A fully automatic energy-saving plastic dropping method

A fully automatic, drop plastic technology, applied in the direction of coating, etc., can solve the problems of low degree of automation and inability to realize mass production on the production line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

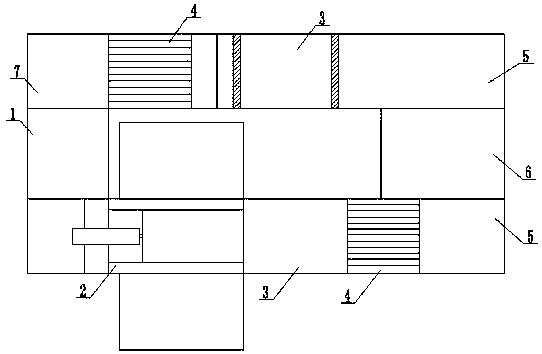

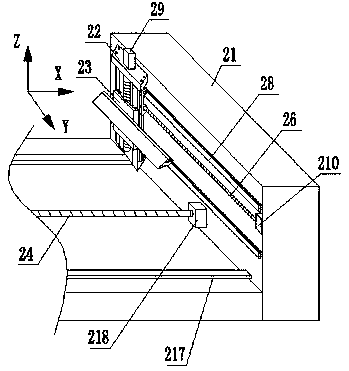

[0092] Such as Figures 1 to 51 Shown, a kind of fully automatic energy-saving dropping plastic method, comprises the following steps:

[0093]a, Positioning, place the mold on the one-cylinder four-claw system 1, when the sensor XQGY2 senses the mold, the cylinder A12 moves down to the right, pushing the first clip 16, the first clip 16 passes through the telescopic rod A15 and the first The shift fork 14 rotates the first baffle 13 inward, and the two first baffles 13 fix the mold in the right-angle rod 11 to position the mold, then the cylinder A12 moves upward to the left, and the first baffle 13 returns to its original shape and loosens mold;

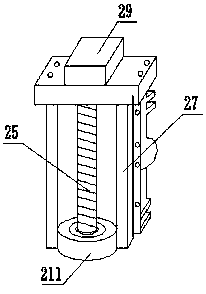

[0094] b, drop plastic, the mold is pushed into the drop plastic system 2 through the telescopic cylinder, and the telescopic cylinder sends the two molds to the slide plate, firstly, the first mold 22212 and the second mold 22213 are respectively sent to the two slide plates 2229, 22214 First, start the motor A2226 to drive the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com