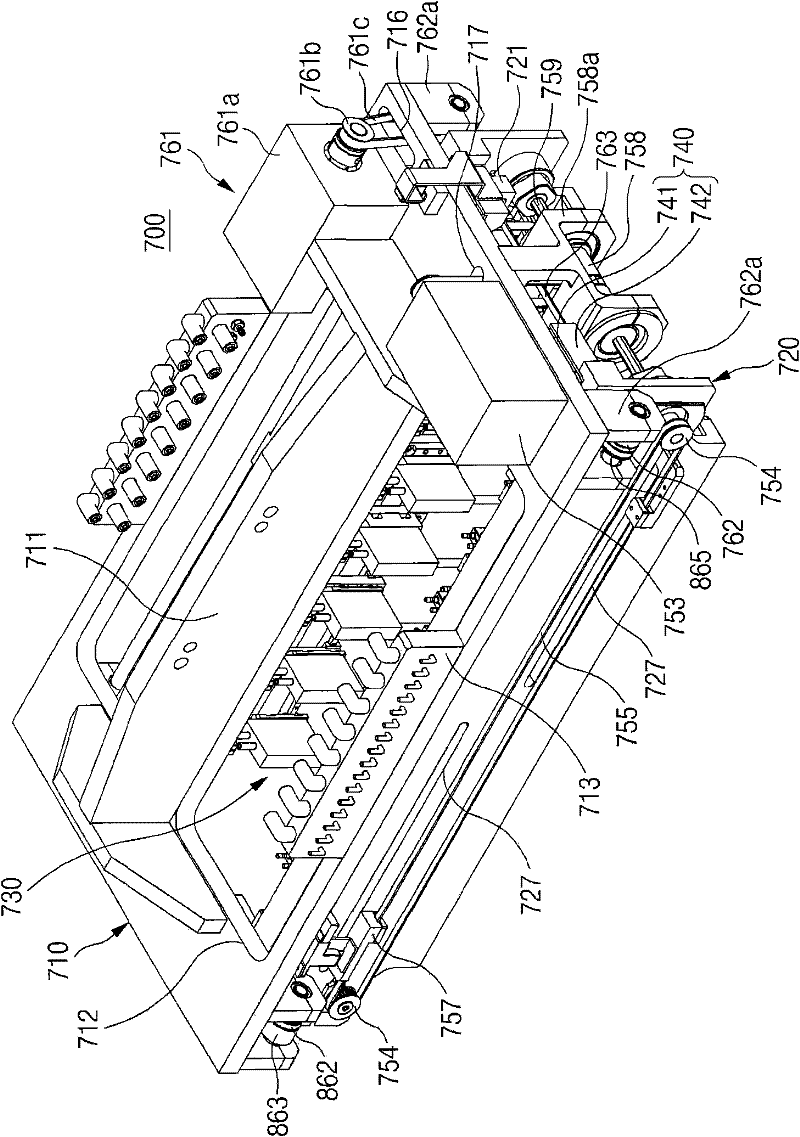

Transfer tool

ActiveCN101630650AAvoid inertial effectsPrecise control of movementSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingLinear motionEngineering

A transfer tool comprises: a first support framer that is installed to be movable along a transfer tool guide track of a semiconductor processor; a pair of second support frames that is connected with the first support frame through a gap and has a plurality of pickups having gap therebetween and picking up the semiconductor devices; and a vertical gap controller for controlling the gap of the pair of the second support frames by moving a pair of second support frames, wherein the vertical gap controller includes: a vertical driving unit installed on the first support frame to generate a vertical driving force; and a linear moving unit installed on the first support frame and connected to the second support frame; the gap between the second support frames is controlled by the linear movement of vertical driving unit.

Owner:JT

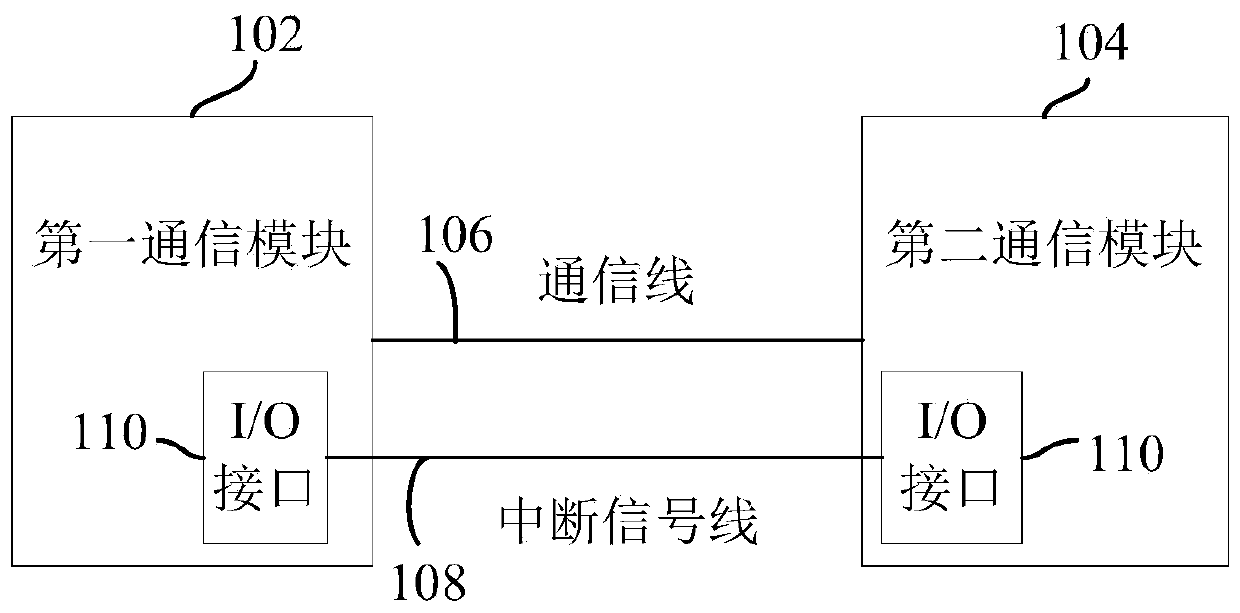

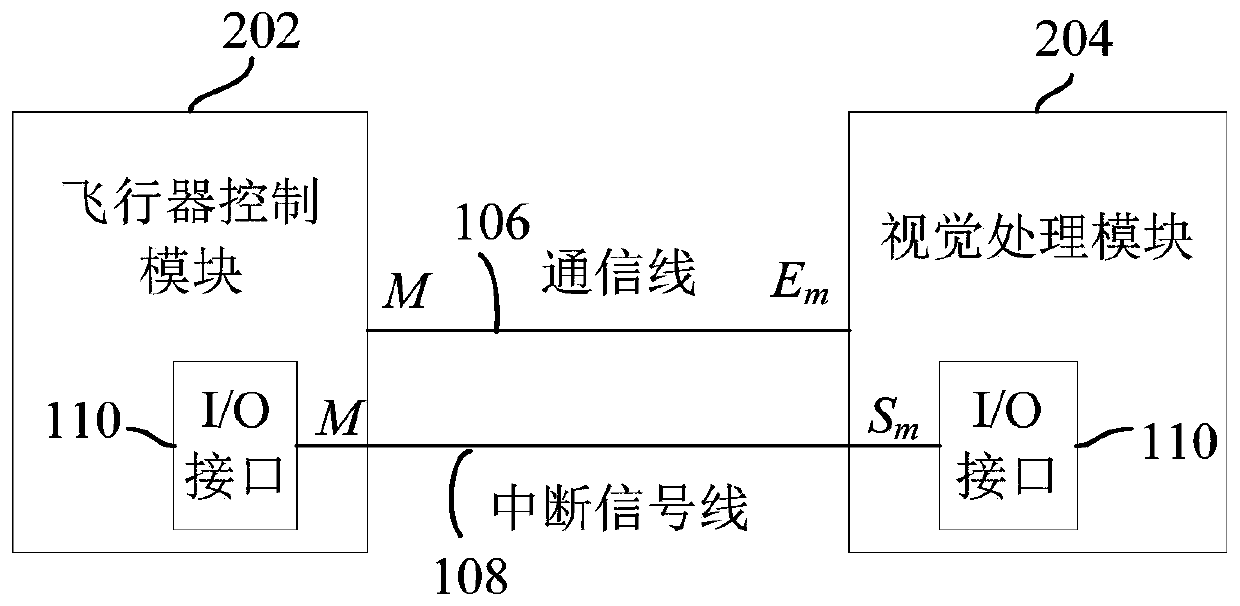

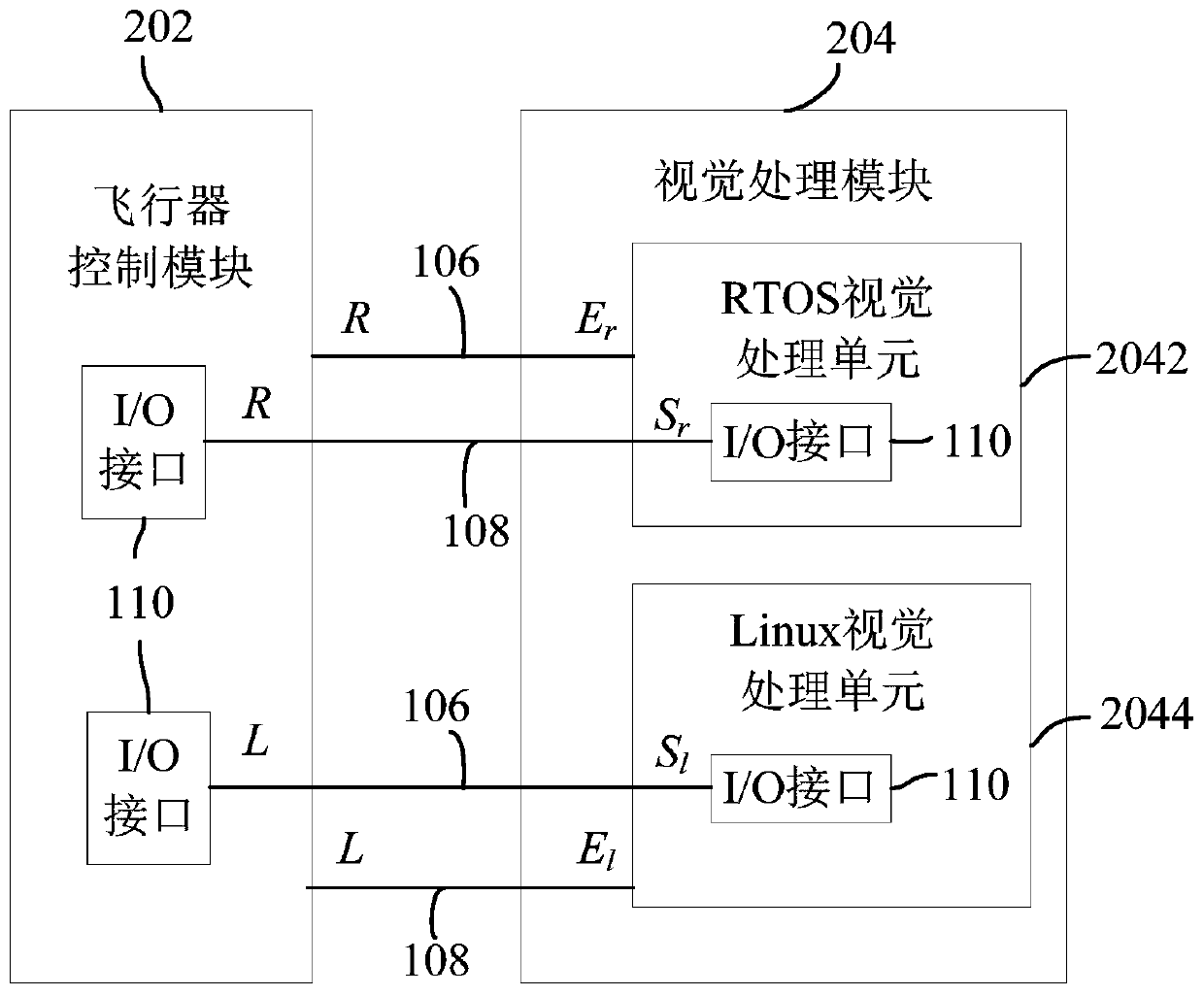

Aircraft time synchronization system and method

InactiveCN110636603APrecise control of movementAccurate timeSynchronisation arrangementParticular environment based servicesData informationSystem time

The embodiment of the invention discloses an aircraft time synchronization system and method. The system comprises a first communication module and a second communication module, data transmission iscarried out between the first communication module and the second communication module through a communication line, and an I / O interface of the first communication module is connected with an I / O interface of the second communication module through an interrupt signal line; the first communication module sends data information to the second communication module through a communication line, and sends a triggered interrupt signal to the second communication module through an interrupt signal line, wherein the data information comprises sending time when the data information is sent and an interrupt signal is triggered; and the second communication module performs time synchronization with the first communication module based on the determined communication time difference and system time difference with the first communication module according to the data information and the receiving time and sending time of the interrupt signal. Accurate time synchronization among different communication modules of the aircraft is realized, so that the movement of the aircraft is accurately controlled.

Owner:SHENZHEN AUTEL INTELLIGENT AVIATION TECH CO LTD

High-efficiency conveying line reversing device

InactiveCN112938459APrecise control of movementSave resourcesConveyor partsReciprocating motionStructural engineering

The invention discloses a high-efficiency conveying line reversing device, and relates to the technical field of assembly line transportation. According to the key points of the technical scheme, the high-efficiency conveying line reversing device comprises a mounting frame provided with supporting feet, a jacking plate, a plurality of rolling shafts and a push plate are mounted on the upper end face of the mounting frame in a vertically sliding mode, the rolling shafts transfer cargoes from an assembly line to the jacking plate, the push plate pushes the cargoes on the jacking plate to an inclined transfer table through reciprocating motion, the push plate is in power connection with a driving device through a first transmission device, so that the cargoes are pushed in a reciprocating mode; and one side of the first transmission device is in power connection with a second transmission device to drive all the rolling shafts to rotate synchronously, and a driving assembly for driving the jacking plate to slide up and down is further arranged on one rolling shaft. According to the technical effects, the use of a power source can be reduced, and the production and equipment manufacturing cost can be saved.

