Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

355results about How to "Guaranteed clamping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

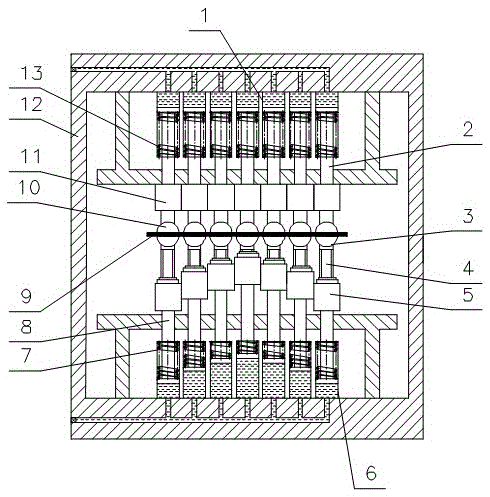

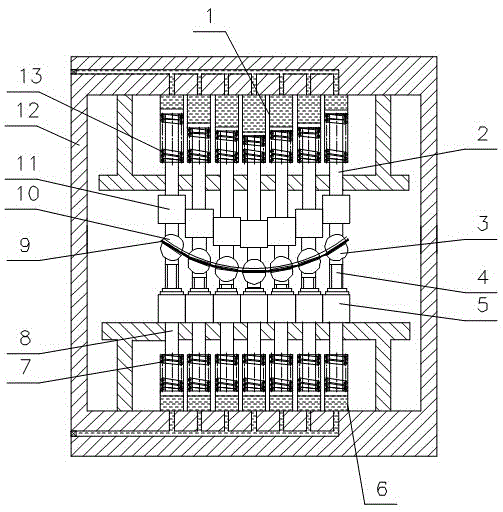

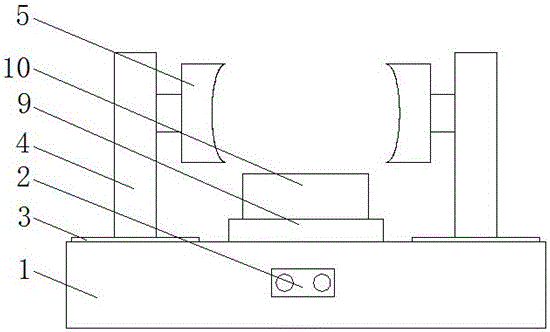

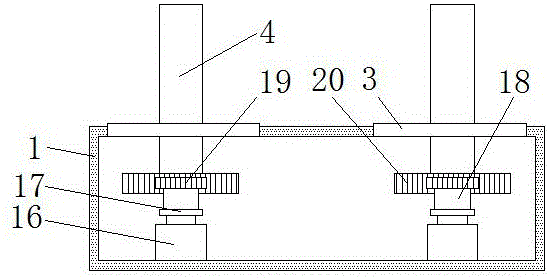

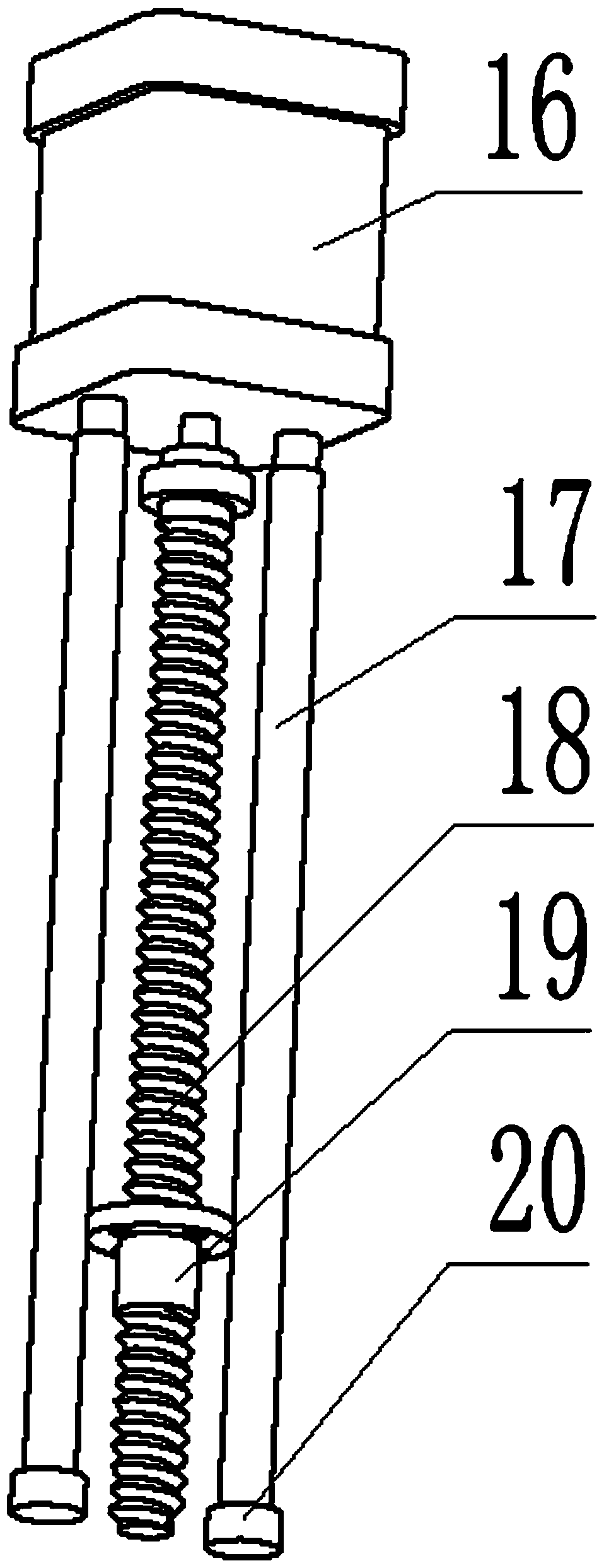

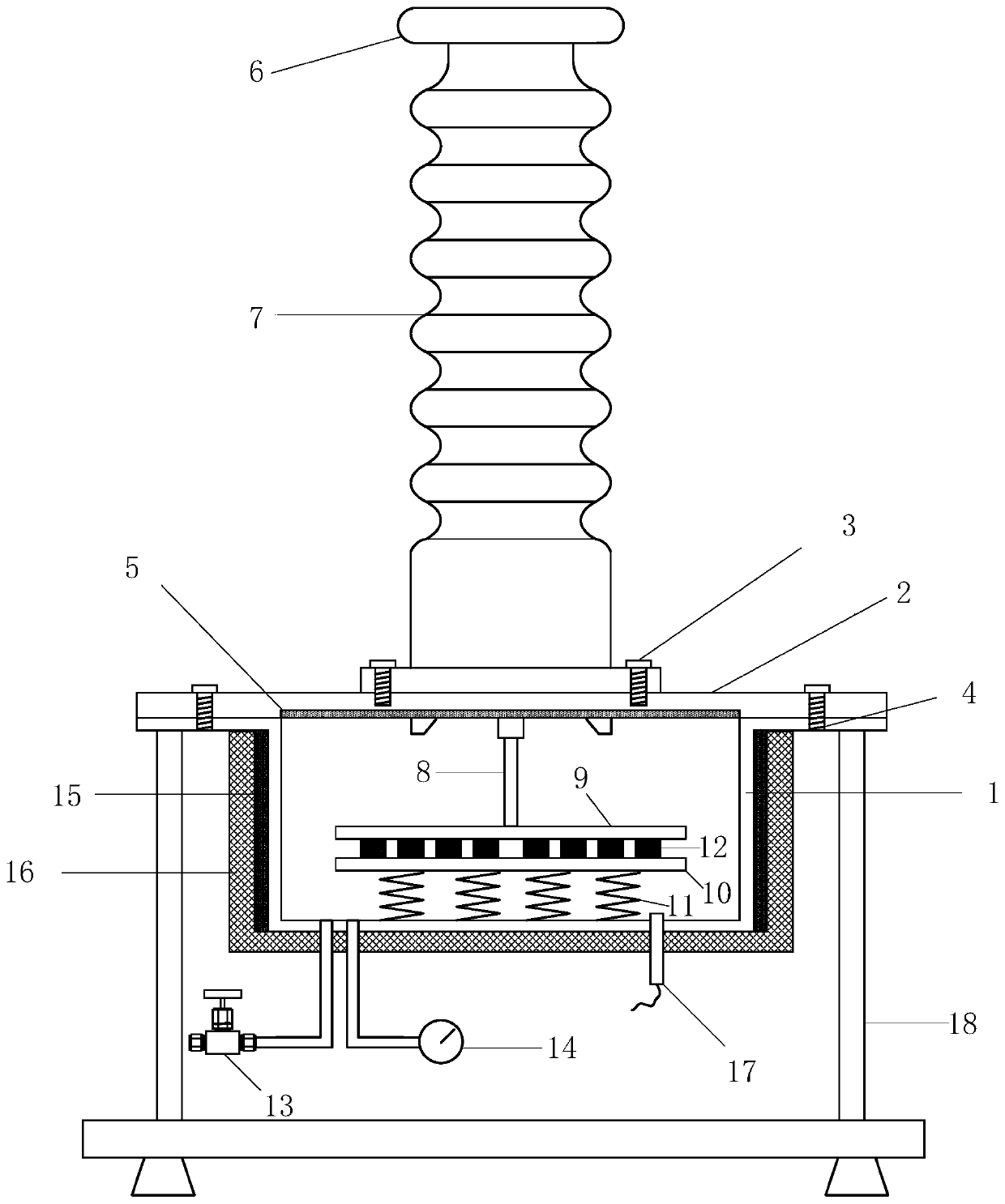

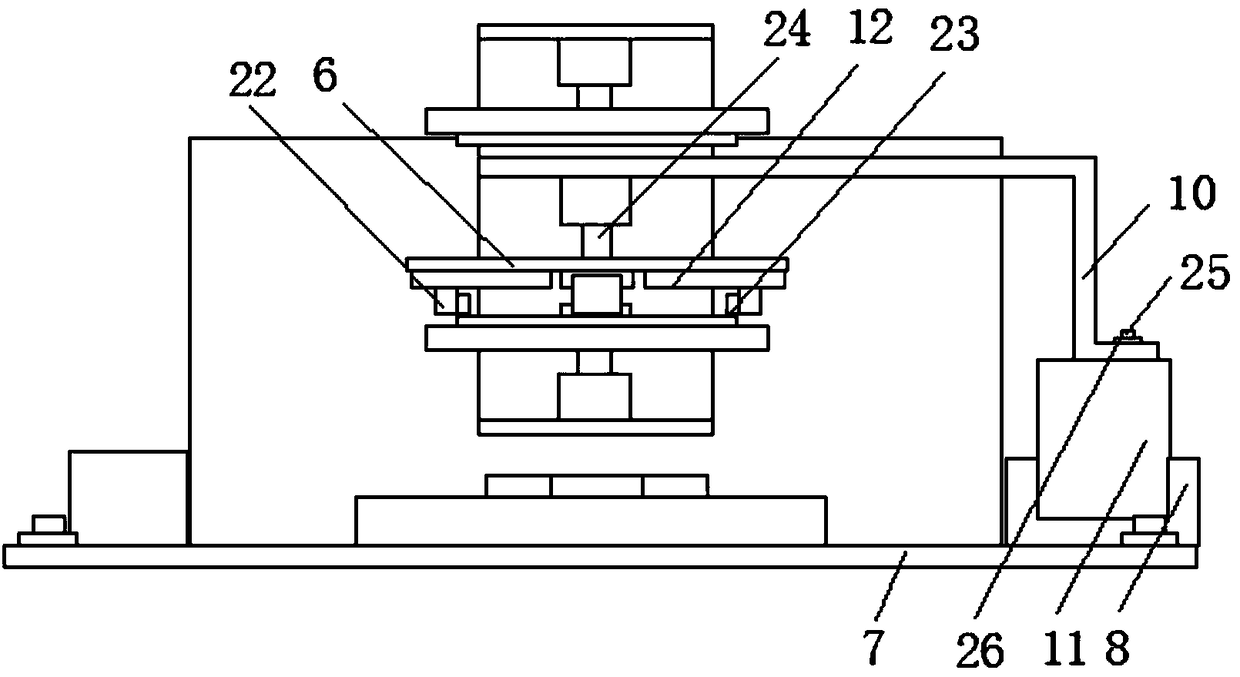

Plate multipoint progressive forming device

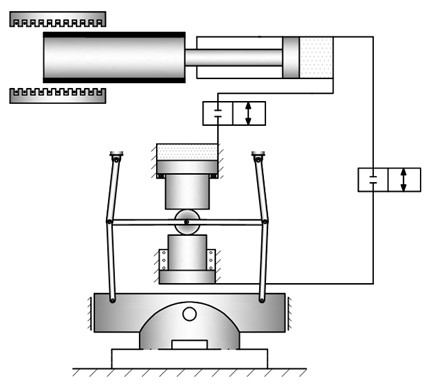

ActiveCN105478539AOptimal forming pathRaise the forming limitShaping toolsPress ramPistonEngineering

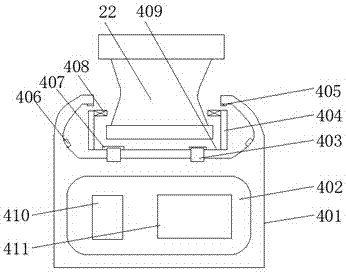

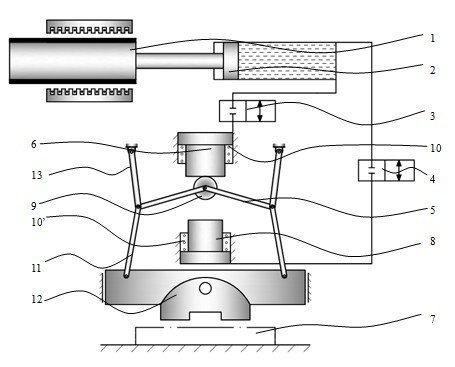

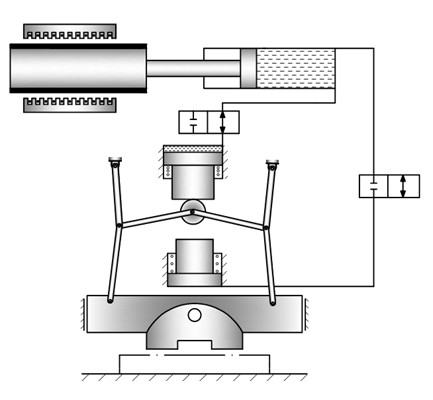

The invention relates to a plate multipoint progressive forming device which comprises a mould stand, a plurality of driving pressurization units and a plurality of shape adjusting and supporting units, wherein the driving pressurization units are mounted on a top plate of the mould stand; each driving pressurization unit consists of an upper pressing head, a driving basic body, a spring, a piston and a driving hydraulic cylinder; the upper pressing heads are movably mounted at the bottom ends of the driving basic bodies; the driving hydraulic cylinders are fixed to the top plate of the mould stand; the shape adjusting and supporting units are mounted on a bottom plate of the mould stand; each shape adjusting and supporting unit consists of a lower pressing head, a supporting basic body, a spring, an adjusting bolt and a supporting hydraulic cylinder; the lower pressing heads are movably mounted at the top ends of the adjusting bolts; the supporting hydraulic cylinders are fixed to the bottom plate of the mould stand; and under the action of the driving hydraulic cylinders and the supporting hydraulic cylinders, multipoint progressive forming of a plate between the upper pressing heads and the lower pressing heads is realized. The plate multipoint progressive forming device is reasonable in structure; by controlling the pressure difference between the two sides of the plate, the optimal forming effect is realized; the forming precision of the plate is high; and the surface quality of the plate is good.

Owner:HARBIN INST OF TECH AT WEIHAI

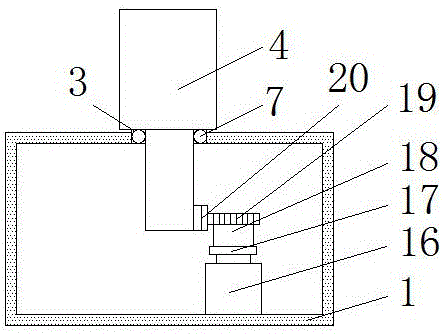

Grinding and painting equipment of locks for metal doors and windows

InactiveCN107497629AGuaranteed position changeReach spray paintLiquid surface applicatorsGrinding machinesWorking environmentArchitectural engineering

The invention discloses a polishing and painting equipment for metal door and window locks, which includes a frame, a first motor is fixedly connected to the top of the inner wall of the frame, and a first cone wheel is fixedly connected to the output shaft of the first motor through a flat key. , the bottom of the first conical wheel is fixedly connected with a second conical wheel, the second conical wheel is fixedly connected with a threaded rod through a flat key, and the top of the inner wall of the frame is fixedly connected with an auxiliary sliding track, the auxiliary An auxiliary slider is slidably connected to the inner wall of the sliding track, and the bottom of the auxiliary slider is fixedly connected to the slider through a connecting rod. The invention relates to the technical field of metal door and window lock processing. The grinding and painting equipment for metal doors and windows locks solves the problem of clamping and grinding workpieces, and can be positioned in different positions. The grinding device can change positions, ensuring the quality and accuracy of grinding and the adaptability to multiple working environments. After grinding The problem of painting and drying the workpiece.

