Elevator brake pad machining device and machining method of elevator brake pad

A technology for elevator brake pads and processing devices, applied to positioning devices, clamping devices, metal processing equipment, etc., can solve time-consuming and labor-intensive problems, reduce tool change time, standardize processing procedures, improve utilization rate and work efficiency of workers Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

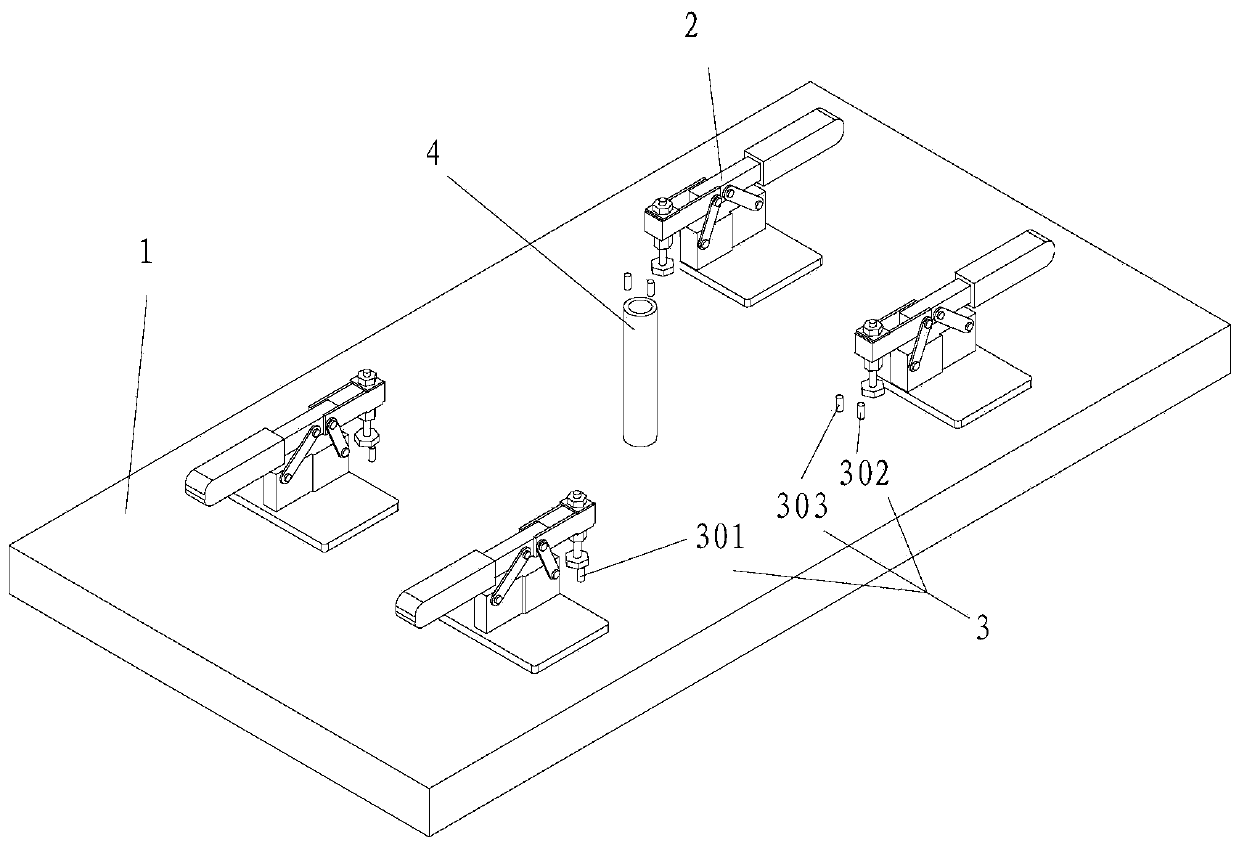

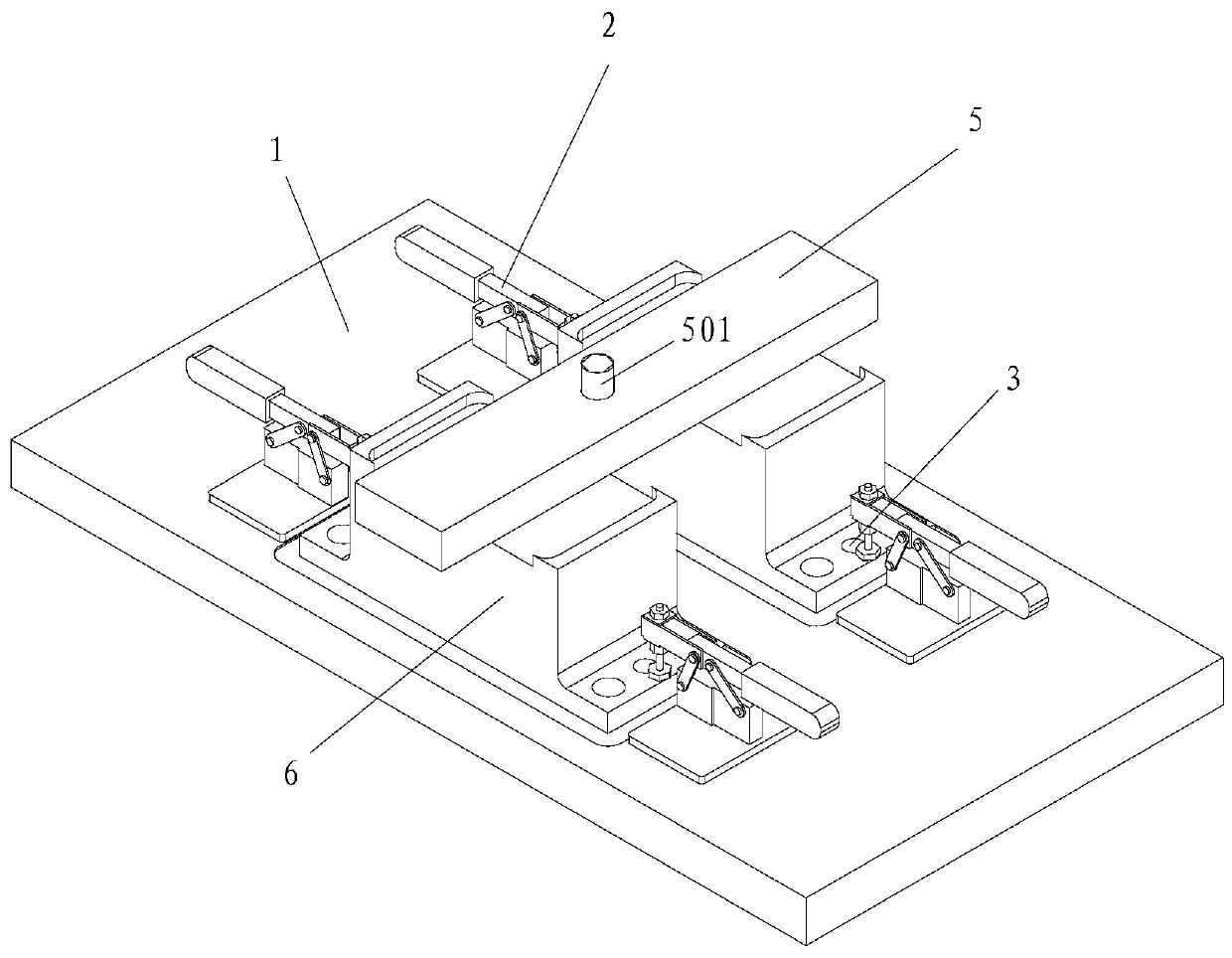

[0070] Refer to attached figure 1 and 2 , a brake pad processing device for an elevator, comprising a bench vise, a first numerically controlled machine tool, a fixture and a second numerically controlled machine tool; On the processing table of the second CNC machine tool; the fixture includes a base 1, a clamping portion 2 and a positioning pin 3; there are multiple clamping portions 2, and gaskets are provided on the base, and the positioning The pin shaft 3 is fixedly connected to the base 1 through a gasket, and there are multiple positioning pin shafts 3; the positioning pin shaft 3 includes a first positioning pin 301, a second positioning pin 302 and an error prevention pin 303; A locating pin 301 and a second locating pin 302 are used to locate the locating pin hole on the elevator brake pad, and the error-preventing pin 302 is used to locate any bolt hole on the side where the bolt hole on the elevator brake pad is collinear with the locating pin hole; The clamping...

Embodiment 2

[0073] Most of the contents of an elevator brake pad processing device in Embodiment 2 are the same as in Embodiment 1, except that the tooling fixture also includes an anti-collision block,

