Automatic pouring system

An automatic pouring and transmission shaft technology, which is applied to the equipment for feeding molten metal into the mold, casting molten material container, manufacturing tools, etc., can solve the problems of high risk, spilled raw materials, rapid cooling, etc., and achieve good pouring quality , Simple structure, prevent raw material cooling or oxidation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

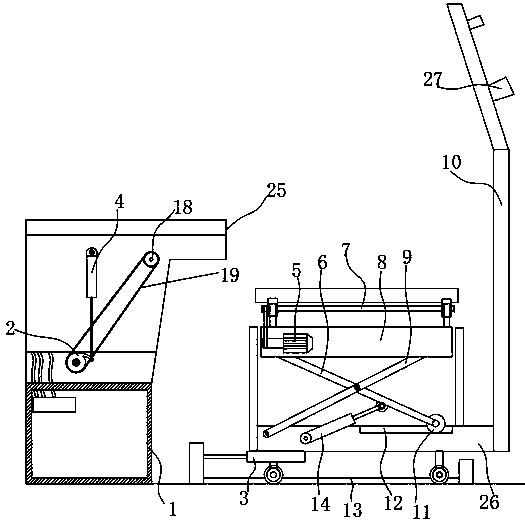

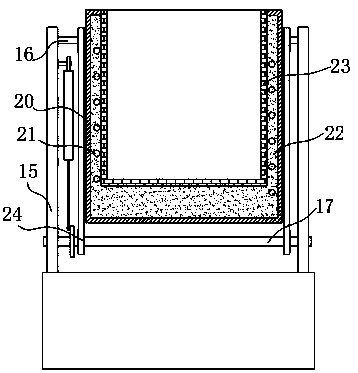

[0018] Embodiment: An automatic pouring system, including a melting furnace, the melting furnace includes a base 1, a vertical plate 15 arranged on the left and right sides of the top of the base 1, and a fixed shaft 16 arranged on the inner top surface of the vertical plate 15 , the heat preservation shell 20 connected to the fixed shaft 16 on the left and right sides, the crucible 23 arranged in the heat preservation shell 20, the heating ring 21 set outside the crucible 23, and the crucible 23 and the The thermal insulation material 22 between the thermal insulation shells 20, the fixed shaft 16 is fixedly connected with the driven wheel 18, the fixed shaft 16 is connected to the vertical plate 15 in rotation, and the inner bottom of the vertical plate 15 is connected in rotation There is a transmission shaft 17, the transmission shaft 17 is rotationally connected with the vertical plate 15, the transmission shaft 17 is parallel to the fixed shaft 16, the transmission shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com