an automatic extractor

An automatic and transmission belt technology, which is applied in the manufacture of inductors/transformers/magnets, coils, electrical components, etc., can solve the problems of high labor intensity, avoid damage to the guide pins, reduce impact, and improve efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

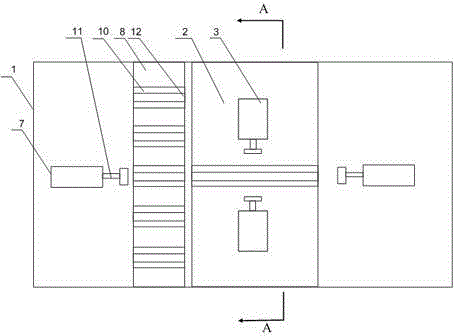

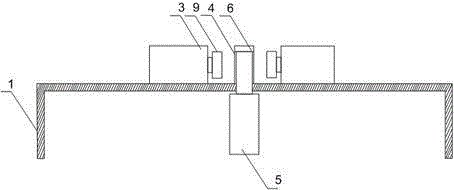

[0021] like figure 1 As shown, the present embodiment includes a working frame 1, and the working frame 1 is provided with a needle pulling device 2 and two driving mechanisms. The needle pulling device 2 is arranged between the two driving mechanisms, and also includes a transmission mechanism. Between the mechanism and the needle pulling device 2, a displacement sensor is also installed on the transmission mechanism; wherein the needle pulling device 2 includes a top plate 6, an upper top cylinder 5 and a baffle plate 4, the baffle plate 4 is arranged under the top plate 6, and the baffle plate 4 is fixed on On the working frame 1, the top plate 6 is connected to the top of the baffle plate 4, the upper top cylinder 5 is arranged vertically, and the telescopic end of the upper top cylinder 5 passes through the baffle plate 4 and is connected with the bottom surface of the top plate 6, and there are also two sets on the working frame 1. The clamping cylinder 3, the baffle is ...

Embodiment 2

[0024] like figure 1 and figure 2 As shown, rubber pads are also provided on the end faces of the two ends of the baffle 4 in this embodiment, and the splints 9 at the left and right ends are driven by the power equipment to quickly move toward the baffle 4, and the guide pins are placed between the baffle 4 and the splint 9. , the fast-moving splint 9 is directly in contact with the guide pin and the baffle plate 4, which will easily cause a certain impact on the guide pin, causing deformation of the guide pin and affecting its performance; The splint 9 provides a certain amount of cushioning to reduce the impact of the splint 9 on the guide needle, so as to ensure that the guide needle is clamped and fixed while preventing the guide needle from being damaged or deformed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com