Polyurethane tube deformation numerical control shaping and rounding device

A polyurethane, disc technology, applied in the direction of tubular items, other household appliances, household appliances, etc., can solve the problems of troublesome, large deformation and large stress of steel pipe sleeves, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

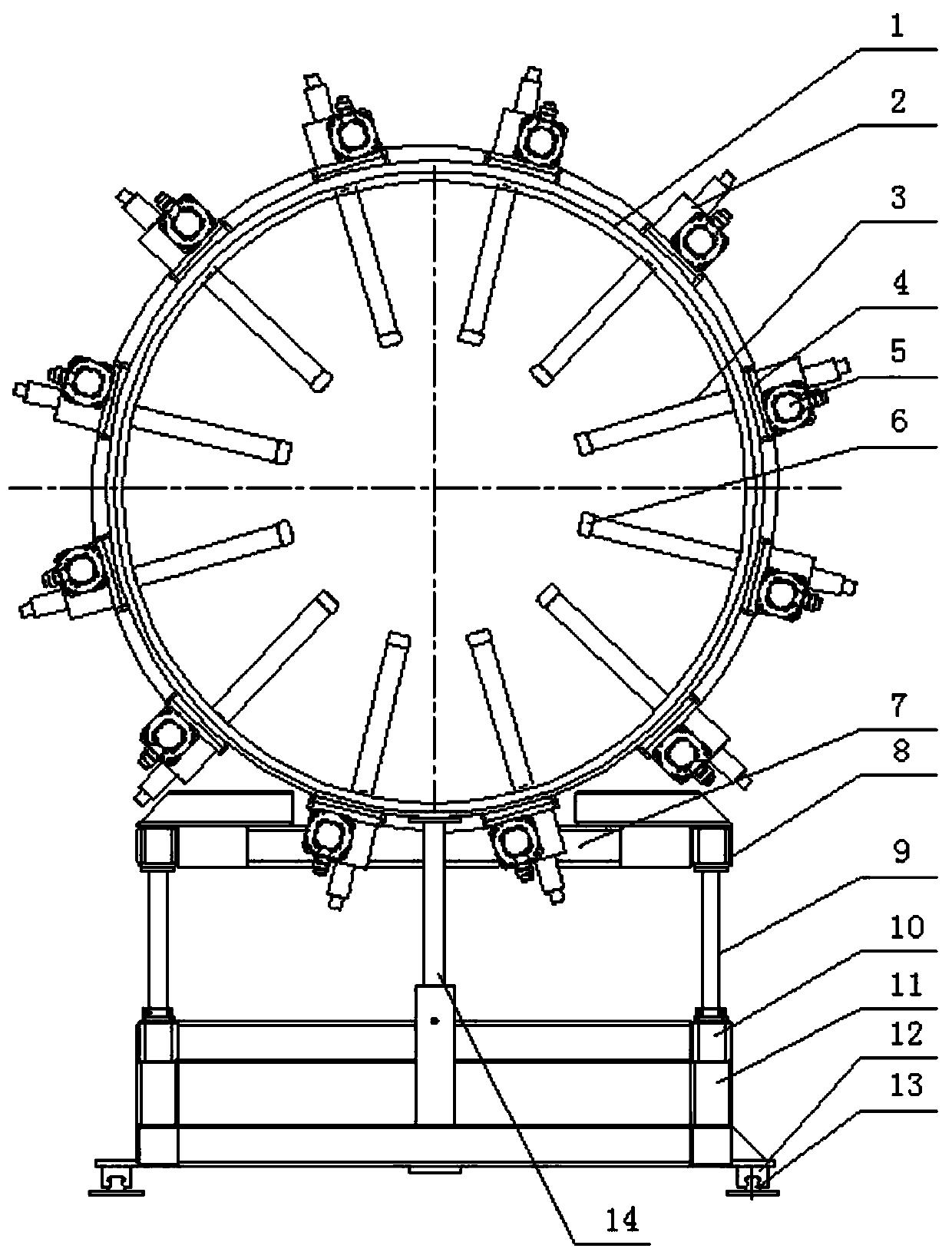

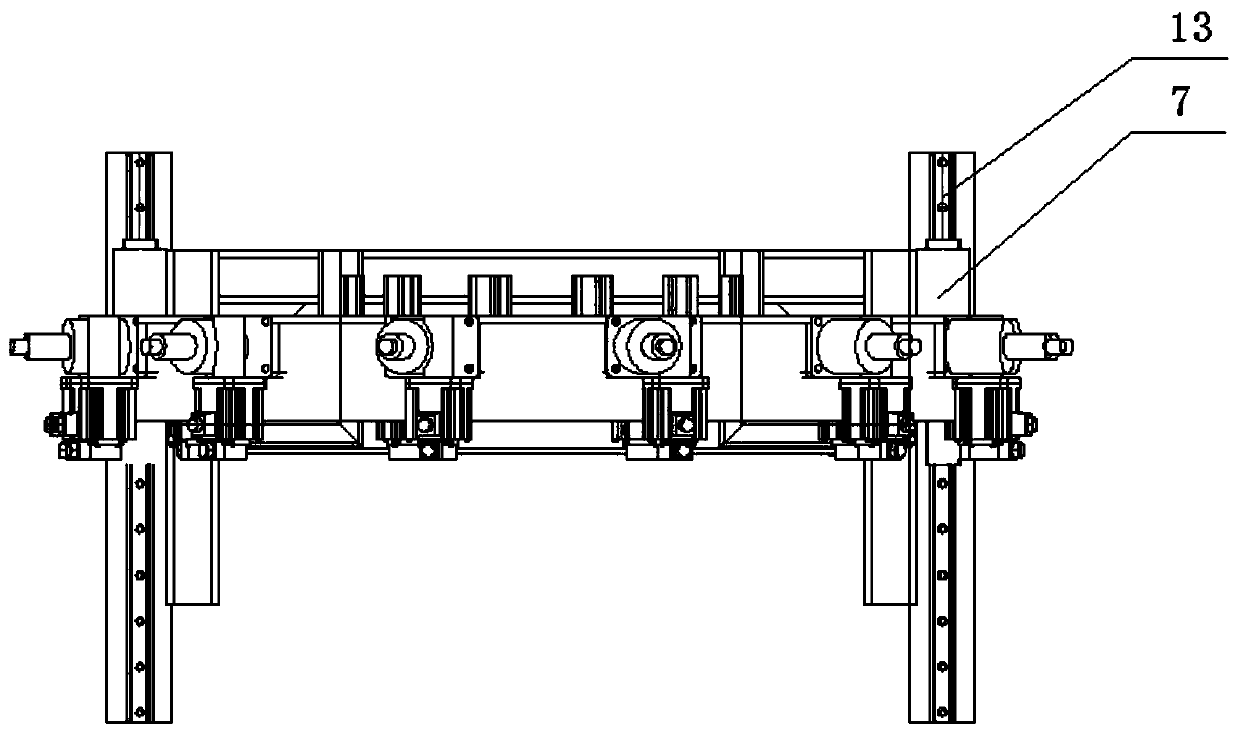

