Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "Play the role of precise positioning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

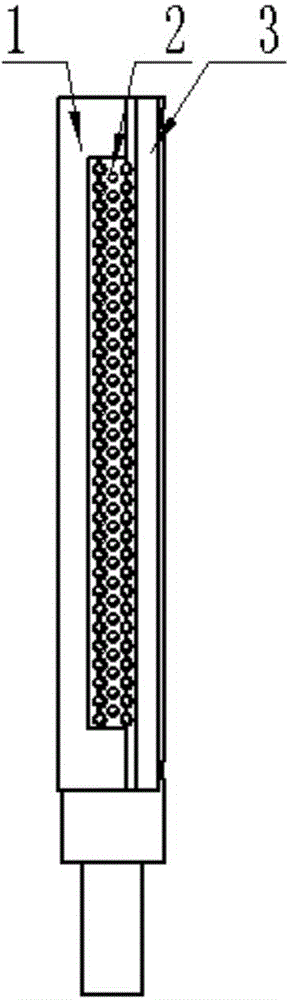

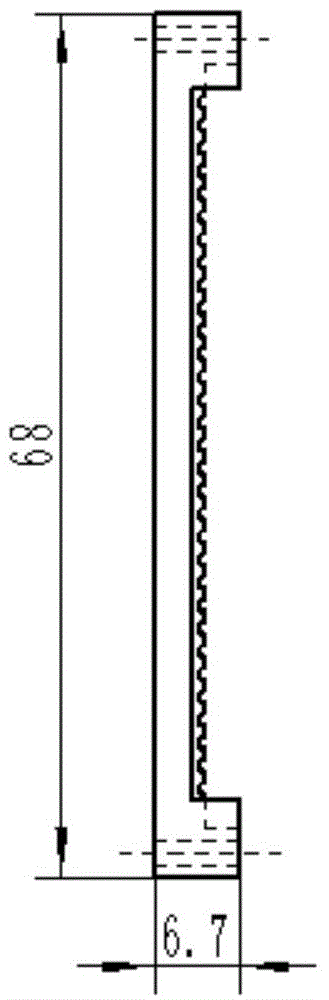

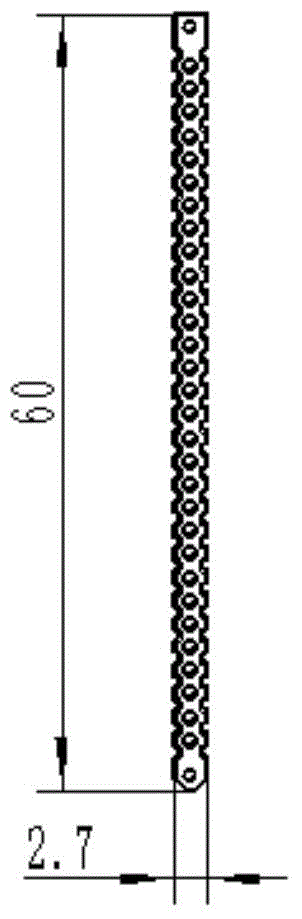

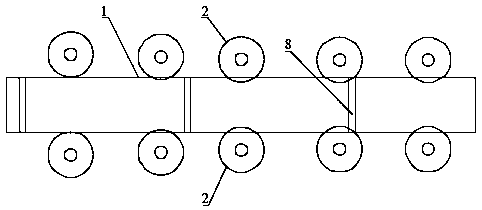

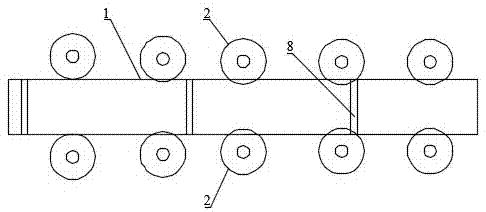

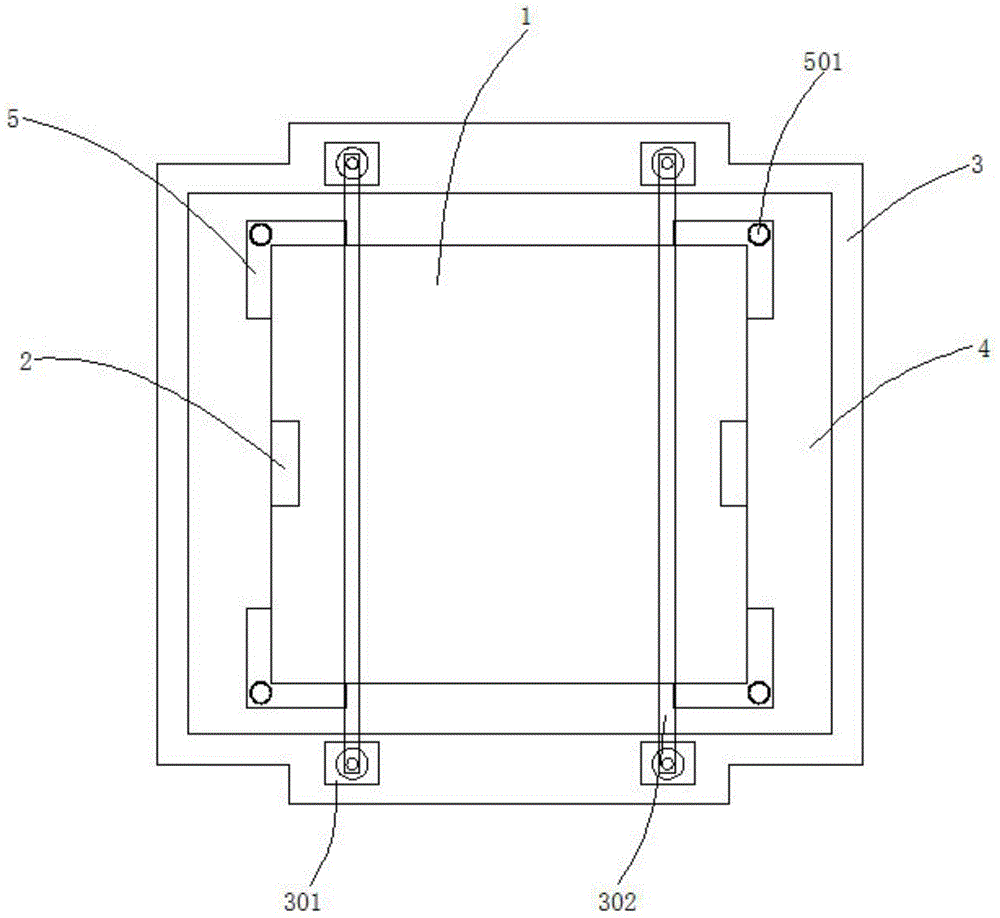

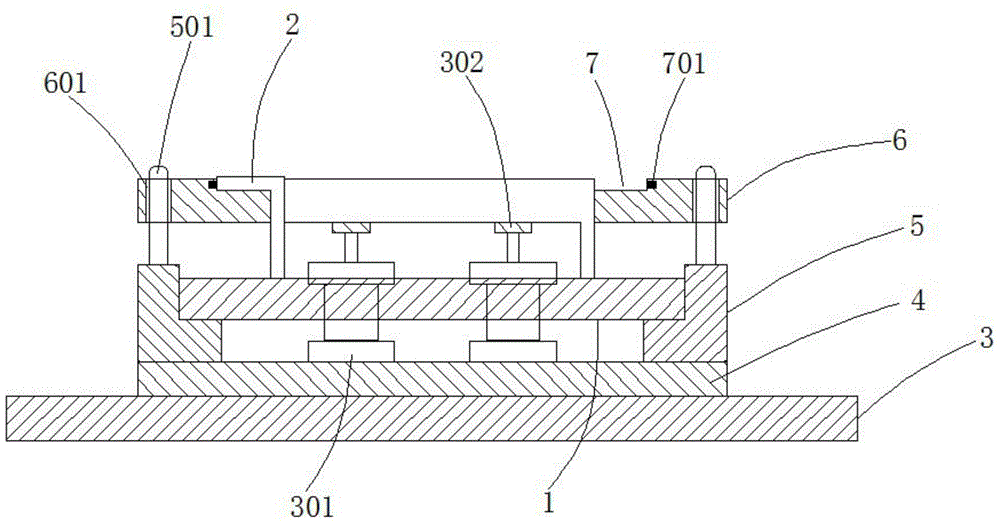

Fixture for welding positioning of micro-diameter thin-walled pipe of heat exchanger

ActiveCN104400306AAvoid disturbanceEasy to assembleWelding/cutting auxillary devicesAuxillary welding devicesPlate heat exchangerTransverse groove

The invention discloses a fixture for the welding positioning of a micro-diameter thin-walled pipe of a heat exchanger. The fixture consists of three parts, i.e. a movable fixture, a partition plate and a fixed fixture, wherein the partition plate is inserted into a transverse groove of the movable fixture, and semicircular holes in the two ends are paired and coupled; the movable fixture is arranged on the section of the fixed fixture, and is fixed by upper and lower screws. According to the fixture, the micro-diameter thin-walled pipe can be accurately positioned when being assembled and welded; the shortcoming that a conventional fixture cannot meet requirements on the accurate positioning of the micro-diameter thin-walled pipe is overcome, the accurate positioning of the micro-diameter thin-walled pipe during assembling and welding is ensured, and a foundation is laid for subsequent part assembling.

Owner:BEIHANG UNIV

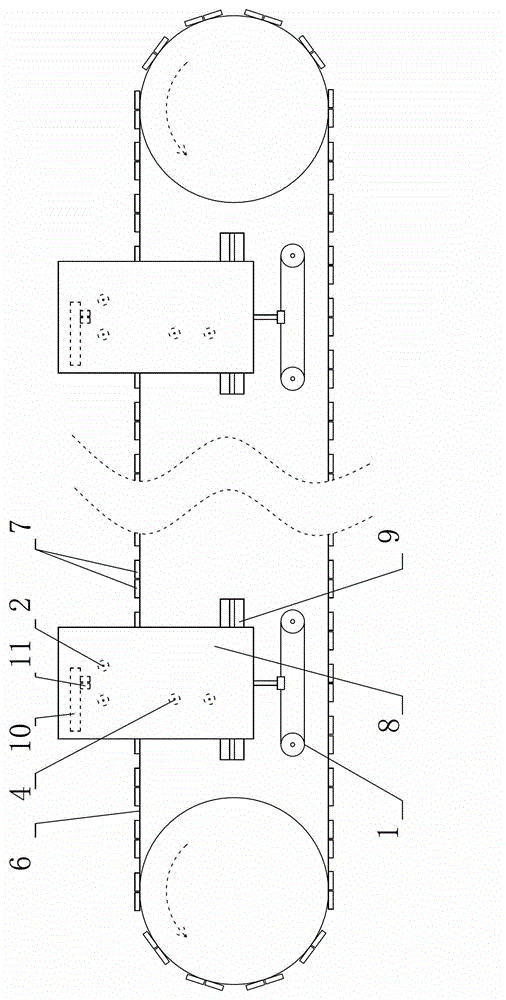

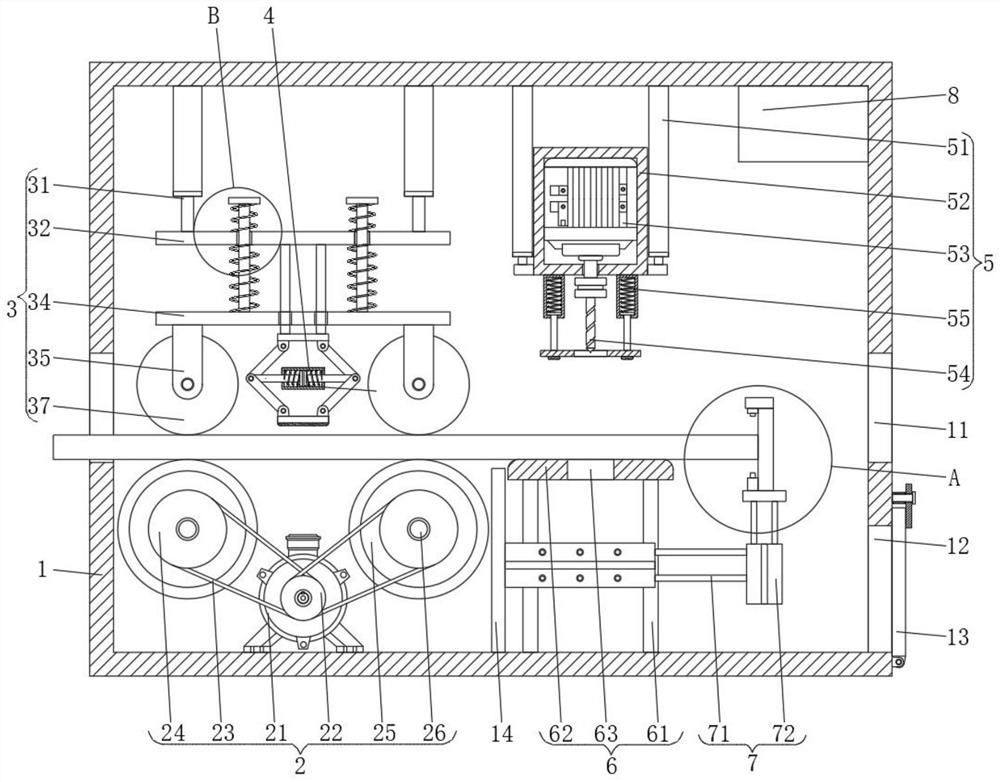

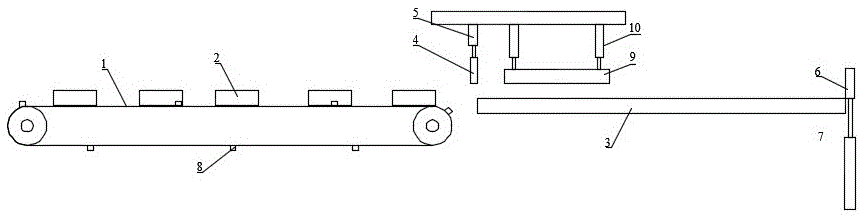

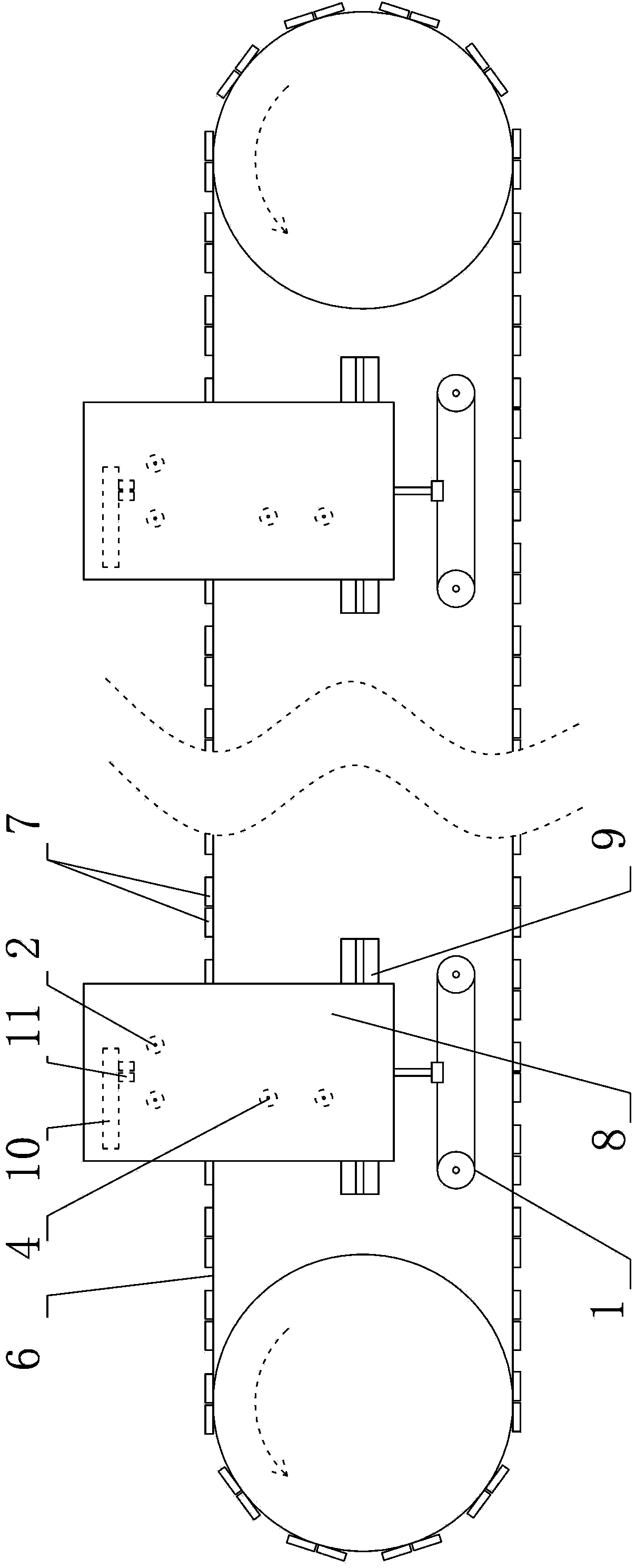

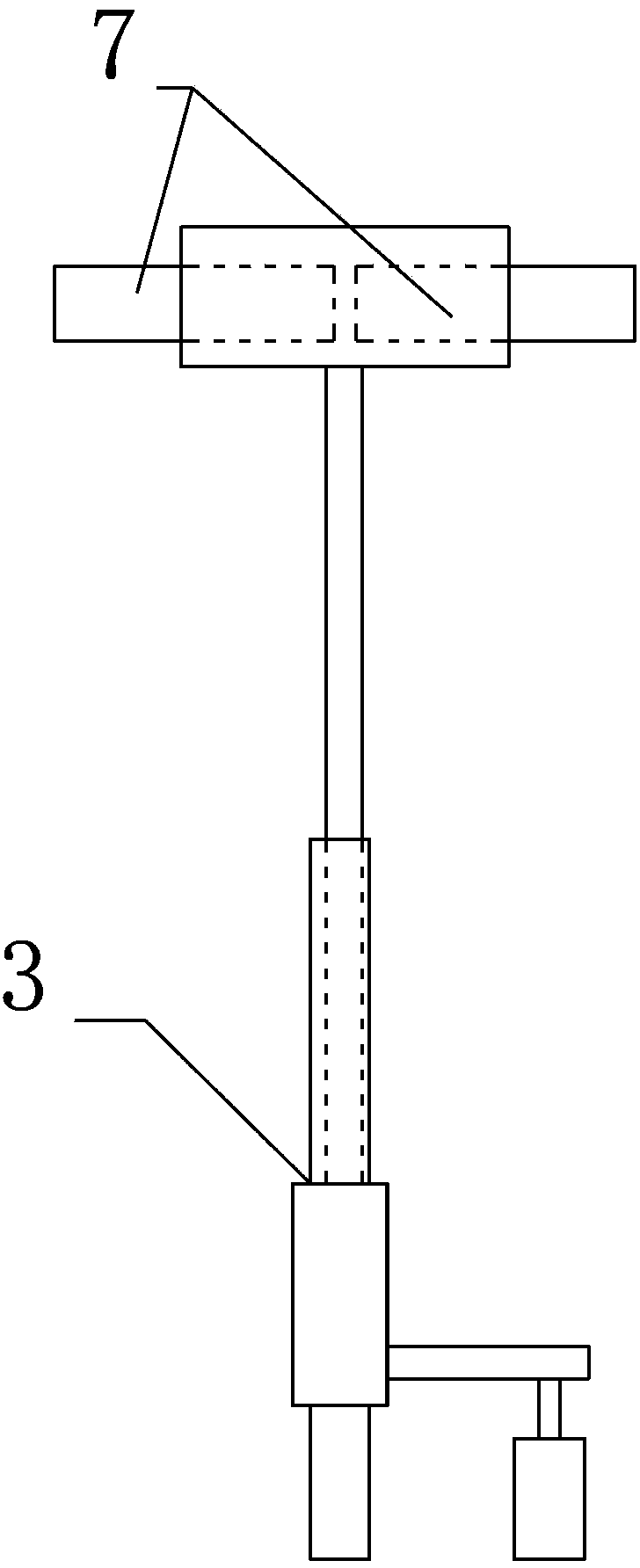

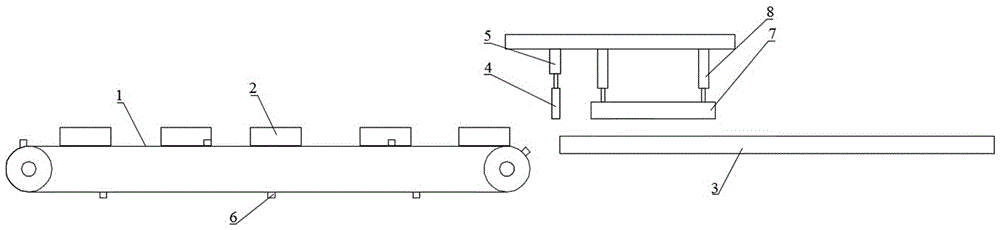

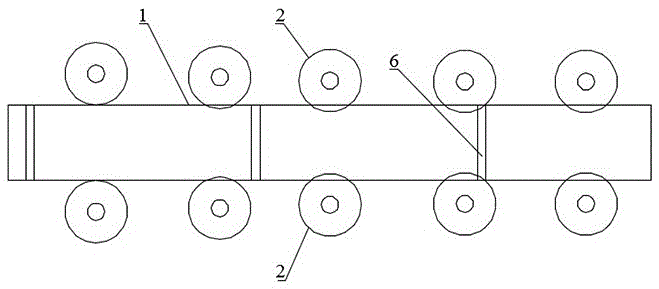

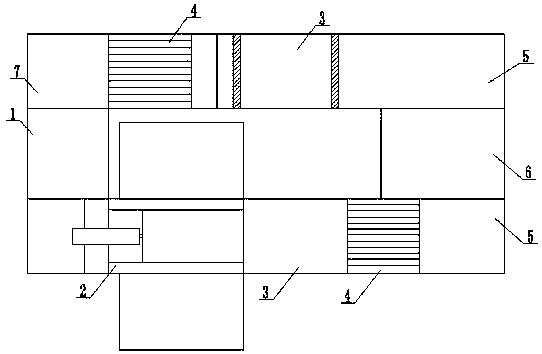

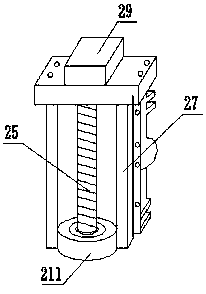

Container clamping conveying device of straight-line filling device

ActiveCN103058111AEliminate positional deviationSimple structureLiquid bottlingEngineeringMechanical engineering

The invention discloses a container clamping conveying device of a straight-line filling device. The container clamping conveying device comprises a circulating conveying mechanism, a container clamping mechanism, an opening and closing mechanism, a lifting mechanism and a position deviation correcting mechanism, wherein both the circulating conveying mechanism and the opening and closing mechanism are movably connected with the container clamping mechanism; the container clamping mechanism is movably connected to the circulating conveying mechanism; the lifting mechanism and the opening and closing mechanism are located on the same station; the container clamping mechanism is located between the lifting mechanism and the opening and closing mechanism; and both the lifting mechanism and the opening and closing mechanism are arranged on the position deviation correcting mechanism. According to the container clamping conveying device of the straight-line filling device, when an obvious position deviation of the container clamping mechanism occurs on the circulating conveying mechanism due to error accumulation, the problem can be detected in time by the position deviation correcting mechanism, and the position of the opening and closing mechanism is adjusted by a driving mechanism, so that the opening and closing mechanism is re-aligned to the container clamping mechanism and the problem of the position deviation of the container clamping mechanism is completely solved.

