Automatic tray loading system and tray loading method for large infusion robot

A large infusion and robot technology, applied in transportation and packaging, packaging automatic control, packaging, etc., can solve the problems of inability to ensure accurate positioning of large infusion, slow speed, poor stability, etc., to achieve shortening the disc replacement gap, accurate grasping, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

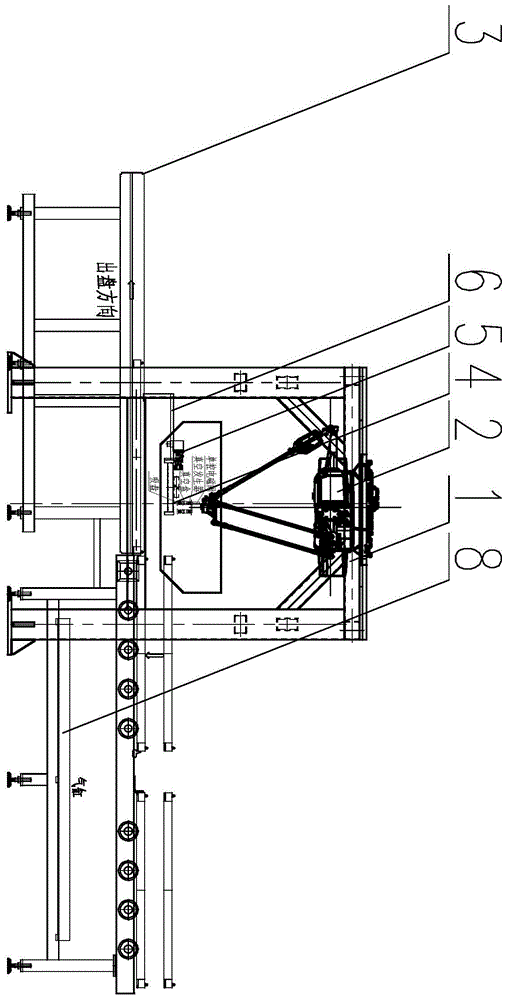

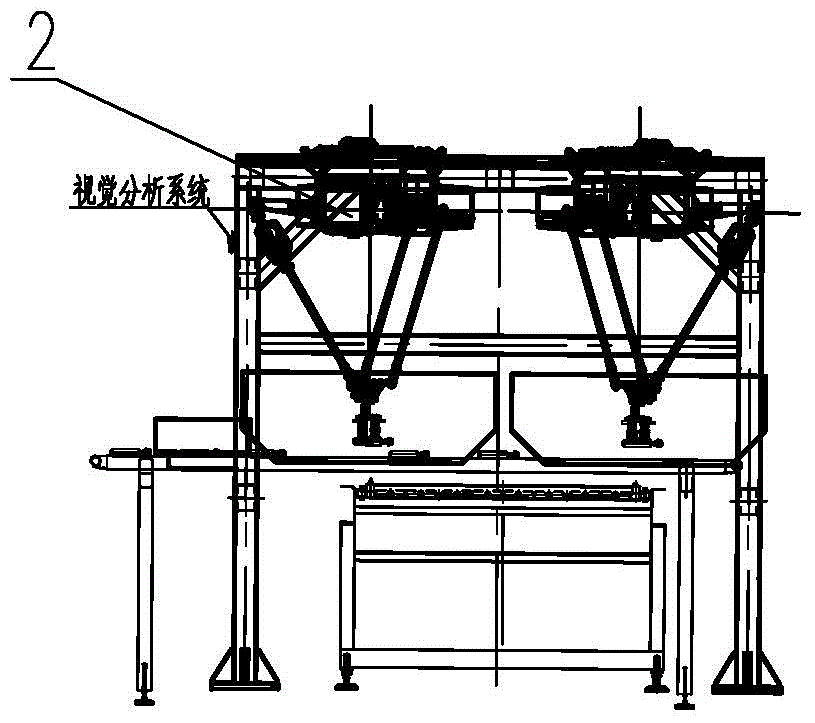

[0043] Embodiment 1: as figure 1 and figure 2 As shown, the automatic tray loading system for large infusion robots includes a bracket 1, on which a series robot assembly 2 is installed, on which the series robot assembly 2 is provided with a visual sensor, and a stepping conveyor 3 for sterilizing trays is provided for sterilizing trays. The bacteria tray stepping conveyor 3 passes through the support 1 and is located below the series robot assembly 2. A large infusion feeding conveying belt conveyor 4 is arranged between the series robot assembly 2 and the sterilization tray stepping conveyor 3, and the large infusion feeding The conveyor belt conveyor 4 is provided with an encoder 5, the support 1 is provided with a disk changing gap buffer assembly 6, and a control device is provided. The control end of the material conveying belt conveyor 4, the encoder 5 and the visual sensor are connected to the communication port of the control device.

Embodiment 2

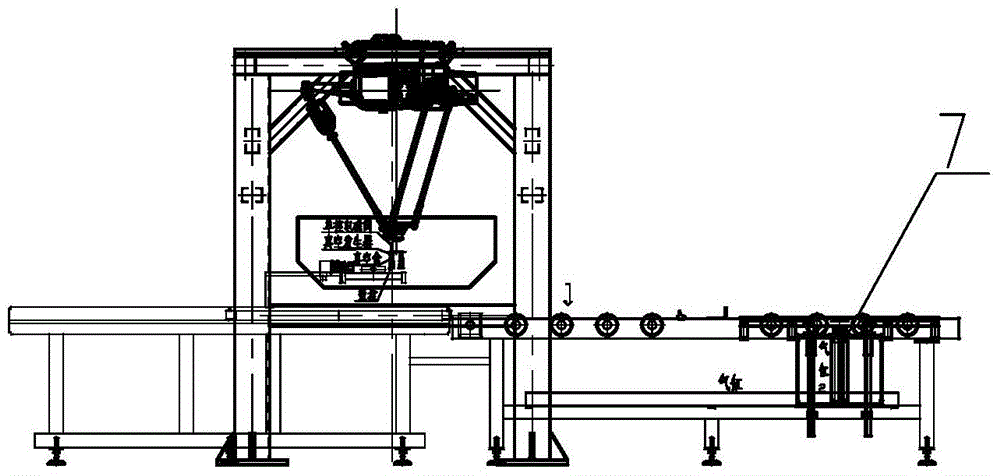

[0044] Embodiment 2: On the basis of the structure described in Embodiment 1, a slide rail is provided on the stepping conveyor 3 for sterilization trays, and a jacking cylinder 7 is provided on the slide rail, and a tray is provided on the jacking cylinder 7 for sterilization. The disc stepping conveyor 3 is provided with a horizontal cylinder 8 parallel to the slide rail, the movable end of the horizontal cylinder 8 is connected to the jacking cylinder 7, and the signal ends of the jacking cylinder 7 and the horizontal cylinder 8 are connected to the communication port of the control device.

Embodiment 3

[0045] Embodiment 3: On the basis of the structure described in Embodiment 2, a hard limit device and a shift block are provided on the sterilization tray stepping conveyor 3, and the series robot assembly includes two robot arms connected in series, and the robot arm is provided with Vacuum pick and place components.

[0046] Below in conjunction with the present invention, the embodiment of the method for automatically loading large infusion robots will be further described:

[0047] Embodiment 1: as image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 and Figure 8 As shown, the large infusion robot automatic loading system described in claim 1 is used for loading, and the large infusion produced by the large infusion production line is coordinated through the large infusion feeding conveying belt conveyor, so that the large infusion feeding conveying belt conveyor can The large infusion is transported to the loading station, and the specific steps are:

[0048] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com