Owner:ZHEJIANG DEQING DETAI DOOR IND

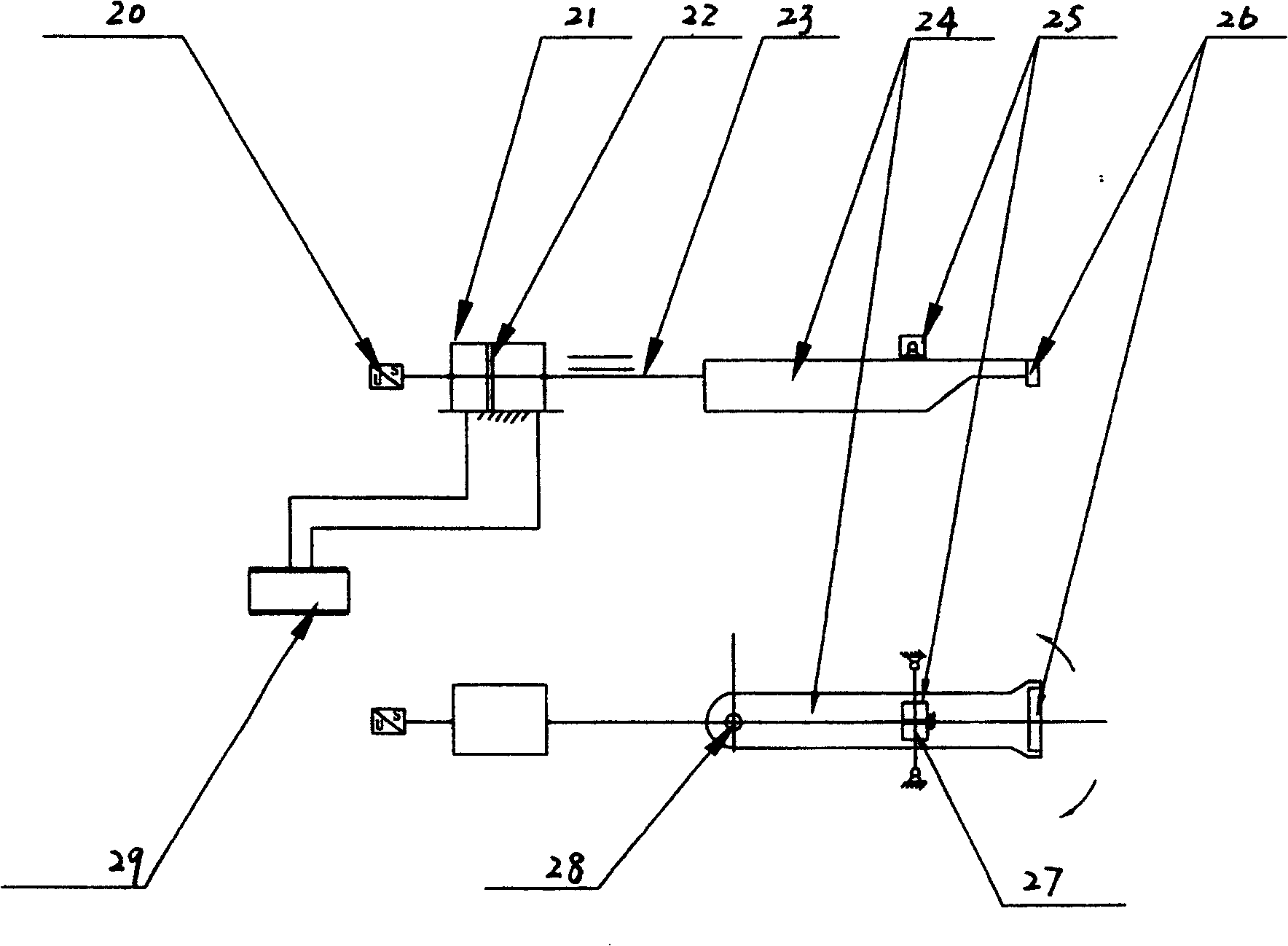

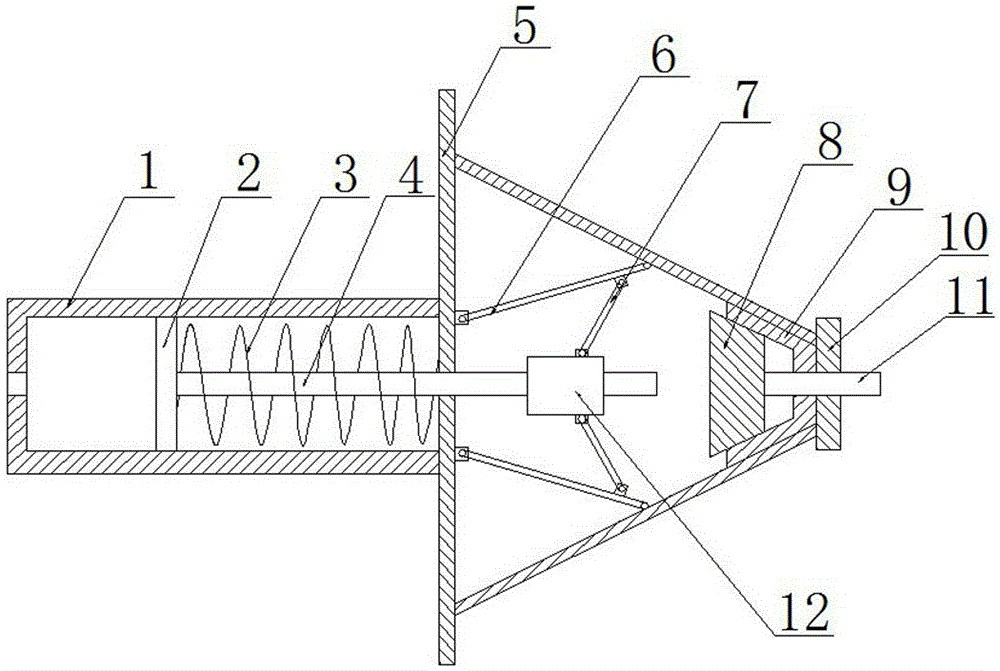

Automatic pipe bending device and pipe bending process thereof

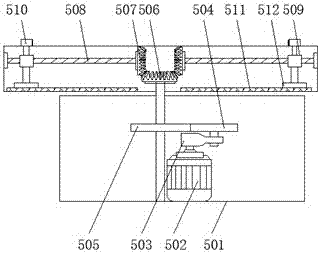

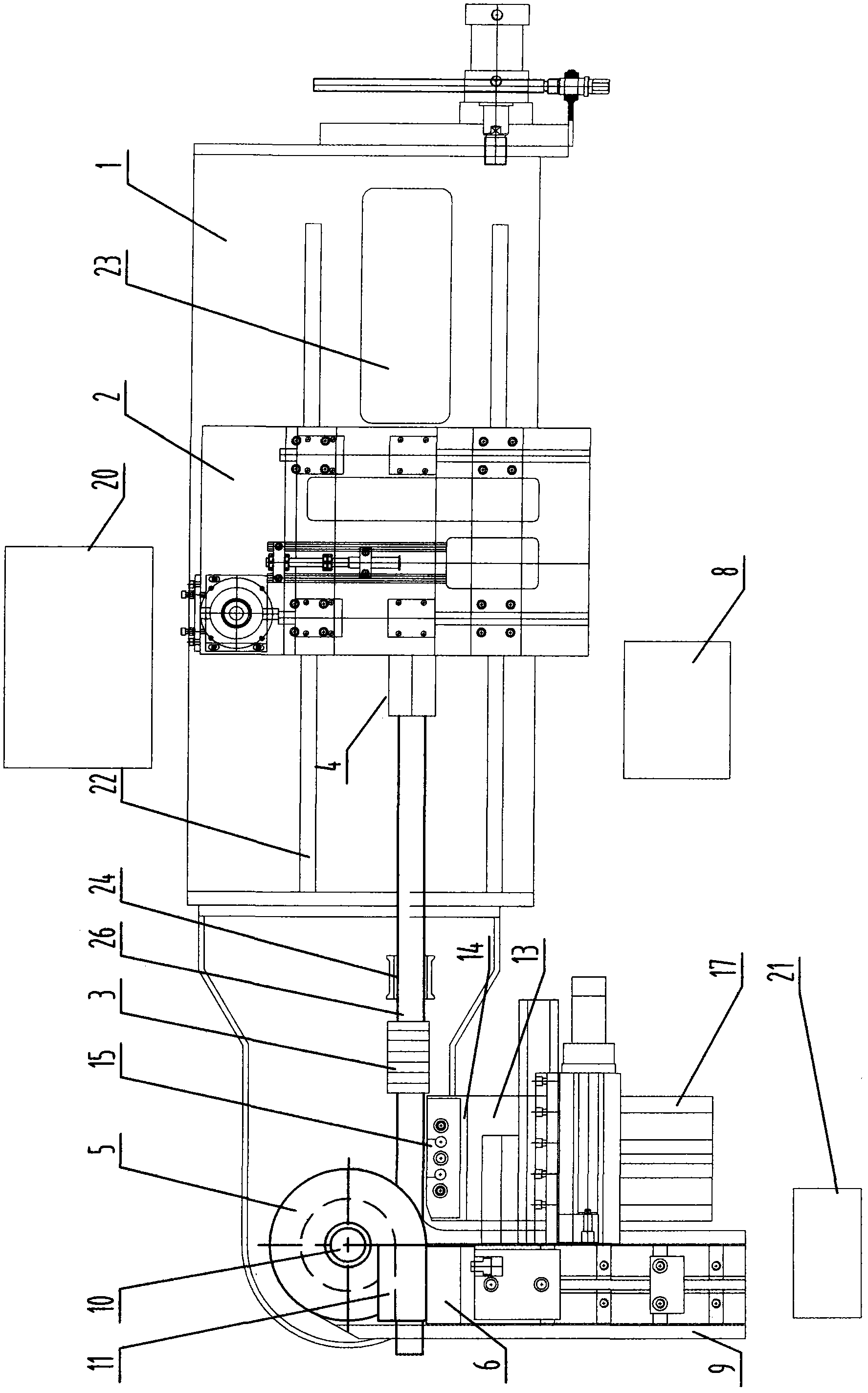

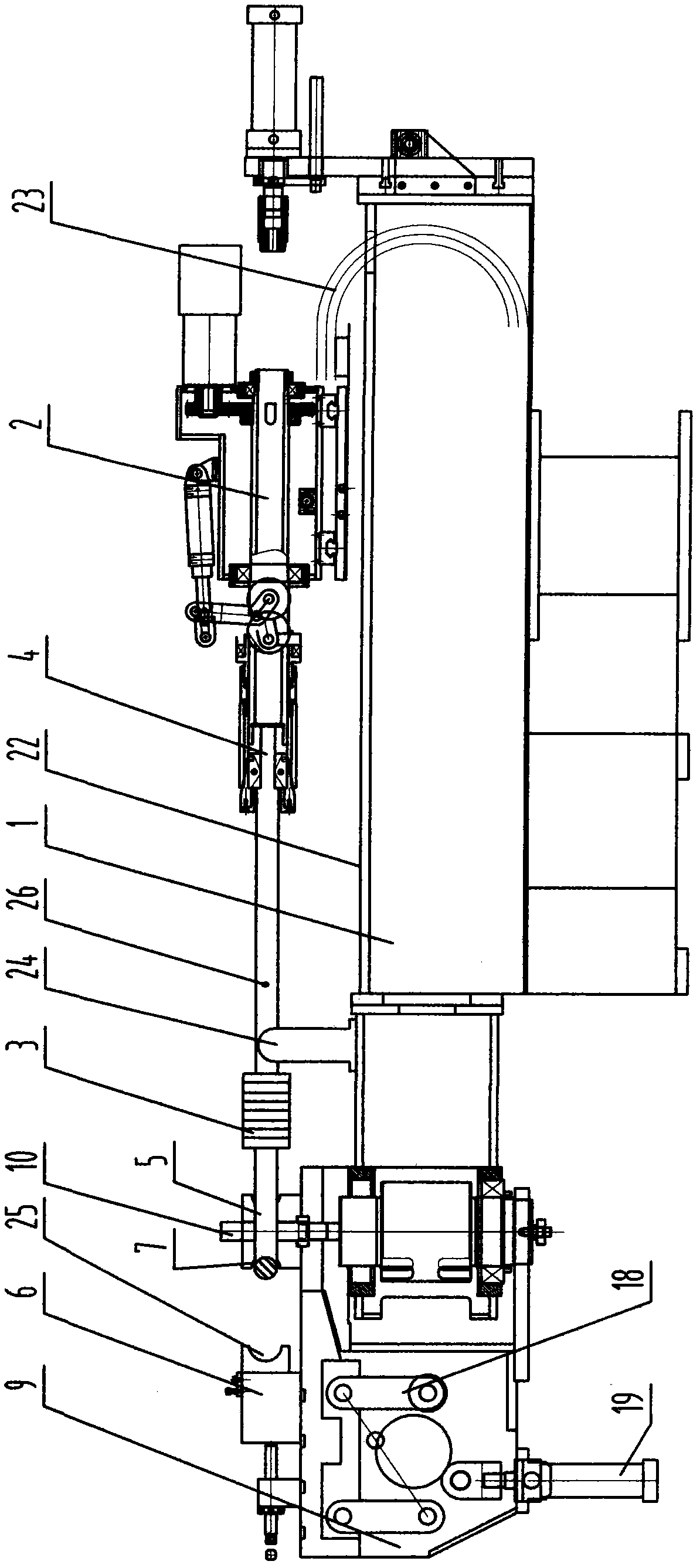

The invention discloses an automatic pipe bending device and a pipe bending process thereof, belonging to the technical field of mechanical processing and manufacturing. The technical scheme adopted by the invention is as follows: under the automatic control of an automatic control platform, a loading claw of a pipe loading machine firstly shifts a single pipe into a rotating fixture of a pinch device, the pinch device drives the pipe to move forward through a heater, the heater heats a bent part of the pipe to 1200-1350 DEG C, the bent part is moved to a bending mold, a follower plate and a movable jaw clamp the pipe, the movable jaw and the bending mold rotate to a bending angle around a rotating shaft, the follower plate and the movable jaw are reset after the pipe is released, the above process is repeated until the bending of the whole pipe is finished, and an unloading manipulator carries out unloading operation, thus finishing the bending process. The system can automatically finish pipe operations such as loading, feeding, heating, rotating, bending, unloading and the like, so that the pipe can be automatically bent and molded, the molding process is more accurate, and theyield is high; and the number of times for transporting the pipe in the processing process is reduced, and the productivity is improved.

Owner:西安德卡汽车系统有限公司

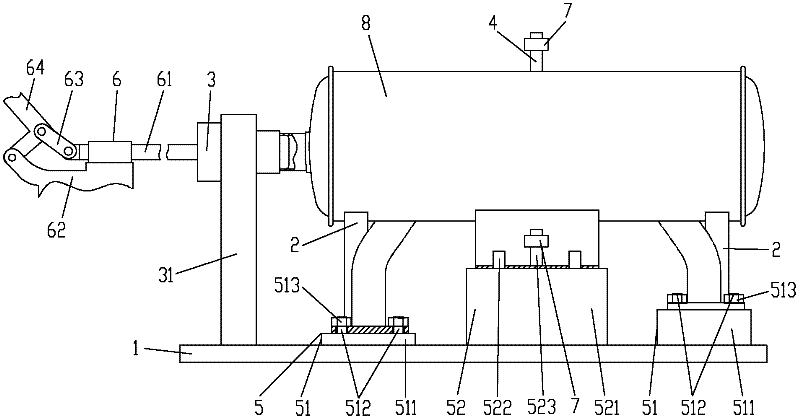

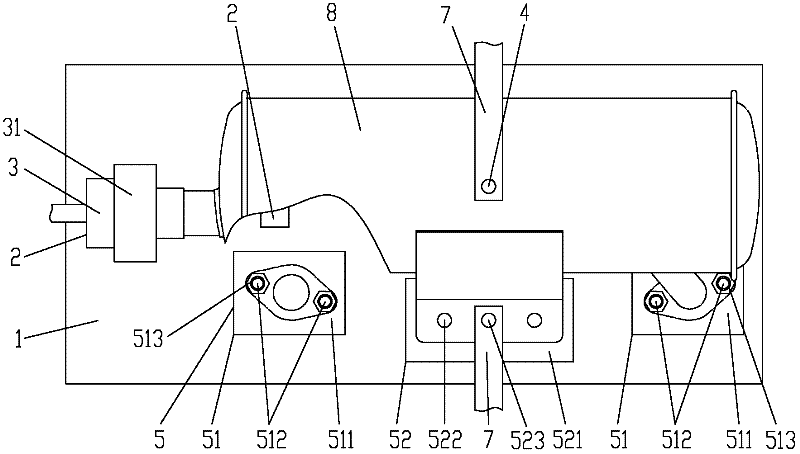

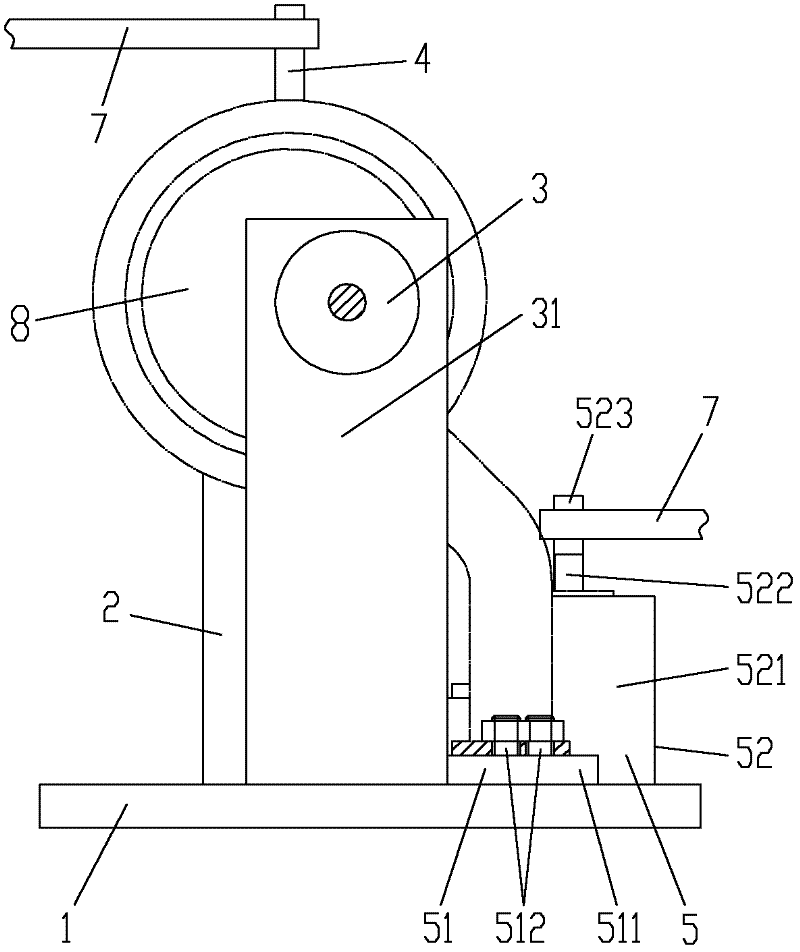

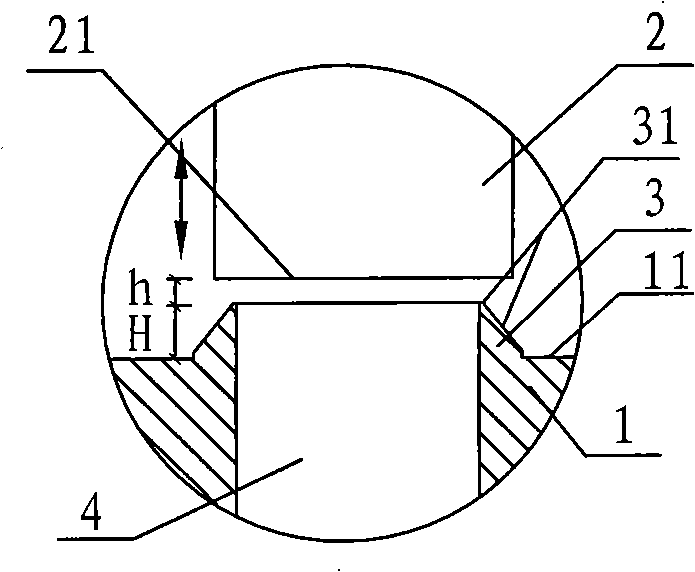

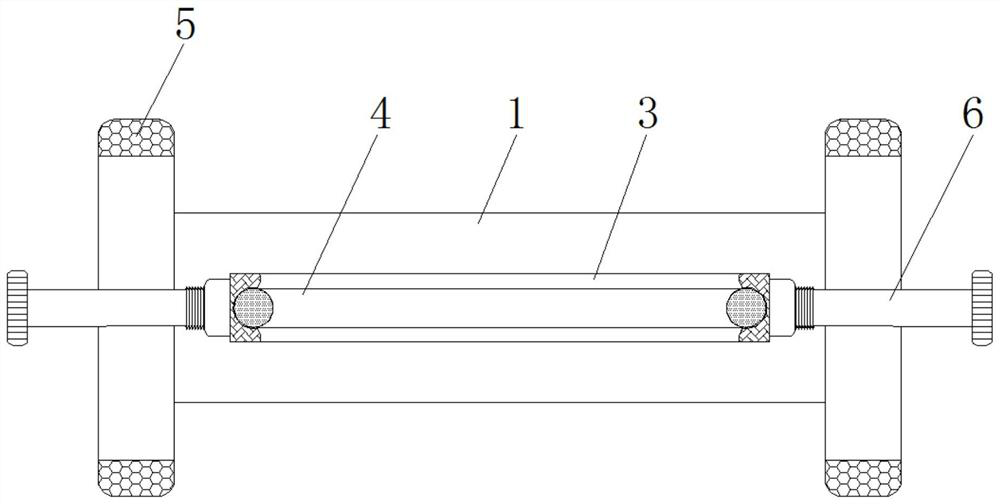

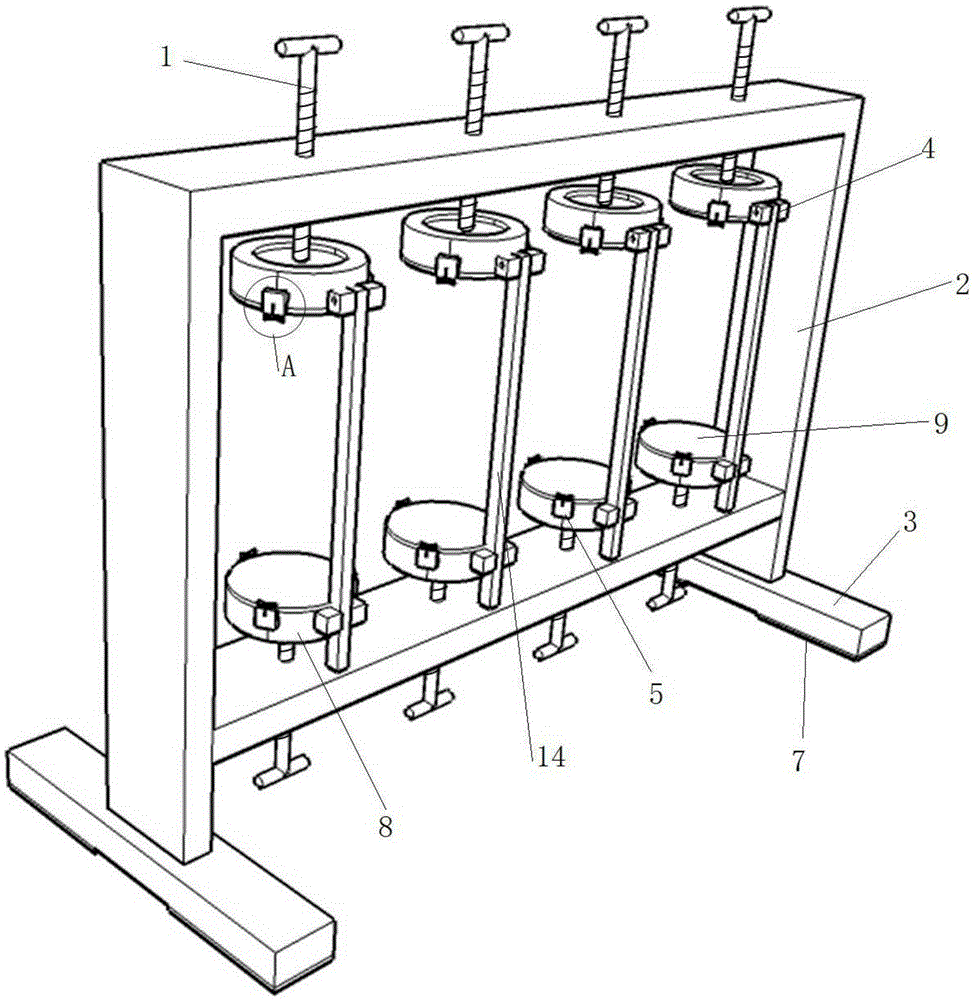

Round silencer assembly welding tooling

InactiveCN102328168AConvenient Relative Dimensional AccuracyGuaranteed relative dimensional accuracyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringFlange

The invention discloses a round silencer assembly welding tooling, which comprises a bottom plate, V-shaped support blocks, a horizontal positioning pin, a compression block and a compression positioning block, wherein the V-shaped support blocks, the horizontal positioning pin and the compression block are used for positioning a silencer outer tube requiring the assembly welding, and the compression positioning block is arranged at the bottom plate corresponding to the position where a support frame and two air inlet pipes need to be welded on the silencer outer tube and is used for compressing and positioning the support frame and the two air inlet pipes needing to be welded on the silencer outer tube. The round silencer assembly welding tooling has the advantages that the structure is simple and compact, the positioning is reliable, the clamping and the dismounting are convenient, when the round silencer assembly welding tooling is used for welding the two air inlet pipes with connecting flanges of the air inlet pipes and the support frame of a round silencer, the relative dimension precision among all welding elements can be ensured, the welding efficiency and the welding quality are effectively improved, the work intensity of workers is reduced, and the product qualification rate is improved.

Owner:CHONGQING BEIBEI DISTRICT FENGHUO MACHINERY MFG

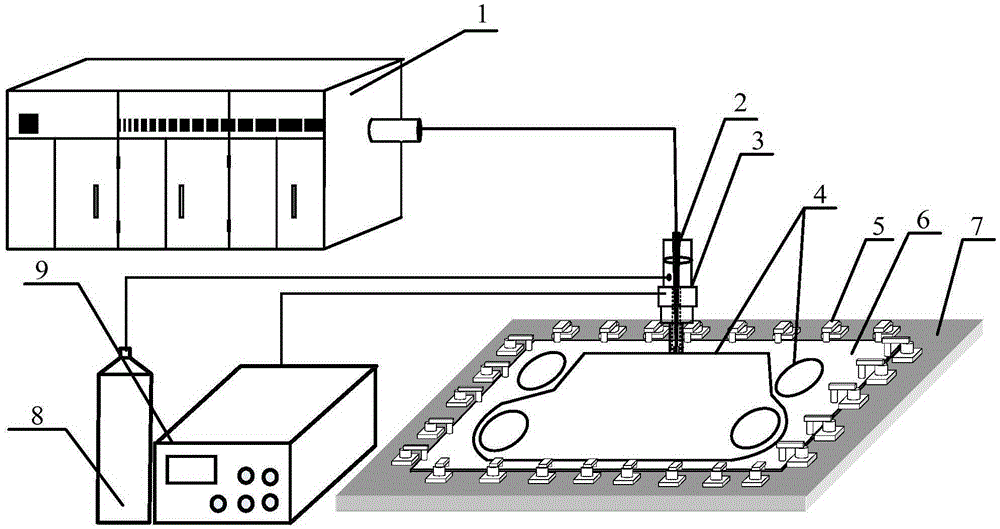

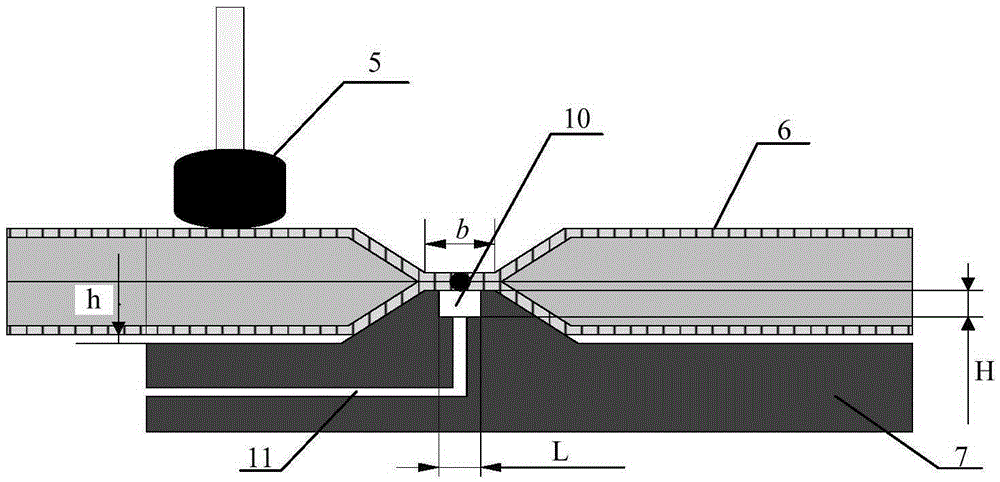

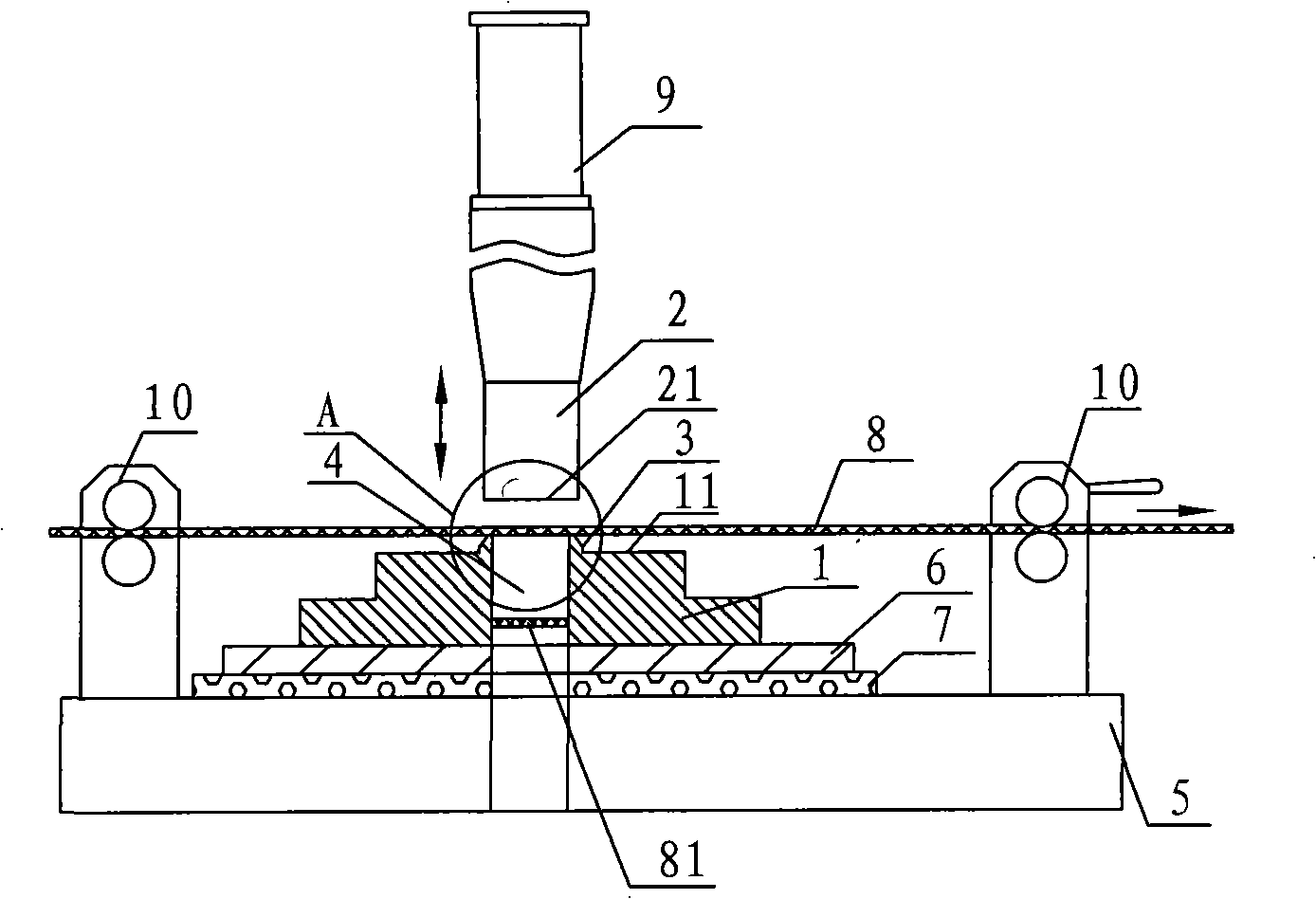

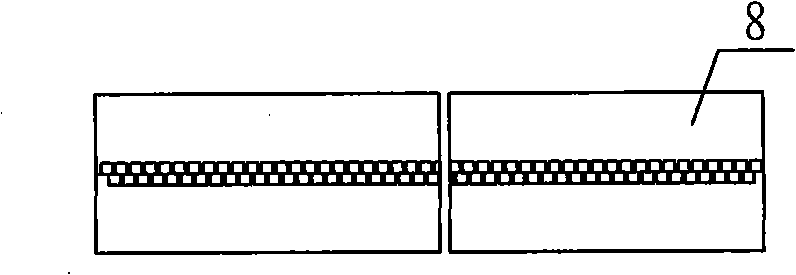

Ultrasonic coaxial auxiliary laser welding method for plate heat exchanger

ActiveCN105414763AImprove weld joint performanceAvoid Weld Porosity DefectsLaser beam welding apparatusWelding residual stressGas protection

The invention discloses an ultrasonic coaxial auxiliary laser welding method for a plate heat exchanger, before a plate sheet of the plate heat exchanger is welded, a self-designed laser welding auxiliary process device is used for clamping the plate sheet of the heat exchanger, in a process of performing the laser welding, high frequency ultrasonic vibration is applied, the ultrasonic vibration and laser beams are applied in a coaxial manner, during laser welding, an ultrasonic vibration tool directly contacts with the plate sheet of the heat exchanger. The laser welding auxiliary process device designed according to the invention can effectively solve the problems of clamping difficulty of plate sheets made from different materials of the heat exchanger and gas protection of a welding connector, meanwhile, an auxiliary action of the ultrasonic vibration can reduce or eliminate a welding residual stress, refine welding seam crystal grains, homogenize a welding seam tissue, and reduce pore and crack defects, thus improving a welding anticorrosion performance and mechanical performances, and prolonging the service life of the plate heat exchanger.