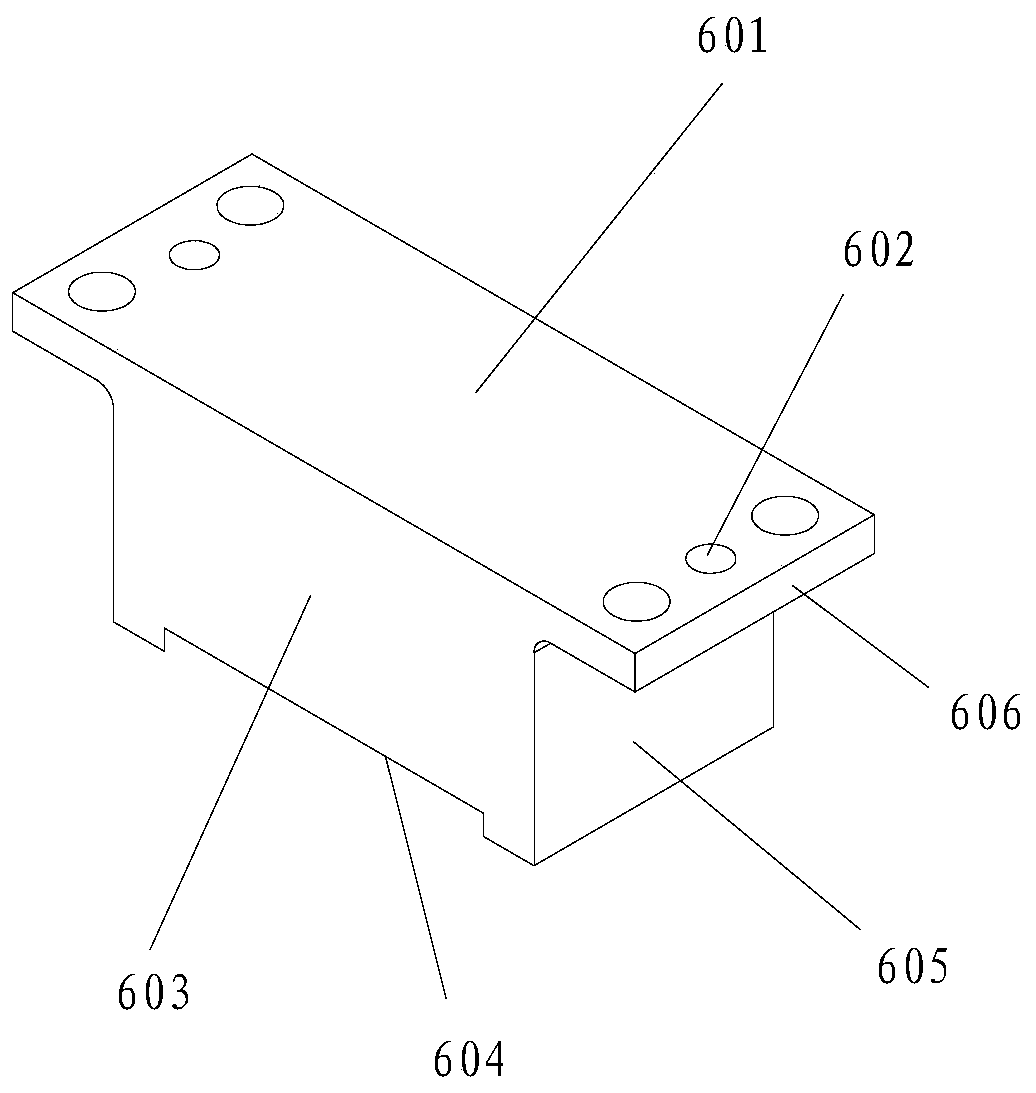

[0074] Such as Figure 6 and Figure 7 As shown in the anti-collision block, the anti-collision block is fixedly connected to the bottom of the pressure block, the anti-collision block is provided with a slot, and the top of the tension rod is provided with a bump, and the tension rod is clamped by the bump. Connected to the slot of the anti-collision block.

[0075] When processing the long side of the elevator brake pad on the side of the tension rod, toggle the tension cylinder switch to retract the tension rod into the cylinder body, and the height of the cylinder body is lower than the height of the gasket. Therefore, when processing the side of the elevator brake pad, The tool will not cut to the first connecting part at the top of the tension rod; when processing the two short s...

Embodiment 3

[0077] A method for processing elevator brake pads by an elevator brake pad processing device;

[0078] The elevator brake pad processing device includes a bench vise, a first numerically controlled machine tool, such as figure 1 Shown fixture and the second CNC machine tool; the bench vise is fixed on the processing table of the first CNC machine tool, and the tooling fixture is fixed on the processing table of the second CNC machine tool; the tooling fixture includes a base 1. The clamping part 2 and the positioning pin shaft 3; the middle part of the base 1 is fixedly connected with a fixing nut 4, and there are four clamping parts 2, and the clamping part 2 is rotatably connected to the base 1, and the positioning The pin shaft 3 is fixedly connected on the base 1, and there are two positioning pin shafts 3; the positioning pin shaft 3 includes a first positioning pin 301, a second positioning pin 302 and an error prevention pin 303; the first positioning pin The second p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com