Hydraulic clamp achieving rapid clamping and locating

A hydraulic fixture and clamping technology, applied in the field of hydraulic fixtures, can solve problems such as inaccurate positioning, unfavorable clamping workpiece displacement and rotation, time-consuming and labor-intensive bolts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

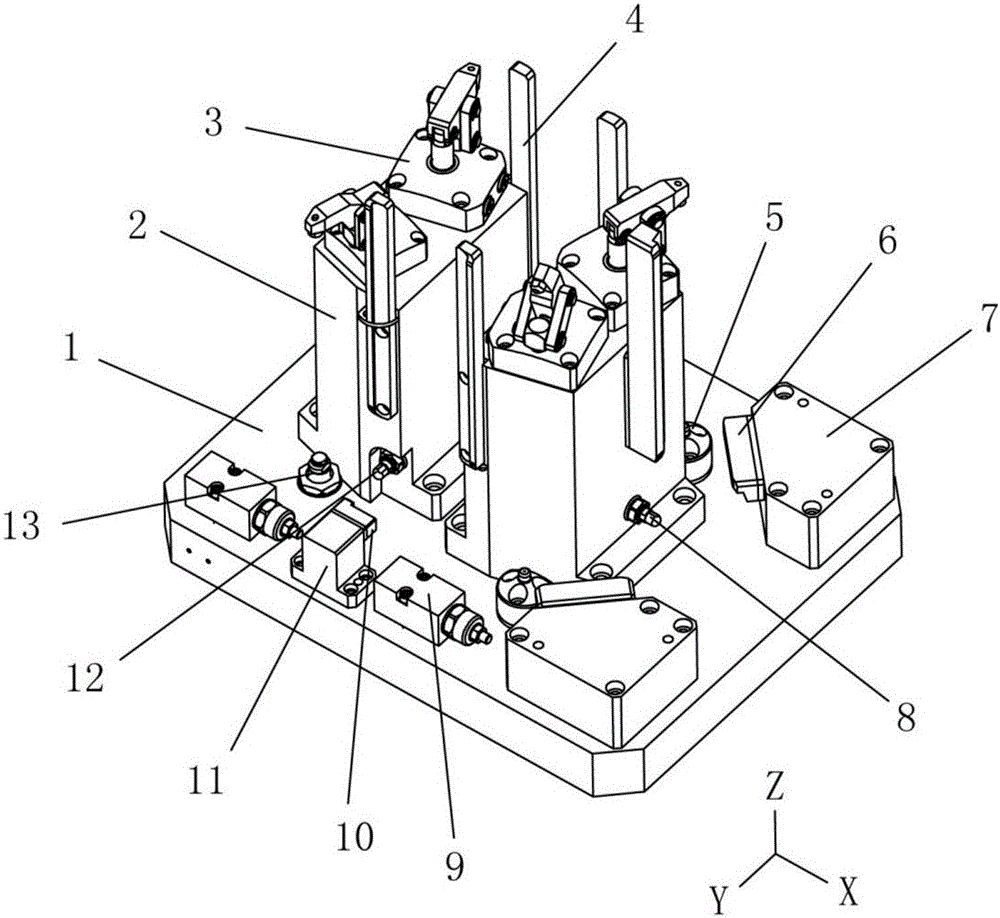

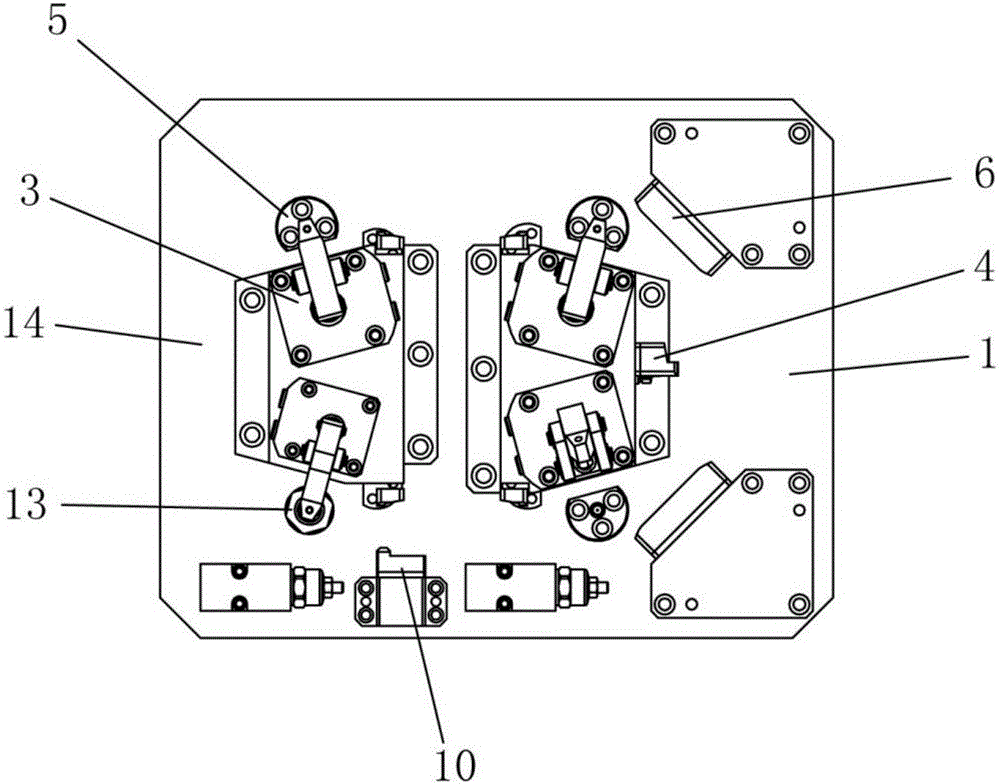

[0017] The present invention is further explained in conjunction with the accompanying drawings.

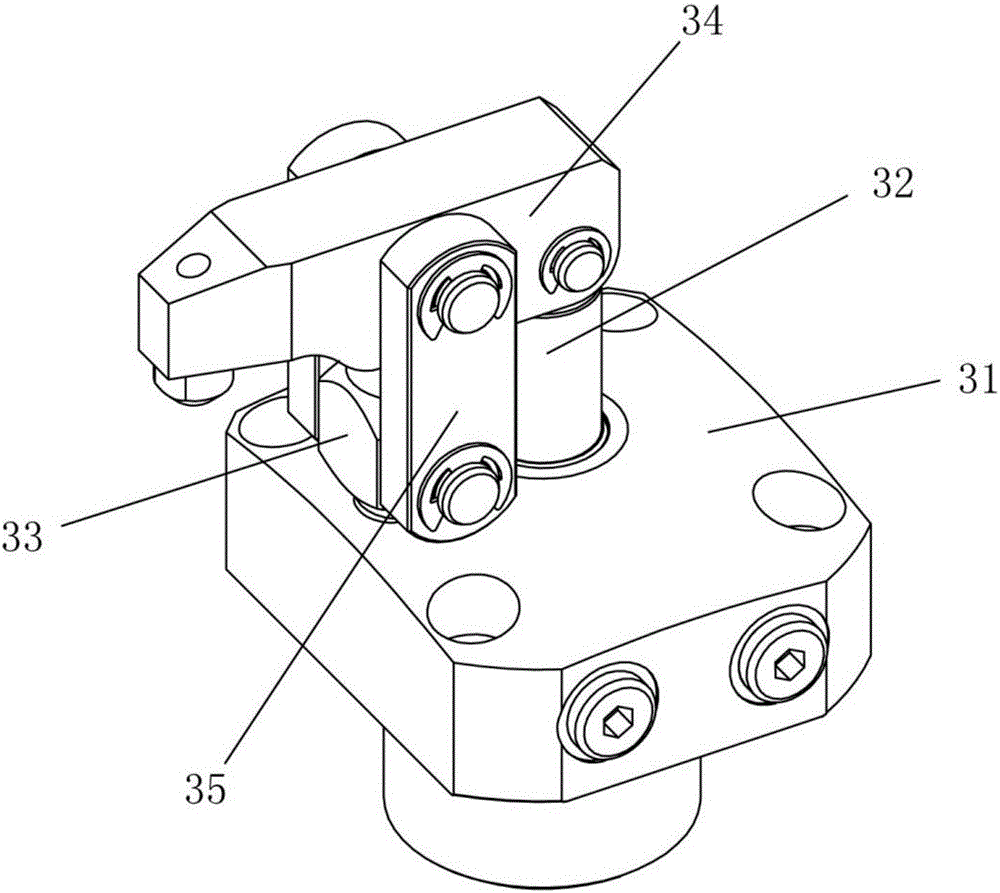

[0018] see Figure 1 to Figure 5 , a hydraulic fixture for fast clamping and positioning, including a base 1, two first mounting seats 2, two second mounting seats 7 and a third mounting seat 11 are arranged on the base 1, two first mounting seats 2 The upper end of each is provided with two lever cylinders 3, and the lever cylinder 3 includes a cylinder body 31, a piston rod 32, a nut 33, a pressure rod 34 and a connecting rod 35, and the cylinder body 31 is fixedly installed on the first mount 2, and the piston Rod 32 protrudes from the upper end of cylinder body 31, nut 33 is fixedly mounted on cylinder body 31, one end of connecting rod 35 is hinged with nut 33, the other end of connecting rod 35 is hinged with the middle of pressure rod 34, and one end of pressure rod 34 is hinged with piston rod 32 , the other end of the pressure rod 34 cooperates with the upper end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com