Owner:CHANGCHUN UNIV OF SCI & TECH

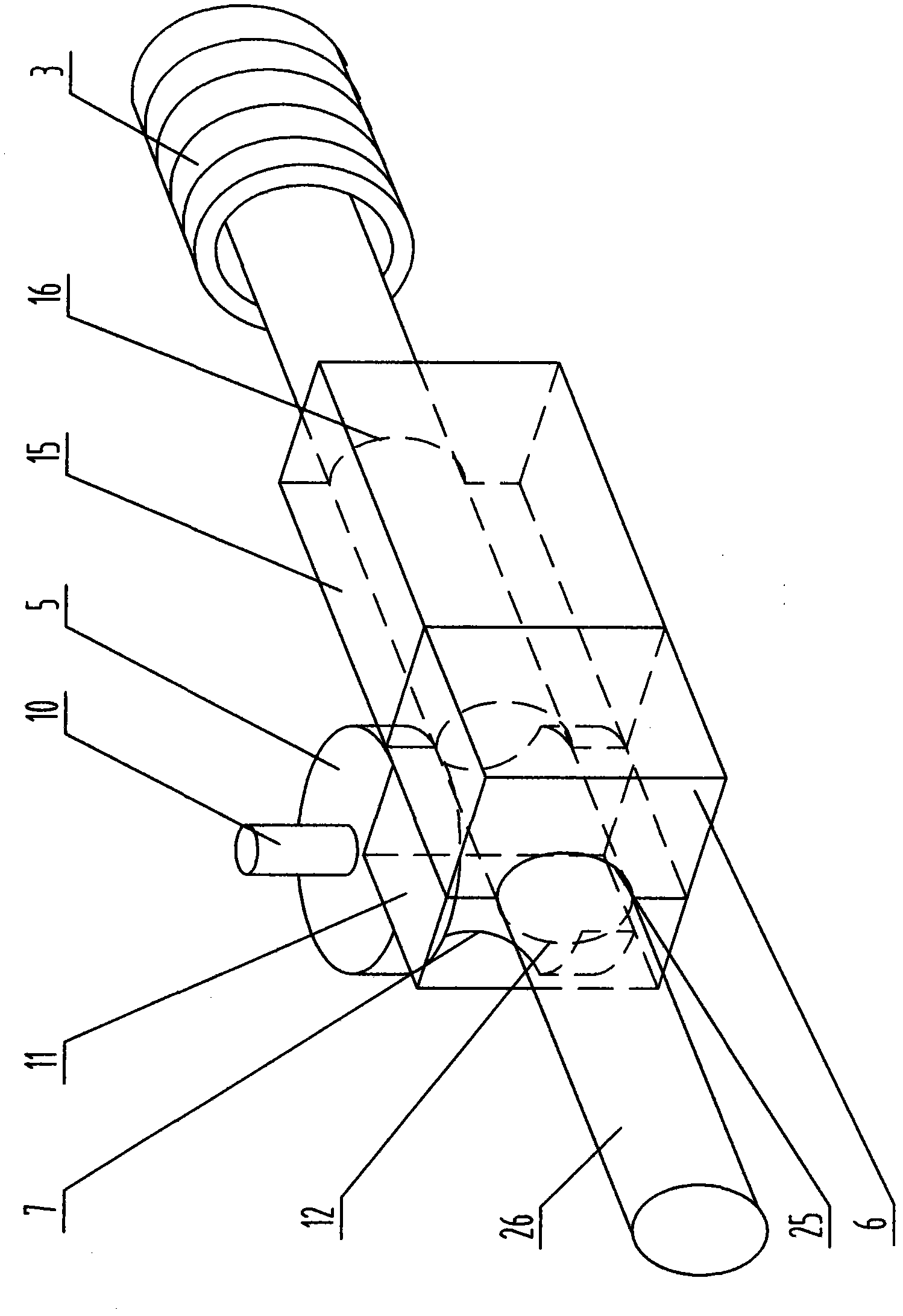

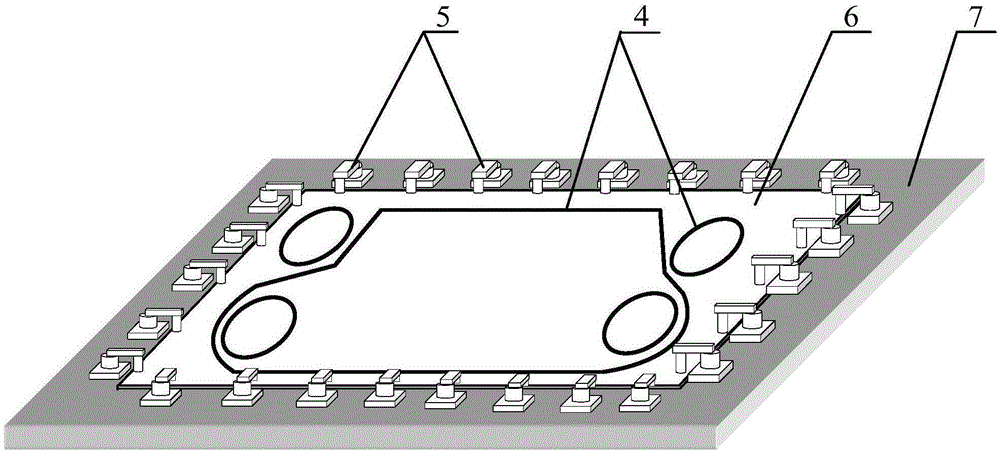

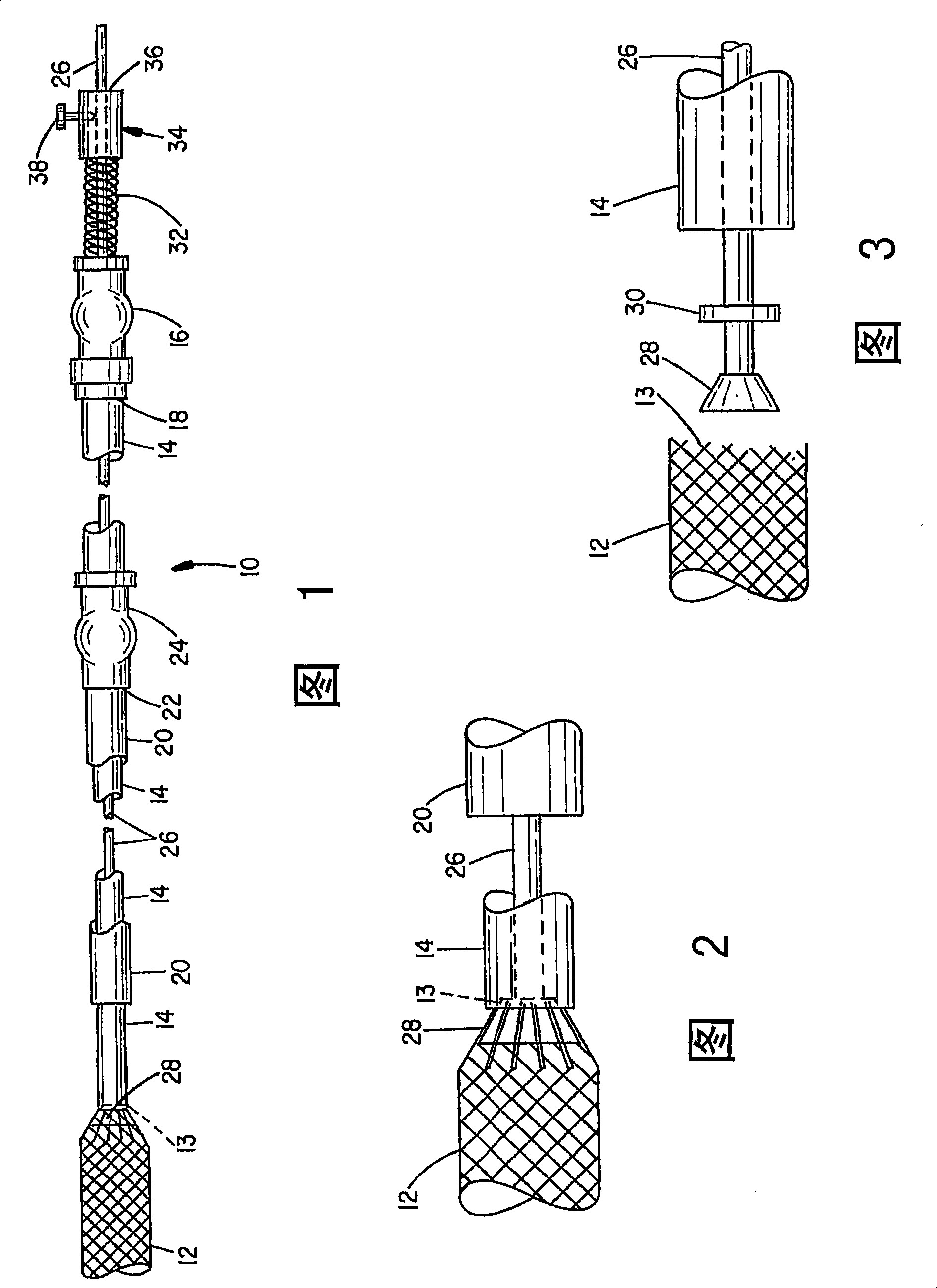

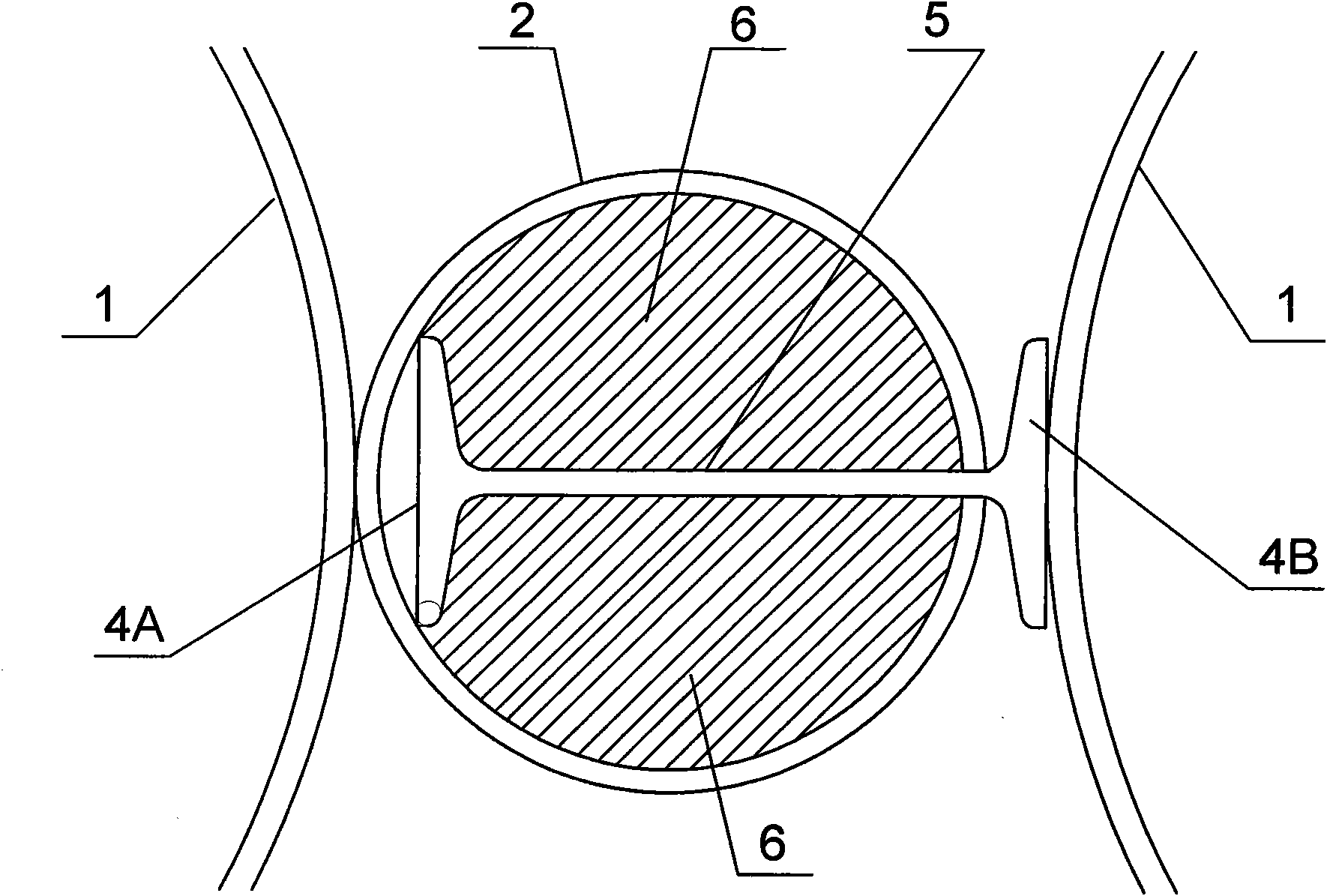

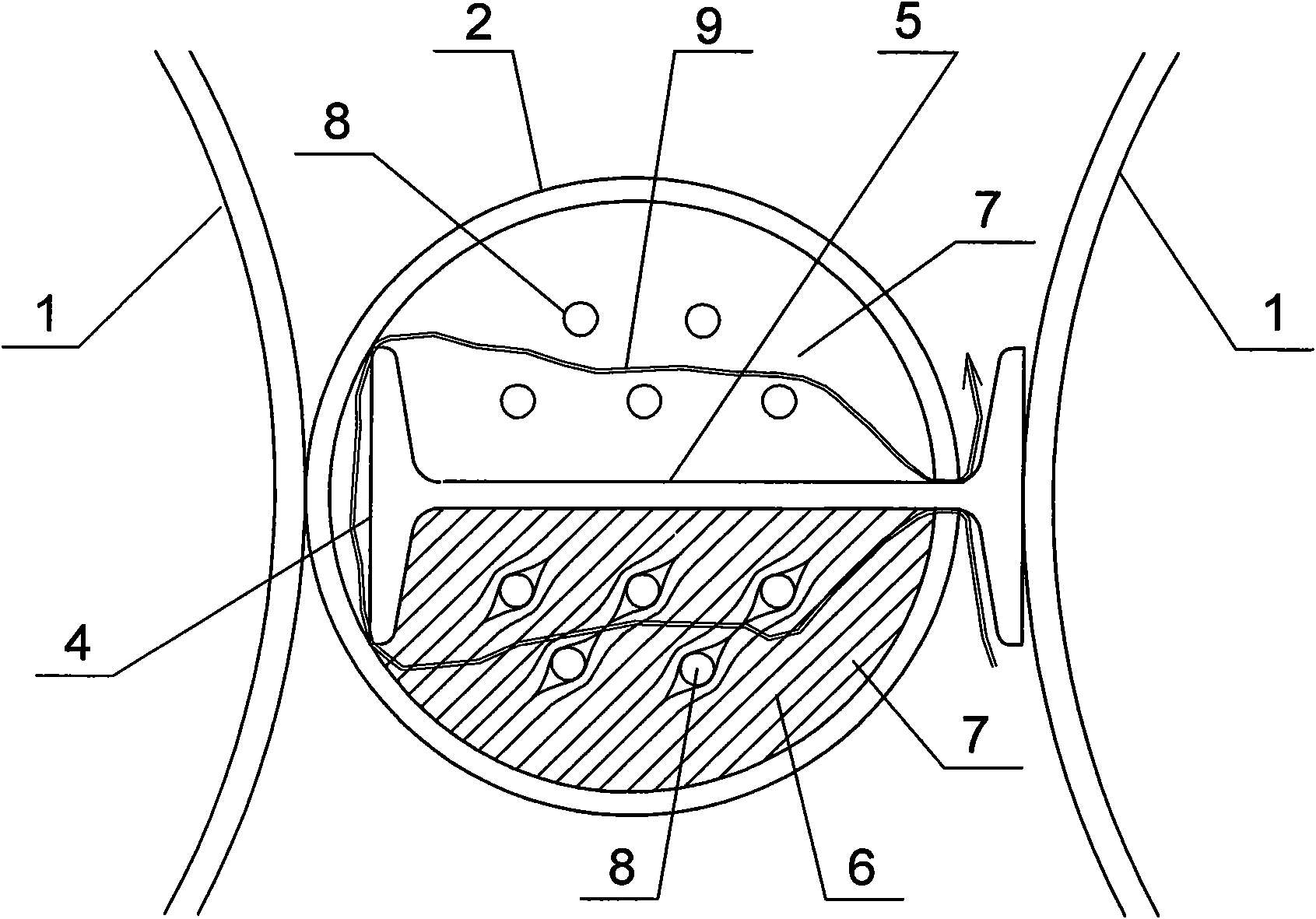

System for controlled delivery of stents and grafts

The present invention provides a delivery mechanism for percutaneously routing a stent or graft through the vascular system and procedures for addressing an aneurysm or an otherwise damaged vessel. The delivery system includes an outer tubular guide catheter (20), an inner tubular delivery (pusher) catheter (14) coaxially disposed and slidable relative to the outer guide catheter and an elongated flexible wire or cable (26) that is coaxially insertable through the lumen of the inner tubular catheter and that has a frusto-conical bead affixed at the distal end thereof which is sized to at least partially fit within the lumen of the inner pusher catheter when a proximally directed tension force is applied between the elongated flexible wire or cable (26) with respect to the pusher catheter (14). By inserting a compressed coil spring between a proximal end portion of the pusher catheter (14) and the proximal end portion of the cable (26), the requisite clamping force is maintained to secure the stent or graft to the distal end of the pusher catheter until the compression spring force is removed. With the stent or graft clamped to the distal end of the inner pusher catheter, it can be drawn within the lumen of the outer guide catheter for delivery therewith to the target site.

Owner:AGA MEDICAL CORP MS US

Self locking device for clamping articles

InactiveCN101386136AIncrease profitImprove stabilityPositioning apparatusMetal-working holdersTemperature controlLiquid medium

The invention discloses a self-locking clamping device which comprises a temperature control micro-displacement driving device, an area effect stroke amplifier and a bilateral single-action reamed pole reinforcing self-locking clamping device. The temperature control micro-displacement driving device comprises a hollow thin-walled tube which is internally provided with a semi-conductor fast heating / cooling element; the area effect stroke amplifier comprises a driving piston input cylinder body; one end of a driving piston is provided with a heat insulating pad and is fixedly connected with the hollow thin-walled tube, while the other end thereof is provided with liquid medium and is respectively connected with a left output piston structure and a right output piston structure by a pipeline; the articulation point of a bilateral single-action reamed pole is positioned between the left output piston structure and the right output piston structure; an idler wheel is arranged on the left output piston structure and the right output piston structure, one end of the left output piston structure and the right output piston structure is fixedly connected with a force output element. By adopting the temperature control micro-displacement driving device, the self-locking clamping device carries out self-locking clamping by the bilateral single-action reamed pole driven by the area effect stroke amplifier, improves energy source utilization efficiency and has good stability, is no pollution and has excellent self-locking performance.

Owner:SUZHOU UNIV

Steel pipe pile locking notch structure and water-stopping method of steel pipe pile cofferdam

The invention discloses a steel pipe pile locking notch structure and a water-stopping method of a steel pipe pile cofferdam by using the structure. The notch-locking structure comprises steel pipe piles and locking notches, wherein the steel pipe piles are arranged at intervals, each locking notch is arranged between two adjacent steel pipe piles, each locking notch comprises a female locking notch and a male locking notch, the male locking notch is I-shaped steel, the female locking notch is a steel pipe which is provided with a slit along the axial direction, and an I-shaped steel web plate is inserted into the slit. When the locking notch structure is used for leak stoppage, clay is pounded into the cavities of the locking notches, and reinforcing steel bars are inserted to carry out compaction processing for the clay. The invention relates to an effective locking notch structure and the water-stopping method thereof which are disclosed specially for solving the problem of difficult water prevention and leak stoppage of the locking notches in the steel pipe pile cofferdam.

Owner:1ST ENG OF CHINA ZHONGTIE MAJORBRIDGE GROUP

Hardware processing and clamping device

The invention discloses a hardware processing and clamping device. The hardware processing and clamping device comprises a base, wherein a controller is arranged on the front surface of the base; slide chutes are embedded into two sides of the top part of the base; a support plate is arranged at the top part of each slide chute, passes through the corresponding slide chute and extends to the inside of the base; a clamping plate is arranged at the inner side of the support plate; a buffer spring is arranged in the clamping plate; balls are arranged at two sides in each slide chute, and are partitioned by a limiting block; a damping device is also arranged at the top part of the base; and a worktable is arranged at the top part of the damping device. By the hardware processing and clamping device, when a hardware part is processed, the support plate can move left and right through the arranged slide chutes; the size of a clamp can be changed; the hardware processing and clamping device can be suitable for processing of most hardware parts; the cost is reduced; the work efficiency is improved; the worktable is in a stable state through the arranged damping device; the condition that the hardware part does not easily deviate in the machining process is ensured; and the machining quality is improved.

Owner:CHANGZHOU JINHAILONG MACHINE MFG

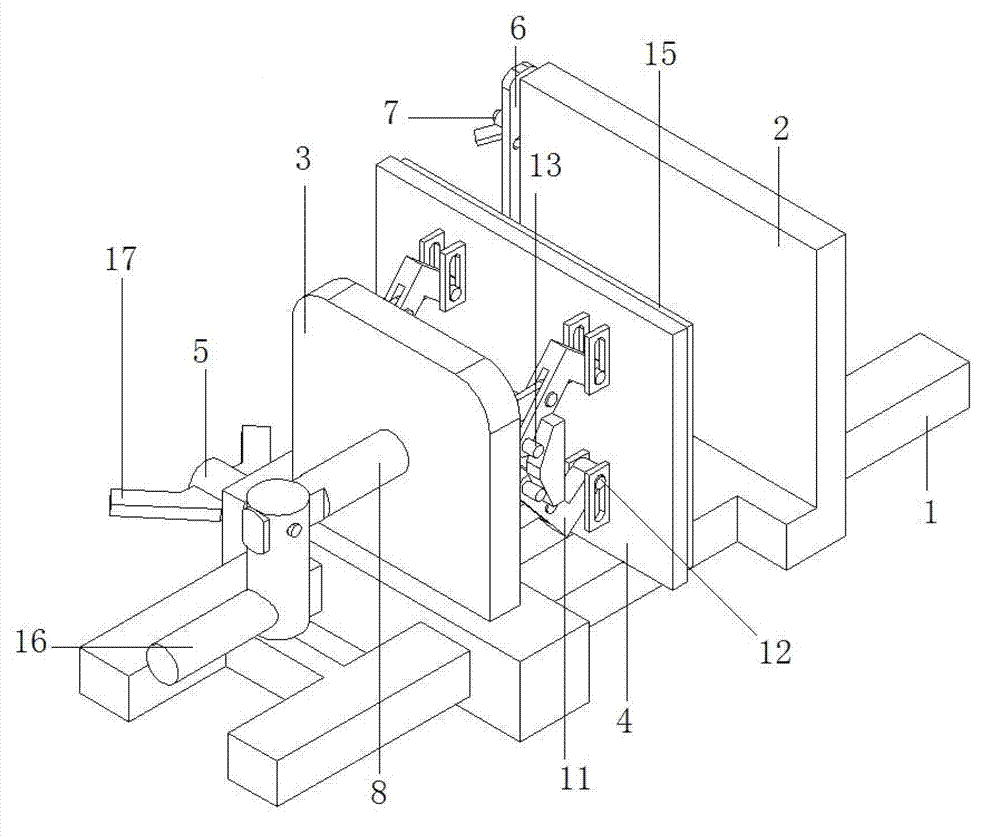

Workpiece clamp

InactiveCN103170847AGuaranteed clampingStable working conditionPositioning apparatusElectrical-based auxillary apparatusWire cuttingEngineering

The invention discloses a workpiece clamp capable of directly achieving positioning without depending on workers and extra tools. The workpiece clamp solves the problem that according to a wire cutting clamp in the prior art, horizontal positioning of a workpiece has to depend on extra tools. According to a novel chopstick barrel, the lower end of a barrel body is provided with a water filtering frame, and the bottom of the barrel body is connected with a water collection cup. The workpiece machining clamp comprises a substrate, a standard base plate and a sliding clamping plate which is opposite to the standard surface of the standard base plate and arranged on a sliding clamping base are arranged on the substrate. The sliding clamping base is connected with the substrate in a sliding mode, a positioning bolt is arranged on a side of the sliding clamping base and is tightly attached to the side edge of the substrate under a tightening state, a limit plate which partially extends towards the direction where the sliding clamping base is located is arranged on a side of the standard base plate, and the surface of the limit plate close to the standard base plate is vertical to the standard surface of the standard base plate. The workpiece clamp is suitable for being used in occasions where an original wire-electrode cutting clamp is suitable, and has the advantages of being capable of achieving quick clamping and loosening, capable of clamping multiple workpieces, and the like.

