Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

185results about How to "Meet the requirements of green construction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

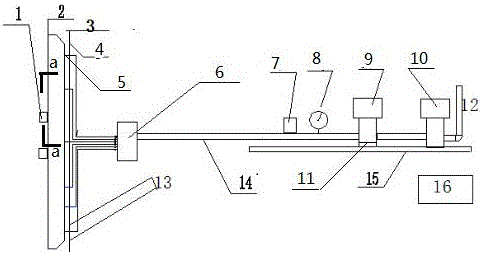

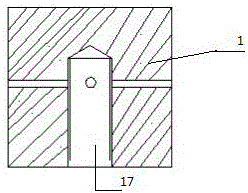

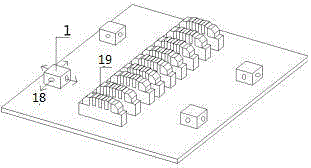

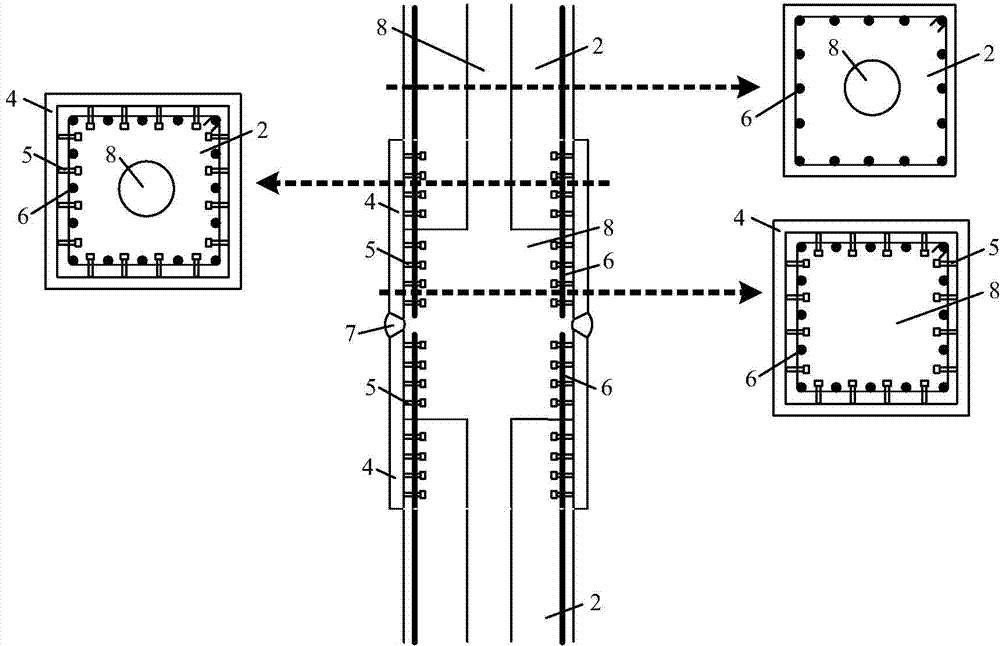

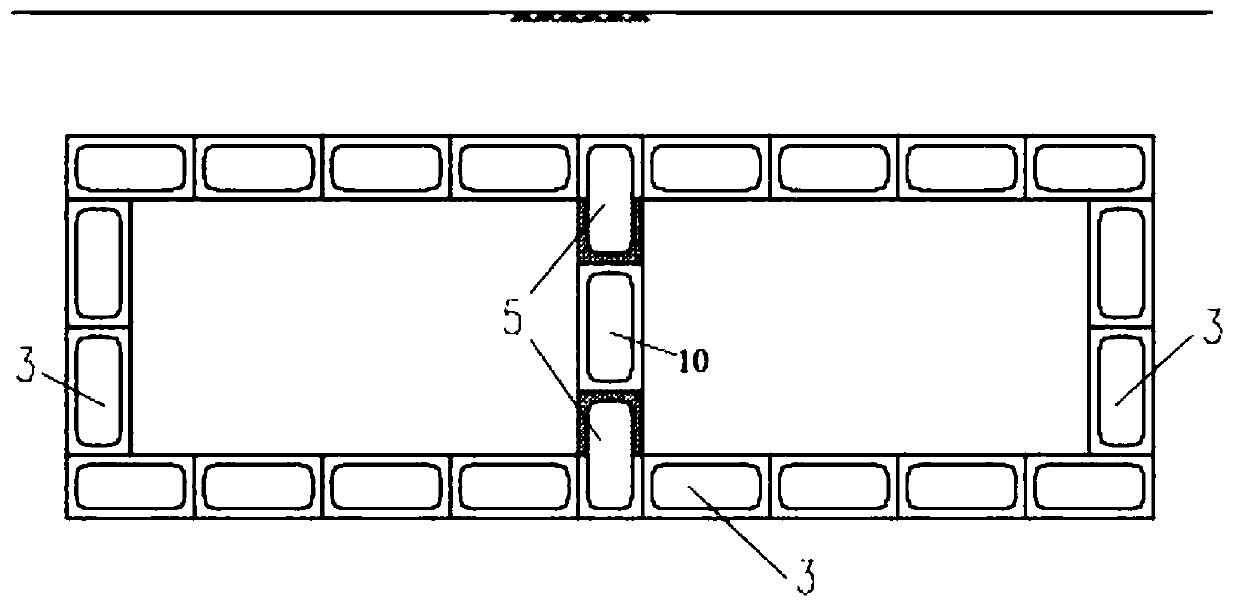

Earth pressure balance shield mud cake prevention system based on synchronous jet flow

ActiveCN106285699AAvoid the risk of mudcake formationImprove abilityTunnelsStructure of the EarthSprayer

The invention provides an earth pressure balance shield mud cake prevention system based on synchronous jet flow. The system comprises a panel fixed sprayer, a cutterhead, a shield body, a soil warehouse separating plate, flushing guns, a flushing position location and tube connection, a high pressure pipeline and pipes, a water separator, a safety valve, a pressure gauge, a high pressure newly increased centrifugal pump, an original centrifugal pump, a base, a water supply pipe, a screw conveyor, a controller and a second trolley. The system provided by the invention has the advantages that working efficiency is high, cost is low, equipment investment is low, operation is simple, no dead angle flushing is carried out on the back of the cutterhead, a bracket of the cutterhead and the soil warehouse separating plate by virtue of the flushing guns at different positions of the soil warehouse separating plate, nozzles of the flushing guns are designed into different specifications, and axial four-hole, axial one-hole and radial four-hole structures are contained, so as to meet flushing requirements of different parts; no dead angle flushing is carried out on a cutter at the center part of the cutterhead by virtue of the panel fixed sprayer of the cutterhead; and mud cake flushing and shield tunneling are synchronous, and mud cake prevention does not influence normal shield tunneling.

Owner:NANCHANG UNIV +2

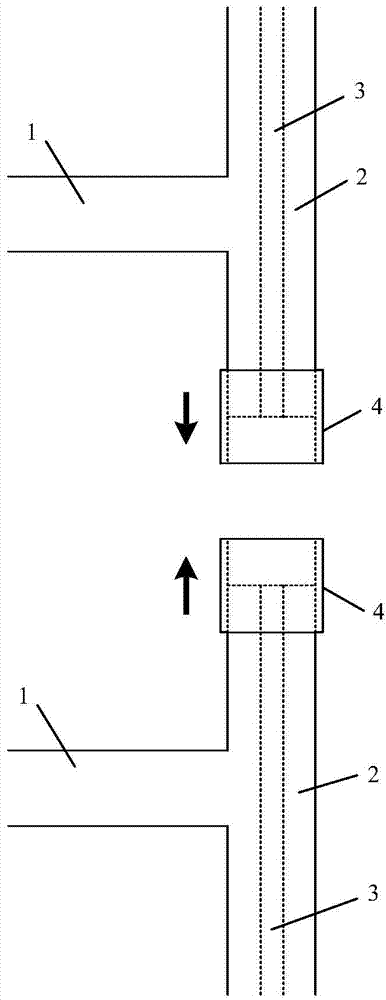

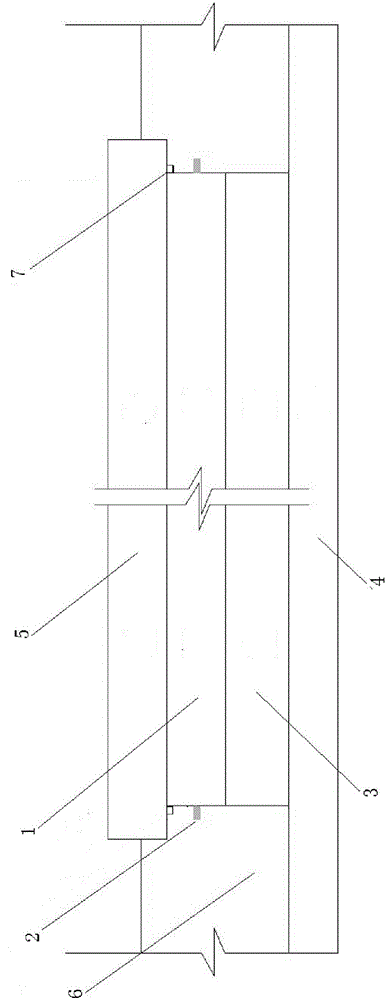

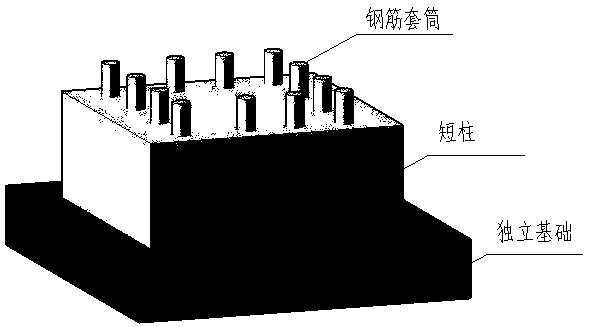

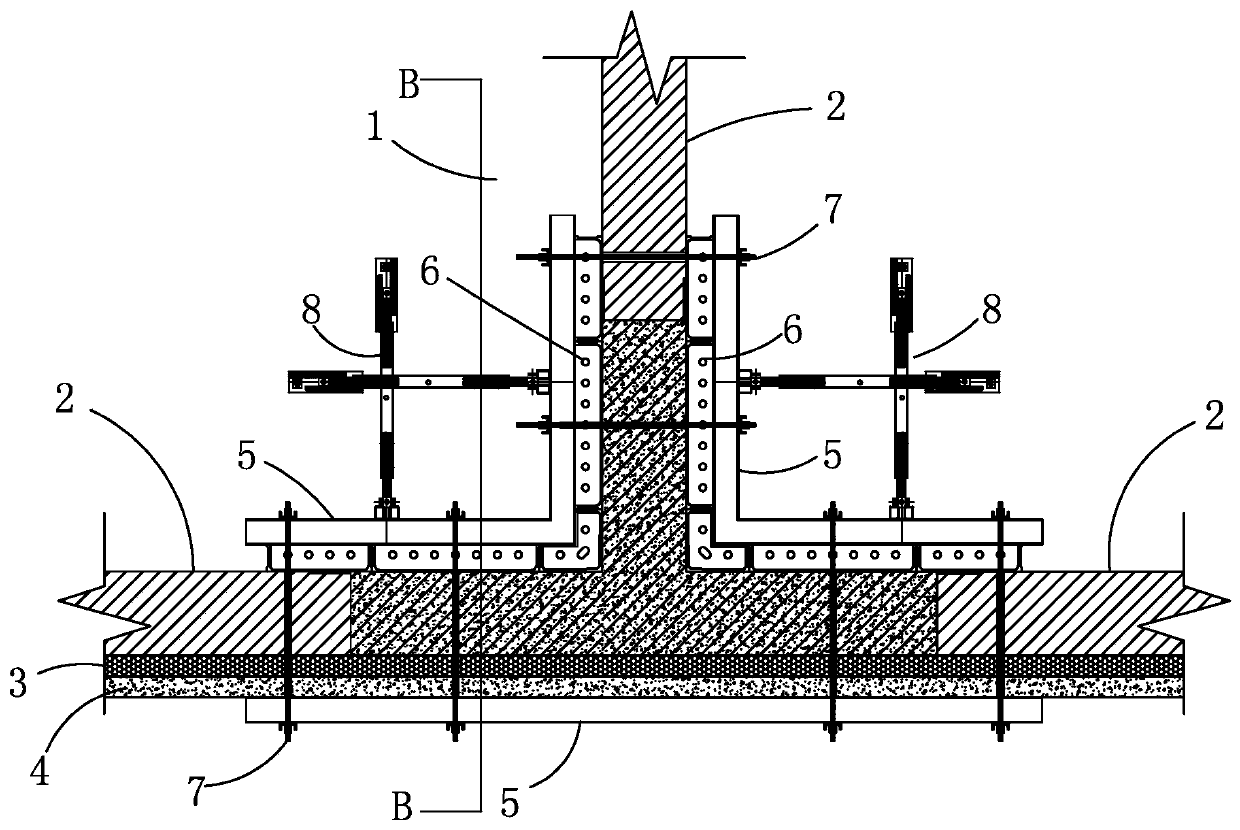

Field connecting method among prefabricated reinforced concrete columns

ActiveCN104775516AGuarantee construction quality and seismic performanceSimple structureBuilding constructionsRebarReinforced concrete column

The invention relates to a field connecting method among prefabricated reinforced concrete columns, facilitates to realize a novel prefabricated assembly technology mode of node factory prefabrication-beam column field connection, prevents the scene casting of concrete in a beam column node area, and belongs to the technical field of structural engineering. The method comprises the following steps: through long round hole ways are reserved in the prefabricated reinforced concrete columns; the ends are coated with steel sleeves; beam column nodes serve as a whole prefabricated unit for lifting on the scene; the steel sleeves at the ends of the upper and lower layers of columns are connected through butt welding joints after being aligned; and finally, concrete is cast in the round hole ways and cavities of the steel sleeves. The method has the advantages of simple configuration, convenience for construction, high field installation speed, low concrete wet operation load, little influence on surrounding environments, excellent stress performance, reliable force transfer, prevention of exposure of concrete cracks in connection areas by means of the steel sleeves, provision of restraint effect, convenience for material taking and processing, low use level of steels and good economical efficiency.

Owner:TSINGHUA UNIV

Self-compacting concrete for prestressed girders with ultra-long span

ActiveCN101570421ASolve small spaces that cannot be traversedSolve small spaceBuilding constructionsFiberQuality of work

The invention discloses a self-compacting concrete for prestressed girders with ultra-long span. The self-compacting concrete comprises the following parts of components by weight: 180-210KG of water; 350-400KG of Portland cement; 30-35KG of a concrete admixture; 700-800KG of fine aggregates which are of medium coarse sand; 900-1000KG of coarse aggregates which are of crushed stone with particle size of 5-20mm; 35-40KG of an efficient concrete reinforcing agent; 0.5-1.0KG of polypropylene anti-crack fiber; and 20-25KG of an antifreezer which can be added so as to meet the needs of construction in winter. The self-compacting concrete has the advantages of self-compactness and high fluidity, and helps solve the problem that small space can not be passed through by ordinary concrete, achieving concrete compactness without vibration, ensuring construction quality of working elements, being capable of greatly lowering labor intensity of workers and improving production efficiency, as well as reducing noise pollution from construction and achieving requirements of environment-friendly construction.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

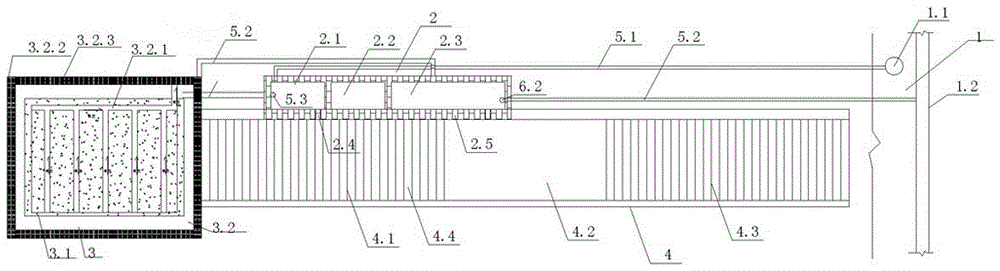

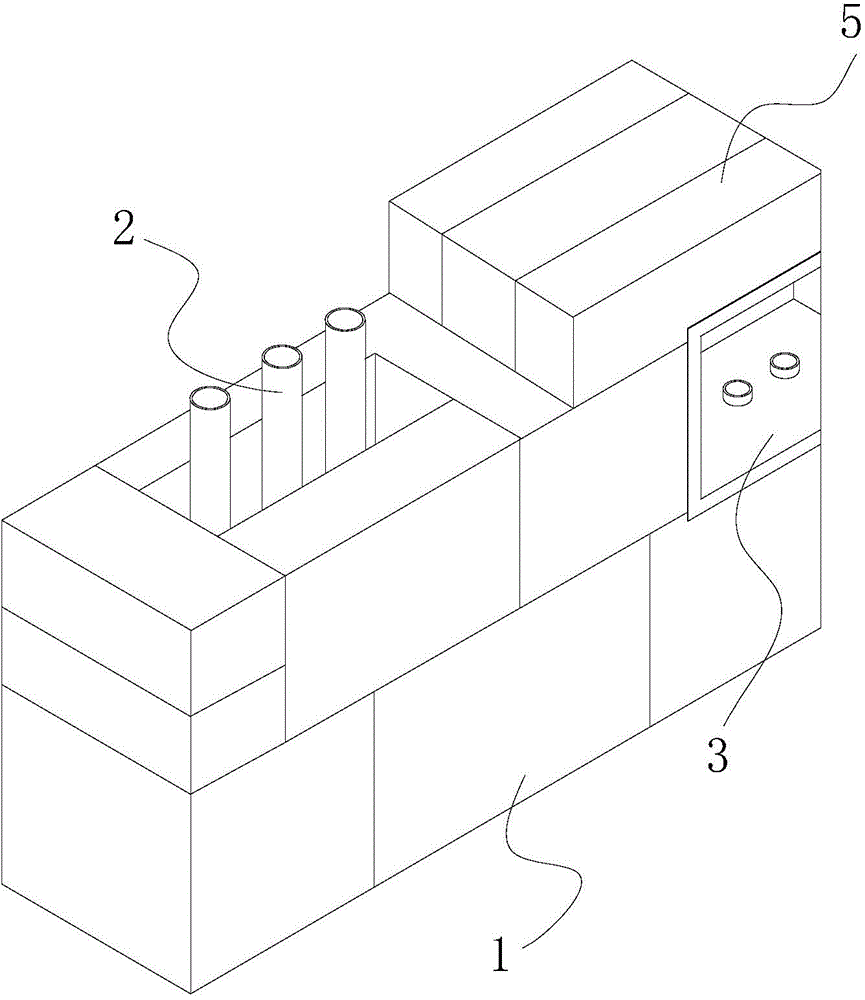

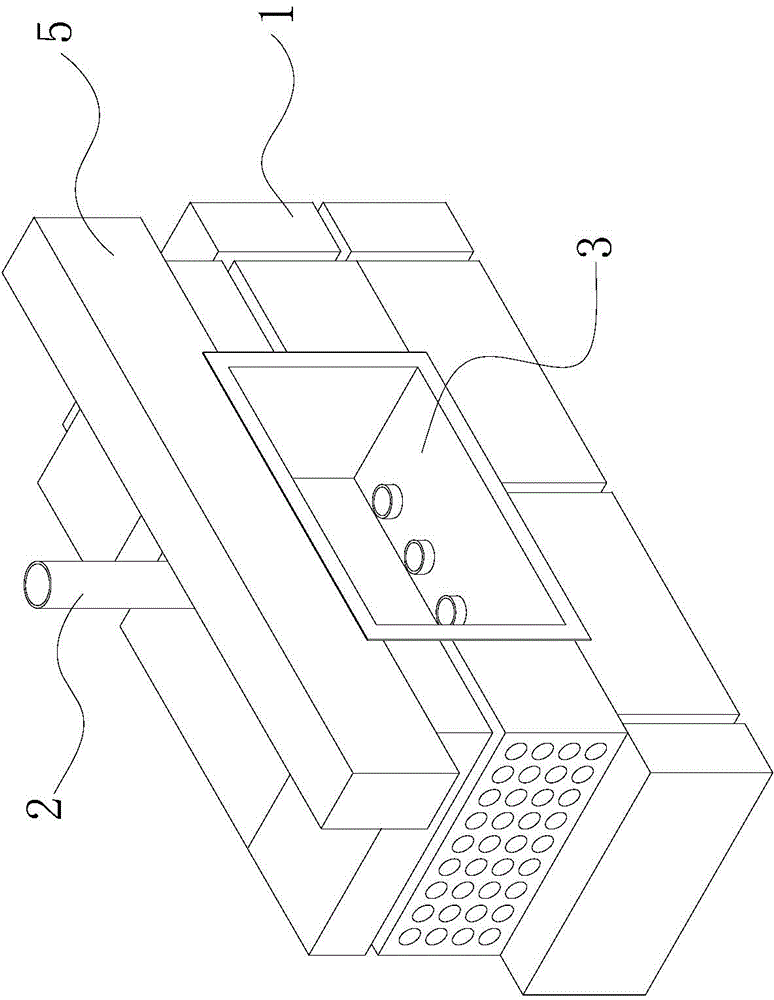

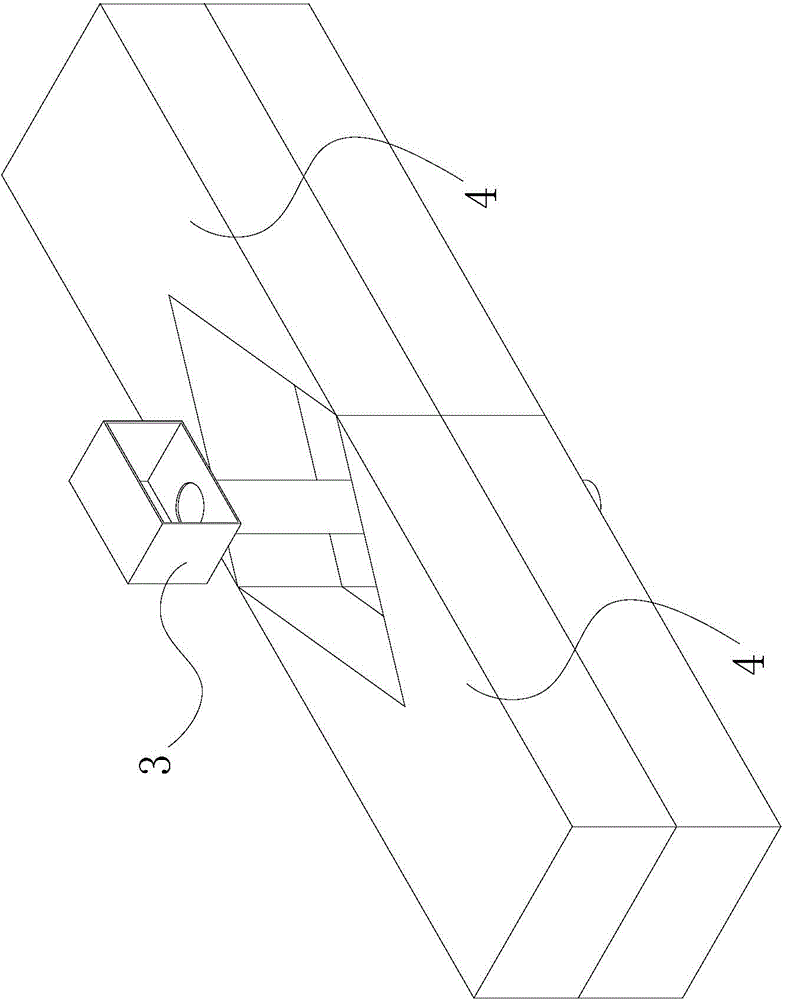

Method and system for self-cleaning water-saving type comprehensive vehicle washing for civil construction site

ActiveCN105966366ANovel and simple methodNovel and simple structureTreatment involving filtrationEnergy based wastewater treatmentWater storageWater saving

The invention belongs to a method and system for self-cleaning water-saving type comprehensive vehicle washing for a civil construction site. The method comprises the steps of foundation ditch precipitation well and drainage ditch system construction, cofferdam pool construction, construction of a wheel washing machine base, a water storage pool, a wheel washing pool, a filtering pool and a settling pool and the like. The system comprises the wheel washing pool used for conducting primary cleaning on tires of a muck vehicle and sludge on a vehicle body, the wheel washing machine base, a wheel washing machine, a foundation ditch precipitation well, a foundation ditch drainage ditch, a cofferdam pool, the water storage pool, the filtering pool and the settling pool. The method and system for self-cleaning water-saving type comprehensive vehicle washing for the civil construction site have the advantages that the method and structure are novel and simple, the vehicle washing efficiency is high, the vehicle washing effect is good, and environment beautifying, energy conservation, environment protection and water recovery circulation utilization are good.

