Light self-climbing shield frame system and construction method thereof

A shielding frame and self-climbing technology, which is applied to the accessories of scaffolding, the scaffolding supported by the building structure, the supporting structure of the building, etc., can solve the cumbersome and heavy cost of the lifting system and the anti-falling device, the difficulty of installation and disassembly, and the cumbersome lifting process, etc. problems, to achieve the effect of saving manpower, fast construction and high insurance factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

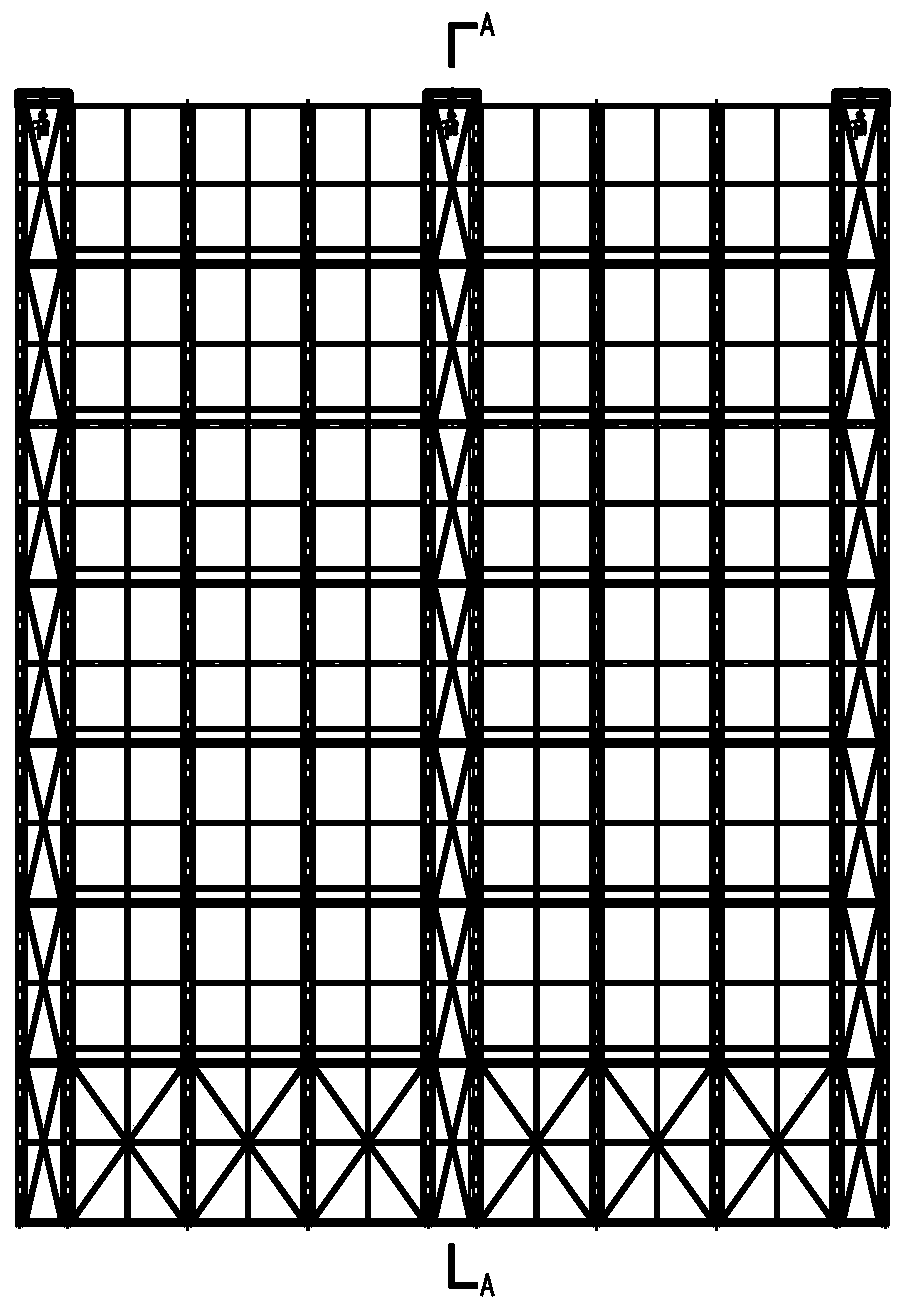

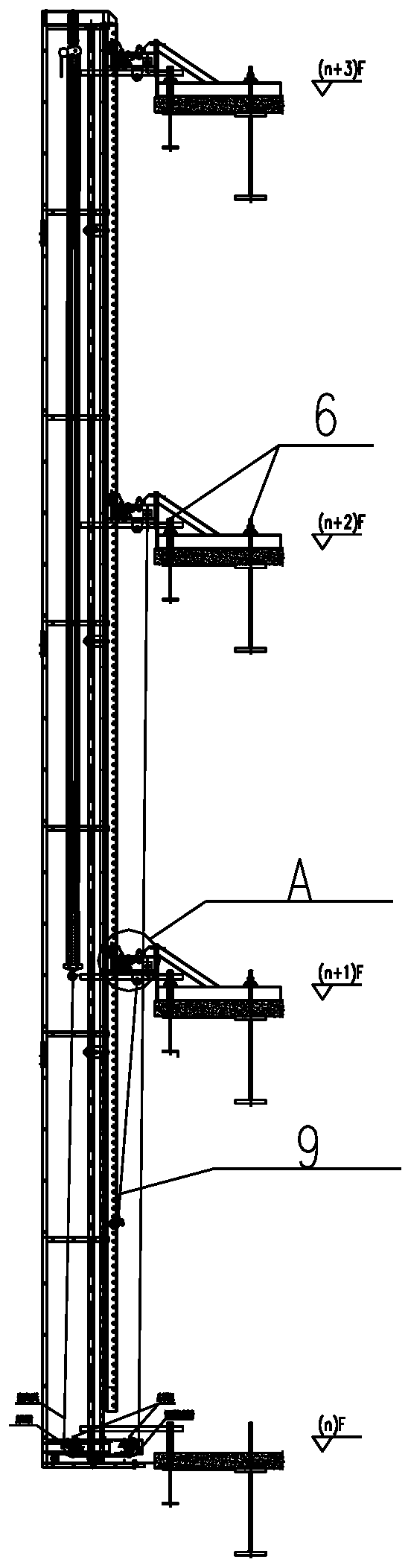

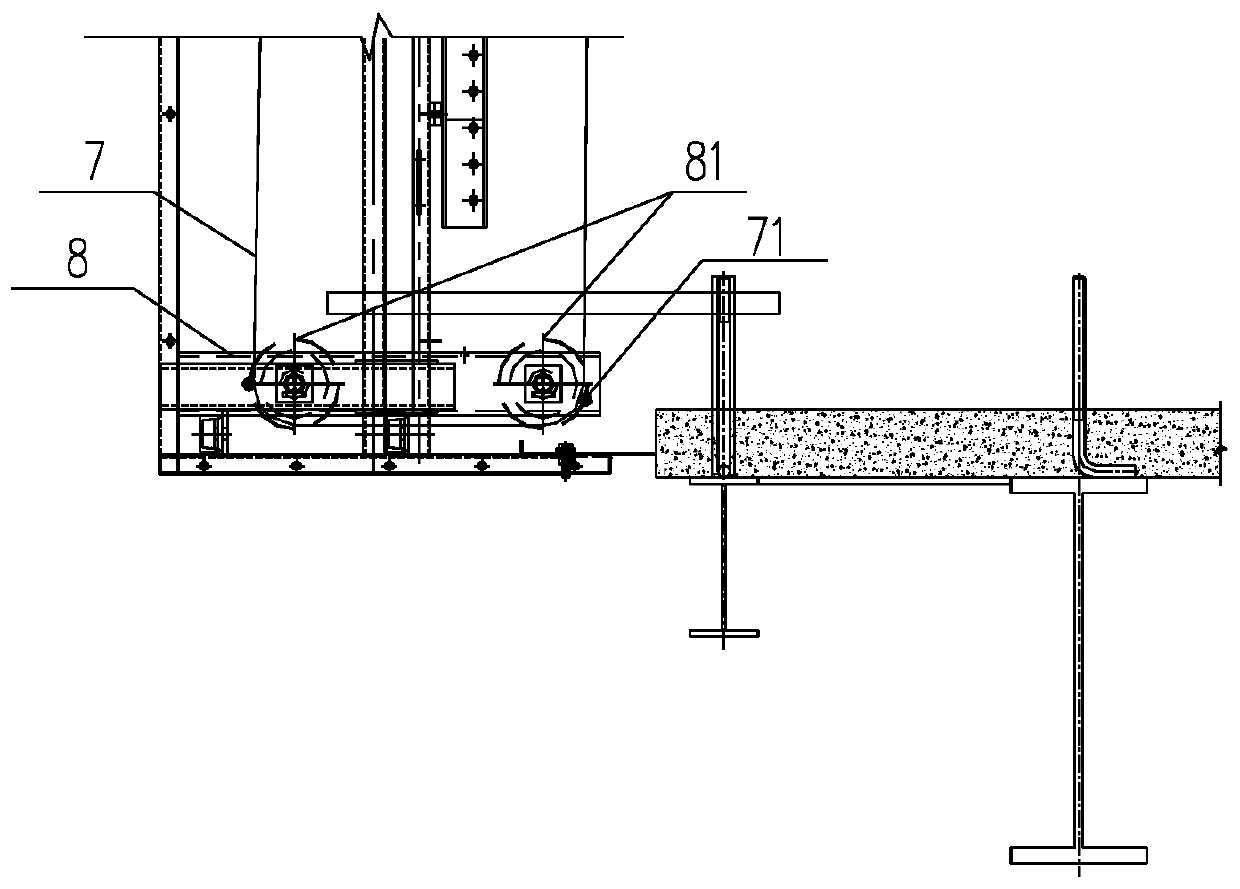

[0039] combine Figure 1 to Figure 7 Describe the structural composition of the lightweight self-climbing shielding frame system of the present invention.

[0040] Please refer to Figure 1 to Figure 7 , a light self-climbing shielding frame system, including a scaffolding system 1, a support system, a lifting system, and an anti-tilt and anti-drop system; the support system includes a load-bearing frame and an oblique load-bearing pull The connecting plate 3 and the rear frame body 4, the rear frame body 4 is fixed on the structural steel beam 5 through embedded parts, the middle connecting plate 3 is vertically arranged, the front frame body 2 and the rear frame body 4 pass through the middle connecting plate 3 fixed connection; the lifting system includes an electric hoist, a lifting wire rope 7 and a bottom guide wheel 81, the electric hoist is fixed on the top of the scaffolding system 1, the bottom guide wheel 81 is fixed on the bottom of the scaffolding system 1, one e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com