Owner:HANGZHOU ZHONGYA MACHINERY CO LTD

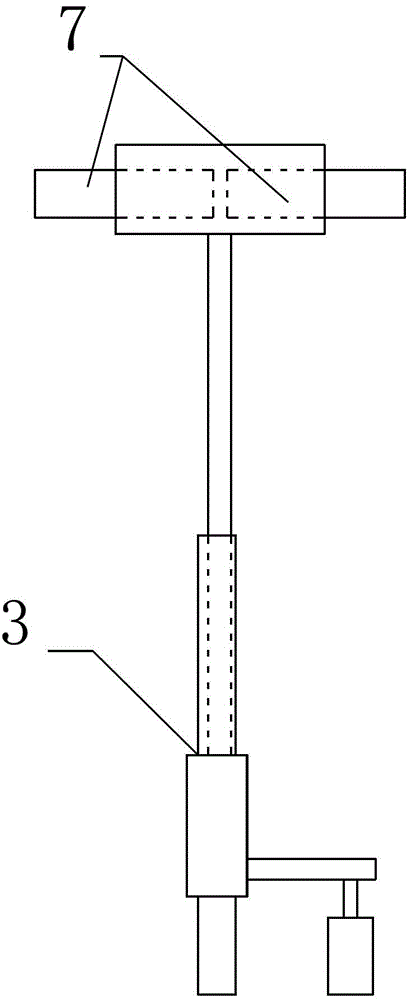

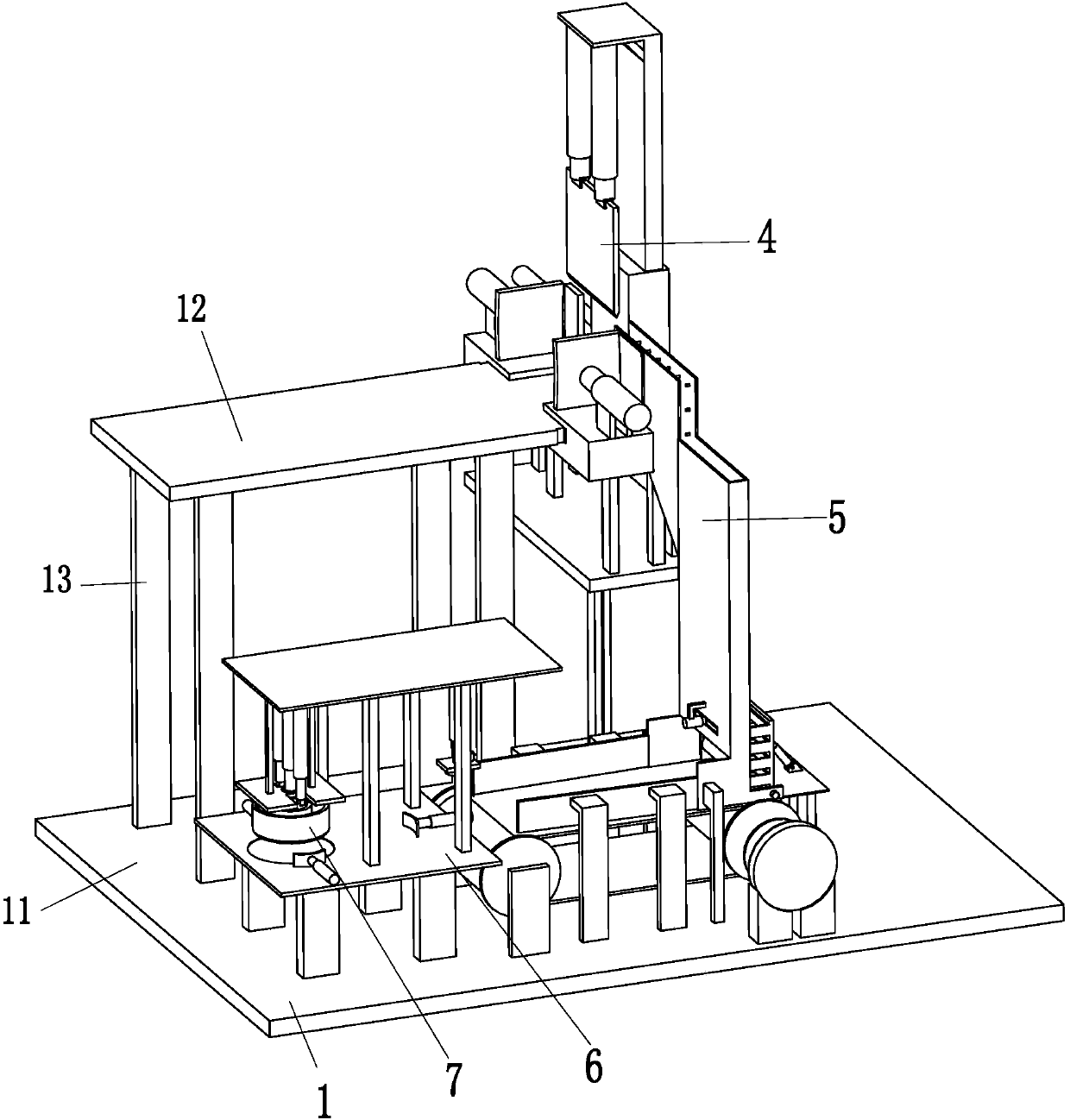

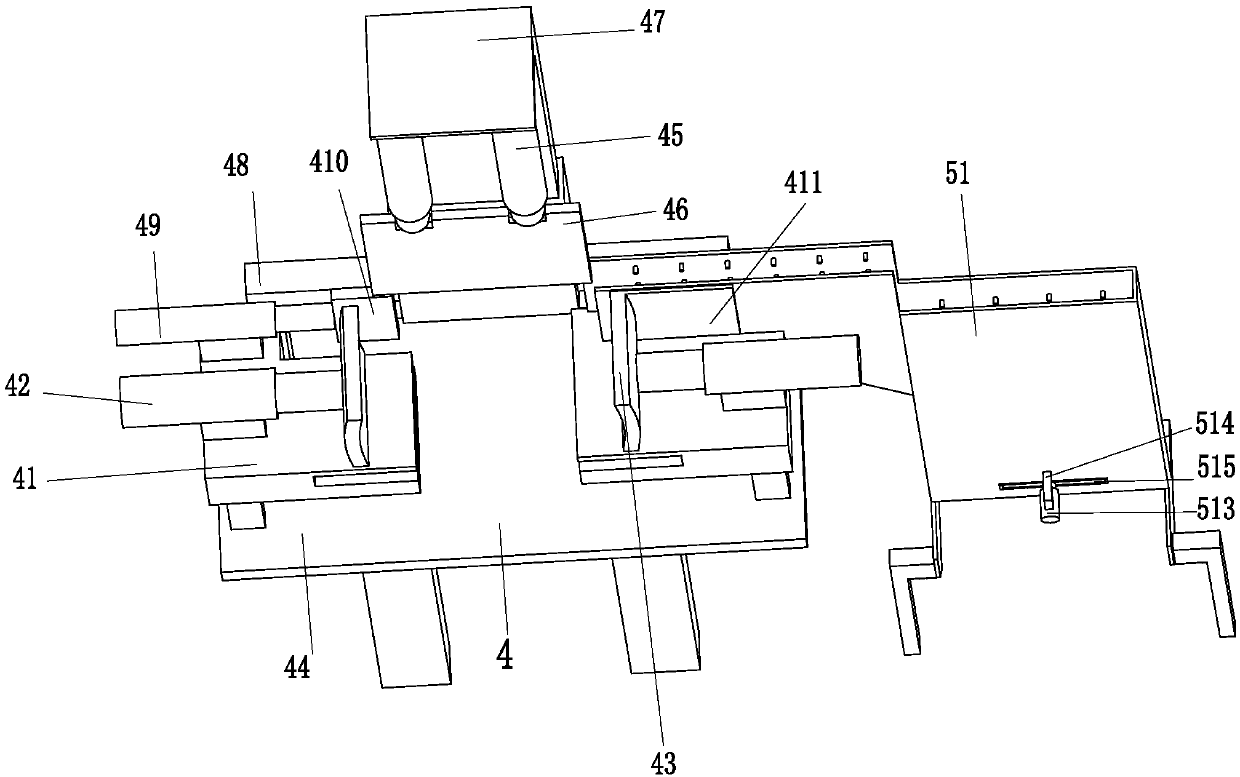

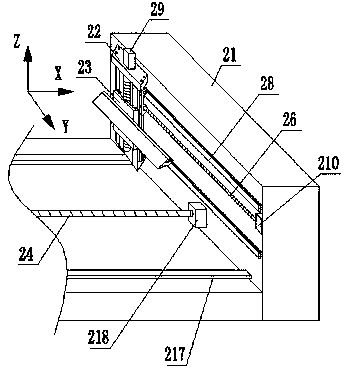

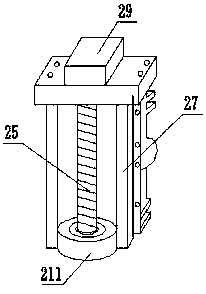

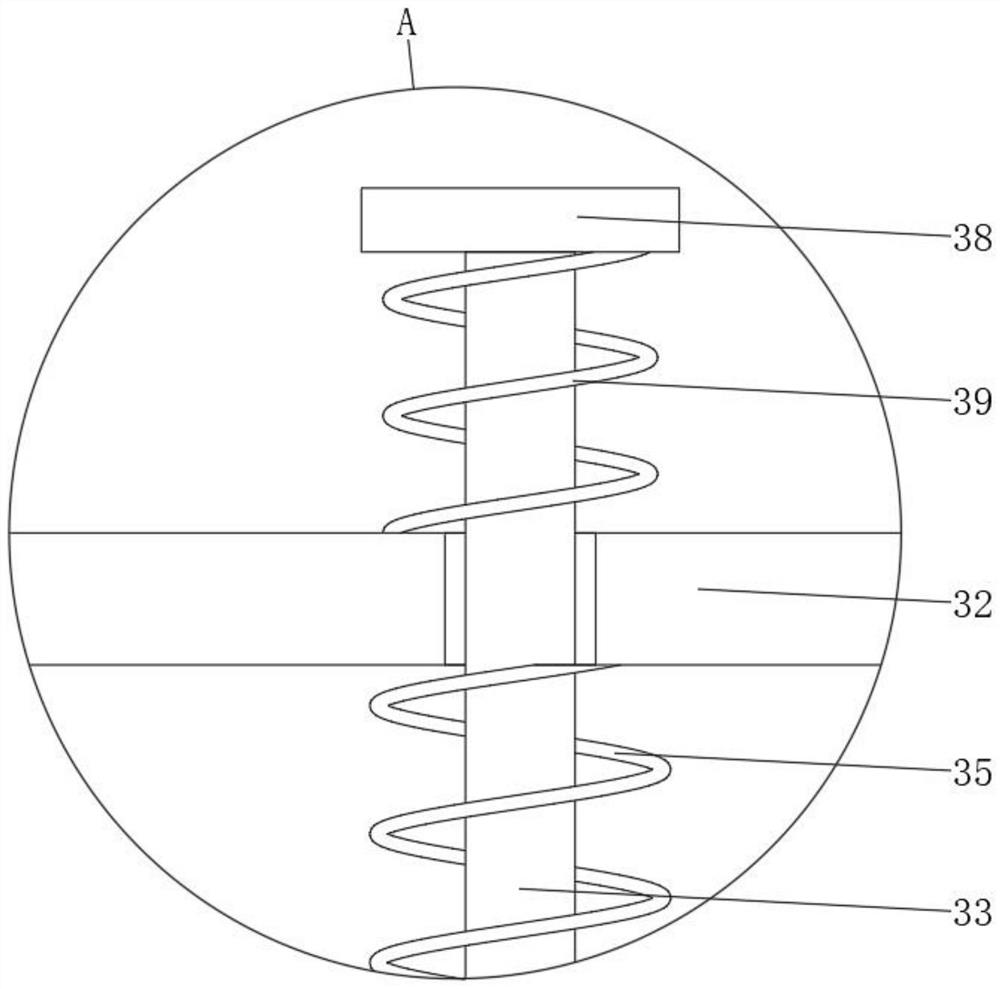

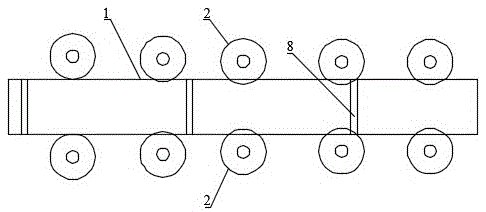

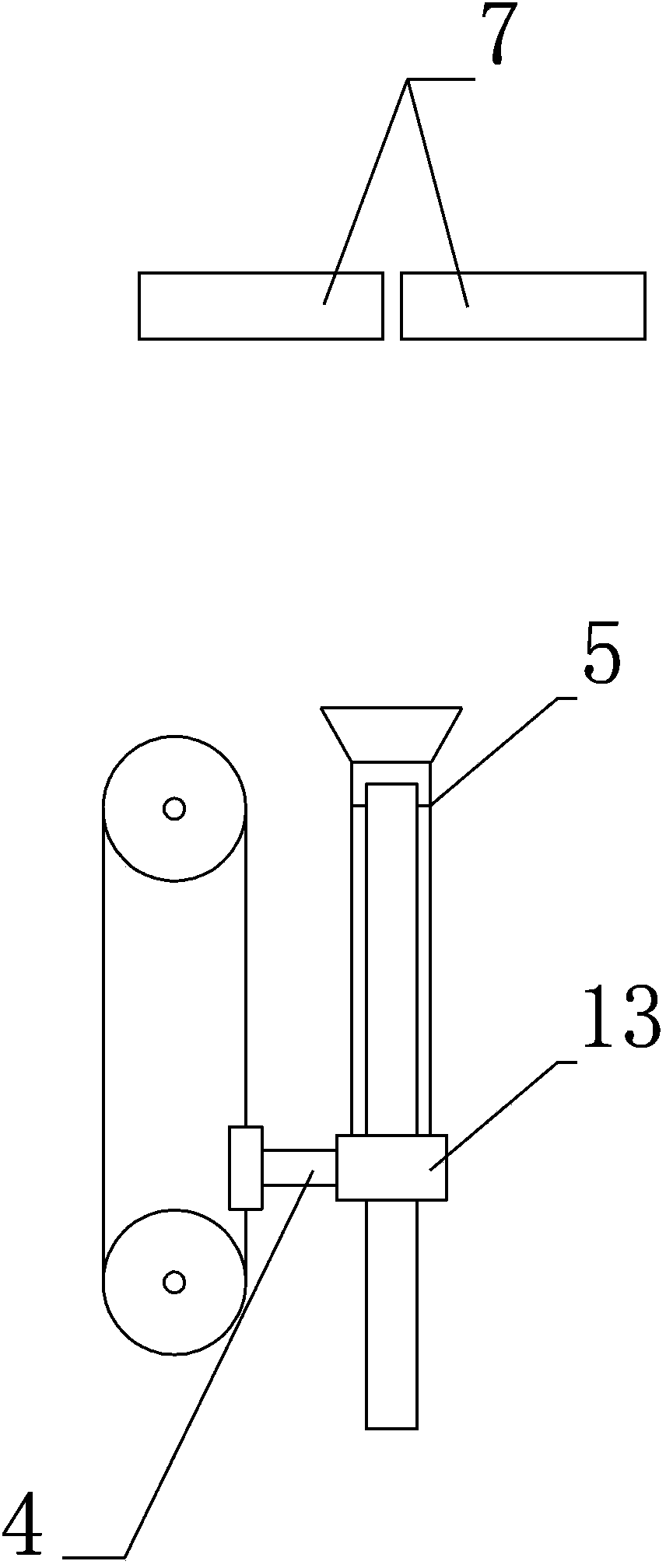

Equipment for automatically conveying metal graphite rod slices and processing graphite gaskets

InactiveCN107599188AImprove work efficiencyHigh degree of mechanizationWorking accessoriesStone-like material working toolsEngineeringGraphite

The invention relates to equipment for automatically conveying metal graphite rod slices and processing graphite gaskets. The equipment comprises a supporting device, a cutting device, a conveying device, a limiting device and a gasket forming device, wherein the cutting device is connected with a supporting bottom plate; the conveying device is installed on the supporting bottom plate; the limiting device is connected with the supporting bottom plate; and the gasket forming device is installed on the limiting device. According to the equipment for automatically conveying the metal graphite rod slices and processing the graphite gaskets, the existing difficult problems that the working efficiency is low, the graphite slices need to be transported manually, accurate positioning cannot be carried out when the graphite slices are subjected to gasket machining, and only one model can be machined at one time when the graphite slices are cut into the gaskets in the gasket machining process of a graphite rod are solved; functions of automatic conveying of graphite rod slices and automatic processing of two kinds of gaskets can be achieved; and the equipment has the advantages that the working efficiency is high, the graphite slices can be automatically transported, accurate positioning can be carried out when the graphite slices are subjected to gasket machining, and the graphite slices can be machined into a plurality of models at one time when being cut into the gaskets.