Owner:CHINA CONSTR MUNICIPAL ENG +1

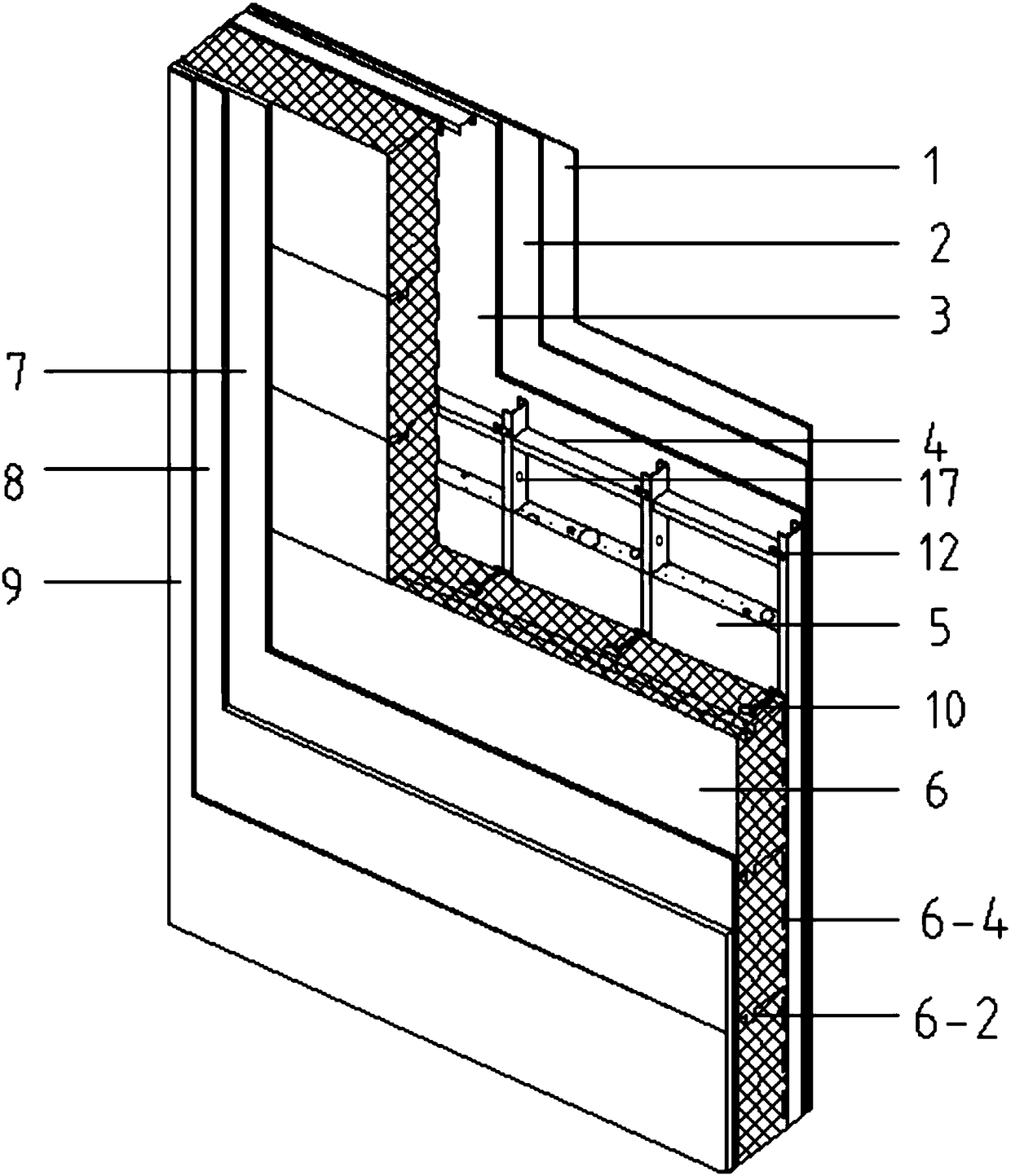

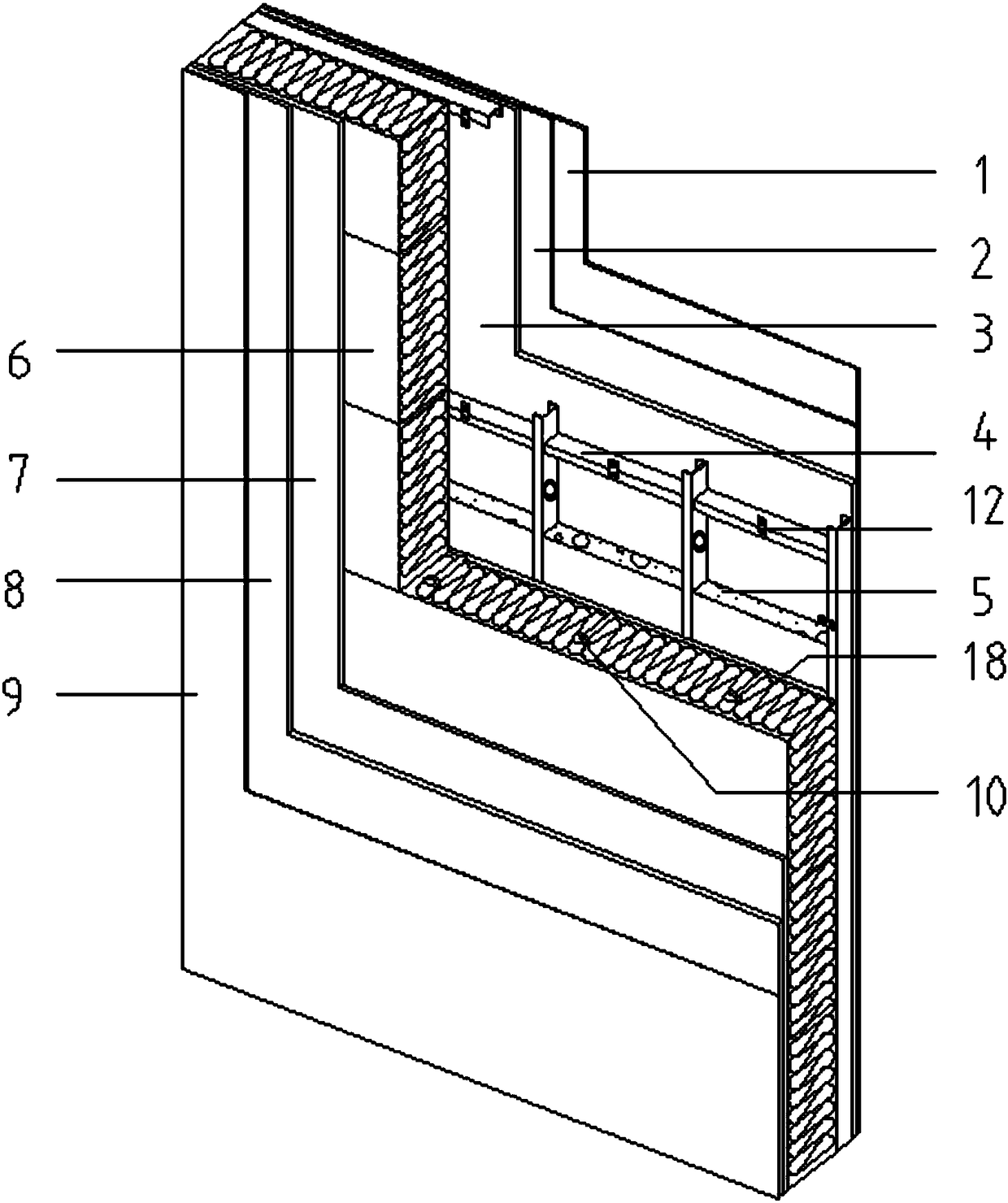

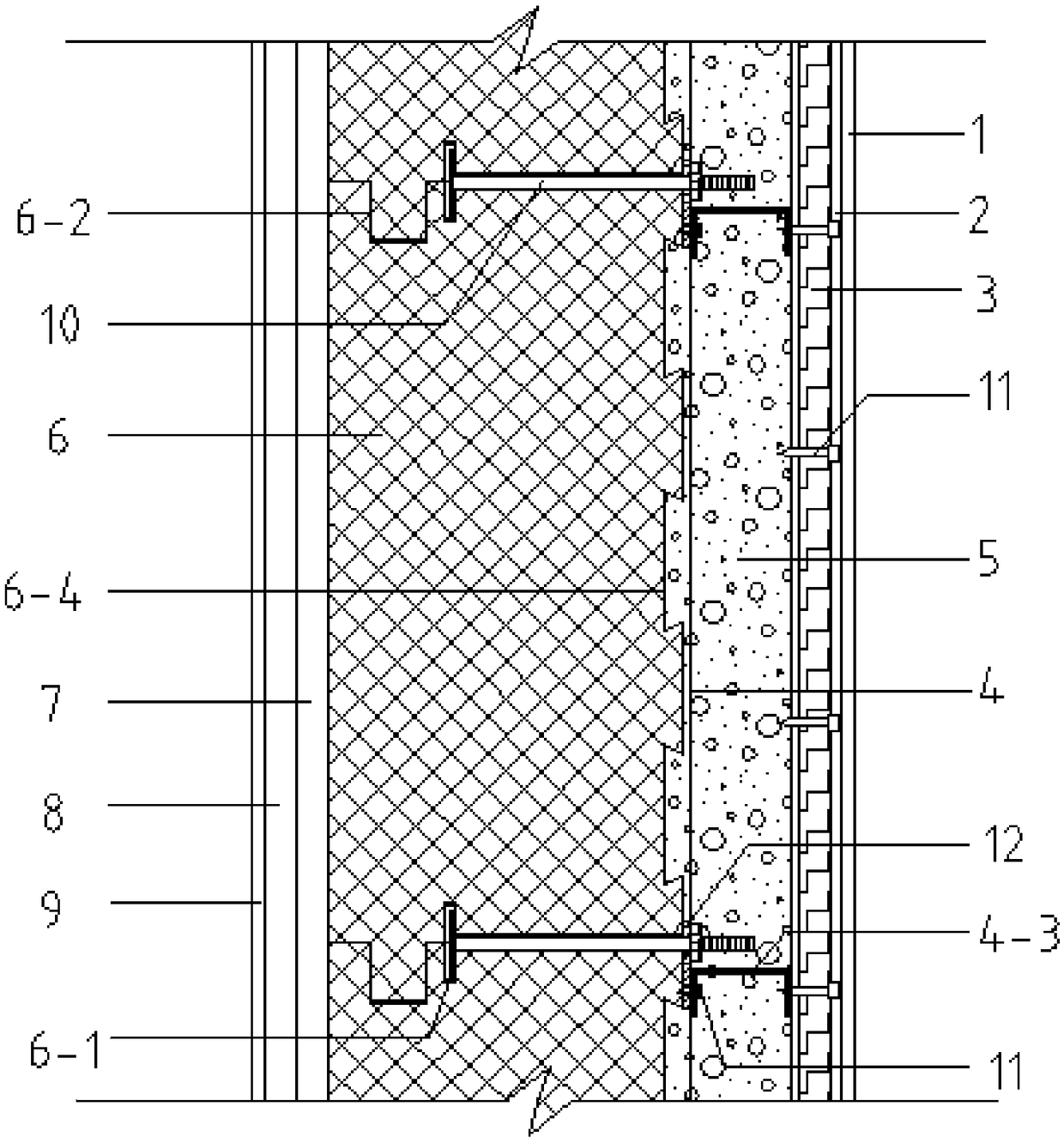

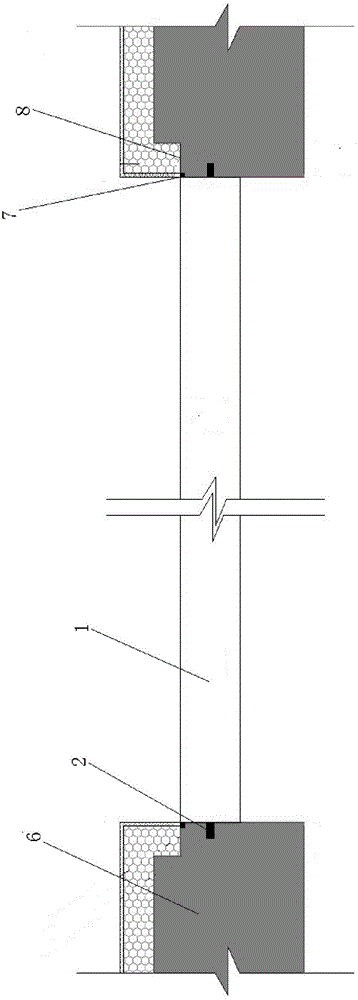

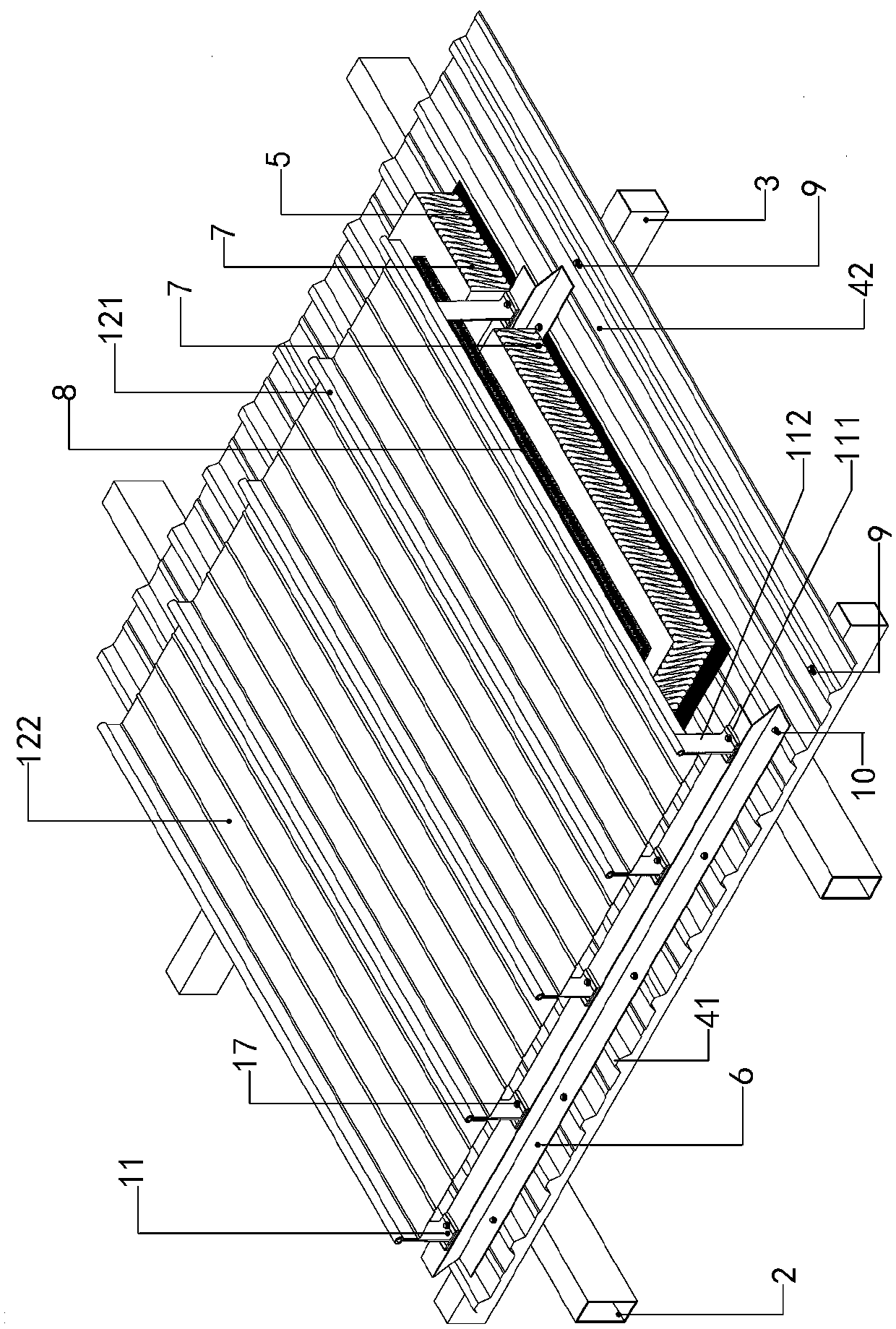

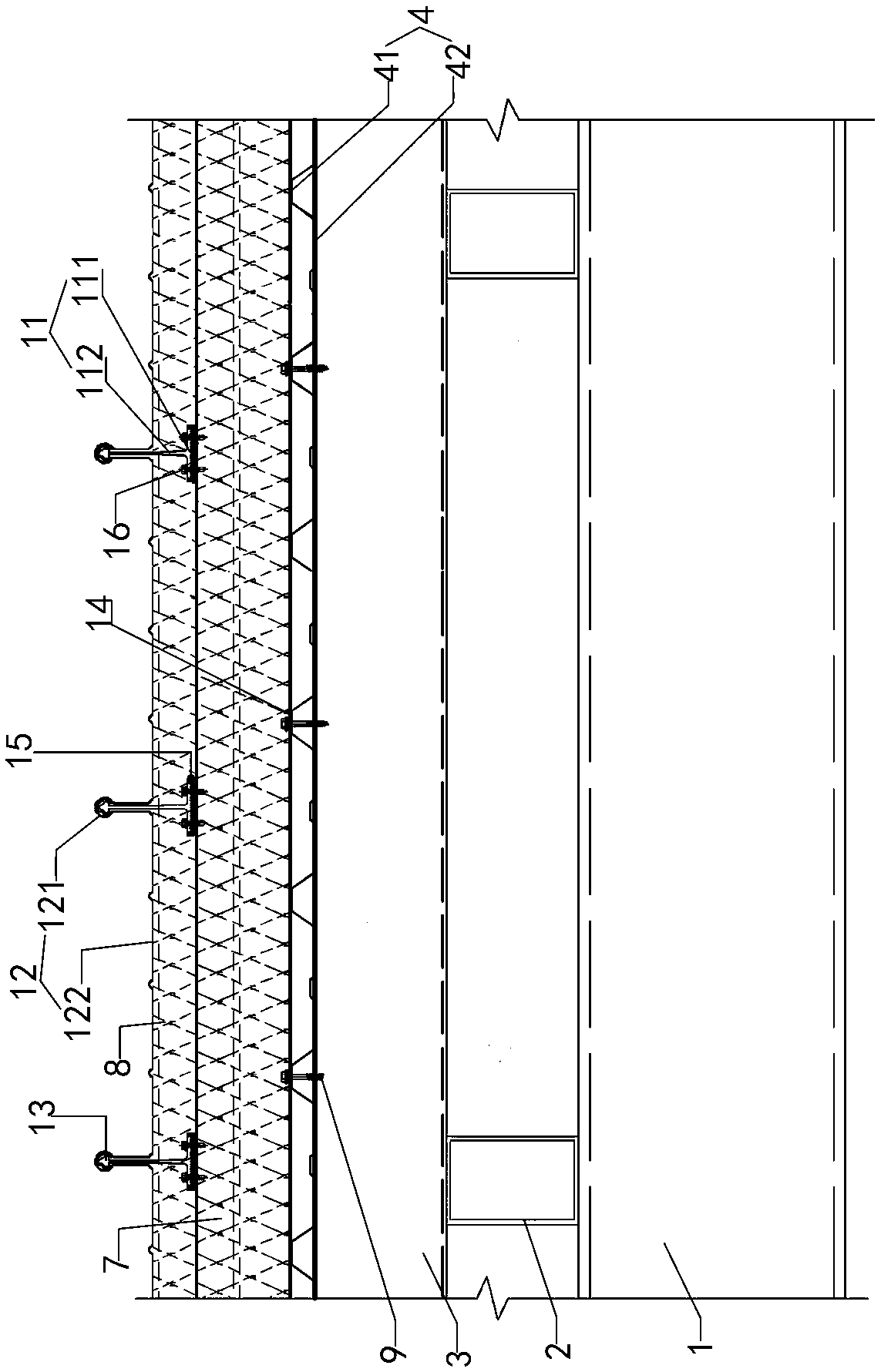

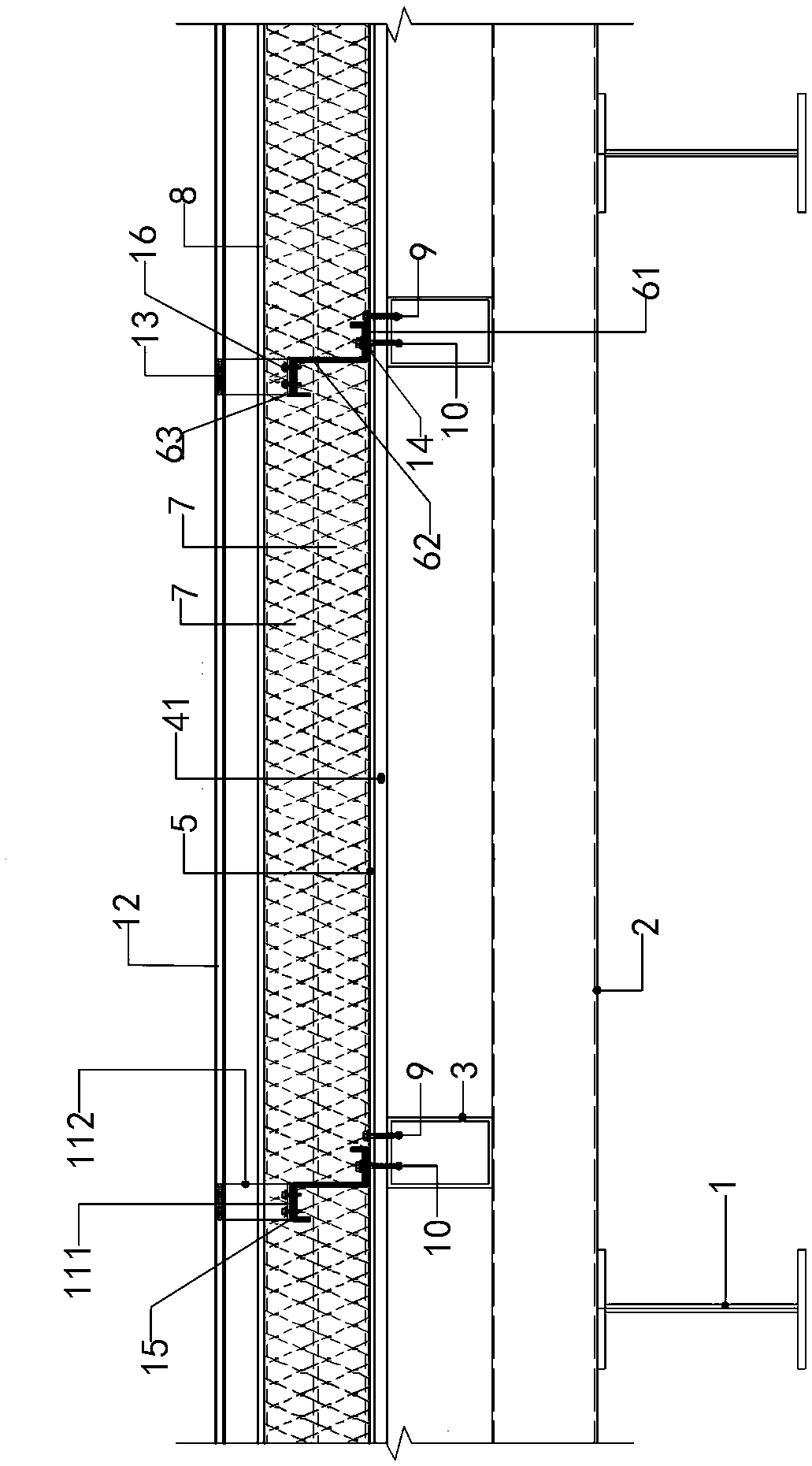

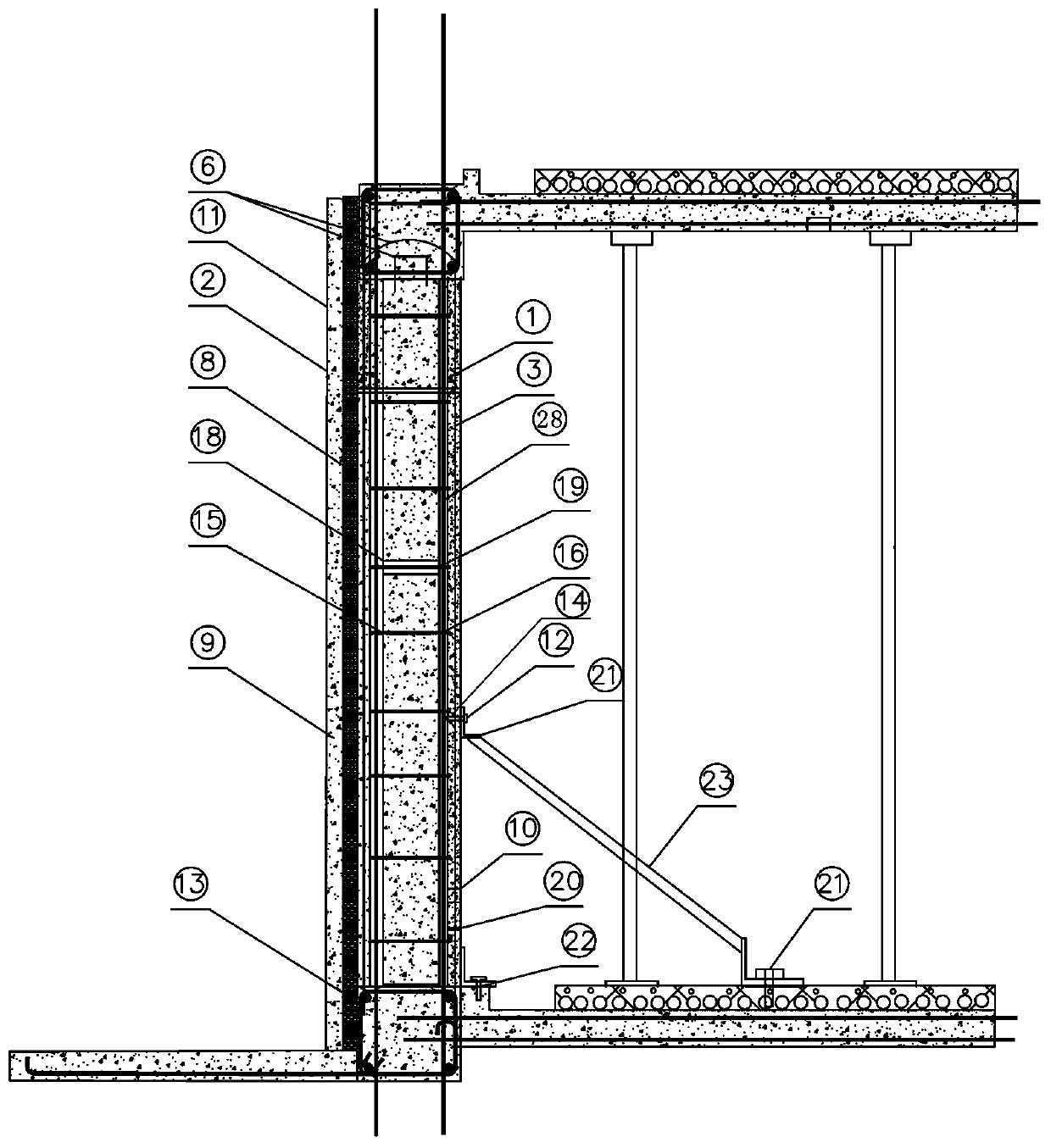

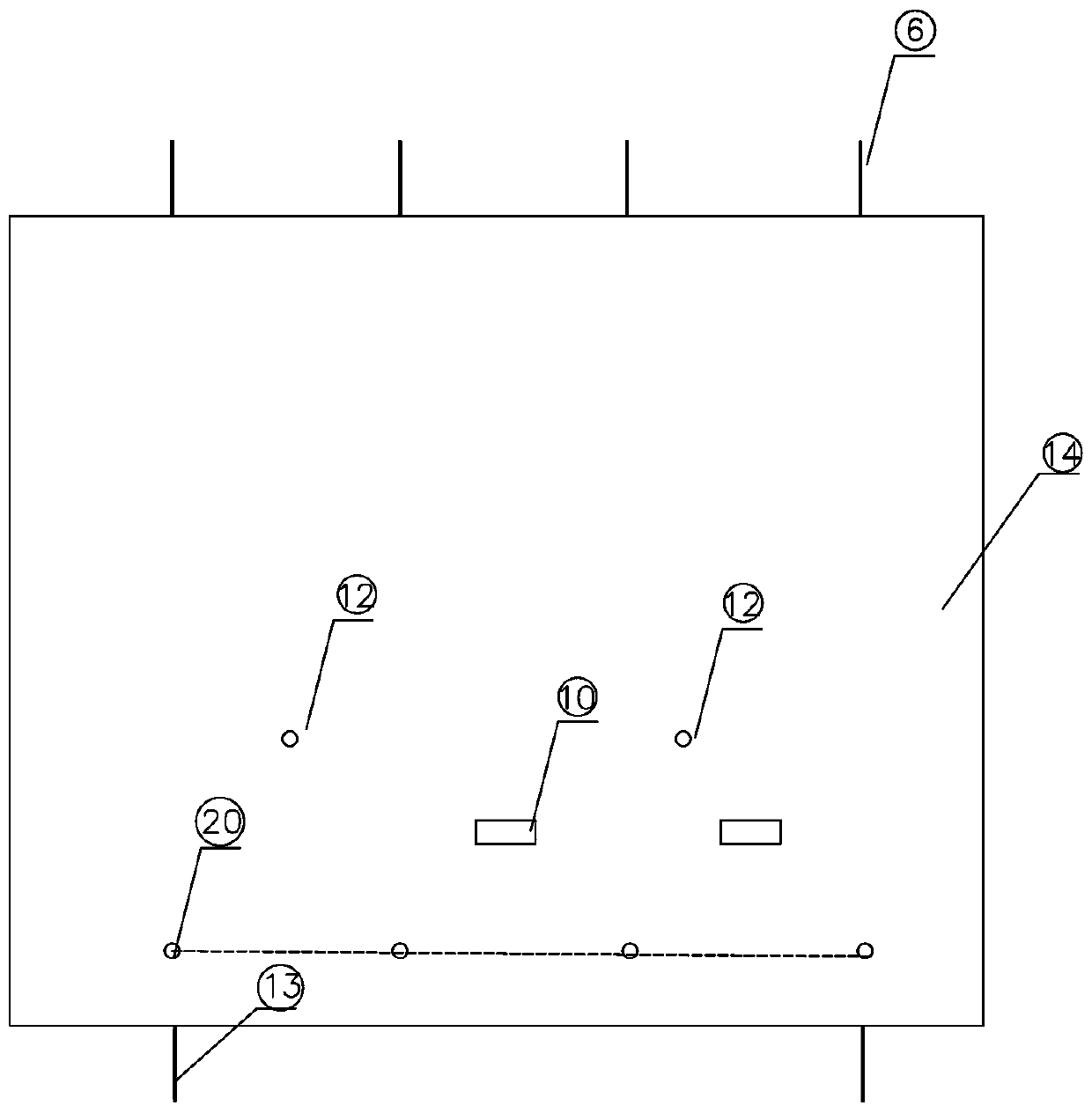

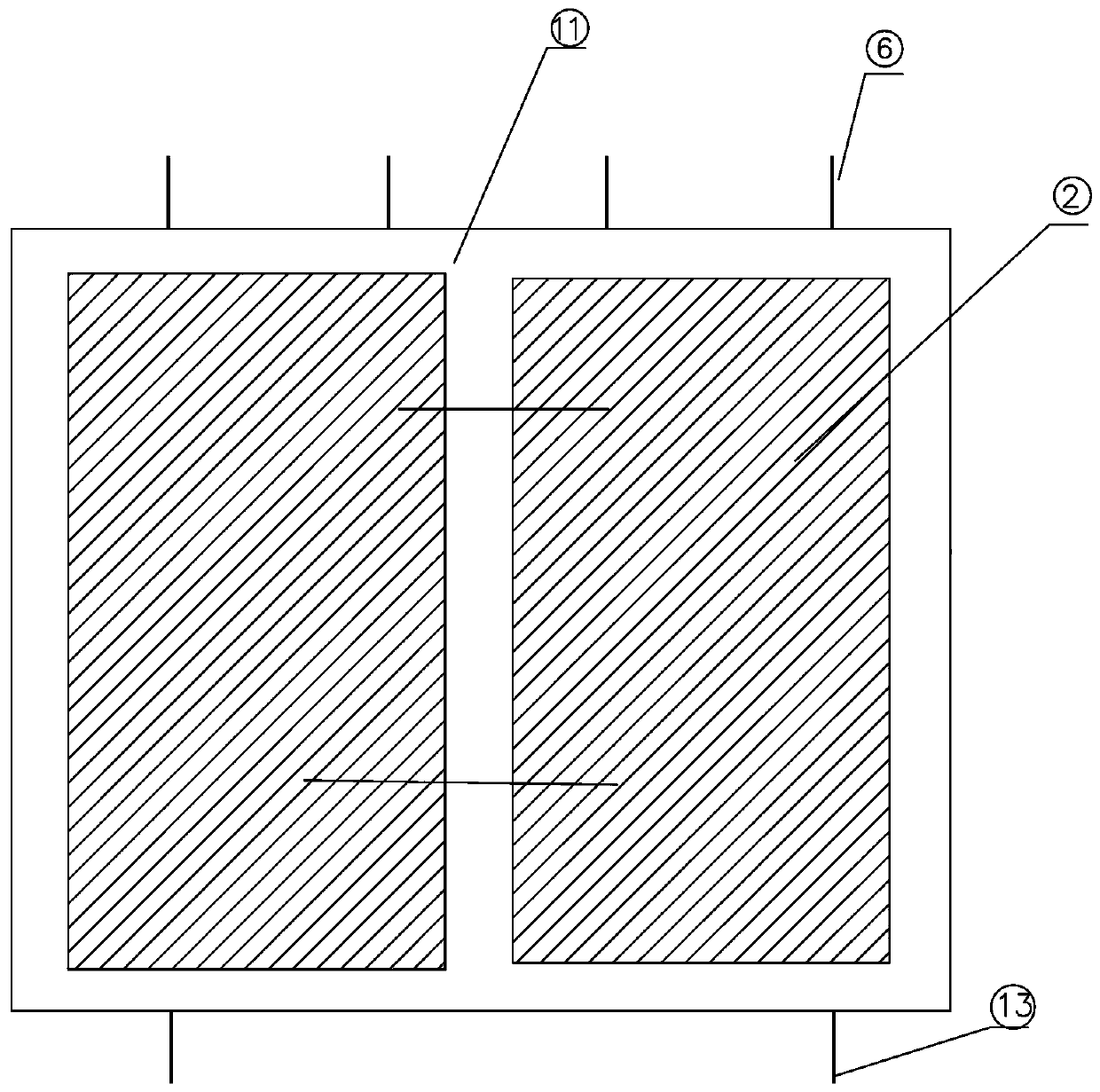

Prefabricated non-thermal bridge external thermal insulation wallboard with C-shaped steel light steel keel and manufacturing method thereof

The invention relates to a prefabricated non-thermal bridge external thermal insulation wallboard with a C-shaped steel light steel keel and a manufacturing method thereof. The wallboard comprises a base wall body, a break thermal bridge anchoring bolt, a connecting piece, a thermal insulation board and a stressed-skin diaphragm. The thermal insulation board and the base wall body are fixedly connected into a whole through the break thermal bridge anchoring bolt and the connecting piece, and the stressed-skin diaphragm is fixedly arranged on the other side, relative to the thermal insulation board, of the base wall body. The prefabricated non-thermal bridge external thermal insulation wallboard is convenient to construct and simple in structure, breaks the inherent concept of ''thermal insulation after wall body'' and proposes the integrated production of a thermal insulation wall body. Factory prefabrication and site assembly can be carried out, batch production and on-site installation are convenient, the construction efficiency is improved, the characteristics of low energy consumption, flexible arrangement and fast construction are achieved, and the requirements of green construction are met. The arrangement of the non-cut-through type break thermal bridge anchoring bolt and dovetail grooves avoids the phenomenon of a thermal bridge caused by joints and the like, the thermal insulation performance of the wall body is improved, and the structural integrity is increased; and the weight of the wall body is greatly reduced due to using of a light steel keel frame and lightweight concrete, and the cost of construction, transportation and seismic design of later structure is reduced.