Owner:ZHEJIANG GEELY POWERTRAIN CO LTD +2

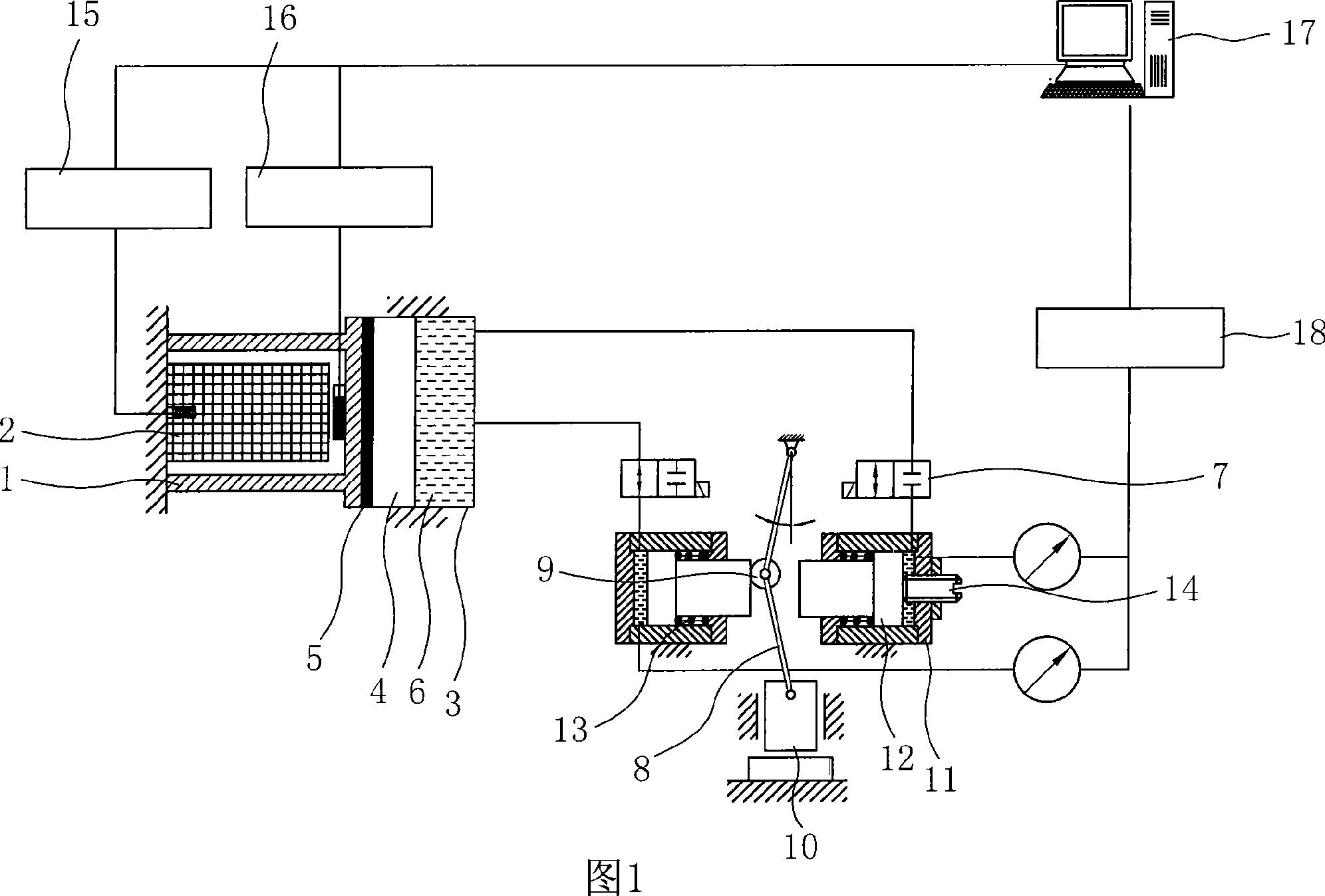

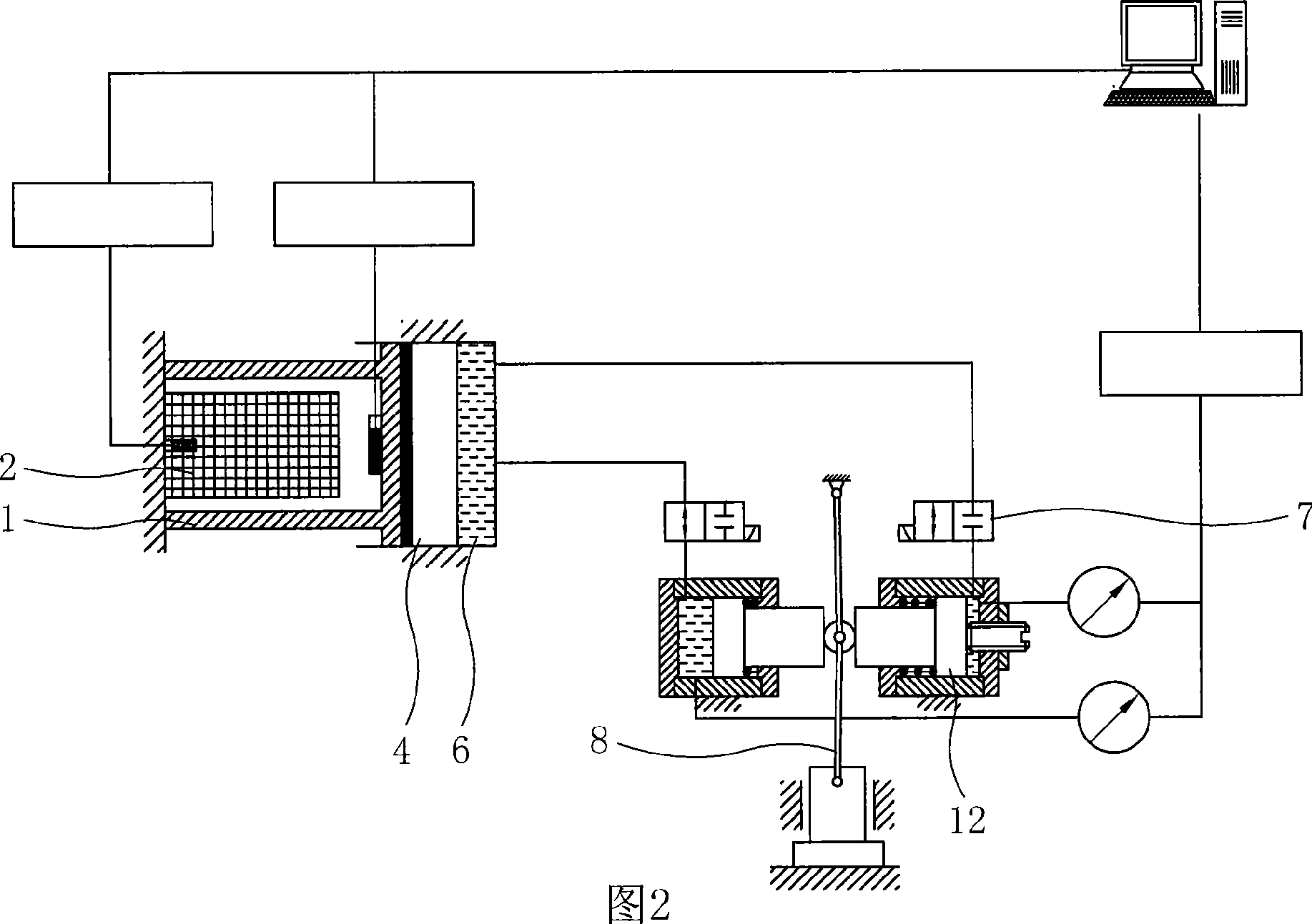

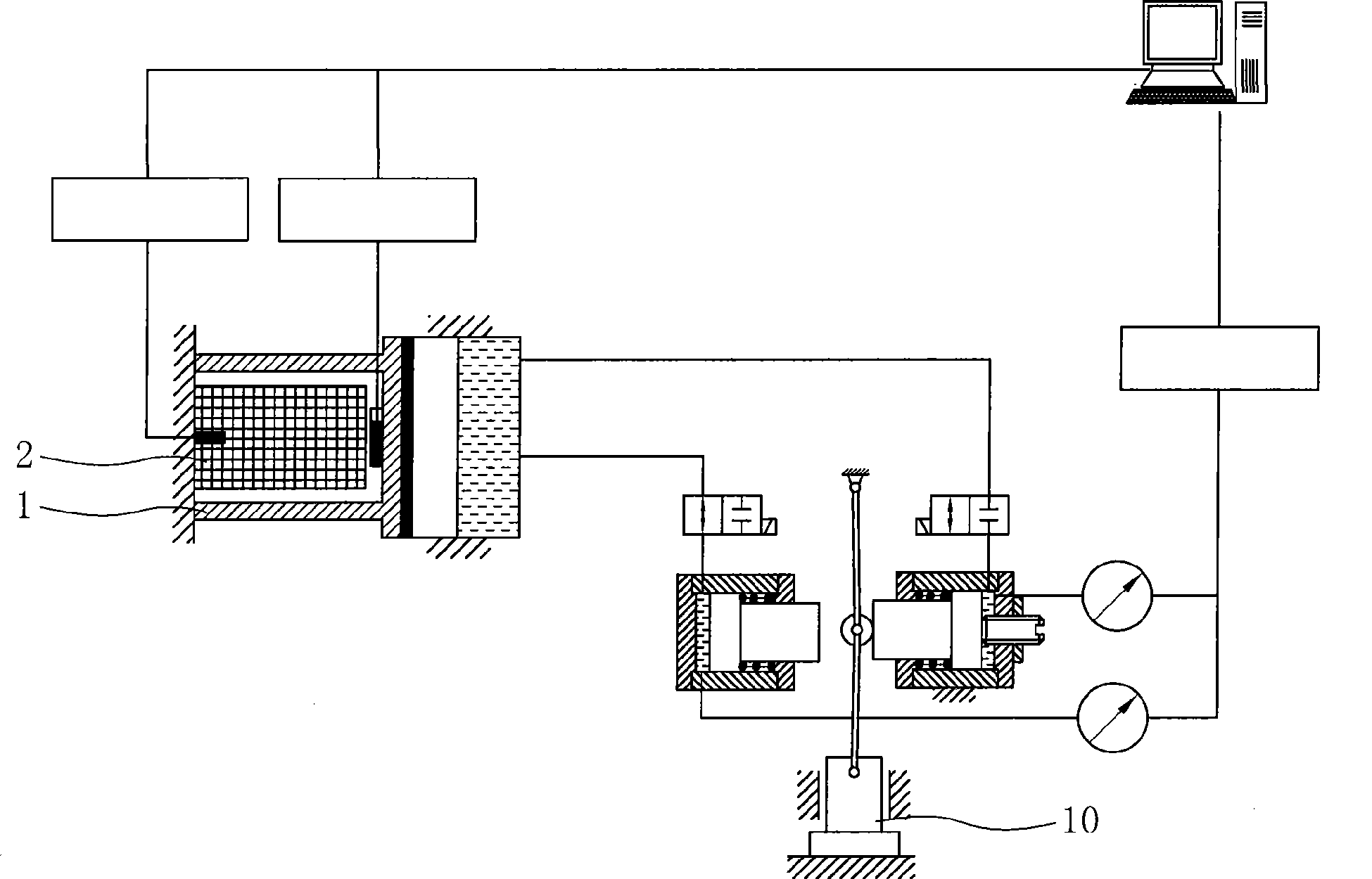

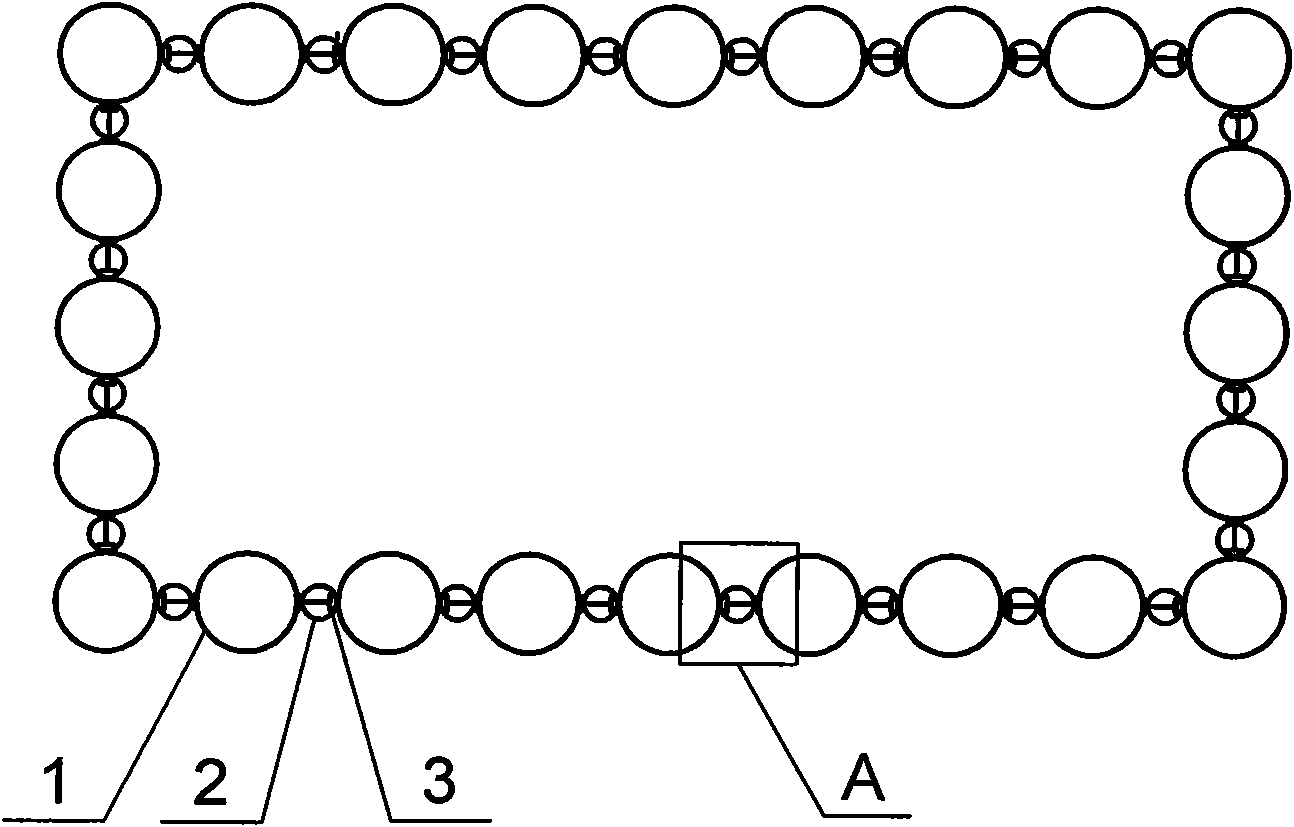

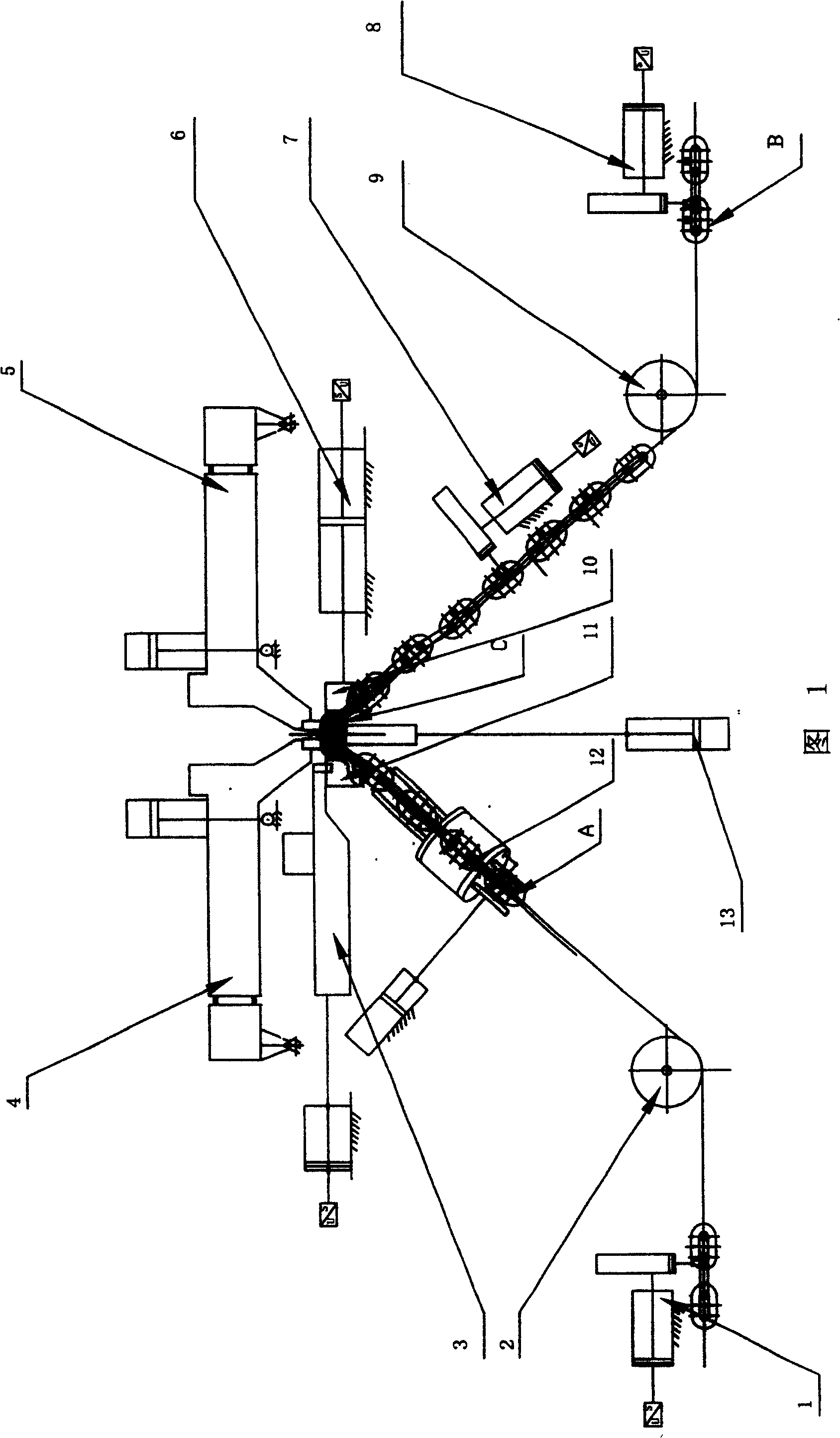

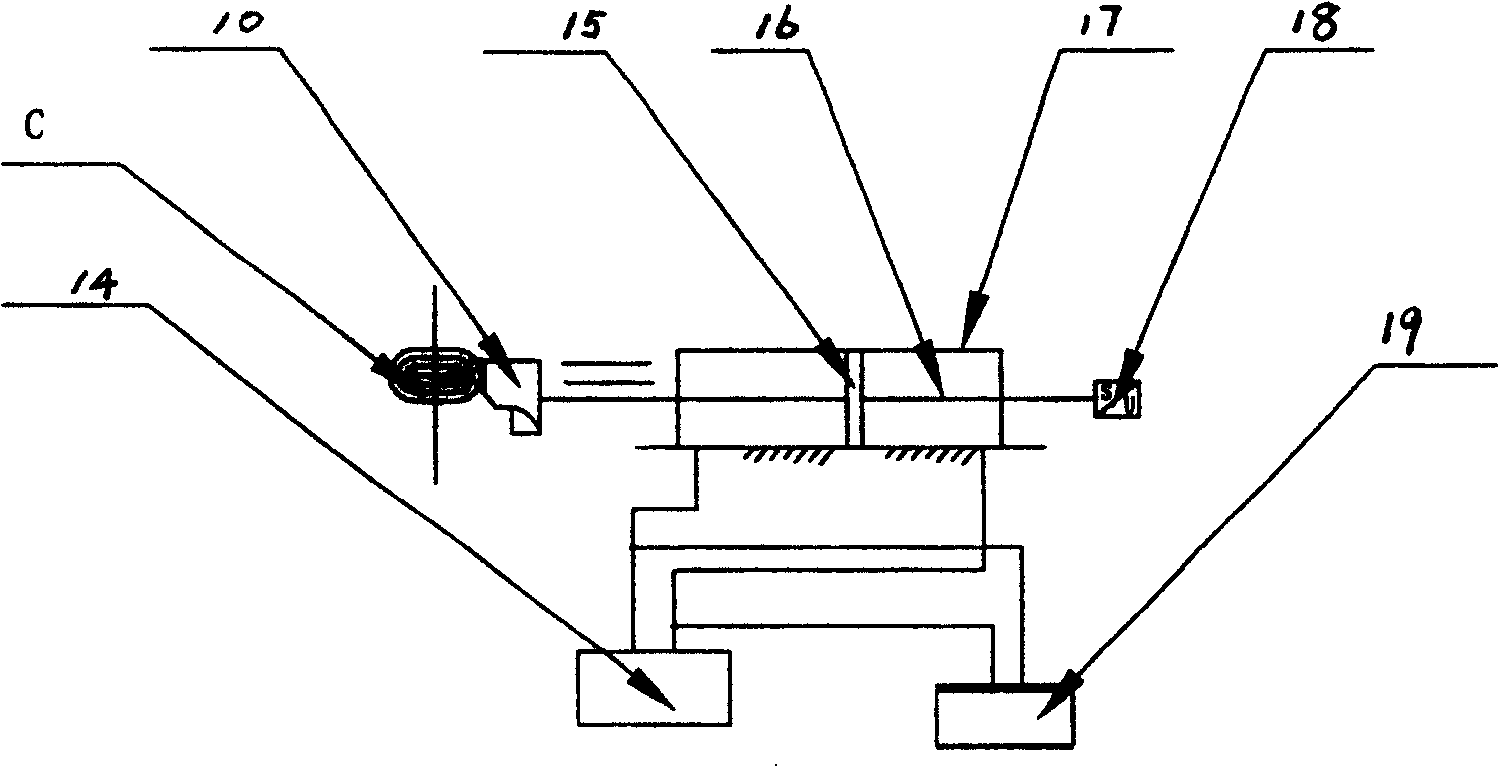

Full automatic hydraulic flash butt welding method of metal circular ring chain and apparatus thereof

ActiveCN100439005CHigh quality excisionFully automaticWelding/cutting auxillary devicesAuxillary welding devicesButt weldingTransducer

The invention relates the metallic bond full-automatic all-hydraulic flash butt welding method and device. The method is that the open of each chain link is automatically welded after the metallic bond is knitted to chain. The method comprises the following step: sending the chain link from left end of machine to position of welding under the combined action of main conveyer and subsidiary conveyer, controlling the hydraulic heading equipment with displacement transducer, servo valve and heading valve, preheating, burning, flashing and heading welding, auto removing the burrs, and exporting the finished chain link from the right end of machine. The whole process is the full-automatic all-hydraulic flash butt welding method. The invention possesses the characters of high automation level, high production efficiency, high product quality and high safe reliability. The said method and device will replace the national current fall behind electric milling cam type FBW method and device.