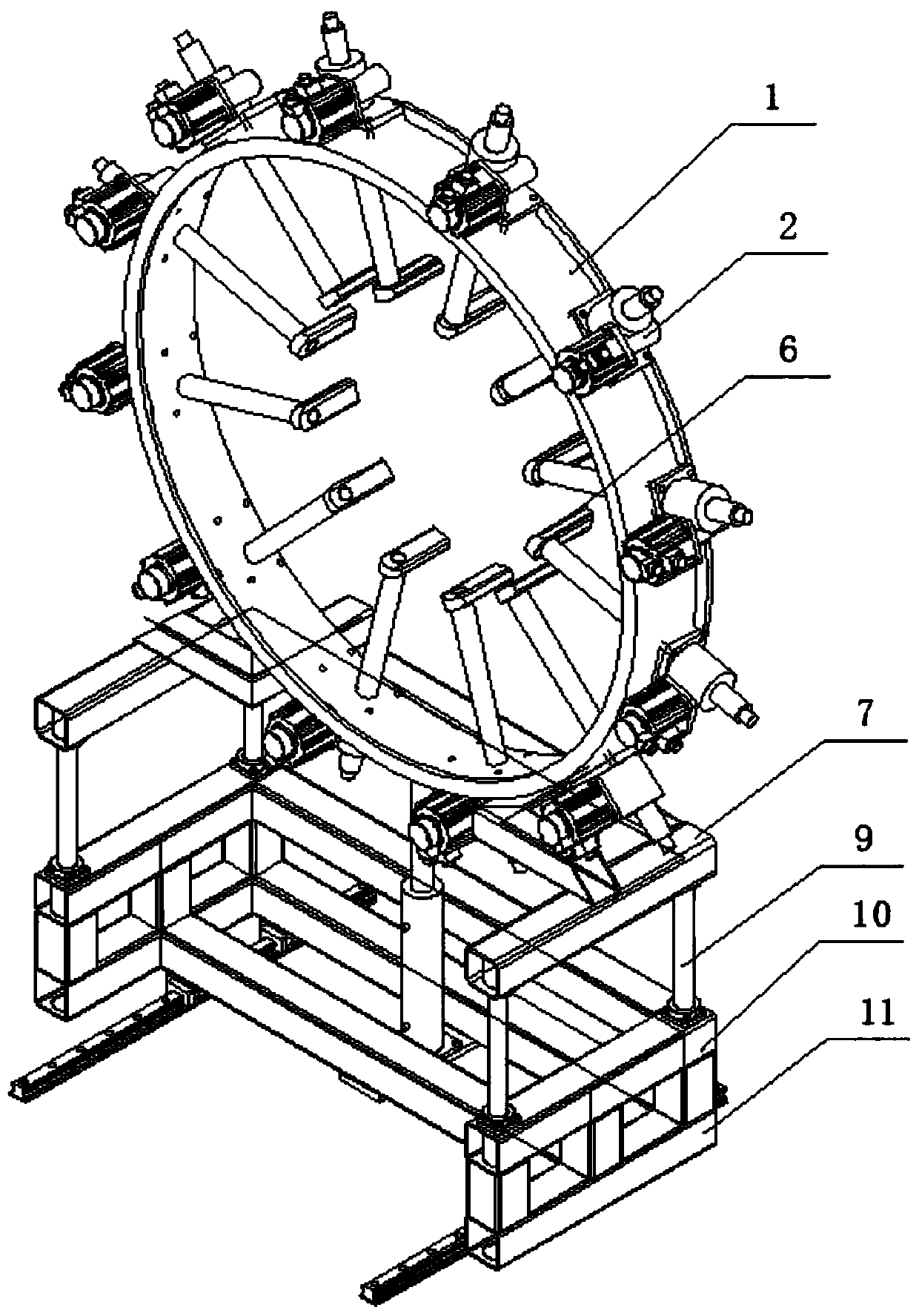

[0023] A polyurethane tube deformation numerically controlled shaping and returning device, which includes a frame 11, a returning disc 1, and a returning jack assembly 2, the returning disc is fixedly installed on the frame, and the returning unit is installed at uniform intervals around the returning disc Jack assembly, the return jack assembly includes a base 4, a servo motor 5, a worm gear mechanism, a screw 3 and a grab hook 6, the base is fixedly installed on the outer circumference of the return disc, the worm gear mechanism is installed on the base, and the worm is driven by the servo Driven by a motor, the outside of the worm wheel is engaged with the worm for transmission, and the inside of the worm wheel is made with a nut for enga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com