Owner:沈阳领创建筑科技有限公司

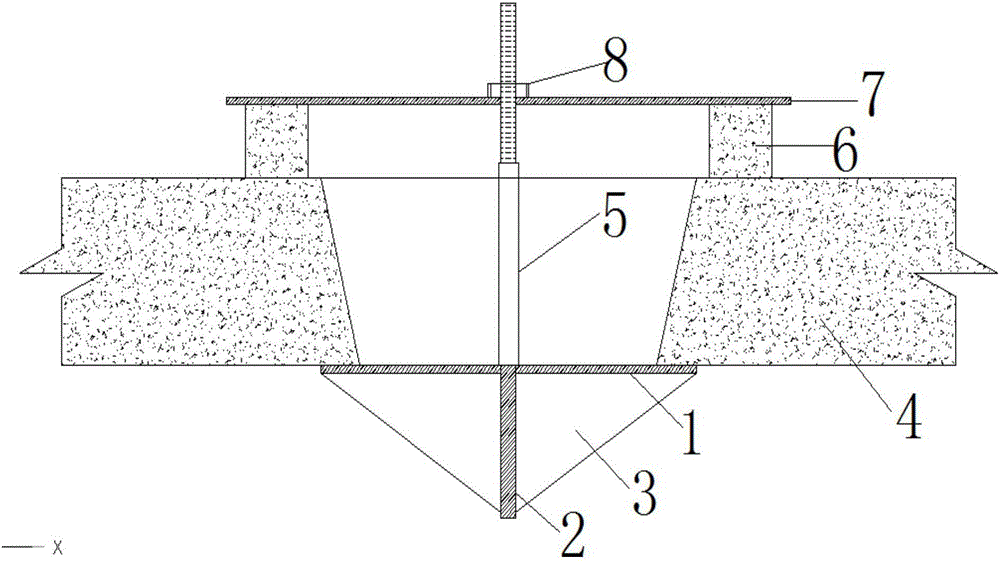

Floor slab hole plugging device and method

InactiveCN106677355AGuarantee the construction qualityAvoid job safety hazardsBuilding repairsBuilding insulationsFloor slabArchitectural engineering

The invention discloses a floor slab hole plugging device and method. The floor slab hole plugging device comprises a supporting plate, a pulling rod and a fixing plate. The supporting plate and the fixing plate are horizontally and parallelly arranged and distributed on the pulling rod in sequence from bottom to top. The pulling rod is sleeved with a sleeve. The length size of the sleeve is larger than the thickness size of a floor slab. The sleeve is arranged between the supporting plate and the fixing plate. The supporting plate and the pulling rod are connected and fixed through welding. The fixing plate is connected with the pulling rod through a thread and can be moved and adjusted up and down along the pulling rod through the thread. A plurality of cushion blocks are further arranged on the lower end surface of the fixing plate and are uniformly distributed along the center of the fixing plate. During working, the supporting plate covers the lower portion of a floor slab hole, is closely attached to the lower end surface of the floor slab and is used for plugging a lower end opening of the floor slab hole; the pulling rod penetrates through the floor slab hole and is connected with the fixing plate covering the upper portion of the floor slab hole; and the cushion blocks are distributed between the fixing plate and the floor slab. Operation is easy; the construction efficiency and the construction safety are improved; turnover repeated use can be achieved; the construction quality is improved; and the cost is reduced.