Owner:上海奉斌贸易有限公司

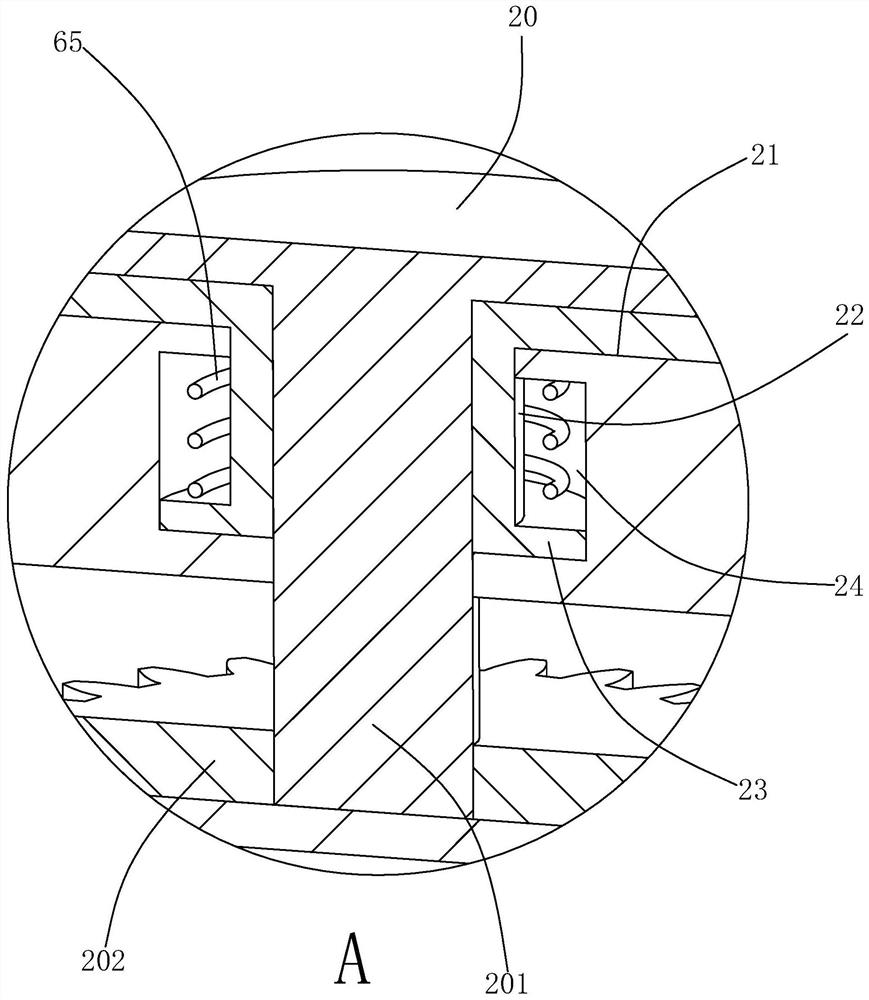

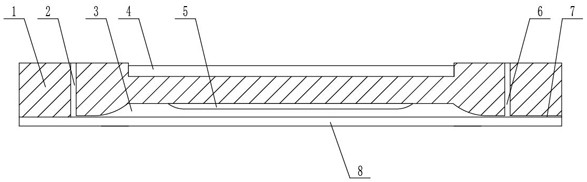

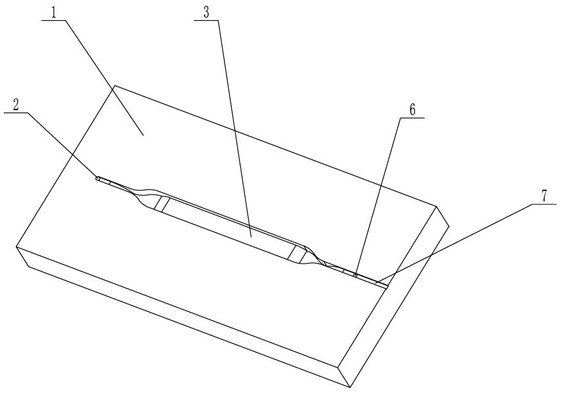

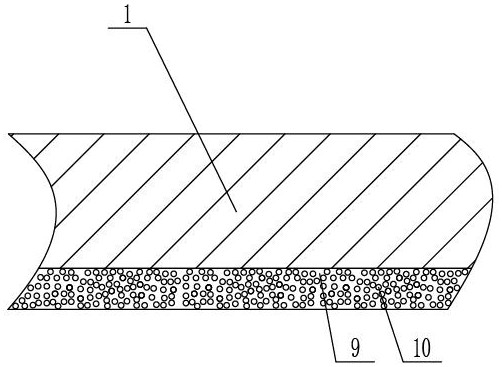

Microfluidic chip with preset magnetic beads, manufacturing method and microfluidic detection equipment

ActiveCN109622086BPrecisely control the amount of captureCatch impactLaboratory glasswaresSoft magnetMagnetic bead

A microfluidic chip with preset magnetic beads, including a core body and a thin film. A microfluidic channel is opened on the core body, and the thin film covers the microfluidic channel. The inlet end of the microfluidic channel is connected with a liquid inlet channel. The outlet end of the flow channel is provided with a valve, the part of the micro-channel close to the outlet end is connected with a waste liquid discharge channel, the middle part of the micro-channel expands to form a magnetic bead reaction tank, and the bottom of the magnetic bead reaction tank is provided with a water-soluble inclusion and The preset magnetic bead coating formed by mixing magnetic beads, the core body is fixed with a preset soft magnet, and the preset soft magnet is located on the back side of the magnetic bead reaction tank. The invention provides a microfluidic chip with pre-set magnetic beads, a manufacturing method and a microfluidic detection device, which can precisely control the amount of magnetic beads captured and the trajectory of the magnetic beads, and improve the adsorption / elution effect of the magnetic beads.

Owner:HENAN UNIV OF SCI & TECH

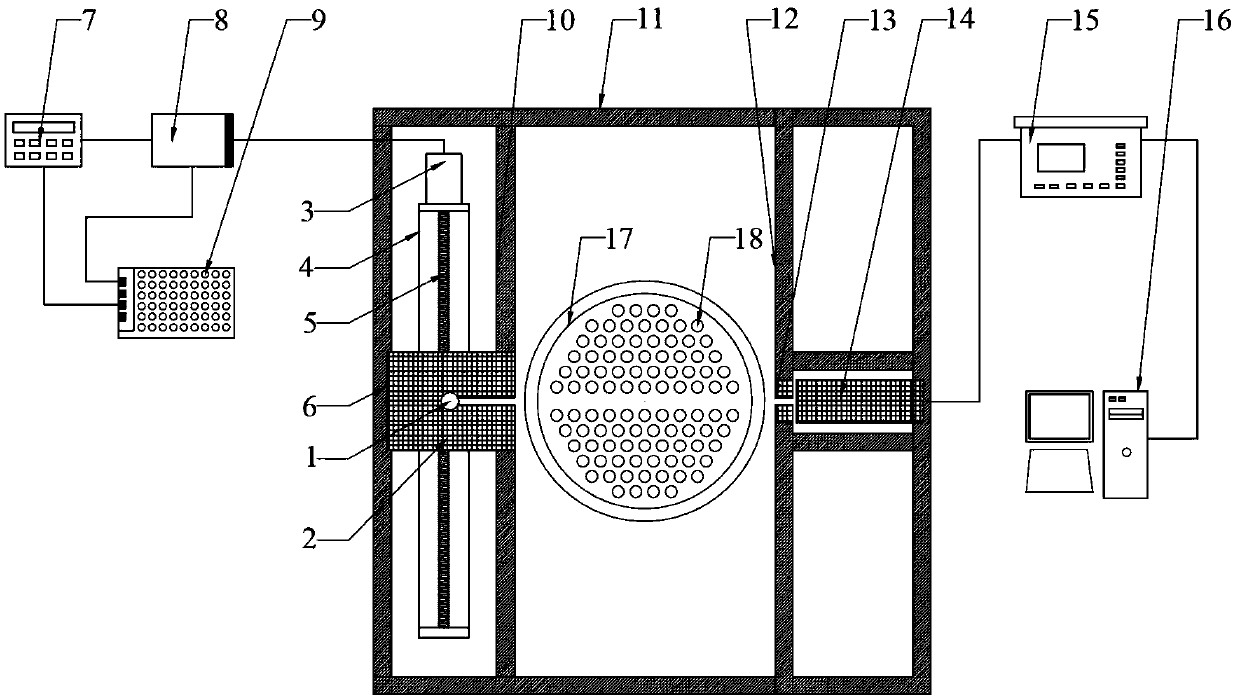

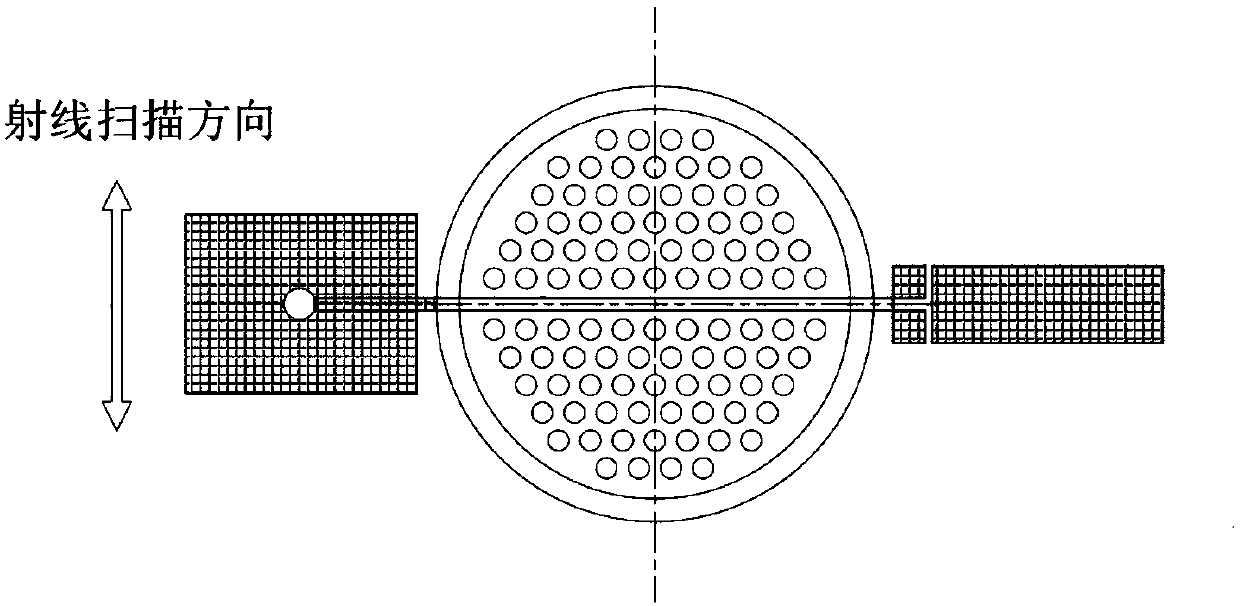

Device and method for measuring section steam content of tube bundle area of steam generator

ActiveCN109540938AAvoid interferenceStable jobMaterial analysis by transmitting radiationCounting rateControl system

The invention discloses a device and a method for measuring section steam content of a tube bundle area of a steam generator. The measuring device comprises a gamma ray emitting and receiving device,a gamma ray scanning mobile measuring platform, a stepping motor driving and control system and a ray counting rate collecting system. Through a gamma ray scanning method, the section steam content onany chord length between secondary side tube bundles of the steam generator can be obtained continuously; and structure parameters and flow parameters of the steam generator are considered, and a calculation formula is corrected, so that complex geometrical structures of the tube bundles and different fluids on the primary and secondary sides can be distinguished accurately, and the difficult problem of measurement of the section steam content between the secondary side tube bundles of the steam generator is solved.

