Method for using guiding and locating box cone component and guiding and locating box cone

A technology of guide positioning and box cone, which is applied in the direction of mold boxes, casting molding equipment, metal processing equipment, etc., can solve the problems of increasing the weight of box cones, increasing the working intensity of box closing, and lack of meat in castings, so as to reduce labor intensity and reduce The difficulty of closing the box, avoiding the effect of rubbing sand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

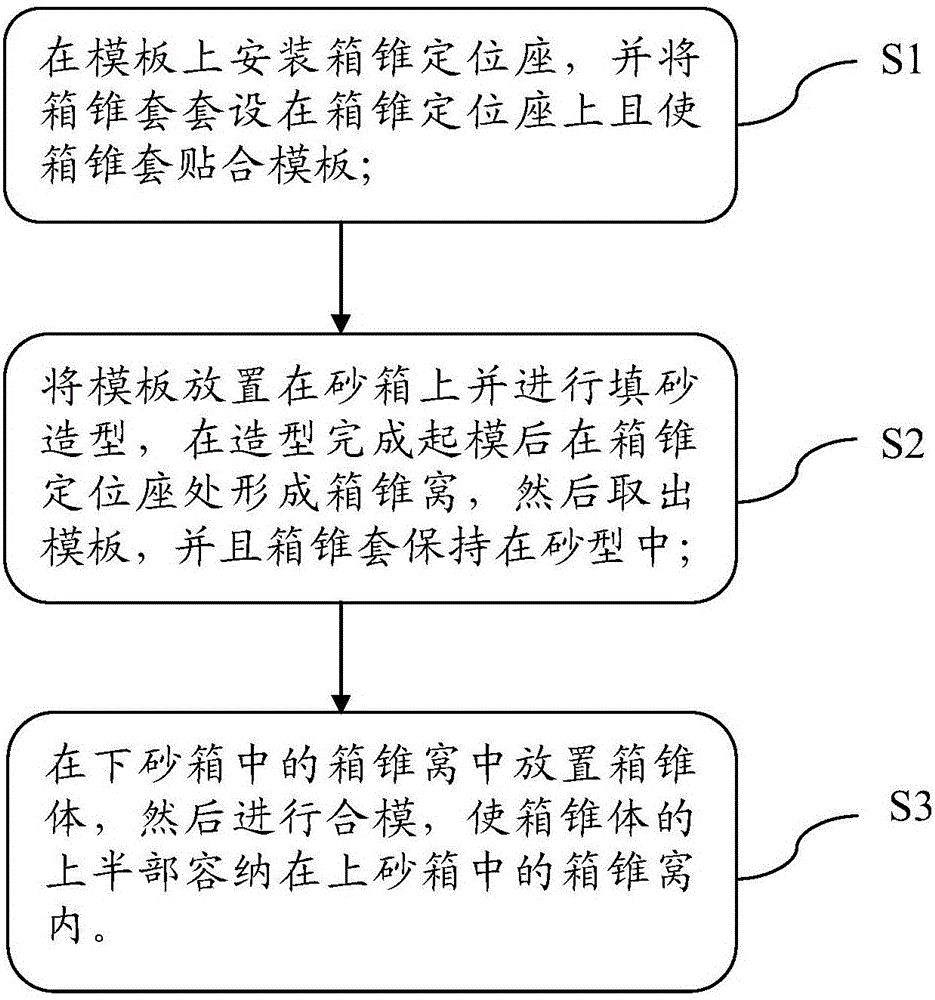

[0031] Such as Figure 1 to Figure 5 As shown, one embodiment of the present invention provides a method for using a guiding and positioning box cone assembly for casting production, including:

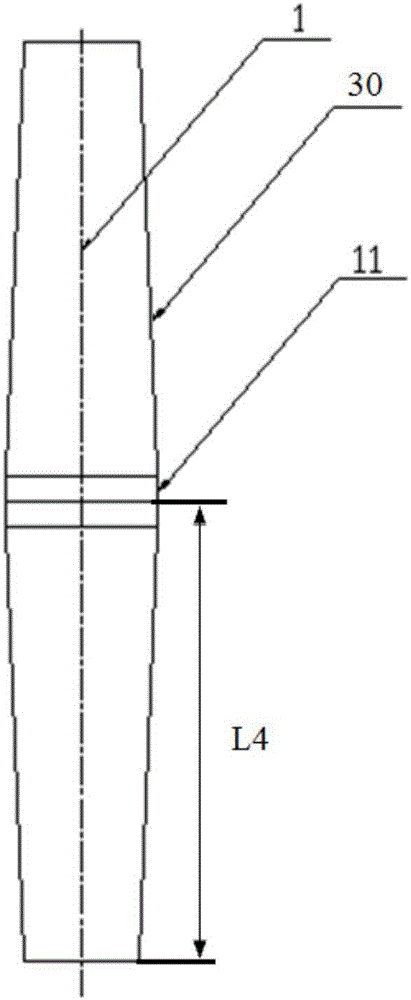

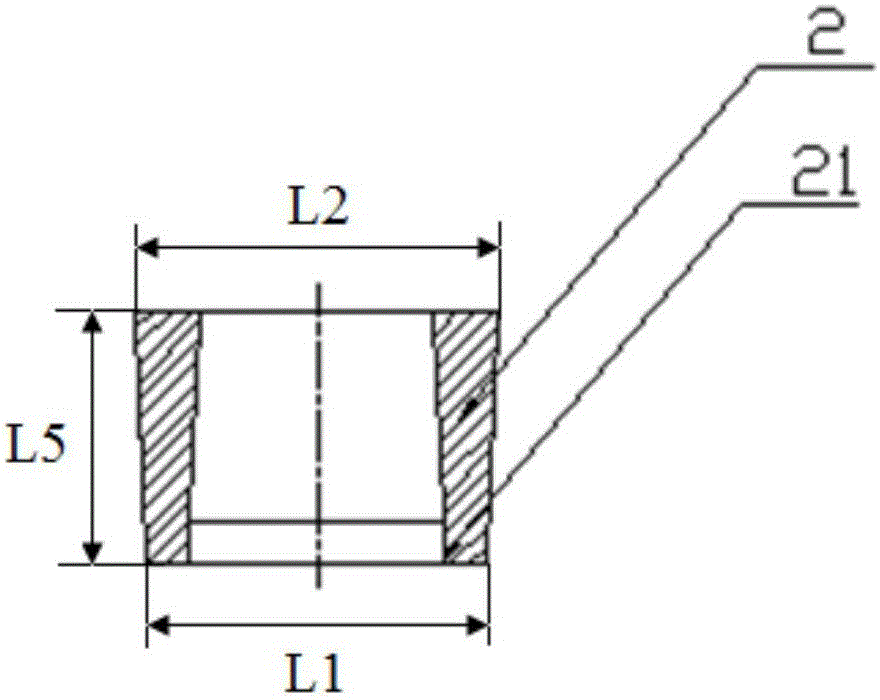

[0032] S1: Install the box cone positioning seat 3 on the template, set the box cone sleeve 2 on the box cone positioning seat 3 and make the box cone sleeve 2 fit the template;

[0033] S2. Place the template on the sand box and carry out sand-filling molding. After the molding is completed, the box cone socket 4 is formed at the box cone positioning seat 3, and then the template is taken out, and the box cone sleeve 2 is kept in the sand mold;

[0034] S3. Place the box cone 1 in the box cone socket 4 in the lower sand box 6, and then close the mold so that the upper half of the box cone 1 is accommodated in the box cone socket 4 in the upper sand box 5.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com