Upturned beam and cast-in-place slab overall pouring construction method

A construction method and integral pouring technology, applied in formwork/formwork/work frame, floor, building, etc., can solve the problem of reducing the integrity and bending resistance of frame beams, cracking of horizontal construction joints, shear cracking of horizontal construction joints, etc. problems, to achieve the effect of good beam-slab structure integrity and durability, meet the structural design requirements, and fast construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

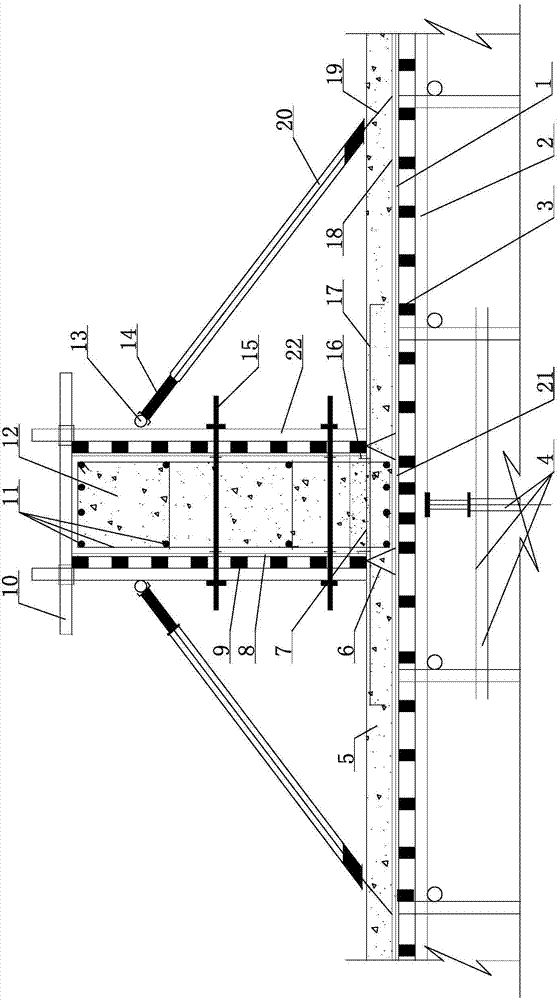

[0025] Such as figure 1 As shown, the integral pouring construction method of the upturned beam and cast-in-place slab of the present invention takes the following steps:

[0026] 1) Installation of the cast-in-place slab and the bottom formwork of the upturned beam: install the main formwork 2 and the secondary formwork 3 on the formwork support system 4, and lay the cast-in-place slab formwork panel 1 and the formwork panel at the bottom of the upturned beam on the formwork secondary formwork 3 twenty one;

[0027] 2) Positioning and setting out of the side formwork of the upturning beam: measure the position of the sideform of the upturning beam on the panel 21 of the bottom formwork of the upturning beam and position and set out the lines;

[0028] 3) Binding of steel bars for cast-in-place slabs: Bind the upper reinforcement 17 of the cast-in-place sla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com