Owner:XI AN JIAOTONG UNIV

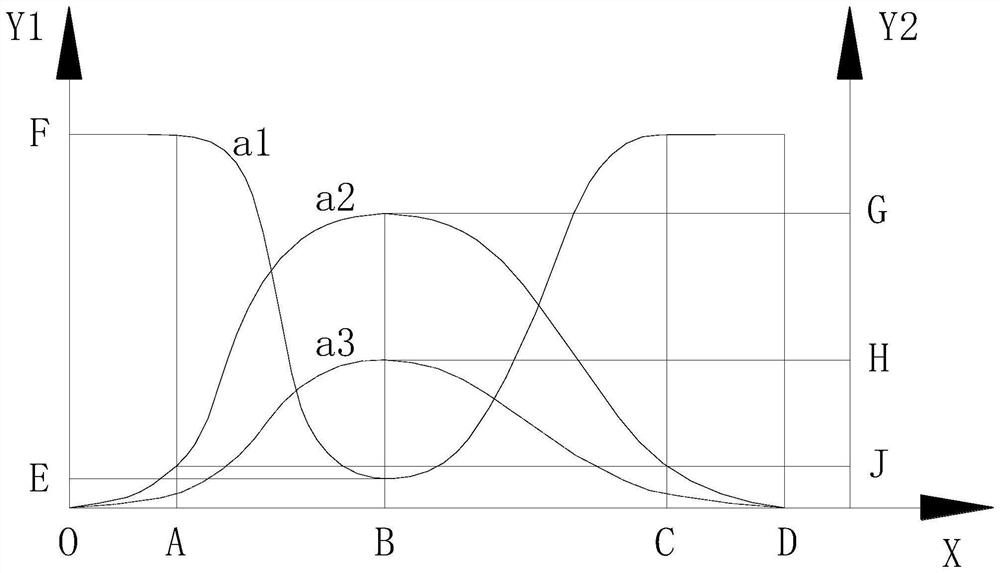

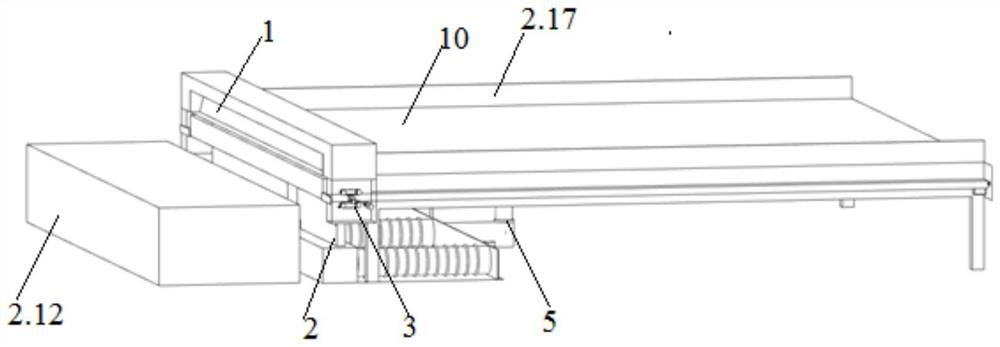

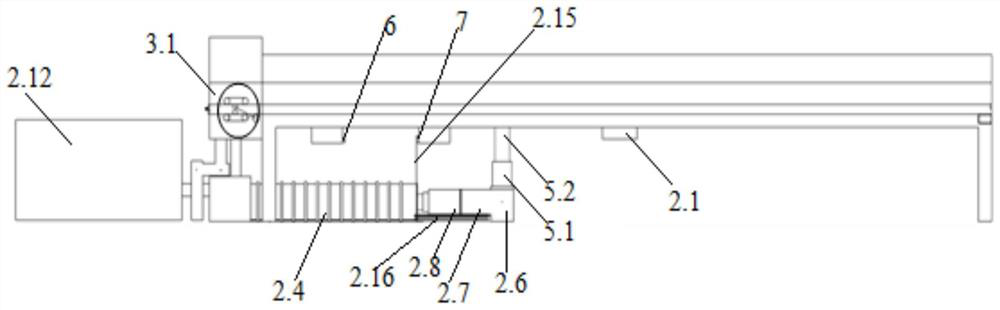

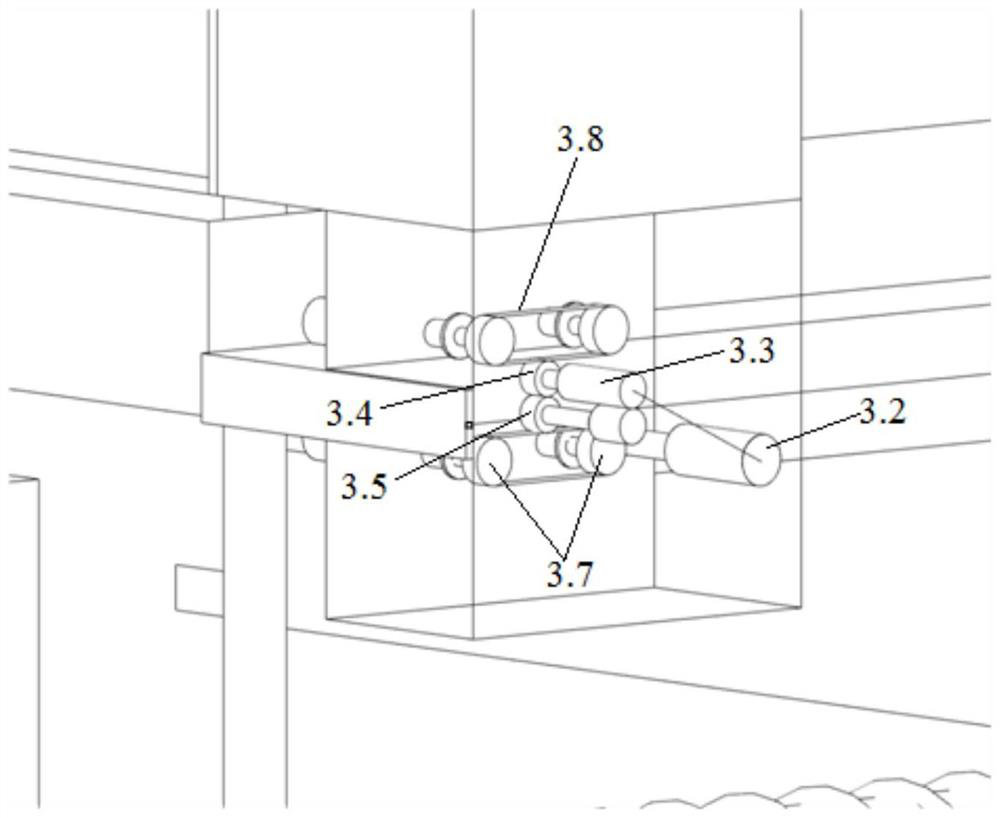

Jointed connecting link mechanism with linkage between moving side mold and bottom mold of bottle blowing machine

The invention discloses a jointed connecting link mechanism with linkage between a moving side mold and a bottom mold of a bottle blowing machine. A side mold rotor arm which drives the side mold to carry out separation and reunion motion synchronously drives the bottom mold to carry out deflection lifting motion while drives the moving side mold to carry out separation and reunion motion, the separation and reunion motion of the moving side mold can be in accurate cooperation with deflection lifting motion of the bottom mold, and then it is implemented that the deflection lifting motion of the bottom mold can be in effective synergy with the separation and reunion motion of the moving side mold. According to the jointed connecting link mechanism with linkage between the moving side mold and the bottom mold of the bottle blowing machine, after a first plane four-bar linkage is connected with a space dual-swing slider mechanism in series, and then a formed tandem type combined connecting rod type bottom mold deflection lifting mechanism is combined with a second plane four-bar linkage. Parts are connected with one another through sliding pairs or revolute pairs or spherical pairs. The jointed connecting link mechanism with linkage between the moving side mold and the bottom mold of the bottle blowing machine is simple and low in live load; and the vibration and impact of the mechanism can be effectively reduced, abrasion of the parts is reduced, the motion of the bottom mold can be accurately controlled, the bottle blowing machine is improved in motion stability and reliability, and the high-speed performance of the whole machine is improved.

Owner:JIANGSU NEWAMSTAR PACKAGING MACHINERY

Cooling, cleaning and detachable mounting device and method for building roof photovoltaic power generation panel

PendingCN114465570AImprove power generation efficiencyPrecise control of movementPhotovoltaic supportsPhotovoltaic monitoringStructural engineeringManufacturing engineering

The invention provides a cooling, cleaning and detachable mounting device and method for a building roof photovoltaic power generation panel, and relates to the field of photovoltaic building integration. The device comprises a cooling and cleaning unit composed of a cleaning part, a cooling part and a first driving part; the cooling part is provided with a temperature sensor installed on the back face of the photovoltaic power generation panel, and when it is monitored that the temperature is too high, cooling and cleaning of the photovoltaic power generation panel are started. Wherein the cleaning part is provided with cleaning cotton, the cooling part is provided with a water spraying mechanism with the water spraying direction facing the cleaning cotton, the water spraying mechanism sprays water to the cleaning cotton through deformation of a plastic telescopic pipe arranged in the water spraying mechanism, then the first driving part drives the cleaning cotton to reciprocate on the light receiving face, and then the light receiving face achieves the cooling and cleaning effects in a water evaporation and heat absorption mode. The photoelectric conversion efficiency of the photovoltaic power generation panel is improved; the photovoltaic power generation panel is detachably installed on the building roof, installation and disassembly are simple and fast, and the installation and disassembly cost is remarkably saved.

Owner:JIANGSU LONG LEAPING ENG DESIGN

an automatic extractor

InactiveCN103500641BPrecise control of movementFully automatedCoils manufactureTransformerAutomation

The invention discloses an automatic pulling and poking device which comprises a work frame. A pin poking device and two driving mechanisms are arranged on the work frame, and the pin poking device is arranged between the two driving mechanisms. The automatic pulling and poking device further comprises a conveying mechanism arranged among the driving mechanisms and the pin poking device, and a displacement sensor is further arranged on the conveying mechanism. The displacement sensor can accurately control movement of the conveying mechanism, namely one driving mechanism can well push a box body to the pin poking device. When the pulling and poking procedure is completed, the other driving mechanism pushes the box body to the conveying mechanism, and finally the conveying mechanism is controlled to convey the pulled and poked box body to the collecting position. Automation of correcting a guide pin of a network transformer is achieved, and correction efficiency is improved.

Owner:ZHONGJIANG KAIXUN ELECTRONICS

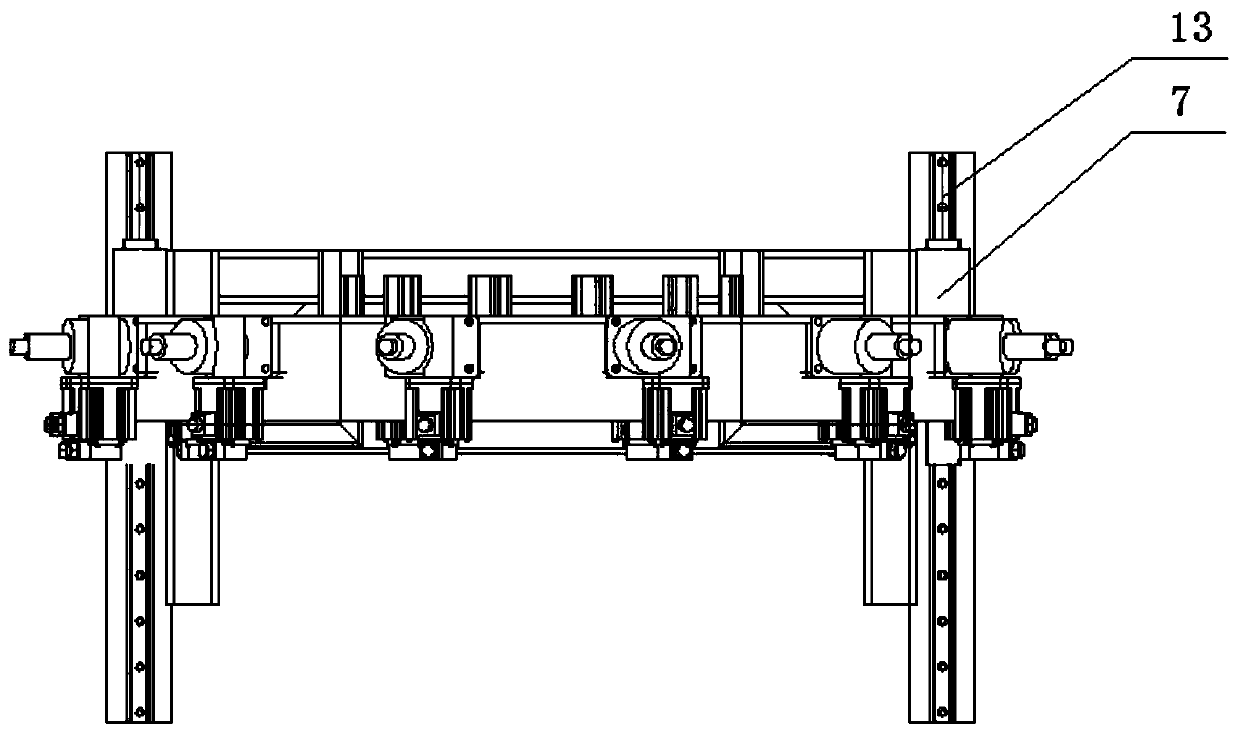

transmission tool

ActiveCN101630650BAvoid inertial effectsPrecise control of movementSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingDevice materialSimulation

A transfer tool comprises: a first support framer that is installed to be movable along a transfer tool guide track of a semiconductor processor; a pair of second support frames that is connected with the first support frame through a gap and has a plurality of pickups having gap therebetween and picking up the semiconductor devices; and a vertical gap controller for controlling the gap of the pair of the second support frames by moving a pair of second support frames, wherein the vertical gap controller includes: a vertical driving unit installed on the first support frame to generate a vertical driving force; and a linear moving unit installed on the first support frame and connected to the second support frame; the gap between the second support frames is controlled by the linear movement of vertical driving unit.

Owner:JT

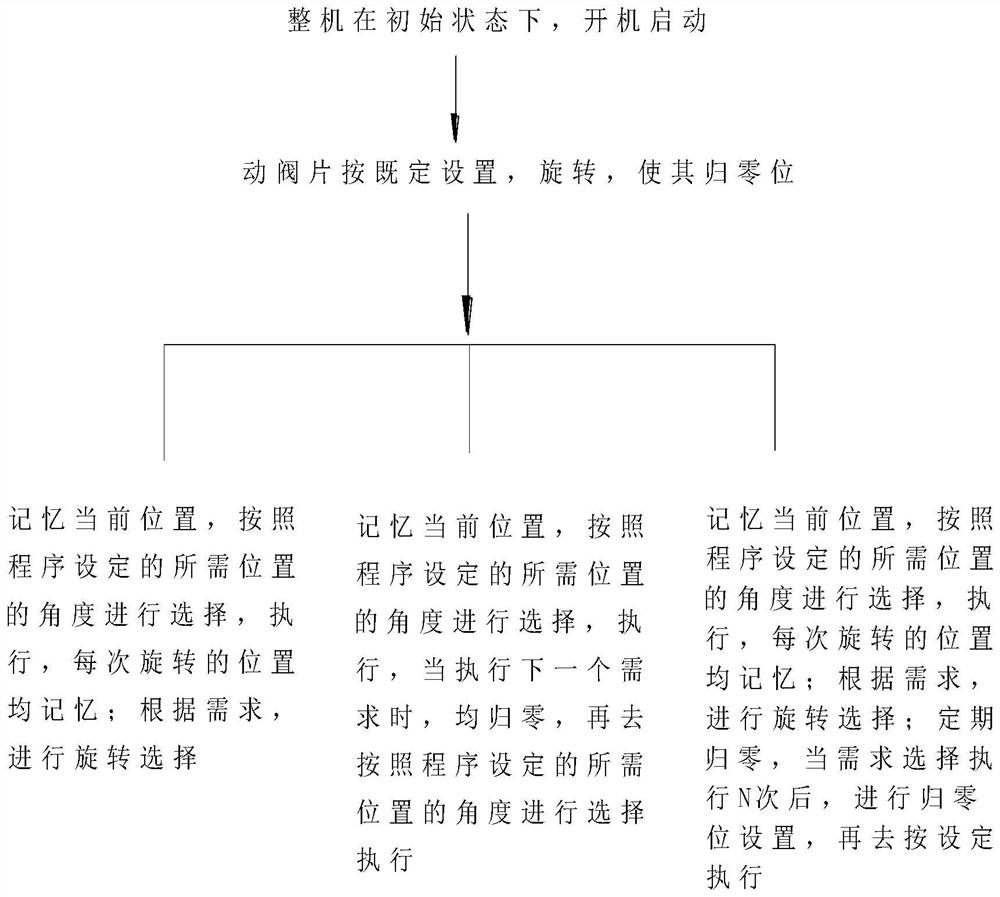

Electric valve, control method and control device thereof, and non-volatile storage medium

ActiveCN114542783AFacilitates precise control of movementPrecise control of movementOperating means/releasing devices for valvesMultiple way valvesBrakeControl theory

The invention provides an electrically operated valve, a control method and device of the electrically operated valve and a nonvolatile storage medium, and the control method of the electrically operated valve comprises the steps that a movable valve plate of the electrically operated valve is made to move to an initial position, and zero alignment is conducted on the movable valve plate; recording an initial position; and the preset movement position of the movable valve plate is obtained, and the brake valve plate is controlled to rotate according to the angle difference value between the preset movement position and the initial position so that the movable valve plate can move to the preset movement position. By means of the technical scheme, the technical problem that in the prior art, large errors exist in the position adjusting precision of an electric valve can be solved.