Owner:倪雨阳

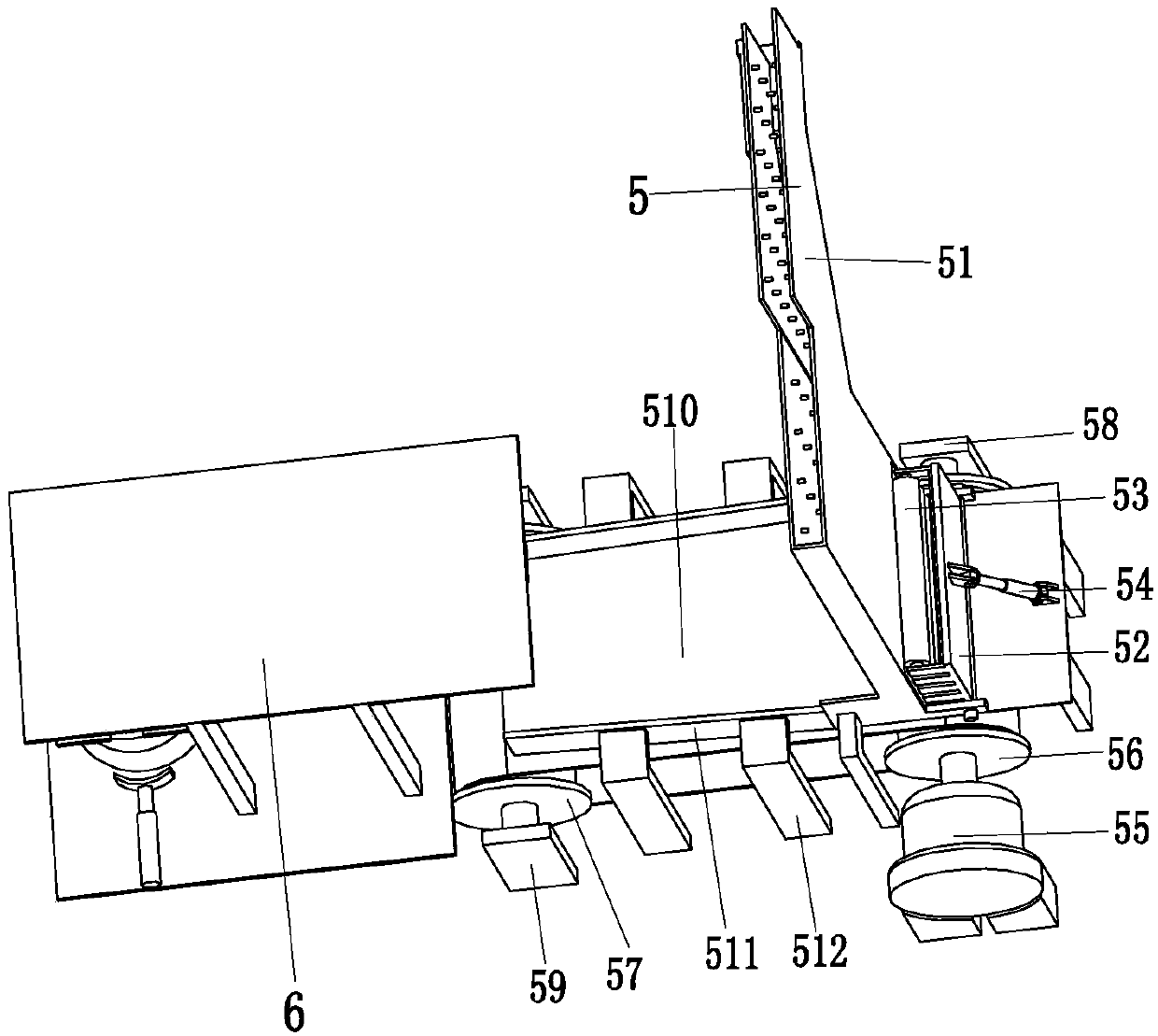

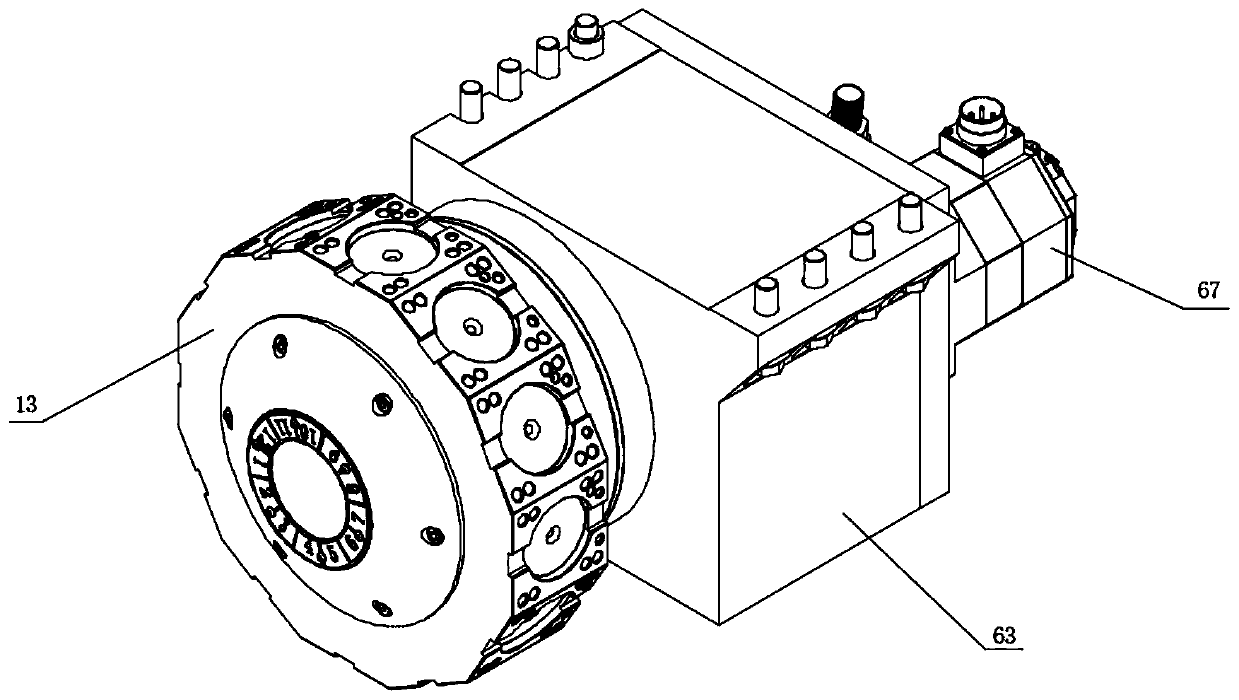

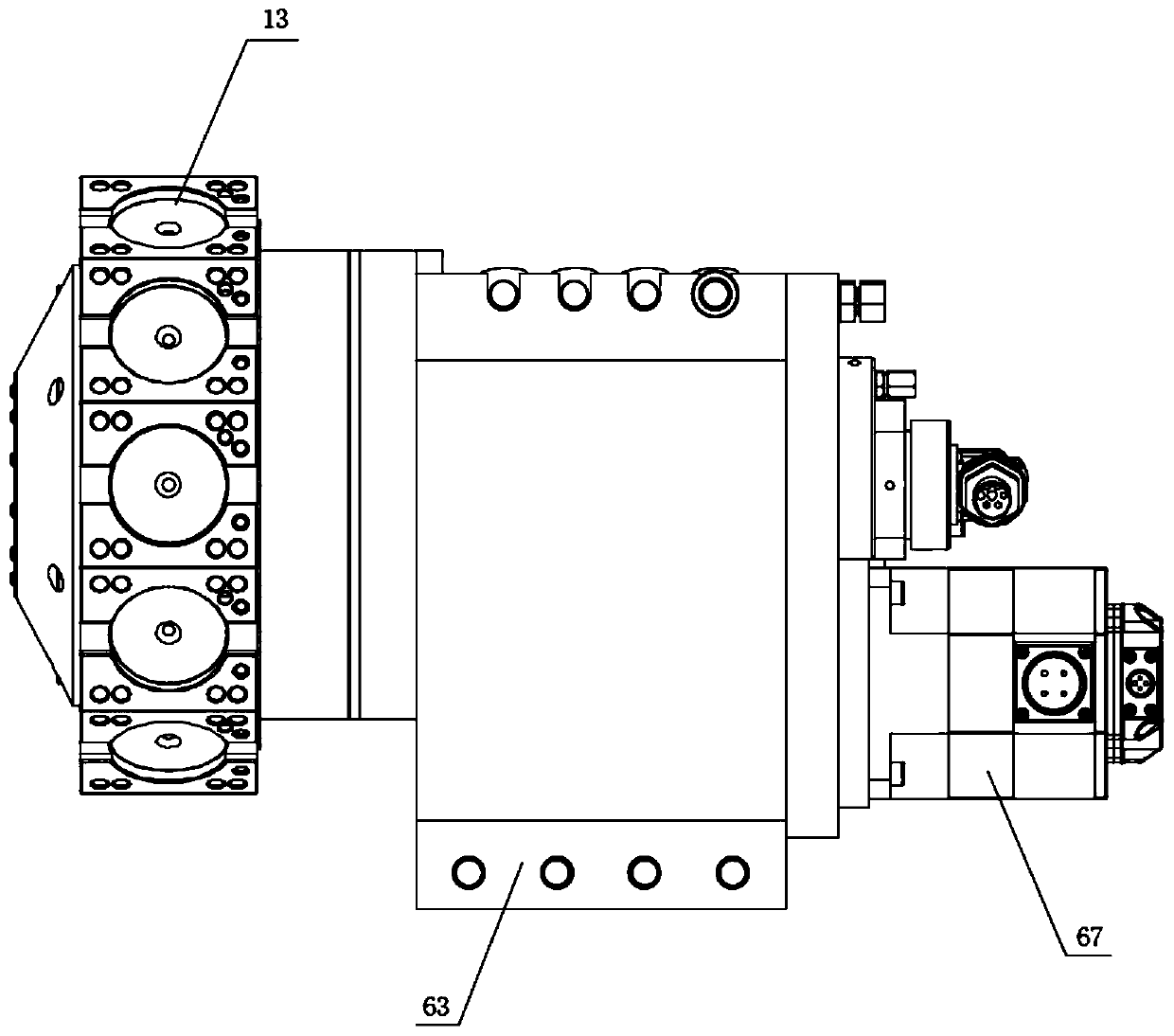

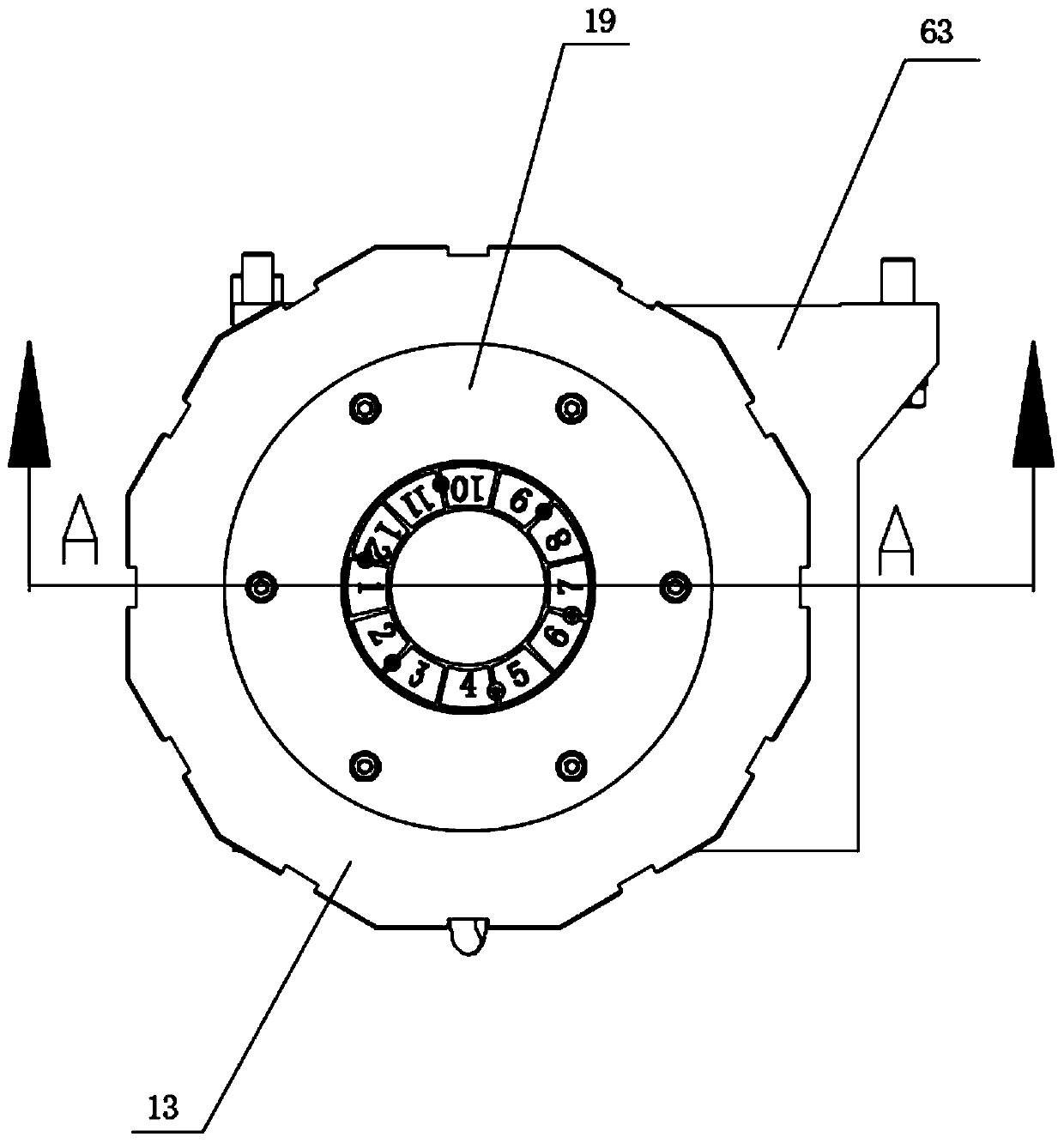

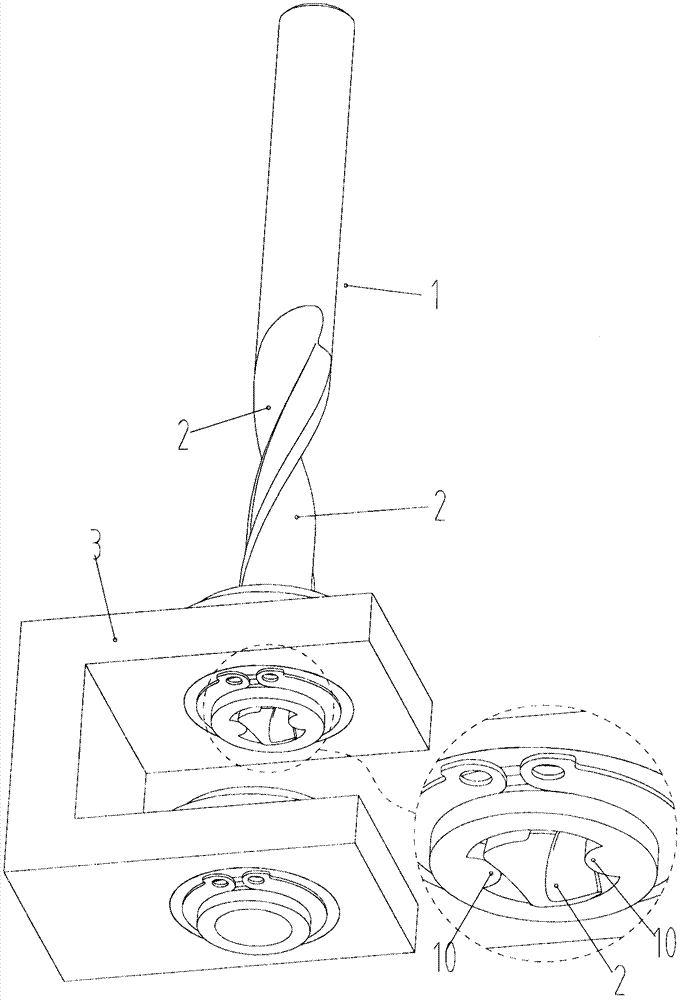

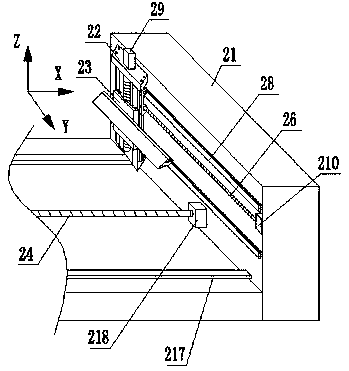

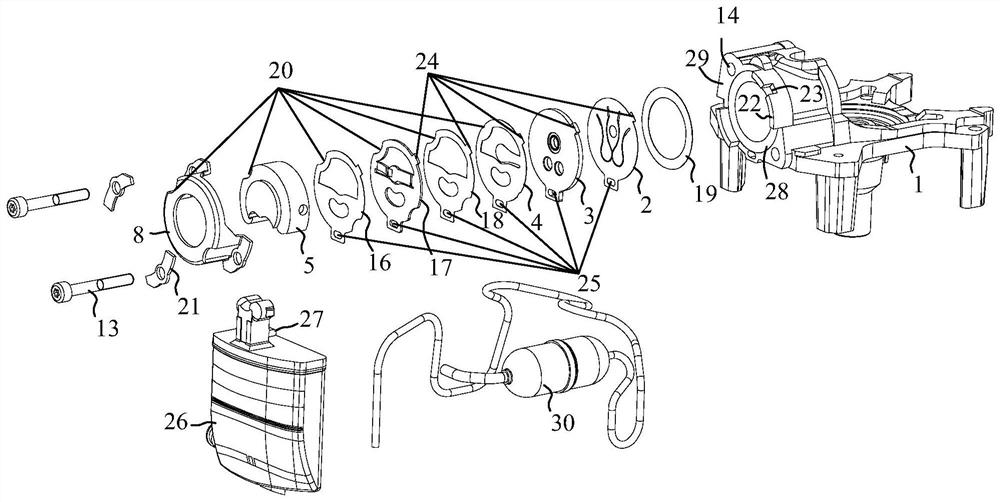

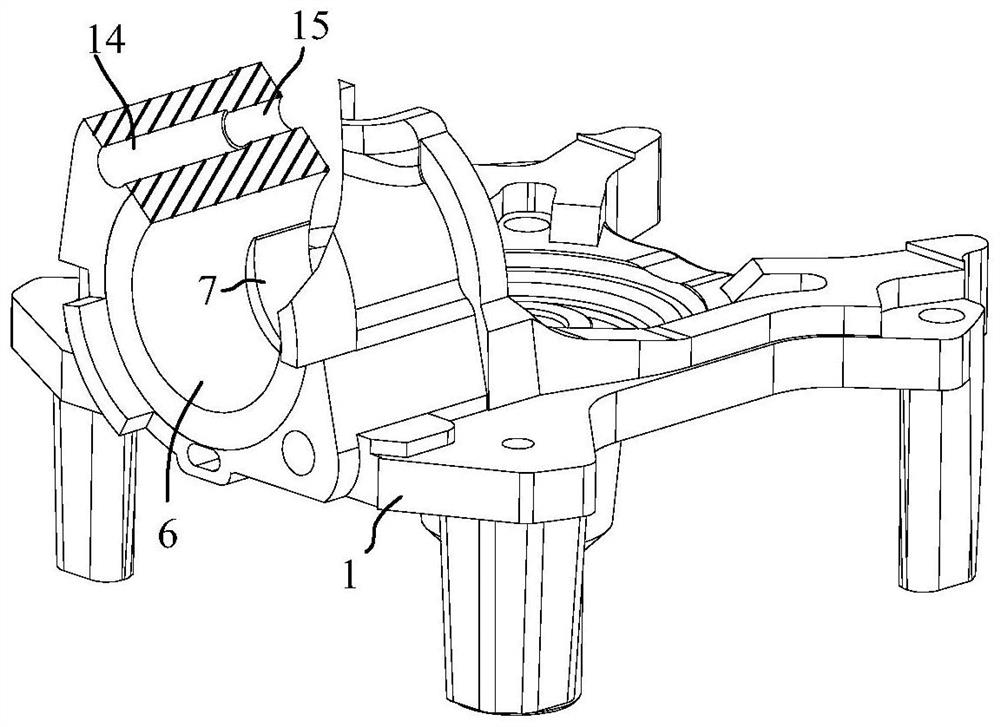

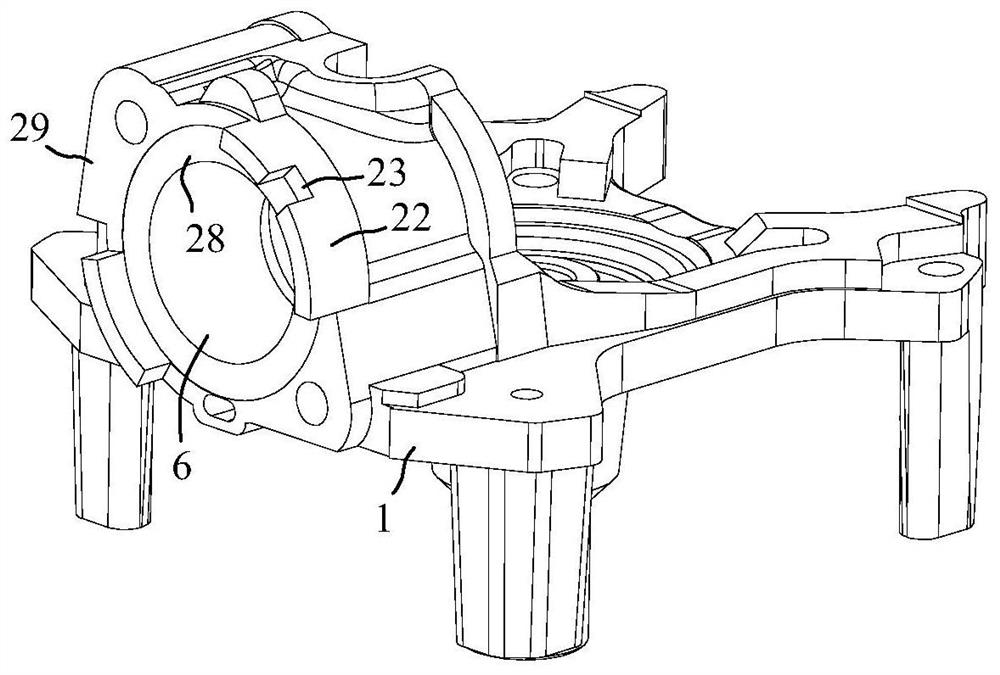

Servo power cutter tower

PendingCN110340390APlay the role of precise positioningPlay the role of tool selection and positioningTool holdersPositioning apparatusGear wheelTower

A servo power cutter tower comprises a box body, a cutter head and a motor. The cutter head and the motor are located on the box body, and the cutter head is rotationally connected with the box body.A central shaft and a gear are arranged in the box body, the gear is in sleeving connection with the central shaft, the gear is rotated around the central shaft, and the gear is driven by the motor through a transmission gear and a reduction device; and a rotating gear disc, a positioning gear disc and a moving gear disc are further arranged in the box body, the moving gear disc is in sleeving connection with the gear, the rotating gear disc is in sleeving connection with the central shaft, and the positioning gear disc is in sleeving connection with the rotating gear disc. Compared with the prior art, the cutter head is driven to rotate under the effect of the rotating gear disc, therefore, a main shaft in the cutter head can correspond to different cutter installation holes in the cutterhead, the cutter replacement effect is achieved, the rotating gear disc can be engaged with the moving gear disc when cutters are not changed and after the cutter are replaced, stability of the rotating gear disc is improved, the number of teeth of the rotating gear disc is matched with that of the cutter installation holes, and using convenience of the cutter head is ensured.

Owner:PINGHU HAICHEN MACHINE

Fully-automatic energy-saving drip molding method

The invention discloses a fully-automatic energy-saving drip molding method which is characterized by comprising the following steps: positioning, namely placing a mold on a one-cylinder four-claw system; carrying out drip molding, namely pushing the mold into a drip molding system through a telescopic cylinder; heating, namely pushing the mold into a heating system through the telescopic cylinderafter a product is formed on the mold through drip molding; cooling, namely heating the drip molded product on the mold, and pushing the mold into a cooling system through the telescopic cylinder; transferring, namely pushing the cooled mold into a transferring system 5 through the telescopic cylinder; clamping, namely transferring the mold into a clamping system; and demolding, namely pushing the mold into a demolding system through the telescopic cylinder. Through steps of positioning, drip molding, heating, cooling, transferring, clamping and demolding, a spraying molding product is moldedon one production line, fully-automatic production is achieved, and the production efficiency is improved.

Owner:遂宁市金虹机械厂

Automatic punching machine with positioning function

ActiveCN113547365AEasy to collectWith collection functionMeasurement/indication equipmentsFeeding apparatusPunchingEngineering

The invention discloses an automatic punching machine with a positioning function, and relates to the technical field of machining. The automatic punching machine comprises a punching box, wherein a conveying assembly is arranged at the left side of the bottom of the inner wall of the punching box; a material pressing assembly is arranged at the left side of the top of the inner wall of the punching box; the material pressing assembly is provided with a positioning and pressing assembly; a punching assembly is arranged at the top of the inner wall of the punching box; a supporting assembly is arranged at the bottom of the inner wall of the punching box and positioned below the punching assembly; the supporting assembly is provided with a positioning assembly; and a controller is arranged at the right side of the top of the inner wall of the punching box. According to the automatic punching device with the positioning function, the position is adjusted and controlled through the positioning assembly, and the right side of a material is limited, so that the effect of precise positioning is achieved. The effects of precise positioning and automatic punching are achieved through the arrangement of the punching box, the conveying assembly, the material pressing assembly, the positioning and pressing assembly, the punching assembly, the positioning assembly and the controller. Automatic positioning and punching are achieved, and the punching work efficiency is improved.

Owner:徐州市晶鑫新材料有限公司

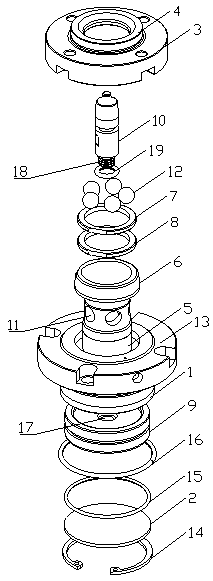

Rapid locking positioner

InactiveCN108381260AQuick lockPlay the role of precise positioningPositioning apparatusMetal-working holdersSteel ballEngineering

The invention discloses a rapid locking positioner. The rapid locking positioned comprises a base, the base comprises a cylinder body, a buffer base plate and a baffle, wherein the buffer base plate and the baffle are arranged on the two ends of the cylinder body; a baffle through hole is formed in the center of the baffle, a convex ring is arranged on the end face, back on to the cylinder body, of the baffle, a positioning sleeve with one end penetrating the convex ring is arranged in the cylinder body, a locking head is arranged at the end, located on the outer side of the convex ring, of the positioning sleeve, the outer wall of the end of the positioning sleeve is in threaded connection with a locking nut and an anti-loosening nut, a check ring is arranged on the outer wall of the end,located in the cylinder body, of the positioning sleeve, a piston is arranged between the check ring and the buffer base plate, a spring is connected between the piston and the check ring, a conicallifting pin facing the baffle is arranged on the center of the piston, multiple through holes corresponding to the position of the conical lifting pin are formed in the positioning sleeve, and are evenly distributed in the circumferential direction of the positioning sleeve, and steel balls are arranged in the through holes. The rapid locking positioner is reasonable in structure, precise positioning is achieved while rapid locking is achieved, and the clamping time is shortened.

Owner:SUZHOU KSC PRECISE MACHINERY

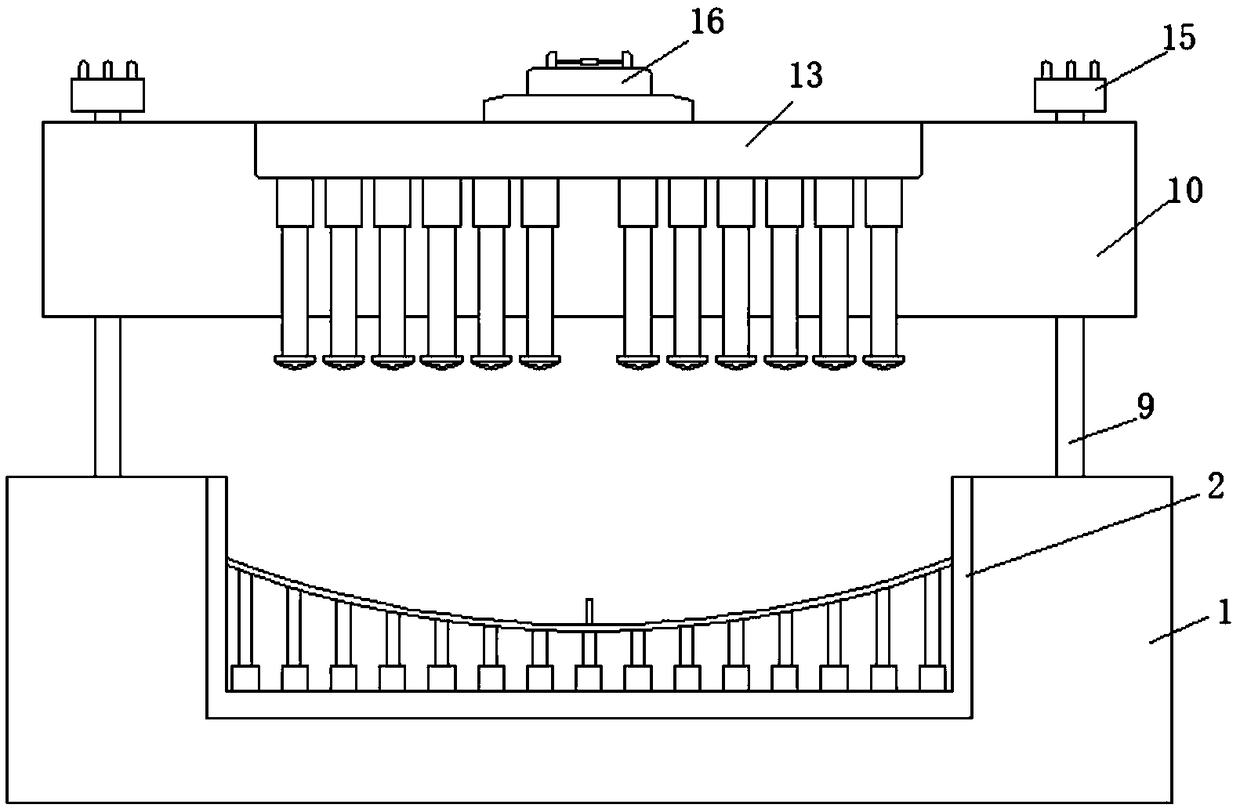

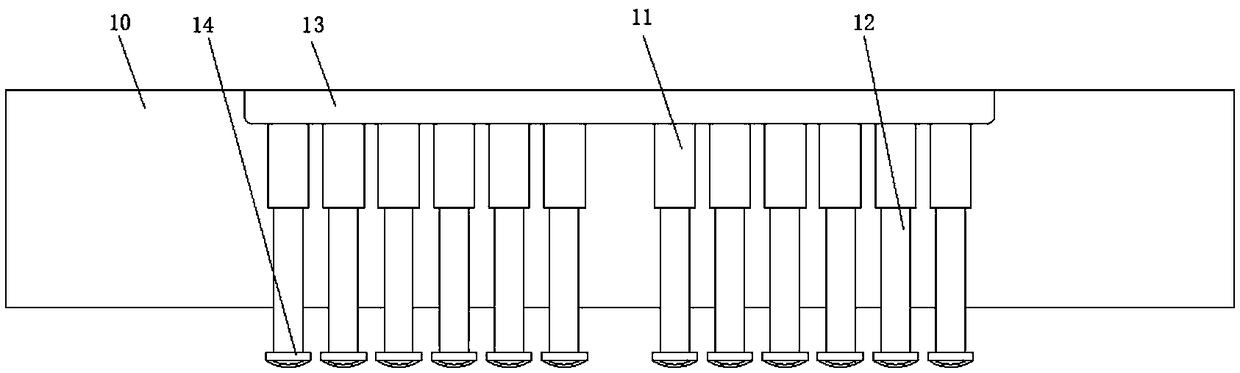

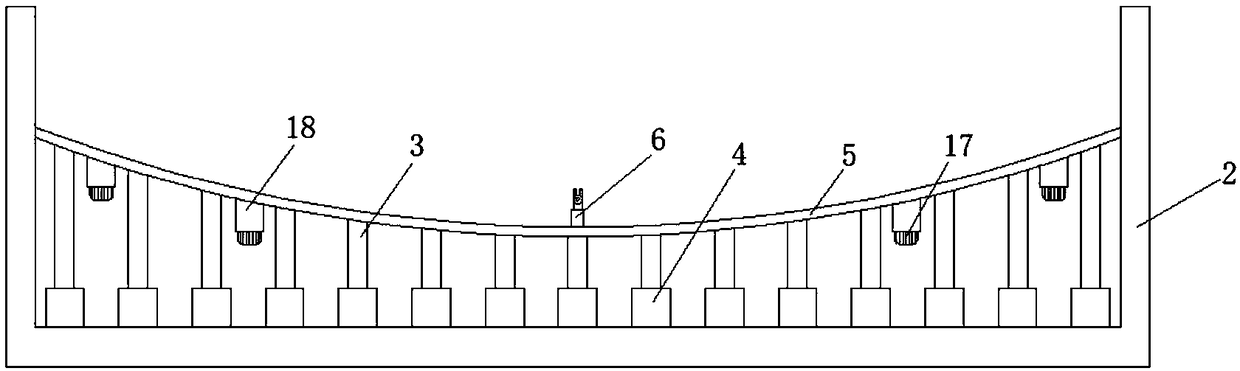

Leaf spring bend-forming die

InactiveCN109351861ASimple structureIncrease flexibilityShaping toolsVehicle componentsHydraulic cylinderEngineering

The invention discloses a leaf spring bend-forming die which comprises a die base, a movable die core, a fixed die and vibration motors. The movable die core is arranged in the die base, a pressed plate is arranged inside the movable die core, and a positioning column is arranged on the surface of the pressed plate. Guide rods are fixedly connected to the top of the die base and the fixed die is fixedly connected to the tops of the guide rods, wherein connecting ports are formed in the tops of the guide rods and a mounting module is fixedly connected to the top of the fixed die. Hydraulic cylinders are arranged inside the fixed die, and hydraulic bases are evenly distributed at the bottom of the hydraulic cylinder, wherein hydraulic rods are arranged at the bottoms of the hydraulic bases,and an arc-shaped pressing plate is fixedly connected to the bottoms of the hydraulic rods. According to the leaf spring bend-forming die, the plurality of hydraulic cylinders are arranged and the electric expansion links are arranged at the bottom of the pressed plate, so that bending angles of the electric expansion links and the hydraulic rods can be adjusted through the expansion and contraction of the electric expansion links and the hydraulic rods correspondingly to adapt to bending processing of leaf springs of different types. The overall structure is simple, and the practicability ishigh.

Owner:仪征上汽通程汽车悬架有限公司

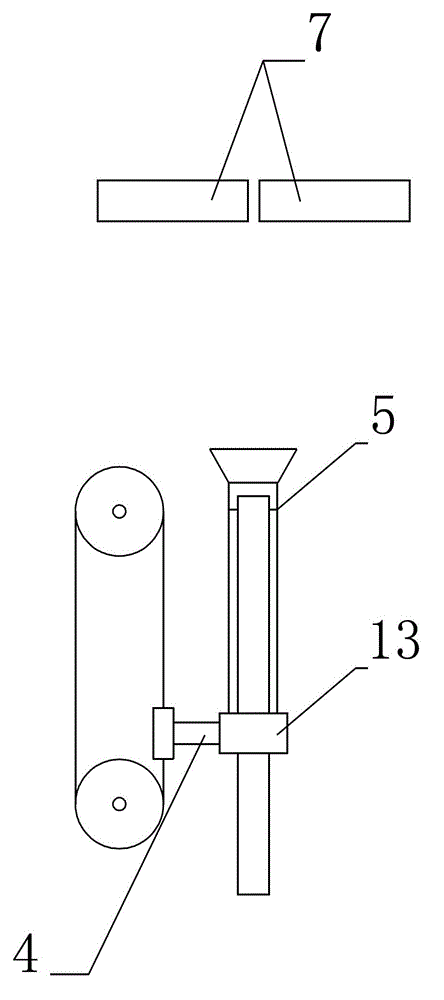

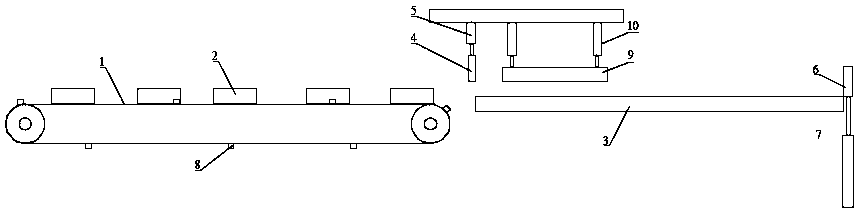

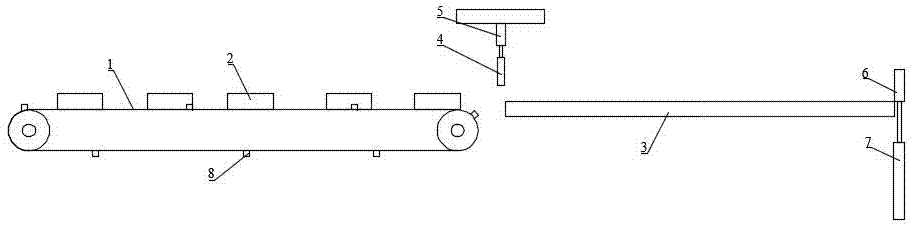

Fixed-size precise shear method of home decoration profiles

InactiveCN105537662AGood impetusImprove efficiencyShearing machinesShearing machine accessoriesHydraulic cylinderFront edge

The invention discloses a fixed-size precise shear method of home decoration profiles. According to the fixed-size precise shear method, a conveyor belt which is arranged on a rack and conveys materials in the horizontal direction and pressing wheels arranged on the two sides of the conveyor belt are included, the material conveying direction of the conveyor belt is considered as the front, the front of the conveyor belt is provided with a workbench, the surface of the workbench is flush with the conveyor belt, the upper portion of the rear edge of the workbench is provided with a scissor plate and a hydraulic cylinder for driving the scissor plate to ascend and descend vertically, and the front side of the front edge of the workbench is provided with a material blocking plate and an air cylinder for driving the material blocking plate to ascend and descend vertically. The fixed-size precise shear method has the advantages that the method can be adapted to the profiles of different sizes, so that a machine tool can use the profiles of different sizes, and use efficiency of the machine tool is improved; the material blocking plate can achieve the function of accurate positioning, and cutting precision is guaranteed; a pressing plate is arranged so that the size can be positioned to the maximum degree.