Owner:王洪军

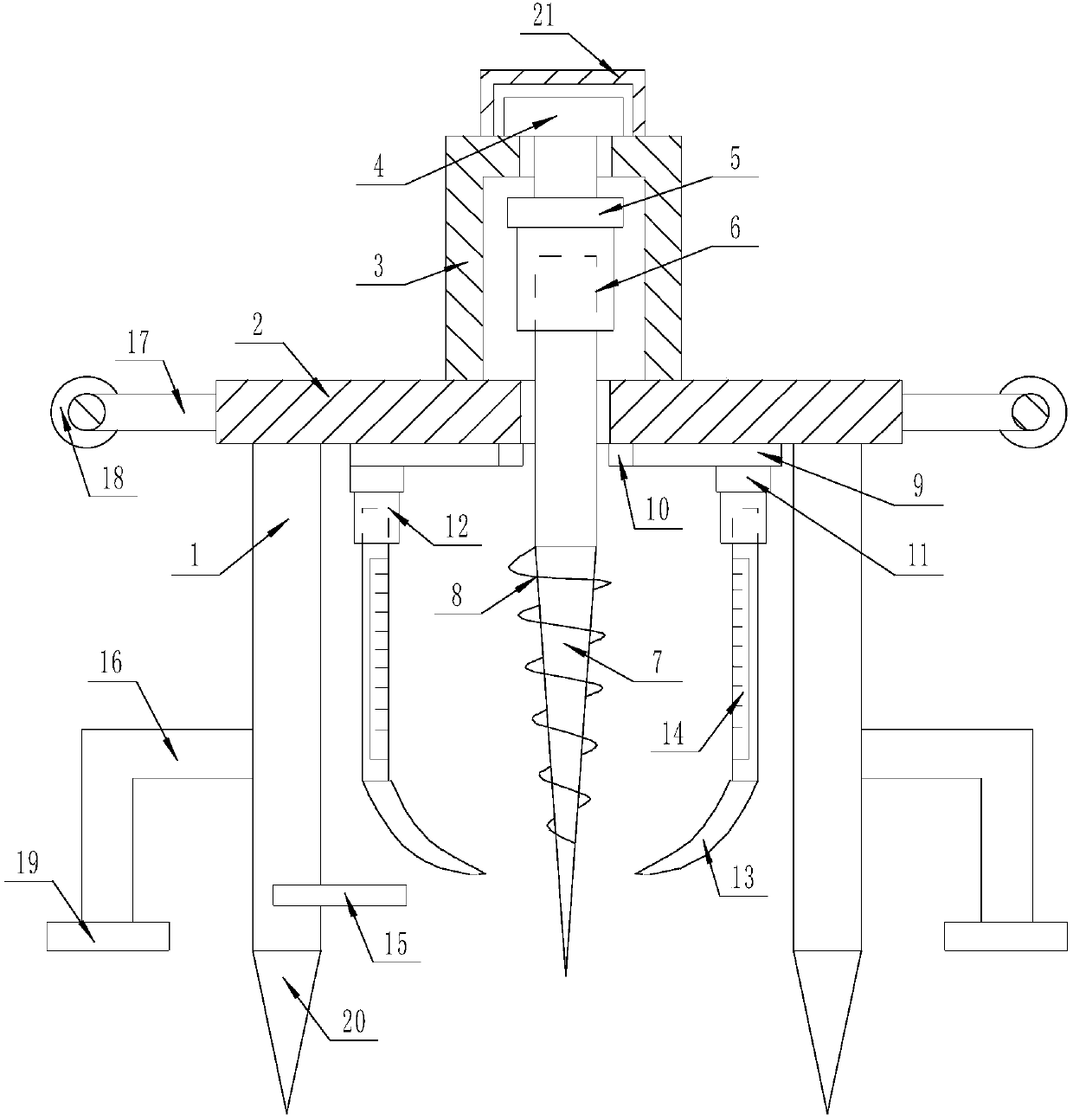

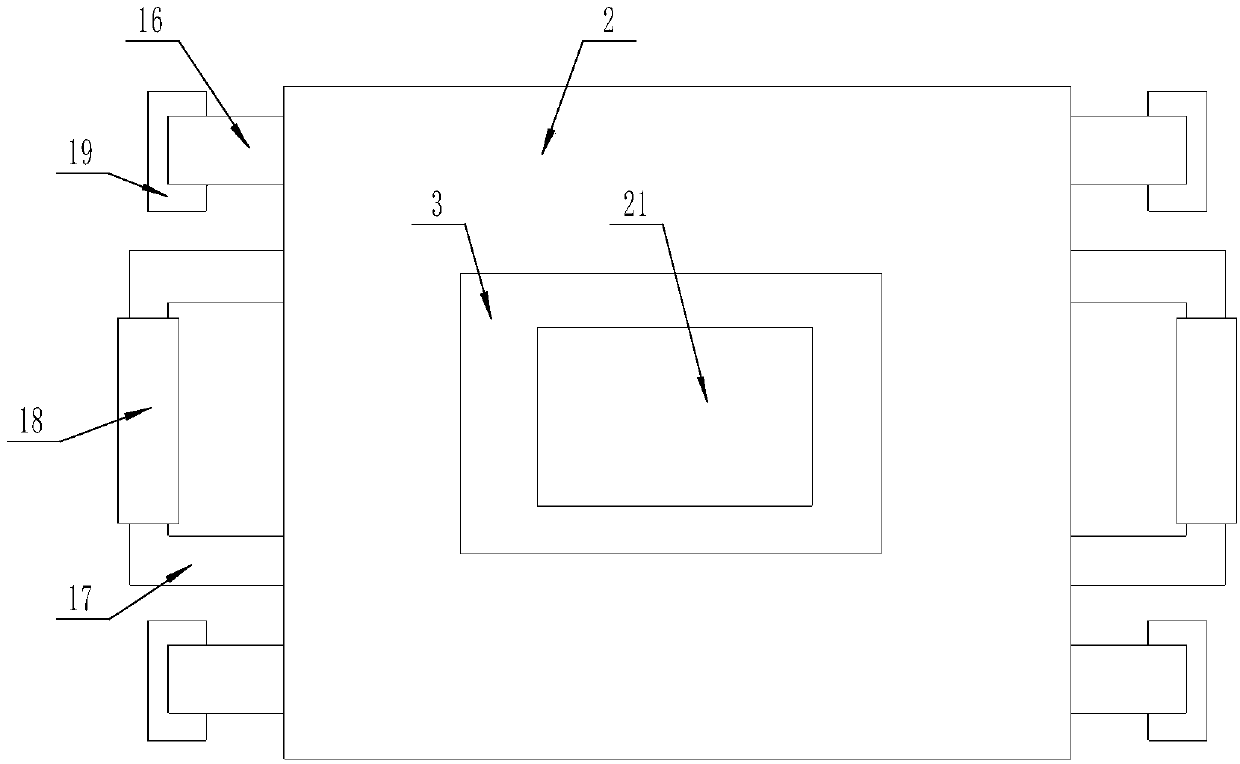

Municipal construction digging equipment

ActiveCN107852896AEasy to watchEasy to measurePlantingFurrow making/coveringHelical bladeArchitectural engineering

The invention discloses municipal construction digging equipment. The equipment comprises two pairs of support legs, a rectangular mounting plate is fixedly connected to the upper surfaces of the twopairs of the support legs, a circular opening is machined in the upper surface of the rectangular mounting plate, a door-shaped support frame is fixedly connected to the upper surface of the rectangular mounting plate, a mounting opening is machined in the upper surface of a beam of the door-shaped support frame, a driving motor with a rotating end facing downwards is installed in the mounting opening in an embedded mode, a circular connecting plate is fixedly connected to the rotating end of the driving motor, a hydraulic telescopic rod which stretches out of the circular opening and is provided with a telescopic end facing downwards is fixedly connected to the lower surface of the circular connecting plate, a conical drill pipe is fixedly connected to the telescopic end of the hydraulictelescopic rod, and helical blades are fixedly connected to the side surface of the conical drill pipe. The municipal construction digging equipment has the advantages of being simple in structure andhigh in practicability.

Owner:中泰建诚(北京)建设工程有限公司

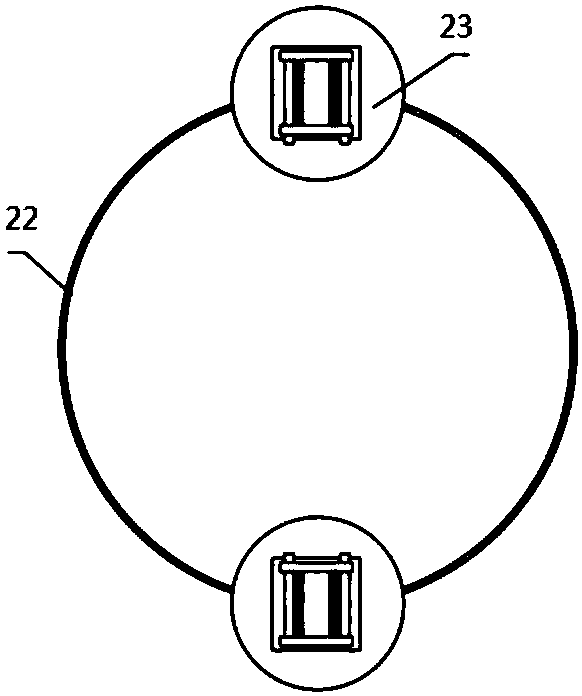

Climbing robot for nuclear power pipeline detection and maintenance and operation method

The invention discloses a climbing robot for nuclear power pipeline detection and maintenance and an operation method. The climbing robot comprises an upper layer clamping mechanism and a lower layerclamping mechanism which are used for clamping a pipeline and connected through a lifting mechanism for driving the upper layer clamping mechanism and the lower layer clamping mechanism to rise and fall. The upper layer clamping mechanism and the lower layer clamping mechanism adopt the same structure. The robot can be used for climbing on the outer wall of the vertical pipeline of a nuclear powerplant, remote control of detecting personnel is facilitated, thus the radioactive pipeline outer wall is detected, and the safety of operators is ensured.