Owner:GREE ELECTRIC APPLIANCES INC

Ejection mechanism and injection mold with the same

ActiveCN111619078BReduce resistancePrevent disengagementScrew-threads articlesDomestic articlesMechanical engineeringThreaded rod

The invention relates to the technical field of demolding of injection molded products and provides an ejection mechanism and an injection mold with the ejection mechanism. The ejection mechanism comprises a slide way arranged on a moving mold, a sliding seat arranged on a fixed mold and an ejector pin. The sliding way is provided with a boss. The sliding seat is provided with an insert pin and athrough hole parallel to the insert pin. The bottom end of the insert pin extends out of the through hole, and the top end of the ejector pin abuts against the molded surface of the formed product. The sliding seat is opposite to the front face of the slide way. The sliding seat can drive the bottom of the ejector pint to move along the slide way to the upper side of the boss. The ejection mechanism is applied to the injection mold, the sliding seat is used for driving the bottom of the ejector pin to move along the slide way to the upper side of the boss, the boss lifts up the ejector pin, the ejector pin ejects upwards the molded surface of the formed product, the formed product is disengaged from the insert pin, and the quality of a threaded rod and injection molded holes such an exhaust hole is guaranteed.

Owner:NINGBO FANGZHENG TOOL

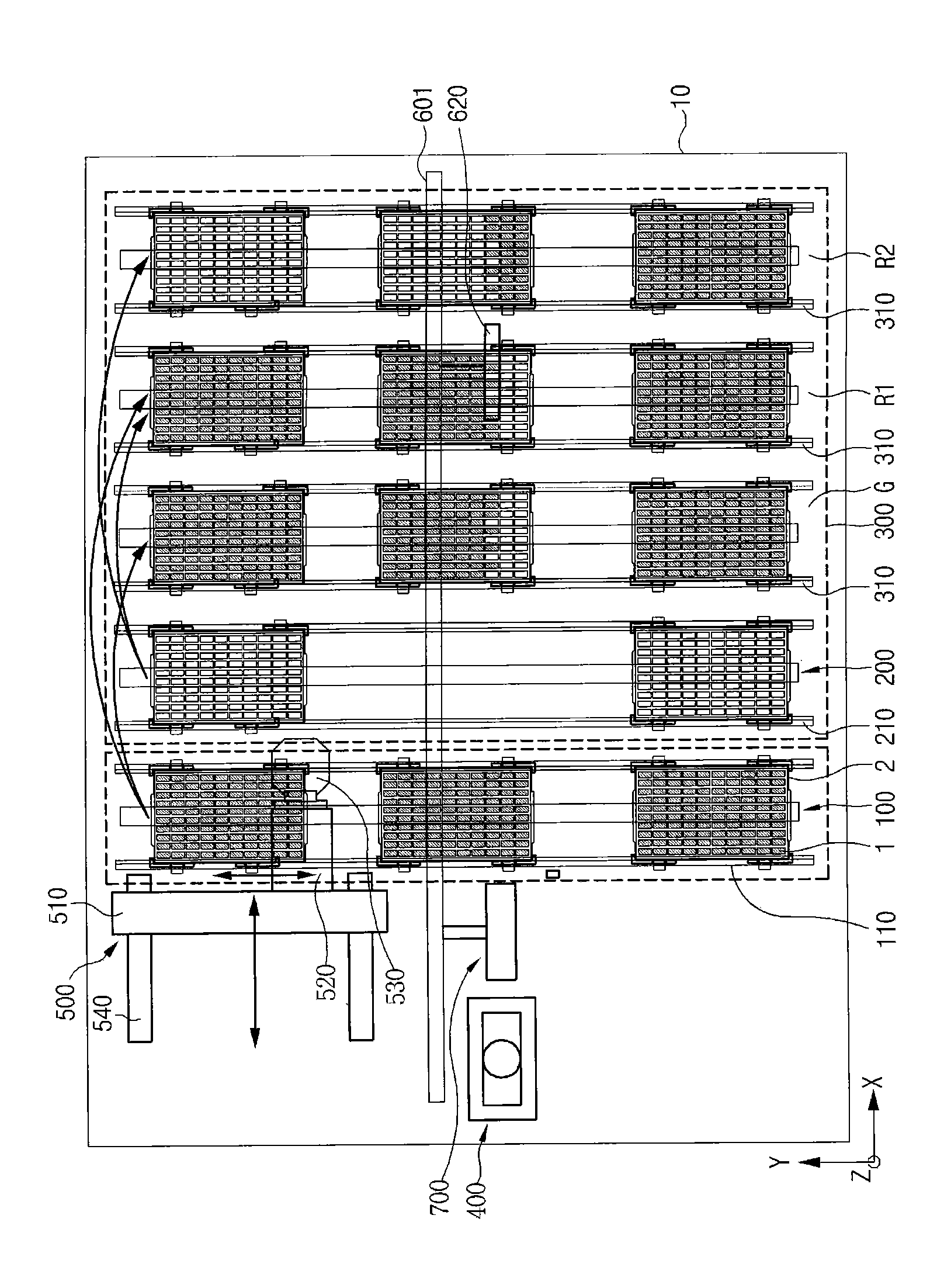

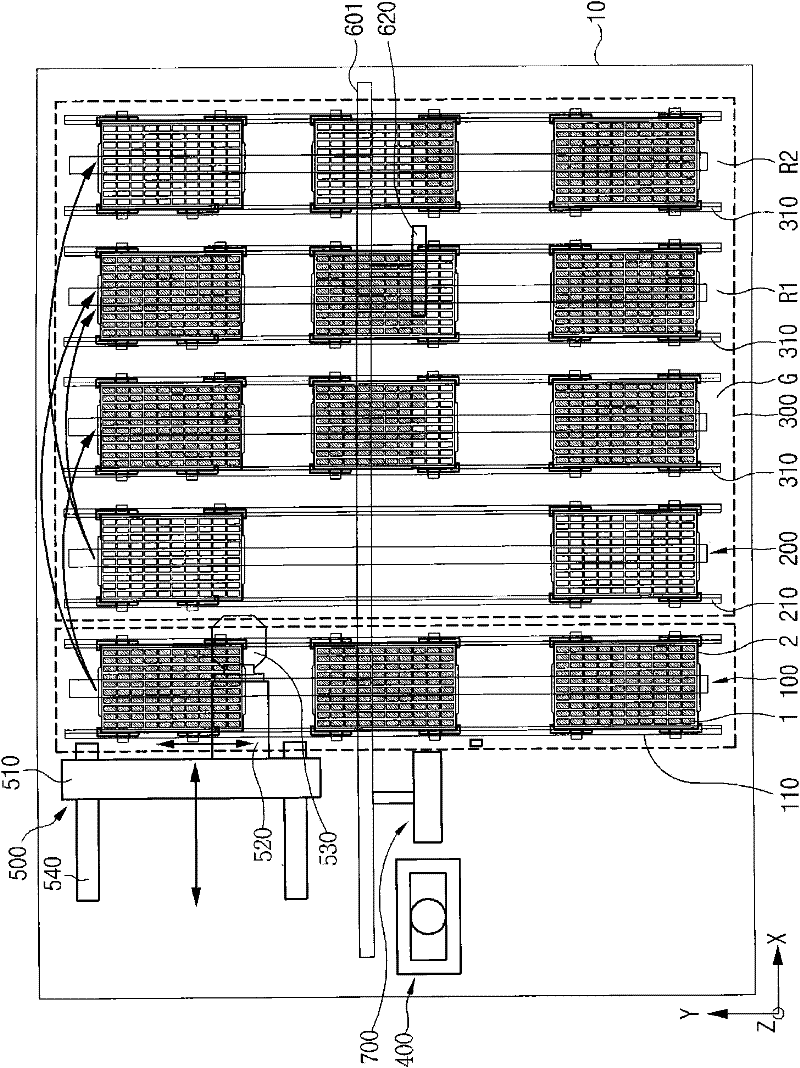

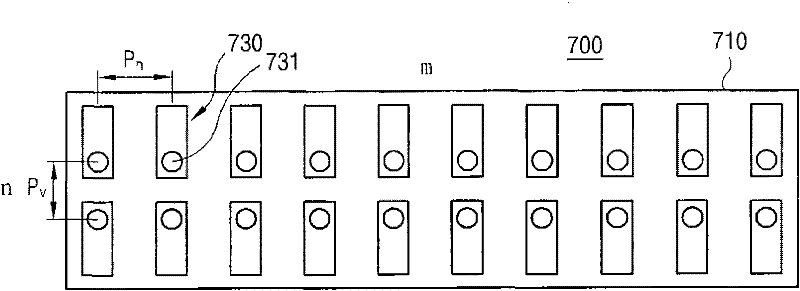

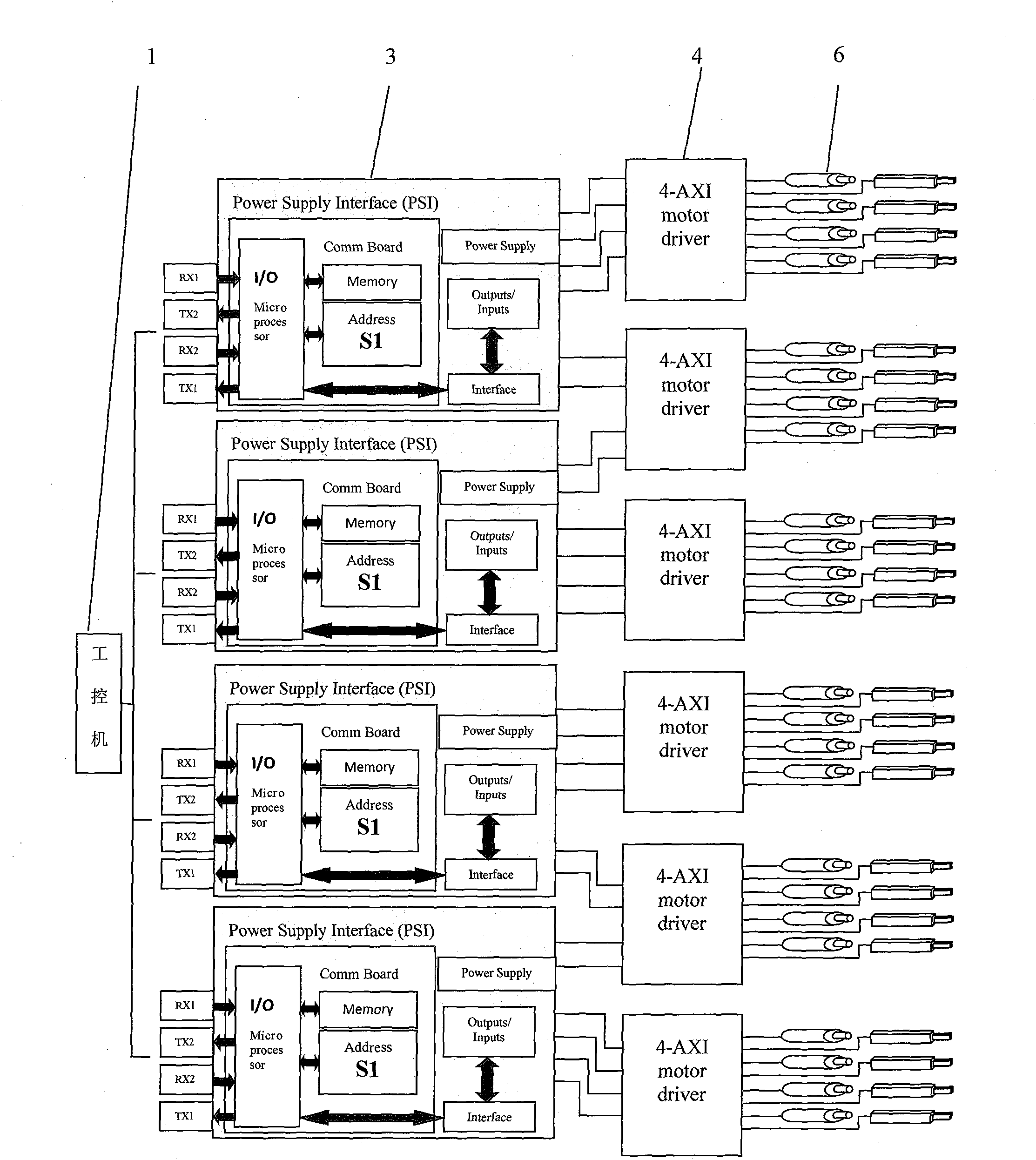

Method for adjusting multi-magnetic-pole motion control

InactiveCN104299873ARealize real-time monitoringAchieve modularityElectric discharge tubesMotor driveMagnetic poles

