Prefabricated concrete column in-situ cast-in-place construction method

A technology of prefabricated concrete and construction methods, applied in the direction of columns, pier columns, pillars, etc., can solve the problems of high cost and low utilization rate of scaffolding, and achieve the effects of high molding quality, saving construction period, and reasonable and effective methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

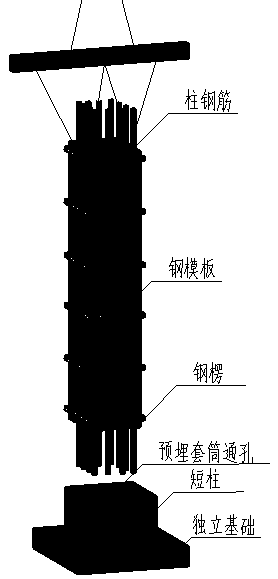

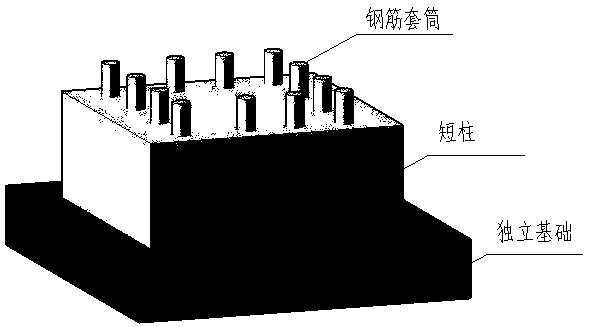

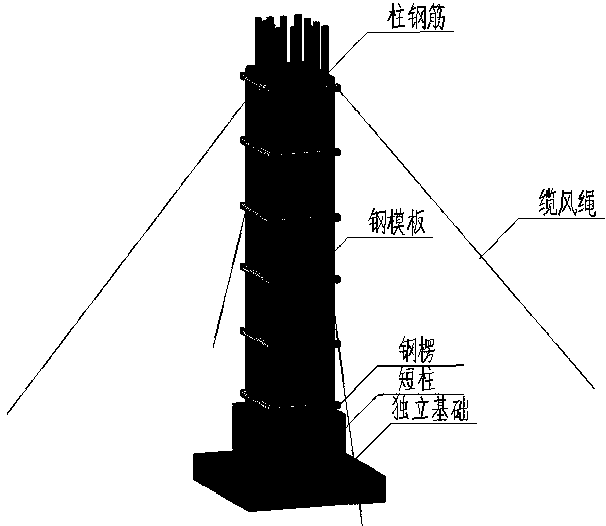

[0018] Such as Figure 1 to Figure 3 As shown, a prefabricated concrete column cast-in-situ construction method includes the following steps:

[0019] A. Pre-embedded steel bar sleeve: In the short column on the independent foundation, pre-embed the steel bar sleeve according to the design size, and then pour concrete on the short column, so that the short column is provided with a number of longitudinal steel bars equal to the number of upper precast concrete column formwork , sleeve through holes at the same position;

[0020] B. Production of prefabricated concrete column formwork: binding column reinforcement on the site in advance, assembling steel formwork and steel corrugation;

[0021] C. Hoisting of precast concrete column formwork: Lift the assembled precast concrete column formwork with a lifting device, and connect the colum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com