Jointed connecting link mechanism with linkage between moving side mold and bottom mold of bottle blowing machine

A connecting rod mechanism and side mold technology, applied in the field of combined connecting rod mechanism, can solve the problems of difficult cam installation and positioning, high machining accuracy requirements, and easy wear of the cam profile, so as to enhance the stability and reliability of motion, reduce the Vibration and shock, the effect of improving high-speed performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

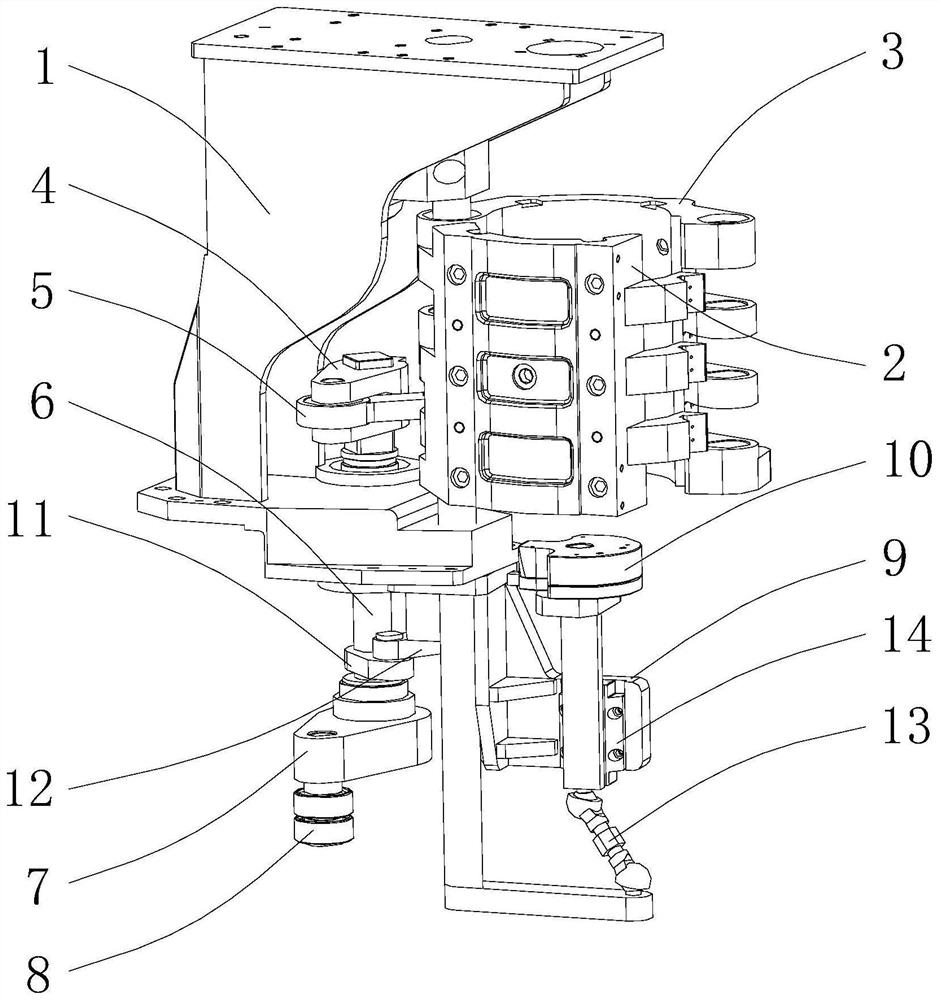

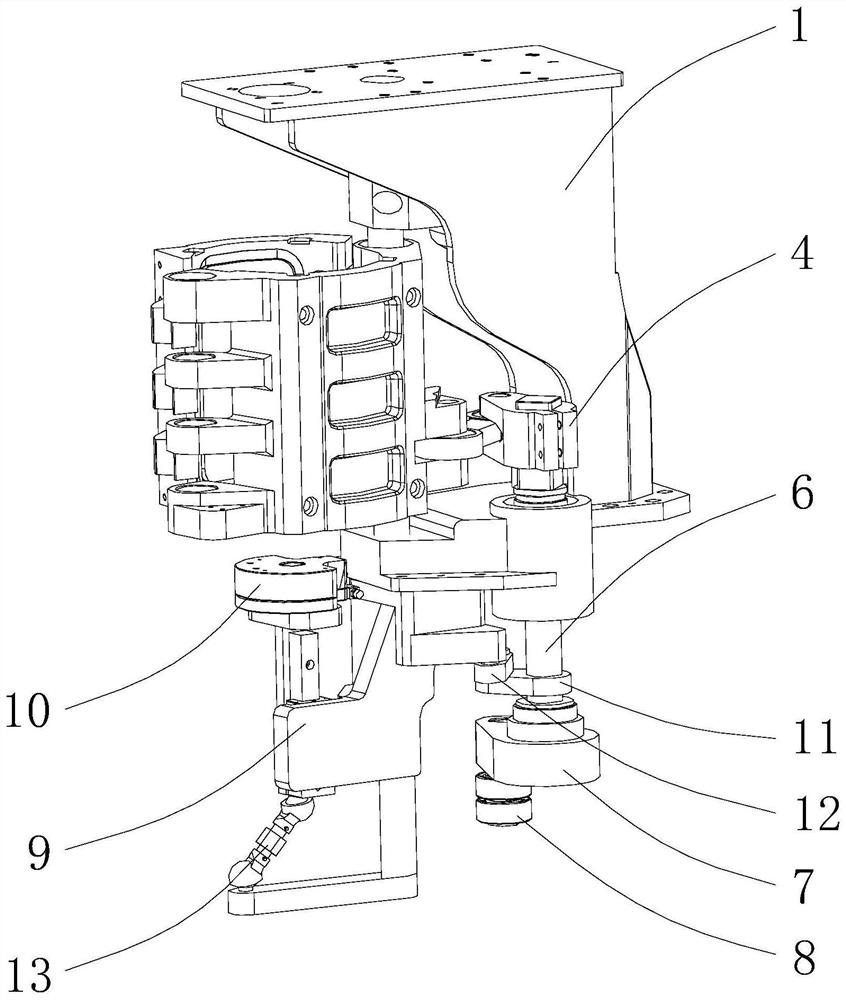

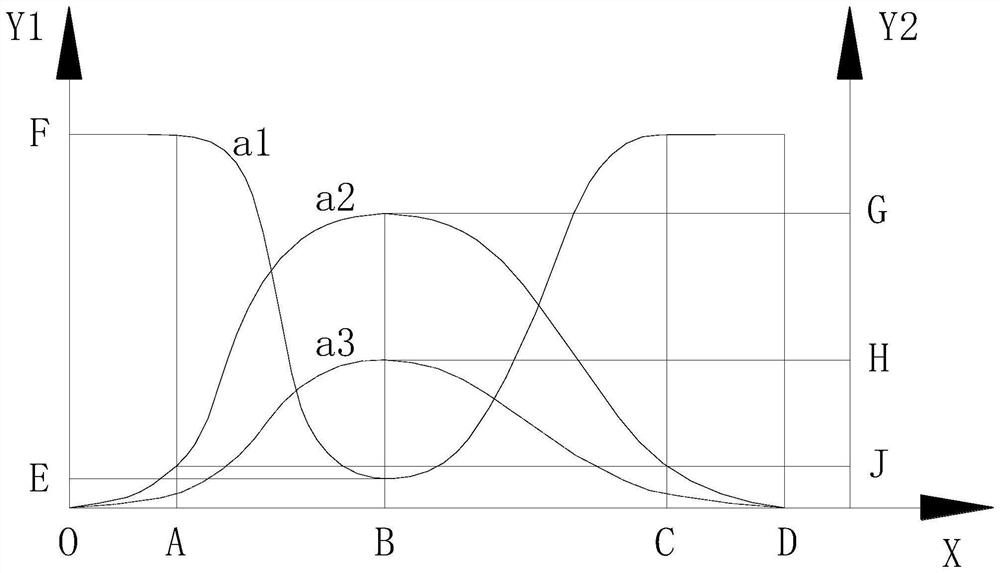

[0029] see Figure 1-2 As shown, the above-mentioned combined linkage mechanism of the blowing motorized side mold and the bottom mold includes a mold frame bracket 1, a fixed side mold 2, a moving side mold 3, a side mold swing arm 4, a side mold connecting rod 5, a side mold Die swing shaft 6, side mold rotor arm 7, side mold cam rotor 8, bottom mold support 9, bottom mold 10, bottom mold swing arm 11, bottom mold connecting rod 12, space connecting rod 13 and bottom mold guide rail 14. The movable side mold 3 can be rotated around the direction of the first axis and is installed on the mold frame bracket 1, the fixed side mold 2 is fixed on the mold frame bracket 1, and the movable side mold 3 rotates close to or away from the fixed side mold 2, Mold opening and closing for mutual cooperation.

[0030] Among the bottom mold 10, the movabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com