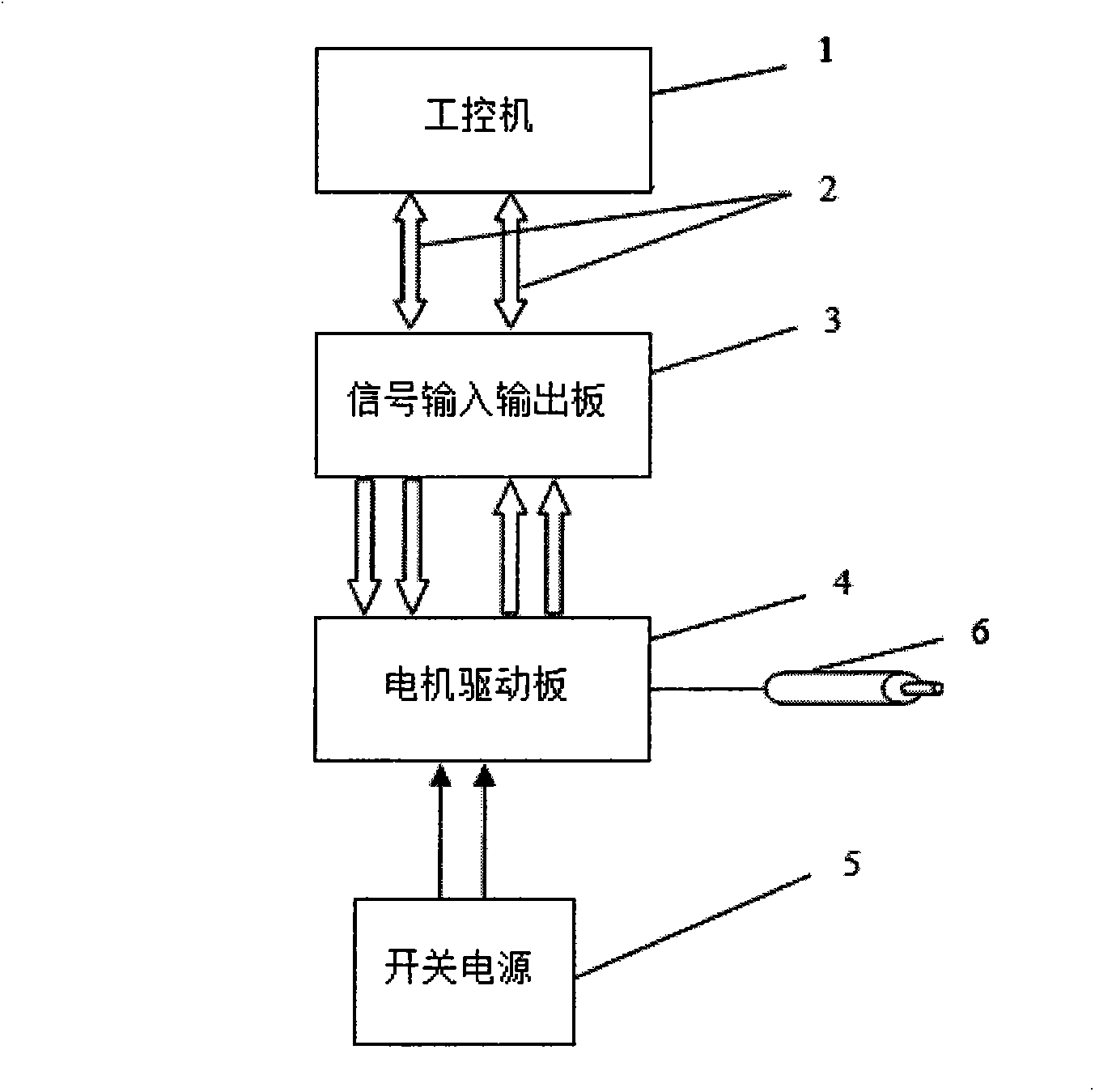

The invention discloses a method for adjusting multi-magnetic-pole motion control. An industrial control computer (1), an optical fiber (2), a signal input and output board (3), a motor driving board (4), a switch power supply (5) and multiple magnetic poles (6) are included. The method for adjusting multi-magnetic-pole motion control is detailed in the instruction, and a specific embodiment scheme is further provided. The device relates to an ion injection device and belongs to the semi-conductor manufacturing field.