Owner:SICHUAN YAHAO REAL ESTATE DEV

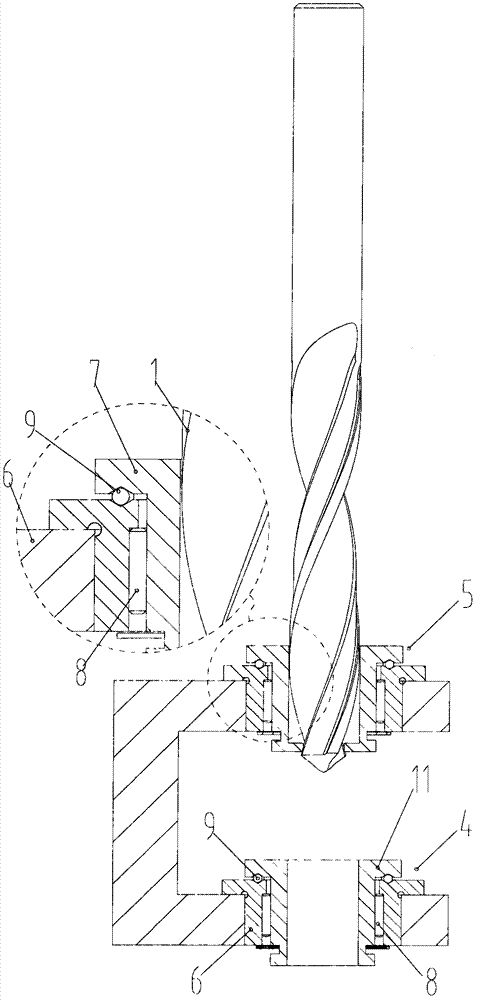

High-speed guiding and chip removing combined drill bush

InactiveCN104722812AReduce frictional resistanceExtended service lifeDrilling/boring measurement devicesMaintainance and safety accessoriesDrill bushingPetroleum engineering

The invention relates to the technical field of mechanical machining and manufacturing, in particular to an auxiliary tool for improving the workpiece drilling machining quality. A high-speed guiding and chip removing combined drill bush is characterized in that a guiding drill bush body and a chip removing drill bush body are included; the guiding drill bush body and the chip removing drill bush body are coaxially arranged and fixedly connected to a support, the guiding drill bush body is located on the lower portion of the chip removing drill bush body, the guiding drill bush body and the chip removing drill bush body has an interval of twenty millimeters to thirty millimeters, and a twist drill is arranged on the upper portion of the chip removing drill bush body. The high-speed guiding and chip removing combined drill bush is used for positioning and guiding a tool to perform drilling machining, aluminum chips are prevented from winding on the twist drill, the straightness of the central axis of the twist drill is remained, the shape precision of the twist drill and the drill bush is remained, the machining precision is improved, and the production continuity is remained.