Owner:CHINA FIRST METALLURGICAL GROUP

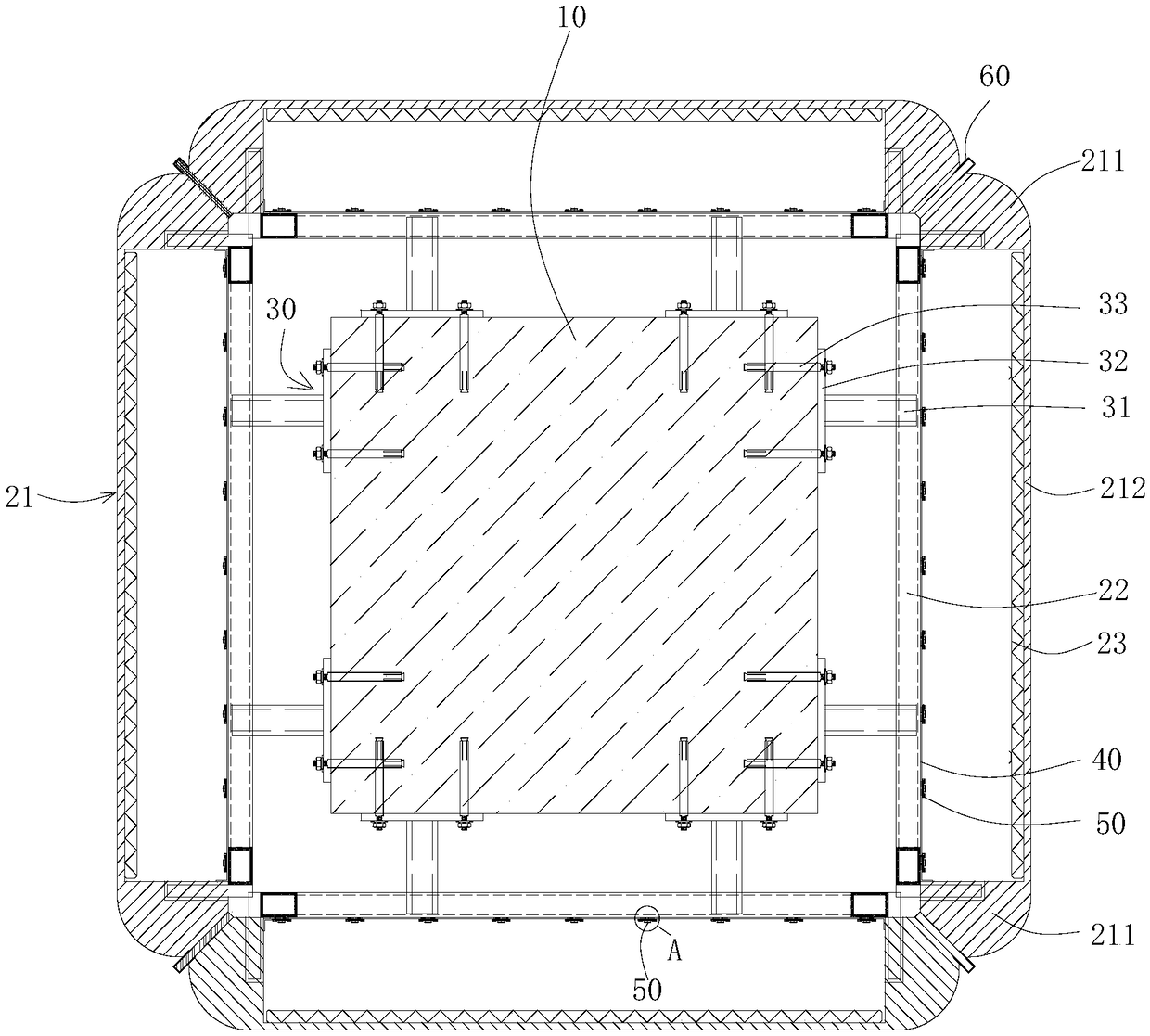

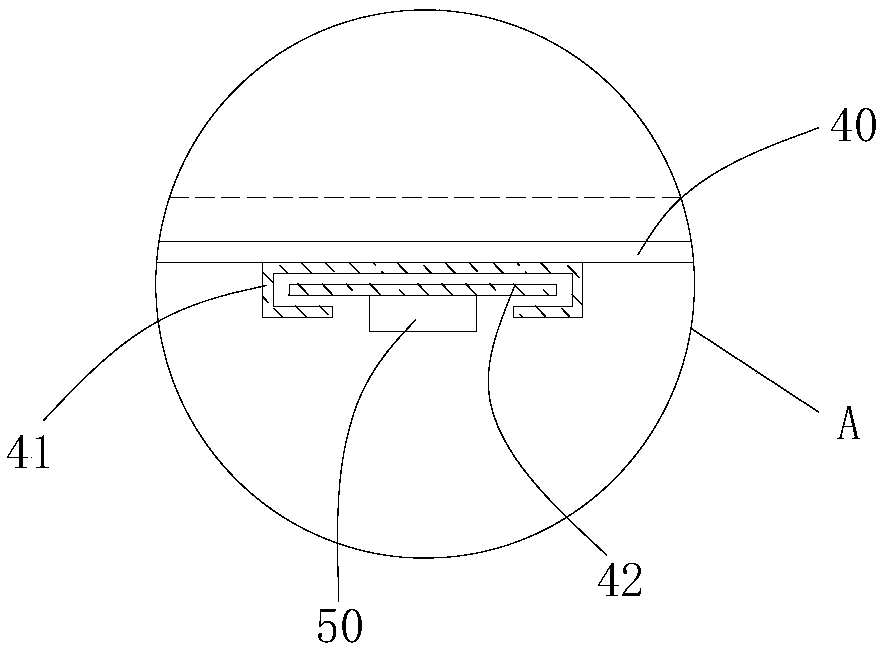

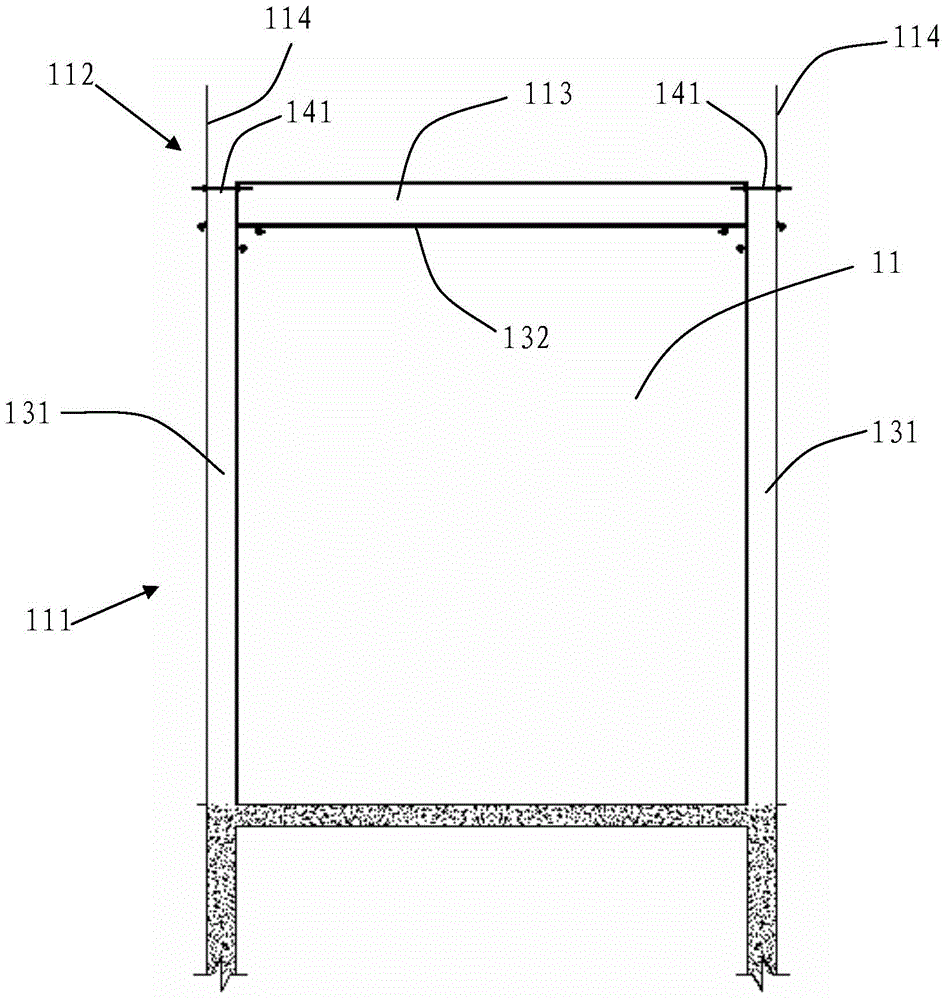

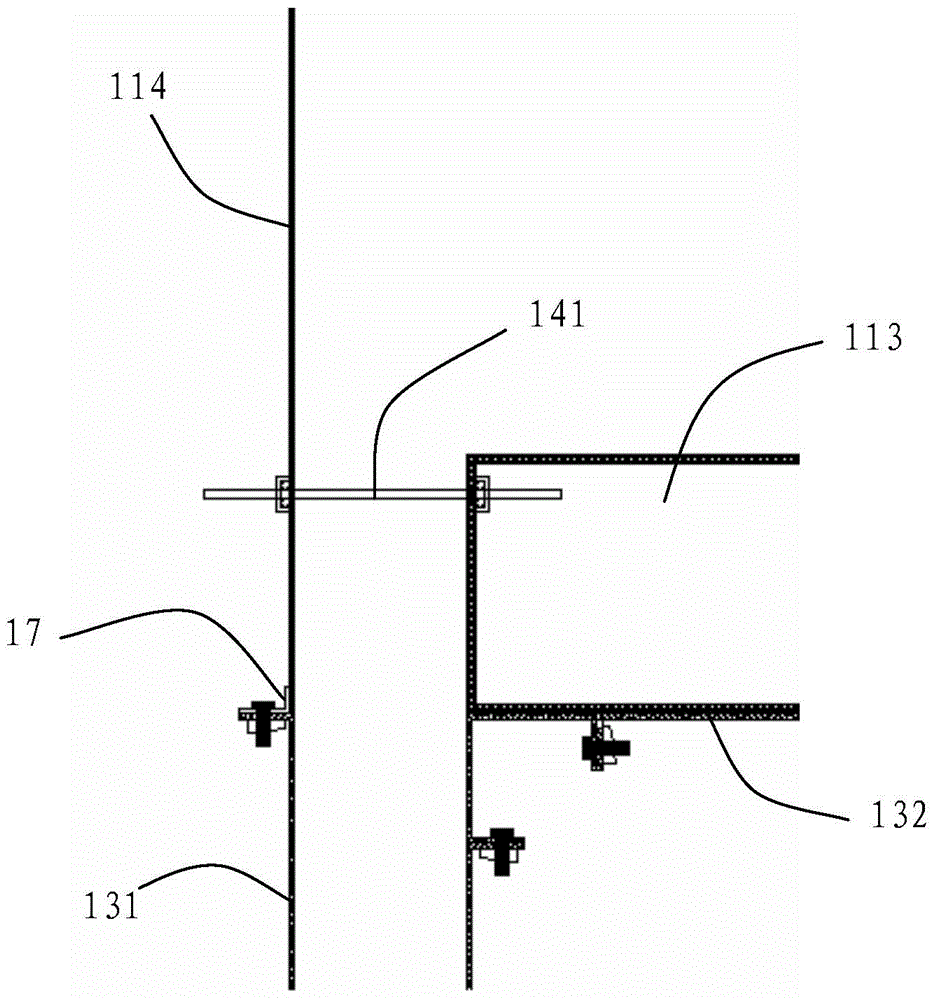

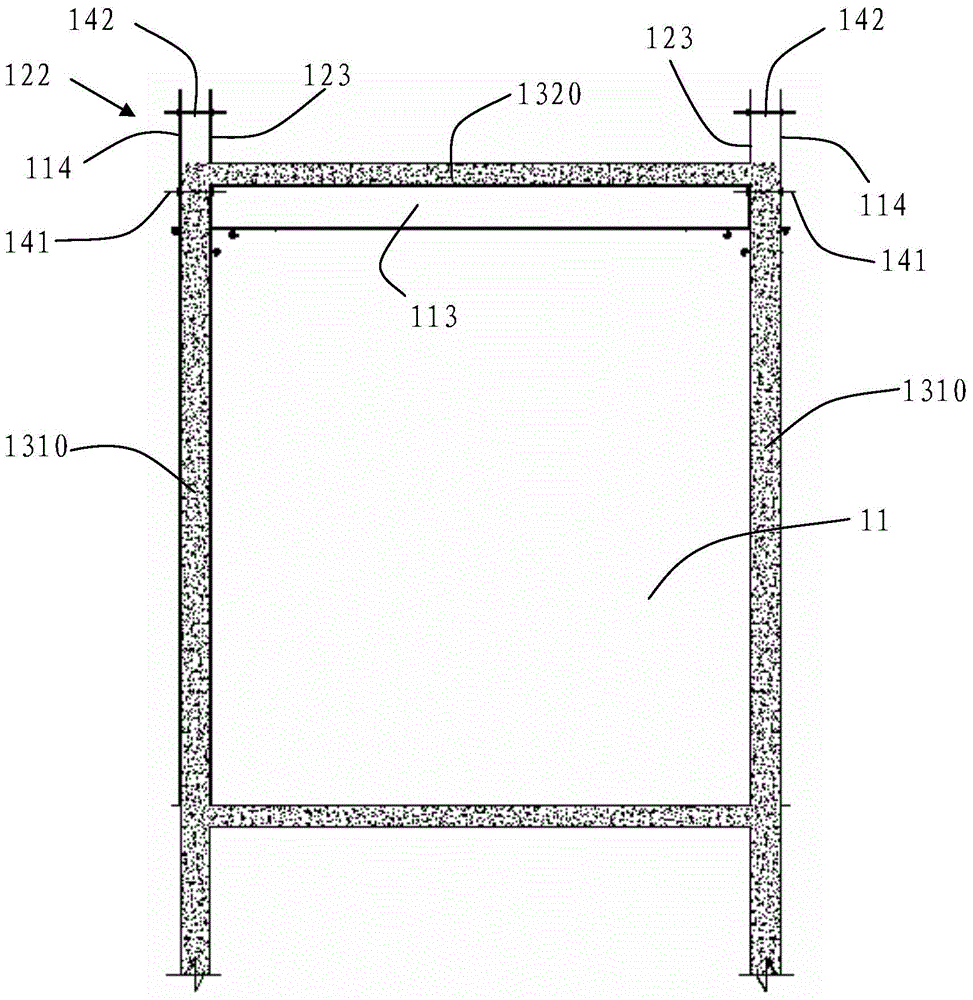

Flexible prefabricated and assembled shear wall-external window integrated construction system and method

ActiveCN105064553AImprove turnover rateMeet the requirements of green constructionWallsFrame fasteningShear wallBuilding construction

The invention discloses a flexible prefabricated and assembled shear wall-external window integrated construction system. The flexible prefabricated and assembled shear wall-external window integrated construction system comprises a wall frame into which concrete is poured. A window hole is reserved in the wall frame. A window frame bench formwork is tightly attached to the inner wall face of the wall frame. A bottom window frame formwork, a window frame and a top window frame formwork are sequentially installed inside the window hole from interior to exterior. One face of the bottom window frame formwork is fixedly connected with the window frame bench formwork. The two sides of the window frame are fixedly provided with window frame embedded parts stretching into the wall frame. According to the flexible prefabricated and assembled shear wall-external window integrated construction system and method, the window frame formworks can be repeatedly utilized, the construction flow is easy and convenient, the time limit for a project is shortened, the higher stability is achieved after the window frame is installed, and the better waterproof and heat preservation effects are achieved.

Owner:NANTONG CONSTR PROJECT GENERAL CONTRACTING

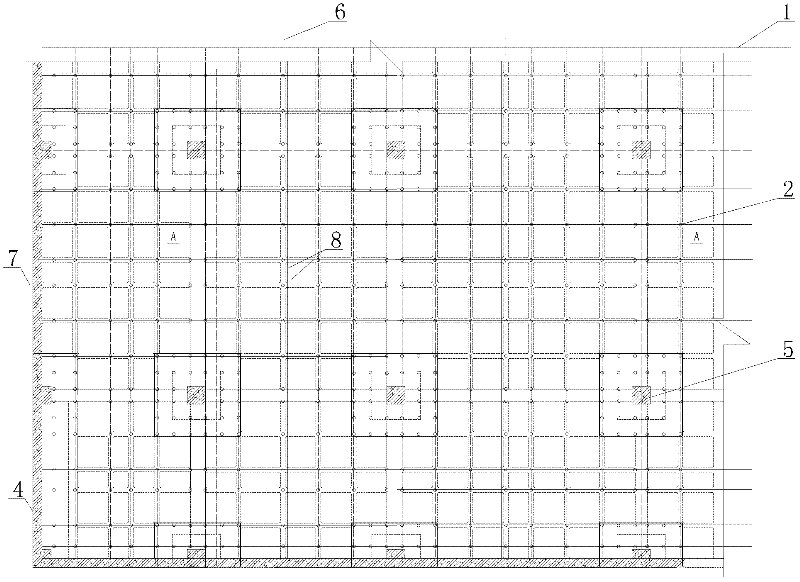

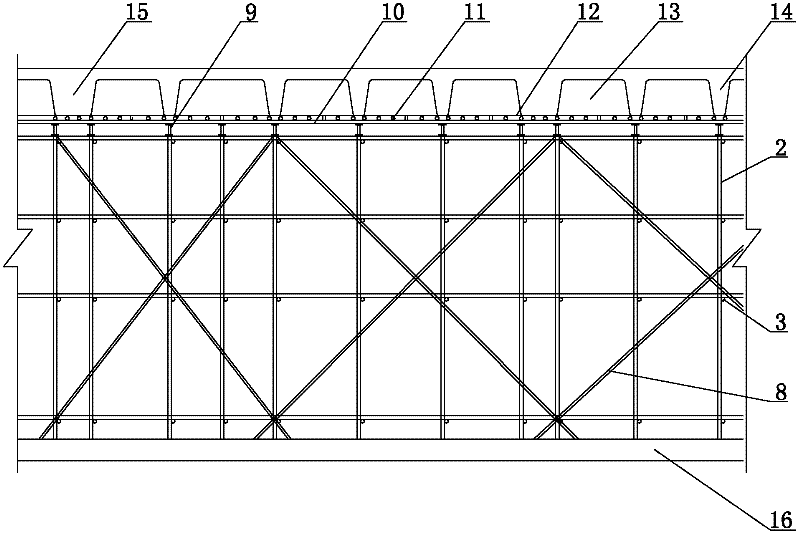

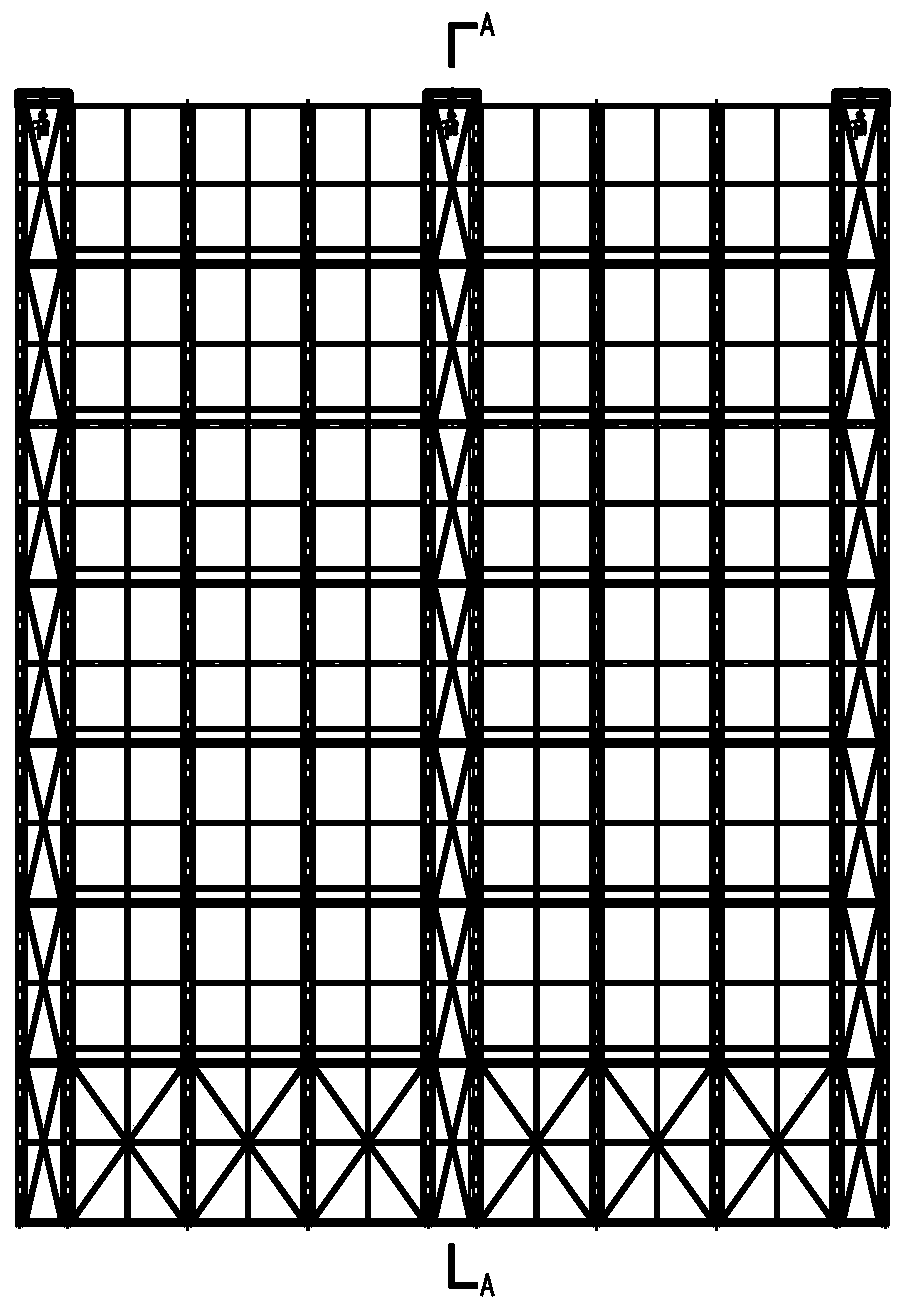

Construction method of membrane shell ribbed floor formwork supporting system

InactiveCN102505849AImprove the two-way anti-sway stiffness and overall stabilityWide space for construction operationBuilding material handlingRebarEngineering

The invention belongs to the technical field of building engineering, and particularly relates to a construction method of a membrane shell ribbed floor formwork supporting system. The construction method includes steps: (1) positioning and drawing lines; (2) erecting vertical rods; (3) erecting horizontal rods; (4) erecting a diagonal bracing; (5) pouring a shear wall and frame column concrete; (6) mounting an adjustable bracket; (7) mounting main ledges; (8) mounting secondary ledges; (9) placing a panel; (10) binding reinforcing steel bars of ribs and concealed frame beams; (11) mounting a membrane shell; (12) binding reinforcing steel bars of cast-in-place plates; and (13) concreting a membrane shell floor. The construction method has the advantages that characteristics of construction force transfer of the membrane shell ribbed floor are met, axial forces of the vertical rods are balanced and consistent, a stress state is safe and reliable, a construction space is large, the vertical rods are saved by five ninths, the floor construction period is halved, and requirements of high-efficiency, energy-saving and green construction are met.

Owner:SHANDONG WANXIN CONSTR

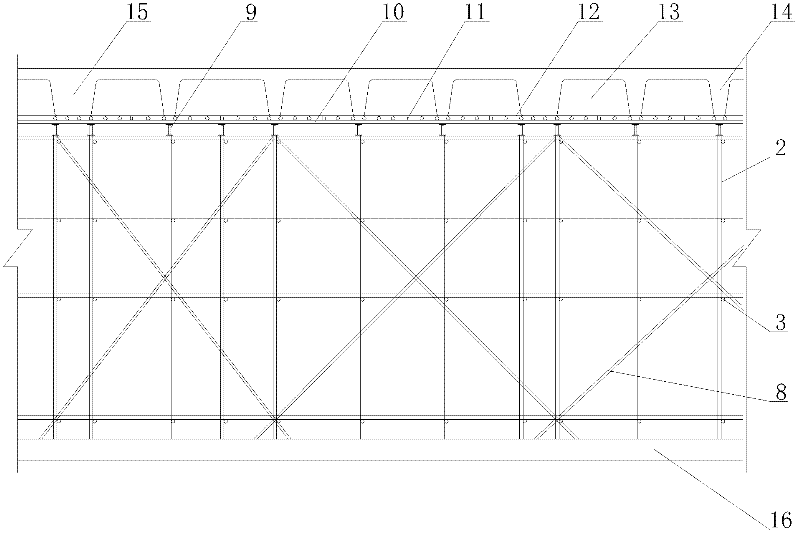

Crest fixed metal roof structure and construction method thereof

InactiveCN111042449AReduce generationPrevent leakageRoof covering using slabs/sheetsRoof improvementVapor barrierInsulation layer

The invention discloses a crest fixed metal roof structure and a construction method thereof. The structure comprises roof steel beams, roof main purlines, roof secondary purlines, metal roof slabs, vapor barriers, Z-shaped keels, thermal insulation layers, waterproof and vapor-permeable membranes (8) and roof boards. Cross sections of the metal roof bottom plates comprise alternately arranged bottom plate crest sections and bottom plate trough sections, the metal roof bottom plates and the roof secondary purlines are fixedly connected through first connecting parts penetrating through the metal roof bottom plates and the roof secondary purlines, the first connecting parts corresponding to the positions of the bottom plate crest sections are transversely arranged at intervals, the Z-shapedkeels, the vapor barrier membranes and the roof secondary purlines are fixedly connected through second connecting parts penetrating through the Z-shaped keels, the vapor barrier membranes and the roof secondary purlines, and the second connecting parts corresponding to the positions of the crest sections are transversely arranged at intervals. The crest fixed metal roof structure successfully utilizes the installation manner of the crest fixed metal roof bottom plate and Z-shaped keels to thoroughly solve the problem that nail holes exist in the metal bottom plate troughs, reduces condensatewater to the greatest extent and avoids leakage of the condensate water.