Owner:BEIJING ZHONGKEXIN ELECTRONICS EQUIP

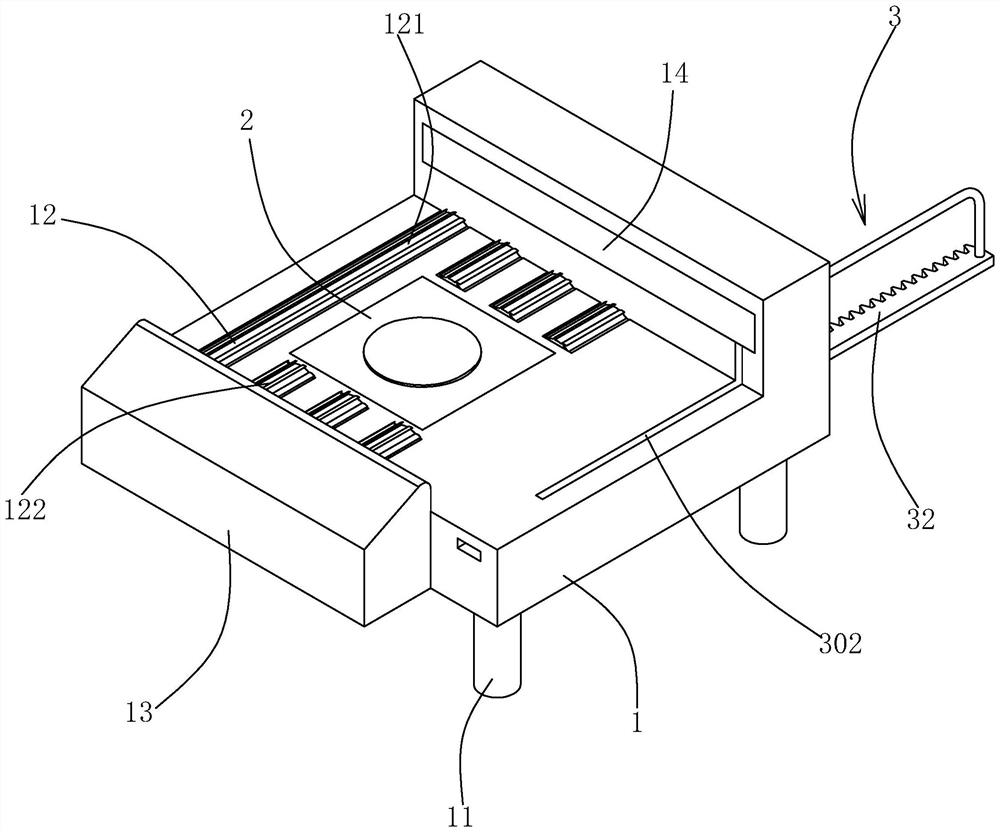

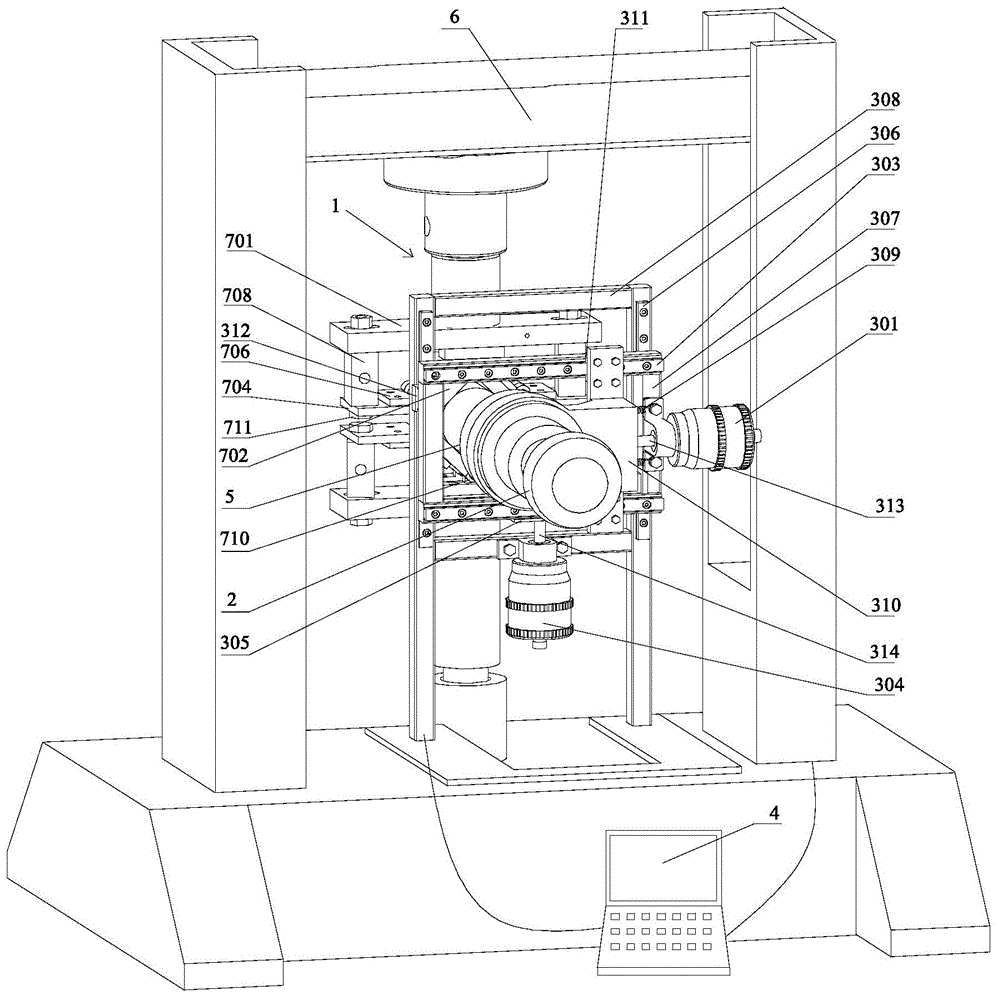

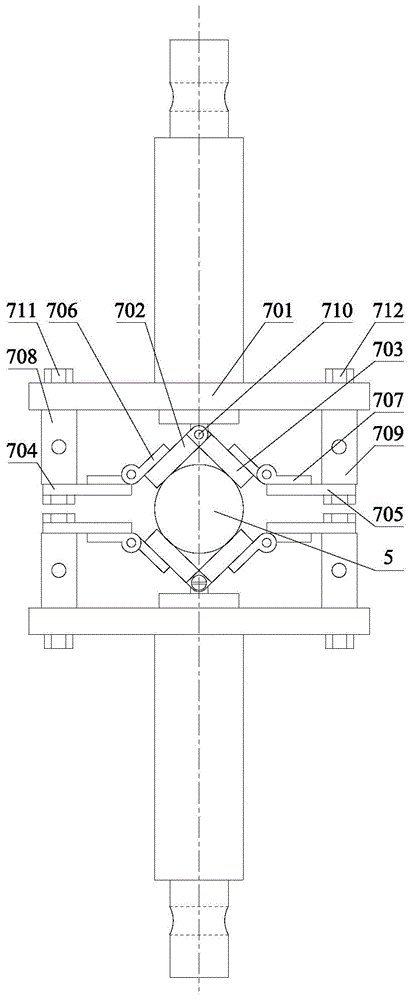

A multi-camera and multi-projector structured light experimental platform

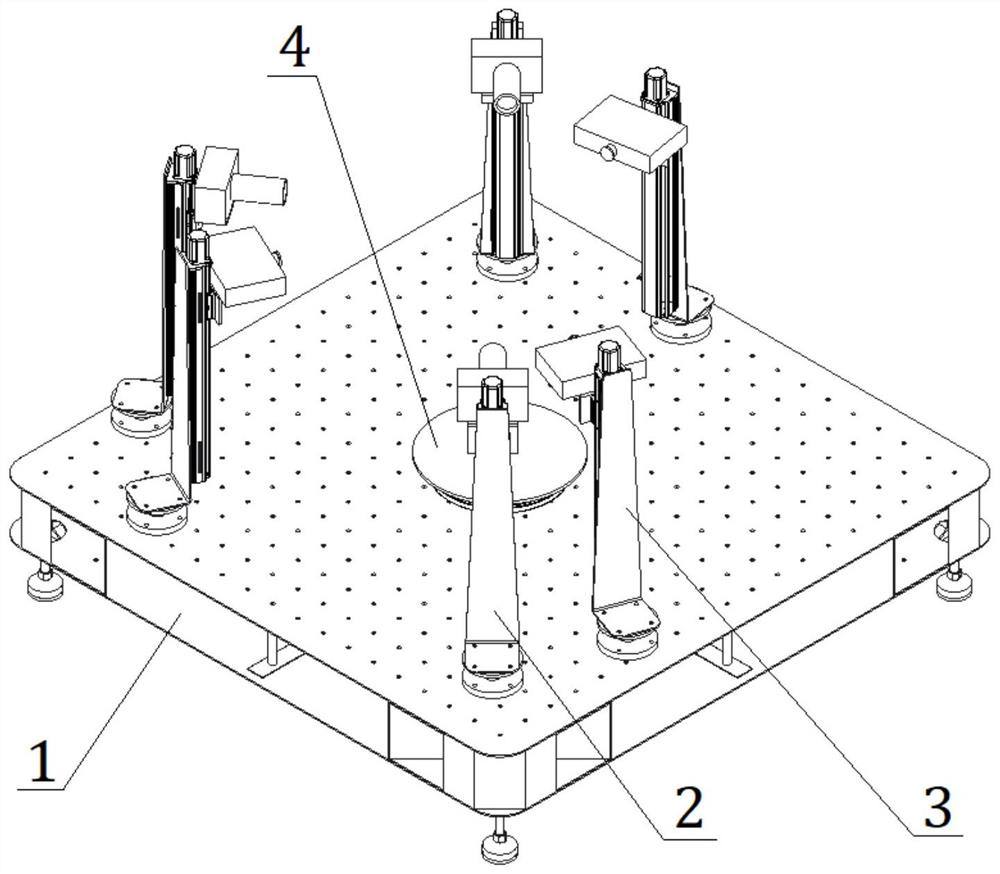

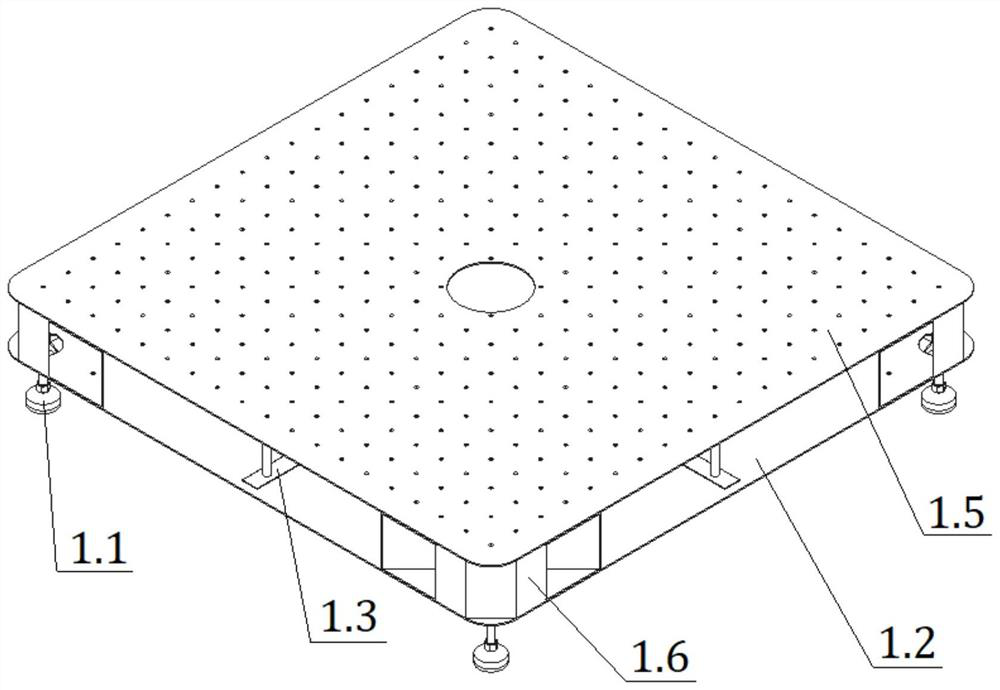

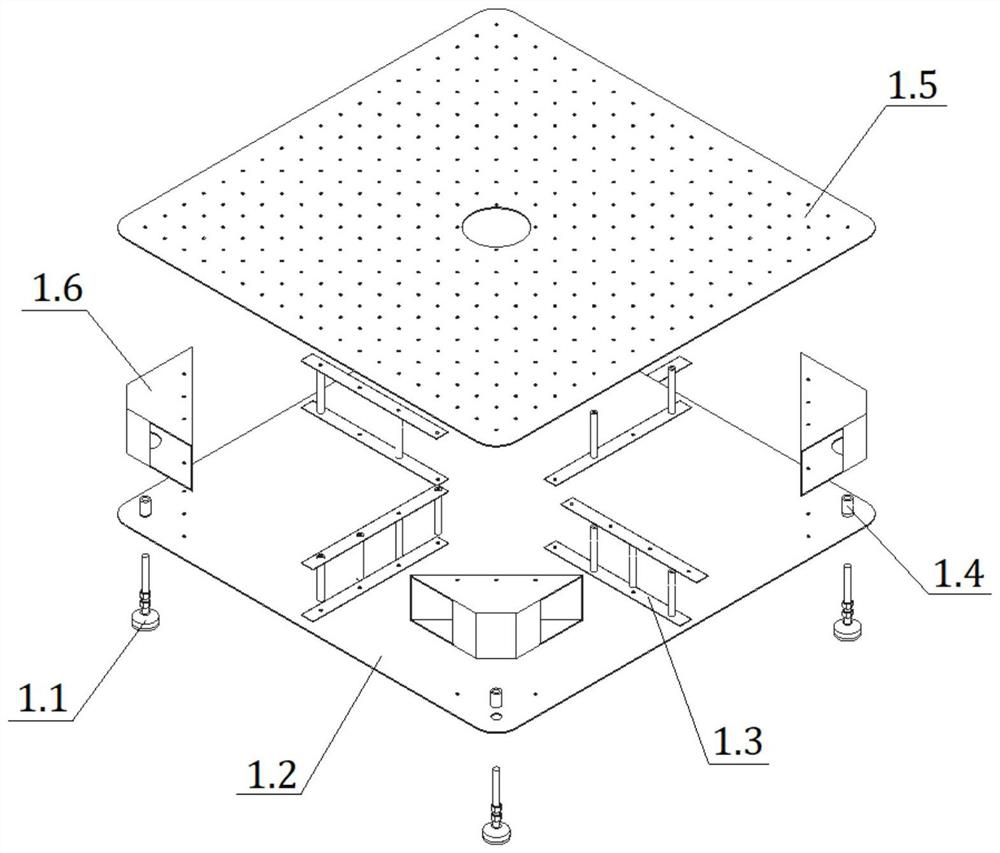

InactiveCN109556516BPrecise 3D Space AdjustmentLarge measuring rangeUsing optical meansEngineeringMechanical engineering

The invention discloses a structured light experiment platform of multi-camera and multi-projector, which comprises an experimental platform, a camera adjustable mount, a projector adjustable mount, and a rotating platform. The array of the X-axis direction and the Y-axis direction of the upper end plate of the experimental platform is uniformly arranged with a plurality of tapping screw holes. The camera adjustable mount and the projection adjustable mount are mounted in the tapping screw holes by bolts, and the position of the camera adjustable mount and the projection adjustable mount on the upper end plate is adjustable. The top platform of the rotating platform can be rotated 360 degrees. The invention can be used for three-dimensional reconstruction of single-camera and single-projection, and can also be used for three-dimensional reconstruction of multi-camera and multi-projection, and can be used for researching reconstruction effects of different camera-projectors at differentpositions for comparison test. The camera adjustable mount, projector adjustable mount and rotating platform are equipped with servo motors, so that important parameters such as running speed and rotation angle can be precisely controlled by the program.

Owner:WUHAN UNIV OF SCI & TECH

Spring Indexing Mechanism

The invention discloses a spring indexing mechanism. The spring indexing mechanism comprises a machine frame. The spring indexing mechanism is characterized in that the machine frame is internally provided with an indexing electromagnet assembly capable of driving springs to turn from horizontal to vertical, a lifting assembly capable of driving the indexing electromagnet assembly to life and lower vertically and a horizontal movement assembly capable of driving the along the indexing electromagnet assembly to move in the horizontal direction. The indexing electromagnet assembly is mounted onthe lifting assembly, and the lifting assembly is mounted on the horizontal movement component. A plurality of horizontally disposed springs are adsorbed side by side on the indexing electromagnet assembly, and the indexing electromagnet assembly, the lifting assembly and the horizontal movement assembly are under unified control by a control system. The spring indexing mechanism is used in the production of spring mattress to turn the springs from horizontal to vertical and drive the springs to move to a next station, improves the production automation level of the spring mattress, reduces the working intensity in the production process, and improves the production efficiency.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

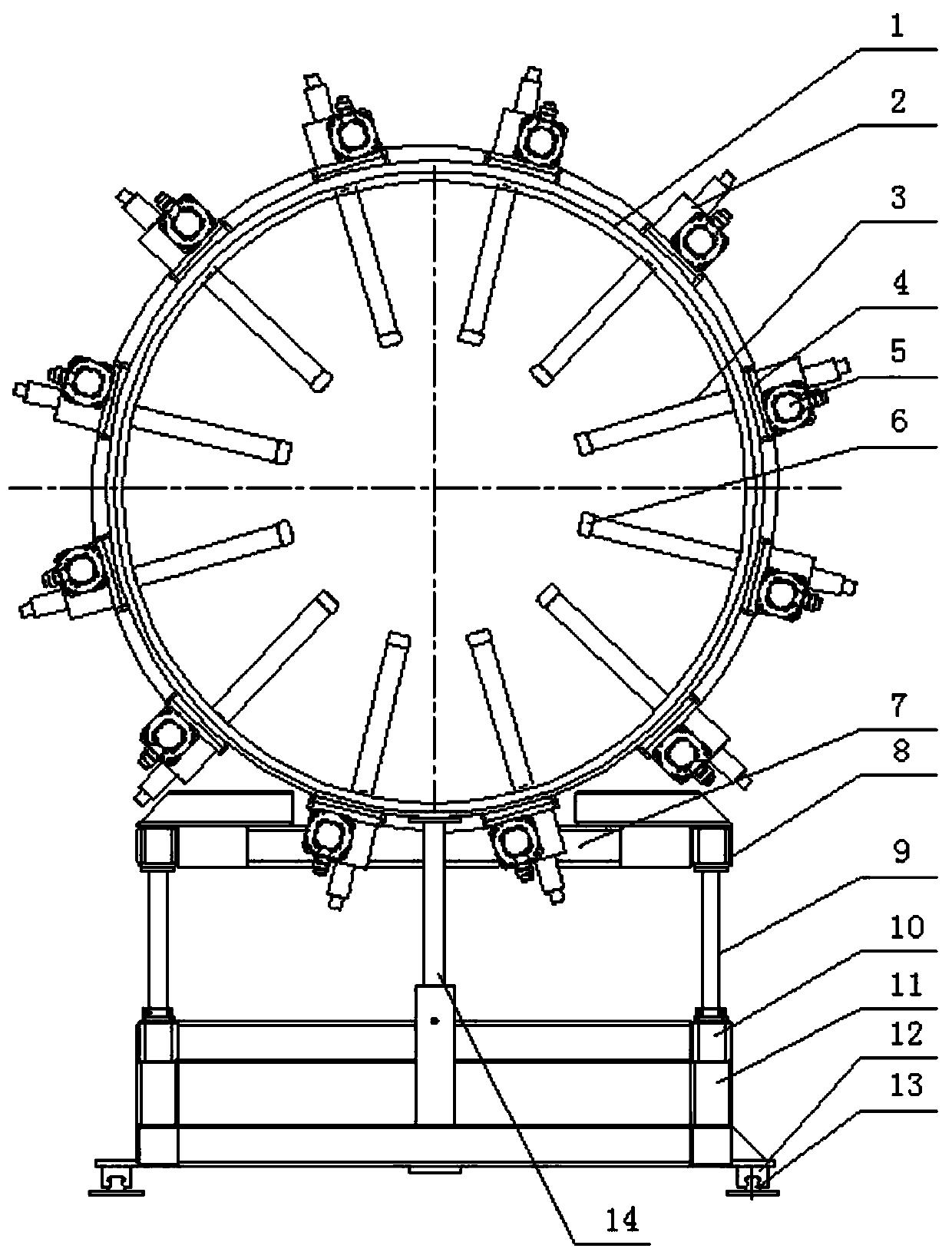

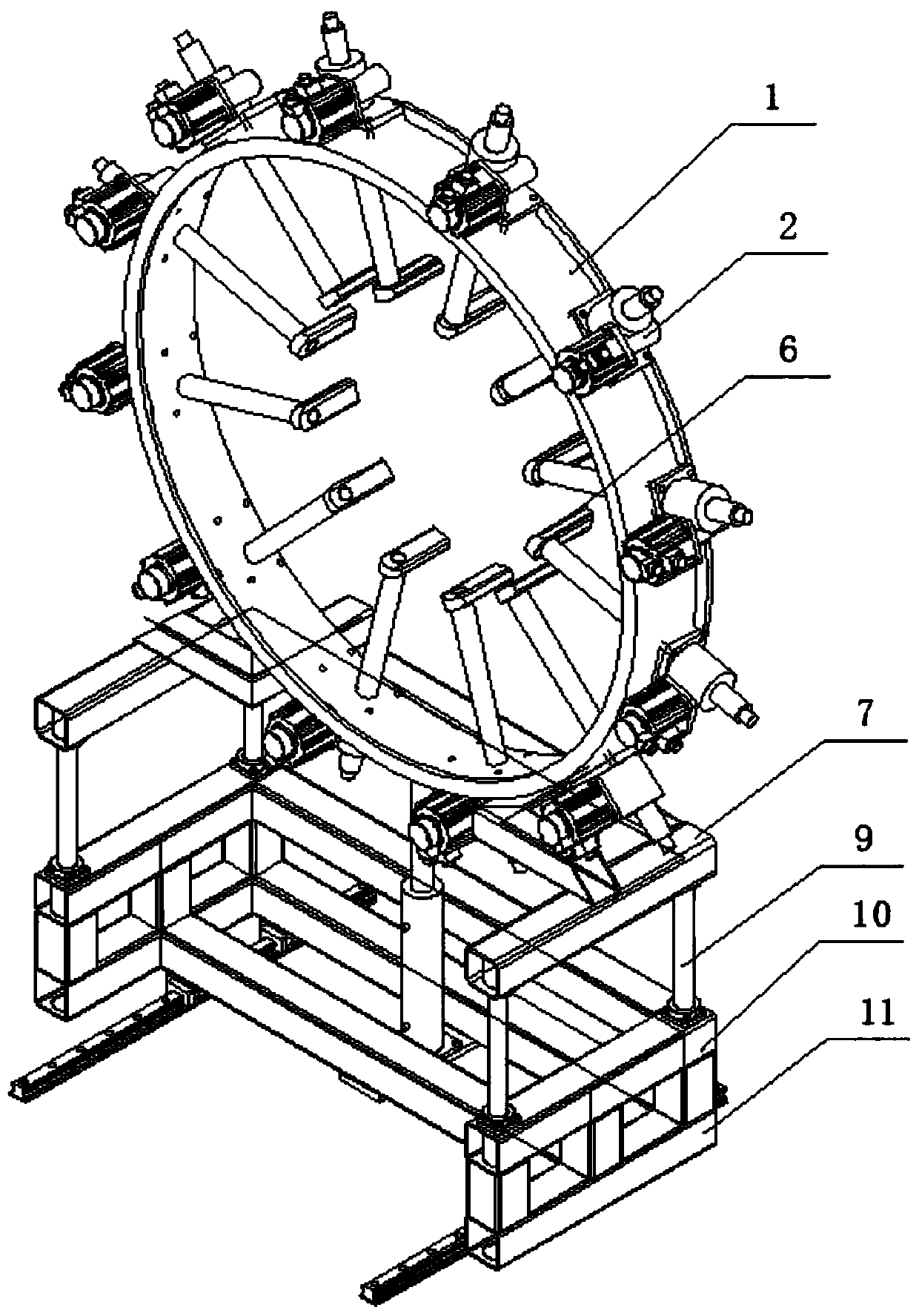

Polyurethane tube deformation numerical control shaping and rounding device

The invention relates to a polyurethane tube deformation numerical control shaping and rounding device which comprises a machine frame, a rounding plate and rounding jack assemblies. The rounding plate is fixedly installed on the machine frame. The rounding jack assemblies are evenly installed on the periphery of the rounding plate at intervals. Each rounding jack assembly comprises a base, a servo motor, a worm and gear driving mechanism, a lead screw and a claw hook, wherein the base is fixedly installed on the periphery of the rounding plate and provided with the worm and gear driving mechanism, a worm is driven by the servo motor, the exterior of a worm gear is in meshing transmission with the worm, and the interior of the worm gear is in meshing transmission with the lead screw. The lead screws of all the rounding jack assemblies extend to the center of the rounding plate, and the ends, facing the center of the rounding plate, of the lead screws are fixedly provided with the clawhooks. The polyurethane tube deformation numerical control shaping and rounding device performs rounding automatically, can allow a steel pipe to be quite conveniently inserted therein and greatly saves the pipe inserting time; and due to one-time rounding, the whole pipe can be inserted in, and work efficiency is effectively improved.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