Owner:WENZHOU POLYTECHNIC

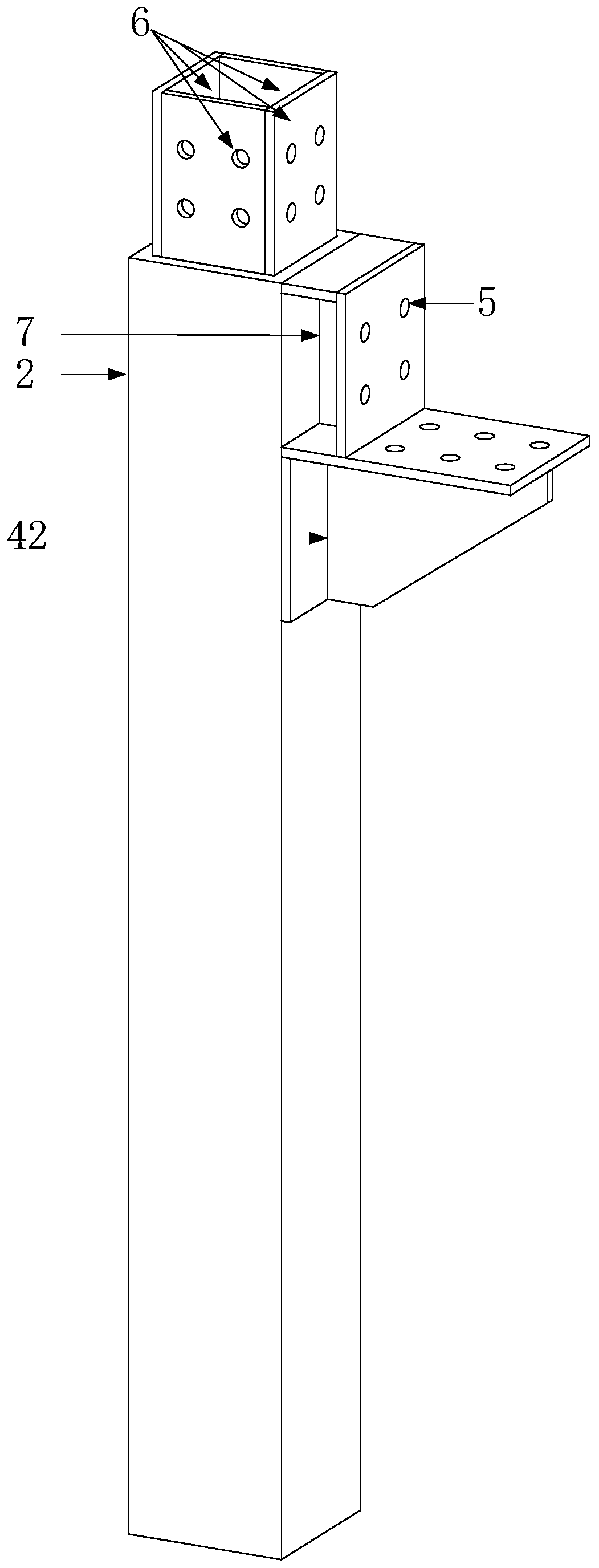

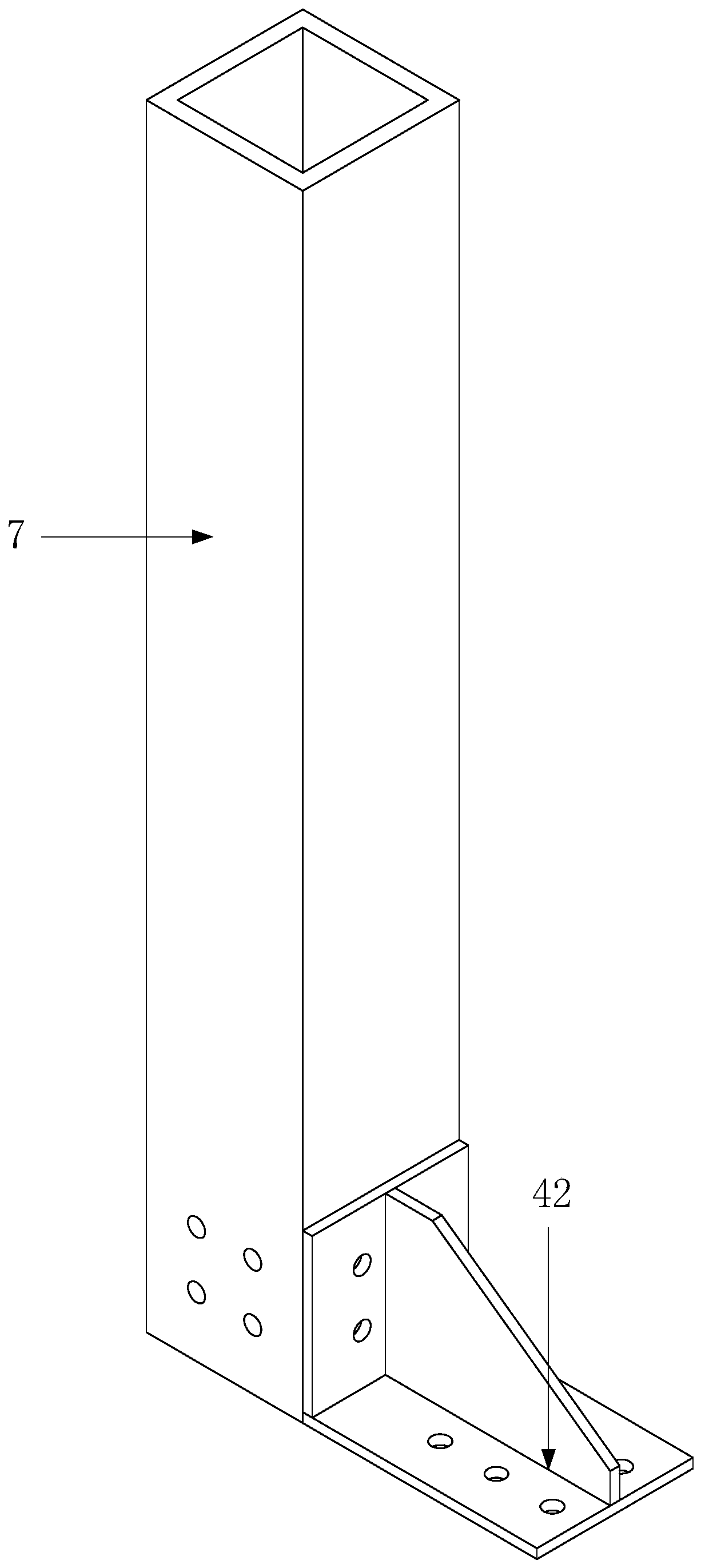

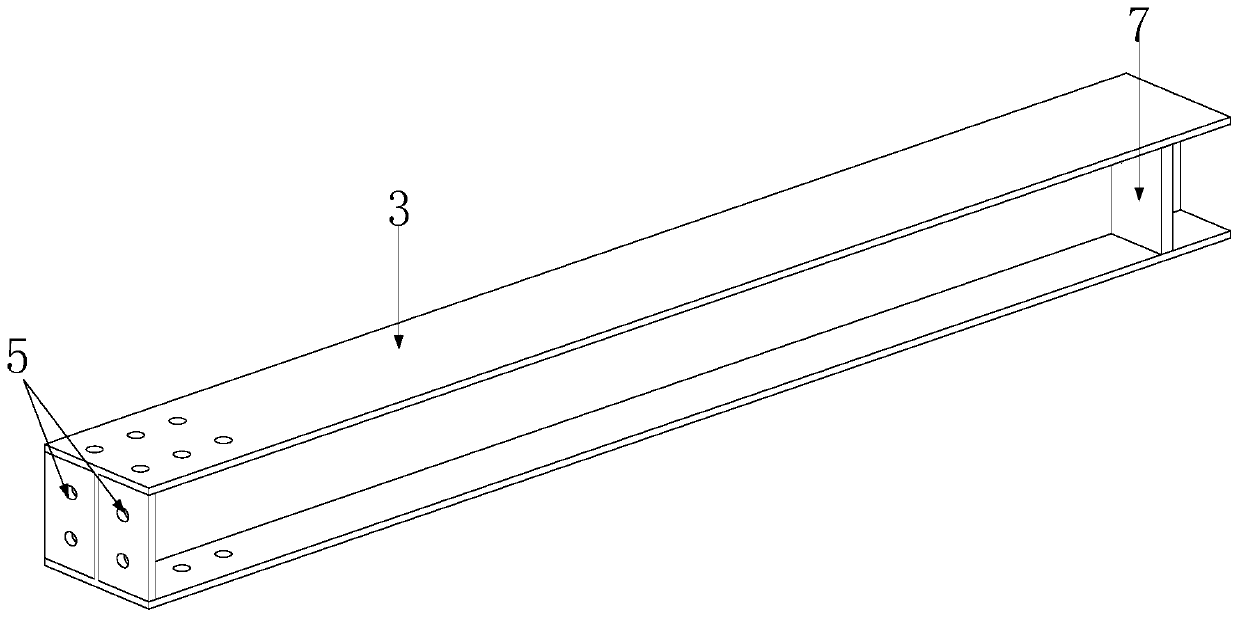

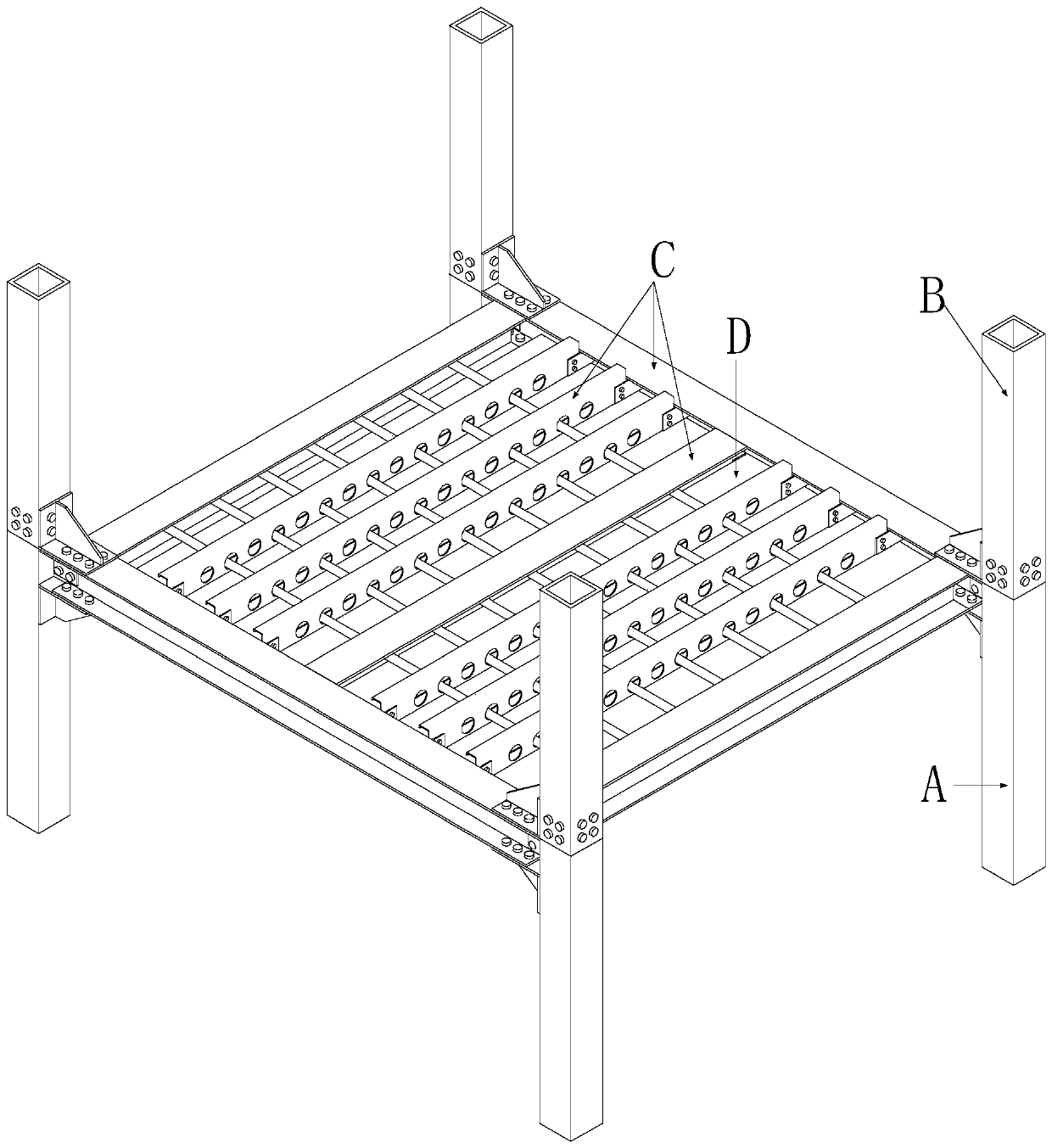

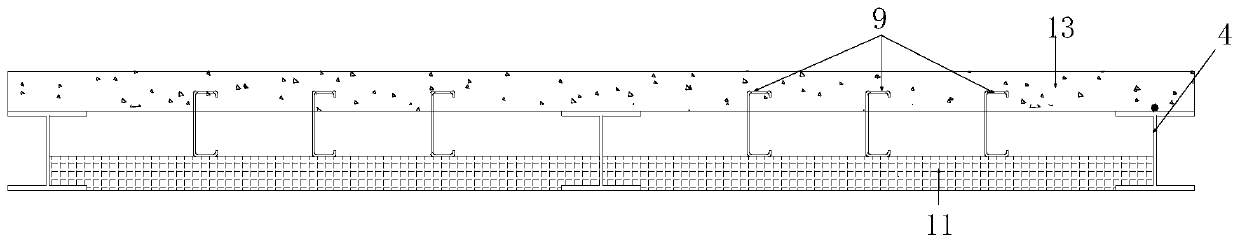

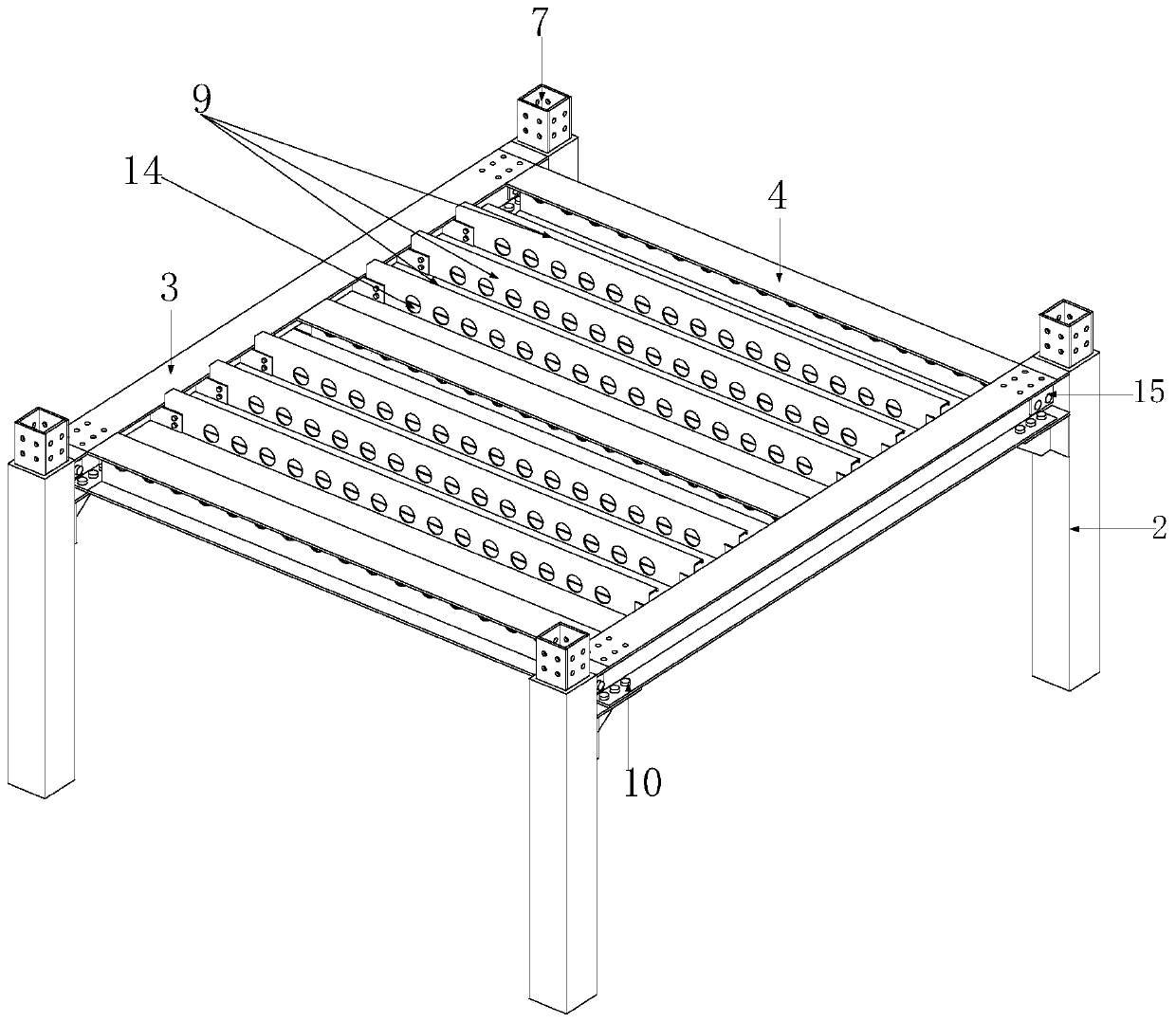

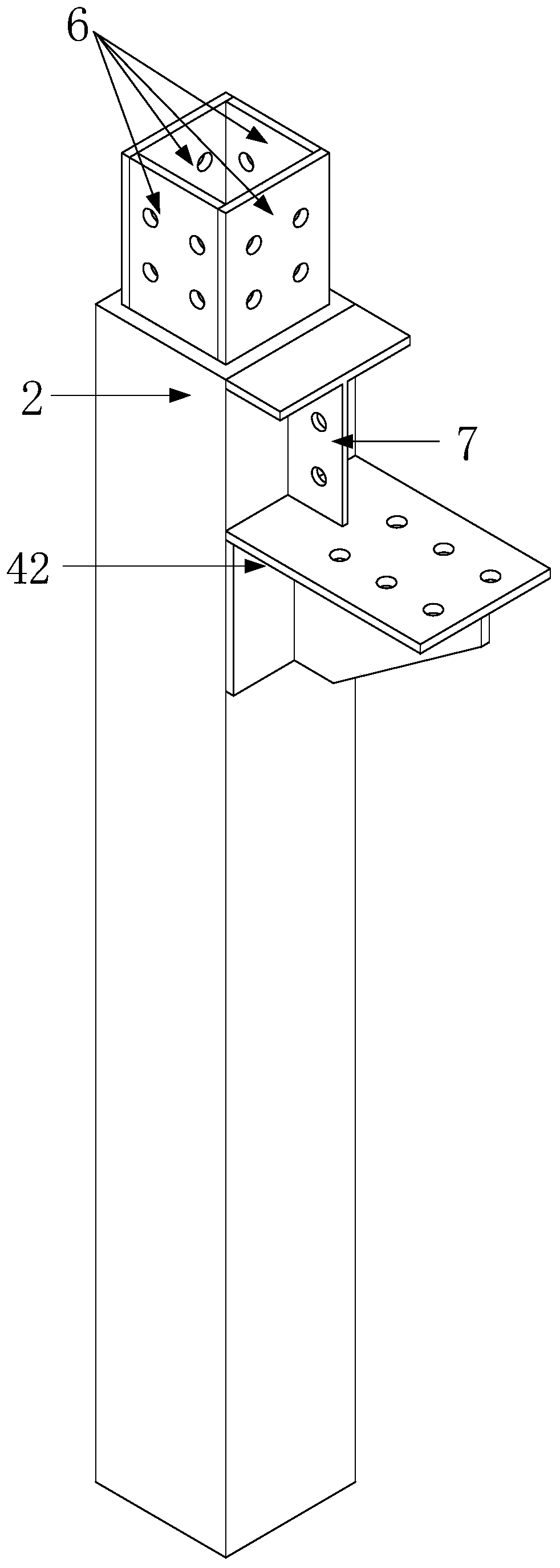

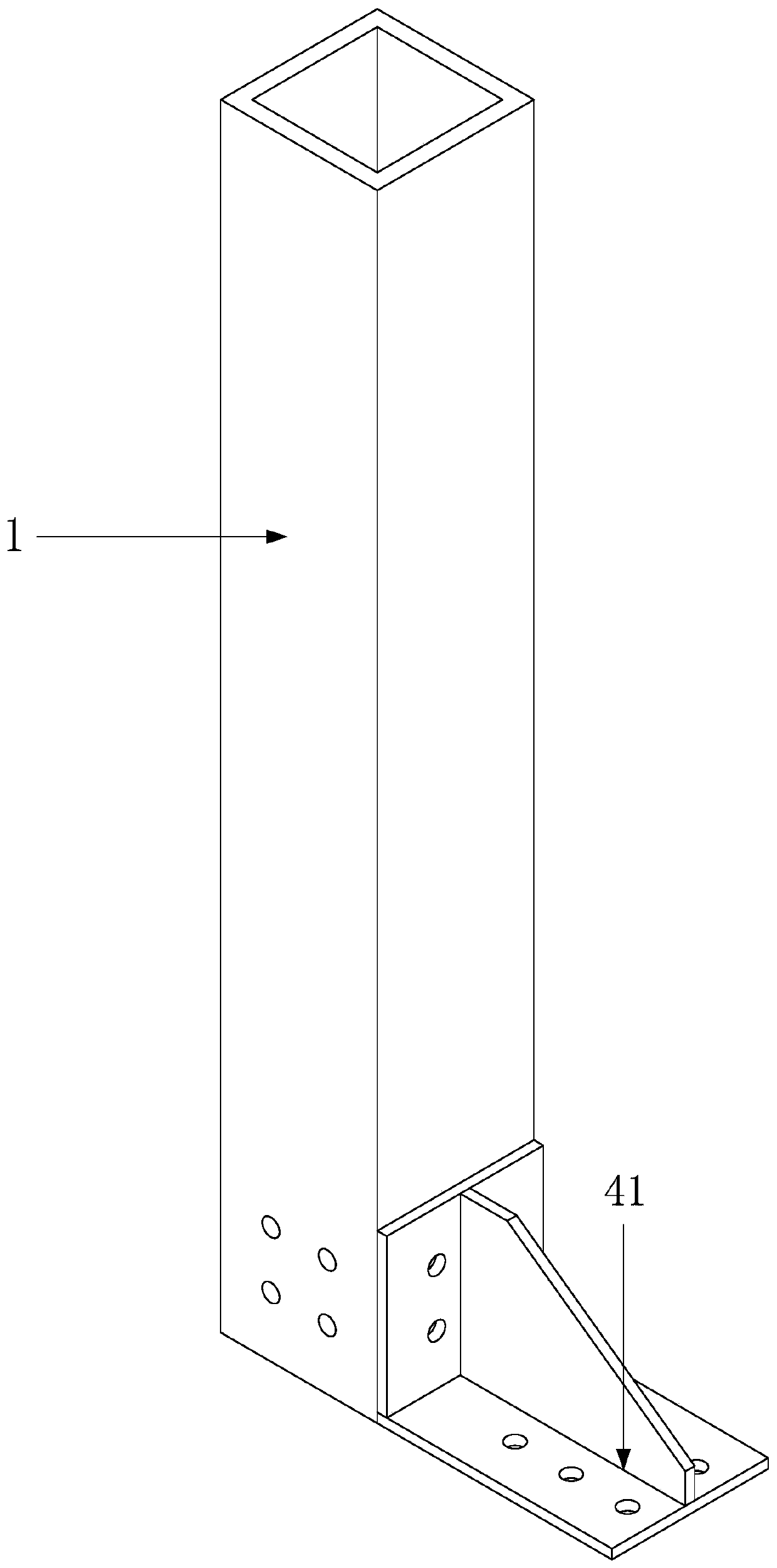

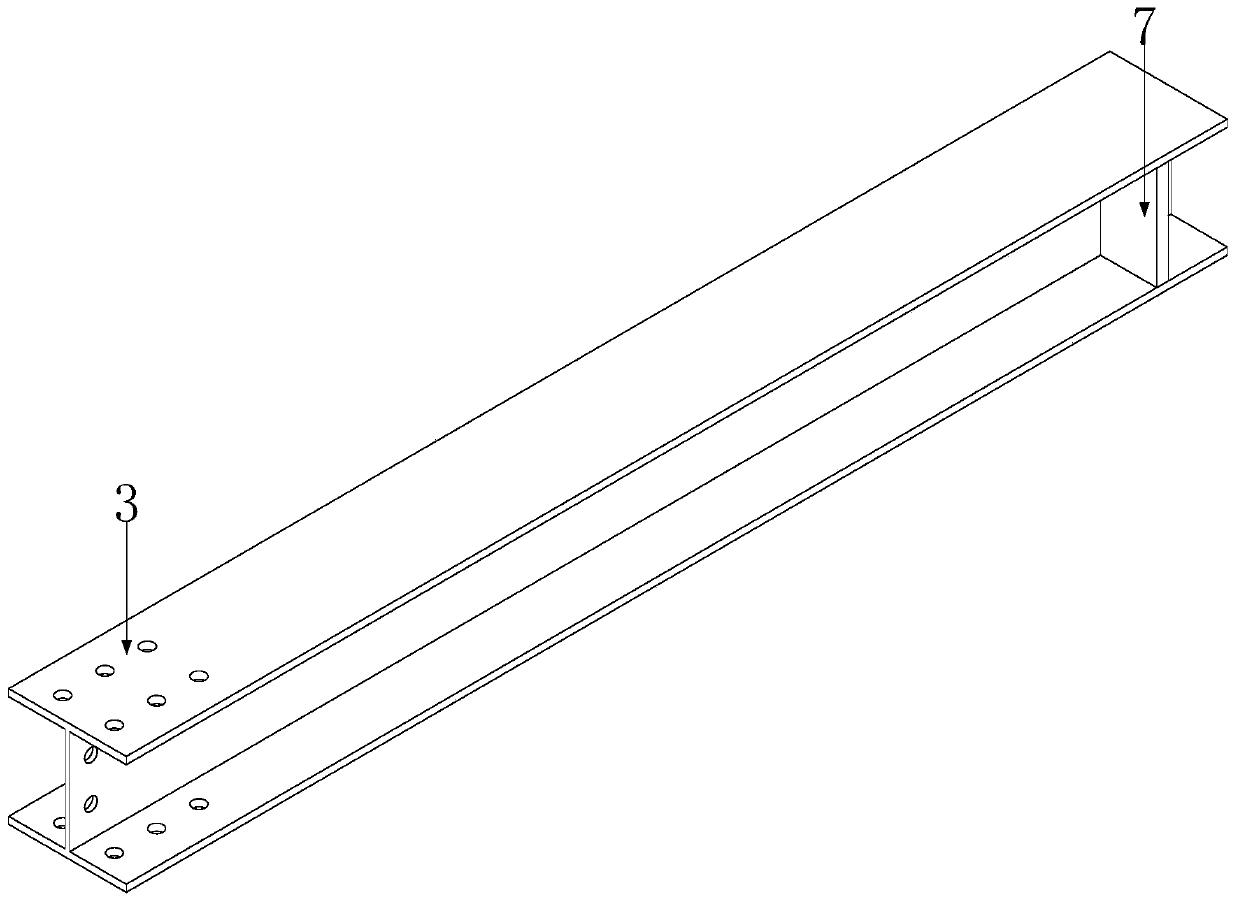

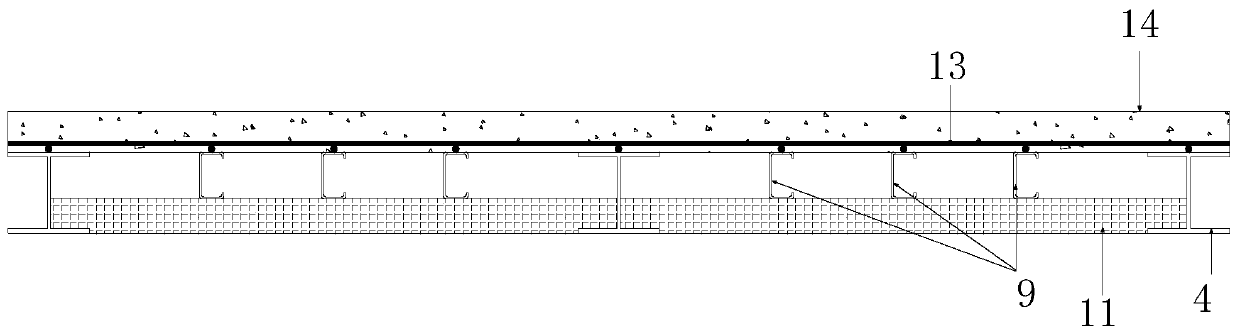

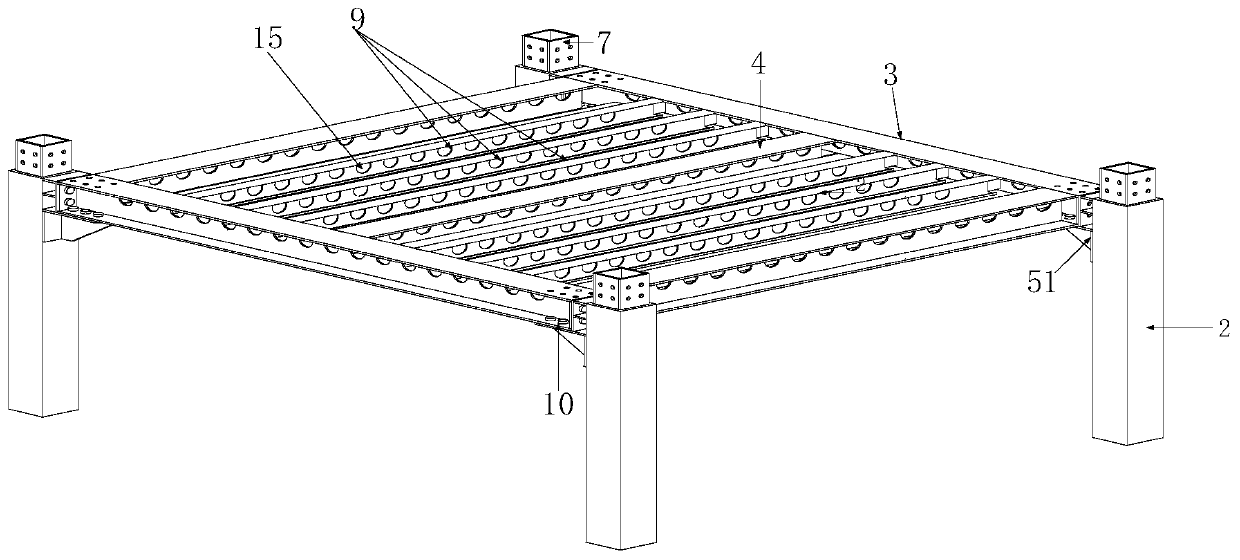

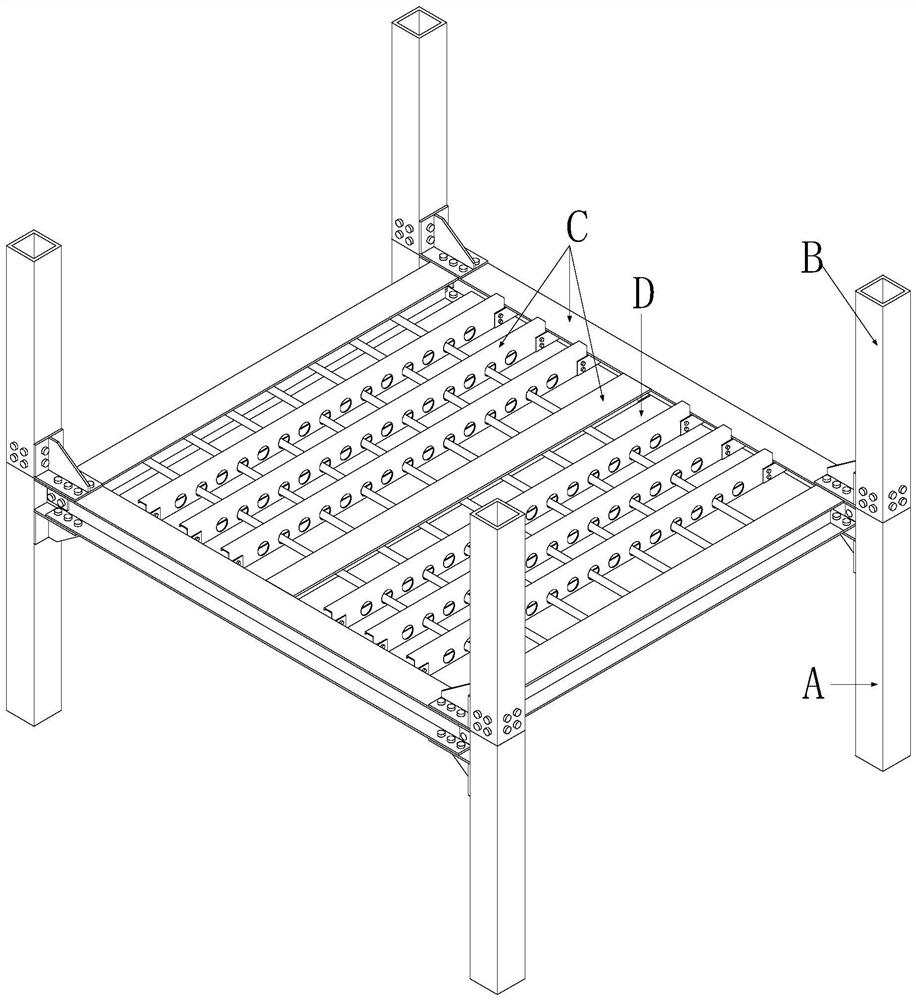

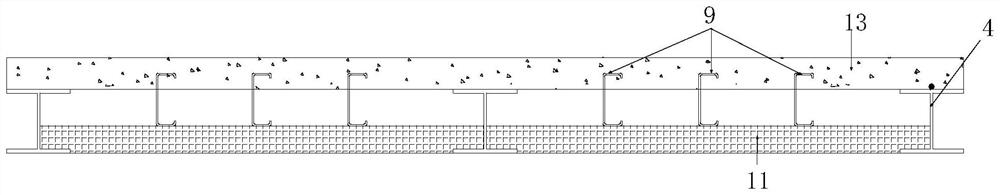

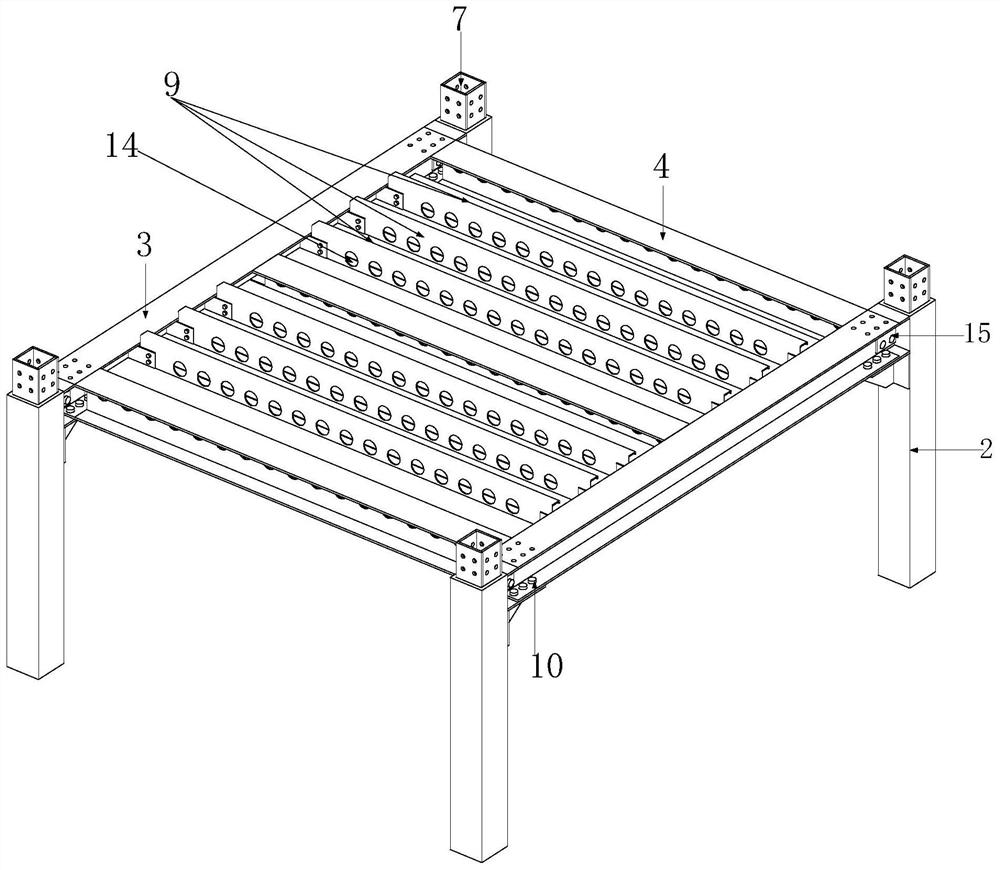

Beam-column joint for connecting end plates of square steel tube columns of prefabricated steel structure inner inserting plate

InactiveCN110359556AIncrease stiffnessImprove bearing capacityBuilding constructionsPlastic hingeBeam column

The invention relates to a beam-column joint for connecting end plates of square steel tube columns of a prefabricated steel structure inner inserting plate. The beam-column joint comprises a lower column module, an upper column module and a beam module. The lower column module is formed by welding a lower column, a ribbed supporting plate, an inner inserting plate and a stiffening rib in a factory, the upper column module is formed by welding an upper column and a ribbed supporting plate in the factory, and the beam module is formed by welding an H-shaped steel beam, end plates and a stiffening rib in the factory. Holes are formed in the reserved parts of the upper column, the H-shaped steel beam, the inner inserting plate, the ribbed supporting plate and the end plates, the components are transported to the site for full bolt assembly. The ribbed supporting plate plays a role in positioning the H-shaped steel beam during assembly, and bears part of the bearing capacity of an H-shapedsteel beam end bending moment lifting node. The inner inserting plate facilitates installation of the upper column module and the lower column module, and the difficulty in hoisting is reduced. Due to the arrangement of the ribbed supporting plate and the end plates, the damaged part is moved out of the node area, and the plastic hinge is moved out. Full bolt connection is adopted, on-site welding operation is avoided, construction is convenient, operation is convenient, and assembly speed is high.

Owner:BEIJING UNIV OF TECH

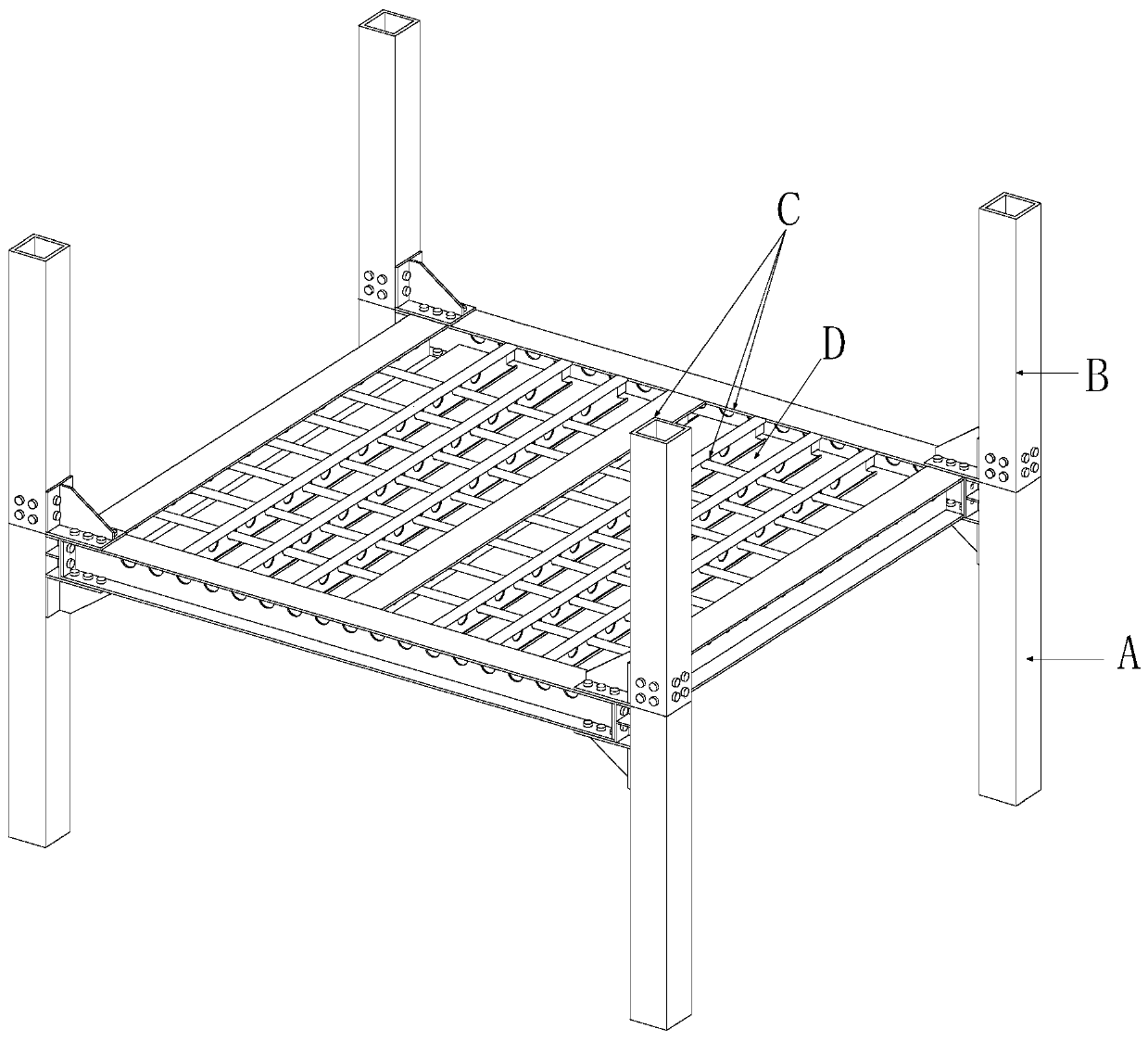

Assembled building system based on inner insertion plate and clamping plate connecting beam column nodes

The invention discloses an assembled building system based on inner insertion plate and clamping plate connecting beam column nodes. A lower column module comprises lower columns; all the lower columns are provided with first support plates, outer extension plates and inner insertion plates; an upper column module comprises upper columns; all the upper columns are provided with second support plates; the upper columns are correspondingly inserted in the inner insertion plates of the lower columns, and are connected through bolts; a beam module comprises a main beam and a secondary beam; wire passing holes are reserved on web plates of the main beam and the secondary beam; and the connection of all the modules is realized through bolts among the main beam web plate, the outer extension plates and clamping plates, between a main beam lower flange and the first support plates and between a main beam upper flange and the second support plates. Beam columns can be assembled in scene only byadopting bolts, so that the assembly speed is high, and the construction period is shortened. Ribbed support plates achieve a positioning effect on the beams to bear part of the bending moment. The upper and lower columns are conveniently installed by the inner insertion plates to reduce the lifting difficulty. The ribbed support plates and the clamping plates are provided to realize outer shifting of plastic hinges. Pipelines are separated from a main body structure, so that the maintenance is convenient, and the clearance is improved.