Owner:CHINA CONSTR FIRST DIV GROUP CONSTR & DEV

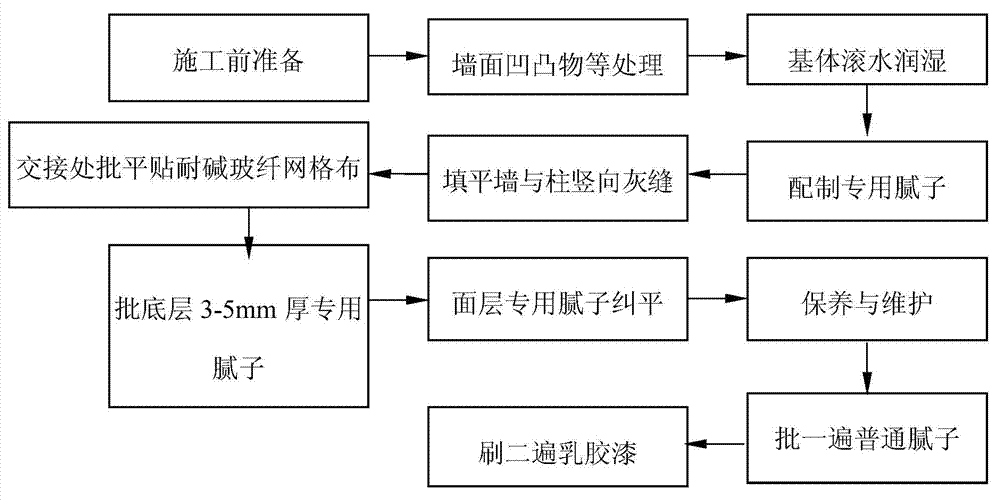

Construction method for whitewashing-free puttying processing of concrete porous brick wall

The invention discloses a construction method for whitewashing-free puttying processing of a concrete porous brick wall. According to the method, special putty is utilized for replacing a traditional composite mortar floated coat process and is directly puttied on the concrete porous brick wall, quality is stable, the method is free of hollowing and cracking, appearance quality is good, green construction requirements are met, and the usable area is increased at the same time. Thus, the construction method has the advantages of being advanced, practical, economical, environmentally friendly and capable of being applied and popularized widely under the current engineering background.

Owner:NANTONG SIJIAN CONSTR GRP

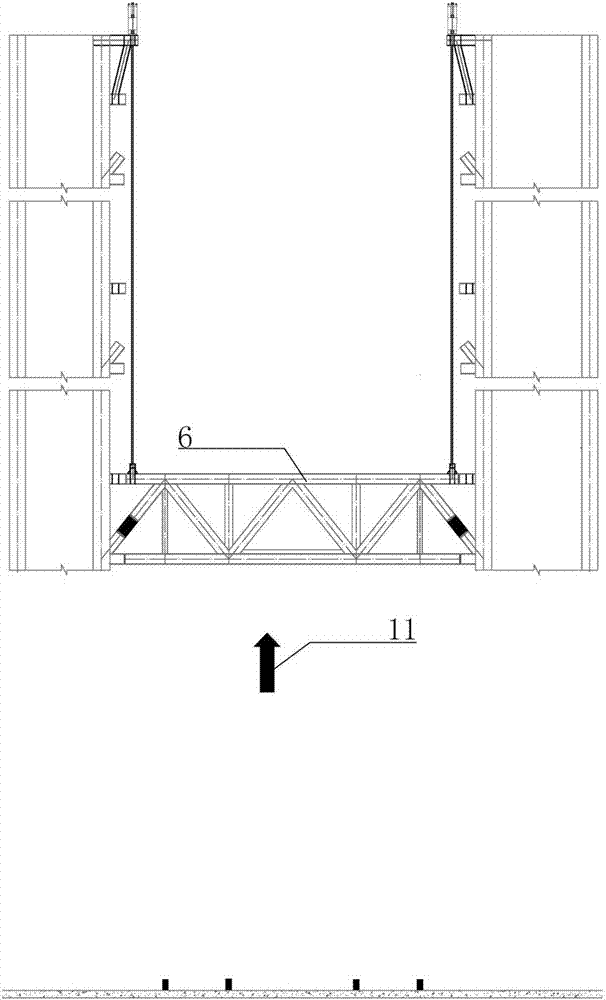

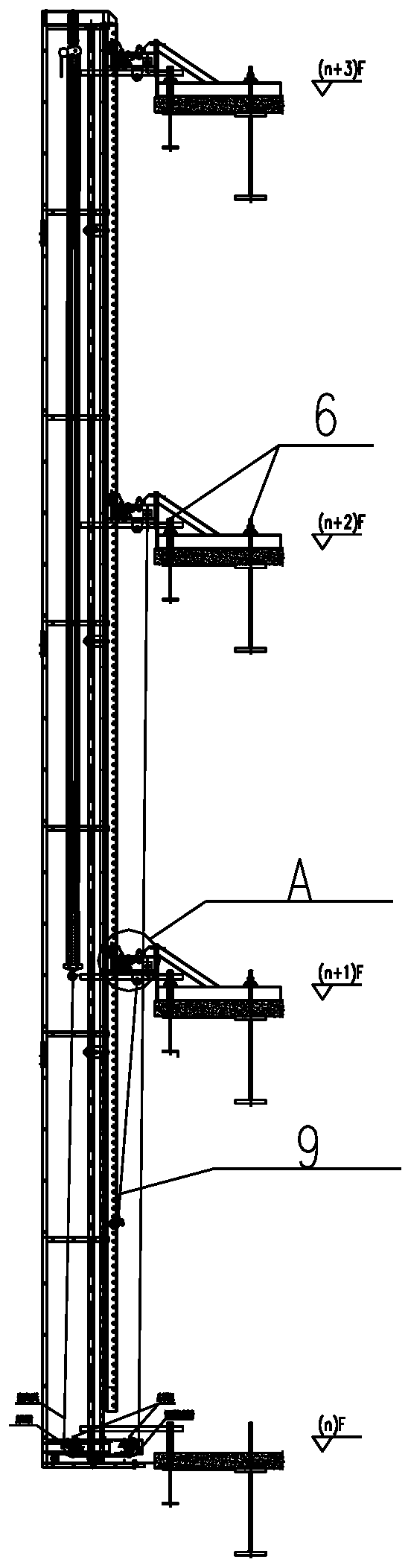

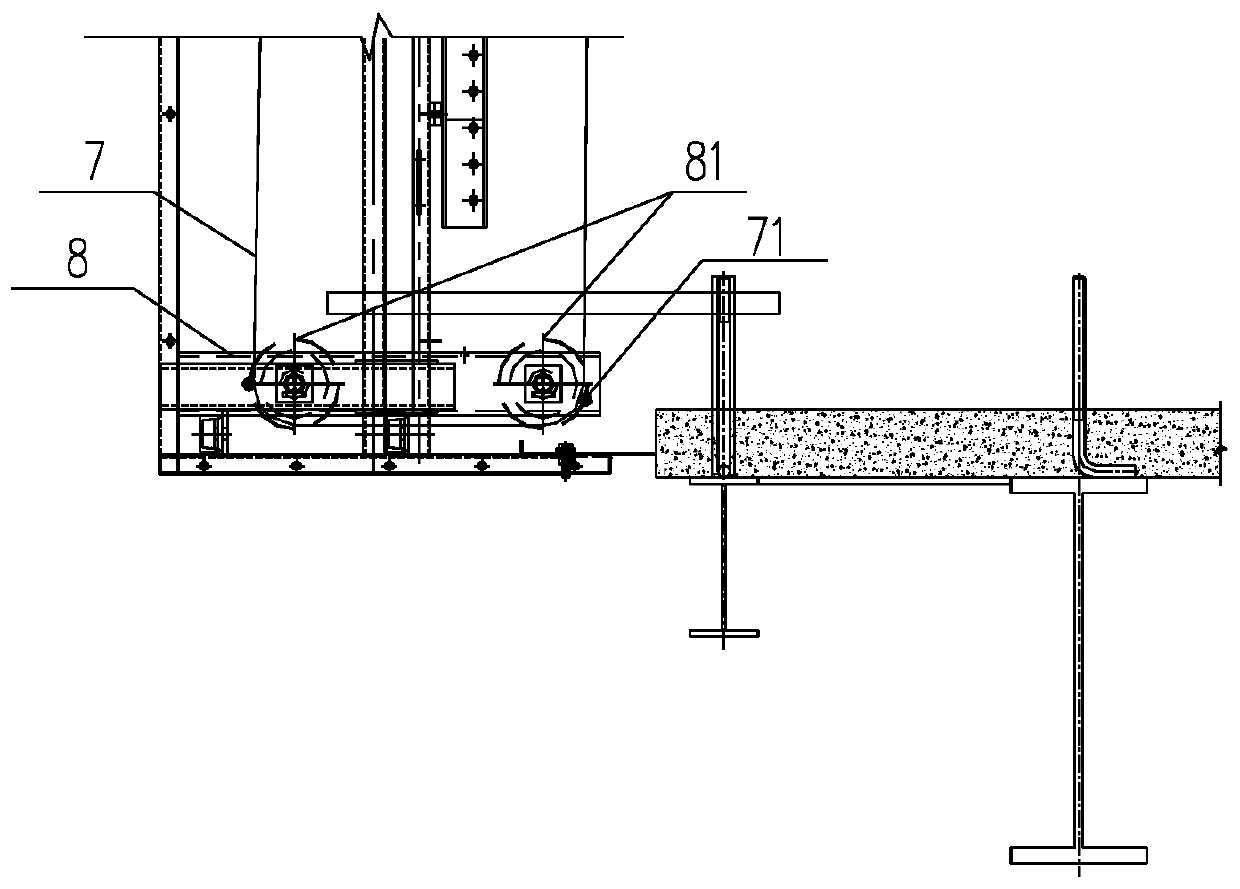

Lifting construction method of plurality of steel galleries between towers

ActiveCN107060105AImprove bearing capacityAvoid reinforcementBuilding constructionsTowerEnergy consumption

The invention discloses a lifting construction method of a plurality of steel galleries between towers. The low-area steel galley, the middle-area steel galley and the high-area steel gallery are lifted in sequence; firstly, pre-installing rod pieces are installed in the elevation positions of the low-area steel galley, the middle-area steel galley and the high-area steel gallery, lifting platforms are arranged, and hydraulic lifters are installed simultaneously; then, the low-area steel galley is assembled on the ground and lifted to the elevation position, jig frames are erected on the low-area steel galley, and the middle-area steel galley is assembled and lifted to the elevation position; and jig frames are erected on the middle-area steel galley, the high-area steel gallery is assembled and lifted to the elevation position, and construction is completed. Construction of the multiple steel galleries between the towers is uncommon; the construction efficiency can be improved obviously through engineering practice of the construction method; construction safety is guaranteed; the hoisting workload is reduced by the maximum margin; energy consumption and time are saved; the construction cost and installing construction difficulty are reduced; the national environment-friendly construction requirement is met; reference and guidance can be provided for later similar engineering construction of the multiple steel galleries between the double towers; and application and popularization prospects are achieved.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD +1

Hollow light-transmitting integral stone decoration vertical column and construction method thereof

PendingCN108915190ASolve the deformationFix damageCovering/liningsElongate light sourcesKeelSteel frame

The invention provides a hollow light-transmitting integral stone decoration vertical column. The hollow light-transmitting integral stone decoration vertical column comprises a vertical column and aplurality of stone unit plates which are hung on the side face of the vertical column, wherein a plurality of groups of keels which are distributed at intervals in the longitudinal direction are fixedto the side face of the vertical column; the keels extend out of a hanging plate along the side face vertical to the vertical column; the stone unit plates comprise stone plates, steel frames and light-transmitting plates; the stone plates comprise arc-shaped chamfered parts with the thicknesses of the two ends being larger, and planar light-transmitting parts which are positioned between two arc-shaped chamfered parts and are thinner; splicing faces positioned on the side faces of the arc-shaped chamfered parts are slopes; the light-transmitting plates are stuck to the inner side faces of the planar light-transmitting parts; the steel frames are fixedly stuck to the inner side faces of the arc-shaped chamfered parts; the steel frames are fixed to the hanging plate of the vertical column;the splicing faces of the stone unit plates on each side face of the vertical column are spliced to form a complete vertical column decoration face; the steel frames are stuck to a bottom plate; thebottom plate is provided with an LED (Light Emitting Diode) lamp strip. The hollow light-transmitting integral stone decoration vertical column has the characteristics of good decorative face integrity and high attractiveness.

Owner:SDCIC CONSTR GRP CO LTD

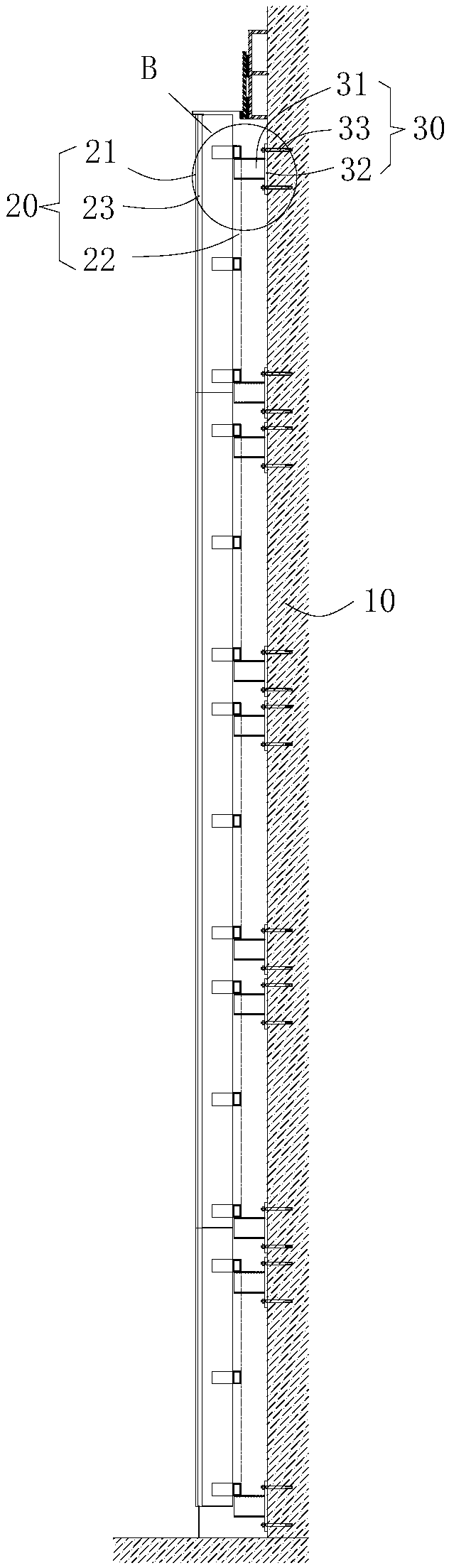

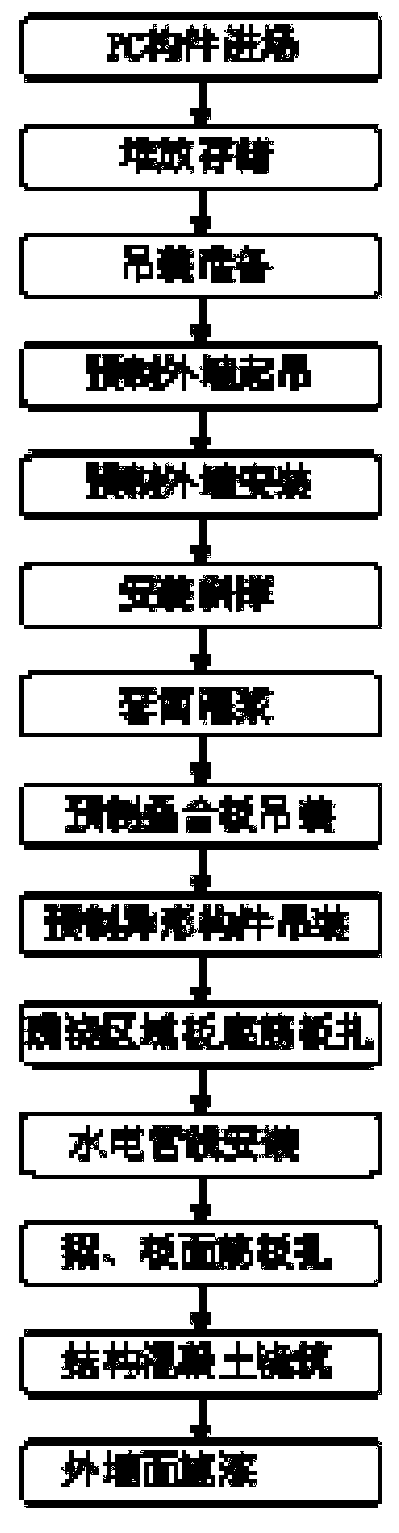

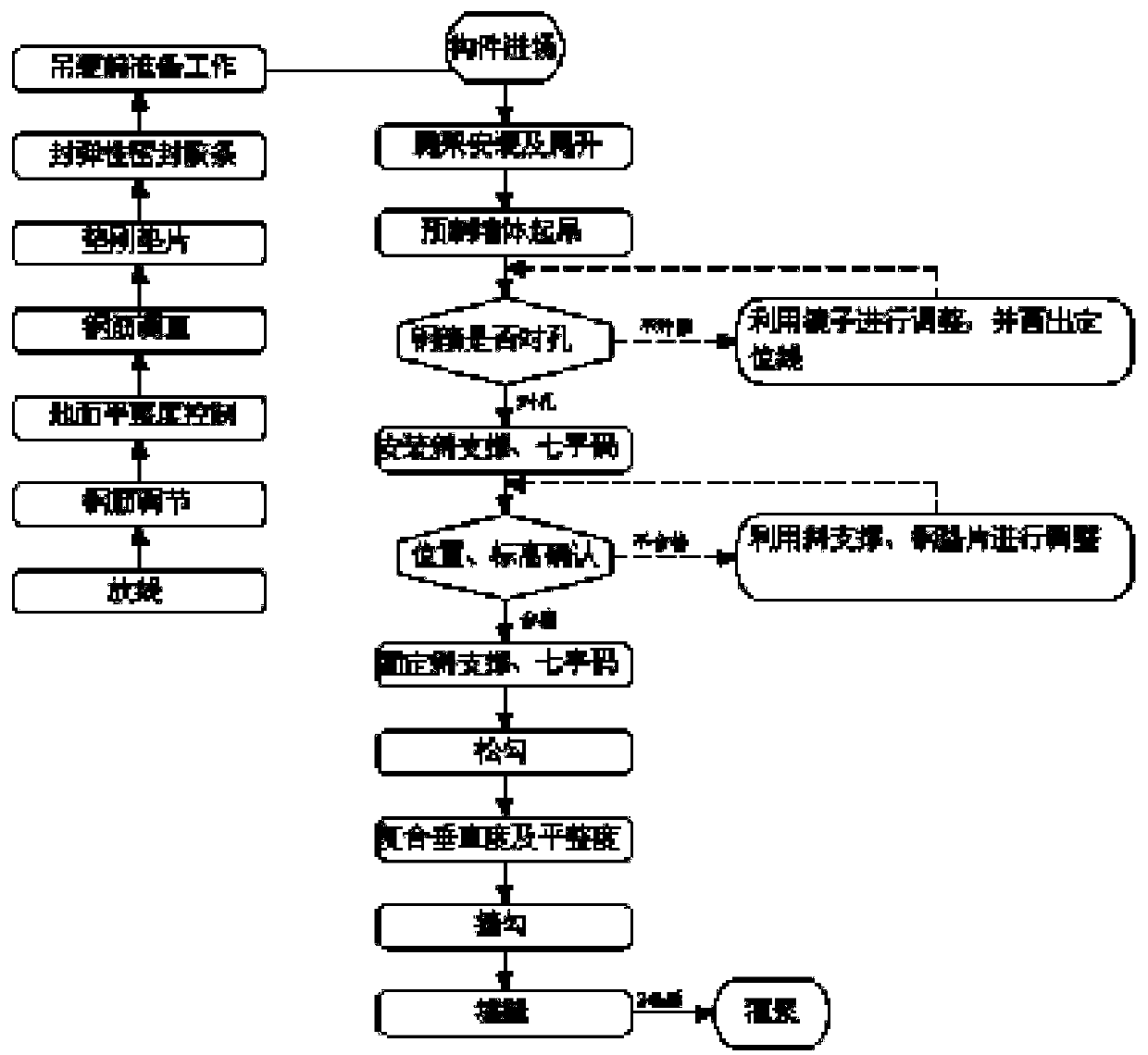

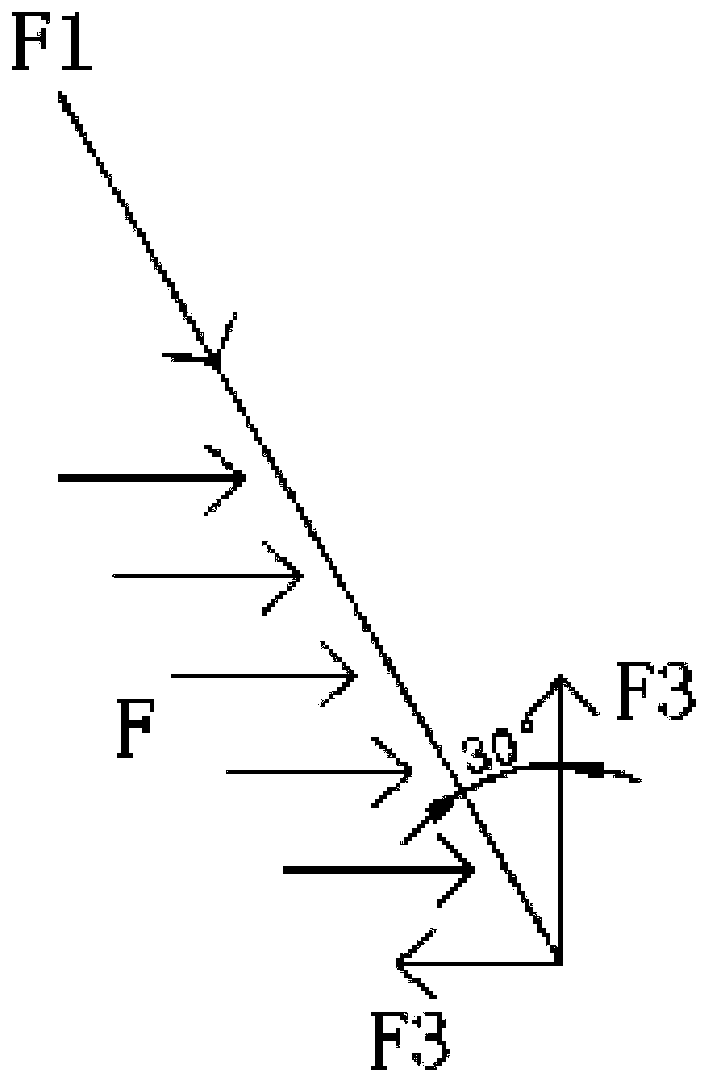

Construction technology process of fabricated shear wall structure

InactiveCN111519909AQuality assuranceAvoid capsizingCovering/liningsWallsArchitectural engineeringSlurry

The invention relates to the technical field of fabricated shear wall, and discloses a construction technology process of a fabricated shear wall structure. The construction technology process comprises the following steps that (1) a PC component enters the site; and (2) before the prefabricated PC component enters the site, the process inspection and tensile strength inspection certificates of areinforcement connection joint are checked. In the construction technology process of the fabricated shear wall structure, according to the principle of liquid level pressure balance, if the liquid level of a slurry discharge hole in a bending section is only settled slightly, the situation that the slurry at the grouting sleeve is dense can be determined, if a large sedimentation occurs, the sealing condition of a grouting layer cavity can be checked immediately, the grouting density is ensured, the situation that grouting is not dense is prevented, a plastering free construction technology is adopted, therefore, the surfaces of prefabricated components are correspondingly constructed in accordance with high-precision and clear light during production, so as to avoid cracking and fallingoff of the decorative surfaces of an external wall in the later stage, the advantages of the prefabricated building are reflected, the requirements of green construction are met, meanwhile the invasion of an internal wall is avoided, and the quality of the shear wall is ensured.