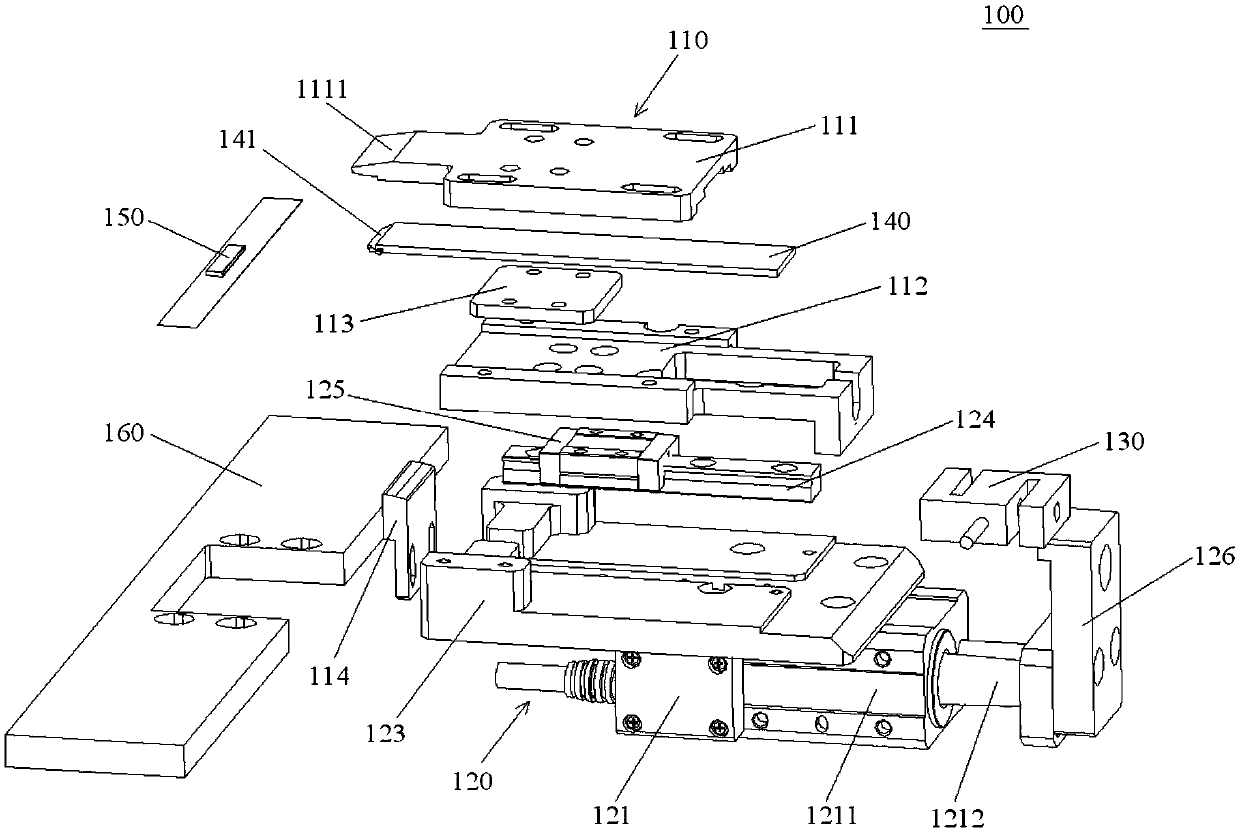

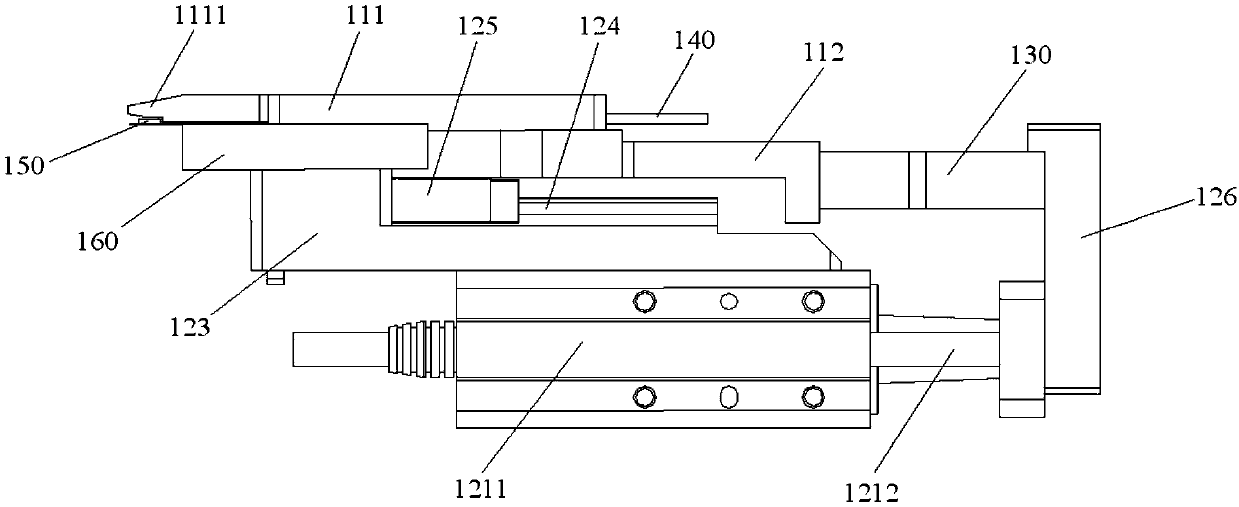

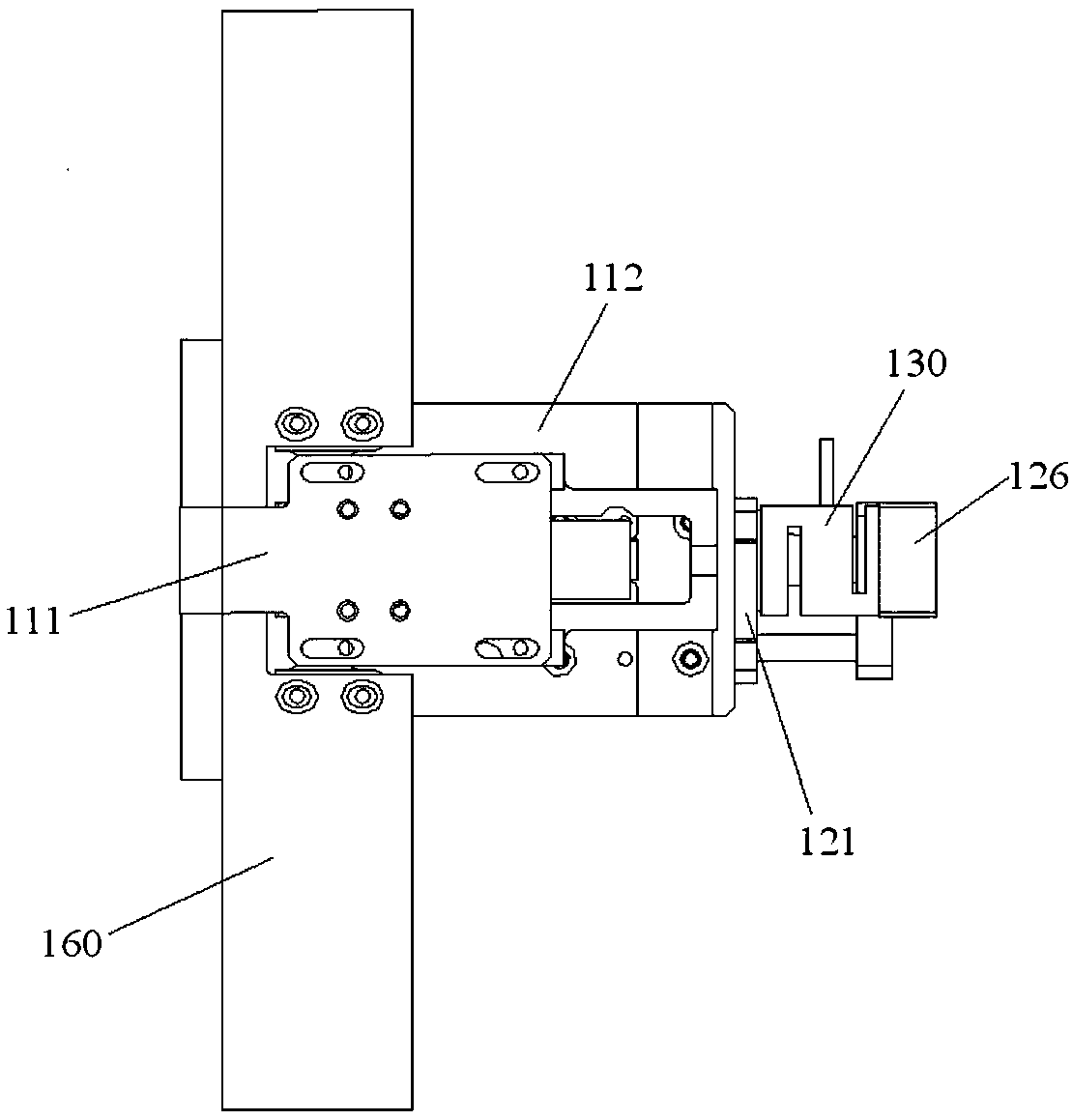

Automatic plugging and unplugging device for electric function testing of circuit boards

InactiveCN109541268AGuaranteed reliabilityAccurateMeasurement instrument housingEngineeringPressure sensor

The invention discloses an automatic plugging and unplugging device (100) for electric function testing of circuit boards. The automatic plugging and unplugging device (100) comprises a flat cable fixing unit (110), a driving unit (120), and a pressure sensor (130), wherein the flat cable fixing unit (110) is used to support and fix a flat cable (140); the driving unit (120) can drive the flat cable fixing unit (110) to move, so that the flat cable (140) can be connected to a circuit board to be tested (150); and the pressure sensor (130) is mounted between the flat cable fixing unit (110) andthe driving unit (120), so as to sense a driving force applied by the driving unit (120) on the flat cable fixing unit (110). The automatic plugging and unplugging device has the advantages that theflat cable can be automatically plugged into the circuit board to be tested, and can be precisely aligned with the circuit board.

Owner:QISDA SUZHOU

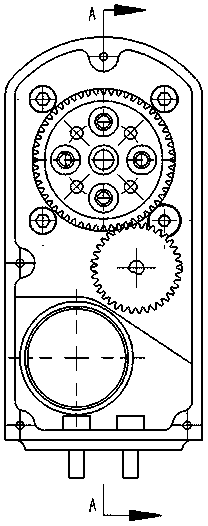

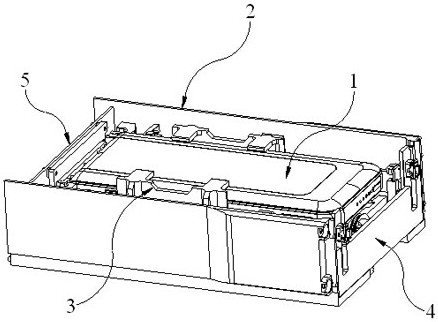

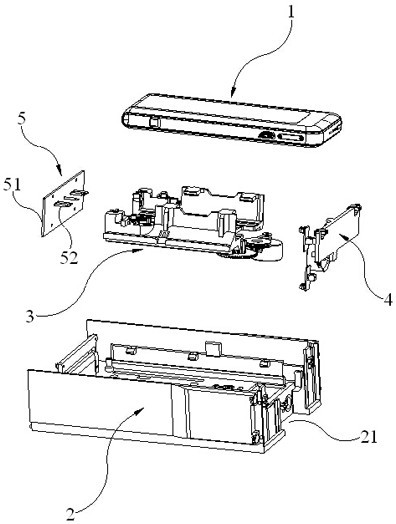

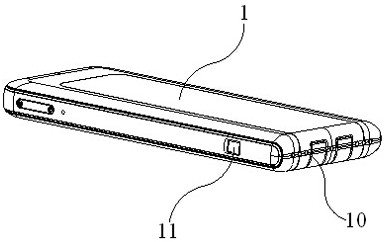

A kind of mifi device transmission equipment

ActiveCN108282176BEasy to installSolve the problem of not being able to connect to the wireless networkGearingNetwork topologiesGear wheelTransmission equipment

The invention provides a MIFI device transmission device, which comprises a shell with a shell opening, a carrier mechanism for carrying the MIFI device, a door mechanism for controlling the opening or closing of the shell opening, and a door mechanism for controlling the carrier mechanism and the door The control mechanism of the mechanism, the carrier mechanism, the door mechanism and the control mechanism are all arranged in the casing; the door mechanism includes a door arranged at the opening of the casing and a door transmission assembly that can drive the door to move up and down. The transmission assembly is connected, and the door transmission assembly is connected with the control mechanism; the carrier mechanism includes a carrier assembly for carrying the MIFI device and a carrier transmission assembly for driving the carrier assembly to move back and forth, the carrier assembly is provided with a carrier gear bar, and the carrier transmission assembly includes a The carrier motor connected to the control mechanism and the carrier gear unit connected to the carrier motor, the carrier gear unit is connected with the carrier gear bar; the trouble of carrying the MIFI device is saved, and it is convenient to use.