Owner:BEIJING UNIV OF TECH

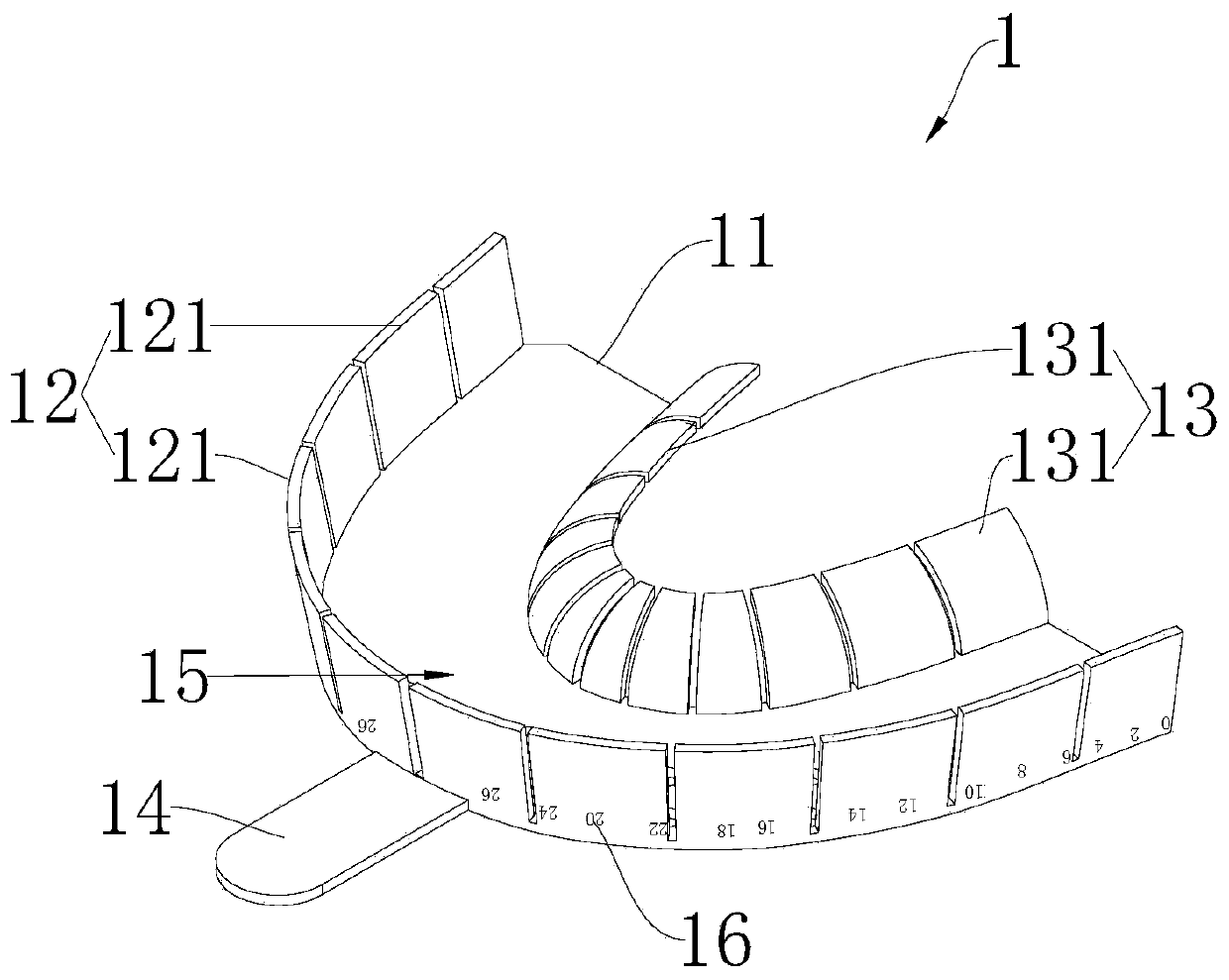

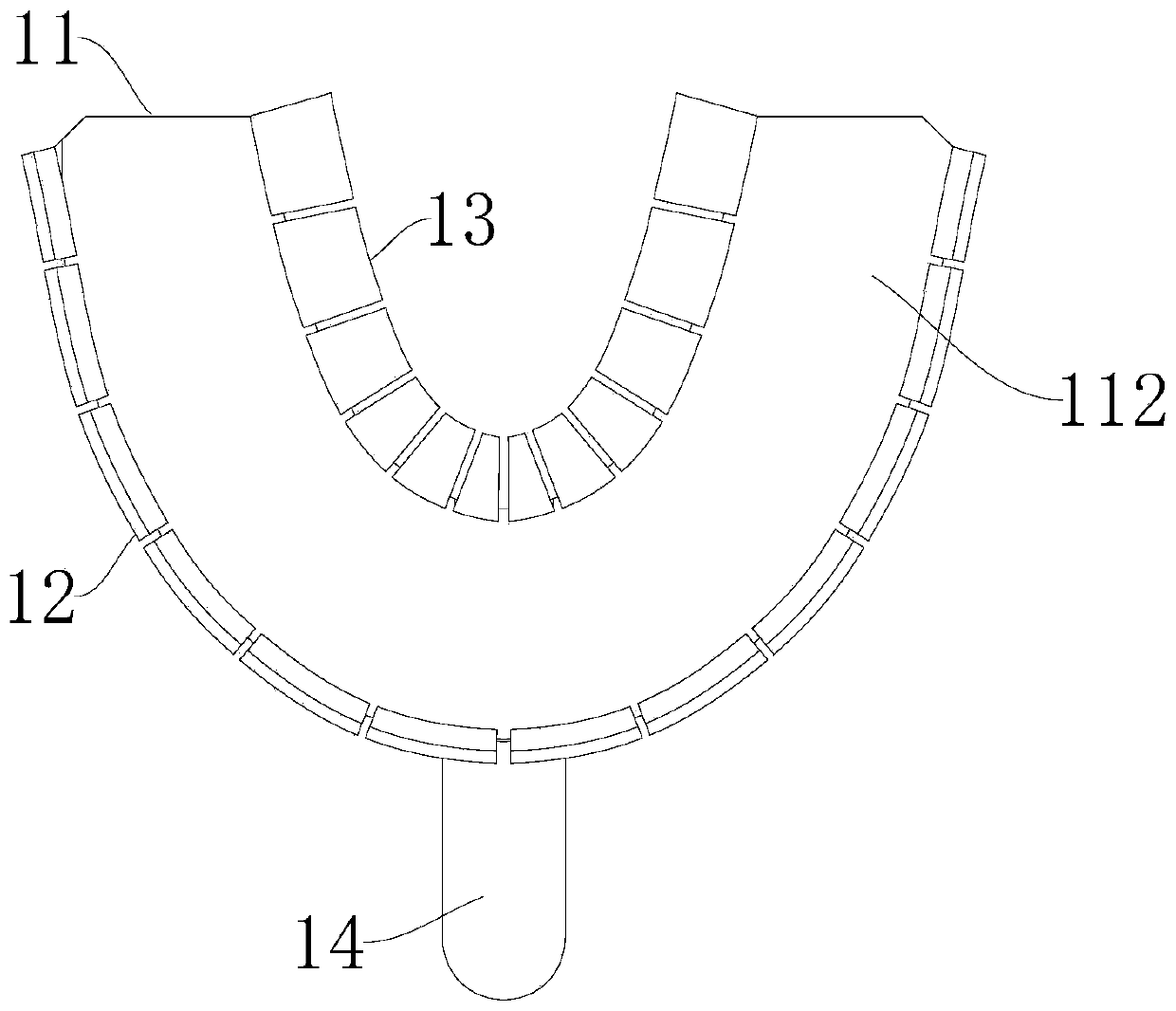

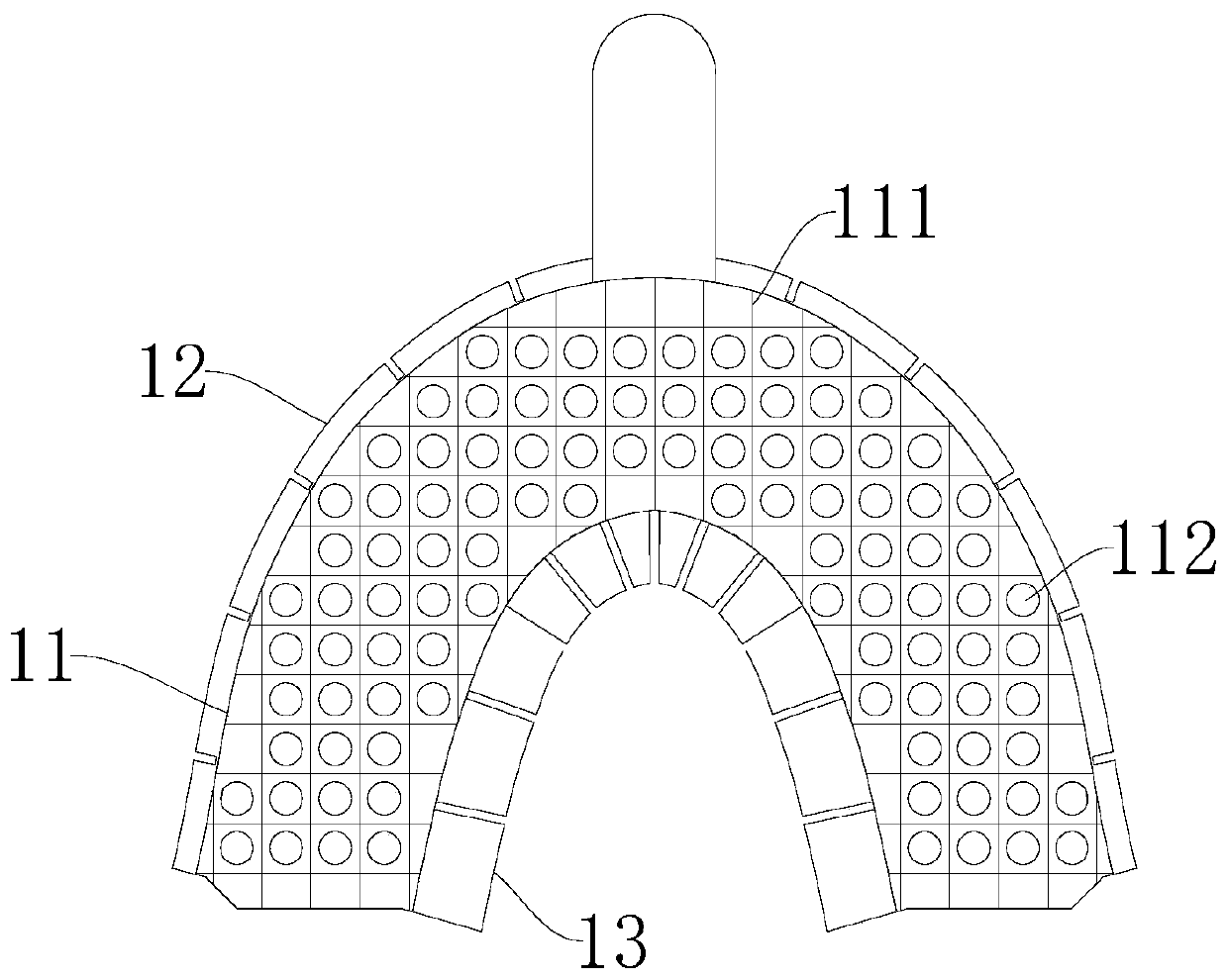

Tray for manufacturing implanting guide plate and method for manufacturing implanting guide plate

PendingCN110200714ARapid positioningReduce bleedingDental implantsImpression capsEngineeringDental cast

The invention discloses a tray for manufacturing an implanting guide plate and a method for manufacturing the implanting guide plate. The tray comprises a bottom plate, cheek side wing plates and tongue side wing plates; grid lines are arranged on the lower surface of the bottom plate, and radiation positioning eyes are formed in the centers of the grids; the cheek side wing plates are fixedly arranged along the outer edge of the bottom plate; one side of each tongue side wing plate is fixedly arranged along the inner edge of the bottom plate; and an accommodating groove is formed between eachcheek side wing plate and the corresponding tongue side wing plate. The method comprises the following steps: preparing a solid model; taking a dental impression by using the tray; shooting CT of anoral cavity with a tray; carrying out software simulation implanting design; S5, filling a temporary guide plate material into the tray, and forming a guide straight hole in the temporary guide platematerial; and S6, replacing the temporary guide plate material with the guide plate material to finish the implanting guide plate. Or the method comprises the steps of after taking the dental impression with the tray, then shooting CT of the oral cavity with the tray, and carrying out 3D printing on plating of the guide plate by CT data. The tray is favorable for accurately positioning implantingpit points, is suitable for non-flap minimally invasive implantation operation, and has low manufacturing requirements and low cost.

Owner:广州巴伦医疗投资管理有限公司

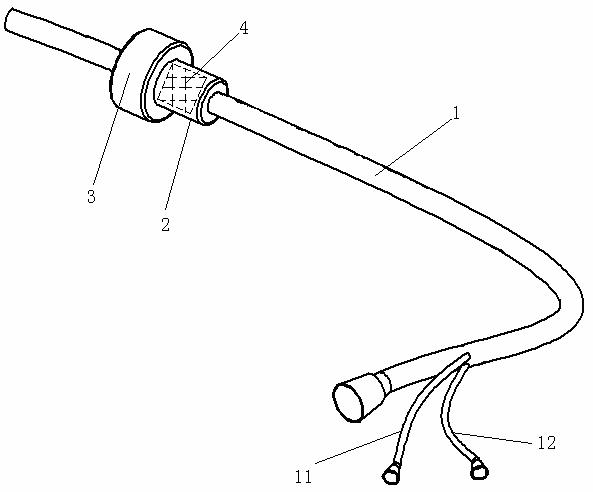

Esophagus-stomach anastomotic fistula occluder and application thereof

The invention relates to an esophagus-stomach anastomotic fistula occluder which is composed of a stomach tube, a columnar balloon, an annular balloon and a support, wherein the support is circular-barrel-shaped as well as is sleeved and fixed on the stomach tube; the columnar balloon is a circular-barrel-shaped air balloon as well as is attached and fixed on the outer surface of the support; the annular balloon is an annular air balloon and is fixed on the surface of the lower end of the support; a gap is disposed between the annular balloon and the columnar balloon; and a columnar balloon pipeline communicated with the columnar balloon and an annular balloon pipeline communicated with the annular balloon are disposed in the tube wall of the stomach tube. The invention further provides an application of the occluder. The esophagus-stomach anastomotic fistula occluder disclosed by the invention has the following advantages that: when the esophagus-stomach anastomotic fistula occluder is in use, a function of accurate location can be realized, and the tension of anastomosis can also be reduced to promote the union of anastomosis; the sealing performance of occlusion is greatly improved, and injury on esophageal wall is greatly reduced; the operation is simple, fistula can be completely isolated from stomach and esophageal cavity, and the pain and mucosal injury caused by the compression of the support can be reduced; and the support has no displacement and is easy to take out.

Owner:XIN HUA HOSPITAL AFFILIATED TO SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE

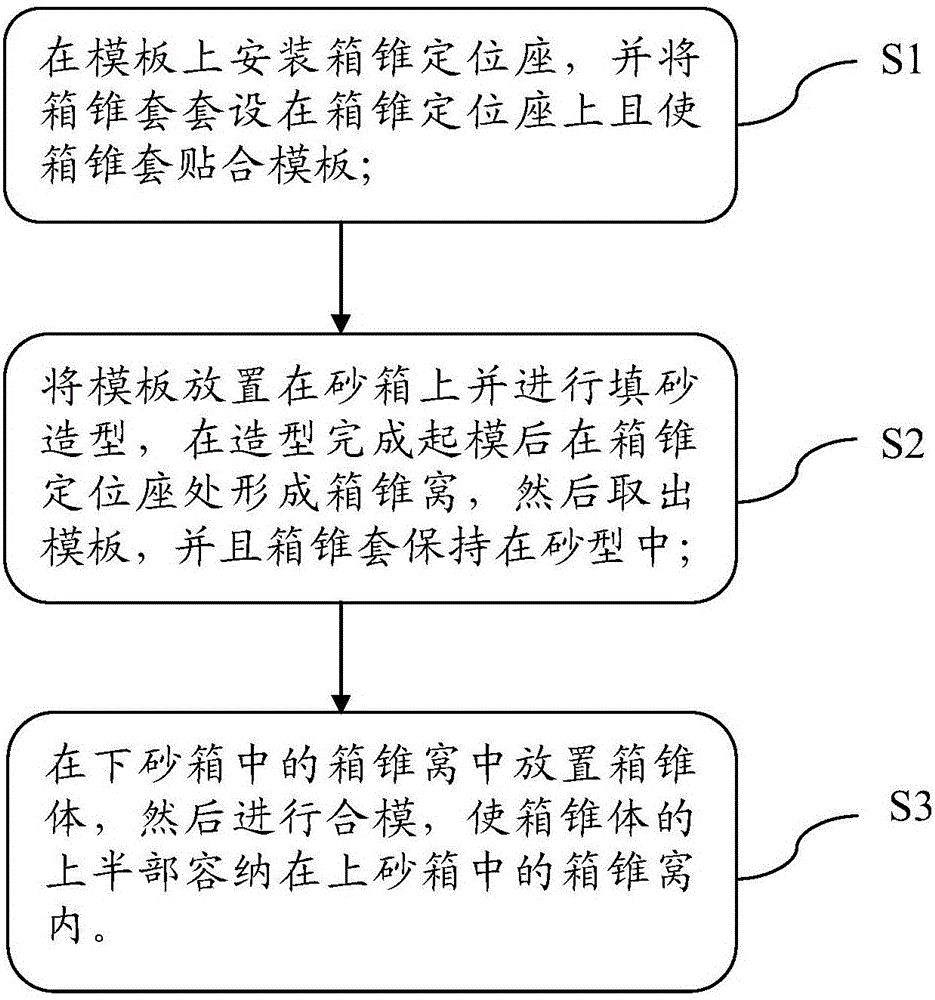

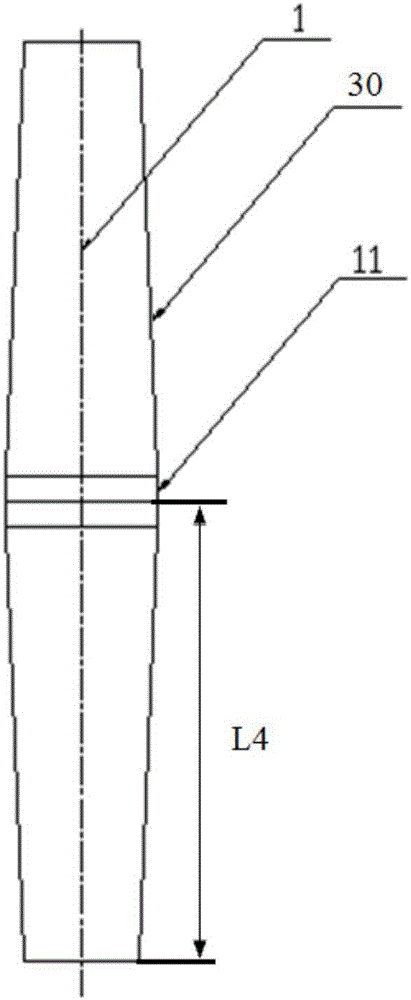

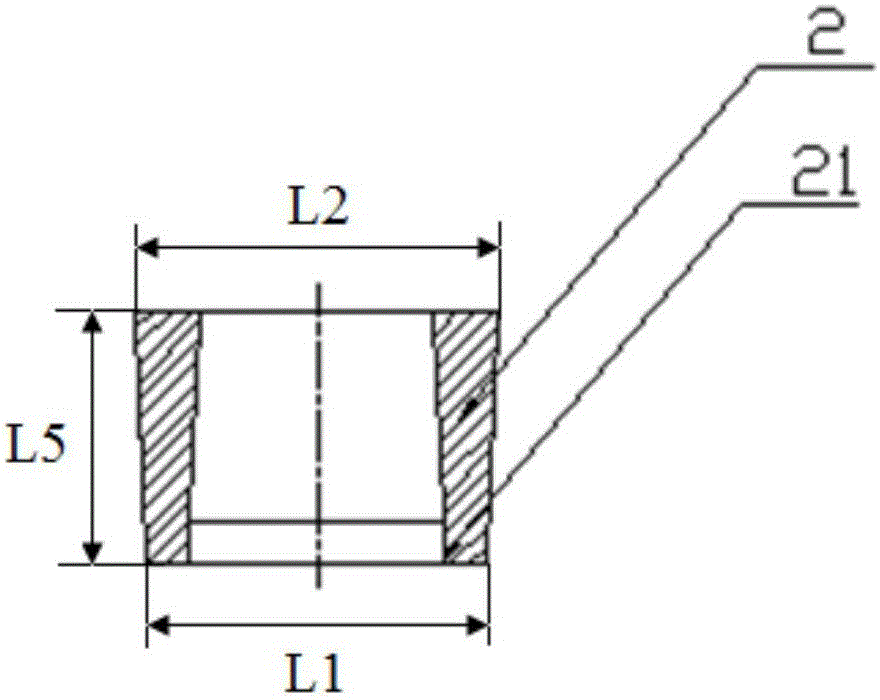

Method for using guiding and locating box cone component and guiding and locating box cone

In order to realize a purpose, the invention, on one hand, provides a method for using a guiding and locating box cone component used for casting production. The method comprises the following steps of mounting a box cone locating seat on a template, arranging a box cone sleeve on the box cone locating seat in a sleeving manner and further making the box cone sleeve abutted with the template; placing the template on a sand box, carrying out sand filling molding, forming a box cone nest at the box cone locating seat after the die stripping when the molding is completed, afterwards, taking out the template, and moreover, maintaining the box cone sleeve in a sand mold; and placing a box cone body in a box cone nest in a lower sand box, then carrying out die closing, and making the upper half part pf the box cone body accommodated in a box cone nest in an upper sand box. The invention also provides a guiding and locating box cone. By using the method for using the guiding and locating box cone component and the guiding and locating box cone, the box staggering can be prevented, and the sand rubbing in a box closing process can be avoided.

Owner:KOCEL EQUIP

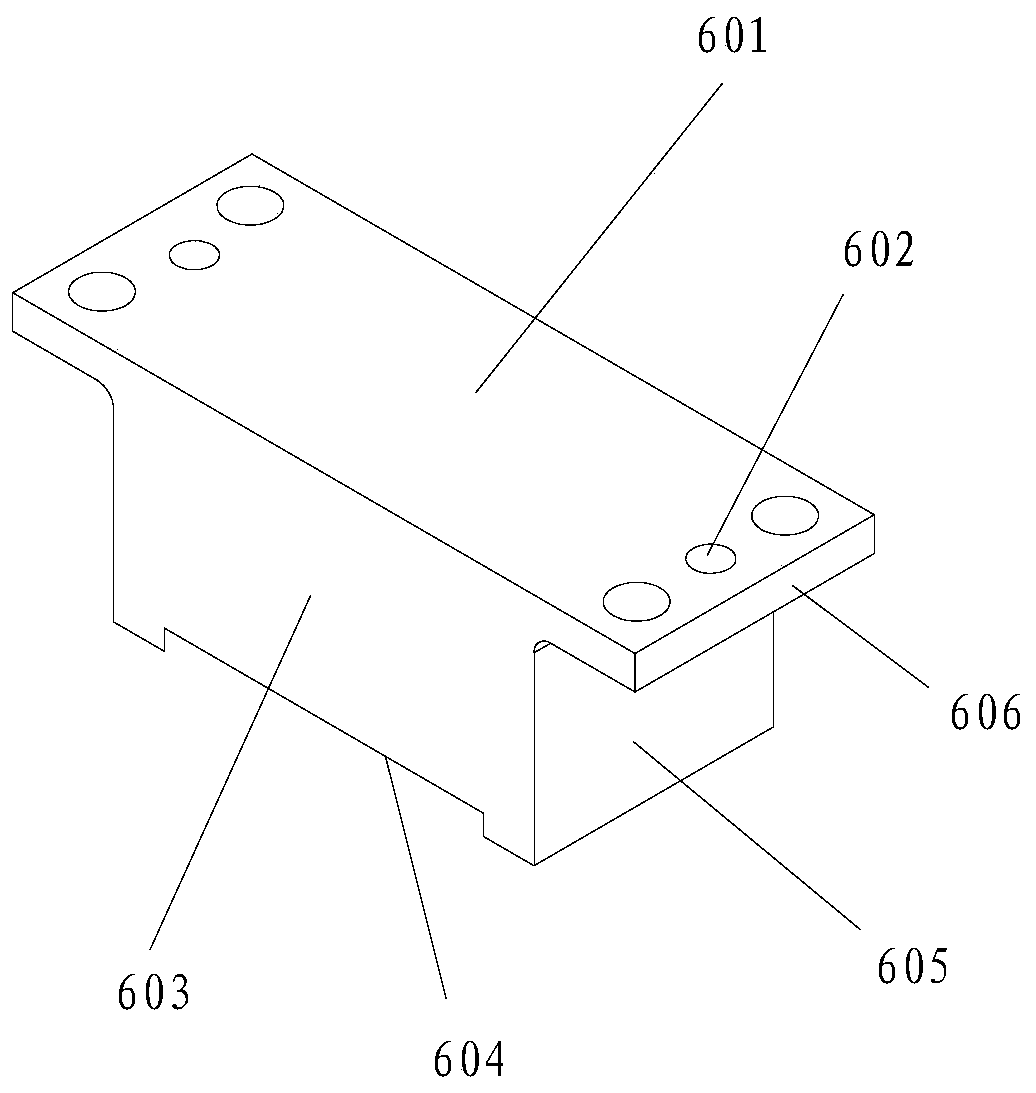

Beam column joint for connecting assembling type steel structure inner inserting plate square steel pipe column clamping plate

InactiveCN110359555AIncrease stiffnessImprove bearing capacityBuilding constructionsComputer modulePlastic hinge

The invention discloses a beam column joint for connecting an assembling type steel structure inner inserting plate square steel pipe column clamping plate. The beam column joint comprises a lower column module, an upper column module, a beam module and a clamping plate. The lower column module is formed by welding a lower column, a rib carrier plate, an inner inserting plate and a stiffening ribin a factory. The upper column module is formed by welding an upper column and rib carrier plate in a factory. The beam module is formed by welding an H-shaped steel beam and the stiffening rib in thefactory. Holes are formed in the reserved portions of the upper column, the H-shaped steel beam, the inner inserting plate, the rib carrier plate and the clamping plate, and the upper column, the H-shaped steel beam, the inner inserting plate, the rib carrier plate and the clamping plate are transported to the site to be assembled through bolts. The rib carrier plates have a function of locatingthe H-shaped steel beam in the assembling process and bear some beam end bending moment to improve the bearing force of the joint. The inner inserting plate facilitates installing of the upper columnmodule and the lower column module, and the hoisting difficulty is reduced. By arranging the rib carrier plates and the clamping plate, the damaged portion is moved to the outside of the joint, and outward moving of plastic hinges is achieved. Full-bolt connection is adopted, no welding operation is carried out on the site, construction is facilitated, operation is convenient, the assembling speedis high, and the quality is ensured easily.

Owner:BEIJING UNIV OF TECH

Container clamping conveying device of straight-line filling device

ActiveCN103058111BEliminate positional deviationSimple structureLiquid bottlingEngineeringMechanical engineering

The invention discloses a container clamping conveying device of a straight-line filling device. The container clamping conveying device comprises a circulating conveying mechanism, a container clamping mechanism, an opening and closing mechanism, a lifting mechanism and a position deviation correcting mechanism, wherein both the circulating conveying mechanism and the opening and closing mechanism are movably connected with the container clamping mechanism; the container clamping mechanism is movably connected to the circulating conveying mechanism; the lifting mechanism and the opening and closing mechanism are located on the same station; the container clamping mechanism is located between the lifting mechanism and the opening and closing mechanism; and both the lifting mechanism and the opening and closing mechanism are arranged on the position deviation correcting mechanism. According to the container clamping conveying device of the straight-line filling device, when an obvious position deviation of the container clamping mechanism occurs on the circulating conveying mechanism due to error accumulation, the problem can be detected in time by the position deviation correcting mechanism, and the position of the opening and closing mechanism is adjusted by a driving mechanism, so that the opening and closing mechanism is re-aligned to the container clamping mechanism and the problem of the position deviation of the container clamping mechanism is completely solved.

Owner:HANGZHOU ZHONGYA MACHINERY CO LTD

Machining device for stably shearing sections in fixed size

The invention discloses a processing device for stably shearing profiles with fixed dimensions, which comprises a conveyer belt arranged on a frame to convey materials in a horizontal direction and pressing wheels arranged on both sides of the conveyer belt. The direction in which the conveyer belt conveys materials is There is a workbench in front of the conveyor belt. The surface of the workbench is flush with the conveyor belt. The upper part of the rear edge of the workbench is equipped with a scissors plate and a hydraulic cylinder that drives the scissors plate vertically. It is located on the front side of the front edge of the workbench. A material baffle plate and a cylinder for driving the material baffle plate to vertically lift are provided. The beneficial effect of the invention is that it can be adapted to profiles of different sizes, so that the machine tool can use profiles of different sizes, and the use efficiency of the machine tool is improved. The setting of the baffle plate can play the role of precise positioning and ensure the cutting accuracy; the setting of the pressing plate can position the size to the greatest extent.