Owner:CHINA THREE GORGES UNIV

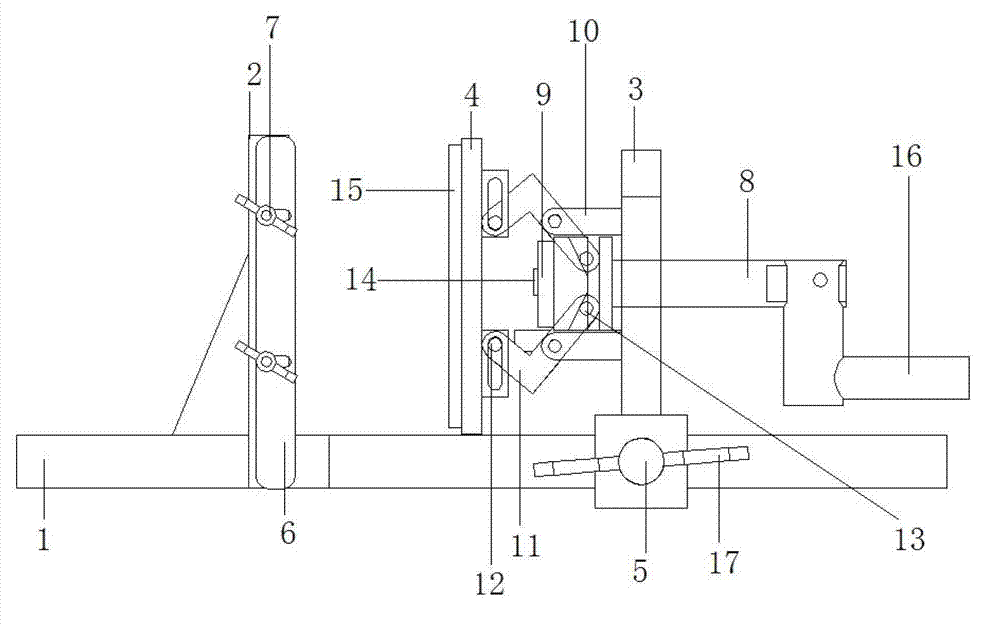

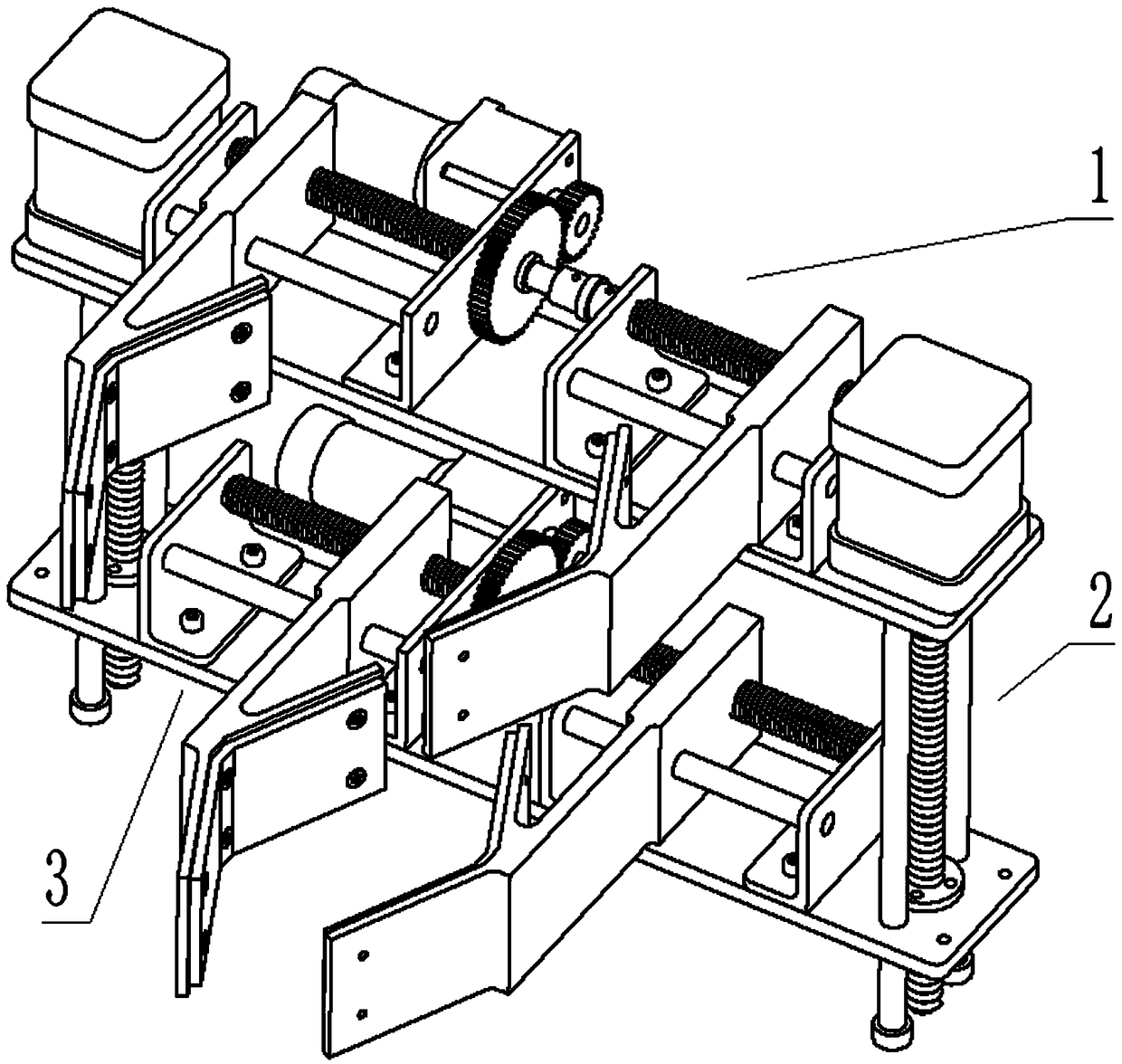

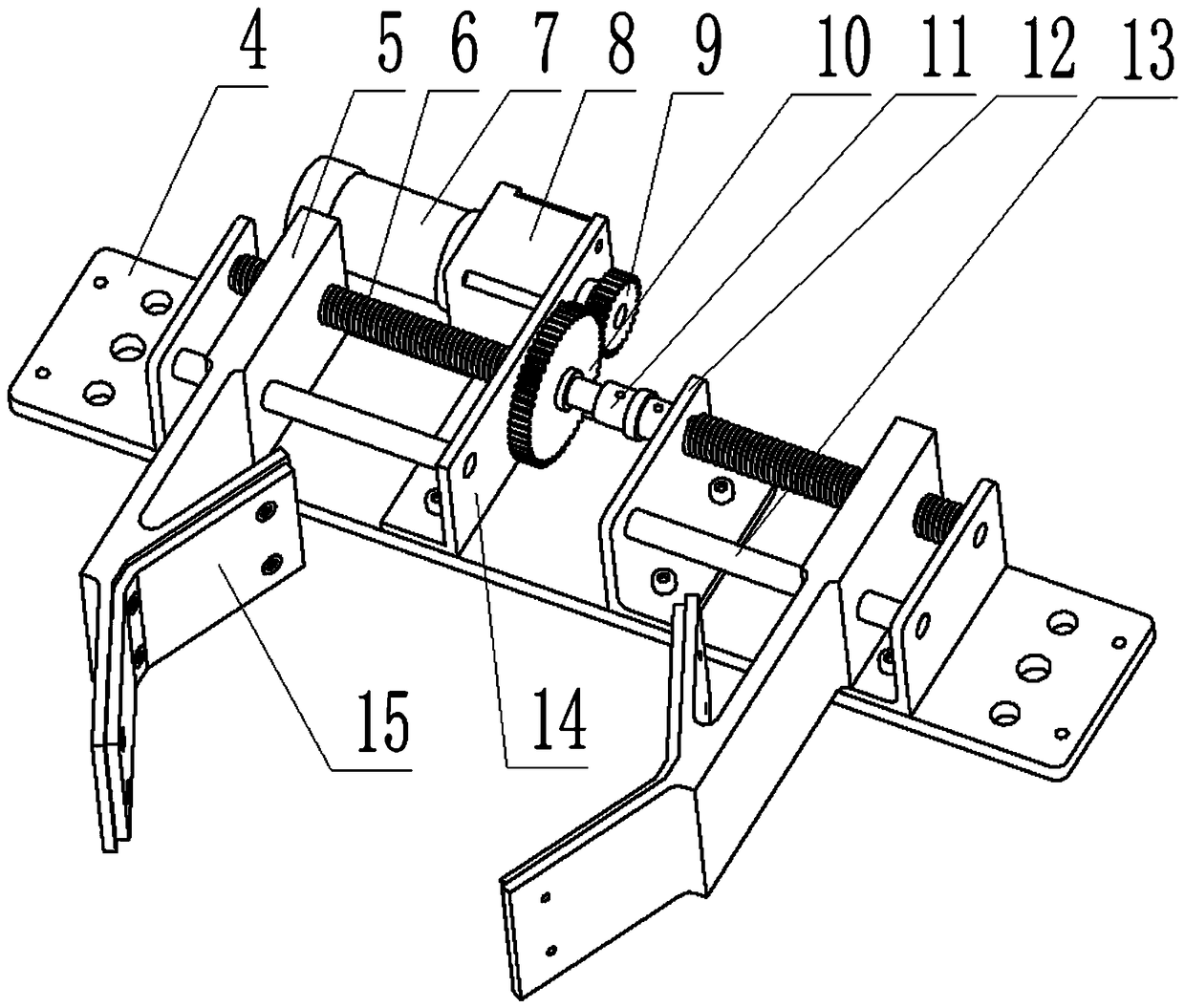

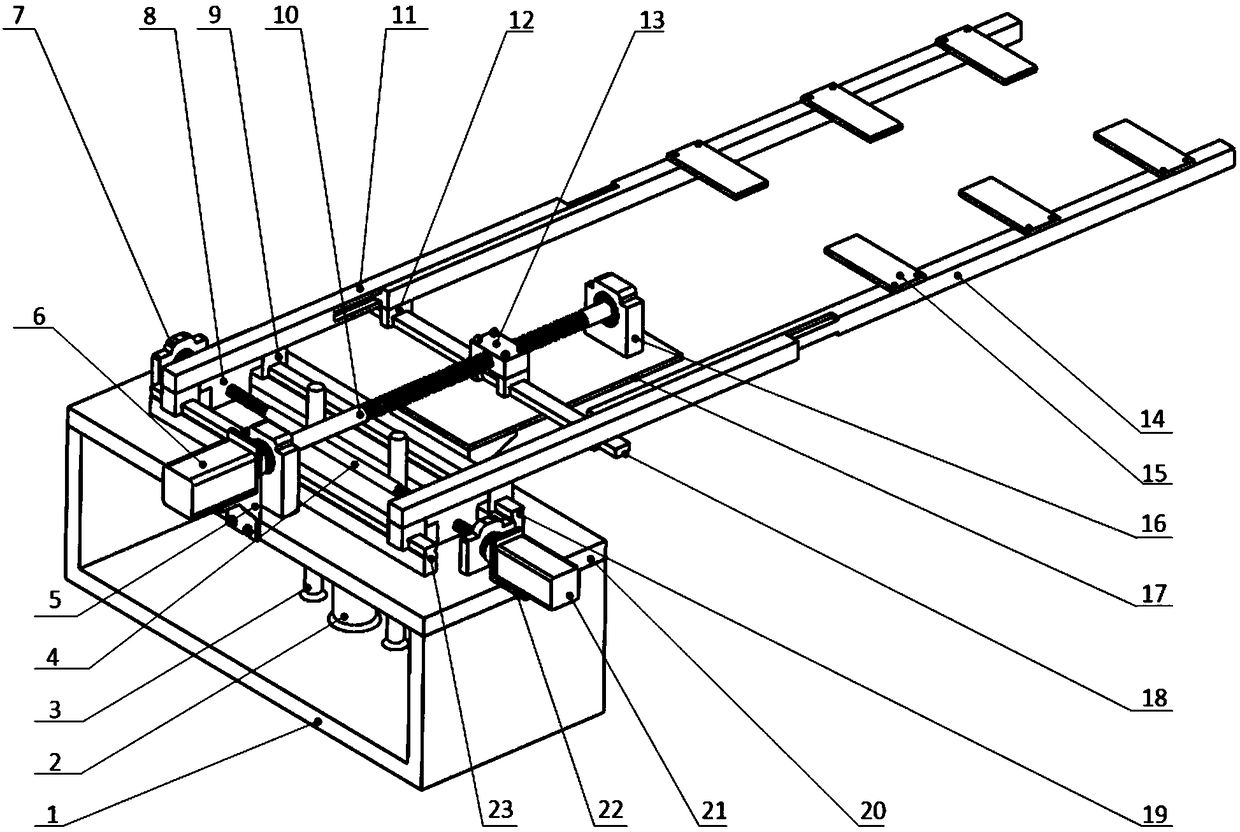

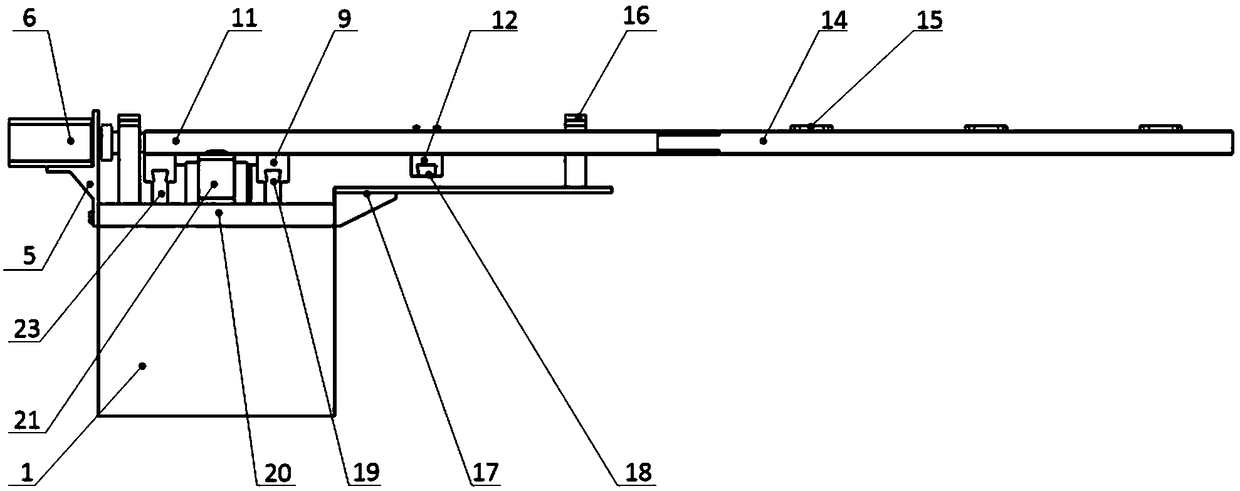

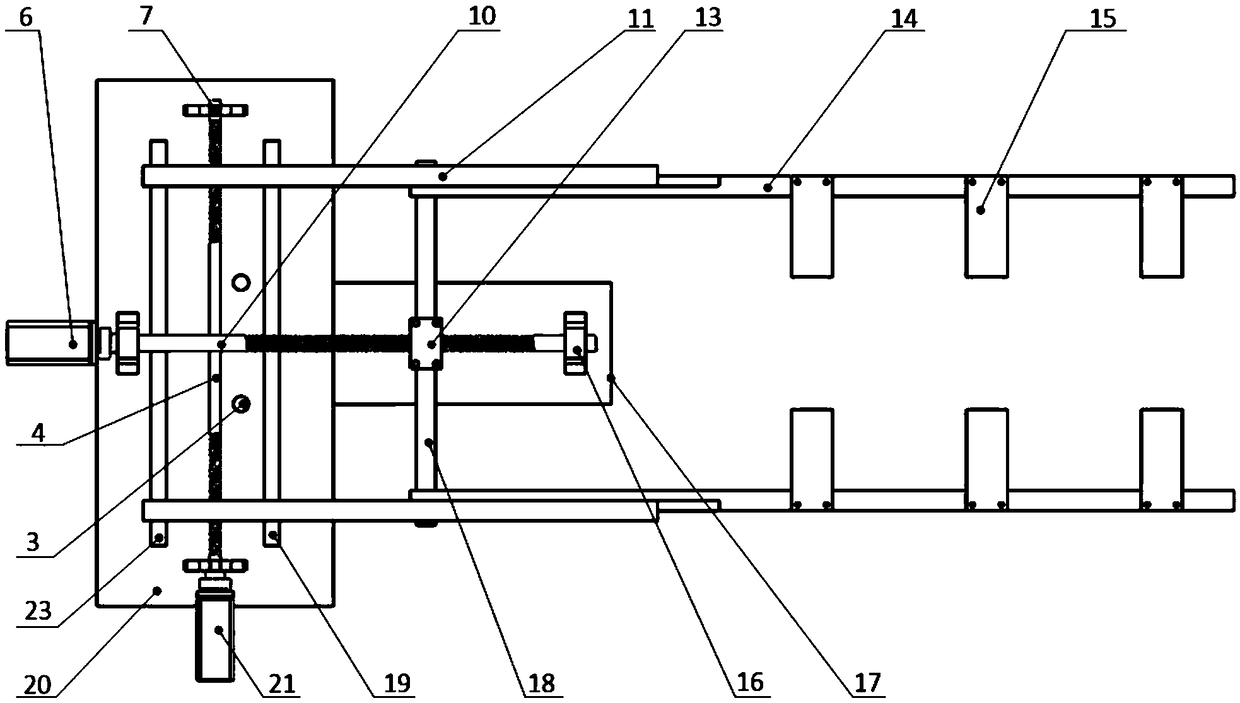

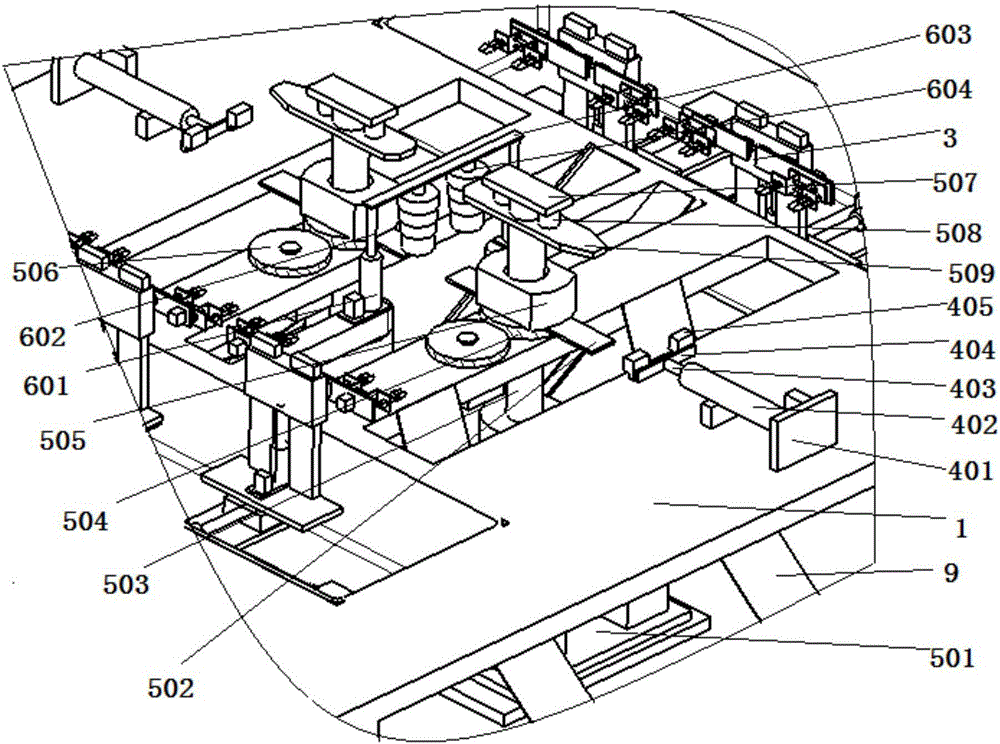

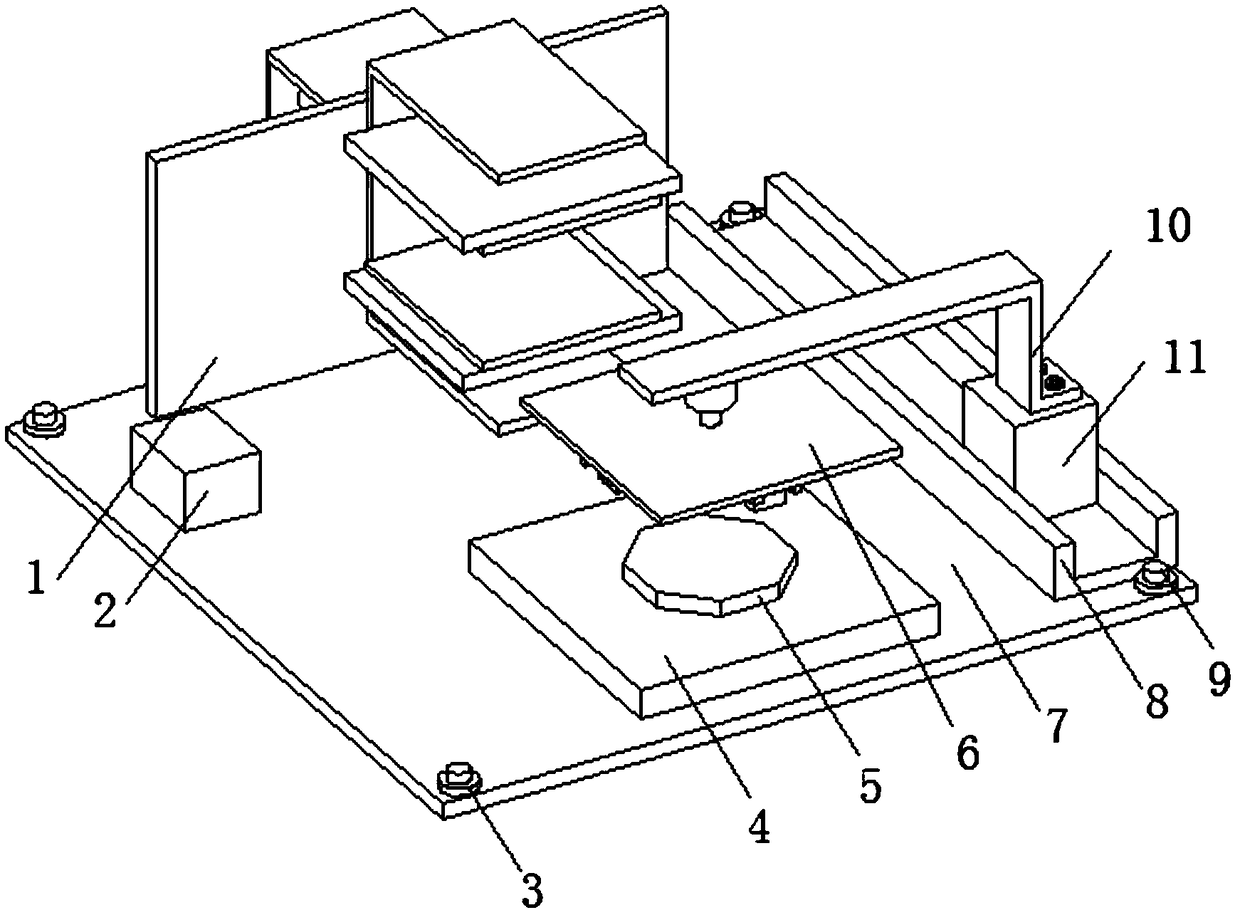

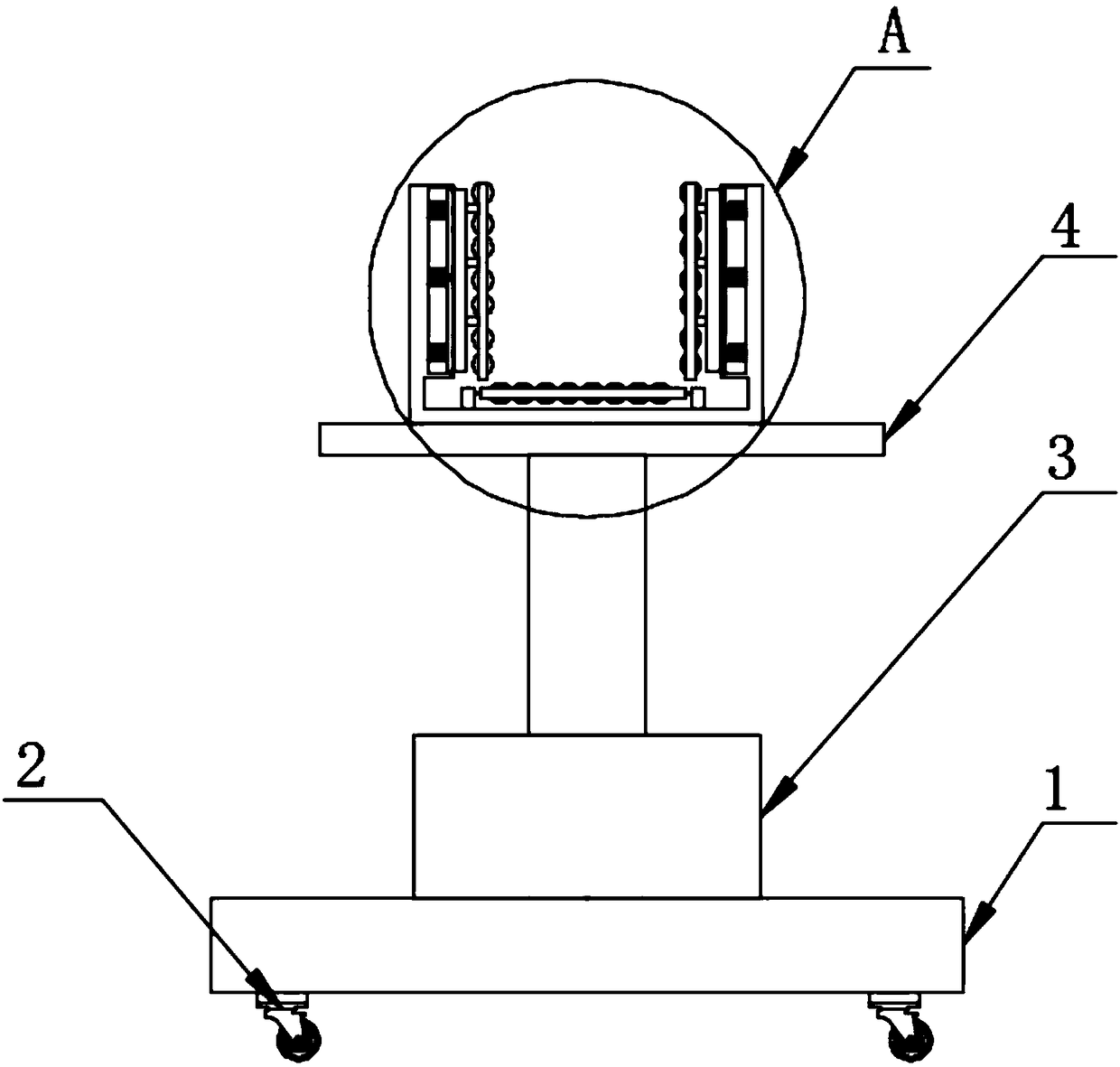

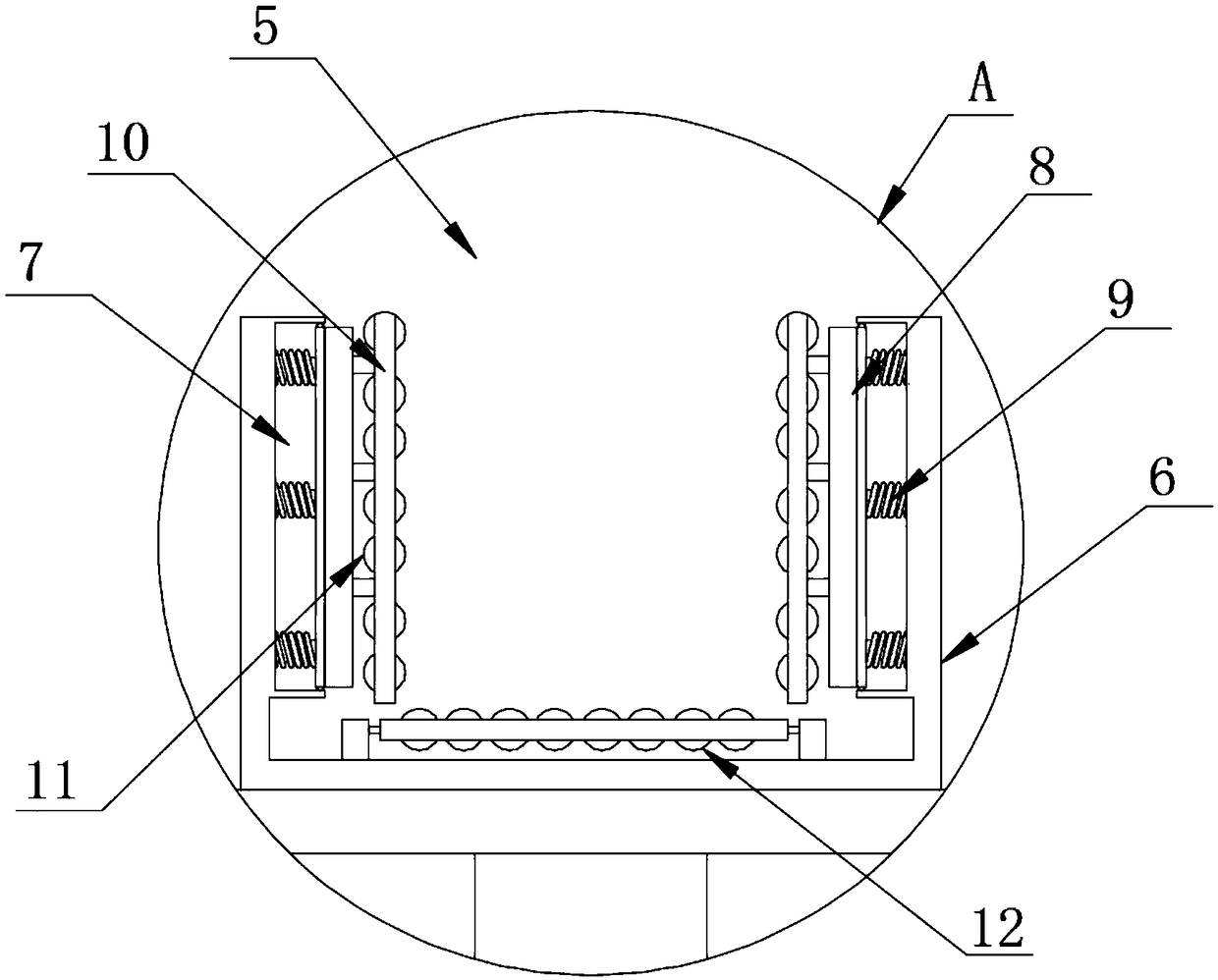

Three-freedom-degree multi-station punching automatic feeding device

ActiveCN108907024AGuaranteed clampingRealize longitudinal reciprocating motionMetal-working feeding devicesPositioning devicesPunchingDrive motor

The invention discloses a three-freedom-degree multi-station punching automatic feeding device, and belongs to the technical field of machine manufacturing equipment. The three-freedom-degree multi-station punching automatic feeding device can be applied to automatic feeding during small and medium size punching part multi-station machining. The device comprises a base, an air cylinder, guide columns, a supporting table, a transverse lead screw, a transverse drive motor, a transverse drive motor support, transverse bearing pedestal assemblies, transverse lead screw nut seats, a first transverse sliding rail, a second transverse sliding rail, a third transverse sliding rail, transverse movement sliding blocks, longitudinal sliding rail supporting rods, a longitudinal drive motor, a longitudinal drive motor support, a longitudinal lead screw, longitudinal bearing pedestal assemblies, longitudinal lead screw nut seat, a longitudinal lead screw supporting plate, guide sliding blocks, longitudinal sliding rails and clamps. According to the working principle of the device, the lead screws are driven by the motors to achieve transverse and longitudinal feed, and then the clamps are drivento complete clamping and conveying on workpieces; and the air cylinder is used for driving the supporting table to ascend and descend, the workpieces are separated from the station upwards, preparations are made for entering the next station, and then automatic feeding work is achieved.

Owner:南京黄石机床制造有限公司

Zipper cutting-off mechanism

ActiveCN101255652AHigh strengthHigh impact strengthSlide fastenersSevering textilesReciprocating motionAcoustics

The invention discloses a zipper cut-off mechanism, comprising a fixed arranged mold, an ultrasonic wave head which is on the same axis with the mold and can do reciprocal motion, an ultrasonic generator which is electrically connected with the ultrasonic wave head; a bulge which is arranged on the working surface of the mold corresponding to the working end surface of the ultrasonic wave head, the peak of the bulge is arranged as a blade; when the distance between the ultrasonic wave head and the mold is minimum, a gap kept between the bulge of the mold and the ultrasonic wave head is smaller than the thickness of a zipper cotton tape. The invention is characterized in that the structure is simple, the property is stable, the operation is convenient, and the invention is suitable for various zipper cut-off, punch mechanisms or cloth fabric cut-off, punch mechanisms.

Owner:KEE (GUANGDONG) GARMENT ACCESSORIES LTD

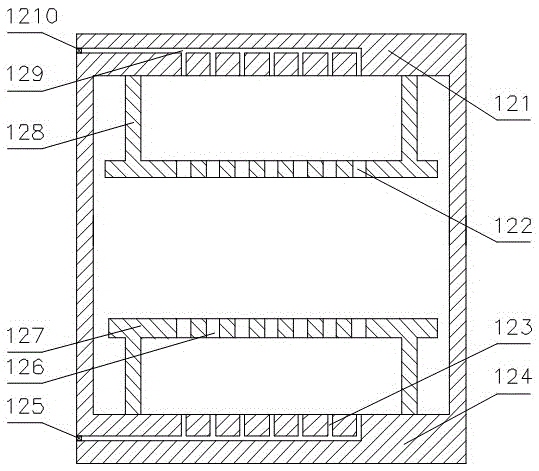

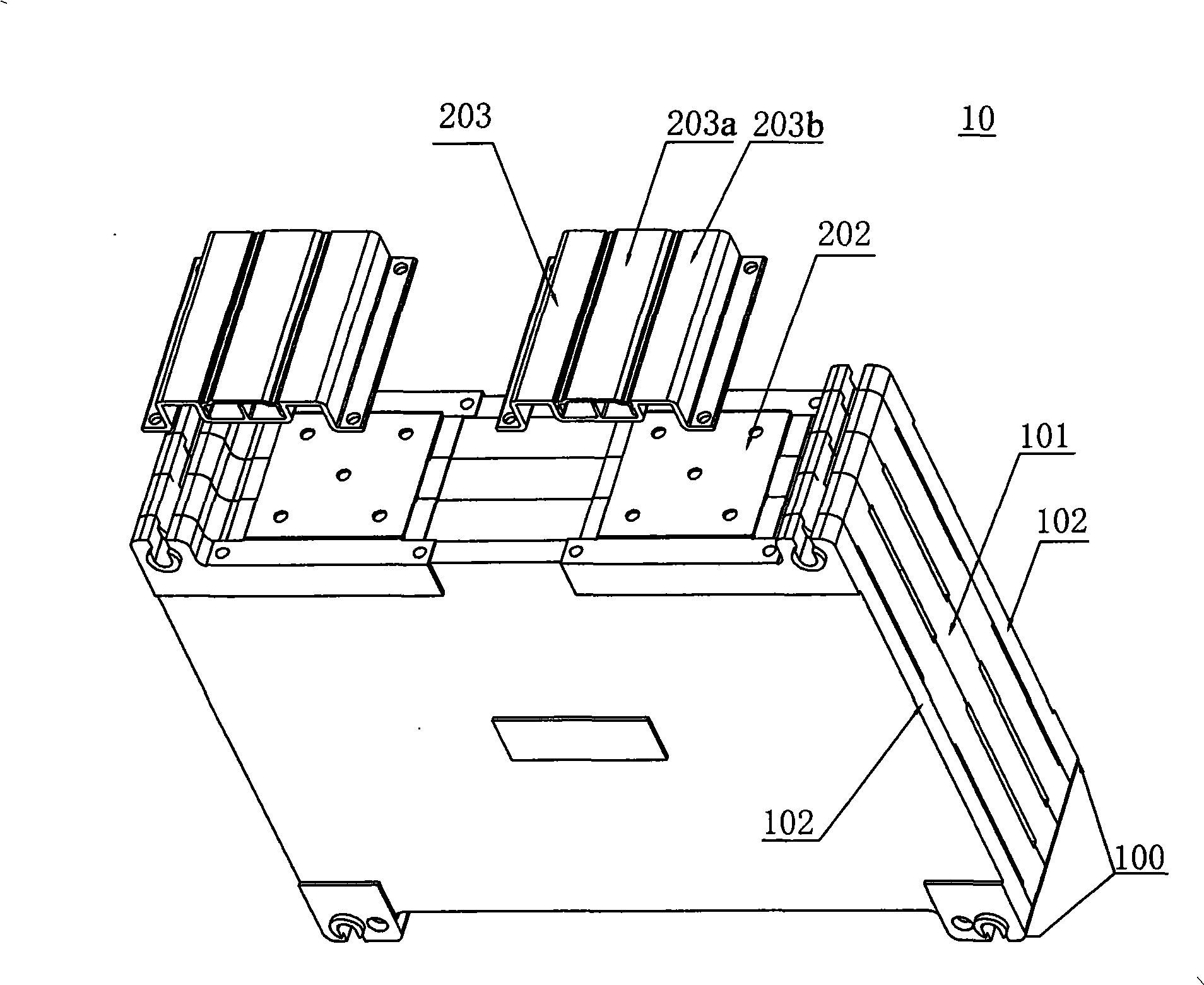

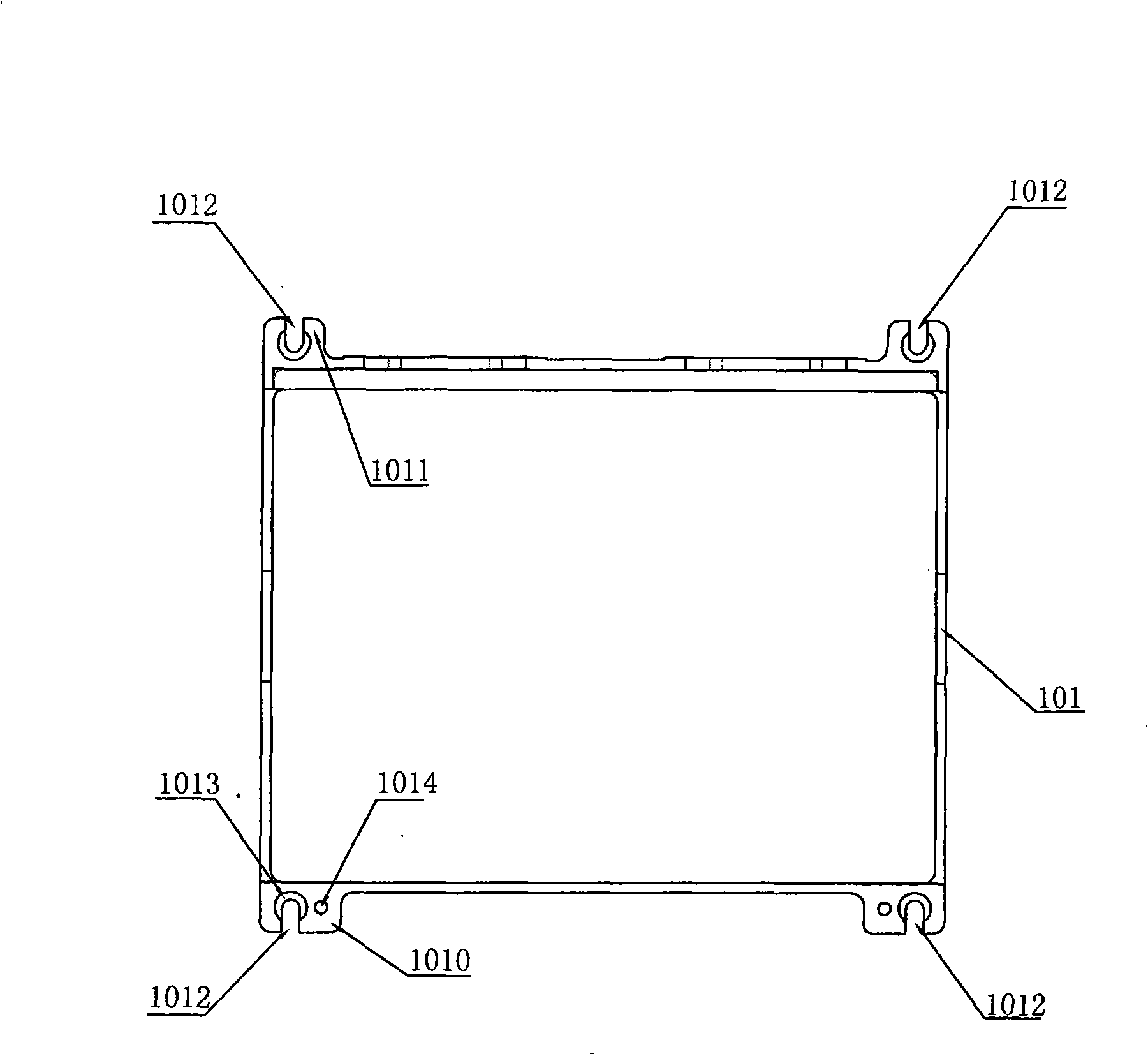

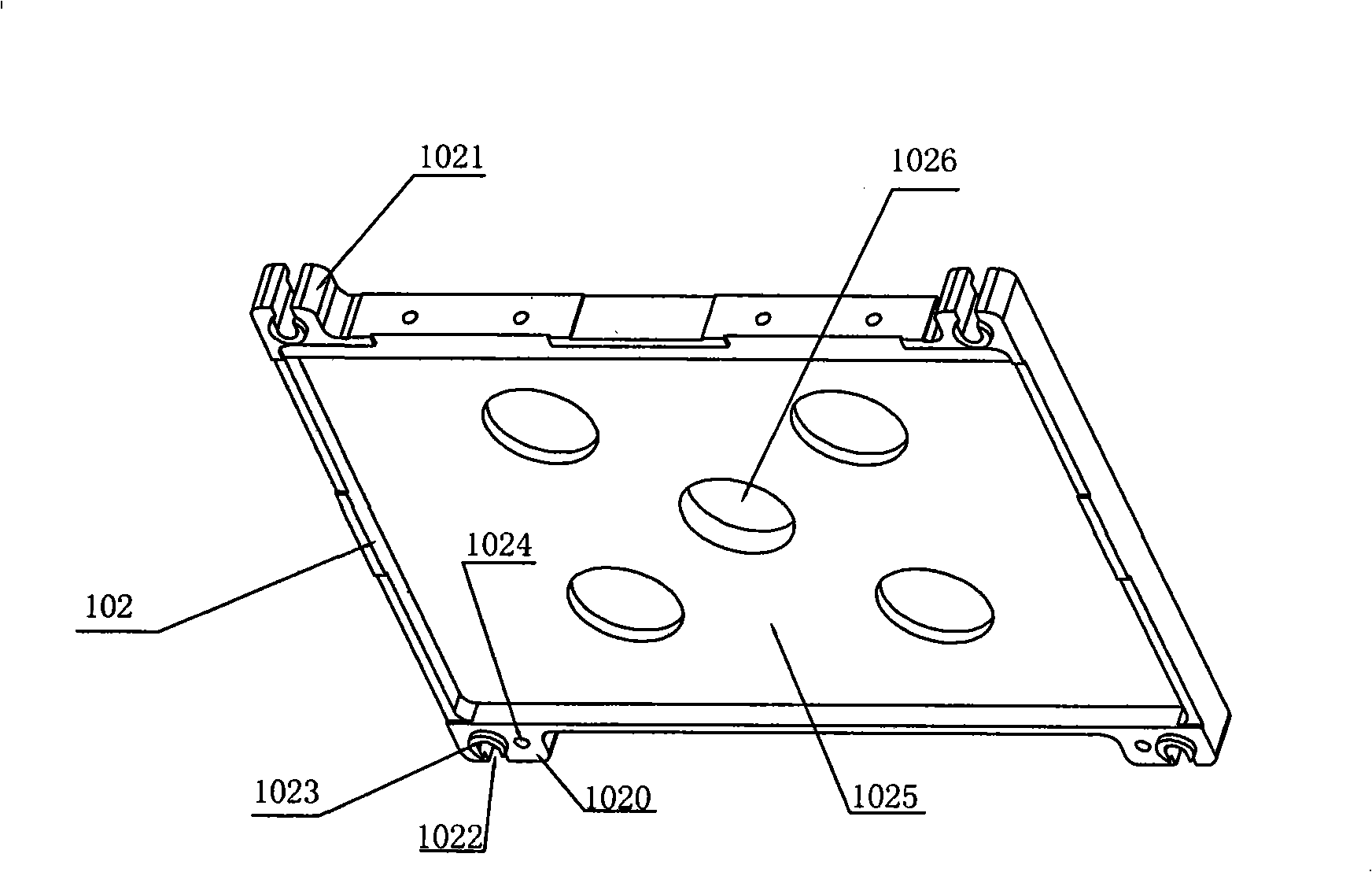

Housing of power cell with adjustable capacity and voltage

The invention provides a shell body capable of enveloping a plurality of power cells, which comprises: an upper end plate provided with an upper end plate groove with a shape corresponding to the outline of the end face of a power cell; at least one intermediate frame body, which is provided with a hollow structure corresponding to the outline of the power cell; and an lower end plate, which is provided with a lower end plate groove with a shape corresponding to the outline of the end face of the power cell. The shell body reasonably meets the requirements on shell body for power cells such as lithium batteries with soft batteries, and realizes the random adjustment of voltage and capacity. The single cells are clamped tightly to ensure the vacuity so as to reduce the vibration of aluminum-plastic film as well as scrapes and damages, to facilitate and ensure the reliability of the connection between a copper press plate and positive and negative plates and to ensure the stable performance and consistency of the cell.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Machining equipment for square tubes

InactiveCN106624178AFully automatedImprove chamfer effectMetal working apparatusPositioning apparatusHydraulic cylinderEngineering

The invention provides machining equipment for square tubes. The machining equipment comprises a bracket and two clamping mechanisms arranged on the bracket. First positioning mechanisms are arranged on the two sides of the two clamping mechanisms. Chamfering mechanisms are arranged in grooves. First blanking holes and second blanking holes are formed in the bracket. A first blanking rail and a second blanking rail are arranged on the bracket. A second positioning mechanism is arranged between the two second blanking holes. The second positioning mechanism comprises first hydraulic cylinders which are arranged in a mirror manner. A through hole is formed in the position, between the two first hydraulic cylinders, of the bracket. A first support is fixedly arranged between first ejector rods of the two first hydraulic cylinders. At least two layered positioning blocks are fixedly arranged at the bottom of the first support. By means of the machining equipment for the square tubes, the square tubes can be machined in batches, inner chamfering and outer chamfering of the square tubes of various specifications can be conducted at the same time, automatic blanking and automatic discharging after machining is completed can be achieved, the degree of automation is high, the machining efficiency is improved, and the production cost is lowered.

