Method for adjusting multi-magnetic-pole motion control

A control method and multi-pole technology, applied in the direction of discharge tubes, electrical components, circuits, etc., to achieve the effects of facilitating production and installation, realizing modularization, and simple circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

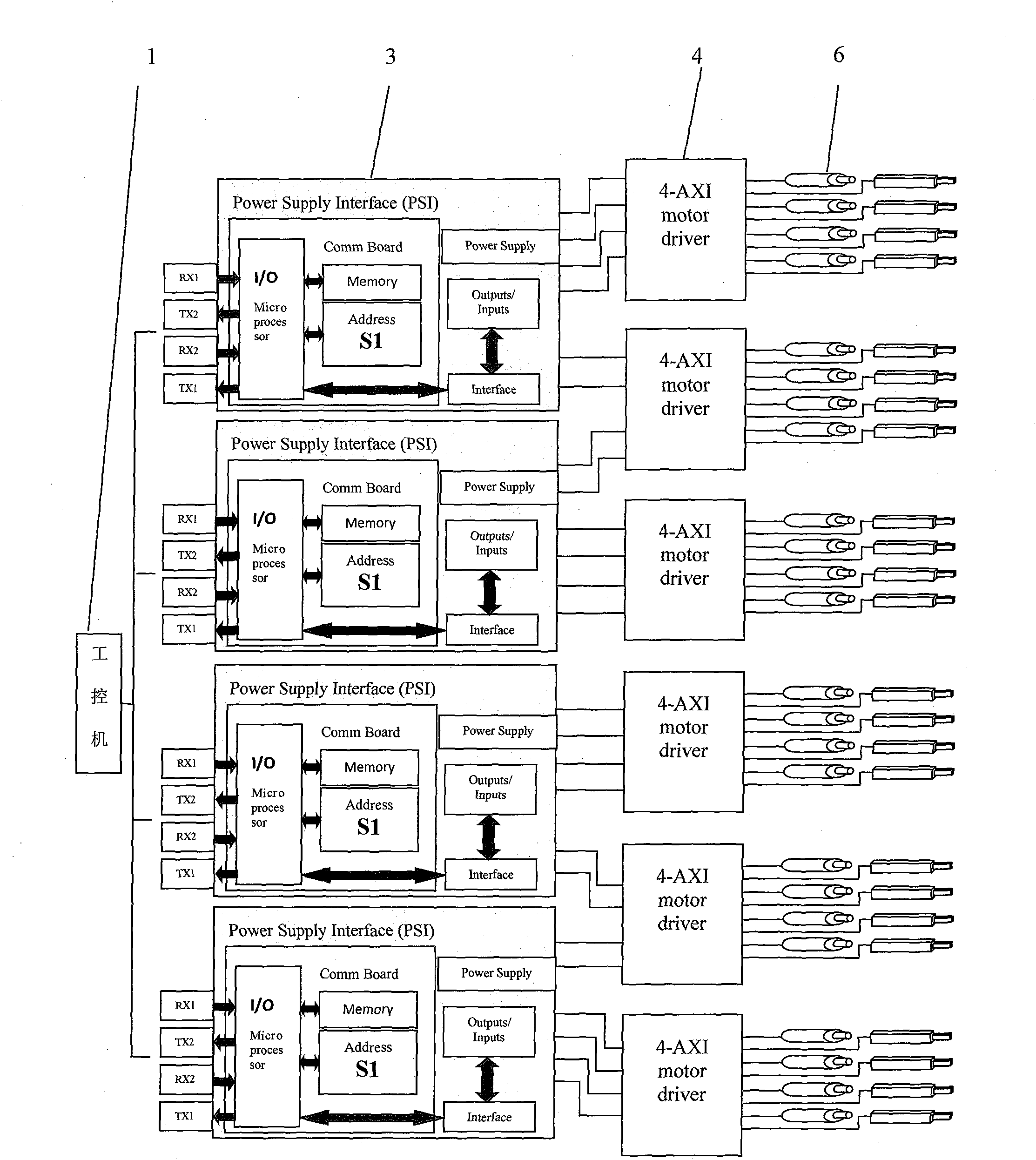

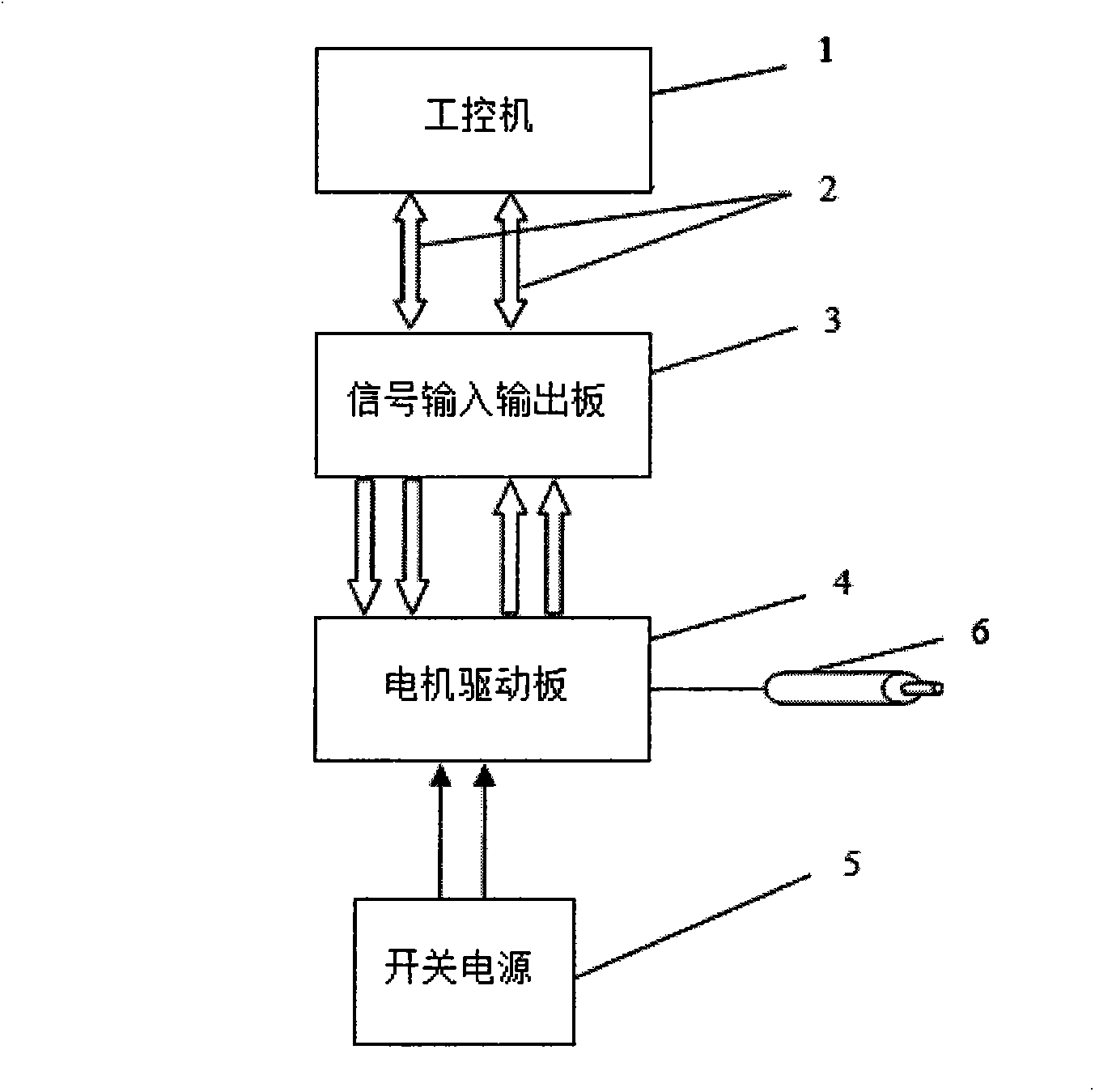

[0015] see figure 1 A control method for adjusting the movement of multi-magnetic poles, comprising an industrial computer (1), an optical fiber (2), a signal input and output board (3), a motor drive board (4), a switching power supply (5), and multi-magnetic poles (6).

[0016] The industrial computer (1) is connected to the signal input and output board (3) through an optical fiber (2) to send and receive data in real time, and the switching power supply (5) provides working voltage for the motor drive board (4), including the motor drive voltage and the displacement sensor. Voltage, the signal input and output board (3) is connected with the motor drive board (4), and the signal input and output board (3) sends the enable signal sent by the industrial computer (1) to the enable end of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com