Owner:李林君

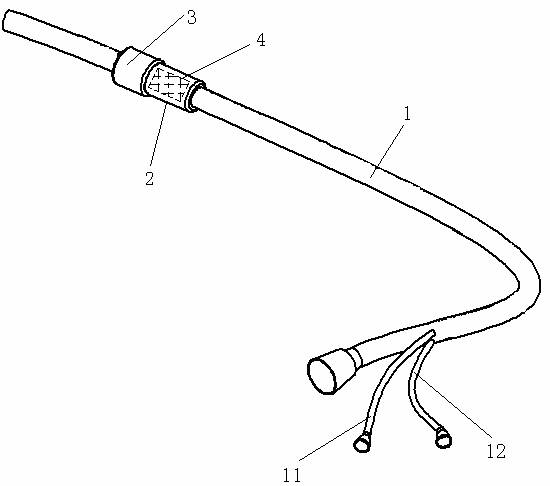

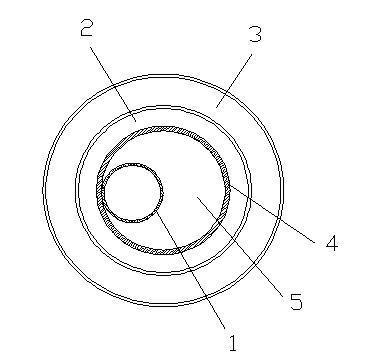

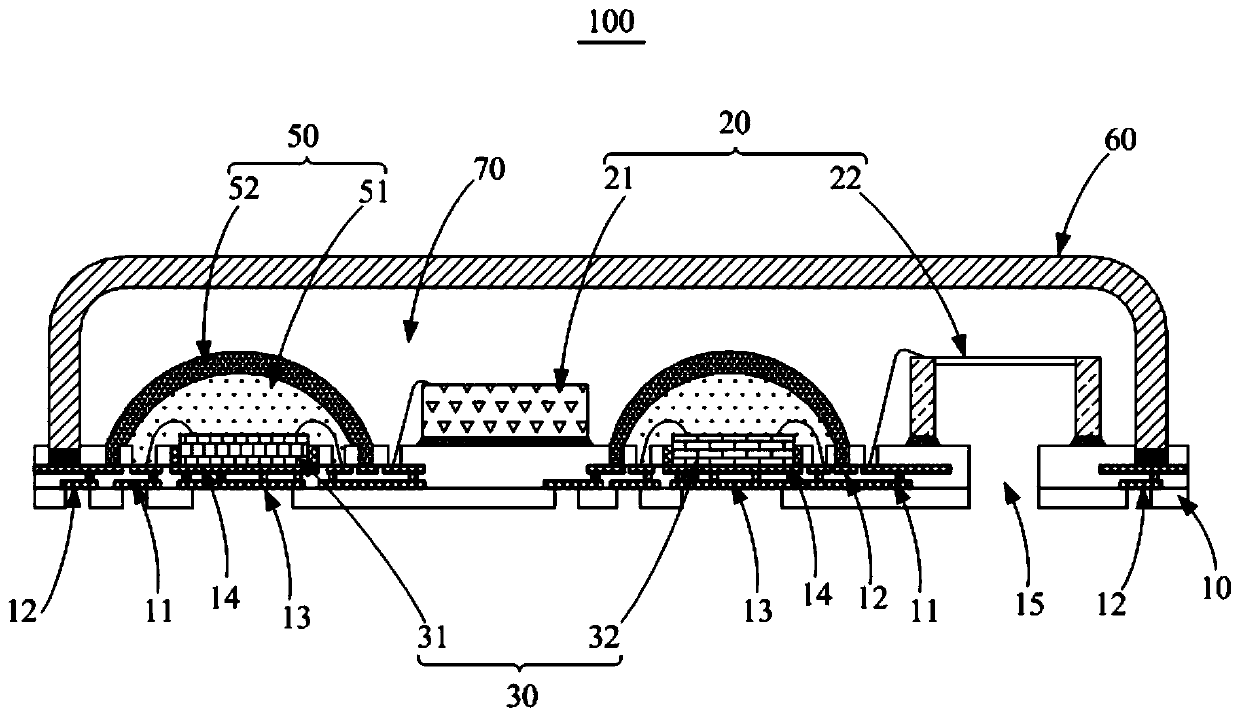

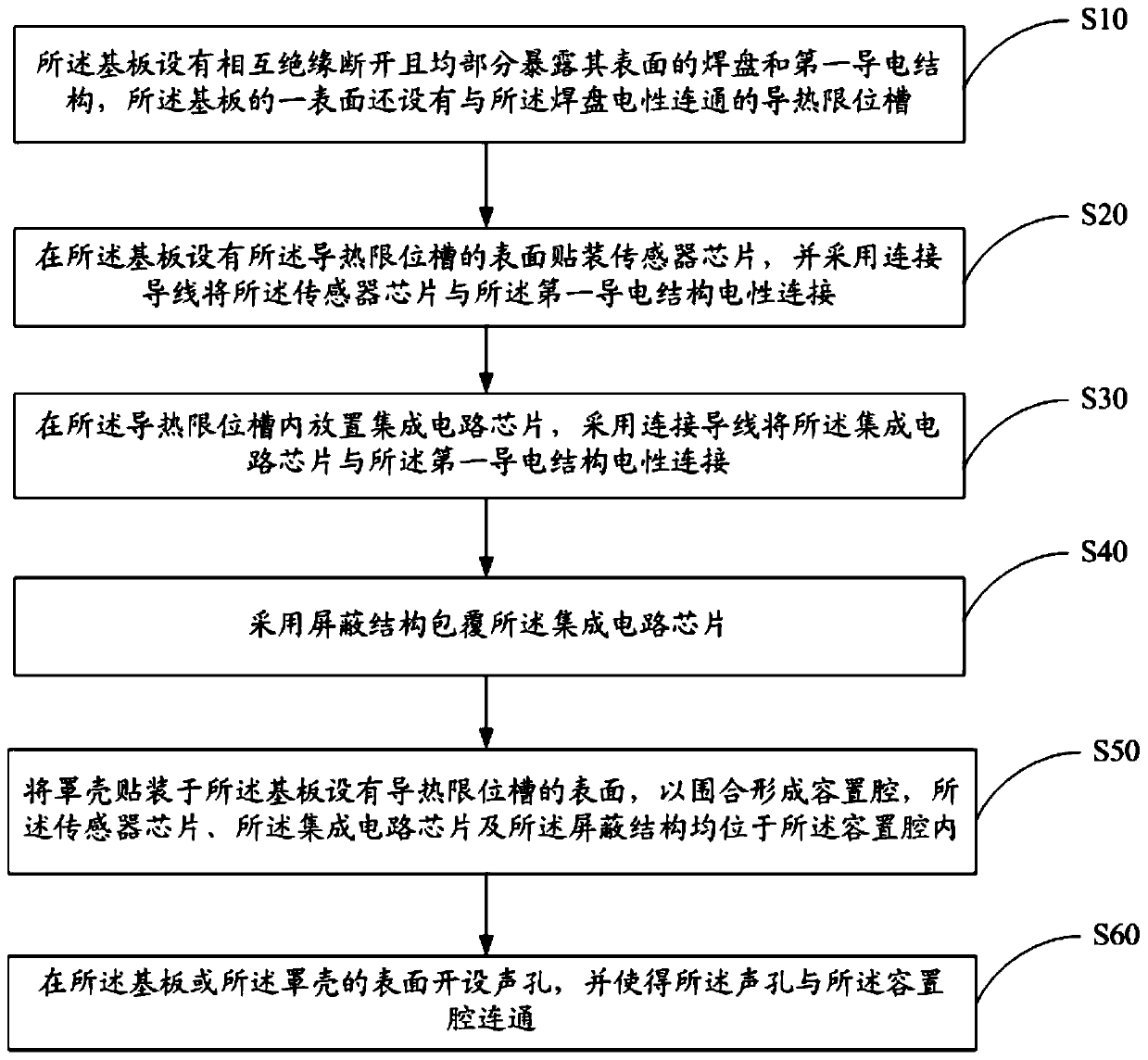

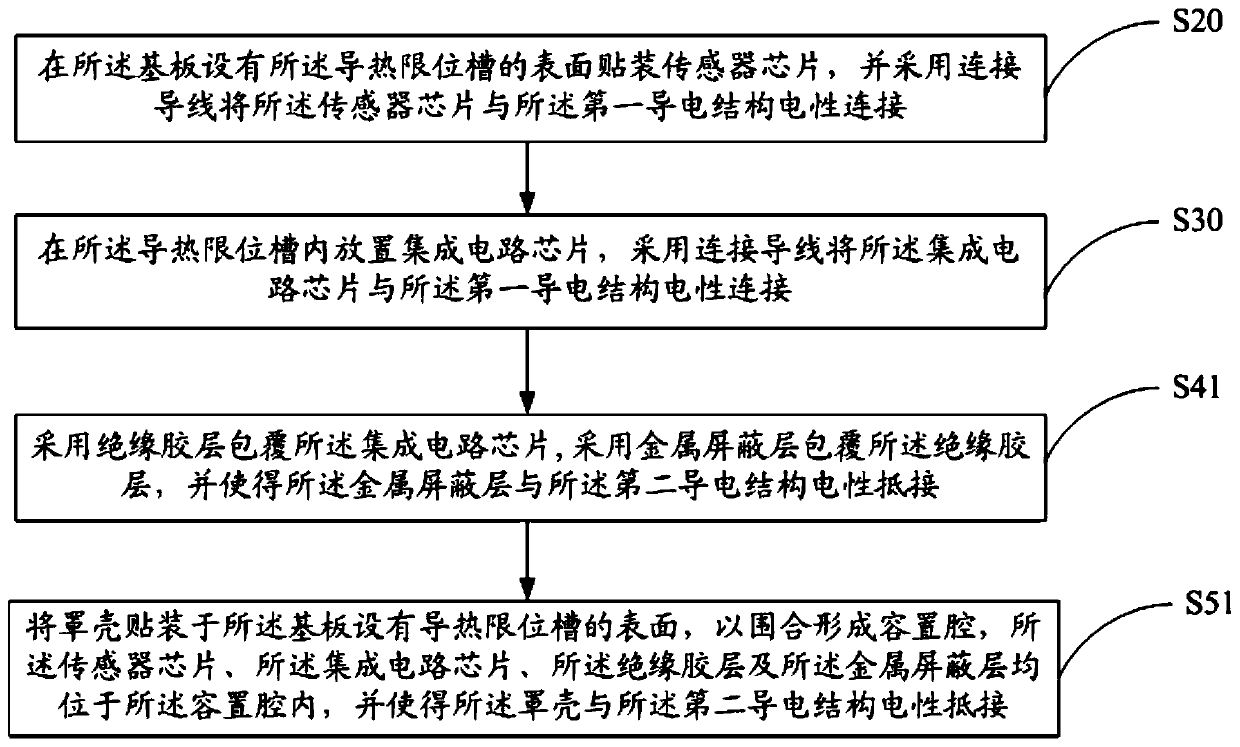

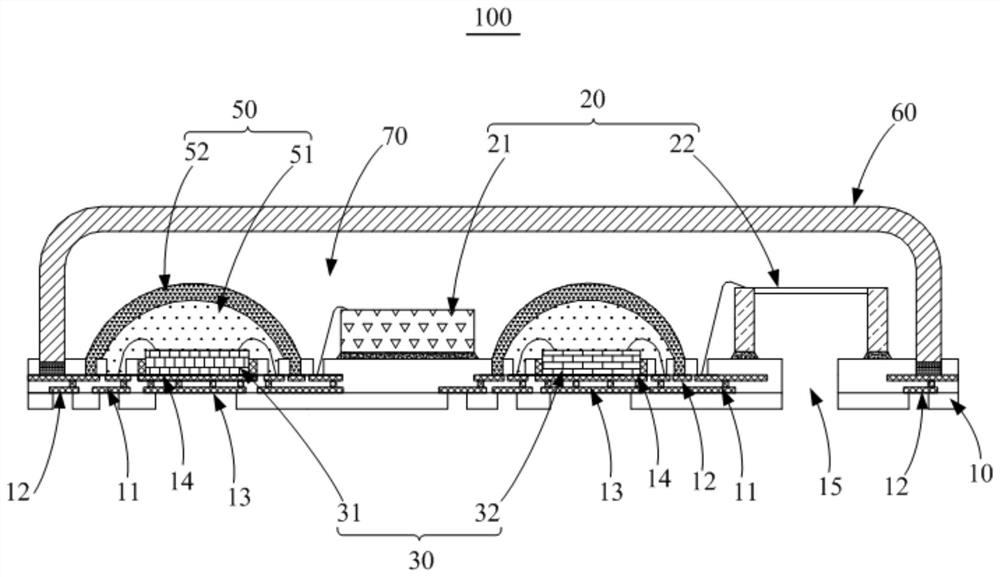

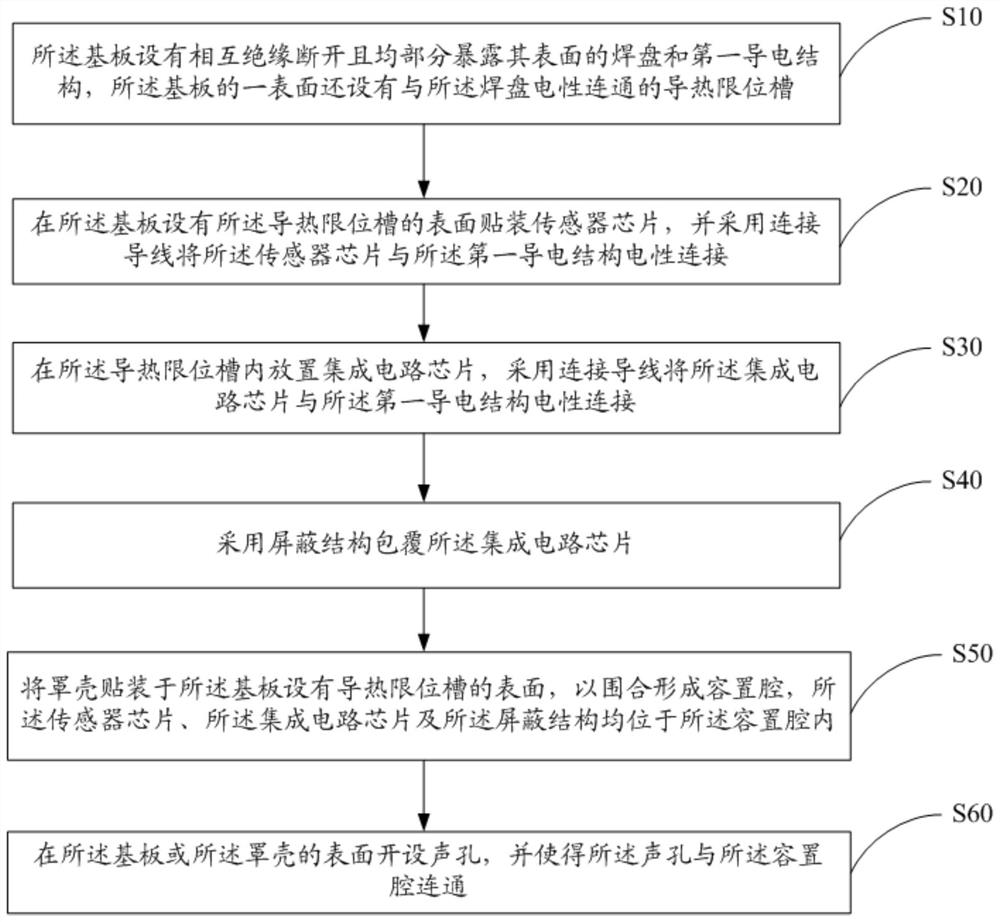

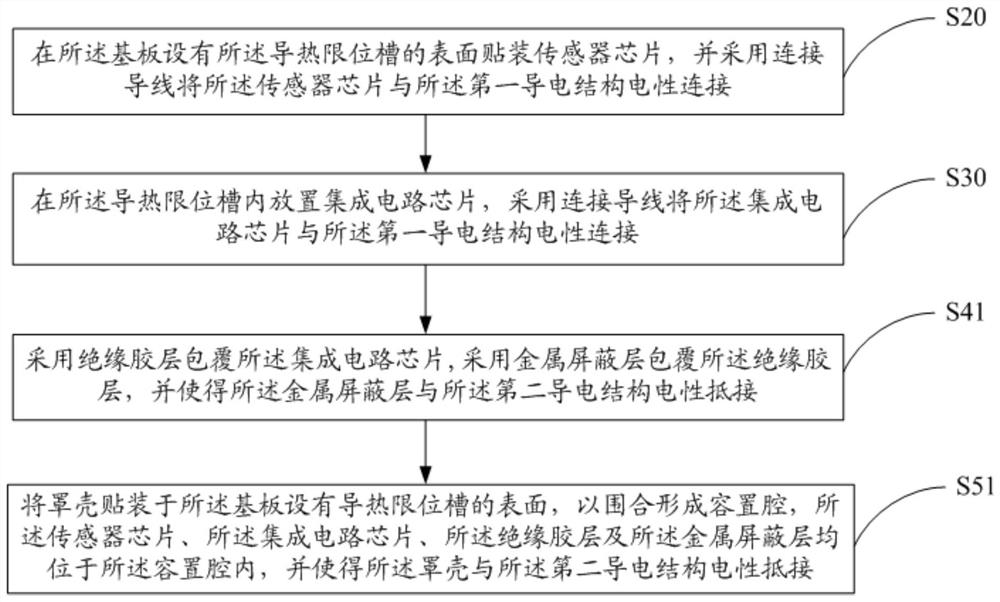

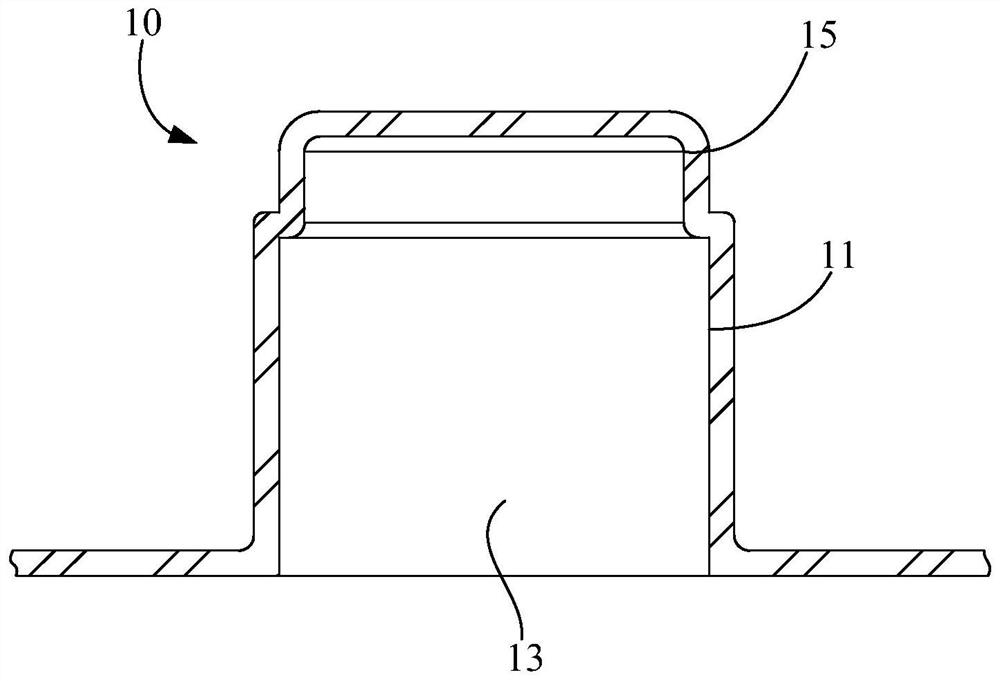

Sensor, manufacturing method thereof and electronic equipment

ActiveCN111463190APlay the role of precise positioningEliminate glue applicationSemiconductor/solid-state device detailsSolid-state devicesEngineeringMechanical engineering

The invention discloses a sensor, a manufacturing method thereof and electronic equipment. The sensor comprises a substrate, wherein a bonding pad and a first conductive structure are arranged in thesubstrate, the bonding pad and the first conductive structure are insulated and disconnected from each other, the surface of the bonding pad and the surface of the first conductive structure are partially exposed, and a heat conduction limiting groove electrically communicated with the bonding pad is further formed in one surface of the substrate; an integrated circuit chip which is arranged in the heat conduction limiting groove and is electrically conducted with the first conductive structure through a connecting wire; and a shielding structure, wherein the shielding structure wraps the integrated circuit chip. According to the technical scheme, interference of external electromagnetism on the chip can be shielded, and meanwhile the heat dissipation effect of the chip is improved.

Owner:QINGDAO GOERTEK INTELLIGENT SENSOR CO LTD

Sectional material cutting device with locating material stop function

InactiveCN105436603AGood impetusImprove efficiencyShearing machine accessoriesHydraulic cylinderEngineering

The invention discloses a sectional material cutting device with a locating material stop function. The sectional material cutting device comprises a conveying belt and compressing wheels arranged on the two sides of the conveying belt, and the conveying belt is arranged on a rack and conveys materials in the horizontal direction. A workbench is arranged in front of the conveying belt with the material conveying direction of the conveying belt as the front. The surface of the workbench is flush with the conveying belt. A scissor plate and a hydraulic cylinder for driving the scissor plate to vertically ascend and descend are arranged on the upper portion of the rear edge of the workbench. A striker plate and an air cylinder for driving the striker plate to vertically ascend and descend are arranged at the front edge of the front edge of the workbench. The sectional material cutting device has the beneficial effects that the sectional material cutting device can be suitable for sectional materials in different sizes, so that a machine tool is suitable for sectional materials in different sizes, and the use efficiency of the machine tool is improved; and due to the striker plate, the function of precise locating can be achieved, and the cutting precision is ensured.