Owner:天津福常科技有限公司

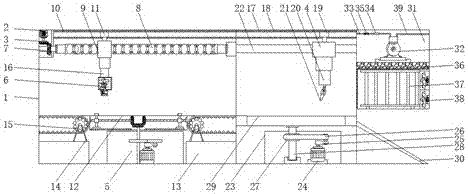

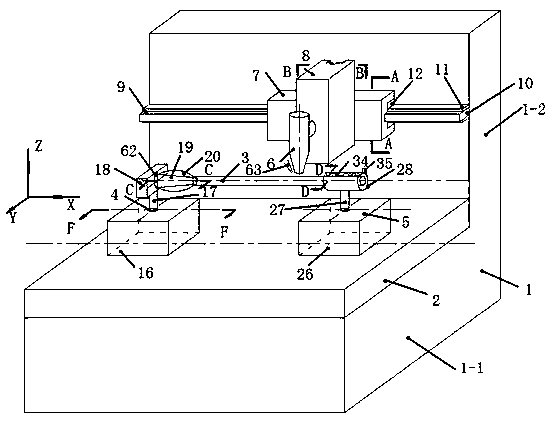

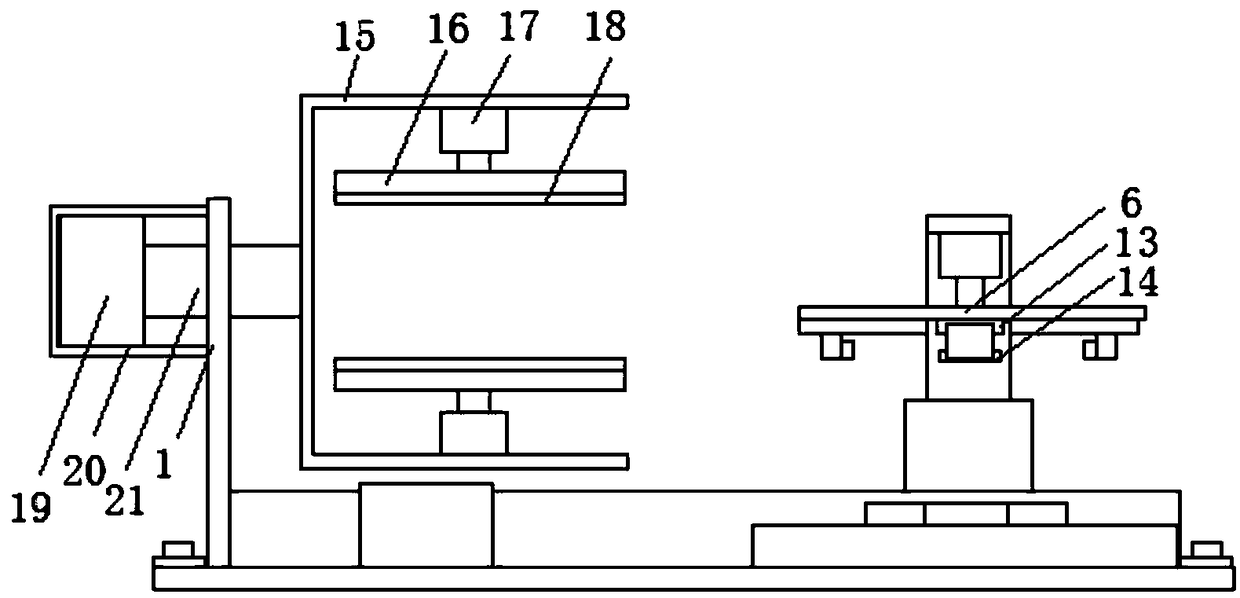

High-precision graphite laser cutting machine and method for machining high-precision graphite pipe by using high-precision graphite laser cutting machine

PendingCN110000480AImprove machining accuracyReduce the impact of machining accuracyWelding/cutting auxillary devicesAuxillary welding devicesSelf adaptiveEngineering

Owner:JIANGSU DNCON LASER TECH

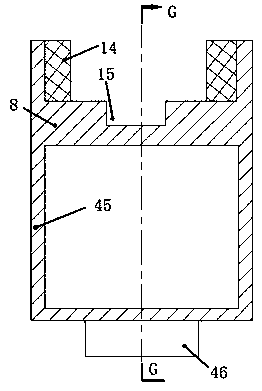

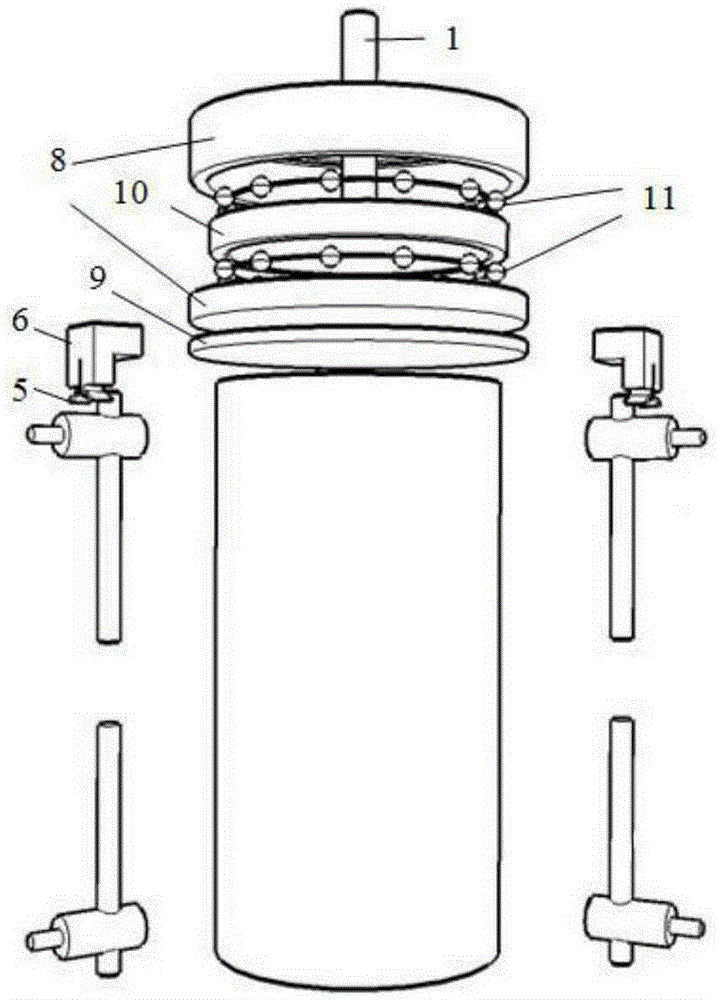

Combined heat-power test device for compatibility between gas and solid material

InactiveCN110501368AGuaranteed to withstand high voltageGuaranteed resistance to high pressureComponent separationMaterial analysis by electric/magnetic meansTransformerHigh voltage

The invention relates to insulation technology, in particular, to a combined heat-power test device for compatibility between gas and a solid material. The combined heat-power test device comprises asealed tank, a high-voltage generating system, an air charging device, and a heating device. The sealed tank includes a tank body with an open upper end and a top cover arranged at the top of the tankbody; and the top cover and the tank body form a sealed cavity. The high voltage generating system includes a metal guide rod connected to a transformer, an insulating casing tube, a grading ring, ahigh-voltage electrode connected to the metal guide rod, a ground electrode connected to the tank body, and a spring connected to the ground electrode, wherein the insulating casing tube and the grading ring are arranged outside the metal guide rod. The air charging device includes a valve and a barometer that are connected to the tank body. The heating device includes a heating belt arranged on the outer wall of the tank body. With the provided combined heat-power test device, high-atmospheric-pressure-resistant, high-temperature-resistant, corrosion-resistant, safe and reliable long-term compatibility testing of the tank body is realized; the local overheating in the sealed tank can be monitored; the high safety of the high voltage test is ensured. The provided device has advantages of small size, low power consumption, reduced test occupation area, and low cost.

Owner:WUHAN UNIV

Turning-over device applicable to polygonal glass surface machining

InactiveCN108908099AGood practicalityImprove work efficiencyGrinding carriagesGrinding feedersFixed frameMachining

The invention discloses a turning-over device applicable to polygonal glass surface machining. The turning-over device comprises a base, a supporting plate is arranged on the rear side of the upper surface of the base, a rotating shaft is rotationally connected to the upper end of the rear side surface of the supporting plate through a bearing, a motor fixing frame is arranged on the rear side surface of the supporting plate, a rotating motor is arranged in the interior of the motor fixing frame, an output end of the rotating motor is connected with the rear end of the rotating shaft, the front end of the rotating shaft extends out of the front side surface of the supporting plate, the front end of the rotating shaft extending out of the front side surface of the supporting plate is provided with a fixing frame, and second electric telescopic rods are arranged in the middle of the upper surface and the lower surface of the inner part of the fixing frame. According to the turning-over device applicable to polygonal glass surface machining, the polygonal glass is clamped by a first suction cup and a second suction cup, positioning and clamping are carried out on the periphery and thecenter of the polygonal special-shaped glass, so that the tight clamping of the polygonal glass is guaranteed, the polygonal glass is turned over through turnover of clamping plates, time and labor are saved, the practicability is good, and the working efficiency is greatly improved.

Owner:安徽名特玻璃有限公司

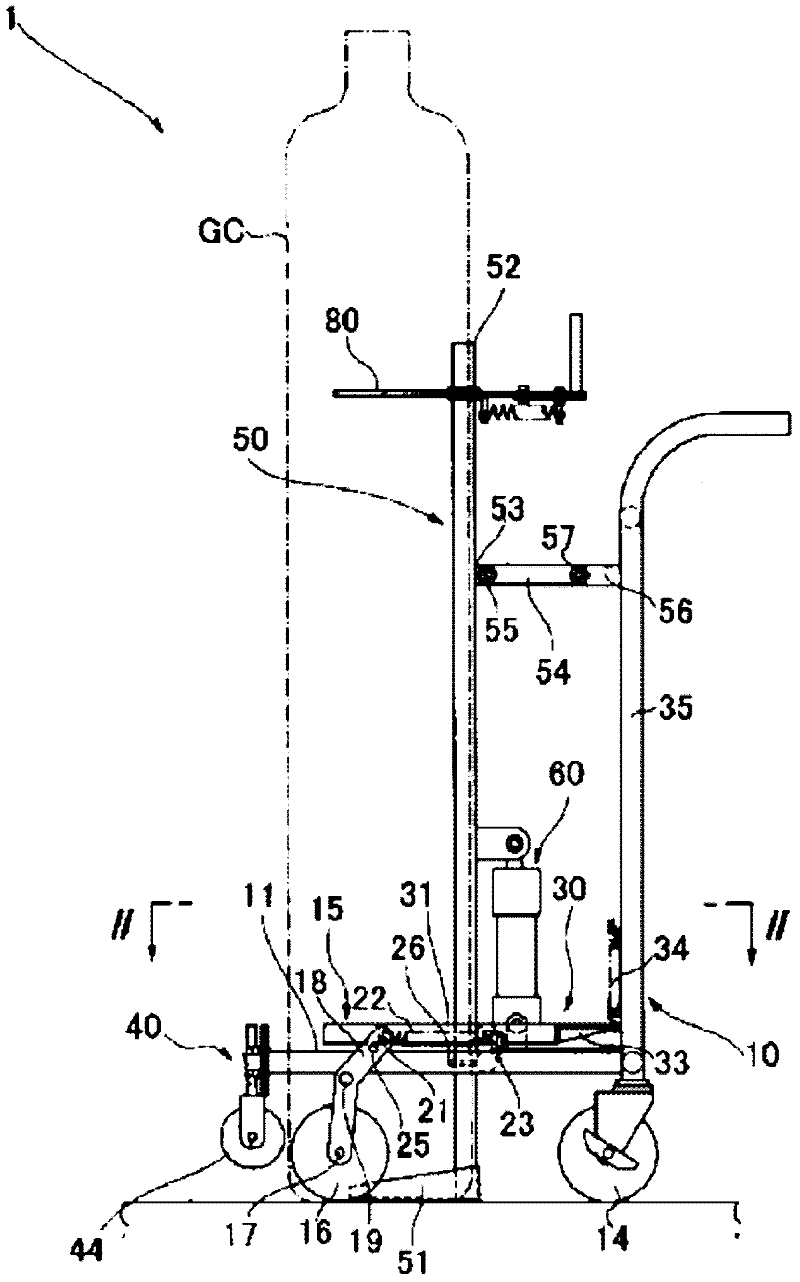

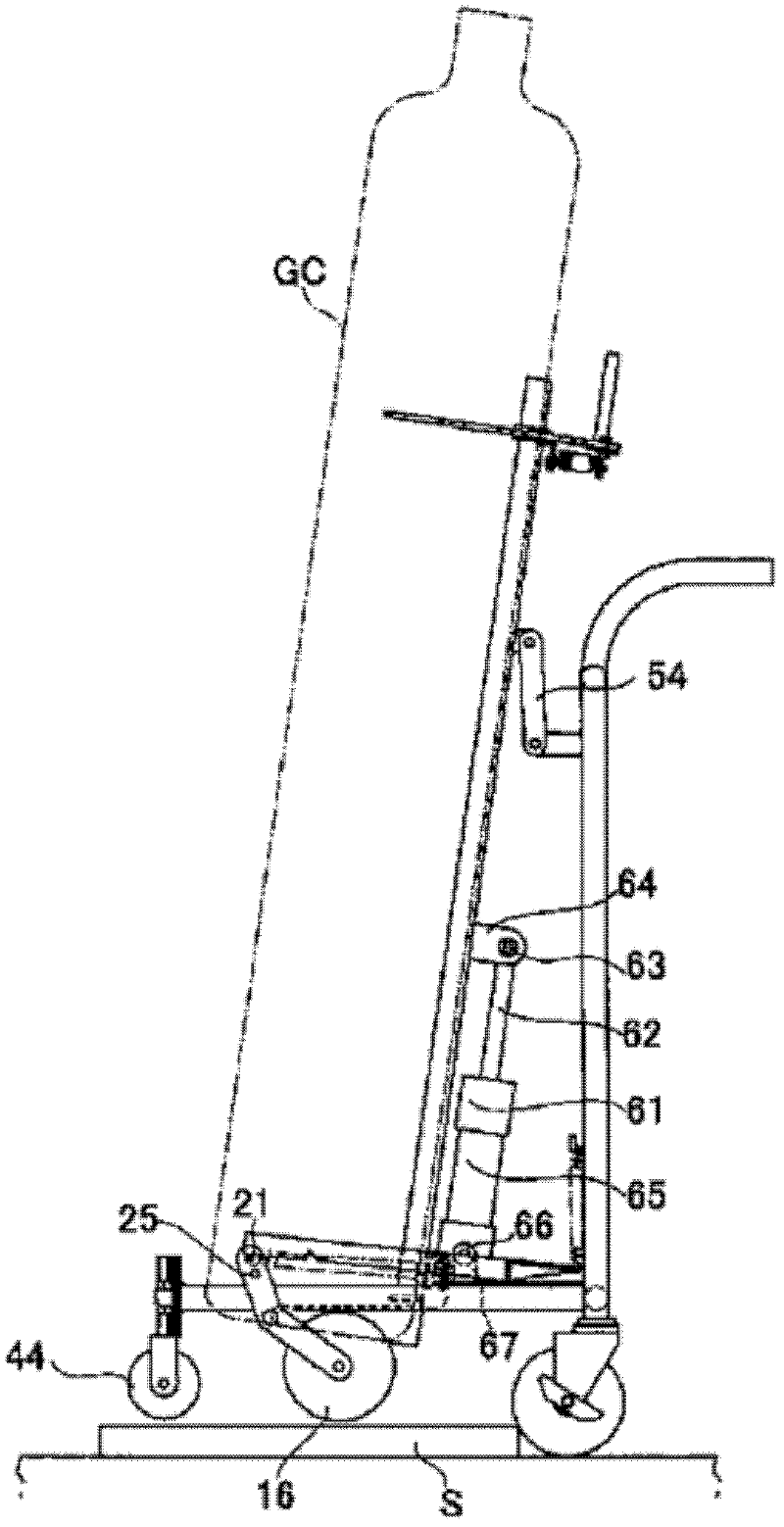

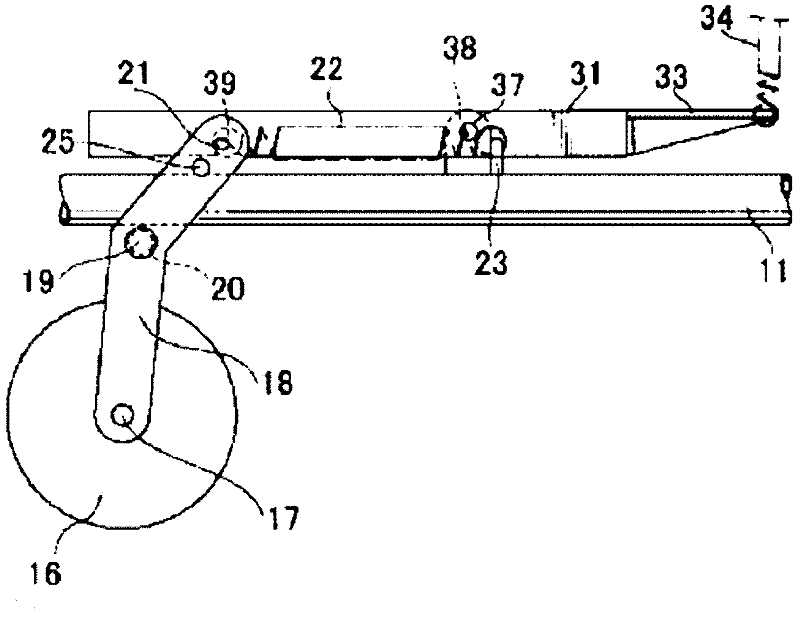

Manual carriage trolley capable of crossing obstacles

InactiveCN102336207ASimple and fast operationEasy to useHand carts with multiple axesAutomotive engineering

The invention relates to a manual carriage trolley capable of crossing obstacles, comprising an operating device, an operating board, rear wheels, a front wheel, an auxiliary wheel, a placing device, a lift cylinder and a clamping device, wherein the operating device comprises two stand columns which are vertical upward and arranged in parallel; the rear wheels are respectively arranged at the bottom ends of the two stand columns; the operating board is parallel to the ground and is fixedly connected with the stand columns; the front end of the operating board is provided with the auxiliary wheel; the diameter of the auxiliary wheel is less than those of the rear wheels; and the front wheel is installed to be higher than the rear wheels. The manual carriage trolley capable of crossing the obstacles is simple in structure and convenient to operate, and is capable of conveniently crossing the obstacles so as to avoid the potential safety hazard; meanwhile, the manual carriage trolley is very convenient to operate and convenient to maintain, thus saving cost and time.