Owner:贵州建工集团第三建筑工程有限责任公司

Assembled integral shear wall and construction method thereof

The invention discloses an assembled integral shear wall and a construction method thereof. The shear wall is composed of a shear wall formwork and a concrete block arranged in the shear wall formwork, and an internal gap of the shear wall formwork is filled with cement paste; the shear wall formwork is made of concrete and a cold-drawn steel bar net piece, the cold-drawn steel bar net piece is bound with stressed steel bars and hanging steel bars, and the hanging steel bars forms hanging rings above the shear wall, extend out of the lower portion of the shear wall and are used for positioningthe shear wall formwork; stirrups are bound on the outer sides of the stressed steel bars; the concrete block is provided with line-shaped stirrup reserved holes; a filling opening is formed in the bottom of the shear wall formwork shell. The shear wall can be used for super high-rise buildings, the assembled integral building is less constrained by weather conditions, extensive construction is changed into precision construction, and various requirements of green construction are met.

Owner:河南聚誉帆工程技术咨询有限公司

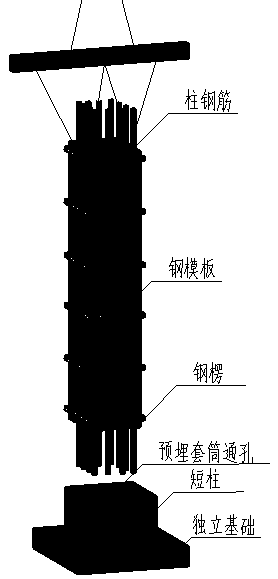

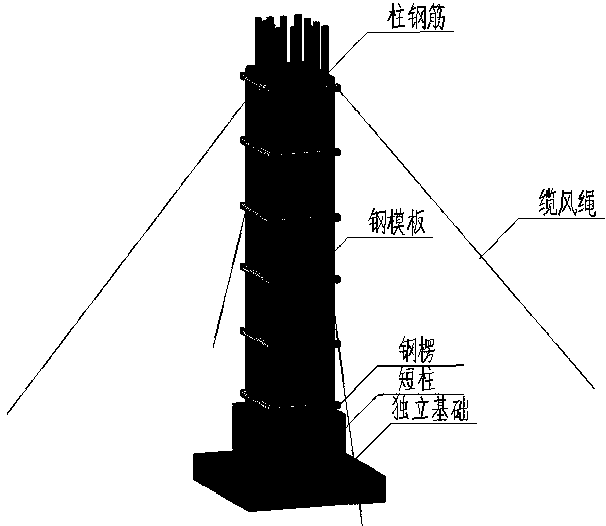

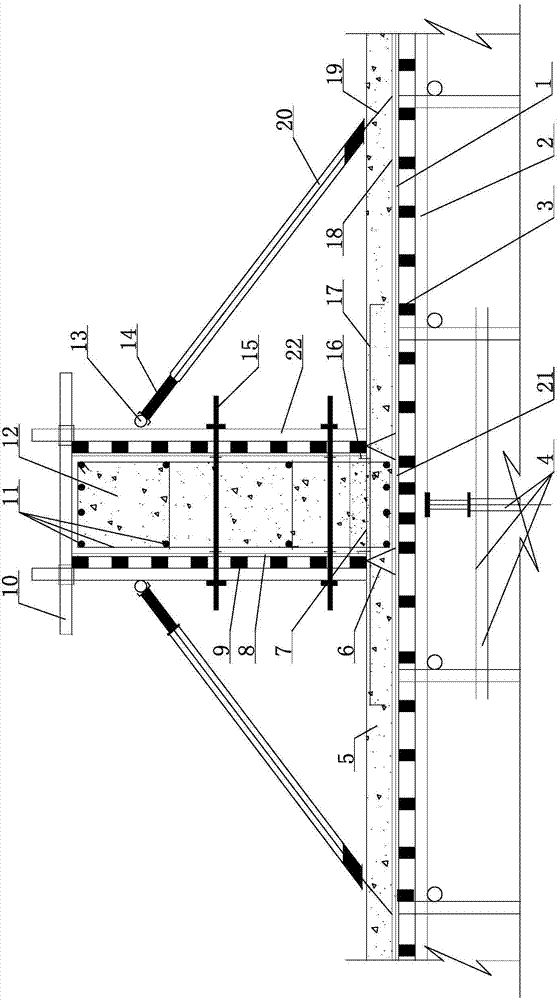

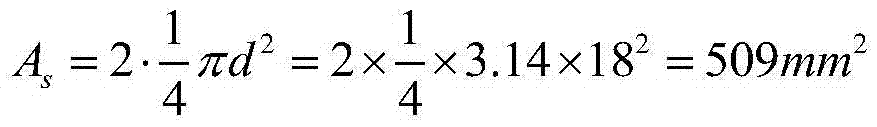

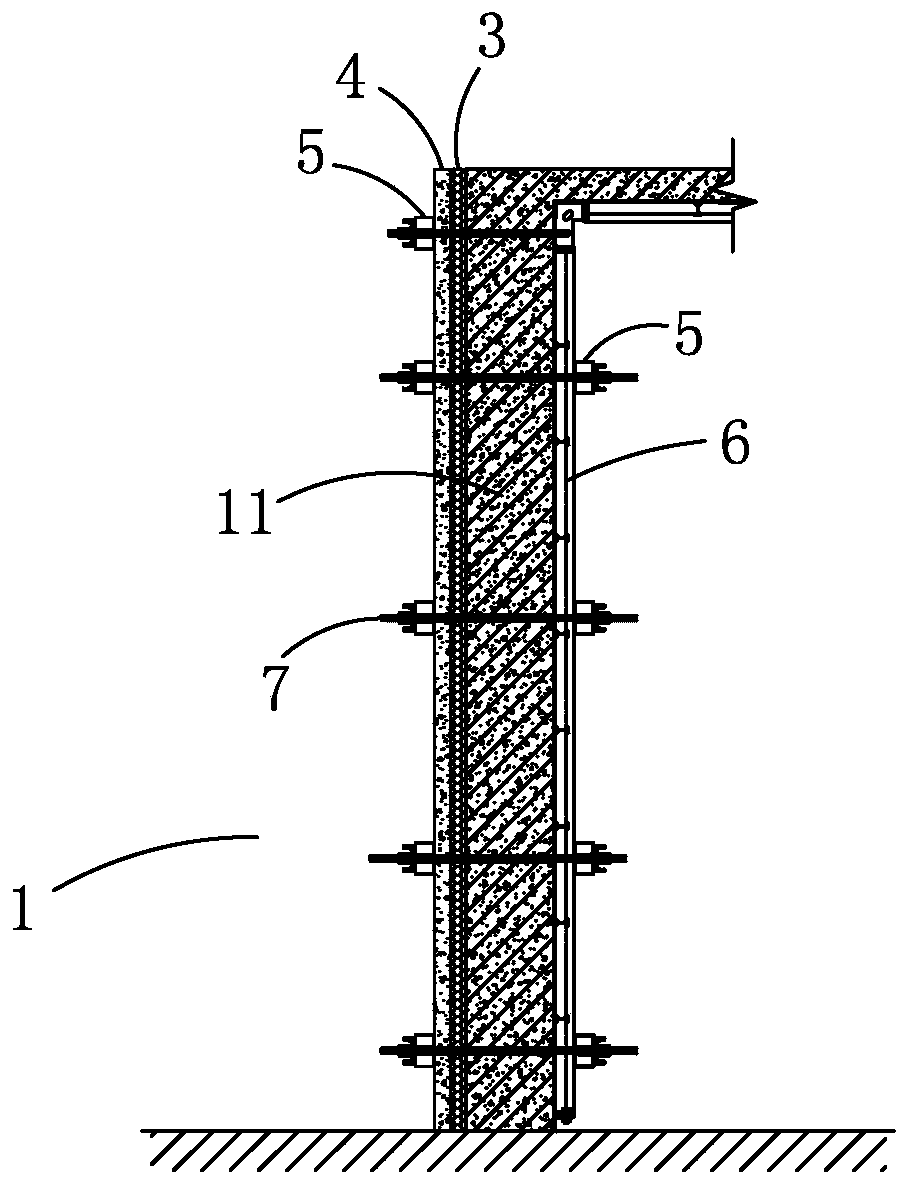

Prefabricated concrete column in-situ cast-in-place construction method

InactiveCN109487955AThe method is reasonable and effectiveShorten the construction periodStrutsForms/shuttering/falseworksRebarEngineering

The invention relates to a prefabricated concrete column in-situ cast-in-place construction method which includes the steps: reinforcing steel bar sleeve pre-burying; prefabricated concrete column template manufacturing; prefabricated concrete column template hoisting; cable wind rope fixing; adjustment; concrete pouring of a prefabricated concrete column template; maintenance; template removal. The method is reasonable and effective, an assembly mode and a concrete cast-in-place mode are reasonably combined, scaffolds erected in reinforcement assembling and template constructing process are omitted, a construction period is shortened, construction cost is saved, concrete molding quality is high, parts of sources can be recycled, reinforcing steel bars can be bound in indoor space, operation environments of constructors are optimized, and green construction requirements are met.

Owner:ZHEJIANG ZHONGCHENG CONSTR GRP

Upturned beam and cast-in-place slab overall pouring construction method

ActiveCN103883052AGood integrity and durability of the beam-slab structureMeet structural design requirementsFloorsForms/shuttering/falseworksSteel tubeRebar

Owner:SHANDONG GOLDENCITY CONSTR

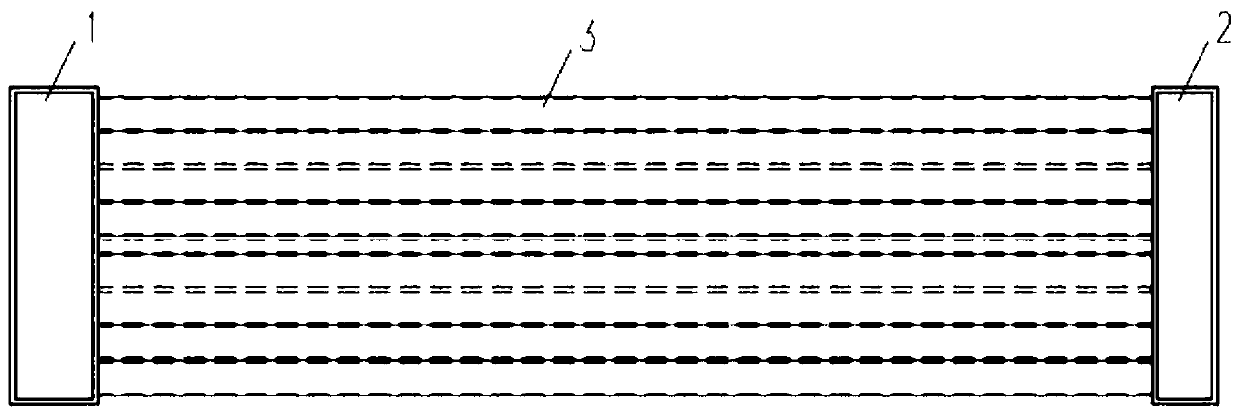

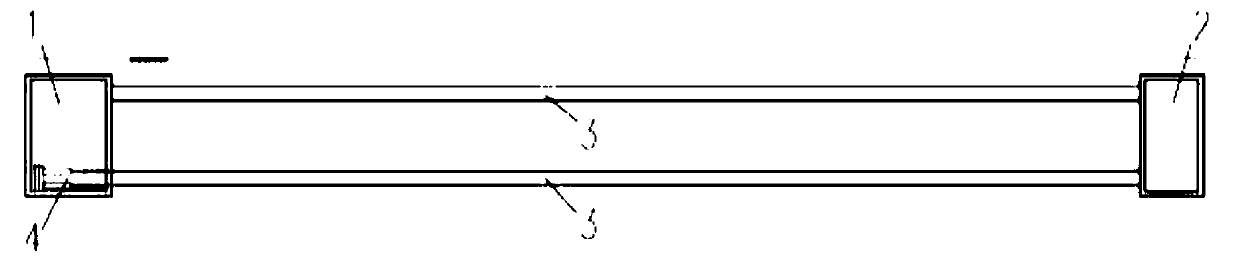

High-performance low-prestressed concrete hollow square pile

InactiveCN105442591AIncrease corrosion allowanceImprove bearing capacityCeramic shaping apparatusBulkheads/pilesFiberPre stress

The invention discloses a high-performance low-prestressed concrete hollow square pile. The high-performance low-prestressed concrete hollow square pile is characterized in that a pile body is composed of at least one unit pile; each unit pile is composed of concrete and parallel reinforcing steel bars tensioned with the prestress of 0.3-0.6 [sigma] in the concrete; the two ends of the reinforcing steel bars are connected with connection plates respectively; the adjacent unit piles are welded through the connection plates to form the pile body; the outer layers of the two connected connection plates are coated with fiber resin with the thickness not smaller than 1.5 mm; the fiber resin layers are wrapped with carbon fiber cloth capable of improving the antiseptic ability and tension resistance. The high-performance low-prestressed concrete hollow square pile has the advantages of being high in corrosion resistance, large in bearing force, low in production cost, high in durability and the like, the problem of the piling illusion is effectively solved, the integrity of the pile body is ensured during construction, the bearing force of the pile body is effectively improved, the weight is lower, cracks caused by mutual collision in the production and transportation process can be avoided, and the phenomena of pile breakage, pile body concrete falling and the like are also not prone to occurring in the site construction.

Owner:WEIHAI QIDE NEW BUILDING MATERIALS

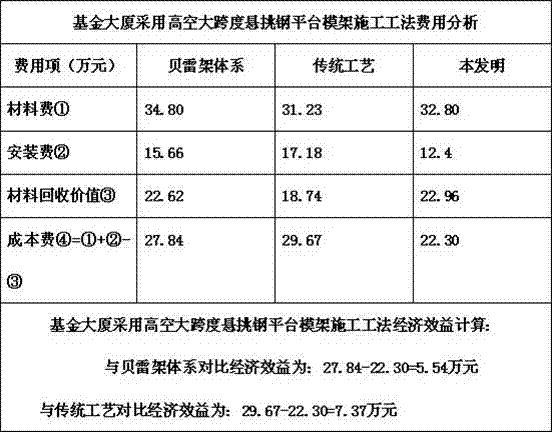

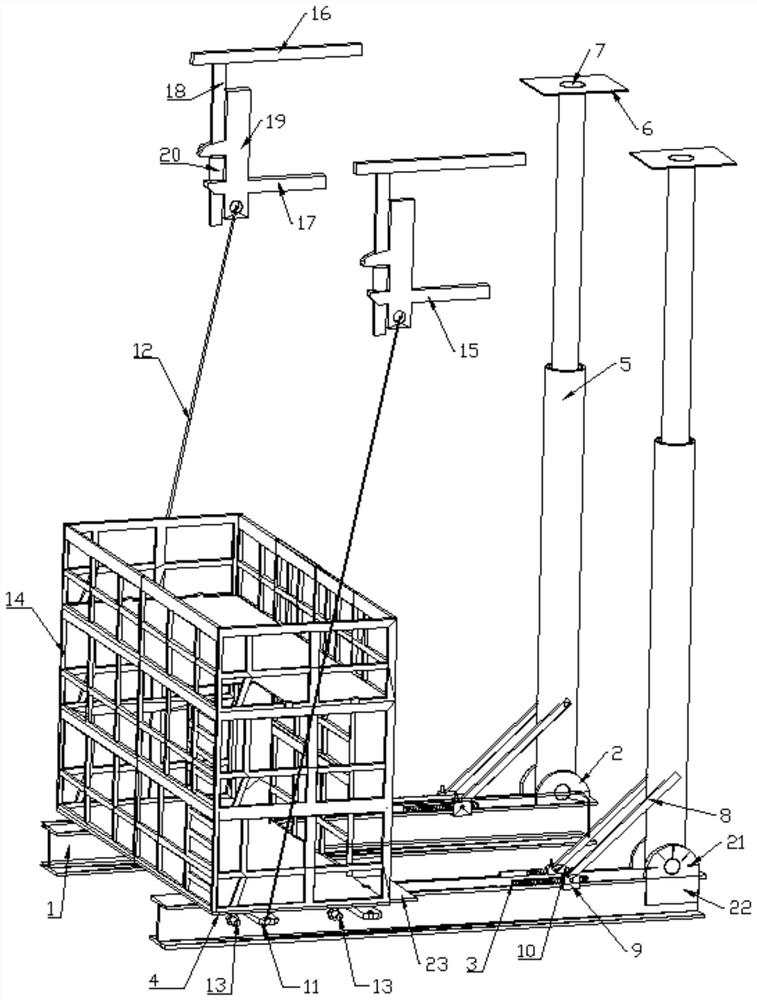

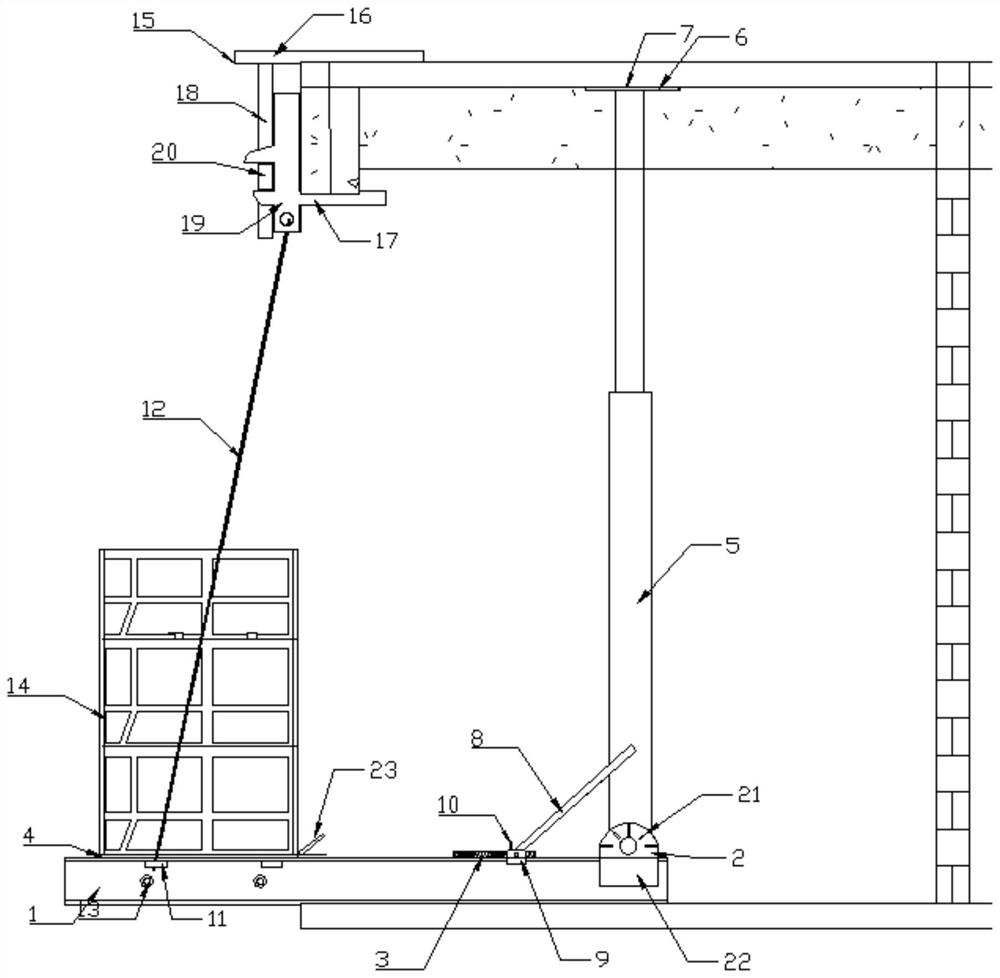

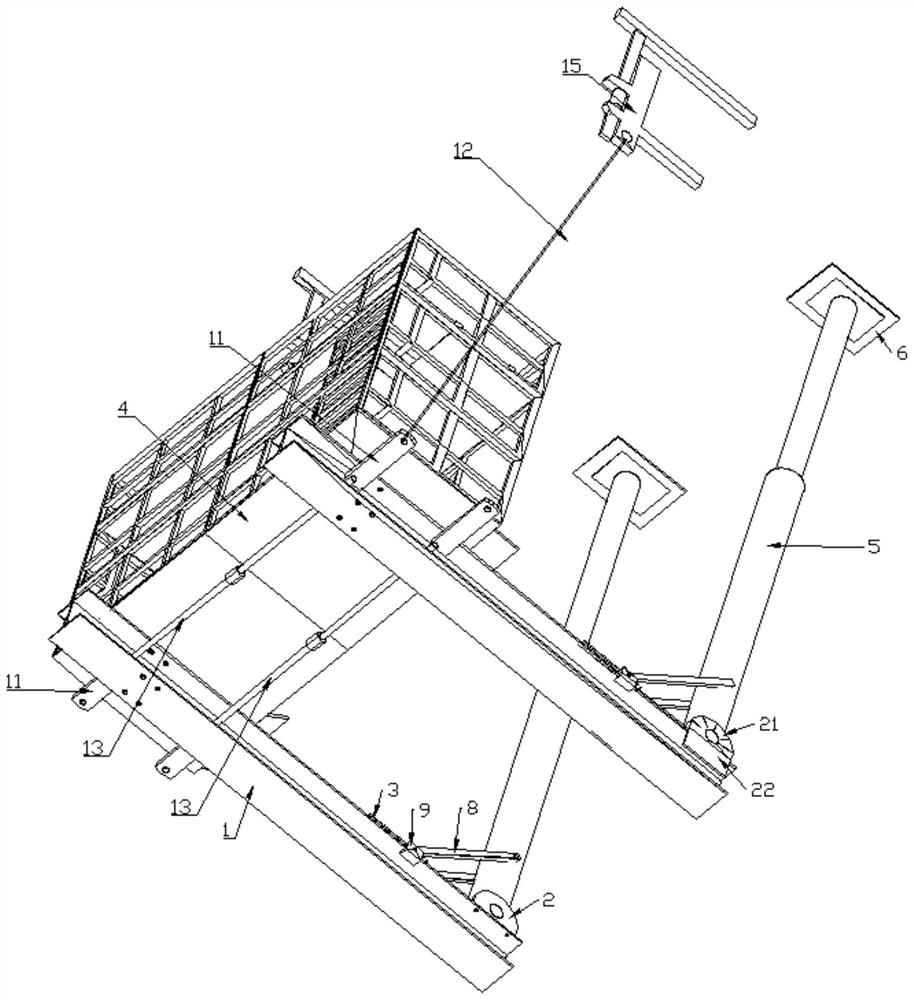

Construction method of high altitude large-span overhanging steel platform formwork