Owner:四川燚成钢结构有限公司

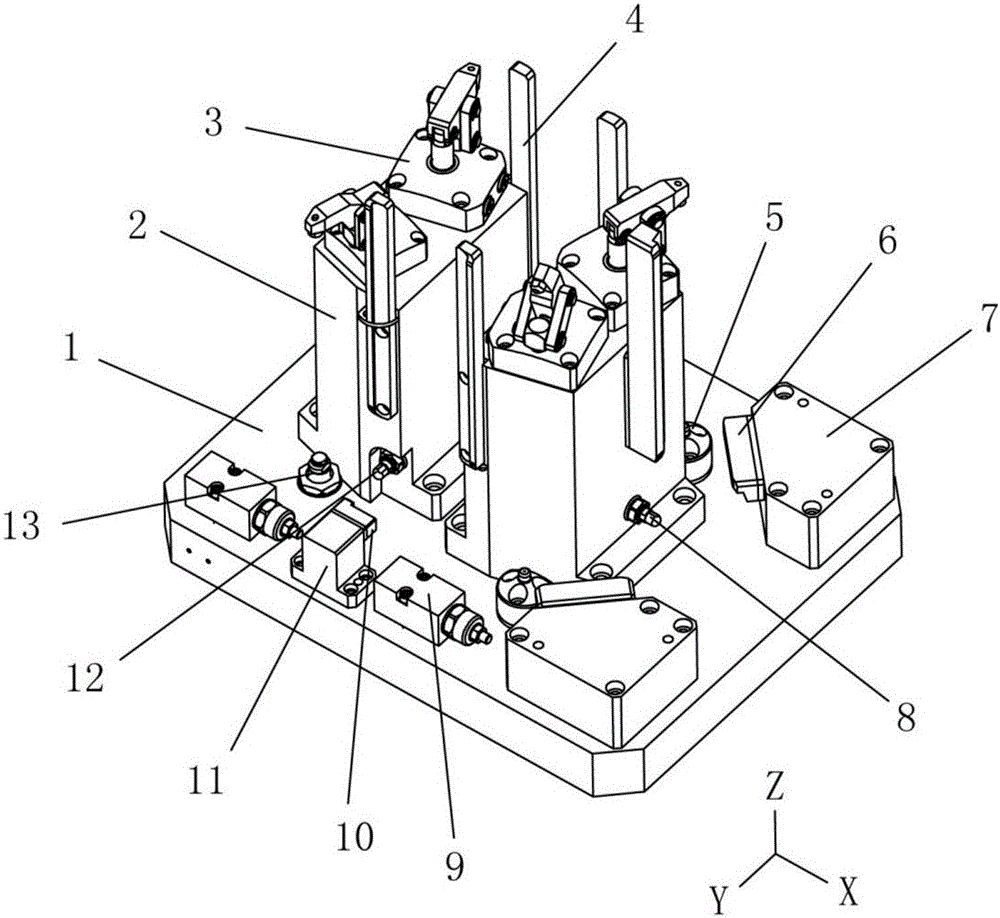

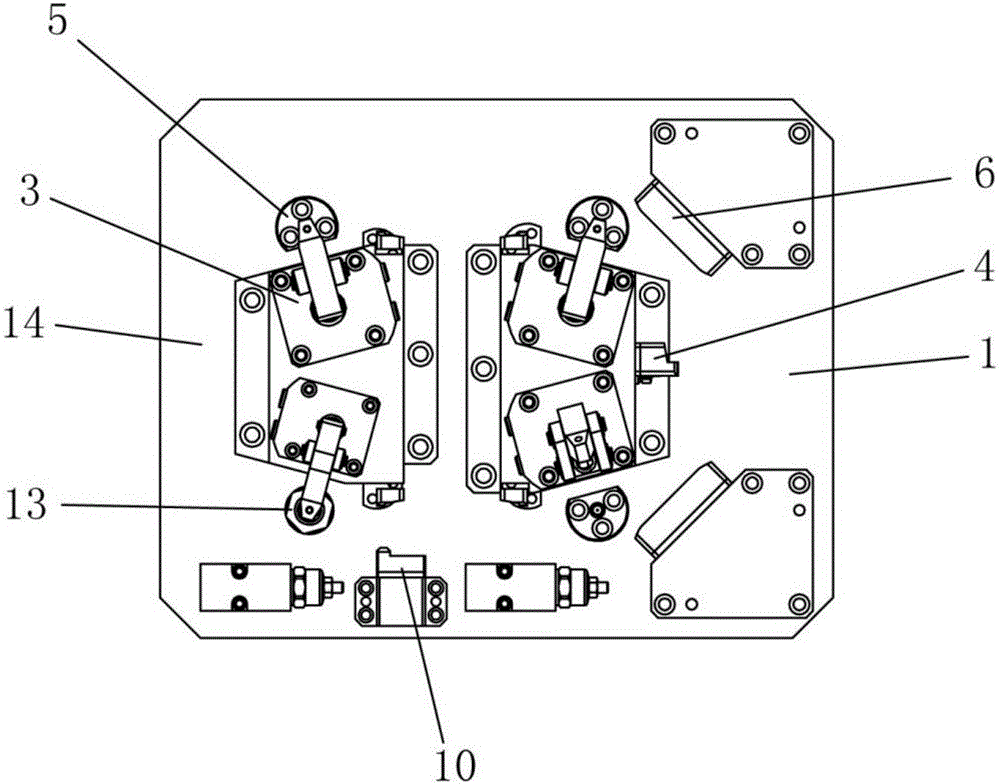

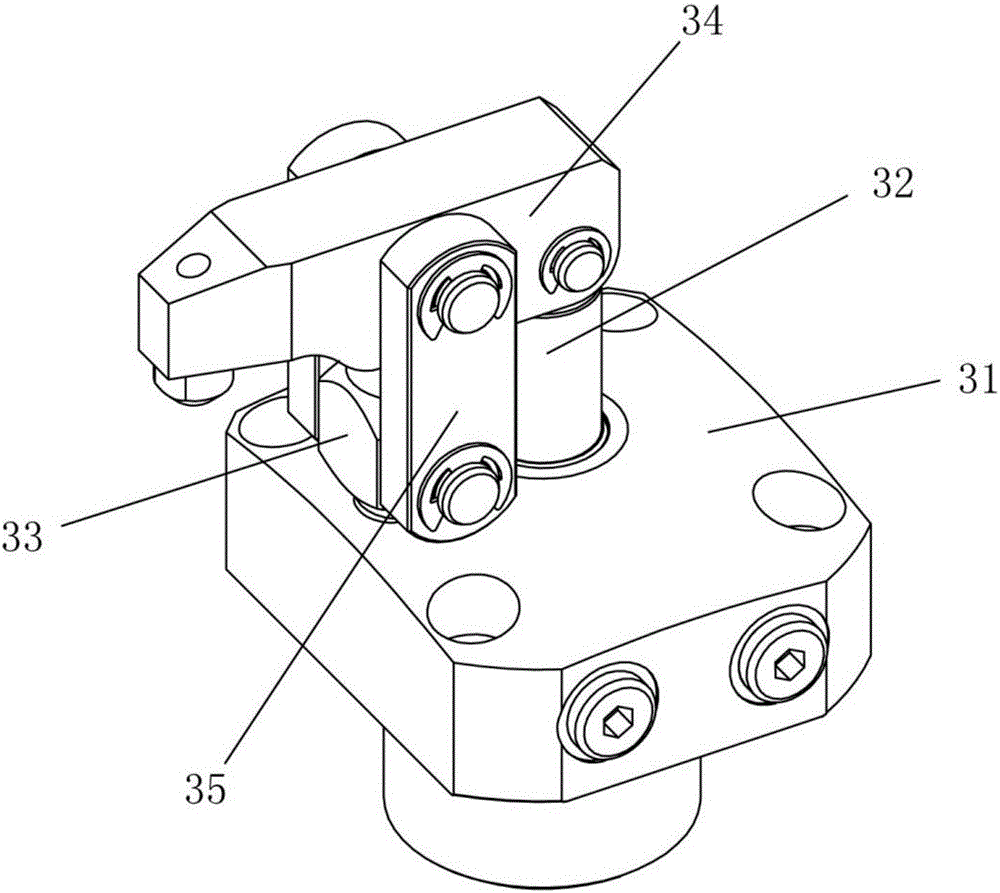

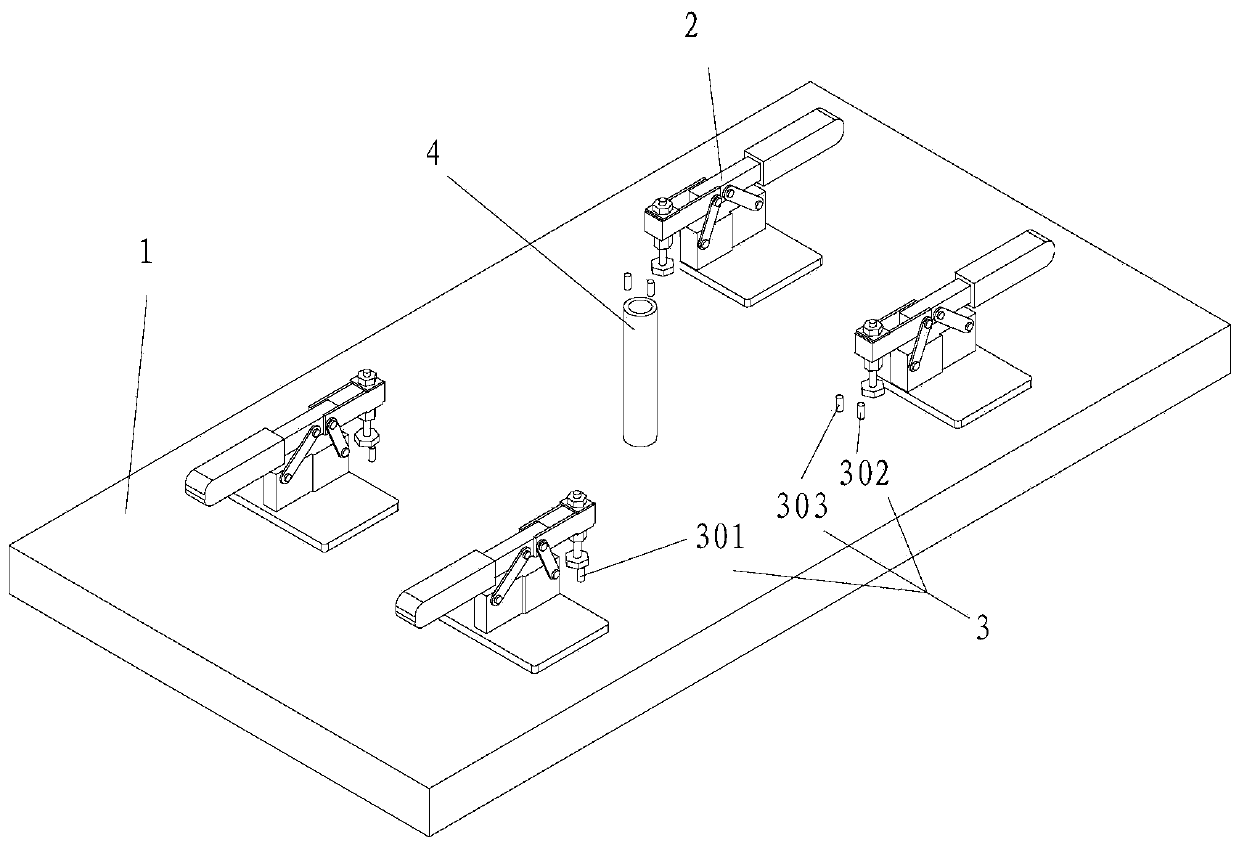

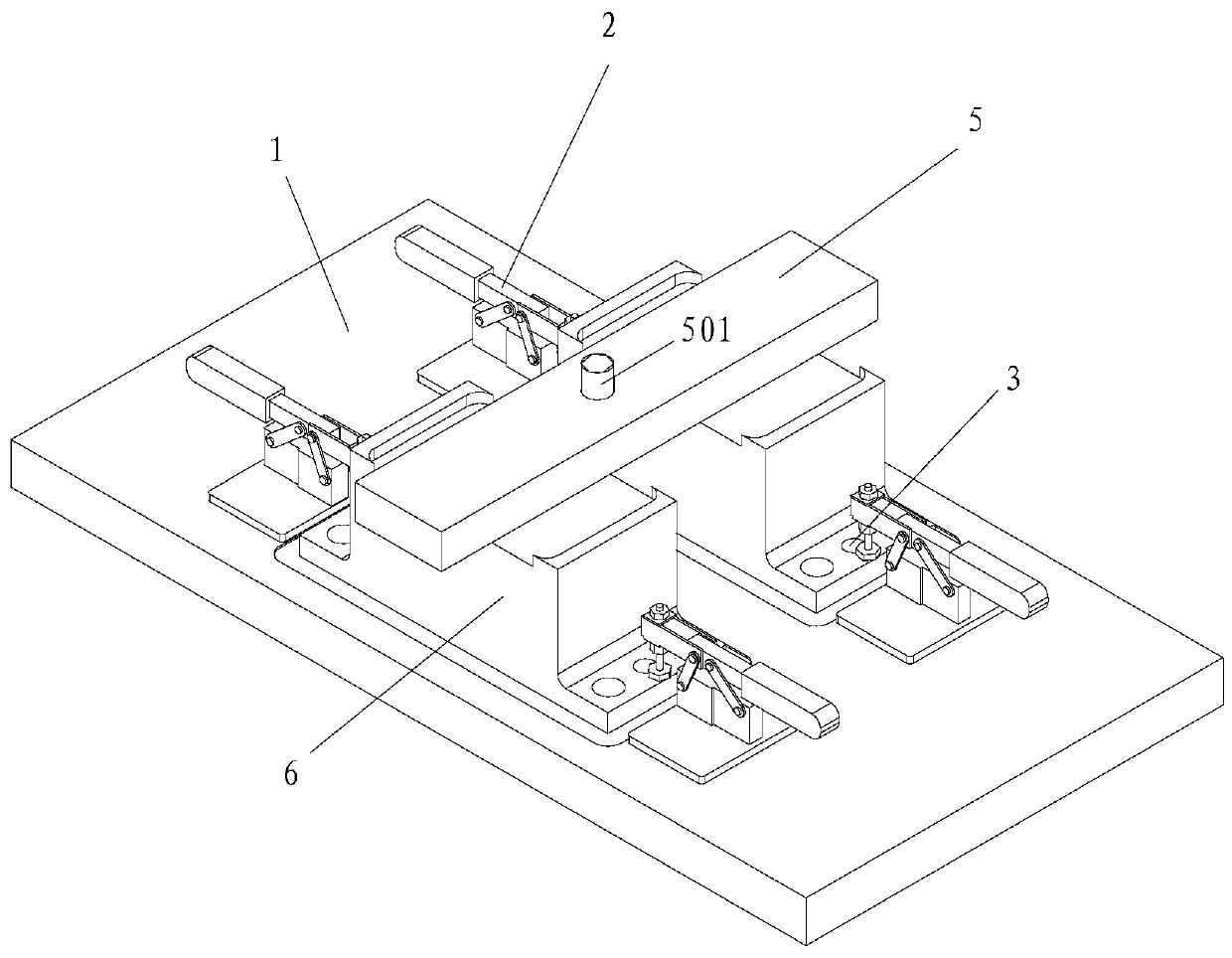

Hydraulic clamp achieving rapid clamping and locating

ActiveCN106041581AFast and accurate loadingAvoid damageWork clamping meansPositioning apparatusEngineeringMachining process

The invention discloses a hydraulic clamp achieving rapid clamping and locating. The hydraulic clamp achieving rapid clamping and locating comprises a base. First installation seats, second installation seats and a third installation seat are arranged on the base. The upper end of each first installation seat is provided with lever cylinders. The side wall of each first installation seat is provided with first stop blocks, a first linear push cylinder and a second linear push cylinder. Each first linear push cylinder and the corresponding second linear push cylinder are orthogonally arranged. Each second installation seat is provided with a second stop block. The third installation seat is provided with a third stop block. The hydraulic clamp achieves rapid clamping and accurate locating, lightens work intensity and improves machining efficiency; and clamped workpieces do not deform in the machining process, and a machining center can conduct displacement and rotation operations on the clamped workpieces beneficially.

Owner:宁波亚吉机电科技有限公司

Precise and rapid shear process of building profile

InactiveCN105537672AGood impetusImprove efficiencyMetal-working feeding devicesNibbling shearing machinesHydraulic cylinderEngineering

The invention discloses a precise and rapid shear process of a building profile. According to the precise and rapid shear process, a conveying belt which is arranged on a rack and conveys materials in the horizontal direction and pressing wheels arranged on the two sides of the conveying belt are included, the material conveying direction of the conveying belt serves the front direction, the front of the conveying belt is provided with a workbench, the surface of the workbench is flush with the conveying belt, the upper portion of the rear edge of the workbench is provided with a scissor plate and a hydraulic cylinder for driving the scissor plate to ascend and descend vertically, and a pressing plate for pressing the profile and an air cylinder for driving the pressing plate to ascend and descend vertically are arranged in front of the scissor plate. The precise and rapid shear process has the advantages that profiles of different sizes can be adapted to, a machine tool can be applicable to the profiles of different sizes, and use efficiency of the machine tool is improved; the pressing plate is arranged so that a precise positioning function can be achieved, and cutting precision is guaranteed.

Owner:SICHUAN YAHAO REAL ESTATE DEV

Elevator brake pad machining device and machining method of elevator brake pad

PendingCN109986386AGuaranteed machining accuracyPrevent reverse installationWork clamping meansMilling equipment detailsNumerical controlEngineering

The invention relates to the field of elevator production, in particular to an elevator brake pad machining device and a machining method of the elevator brake pad. The machining method comprises thesteps of 1, clamping the elevator brake pad on a table vice with the top surface of the elevator brake pad facing upward, and clamping the two short side surfaces; 2, milling the top surface and two long side surfaces of the elevator brake pad by using a first numerical control machine tool; 3, milling two positioning pin holes of the elevator brake pad by using a first numerical control machine tool by taking the long side surfaces as a machining reference; 4, placing the elevator brake pad on a tooling fixture with the bottom surface of the elevator brake pad facing upward, positioning by using a positioning pin shaft, and pressing two thin wings of the elevator brake pad; 5, milling the bottom surface of the elevator brake pad by using a second numerical control machine tool by taking the top surface of the elevator brake pad as a machining reference; and 6, pressing a pressing block on the bottom surface of the elevator brake pad. The machining device and the machining method are used for mass production of elevator brake pads.

Owner:福建省华银铝业有限公司

Fabricated type building system based on inner insertion plate and end plate connection beam-column joint

The invention discloses a fabricated type building system based on an inner insertion plate and end plate connection beam-column joint. A lower column module comprises a lower column. A first supportplate, a first end plate and an inner insertion plate are installed on each lower column. An upper column module comprises upper columns. Each upper column is provided with a second support plate. Theupper columns are correspondingly inserted into the inner insertion plates of the lower columns and are connected with the inner insertion plates through bolts. A beam module comprises main beams andauxiliary beams. Webs of the main beams and the auxiliary beams are provided with reserved wire passing holes. The two ends of the main beam are provided with second end plates. By means of connection between the first end plates and the second end plates, connection between the main beam lower flanges and the first support plates and connection between main beam upper flanges and the second support plates achieve connection of all the modules through bolts. The beams and the columns can adopt full bolt on-site assembly, the assembly speed is rapid, and the construction period is shortened. Ribbed support plates achieve the locating function on the beams and bear part of bending moment. The inner insertion plates can facilitate installation of an upper column and a lower column and lowerthe hoisting difficulty. The arranged ribbed support plates and the end plates achieve outward movement of plastic hinges. A pipeline is separated from a body structure, so that overhauling is convenient, and headroom is improved.

Owner:BEIJING UNIV OF TECH

Sensor, manufacturing method thereof, and electronic device

ActiveCN111463190BPlay the role of precise positioningEliminate glue applicationSemiconductor/solid-state device detailsSolid-state devicesCooling effectElectromagnetic interference

The invention discloses a sensor, a manufacturing method thereof, and electronic equipment. Wherein, the sensor includes: a substrate, the substrate is provided with a pad and a first conductive structure that are insulated from each other and partially exposed on the surface, and a surface of the substrate is also provided with a pad that is electrically connected to the pad. The heat conduction limiting groove; the integrated circuit chip, the integrated circuit chip is arranged in the heat conduction limiting groove, and is electrically connected to the first conductive structure through the connecting wire; and the shielding structure, the shielding structure includes cover the integrated circuit chip. The technical scheme of the invention can shield the chip from external electromagnetic interference, and at the same time improve the cooling effect of the chip.

Owner:QINGDAO GOERTEK INTELLIGENT SENSOR CO LTD

A prefabricated building system based on interposers and splints connecting beam-column nodes

The invention discloses an assembled building system based on inner insertion plate and clamping plate connecting beam column nodes. A lower column module comprises lower columns; all the lower columns are provided with first support plates, outer extension plates and inner insertion plates; an upper column module comprises upper columns; all the upper columns are provided with second support plates; the upper columns are correspondingly inserted in the inner insertion plates of the lower columns, and are connected through bolts; a beam module comprises a main beam and a secondary beam; wire passing holes are reserved on web plates of the main beam and the secondary beam; and the connection of all the modules is realized through bolts among the main beam web plate, the outer extension plates and clamping plates, between a main beam lower flange and the first support plates and between a main beam upper flange and the second support plates. Beam columns can be assembled in scene only byadopting bolts, so that the assembly speed is high, and the construction period is shortened. Ribbed support plates achieve a positioning effect on the beams to bear part of the bending moment. The upper and lower columns are conveniently installed by the inner insertion plates to reduce the lifting difficulty. The ribbed support plates and the clamping plates are provided to realize outer shifting of plastic hinges. Pipelines are separated from a main body structure, so that the maintenance is convenient, and the clearance is improved.

Owner:BEIJING UNIV OF TECH

A fully automatic energy-saving plastic dropping method

The invention discloses a fully-automatic energy-saving drip molding method which is characterized by comprising the following steps: positioning, namely placing a mold on a one-cylinder four-claw system; carrying out drip molding, namely pushing the mold into a drip molding system through a telescopic cylinder; heating, namely pushing the mold into a heating system through the telescopic cylinderafter a product is formed on the mold through drip molding; cooling, namely heating the drip molded product on the mold, and pushing the mold into a cooling system through the telescopic cylinder; transferring, namely pushing the cooled mold into a transferring system 5 through the telescopic cylinder; clamping, namely transferring the mold into a clamping system; and demolding, namely pushing the mold into a demolding system through the telescopic cylinder. Through steps of positioning, drip molding, heating, cooling, transferring, clamping and demolding, a spraying molding product is moldedon one production line, fully-automatic production is achieved, and the production efficiency is improved.

Owner:遂宁市金虹机械厂

A cylinder head assembly and compressor

ActiveCN109488570BSmall sizeAvoid rotational movementPositive displacement pump componentsPositive-displacement liquid enginesExhaust valveCylinder head

The invention discloses a cylinder end assembly and a compressor. The cylinder end assembly and the compressor are used in the field of compressors. The cylinder end assembly comprises a cylinder seatand a cylinder end component. The cylinder end component comprises an air suction valve plate, a valve plate, an exhaust valve plate and a cylinder head. The cylinder end component is circular. A cylinder hole is formed in the cylinder seat. The cylinder end component is installed at the front end of the cylinder hole of the cylinder seat through fasteners. A radial positioning fence is arrangedon the cylinder seat. A rotary limiting groove is formed in the radial positioning fence. The air suction valve plate, the valve plate and the exhaust valve plate are all provided with rotary limitingprotrusions matched with the rotary limiting groove. The compressor comprises the cylinder end assembly. The cylinder end component adopts a circular design, and the cylinder end component is installed on the cylinder seat through the fasteners, so that the overall size of the cylinder end component is saved, the material is saved, the weight is reduced, the cost is reduced, and the vibration noise generated when the compressor works is reduced; and meanwhile, the cylinder end component adopts the circular design, and the rotary limiting groove is matched with the rotary limiting protrusionsof the cylinder end component, so that the cylinder end component is prevented from rotationally moving, and the function of accurate positioning is played.

Owner:WANBAO GROUP COMPRESSOR CO LTD

Welding positioning device

InactiveCN104785984AImprove welding efficiencyImprove welding qualityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding

The invention discloses a welding positioning device which comprises a backing plate, clamping plates, a working table, an installing plate, positioning blocks, a welding plate and positioning grooves. The installing plate is located at the top of the working table, the positioning blocks are located on the periphery of the installing plate and connected with the installing plate in a welding mode, the welding plate is located at the upper ends of the positioning blocks and connected with the positioning blocks in a sliding mode, and the positioning grooves are located on the edges of the top of the welding plate and are in a rectangular shape. According to the welding positioning device, the backing plate is firstly arranged on the upper portion of the installing plate, the fine positioning function can be achieved through the positioning blocks on the periphery, then the welding plate is arranged, the clamping plates are lastly arranged in the positioning grooves in the welding plate to achieve quick positioning, and then welding can be directly conducted. The welding steps are simplified, and the welding efficiency and quality of the clamping plates can be greatly improved.

Owner:池州信安电子科技有限公司

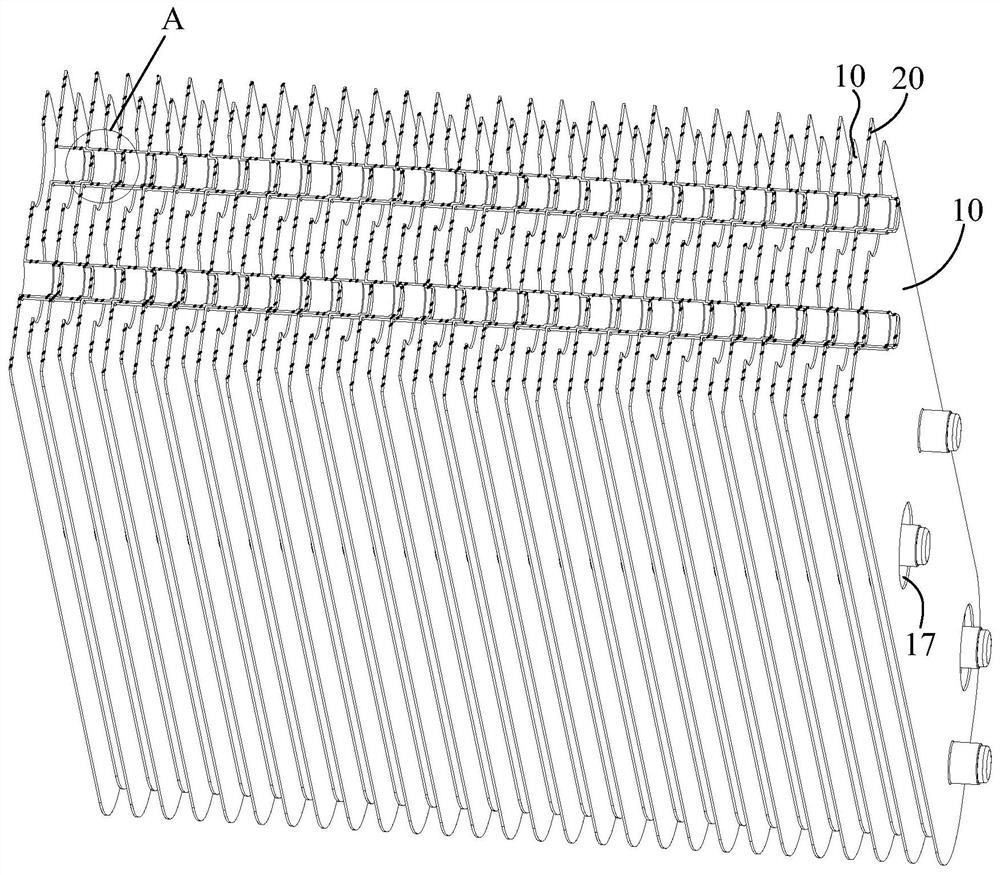

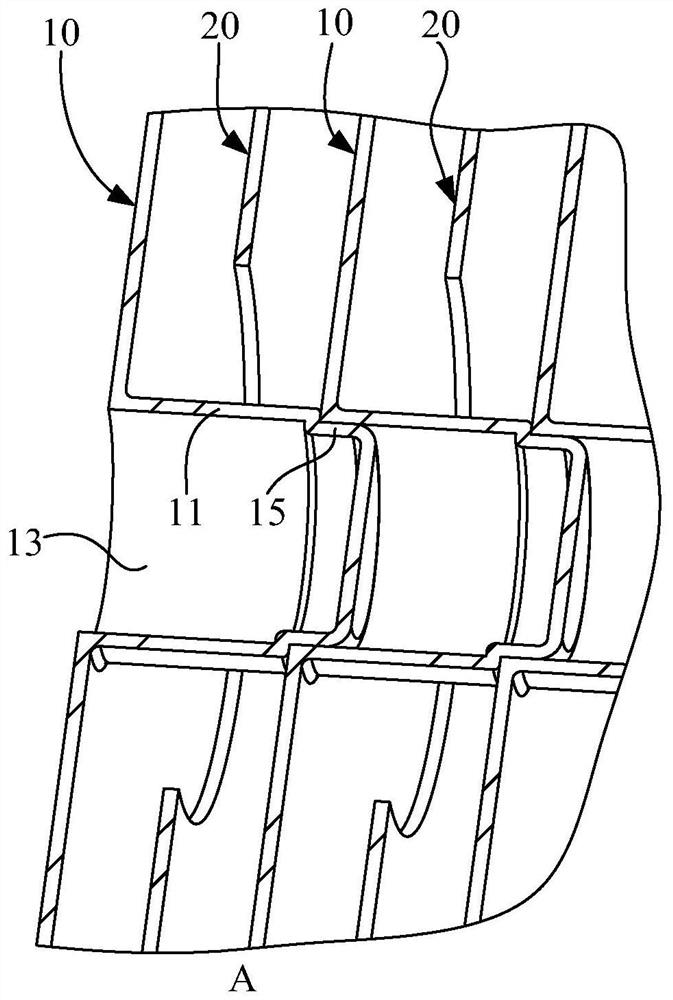

Purifier plate assembly and purifier

ActiveCN110801939BEasy to installImprove efficiencyElectrode carrying meansElectrode constructionsStructural engineeringMechanical engineering

The invention relates to the technical field of purifiers, in particular to a purifier plate assembly and a purifier. The purifier plate assembly includes a high-voltage plate and a low-voltage plate, the high-voltage plate and the low-voltage plate are arranged at intervals, and the high-voltage plate is formed with a first installation boss facing the adjacent high-voltage plate. The pole plate is formed with a first installation groove that cooperates with the first installation boss, and the two adjacent high-voltage pole plates are supported by the first installation boss and the first installation groove, and the low-pressure pole plate is formed with a first Install the second avoidance groove of the boss, and the high-voltage plates are continuously superimposed to realize reliable installation. Compared with the connection method that adopts the guide post and the sleeve in the prior art, the parts required for the purifier to install the high-voltage plates are more. Less, the overall structure is more concise, higher efficiency and lower cost in mass production.

Owner:GREE ELECTRIC APPLIANCES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com