Owner:四川欧曼机械有限公司

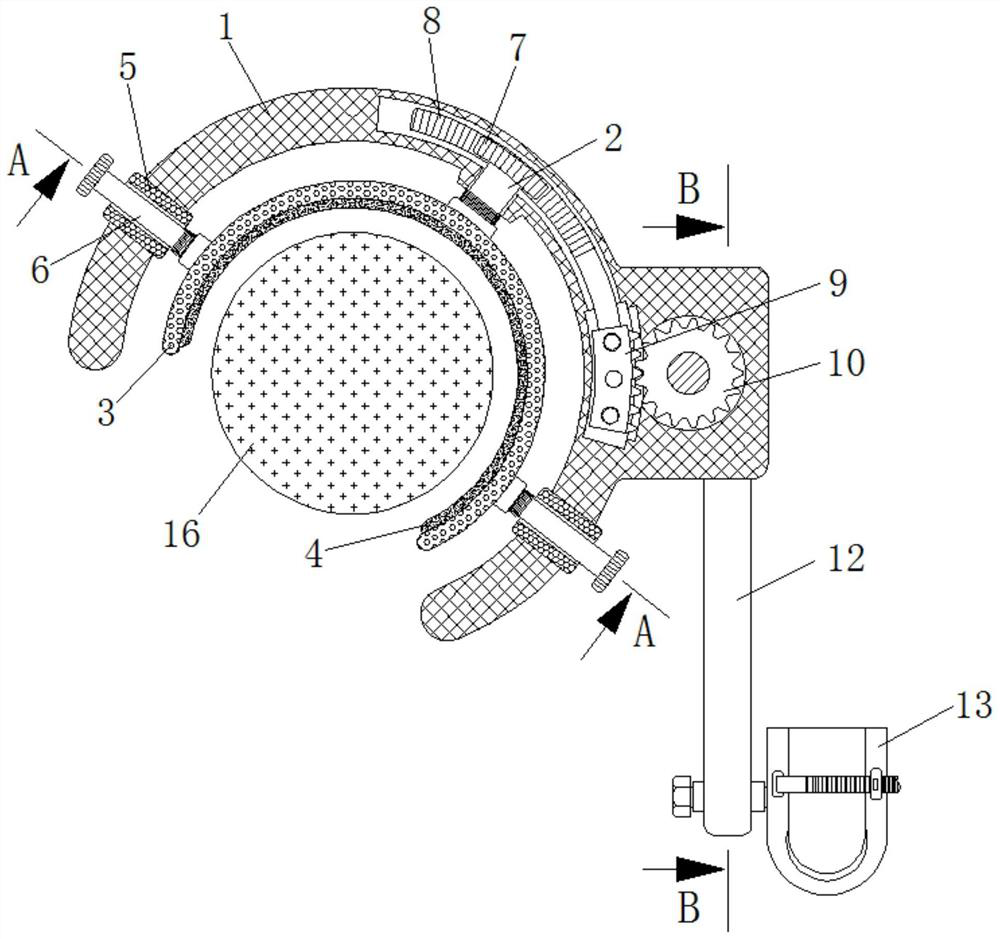

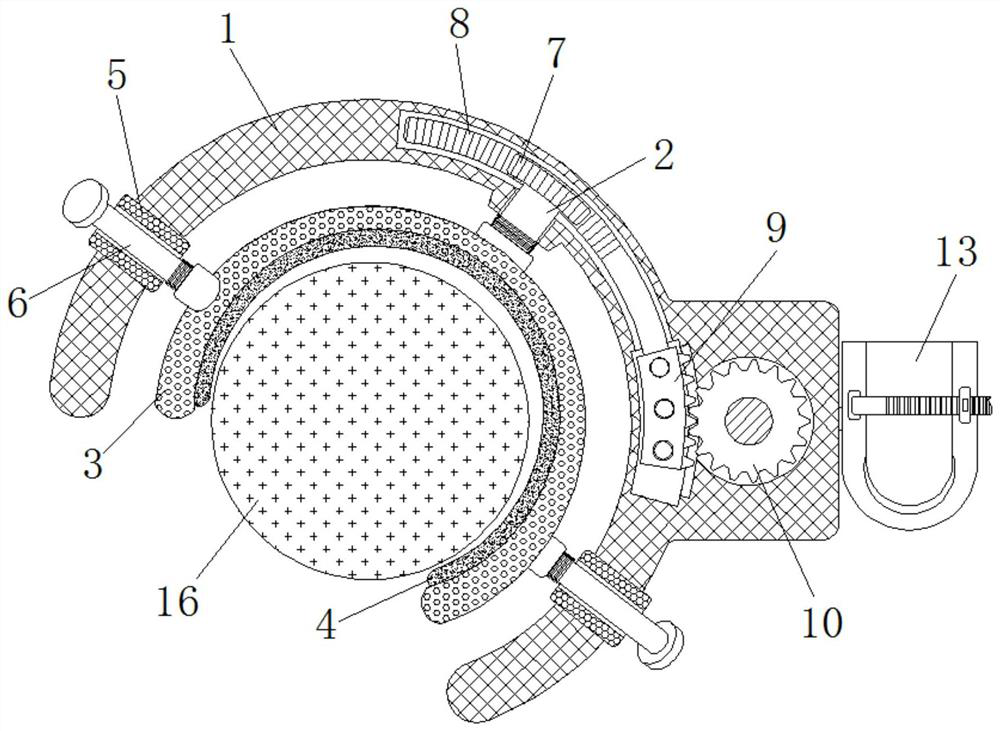

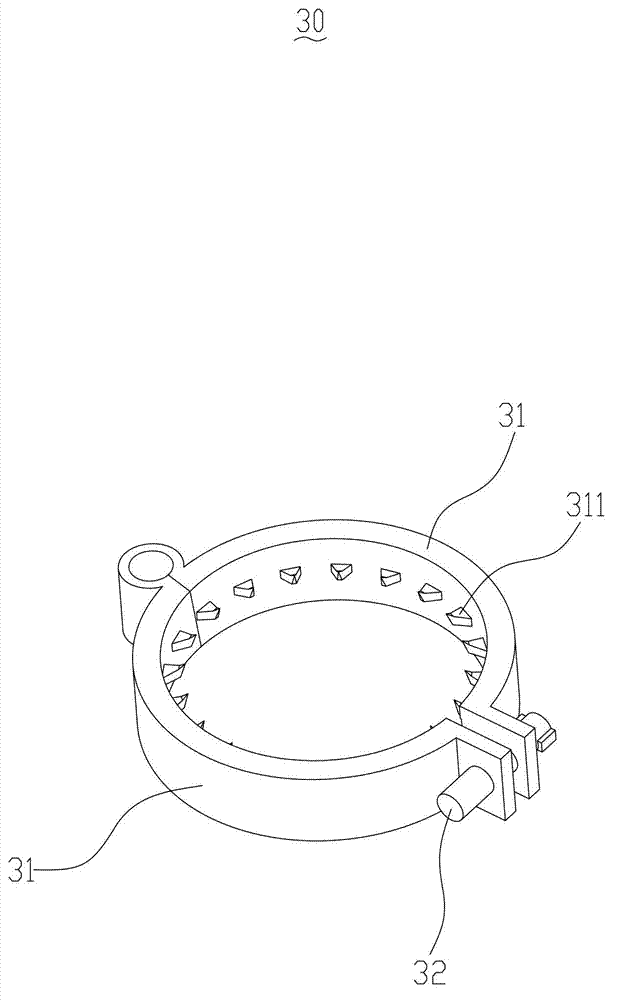

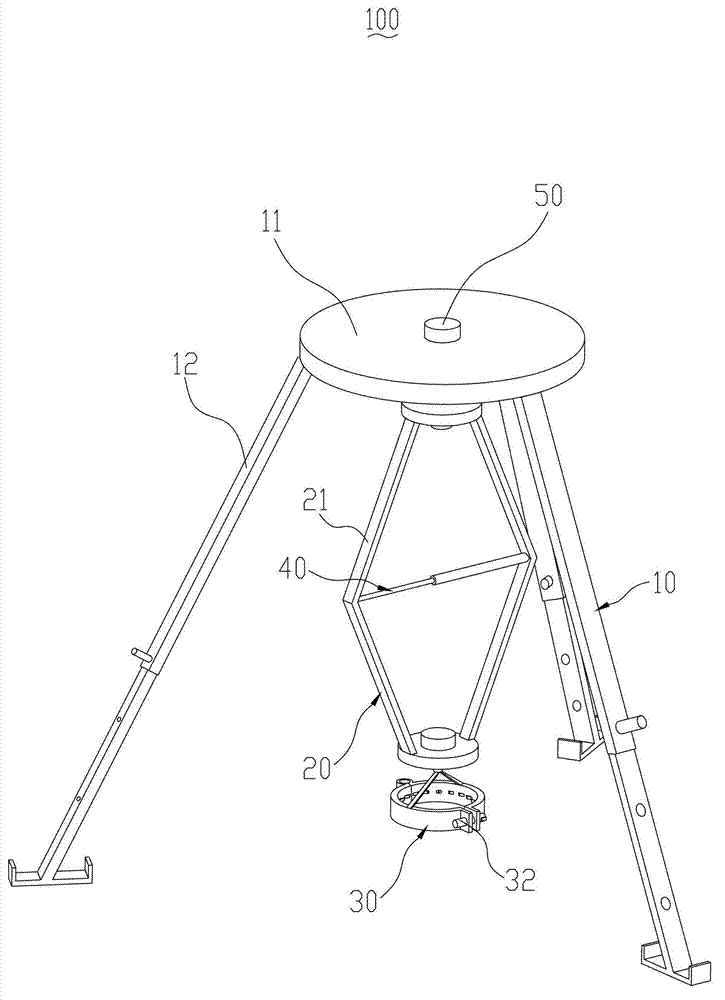

Auxiliary device for building pipeline installation

InactiveCN108793001AReduce work intensityEasy to useLifting framesEngineeringUltimate tensile strength

The invention discloses an auxiliary device for building pipeline installation. The auxiliary device comprises a base, wherein universal wheels are arranged at four corners of the bottom end of the base, and an electric telescopic rod is arranged at the top end of the base; the bottom end of the electric telescopic rod is fixedly connected to the surface of the base, and a supporting plate is arranged at the top end of the electric telescopic rod; the bottom end of the supporting plate is fixedly connected to the top end of the electric telescopic rod, and a clamping device is arranged at thetop end of the supporting plate; and the clamping device comprises a fixed shell. According to the auxiliary device, by arranging the clamping device, when the auxiliary device needs to be used, the auxiliary device is moved to a designated working area by the universal wheels, a pipeline is placed in the clamping device, the supporting plate is driven to move upwards by elongating the electric telescopic rod, the upward movement of the supporting plate drives the pipeline to reach the required height, the use is convenient, the reduction of the phenomenon of the need for manual lifting by means of a scaffold is facilitated, and therefore the labor intensity is reduced.

Owner:安徽百匠信息科技有限公司

Labor-saving and high-safety telegraph pole climbing device for electric power overhaul

The invention provides a labor-saving and high-safety telegraph pole climbing device for electric power overhaul, and relates to the technical field of electric power facilities. The labor-saving andhigh-safety telegraph pole climbing device for electric power overhaul comprises a frame body, a rotating shaft is rotatably connected to the inner side of the top of the frame body, a clamping stripis in threaded connection with the bottom end of the rotating shaft, a rubber ring is fixedly installed on the inner side of the clamping strip, and a limiting groove is fixedly formed in the outer ring of the frame body; and a connecting rod is slidably connected into the limiting groove, and a first gear is fixedly connected to the end, located in the frame body, of the rotating shaft. Accordingto the labor-saving and high-safety telegraph pole climbing device for electric power overhaul, the pedals can be clamped without being kept in an inclined state, and the pedals can rotate after being fixed, so that more labor is saved, fatigue of feet is relieved, and limiting and fixing between the frame body and the telegraph pole are more stable in the climbing process of a human body. The slipping phenomenon is avoided, and the safety of the climbing device is improved.

Owner:NINGDE POWER SUPPLY COMPANY STATE GRID FUJIAN ELECTRIC POWER +1

Cable test specimen clamping device and insulation layer peeling equipment

PendingCN108037330AAchieve clampingEasy to cutMeasurement instrument housingApparatus for removing/armouring cablesInsulation layerEngineering

The invention discloses cable test specimen clamping device and insulation layer peeling equipment. The cable test specimen clamping device comprises a pair of clamping arms and a clamping driving mechanism, wherein the free end of each clamping arm is provided with a clamping V-shaped block and is used for clamping the outer surface of a cable test specimen; one pair of clamping arms do synchronous movement in the mutual approaching or mutual leaving directions through being driven by the clamping driving mechanism; the centering clamping is realized. The clamping on a cable test specimen canbe conveniently realized through the cable test specimen clamping device; on one hand, the axial line position of the cable test specimen in the clamping process keeps unchanged, so that the operations such as the subsequent insulation layer cutting can be conveniently performed; on the other hand, the clamping device per se can adapt to the cable test specimens of various diameters.

Owner:UNIV OF JINAN

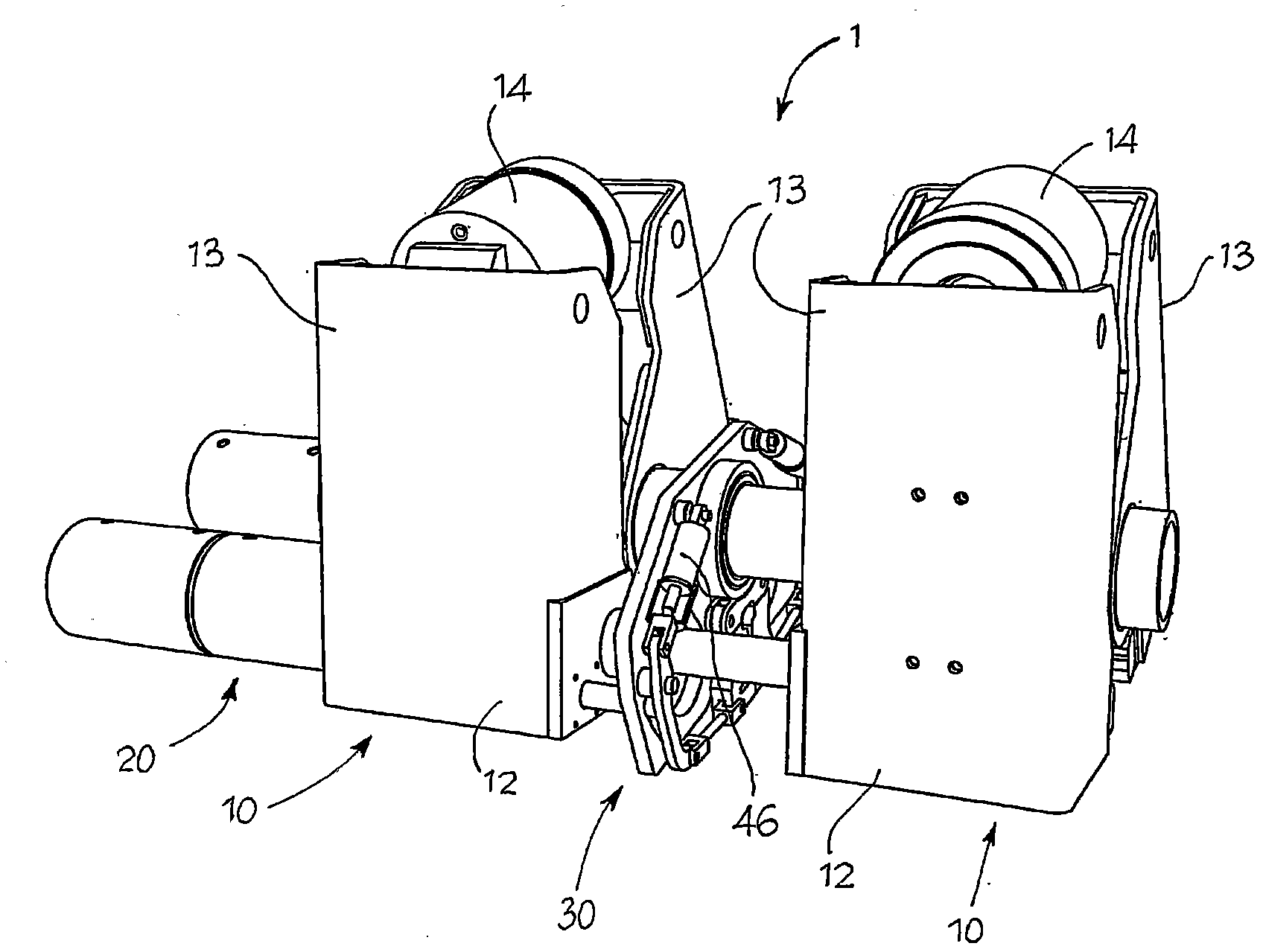

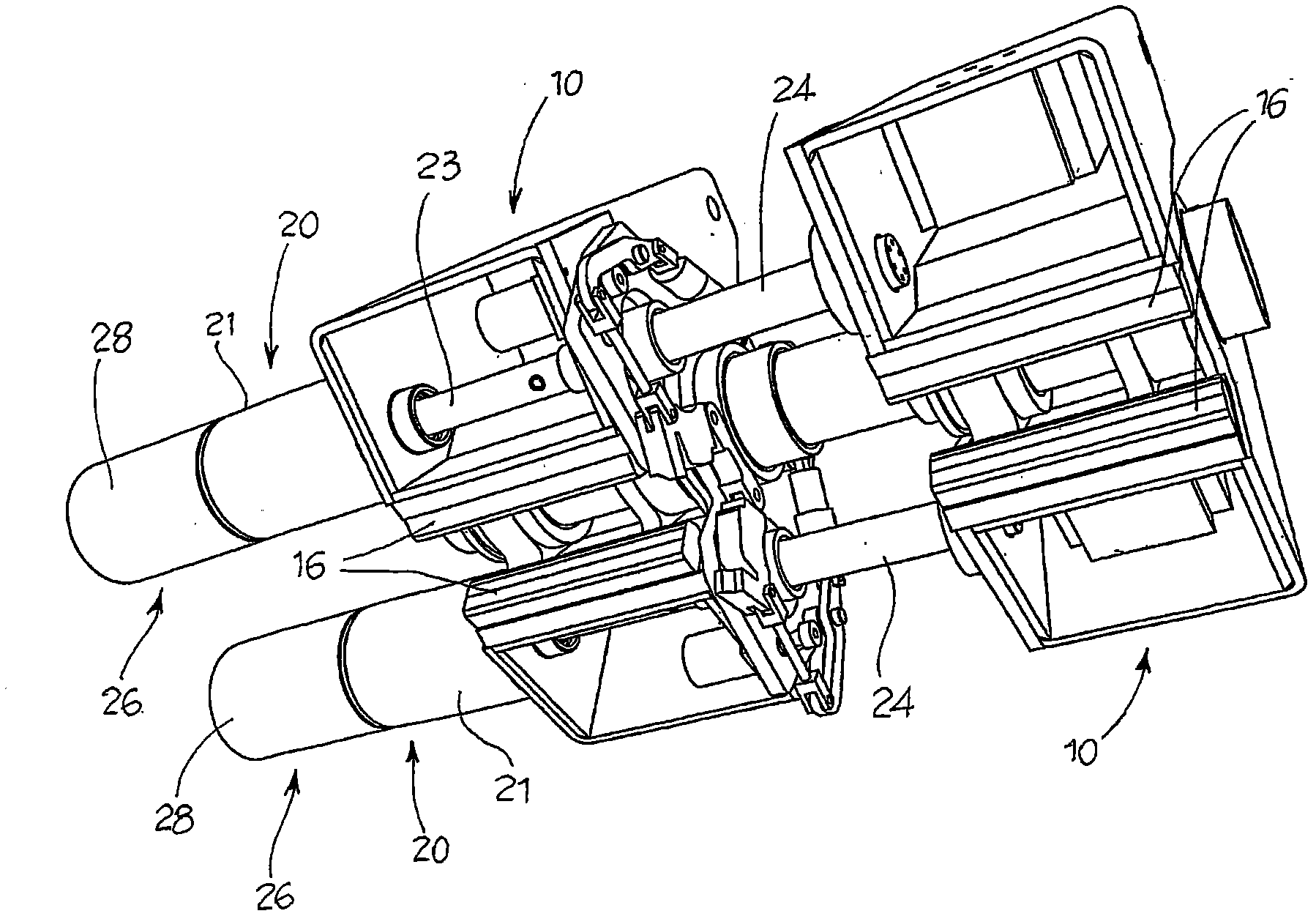

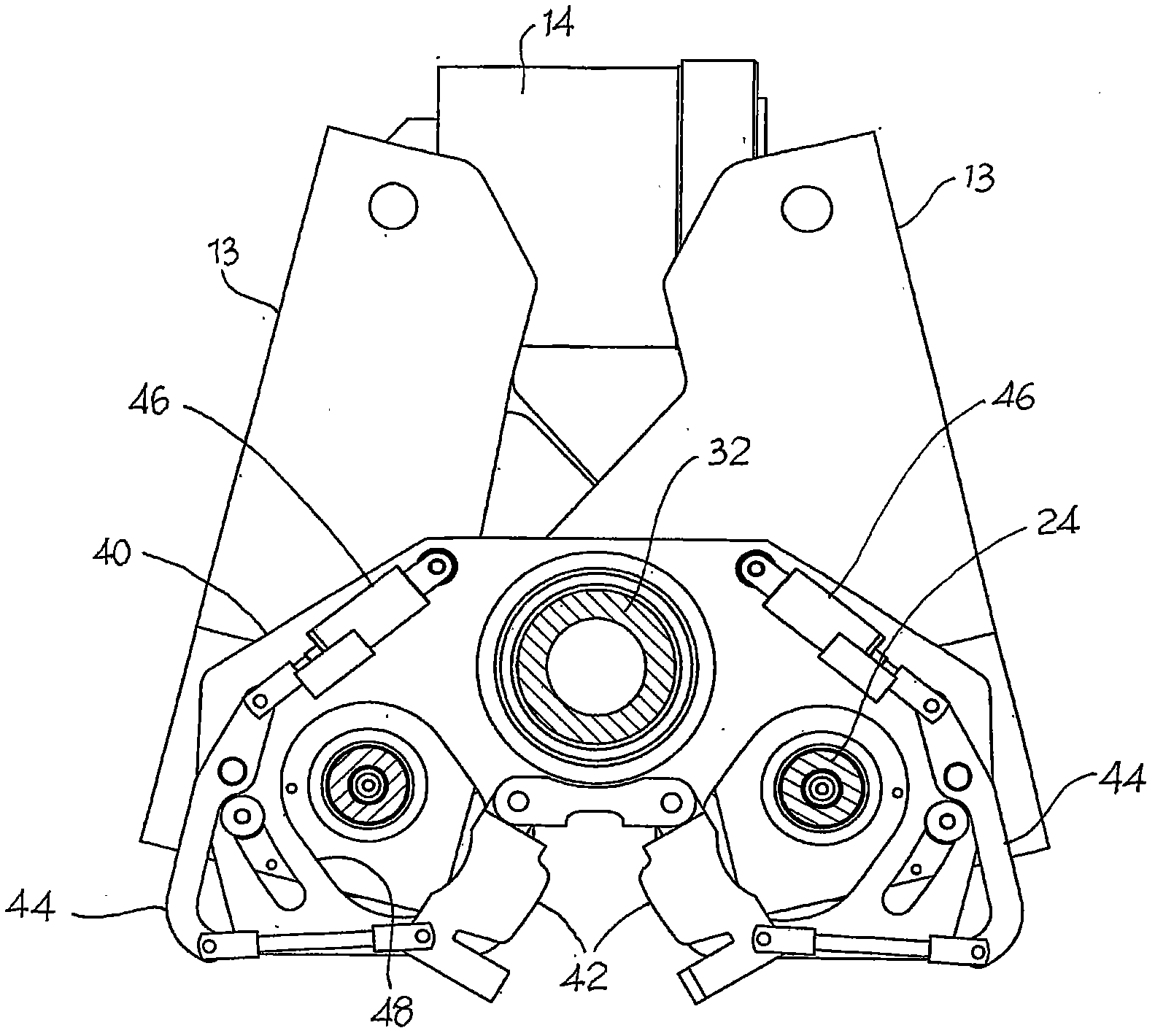

Welding head for rail welding

This invention concerns a welding head for welding the extremities of two sections of rail and comprises two half -heads (10) aligned and sliding with regard to one another in a longitudinal direction. Each half -head comprises grip means (12, 13) to grasp a respective section of rail and two electrodes (16) suitable for contact with respective sections of rail in order to carry out a flash butt weld. The head also comprises traction actuator means (20) which extend in a longitudinal direction and are connected to the two half- heads (10) to shift the two half-headsin a longitudinal direction one towards the other, said traction actuator means (20) having a stroke suitable for allowing, during a cycle of welding two sections of rail, simultaneous regulation of rail tensions.

Owner:达维德瓦亚

Device for removing bamboo head

Owner:HE YI SHENG XIAMEN AGRI SCI & TECH +4

Double toggle rod self-locking clamping device

InactiveCN102581633AAchieve clampingReliable self-locking statePositioning apparatusMetal-working holdersHydraulic cylinderLiquid medium

The invention discloses a double toggle rod self-locking clamping device which comprises a driving mechanism and a toggle rod force-increasing self-locking clamping mechanism. The driving mechanism comprises a linear motor, an active piston and a hydraulic cylinder; one end of the active piston is fixedly connected with the output end of the linear motor, and the other end is provided with a liquid medium; the driving mechanism is used for driving an output mechanism and a reset mechanism through pipes; each pipe is provided with a controllable switch valve; the toggle rod force-increasing self-locking clamping mechanism comprises at least two toggle rod groups; each toggle rod group comprises an upper toggle rod, a lower toggle rod and a first-stage toggle rod; the upper toggle rod is articulated with the lower toggle rod; the first-stage toggle rod is articulated with the upper toggle rod; and the first-stage toggle rods are articulated together and the articulation points are located between an output piston and a reset piston. The driving mechanism of the double toggle rod self-locking clamping device adopts the Pascal's principle, takes the fluid within a sealed space as the transmission medium and uses the piston with a small diameter to push the piston with a large diameter to move to realize the force increase and the stroke reduction. The double toggle rod self-locking clamping device can be used for clamping rapidly with large clamping force at high efficiency.

Owner:SUZHOU UNIV

Automatic straw pulverizer

InactiveCN102197747AImprove work efficiencyHigh degree of automationLoadersCrop conditionersImpellerElastic compression

The invention discloses an automatic straw pulverizer, which comprises a frame, a draw rod, a front wheel and a rear wheel. The frame is provided with an engine, a fan, a gearbox and a pickup tool. One end of a spindle of the fan is in drive connection with the engine. The automatic straw pulverizer is characterized in that blades are uniformly distributed on a fan impeller; the frame is provided with a transverse delivery mechanism and a material clamping bin; an elastic compression roller and a supporting roller are arranged in the material clamping bin up and down; a plurality of feed rollers are arranged above the frame; the front parts of the feed rollers are provided with auger blades; the other end of the spindle of the fan is in drive connection with an input shaft end of the gearbox; the gearbox is provided with two output shaft ends; one end of the supporting roller is in drive connection with one output shaft end of the gearbox; a drive roller, the feed rollers and the elastic compression roller of the transverse delivery mechanism are respectively in drive connection with the other end of the supporting roller; and the other output shaft end of the gearbox is in drive connection with the pickup tool. The automatic straw pulverizer has the advantages that harvested straws which are stacked in the field can be picked up, pulverized and collected; and the working efficiency and the automation degree are high.

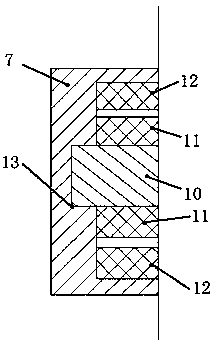

Magnetic device and method for fixing rock axial tensile specimen extensometer auxiliary assembly

ActiveCN105352797AGuaranteed clampingFlexible rotationMaterial strength using tensile/compressive forcesEngineeringSteel frame

The invention discloses a magnetic device and method for fixing a rock axial tensile specimen extensometer auxiliary assembly. The device comprises a steel frame; the steel frame is provided with an upper beam and a lower beam; a plurality of T-type handles are connected to the upper beam through screw threads; turntables are installed on the lower ends of the T-type handles; chassis paired with the turntables are arranged on the lower beam; guide grooves extend on the turntables and the chassis; guide rods passing through the guide grooves are arranged on the lower beam; a plurality of groups of paired reinforcement magnets are arranged on the turntables and the chassis; each reinforcement magnet is connected with an arc magnetic suction device; the arc surface of the arc magnetic suction device adsorbs an extensometer auxiliary assembly; and one end of the extensometer auxiliary assembly is bonded with a rock cylinder core specimen. The operation steps using the test device provided by the invention rely on the designed centering scribed lines to realize positioning and centering; and artificial fuzzy operation intervention is less, so as to ensure the accurate position of the extensometer and the bond end of the rock specimen.

Owner:HOHAI UNIV

Cone-shaped tube machining and locating device

InactiveCN105014294AGuaranteed clampingGuaranteed positioningWelding/cutting auxillary devicesAuxillary welding devicesCircular surfaceMachining

The invention discloses a cone-shaped tube machining and locating device which comprises a locating plate and a movable block. A shell is arranged on one side of the locating plate. A valve element matched with the shell is arranged in the shell. A valve rod is connected with the valve element, penetrates through the locating plate, and is connected with a fixed block. The fixed block is connected with multiple supporting rods in a rotating mode. A spring is arranged between the valve element and the locating plate. Multiple clamping rods are arranged on the other side of the locating plate in a rotating mode and connected with the supporting rods in a rotating mode. The shell is provided with an air inlet. A pulling rod is arranged on the movable block, an annular column is fixedly connected with one end of the pulling rod, the outer circular surface of the annular column is a conical surface, and the annular column is provided with an expansion cone matched with the conical surface of the annular column. The cone-shaped tube machining and locating device improves work efficiency and lowers cost.

Owner:CHENGDU MATSUKAWA METAL MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com