InactiveCN107165281AEasy to processImprove stabilityExtraordinary structuresScaffold accessoriesSheet steelCable stayed

The invention discloses a construction method of a high altitude large-span overhanging steel platform formwork. The construction method includes the steps of preparation of construction, construction of embedded parts, installation of primary beam, installation of a large corner single truss, installation of a bracing piece, installation of a secondary beam, laying of a steel plate, welding of an outer frame anti-skid positioning pile, building of an outer frame, installation of a cable-stayed bar, removing and the like. By adoption of the construction method, the construction problem of a structure-complex special-shaped large-span high altitude overhanging structure of hanging garden layer is solved successfully. Machining is simple, the construction is simple and convenient, the safety factor is high, the construction efficiency is high, the influence to a construction working face is extremely low, the influence to the construction period is low, the installation and removing construction are simple and convenient, materials can be repeatedly used for circulation, and the requirement for environmental-protection construction is met.

Owner:CHINA HUASHI ENTERPRISES

Operation platform for edge-near operation

PendingCN111980389AImprove integrityEffective Protection AdjustabilityScaffold accessoriesBuilding support scaffoldsRotational axisHook plate

Owner:THE FIRST COMPARY OF CHINA EIGHTH ENG BUREAU LTD

Pouring formwork structure for non-standard layer structure and construction method

ActiveCN104153579AEasy constructionEasy to operateForms/shuttering/falseworksBuilding material handlingHeight differenceMaterials science

The invention discloses a pouring formwork structure for a non-standard layer structure and a construction method. The non-standard layer structure comprises at least one first non-standard layer, and height difference of the first non-standard layer higher than a standard layer is delta 1. The first non-standard layer is constructed by adopting a first aluminum alloy setting formwork of the standard layer through the following steps that the first aluminum alloy setting formwork is installed and comprises first wall column formworks and a first beam slab formwork arranged between the first wall column formworks; a wooden bottom mold is laid on the first beam slab formwork, and the height of the wooden bottom mold is equal to delta 1; a first wooden mold plate corresponding to the wooden bottom mold is installed on the outer side of an outer mold plate of each first wall column formwork and in tension joint with the outer side of the wooden bottom mold through a first split bolt. The aluminum alloy formwork and the wooden mold plate combined formwork system is adopted for construction, under the condition of not changing the aluminum alloy formwork, the floor height meets that of the non-standard layer, materials, manpower and time cost and the like are saved, and the requirement for green construction is met.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

Light self-climbing shield frame system and construction method thereof

PendingCN110043020ASimple structureSmall sizeBuilding material handlingScaffold accessoriesSupporting systemEngineering

The invention discloses a light self-climbing shield frame system and a construction method thereof, and relates to the technical field of formwork systems. The light self-climbing shield frame systemand the construction method thereof are used for solving the problems of the tedious lifting process of a lifting system and an anti-falling device and low safety. The light self-climbing shield frame system includes a scaffold system, a supporting system, a lifting system and an anti-tilting and anti-falling system. The supporting system includes a bearing frame which is fixed on a structural steel beam; the lifting system includes an electric block, a bottom guiding wheel and a steel wire rope, wherein the electric block is arranged at the top of the scaffold system, the bottom guiding wheel is fixed to the bottom of the scaffold system, one end of the steel wire rope is connected with the electric block, and the other end of the steel wire rope passes through the bottom guiding wheel to be arranged at the bottom of the bearing frame in a hung mode; the anti-tilting and anti-falling system includes a guiding rail installed on a scaffold frame body, and an anti-falling pawl wheel, alimiting spring, an anti-falling pawl and a limiting baffle are arranged on the bearing frame; the anti-falling pawl wheel meshes with the guiding rail, the limiting spring is used for limiting the stroke of the anti-falling pawl, and the anti-falling pawl and the limiting baffle are used for preventing the anti-falling pawl wheel from rotating counterclockwise. Therefore, falling of the scaffoldframe body and the guiding rail is prevented, and the anti-falling effect is achieved advantageously.

Owner:SHANGHAI CONSTR NO 1 GRP

Method for realizing large-section underground space excavation by virtue of small-section combined jacking pipe

InactiveCN110593881AEnsure safetyThe construction site is smallUnderground chambersTunnel liningLine tubingReinforced concrete

The invention discloses a method for realizing large-section underground space excavation by virtue of a small-section combined jacking pipe, and relates to the technical field of tunnel construction.The method comprises the following steps: producing a jacking pipe starting well and a jacking pipe receiving well through open cutting; connecting small-section jacking pipe sections into an integrated-structure frame; sequentially excavating a soil mass in an underground structure in a layered manner from top to bottom under a supporting condition formed by the whole pipe sections; detaching reinforced concrete at the positions of vertical columns, steel pipe sections in sectional-steel combined pipe sections, and middle universal pipe sections, and producing a vertical column structure; and detaching reinforced concrete among the vertical columns, the steel pipe sections in the sectional-steel combined pipe sections, and the middle universal pipe sections, arranging corner reinforcingbrackets, and producing a portal ring beam. According to the method, the construction occupies less space and basically has no influence on ground transportation, municipal pipelines do not need to bemoved, and high construction efficiency is achieved; and meanwhile, the own retaining soil mass of the structure is utilized, a building envelope is omitted, the engineering investment is saved, andthe requirement of green construction is also met.

Owner:CHINA RAILWAY LIUYUAN GRP CO LTD

Direct-burial complete-set constructing process for electromechanical pipelines and wire boxes of masonry engineering

InactiveCN104806025AReduce loss costReduce labor costsBuilding material handlingBrickArchitectural engineering

The invention discloses a direct-burial complete-set constructing process for electromechanical pipelines and wire boxes of masonry engineering. The direct-burial complete-set constructing process comprises the following steps of the step 1 of laying wires for a masonry, embedding steel bars for the masonry and installing a water stopping belt module; the step 2 of installing the electromechanical pipelines, previously setting the electromechanical pipelines and the wire boxes to be in place, previously configuring tubes for installing the wire boxes and previously bending the pipelines to be in place; the step 3 of pouring the water stopping belts, prefabricating lintels and building bricks; the step 4 of building the masonry, performing, embedding and centralizing the electromechanical pipelines and wire boxes, building stripe-shaped or U-shaped bricks on the two sides of reserved spaces for the electromechanical pipelines and wire boxes in a sleeving mode, arranging single-edge lintels at the upper portions of the wire boxes if reserved holes for the wire boxes exceed 300mm and building U-shaped brick or prefabricating U-shaped bricks to enable the pipelines to be embedded into a wall if the thickness of a wall body is smaller than 100mm; the step 5 of forming the masonry and filling and leveling gaps between the electromechanical pipelines, the wire boxes and the bricks with masonry mortar. According to the direct-burial complete-set constructing process, grooving and secondary pipe distribution after masonry construction are avoided, the work efficiency is improved, and the construction time is saved.

Owner:中建五局(安徽)投资建设有限公司

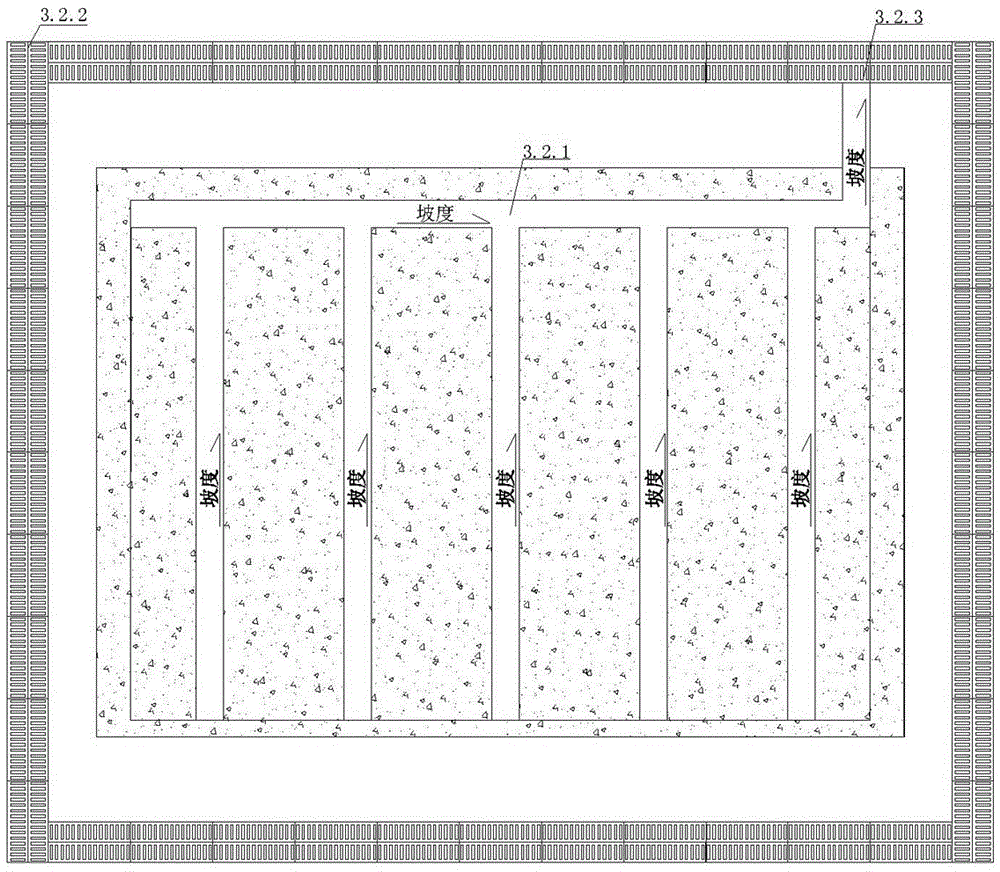

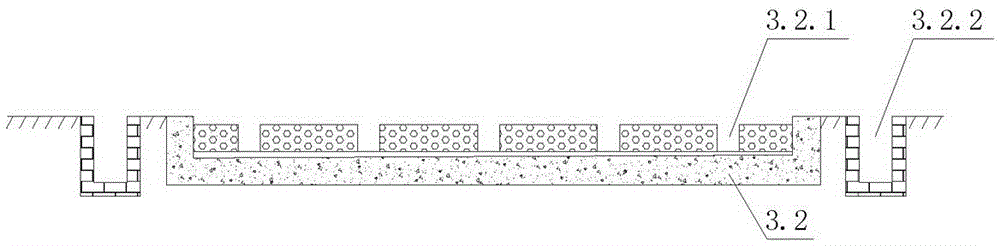

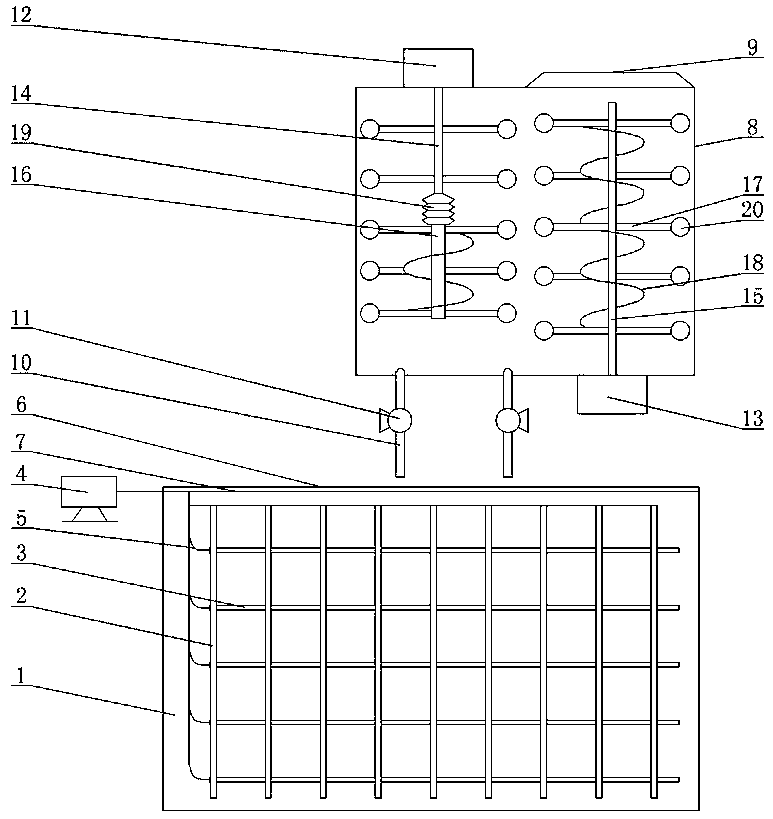

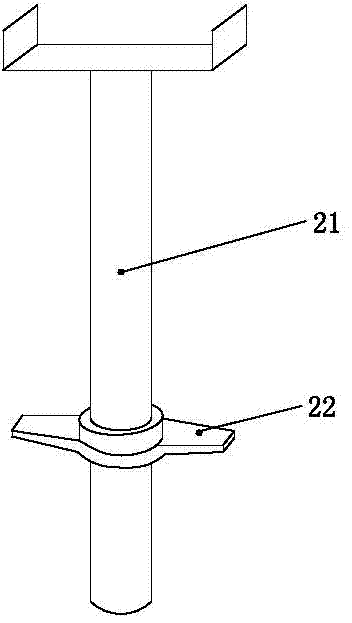

System and method of flocculation combined with vacuum preloading for treatment of blown fill foundation

InactiveCN109267562AStir wellReduce accumulationBuilding constructionsOrganic fertilisersFlocculationGeomembrane

The invention discloses a flocculation combined vacuum prepressing system for treating blow-filled soil foundation, which comprises a treatment area, a vertical drainage plate, a transverse drainage plate and a vacuum pump, wherein the vertical drainage plate and the transverse drainage plate are respectively connected with the vacuum pump through a drainage pipe, the processing area covered withgeomembrane and geotextile. A stirring device is arranged on one side of the processing area, comprising a tank body, wherein the upper end is provided with an inlet, the lower end is provided with aconveying pipe, a conveying pump is arranged on the conveying pipe, the first motor is arranged at the upper end of one side of the tank body, the second motor is arranged at the lower end of the other side of the tank body, a first rotating shaft connected with a first motor and a second rotating shaft connected with a second motor are arranged in the tank body, an electric push rod is arranged at the lower part of the first rotating shaft, the second rotating shaft and the electric push rod are both provided with stirring rods. The system enables a mixture to be stirred more uniformly. The invention also discloses a method for treating the filling soil foundation by combining flocculation and vacuum prepressing.

Owner:WENZHOU UNIVERSITY

Advanced positioning directly-buried anchor bolt prefabricated pipeline support construction technology based on BIM

InactiveCN111853347AAvoid buryingAvoid drilling holesPipe laying and repairBuilding material handlingLine tubingConstruction engineering

The invention discloses an advanced positioning directly-buried anchor bolt prefabricated pipeline support construction technology based on BIM. The technology comprises the following steps of (1) construction preparation; (2) optimizing a BIM pipeline; (3) drawing a directly-buried anchor bolt installation drawing; (4) main body pre-burying construction; (5) manufacturing a support; and (6) mounting the support. According to the construction technology, the construction procedure of an original pipeline support and hanger is improved, the construction period of the pipeline support is effectively shortened by combining the precise positioning technology of BIM and machining and distribution of factory supports, meanwhile, the steps of on-site welding and paint brushing processes are reduced, the green construction requirement is met, and the construction quality is remarkably improved; and pipeline integration and collision inspection are carried out through BIM, the pipeline is optimized and adjusted, positioning and paying-off are carried out on the surface of a formwork according to an optimized drawing, the directly-buried anchor bolt is fixed to the formwork, and accurate pre-burying of the anchor bolt is completed in advance through construction of main body concrete.

Owner:QINGDAO XINHUAYOU CONSTR GROUP

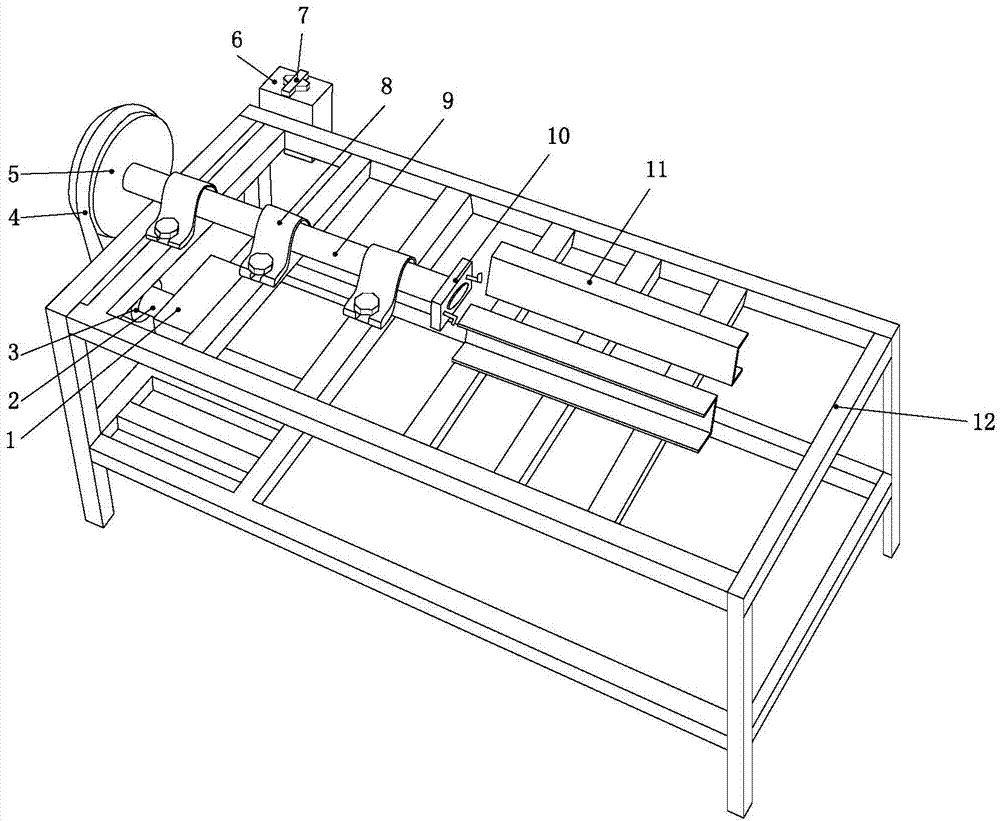

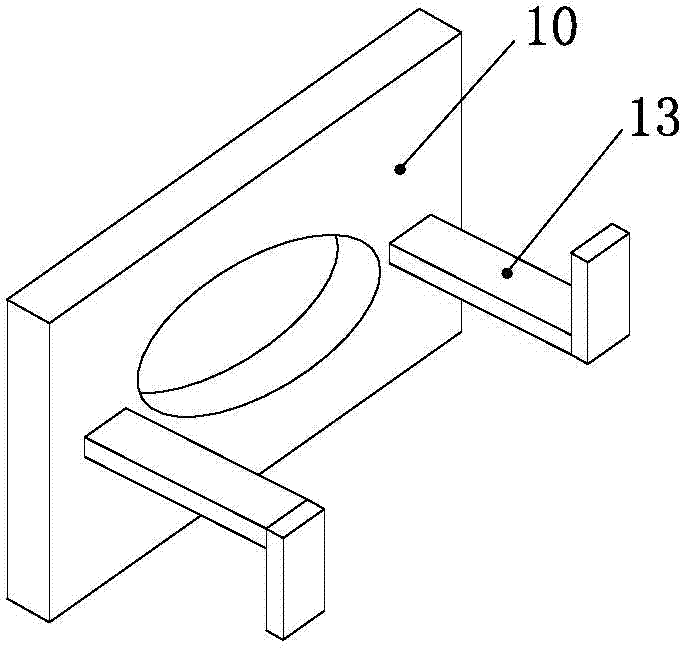

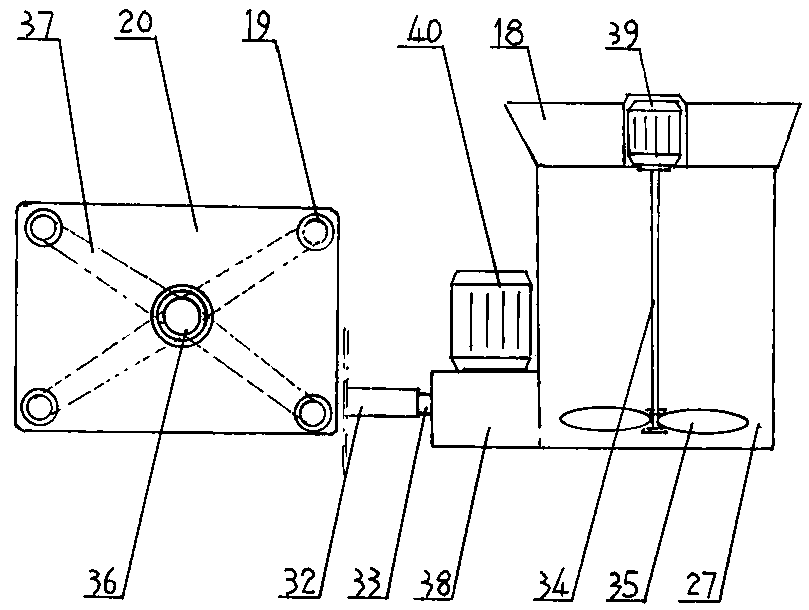

U-support lead-screw washing maintaining device

InactiveCN104775618AEasy to operateReduce labor intensityForm treatmentEngineeringEnergy consumption

The invention relates to a U-support lead-screw washing maintaining device. According to the technical scheme, the U-support lead-screw washing maintaining device comprises an operating platform, a rotating shaft is driven by a motor by virtue of an output shaft and a transmission device, the rotating shaft is fixed on the operating platform by virtue of a bearing seat, one end of the rotating shaft penetrates through a chuck, the chuck is provided with a clamping jaw, two guide channel steel which is fixed on the operating platform is arranged on the front end of the chuck, a guide passage is formed between the two guide channel steel, a control platform with a control button is fixed on the operating platform, and the control button is connected with the motor. The U-support lead-screw washing maintaining device is simple and rapid to operate, simple for replacing vulnerable parts, high in efficiency and low in energy consumption; the oiling work is completed while cement residues in a U-support lead screw can be effectively cleared, the labor intensity is alleviated, the working efficiency is improved, the manpower and cost can be saved, and environmental protection can be realized.

