Fixture for welding positioning of micro-diameter thin-walled pipe of heat exchanger

A technology for welding positioning and thin-walled tubes, which is applied in the field of aerospace science and can solve problems such as the inability to meet the precise positioning requirements of micro-diameter thin-walled tubes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

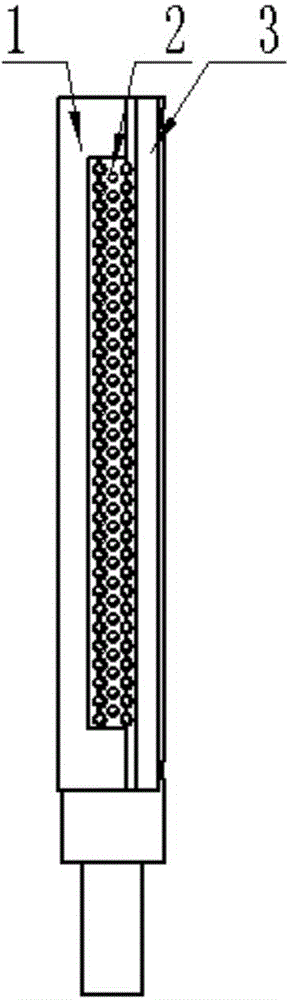

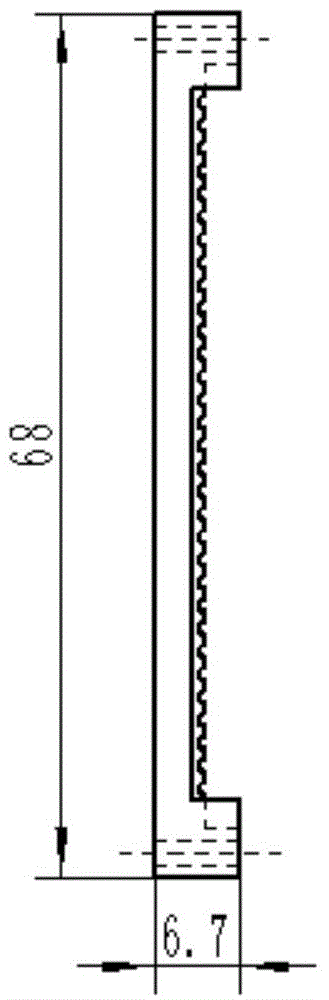

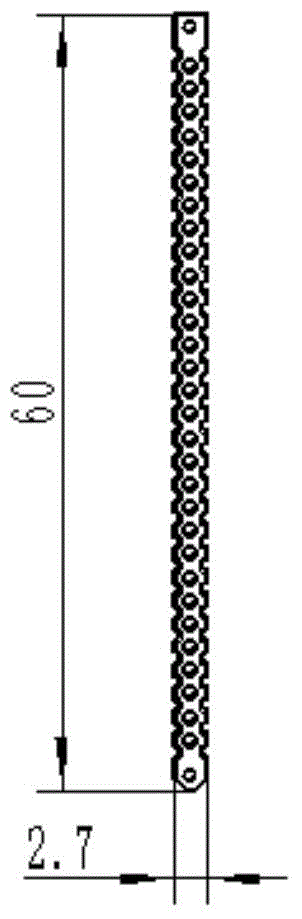

[0025] See figure 1 — Figure 4 , the invention is a fixture for welding and positioning micro-diameter thin-walled tubes of heat exchangers. It mainly includes movable fixture 1, partition plate 2, and fixed fixture 3 parts. The positional relationship between them is: the partition plate 2 is inserted into the transverse groove of the movable fixture 1, and the semicircular holes at both ends are paired and coupled; then the movable fixture 1 is installed on the section of the fixed fixture 3 and fixed by upper and lower screws.

[0026] When the fixture is working, firstly, the second row of micro-diameter thin-walled tubes are passed through a series of circular holes in the middle of the partition plate 2, and then the first row of micro-diameter thin-walled tubes are placed in a series of semicircular holes in the fixing fixture 3, Then let the partition plate 2 cooperate with the fixing fixture 3, so that a series of semicircular holes of the parts are coupled and pai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com