Owner:河北华舟电子科技有限公司

Large-stroke displacement high-precision measuring device based on dynamic balance work principle

InactiveCN105675397AHigh angular displacement detection accuracyPrecise control of movementMaterial strength using tensile/compressive forcesMaterial strength using steady shearing forcesHydraulic cylinderDynamic balance

The invention belongs to the field of mechanical engineering testing, and provides a large-stroke displacement high-precision measuring device based on a dynamic balance work principle. A, B and C hydraulic cylinder subsystems are designed below a measured moving shaft, the A subsystem and the B subsystem are plunger type hydraulic cylinders and have the diameter ratio of 1:3; incompressible hydraulic oil is used as a transmission medium; displacement detected by a B system sensor is magnified by 9 times, and a high-precision servo motor can control precisely motion of a lead screw, so that a signal outputted by the B system high-precision displacement sensor can always be maintained in a dynamic stable invariant state. The device has the advantages of smart structure, reasonable layout, strong adaptability, long service life and high measuring precision, can solve the problem of high-accuracy and bidirectional measurement in a wide-range full range, and has good economy and popularization value.

Owner:DALIAN UNIV OF TECH

A precise control system dedicated to single-side galvanized steel plate surface

ActiveCN108796421BGuaranteed uniformityMovement precisionHot-dipping/immersion processesControl systemEngineering

Owner:上海建立电镀有限公司

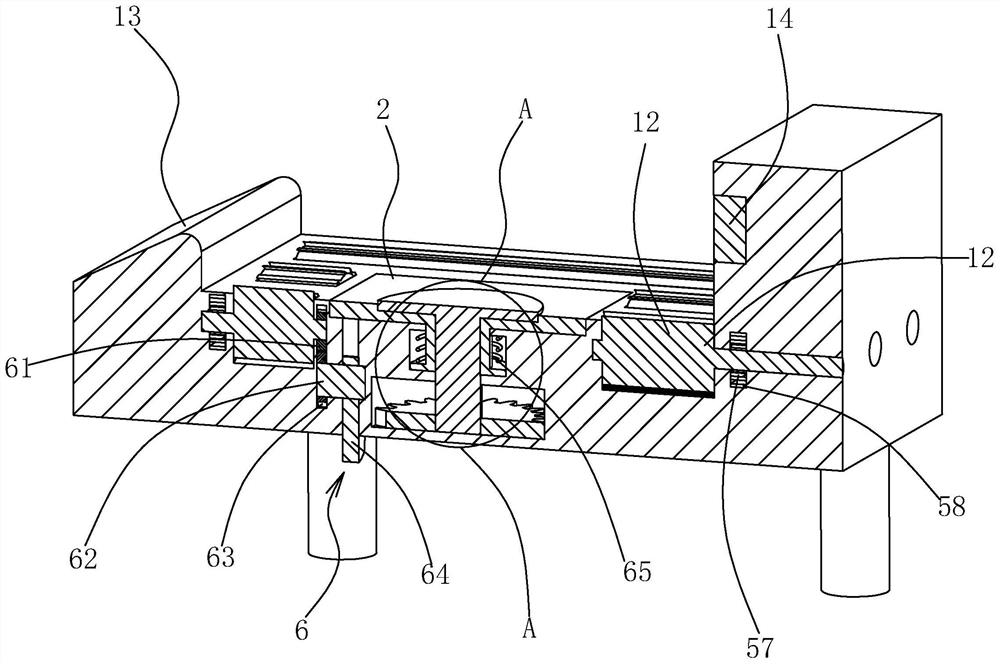

Platform and method for real-time image observation and acquisition of material microstructure under download

ActiveCN103592182BSimple structureSimple and fast operationStrength propertiesMaterials testingStrength of materials

The invention discloses a real-time image observation and acquisition platform and method for the microstructure of a material with loads. The platform comprises a loading device, an image observation and capture device and an XY double-coordinate micro-control mobile device and a PC, (Personal Computer), wherein the image observation and capture device is fixedly connected onto the XY double-coordinate micro-control mobile device; the XY planes of the XY double-coordinate micro-control mobile device are parallel to the surface to be observed of a material; the image observation and capture device and the loading device are respectively connected with the PC through data lines. The method comprises the following steps: dynamically capturing the images of the microstructure of the material with the loads, and associating a universal material testing machine sensor to synchronously obtain mechanics data; causing the PC to track the mechanics data flow acquired by the sensor, recognize a key point and trigger the image observation and capture device to take pictures; in the late, realizing correlation analysis of the data and the images through a computer and modeling. The acquisition platform and the method perfect the analysis method of mechanics of materials, disclose the damage evolution mechanism of materials, and provide a new method for study of damage mechanics of materials.

Owner:SOUTH CHINA AGRI UNIV

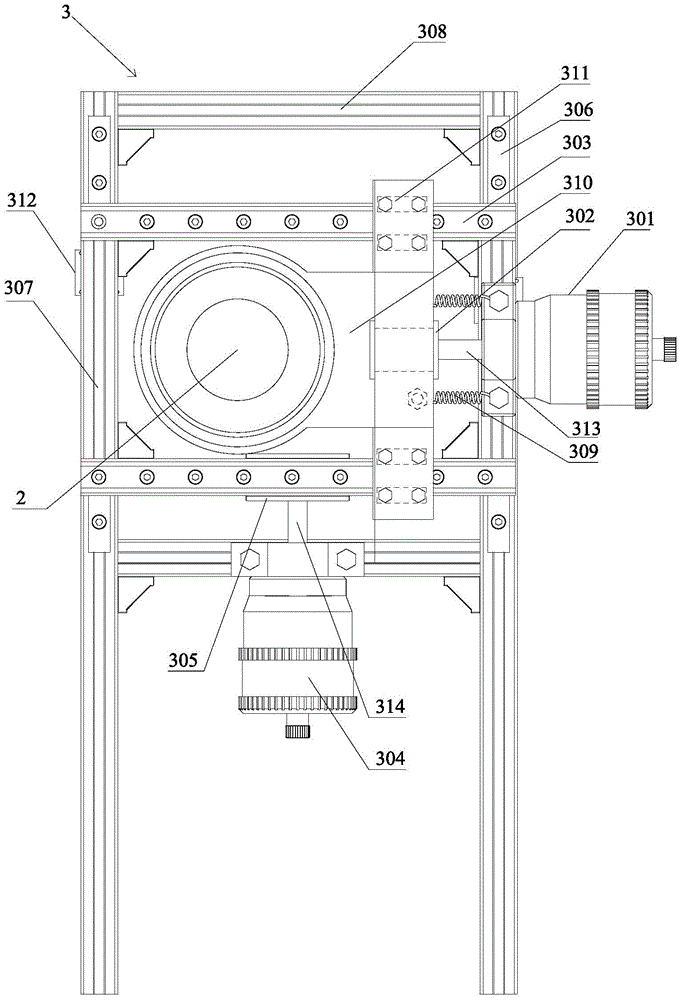

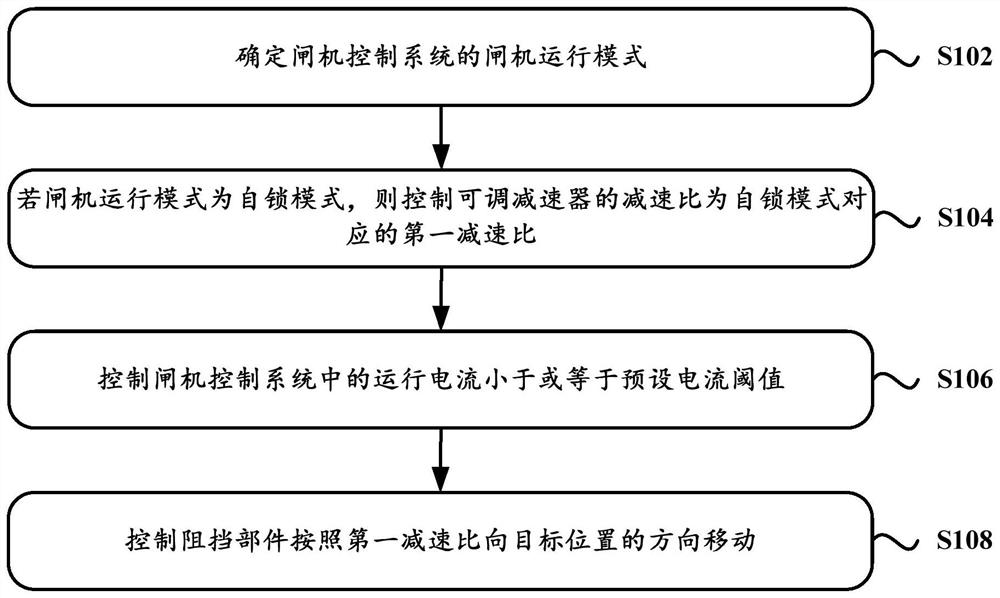

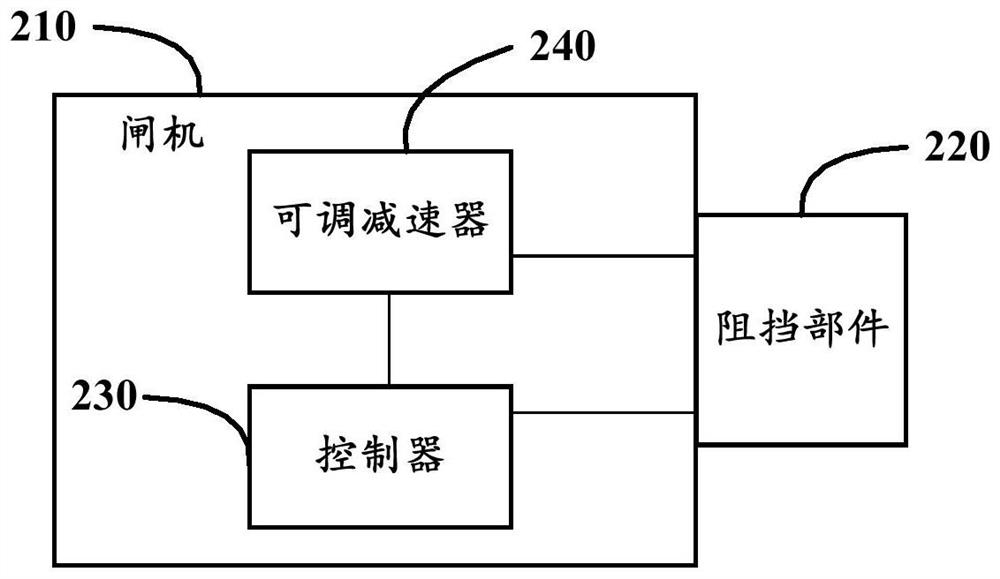

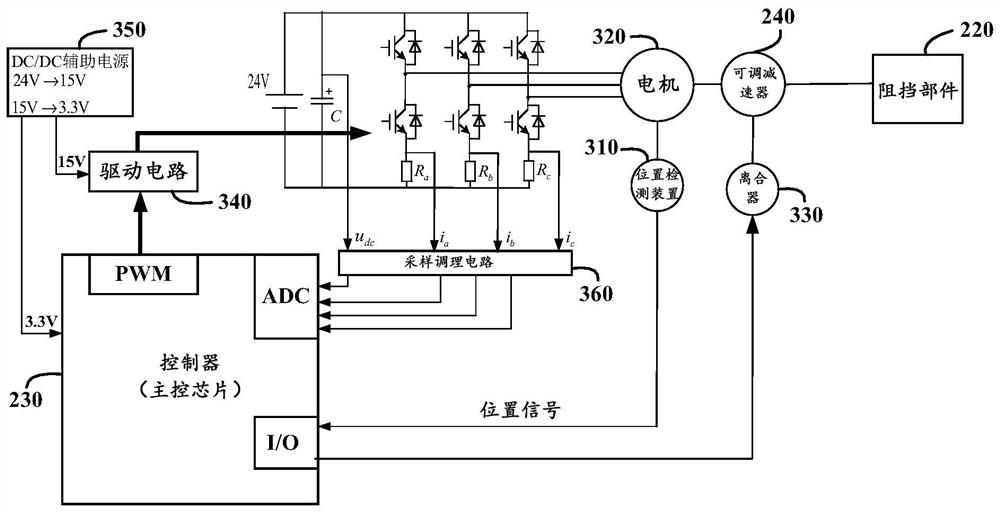

Self-locking control method of gate blocking component, gate control system and equipment

PendingCN114115019AIncrease self-locking torqueNot easy to moveProgramme controlComputer controlControl systemReduction drive

The embodiment of the invention discloses a self-locking control method of a gate blocking part, a gate control system and equipment, which are used for solving the problem that the self-locking mode of the existing gate blocking part is difficult to consider the moving speed and the self-locking torque of the blocking part, so that the gate is easily damaged or the self-locking fails. The method comprises the following steps: determining a gate operation mode of a gate control system; if the gate operation mode is the self-locking mode, the reduction ratio of the adjustable speed reducer is controlled to be a first reduction ratio corresponding to the self-locking mode; the operation current in the gate control system is controlled to be smaller than or equal to a preset current threshold value; and controlling the blocking part to move towards the target position according to the first reduction ratio. According to the technical scheme, the self-locking torque of the blocking component in the self-locking mode and the moving speed of the blocking component in the non-self-locking mode can be considered, meanwhile, the situation that a gate control system breaks down due to the fact that the running current is too large can be avoided, and stable self-locking of the blocking component is achieved.

Owner:HANGZHOU HIKVISION DIGITAL TECH

A high-precision measuring device for large-stroke displacement based on the working principle of dynamic balance

InactiveCN105675397BHigh angular displacement detection accuracyPrecise control of movementMaterial strength using tensile/compressive forcesMaterial strength using steady shearing forcesHydraulic cylinderDynamic balance

The invention belongs to the field of mechanical engineering testing, and provides a large-stroke displacement high-precision measuring device based on a dynamic balance work principle. A, B and C hydraulic cylinder subsystems are designed below a measured moving shaft, the A subsystem and the B subsystem are plunger type hydraulic cylinders and have the diameter ratio of 1:3; incompressible hydraulic oil is used as a transmission medium; displacement detected by a B system sensor is magnified by 9 times, and a high-precision servo motor can control precisely motion of a lead screw, so that a signal outputted by the B system high-precision displacement sensor can always be maintained in a dynamic stable invariant state. The device has the advantages of smart structure, reasonable layout, strong adaptability, long service life and high measuring precision, can solve the problem of high-accuracy and bidirectional measurement in a wide-range full range, and has good economy and popularization value.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com