Owner:JIANGSU NANTONG NO 2 CONSTR ENG GRP

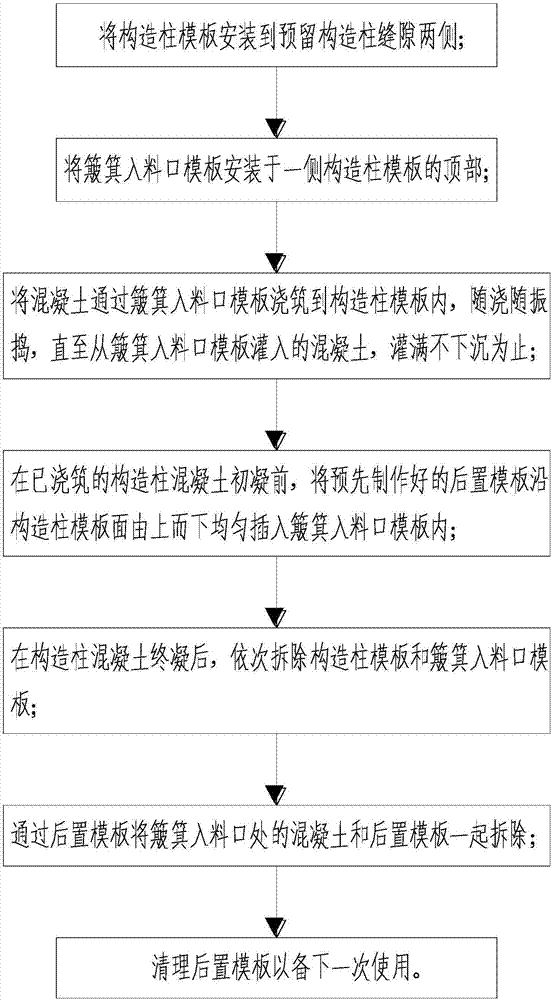

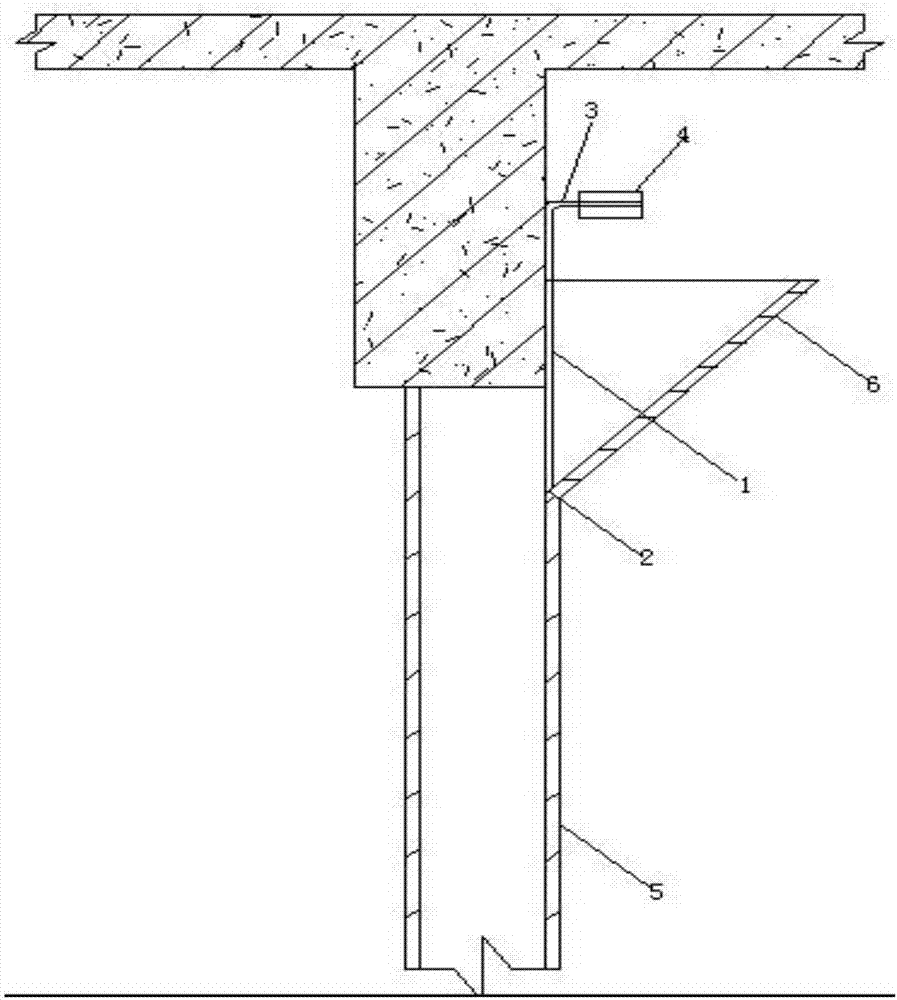

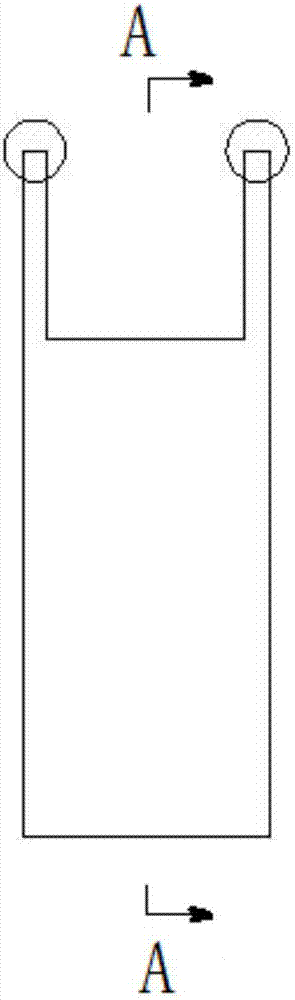

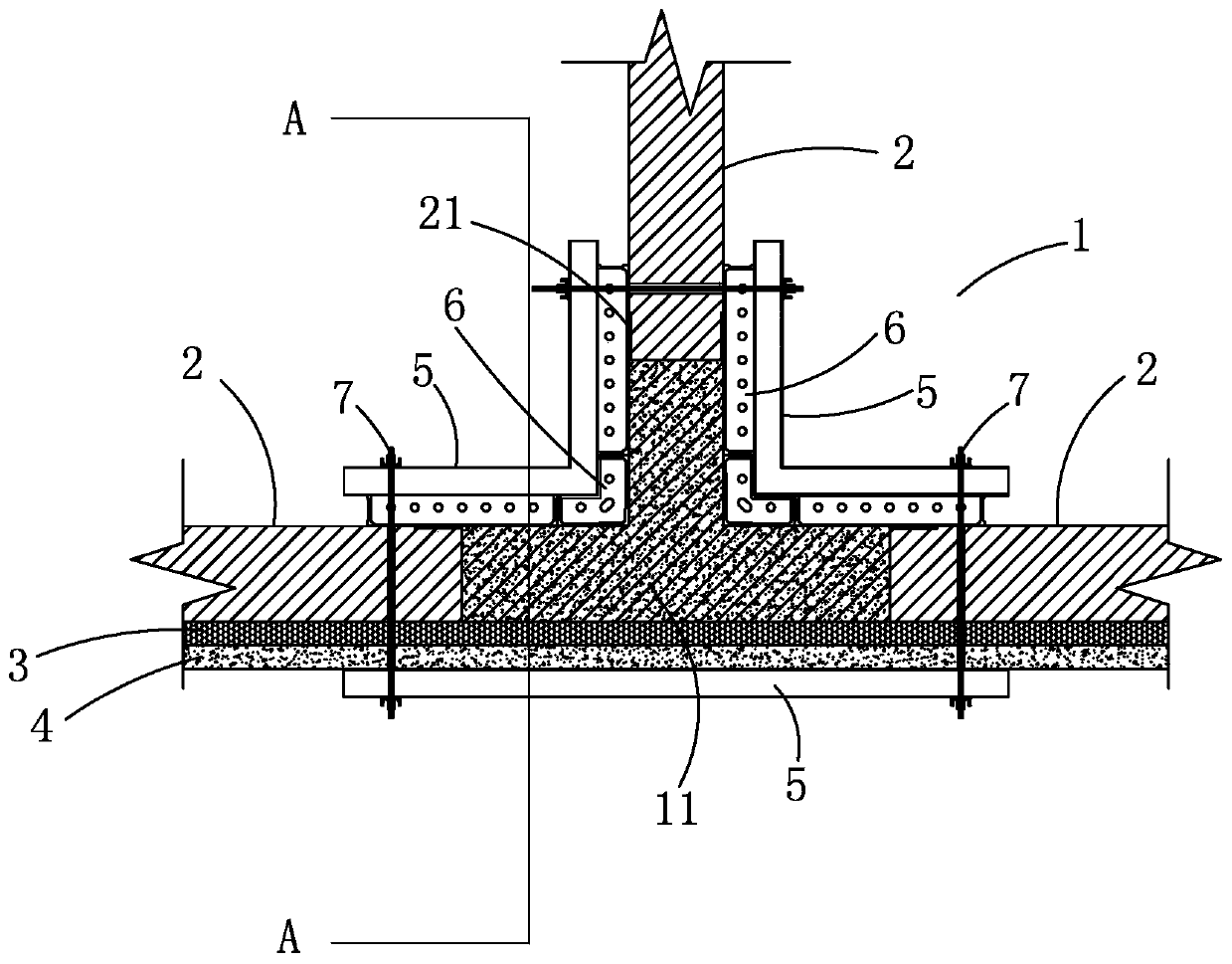

Method for dismantling concrete of dustpan feeding inlet of constructional column

InactiveCN106894632AGuarantee the appearance qualityGuarantee the construction qualityForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksStructural engineeringBuilding construction

Owner:CHINA FIRST METALLURGICAL GROUP

Plastering-free construction method for fabricated building

InactiveCN109826442AReduce the difficulty of pouring on siteImprove construction qualityBuilding material handlingEngineeringAluminium alloy

The invention relates to a plastering-free construction method for a fabricated building. The method comprises the following steps that 1, PC components are prefabricated; 2, the PC components are rigidly connected by means of anchoring measures in a cast-in-situ section; 3, windowsill cast-in-place walls, T-shaped cast-in-place walls, L-shaped columnar cast-in-place walls and I-shaped cast-in-place walls are manufactured; 4, an operating platform is constructed, an installation area is constructed on the top of the operation platform, and then concrete is poured onto the installation area toform a floor. By adopting the steps above, the complex and lightweight components with a poor molding effect are prefabricated in a factory, the cast-in-place difficulty is reduced, and the work efficiency is improved; meanwhile, an aluminum alloy formwork is used in cooperation with the PC components or a PCF board formwork is used in cooperation with the PC components, so that the construction time is shortened; moreover, the aluminum alloy formwork is a new back-to-back formwork system with a sustainable use effect and is convenient to carry. After aluminum alloy is disassembled, the surfaces of the walls are flat, and a plastering-free effect is achieved.

Owner:广东国晟建设监理有限公司

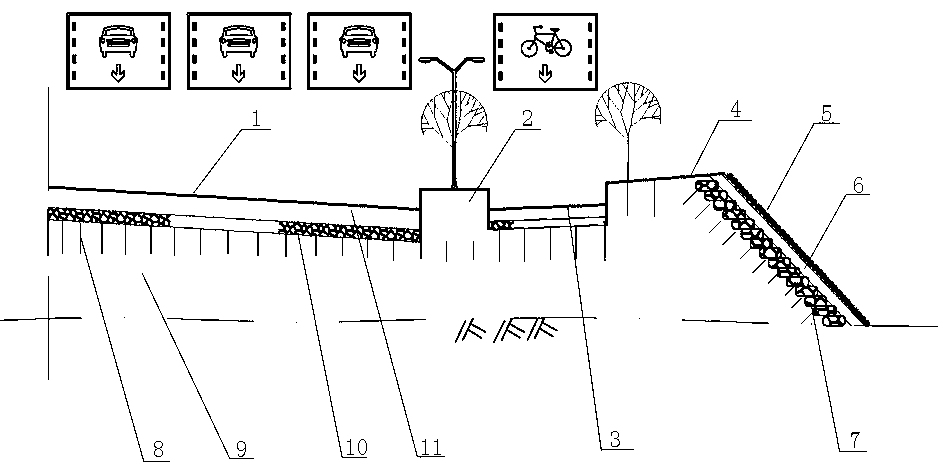

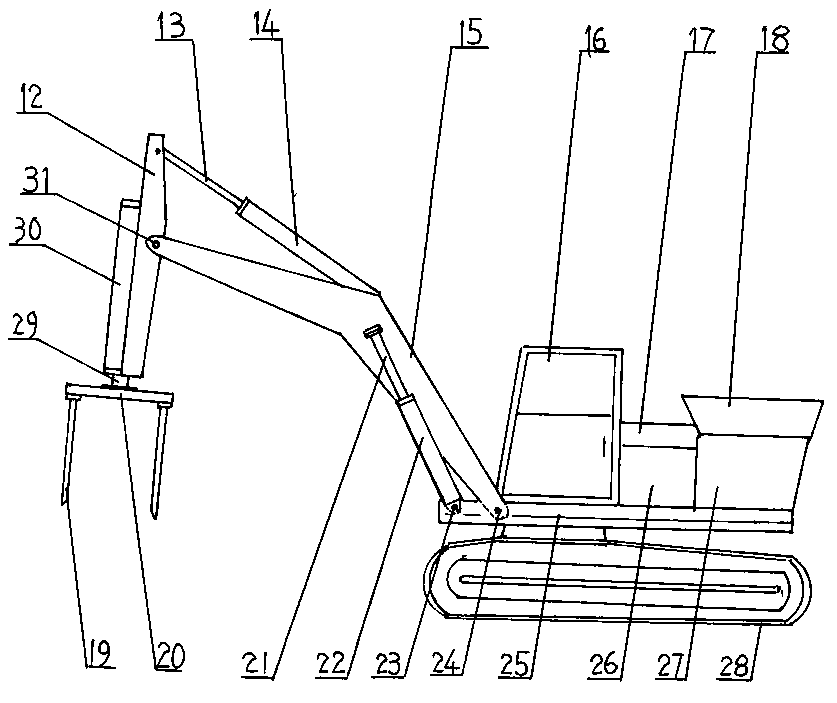

Subgrade construction method for aeolian sand section and structure and device thereof

The invention belongs to a subgrade construction method for an aeolian sand section and a structure and a device thereof; the method comprises the steps of construction preparation, filler sampling inspection, aeolian sand loading and transportation, aeolian sand laying and leveling, water replenishing for aeolian sand, aeolian sand compaction, testing detection of compacted aeolian sand, formation of sand fixing columns by grouting the interior of the upper part of a rolling-compacted molded aeolian sand filling layer by a rapid sand fixing column construction machine, slope stacking with sand bags, road bed acceptance, sand gravel loading and transportation, sand gravel layer laying, sand gravel watering compaction, testing detection of a sand gravel layer and compound slope protection.The device is the rapid sand fixing column construction machine, can form four sand fixing columns distributed at intervals. The method and the device can effectively build a road in the aeolian sandsection, provide the feasible subgrade structure and rapid reinforcement equipment, and have the advantages of simple and practical method, stable subgrade slope, low construction risk, low cost, construction period saving, no pollution, long service life of highways and good use effect.

Owner:CHINA CONSTR MUNICIPAL ENG +1

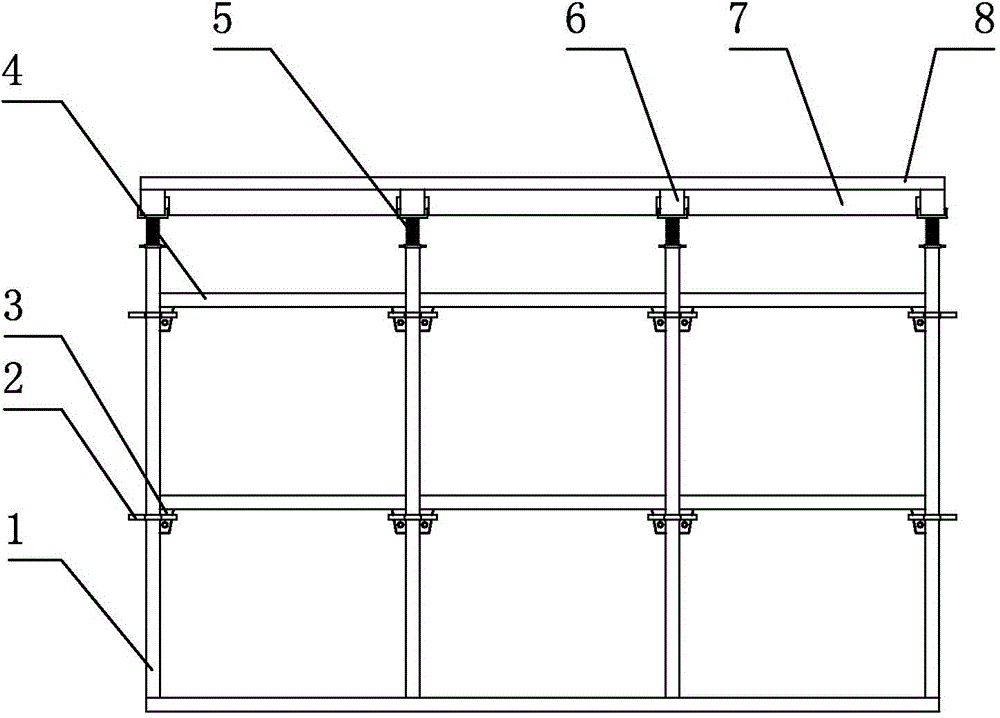

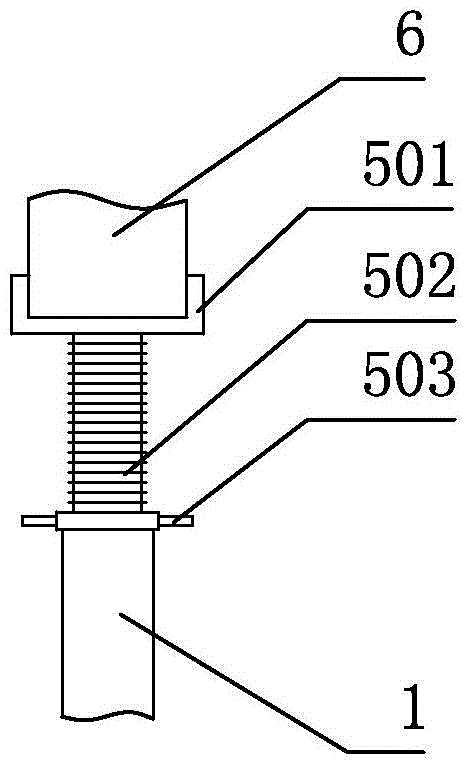

Normalized support system and construction method of weather-proof PVC (polyvinyl chloride) composite plastic template

InactiveCN104818844AIncrease the number of recyclingMeet the requirements of green constructionForms/shuttering/falseworksForming/stuttering elementsSupporting systemReinforced concrete

The invention relates to a normalized support system and construction method of a weather-proof PVC (polyvinyl chloride) composite plastic template, belonging to cast-in-place reinforced concrete structure beam and template support. According to the normalized support system of the weather-proof PVC composite plastic template, a vertical rod and a cross rod constitute a three-dimensional net-shaped structure, the top of the vertical rod is provided with an adjustable support, a lengthways main keel is erected at the top of the adjustable support, weather-proof PVC composite plastic templates are arranged above the main keel and a secondary keel. The construction method of the weather-proof PVC composite plastic template comprises the steps of: 1) designing the support system; 2) detecting a position line via flip; 3) designing the normalized support system of an erected template; 4) adjusting an elevation to install the plastic template; 5) strapping the reinforcing steel bars of the beam and a plate and pouring concrete; 6) lowering the main keel and the secondary keel; 7) dismantling the secondary keel; 8) dismantling the plastic template; 9) dismantling the main keel, the cross rod and the vertical rod successively. The normalized support system and construction method of the weather-proof PVC composite plastic template can save wood, and are simple to operate, and safe and reliable.

Owner:SHANDONG GOLDENCITY CONSTR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com